Analysis of Collapse Strength and Life Prediction of Casings in Formation Water Service Environments

Abstract

:1. Introduction

2. Materials and Methods

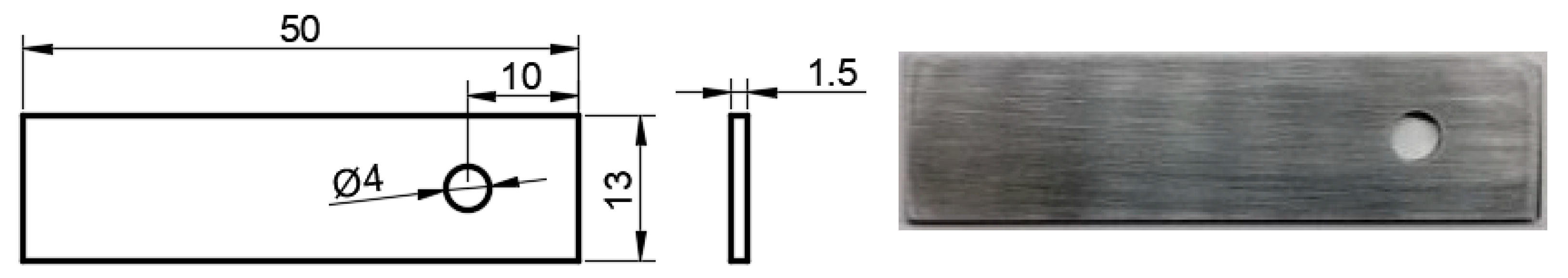

2.1. Materials and Specimen Preparation

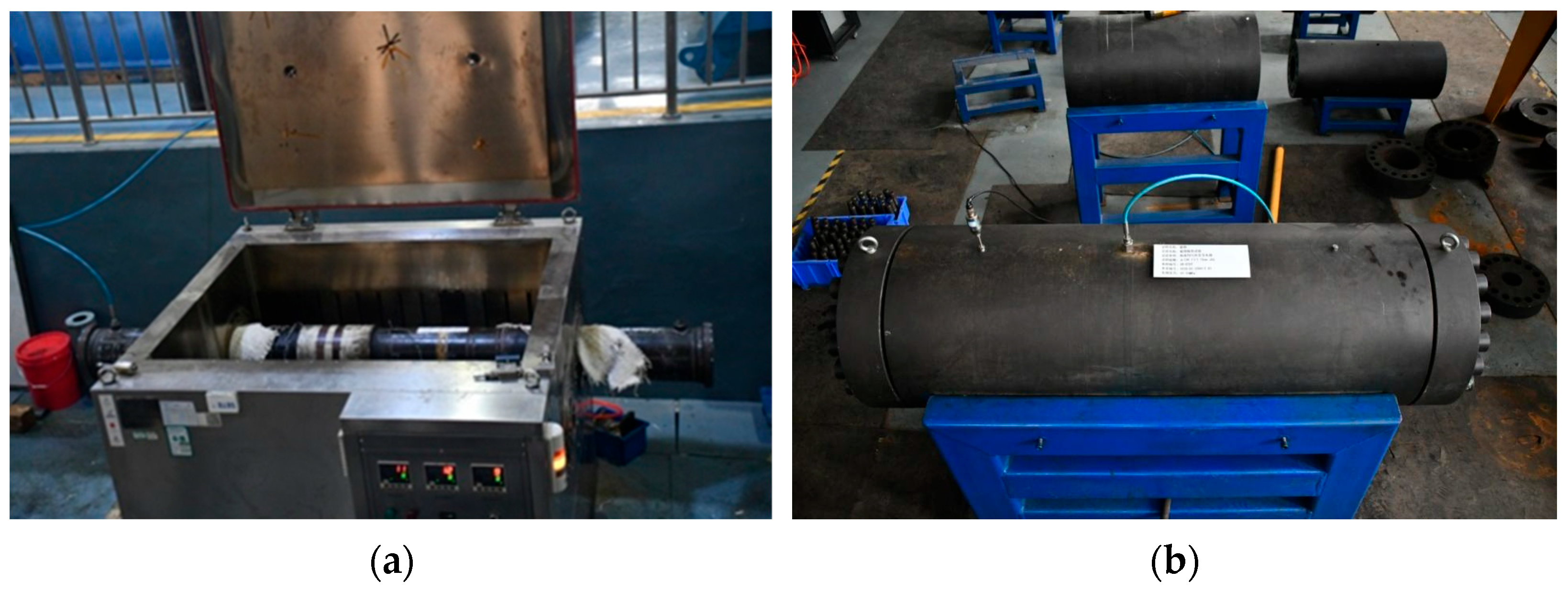

2.2. Corrosion Test of Hanging Coupon Specimens

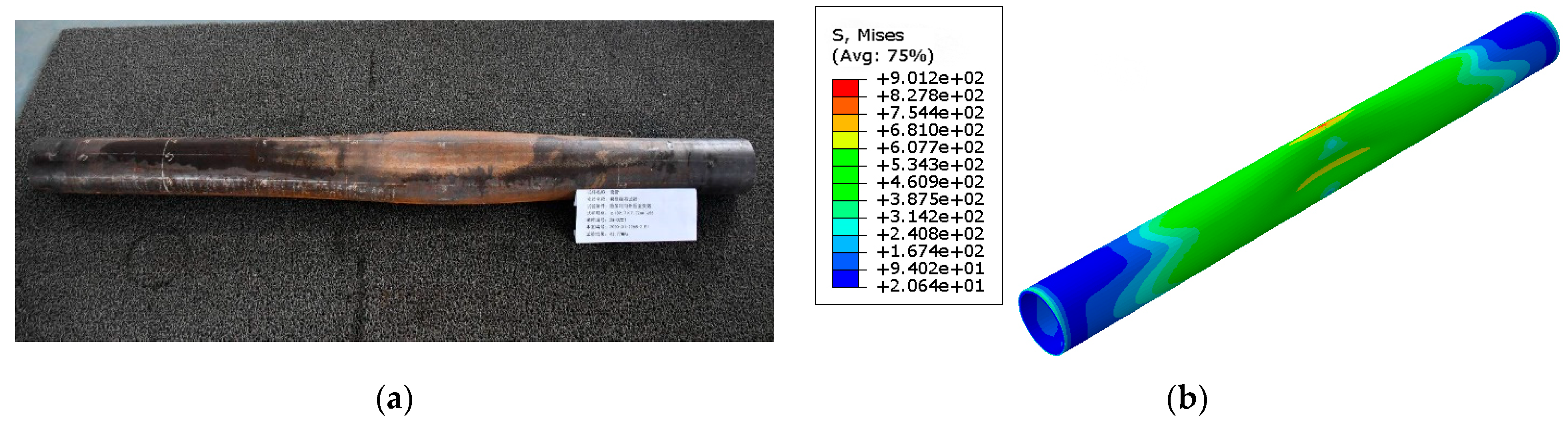

2.3. Full-Scale Casing Corrosion Test and Collapse Strength Evaluation

2.4. Finite Element Model of Casing with Corrosion Defects

- (1)

- The shape of the corrosion pits on the casing surface is simplified to regular cylindrical, conical, and semi-ellipsoidal forms, and these pits are uniformly distributed along the central area of the casing’s outer wall.

- (2)

- The material is assumed to be homogeneous and isotropic.

