Gradient Joule Heating Curing Performance of Steel-Fiber-Reinforced High-Performance Concrete in Severe Cold Environments: A Preliminary Attempt for Deep-Cold Concrete Construction

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

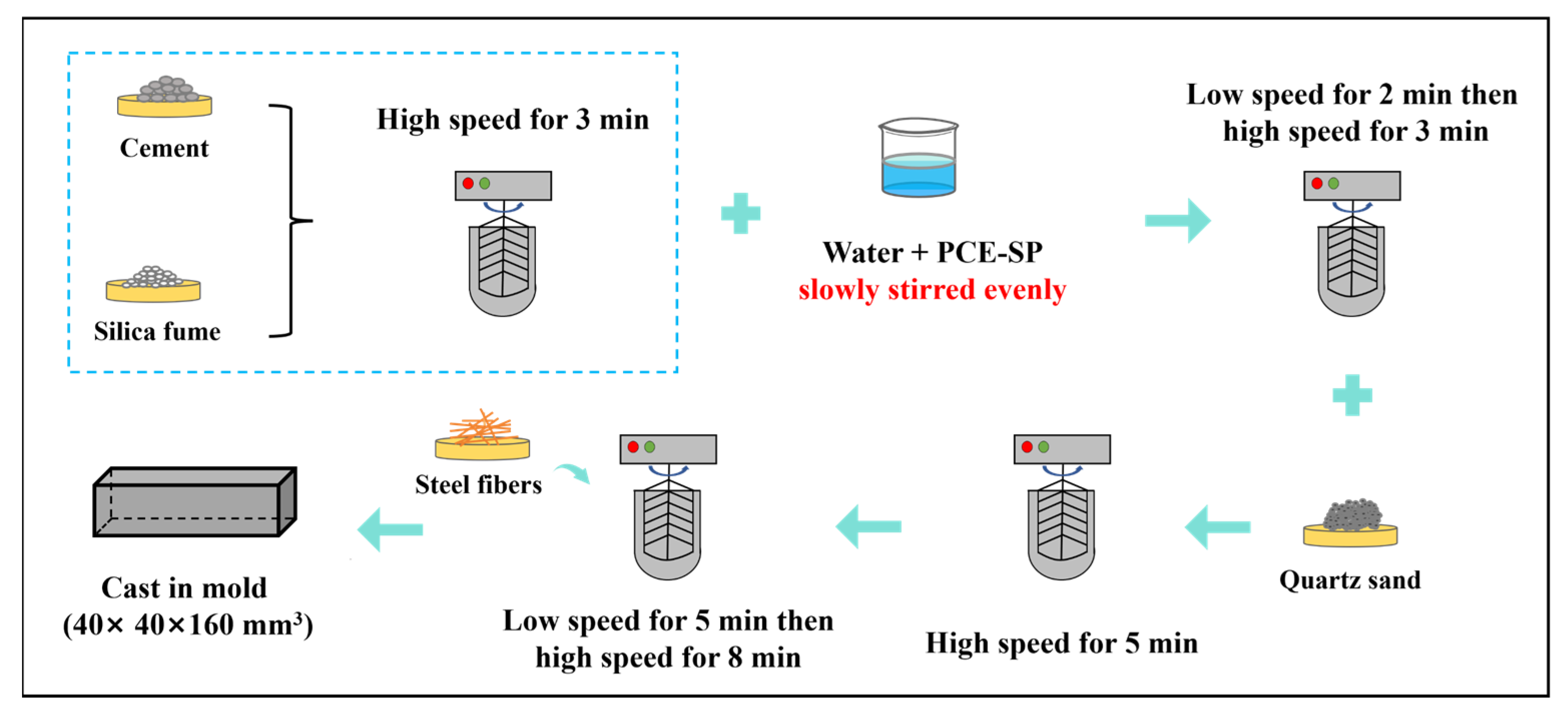

2.2. Mixing Proportion and Preparation of SFR-HPC Specimens