3. Results and Discussion

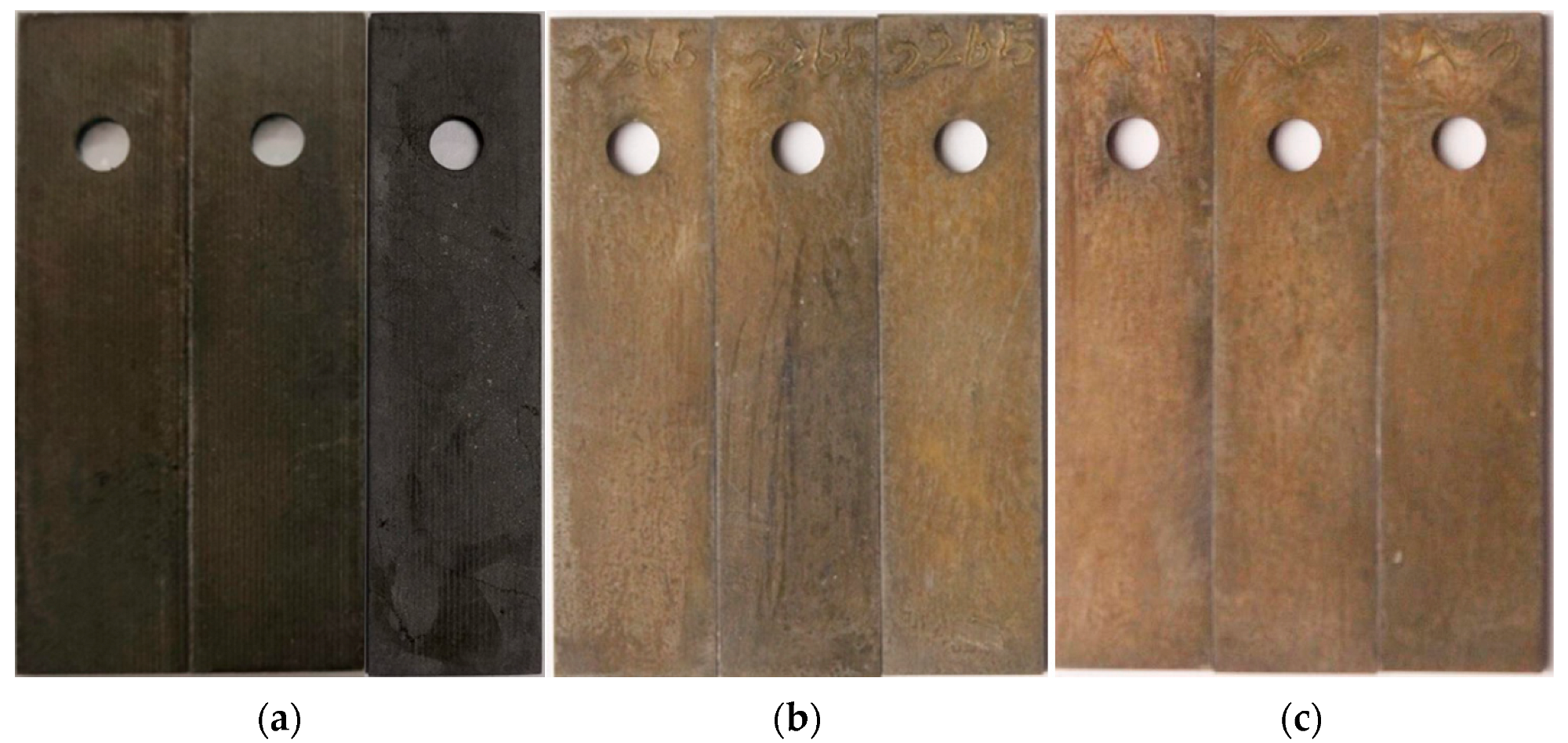

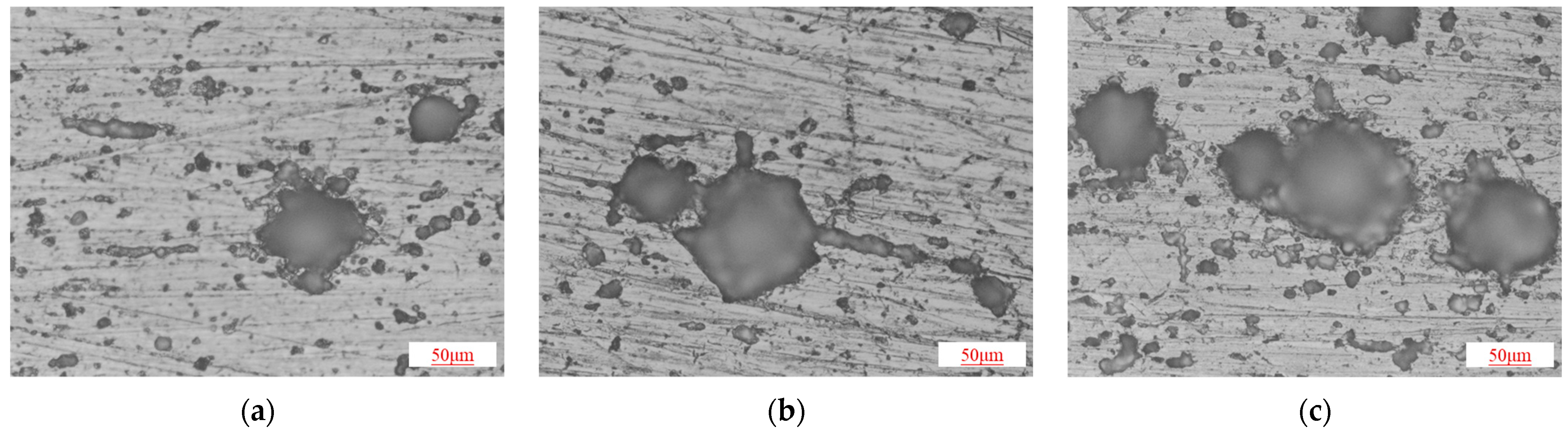

3.1. Influence of Temperature and Pressure on Casing Corrosion Behavior

3.2. Collapse Strength of Corroded Casing and Model Validation

- (1)

- The corrosion defects modeled in the finite element simulation differ from the actual defect morphology;

- (2)

- The casing was modeled as having a perfectly circular cross-section, and the influence of ovality on collapse strength was not considered;

- (3)

- The simulation of the plastic deformation stage involves complex nonlinear behavior, leading to deviations from the actual test results.