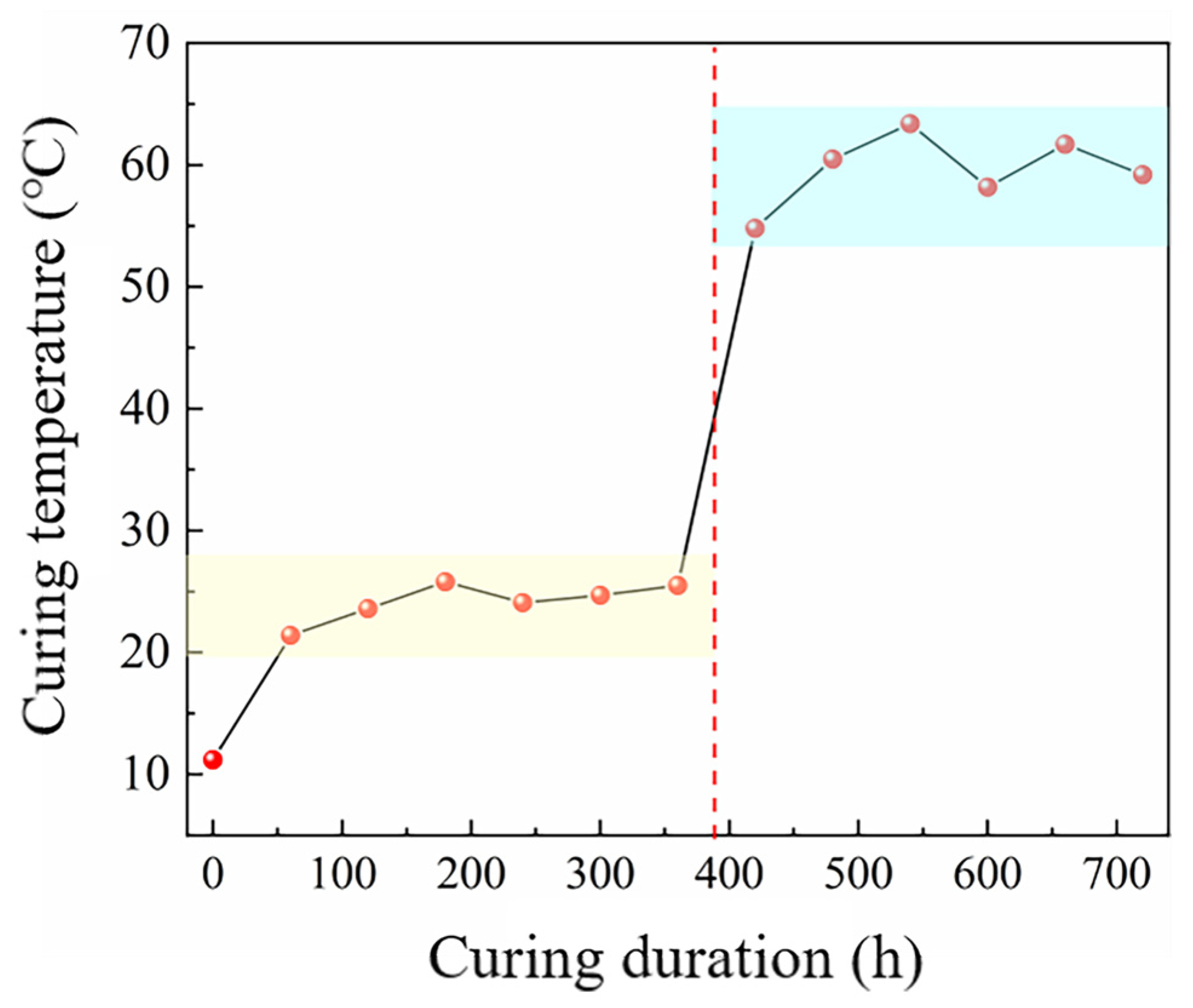

2.3. Curing Regime

2.4. Temperature Monitoring

2.5. Mechanical Property Test

2.6. Microstructure Characterization