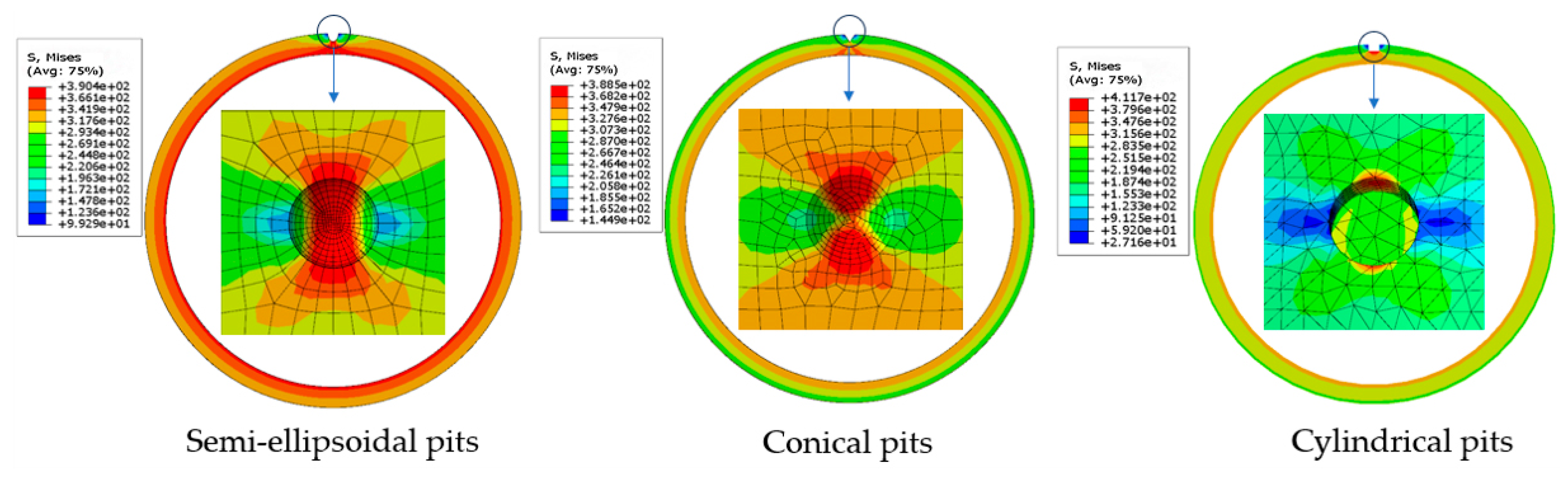

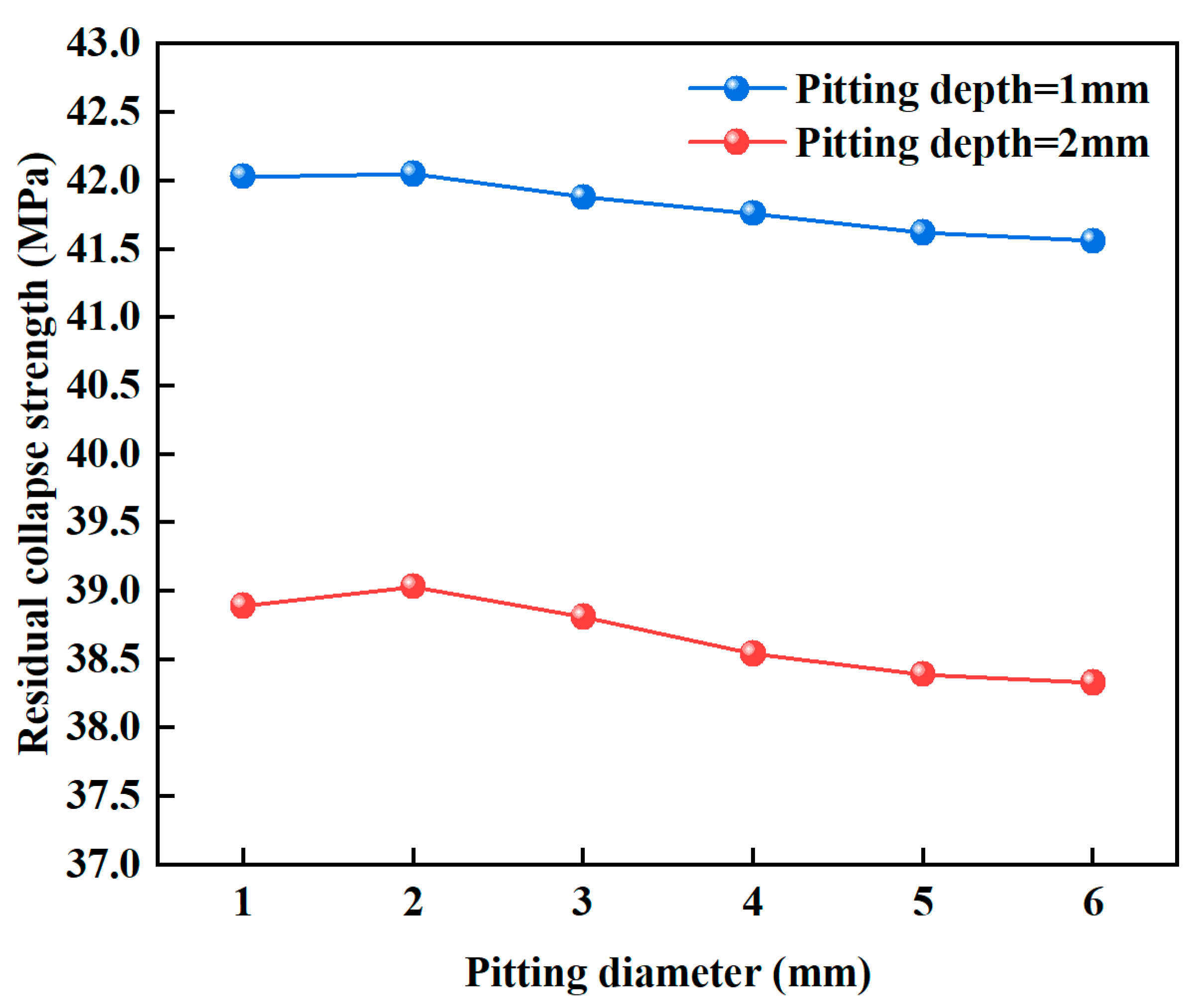

3.3. Influence of Pit Geometry on Collapse Strength

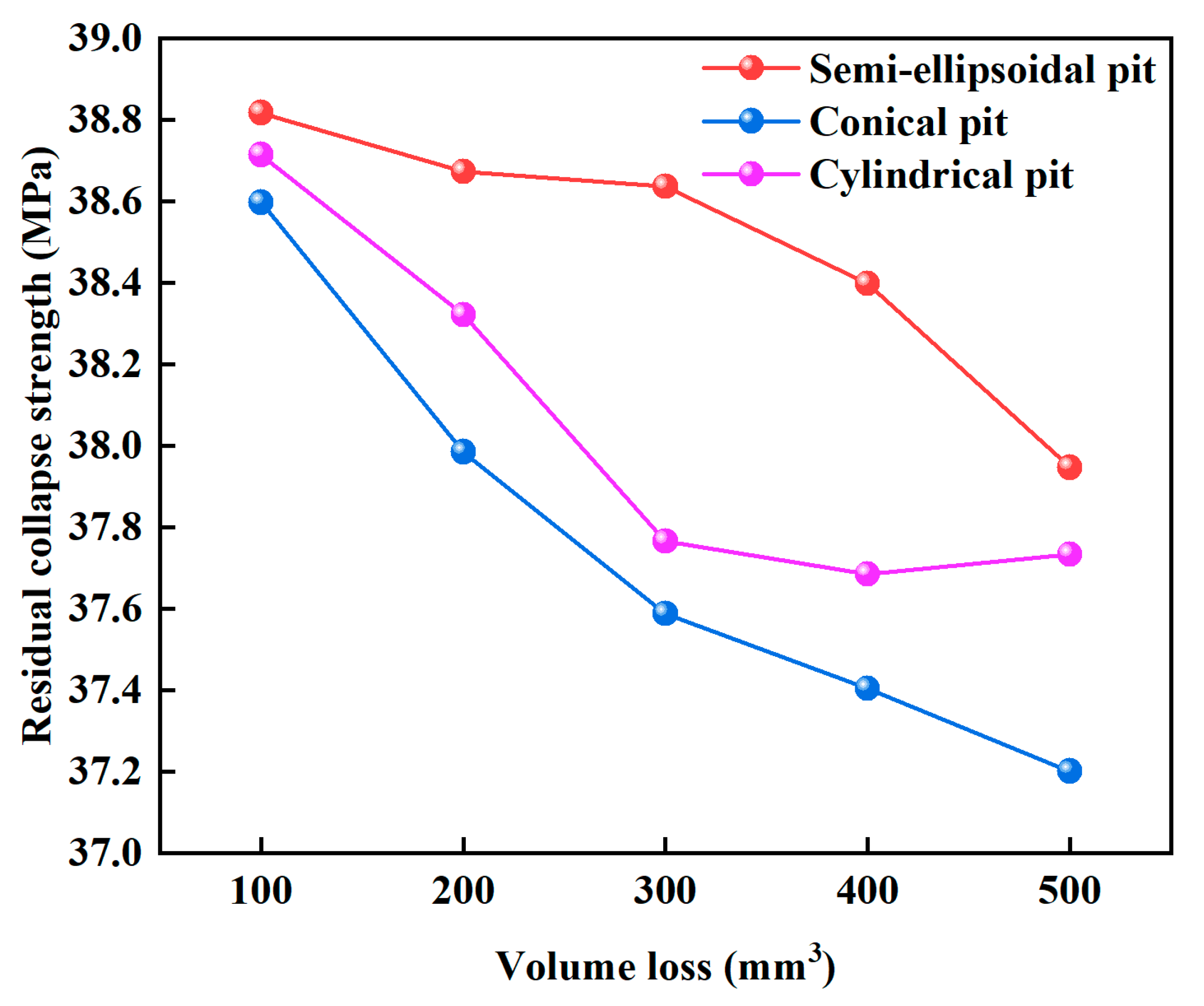

3.4. Influence of Volume Loss on Collapse Strength

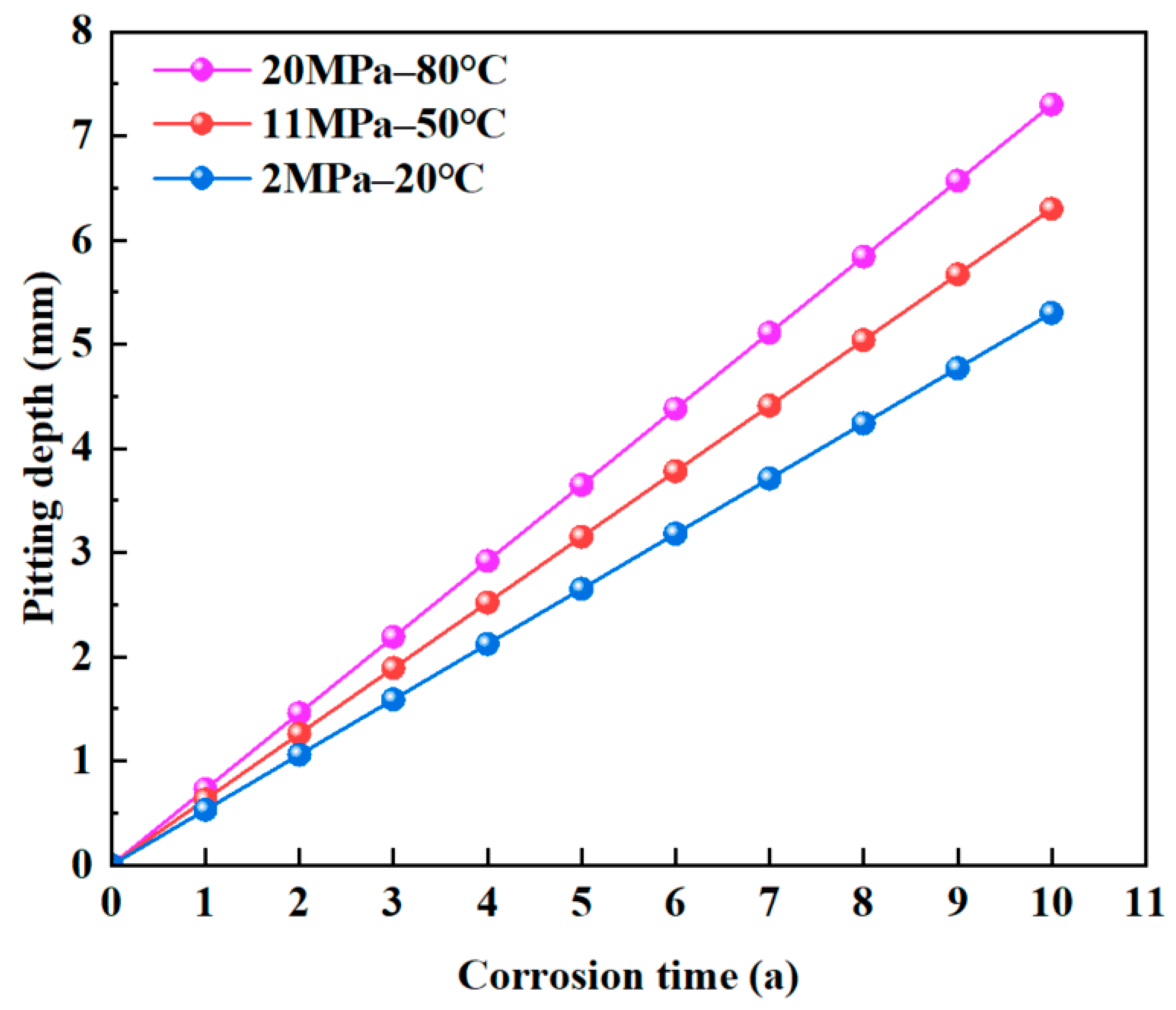

3.5. Prediction of Residual Service Life

4. Conclusions

- (1)

- Elevated temperature and pressure significantly accelerate casing corrosion and reduce collapse strength. Under the 20 MPa–80 °C condition, the corrosion rate increased by 87.5% compared to the 2 MPa–20 °C condition, with greater pit depth and density, leading to a 1.3% reduction in collapse strength.

- (2)

- The collapse strength of casing is influenced by multiple factors, including corrosion pit shape, pit depth, and the volume loss induced by corrosion. As pit depth increases, the collapse strength decreases accordingly. Under the same pit depth, the collapse strength declines with increasing volume loss. Cylindrical pits result in the greatest volume loss and thus the most severe reduction in collapse strength, whereas conical pits cause the least volume loss and have the weakest detrimental effect on collapse resistance.

- (3)

- By combining corrosion test data with finite element simulations, the safe service life of casing was predicted for different well conditions. The predicted lifespans were 4.84 years, 7.57 years, and 11.61 years under 80 °C–20 MPa, 50 °C–11 MPa, and 20 °C–2 MPa conditions, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wu, T.; Xu, J.; Sun, C.; Yan, M.; Yu, C.; Ke, W. Microbiological Corrosion of Pipeline Steel under Yield Stress in Soil Environment. Corros. Sci. 2014, 88, 291–305. [Google Scholar] [CrossRef]

- Mubarak, G.; Verma, C.; Barsoum, I.; Alfantazi, A.; Rhee, K.Y. Internal Corrosion in Oil and Gas Wells during Casings and Tubing: Challenges and Opportunities of Corrosion Inhibitors. J. Taiwan Inst. Chem. Eng. 2023, 150, 105027. [Google Scholar] [CrossRef]

- Tang, F.; Lin, Z.; Chen, G.; Yi, W. Three-Dimensional Corrosion Pit Measurement and Statistical Mechanical Degradation Analysis of Deformed Steel Bars Subjected to Accelerated Corrosion. Constr. Build. Mater. 2014, 70, 104–117. [Google Scholar] [CrossRef]

- Li, Y.; Liu, W.; Yan, W.; Deng, J.; Li, H. Mechanism of Casing Failure during Hydraulic Fracturing: Lessons Learned from a Tight-Oil Reservoir in China. Eng. Fail. Anal. 2019, 98, 58–71. [Google Scholar] [CrossRef]