3. Results and Discussion

3.1. The Temperature Development Regulation of GJH-Cured Specimens

3.2. Mechanical Properties of SFR-HPC Specimens Cured by GJH Curing

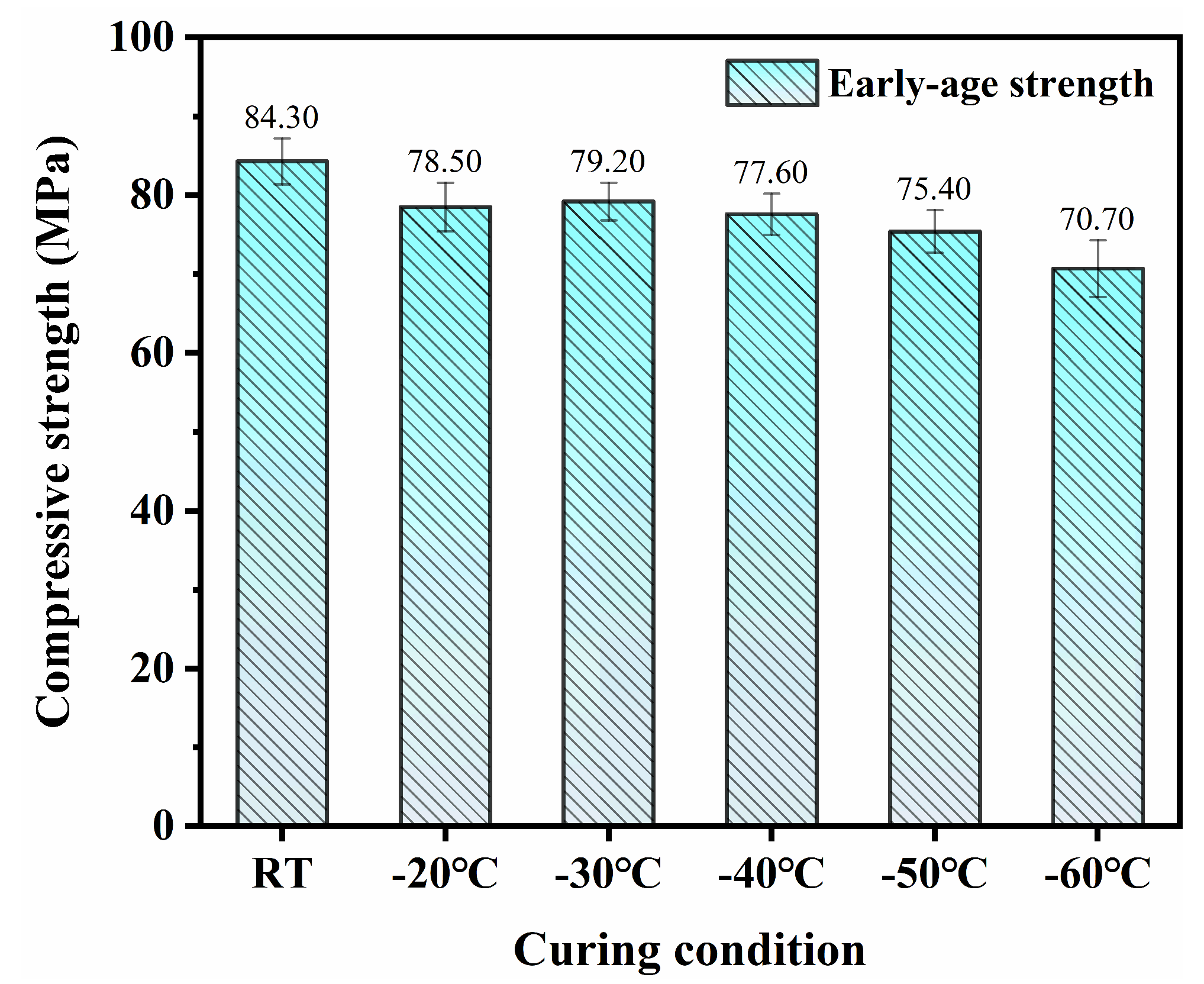

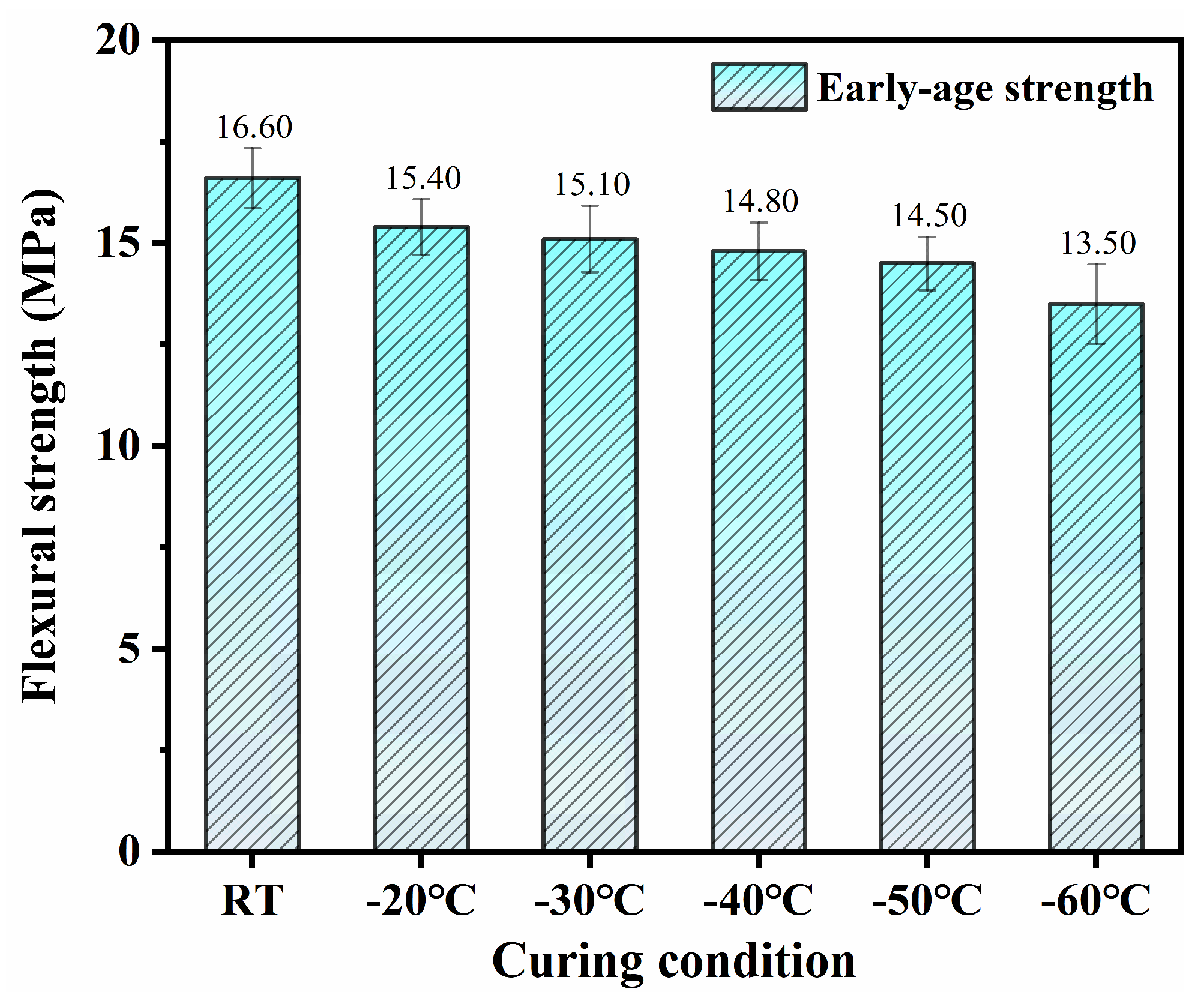

3.2.1. Early-Age Mechanical Properties

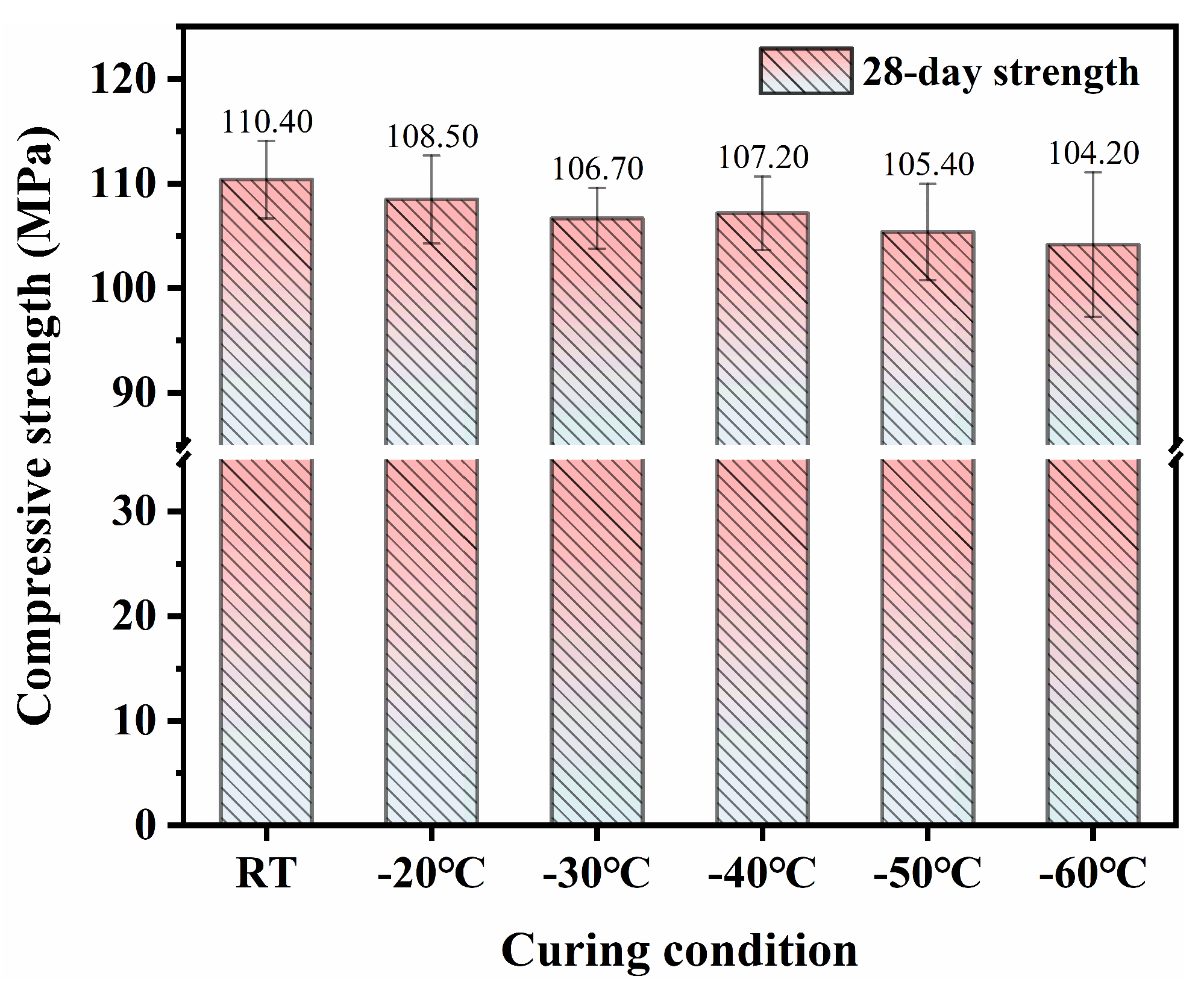