- Yin, F.; Deng, Y.; He, Y.; Gao, D.; Hou, B. Mechanical Behavior of Casing Crossing Slip Formation in Waterflooding Oilfields. J. Pet. Sci. Eng. 2018, 167, 796–802. [Google Scholar] [CrossRef]

- Wu, T.; Li, M.; Liu, N.; Zhang, T.; Su, J. Research on Mechanism of Non-Uniform In-Situ Stress Induced Casing Damage Based on Finite Element Analysis. Appl. Sci. 2024, 14, 5987. [Google Scholar] [CrossRef]

- Zachary, C.; Bello, O.; Teodoriu, C. Calculation and Prediction of Casing Collapse Strength Based on a New Yield Strength Acquisition Method. J. Nat. Gas Sci. Eng. 2021, 95, 104149. [Google Scholar] [CrossRef]

- Dou, Y.; Li, Z.; Cheng, J.; Zhang, Y. Experimental Study on Corrosion Performance of Oil Tubing Steel in HPHT Flowing Media Containing O2 and CO2. Materials 2020, 13, 5214. [Google Scholar] [CrossRef]

- Zhou, L.; Huang, X.; Song, W.; Huang, C.; Liu, H.; Wang, H. Multi-Factor Corrosion Model of TP110TS Steel in H2S/CO2 Coexistence and Life Prediction of Petroleum Casings. Int. J. Press. Vessel. Pip. 2024, 209, 105204. [Google Scholar] [CrossRef]

- Li, Y.; Cai, Z.; Huang, L.; Liao, R. A Comparative Study of the Corrosion Behavior of P110 Casing Steel in Simulated Concrete Liquid Containing Chloride and Annulus Fluid from an Oil Well. Coatings 2024, 14, 294. [Google Scholar] [CrossRef]

- Dong, B.; Zeng, D.; Yu, Z.; Cai, L.; Yu, H.; Shi, S.; Tian, G.; Yi, Y. Major Corrosion Influence Factors Analysis in the Production Well of CO2 Flooding and the Optimization of Relative Anti-Corrosion Measures. J. Pet. Sci. Technol. 2021, 200, 108052. [Google Scholar] [CrossRef]

- Cheng, S.; Zhao, X.; Fu, A.; Li, D.; Yin, C.; Feng, Y. Corrosion Behavior of J55 and N80 Carbon Steels in Simulated Formation Water under Different CO2 Partial Pressures. Coatings 2022, 12, 1402. [Google Scholar] [CrossRef]

- Yan, Y.; Shao, B.; Zhou, X.; Song, S.; Zhou, X.; Yan, X. A Study on the Influence of Double Ellipsoidal Pitting Corrosion on the Collapsing Strength of the Casing. Eng. Fail. Anal. 2019, 100, 11–24. [Google Scholar] [CrossRef]

- Li, S.; Zhang, Z.; Qian, H.; Wang, H.; Fan, F. Research on Remaining Bearing Capacity Evaluation Method for Corroded Pipelines with Complex Shaped Defects. Ocean Eng. 2024, 296, 116805. [Google Scholar] [CrossRef]

- Sedmak, A.; Arsić, M.; Šarkoćević, Ž.; Medjo, B.; Rakin, M.; Arsić, D.; Lazić, V. Remaining Strength of API J55 Steel Casing Pipes Damaged by Corrosion. Int. J. Press. Vessel. Pip. 2020, 188, 104230. [Google Scholar] [CrossRef]

- Wang, H.; Yu, Y.; Yu, J.; Jin, C.; Zhao, Y.; Fan, Z.; Zhang, Y. Effect of 3D Random Pitting Defects on the Collapse Pressure of Pipe—Part II: Numerical Analysis. Thin-Walled Struct. 2018, 129, 527–541. [Google Scholar] [CrossRef]

- Nakai, T.; Matsushita, H.; Yamamoto, N. Effect of Pitting Corrosion on the Ultimate Strength of Steel Plates Subjected to In-Plane Compression and Bending. J. Mar. Sci. Technol. 2006, 11, 52–64. [Google Scholar] [CrossRef]

- Sheng, J.; Xia, J. Effect of Simulated Pitting Corrosion on the Tensile Properties of Steel. Constr. Build. Mater. 2017, 131, 90–100. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, S.; Wang, H.; Li, A. Predicting the Residual Strength and Deformability of Corroded Steel Plate Based on the Corrosion Morphology. Constr. Build. Mater. 2017, 152, 777–793. [Google Scholar] [CrossRef]

- Wang, H.; Yu, Y.; Yu, J.; Xu, W.; Chen, H.; Wang, Z.; Han, M. Effect of Pitting Defects on the Buckling Strength of Thick-Wall Cylinder under Axial Compression. Constr. Build. Mater. 2019, 224, 226–241. [Google Scholar] [CrossRef]

- Dobson, T.; Larrosa, N.; Coules, H. The Role of Corrosion Pit Topography on Stress Concentration. Eng. Fail. Anal. 2024, 157, 107900. [Google Scholar] [CrossRef]

- Li, F.; Yan, W.; Kong, X.; Li, J.; Zhang, W.; Kang, Z.; Yang, T.; Tang, Q.; Wang, K.; Tan, C. Study on Multi-Factor Casing Damage Prediction Method Based on Machine Learning. Energy 2024, 296, 131044. [Google Scholar] [CrossRef]

- Hu, J.; Tian, Y.; Teng, H.; Yu, L.; Zheng, M. The Probabilistic Life Time Prediction Model of Oil Pipeline Due to Local Corrosion Crack. Theor. Appl. Fract. Mech. 2014, 70, 10–18. [Google Scholar] [CrossRef]

- Ossai, C.I.; Boswell, B.; Davies, I. Markov Chain Modelling for Time Evolution of Internal Pitting Corrosion Distribution of Oil and Gas Pipelines. Eng. Fail. Anal. 2016, 60, 209–228. [Google Scholar] [CrossRef]

- El Amine Ben Seghier, M.; Keshtegar, B.; Elahmoune, B. Reliability Analysis of Low, Mid and High-Grade Strength Corroded Pipes Based on Plastic Flow Theory Using Adaptive Nonlinear Conjugate Map. Eng. Fail. Anal. 2018, 90, 245–261. [Google Scholar] [CrossRef]

- SY/T 6128-2012; Procedure for Evaluation Tests of Tubing and Casing Connection Properties. Petroleum Industry Press: Beijing, China, 2012.

- GB/T 17897-2016; Corrosion of Metals and Alloys—Corrosion Test for Pitting Corrosion Resistance of Stainless Steels in the Ferric Chloride Solution. Standards Press of China: Beijing, China, 2016.

- Li, H.; Huang, K.; Zeng, Q.; Sun, C. Residual Strength Assessment and Residual Life Prediction of Corroded Pipelines: A Decade Review. Energies 2022, 15, 726. [Google Scholar] [CrossRef]

- Zaferani, S.H. The Application of Finite Element Analysis as a New Approach in Corrosion and Integrity Assessment Programs. Int. J. Petrochem. Sci. Eng. 2017, 2, 18–20. [Google Scholar] [CrossRef]

- Civan, F. Correlation of the Pit Depth in Crystal Etching by Dissolution. J. Colloid Interface Sci. 2000, 222, 156–158. [Google Scholar] [CrossRef]

| C | Si | Mn | P | S | Cu | Ni | Cr | Mo | Nb | V | Ti |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.18 | 0.17 | 0.90 | 0.014 | 0.005 | 0.013 | 0.013 | 0.028 | 0.006 | 0.013 | <0.005 | 0.0019 |

| Steel | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation | Young’s Modulus (GPa) | Poisson’s Ratio | HRC |

|---|---|---|---|---|---|---|

| J55 | 388 | 630 | 31% | 200 | 0.3 | 14.5 |

| Pressure (MPa) | Temperature (°C) | Duration (Days) | Specimen Type |

|---|---|---|---|

| 2 | 20 | 7 | Hanging coupon specimen |

| 11 | 50 | 7 | |

| 20 | 80 | 7 | |

| 2 | 20 | 30 | Full-scale casing |

| 11 | 50 | 30 | |

| 20 | 80 | 30 |

| Pressure (MPa) | Temperature (°C) | Average Corrosion Rate (mm/a) | Maximum Pit Depth (μm) | Pitting Density (m−2) |

|---|---|---|---|---|

| 2 | 20 | 0.008 | 10 | 7 × 106 |

| 11 | 50 | 0.015 | 13 | 7 × 106 |

| 20 | 80 | 0.017 | 13 | 8 × 106 |

| Pressure (MPa) | Temperature (°C) | Experimental Result (MPa) | Finite Element Result (MPa) | Error (%) |

|---|---|---|---|---|

| 2 | 20 | 43.93 | 42.51 | −3.2 |

| 11 | 50 | 43.77 | 42.12 | −3.8 |

| 20 | 80 | 43.37 | 41.96 | −3.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Fan, J.; Huo, P.; Zhang, Y. Analysis of Collapse Strength and Life Prediction of Casings in Formation Water Service Environments. Materials 2025, 18, 2934. https://doi.org/10.3390/ma18132934

Li W, Fan J, Huo P, Zhang Y. Analysis of Collapse Strength and Life Prediction of Casings in Formation Water Service Environments. Materials. 2025; 18(13):2934. https://doi.org/10.3390/ma18132934

Chicago/Turabian StyleLi, Wanzhong, Jinlong Fan, Pengbo Huo, and Yongqiang Zhang. 2025. "Analysis of Collapse Strength and Life Prediction of Casings in Formation Water Service Environments" Materials 18, no. 13: 2934. https://doi.org/10.3390/ma18132934

APA StyleLi, W., Fan, J., Huo, P., & Zhang, Y. (2025). Analysis of Collapse Strength and Life Prediction of Casings in Formation Water Service Environments. Materials, 18(13), 2934. https://doi.org/10.3390/ma18132934