3.2.2. Long-Term Mechanical Properties

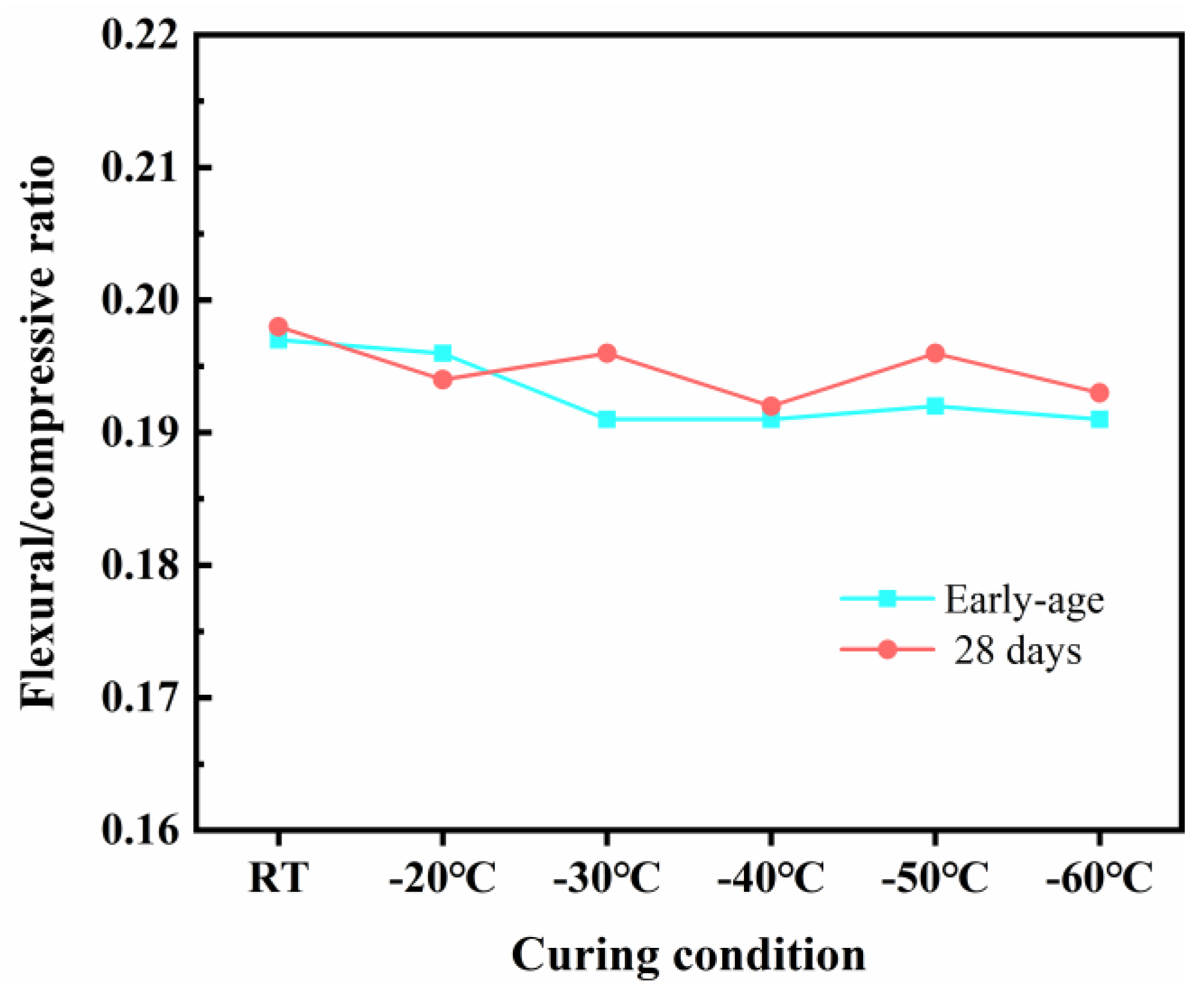

3.2.3. The Ratio of Flexural to Compressive Strength

3.3. Hydration Product Analysis

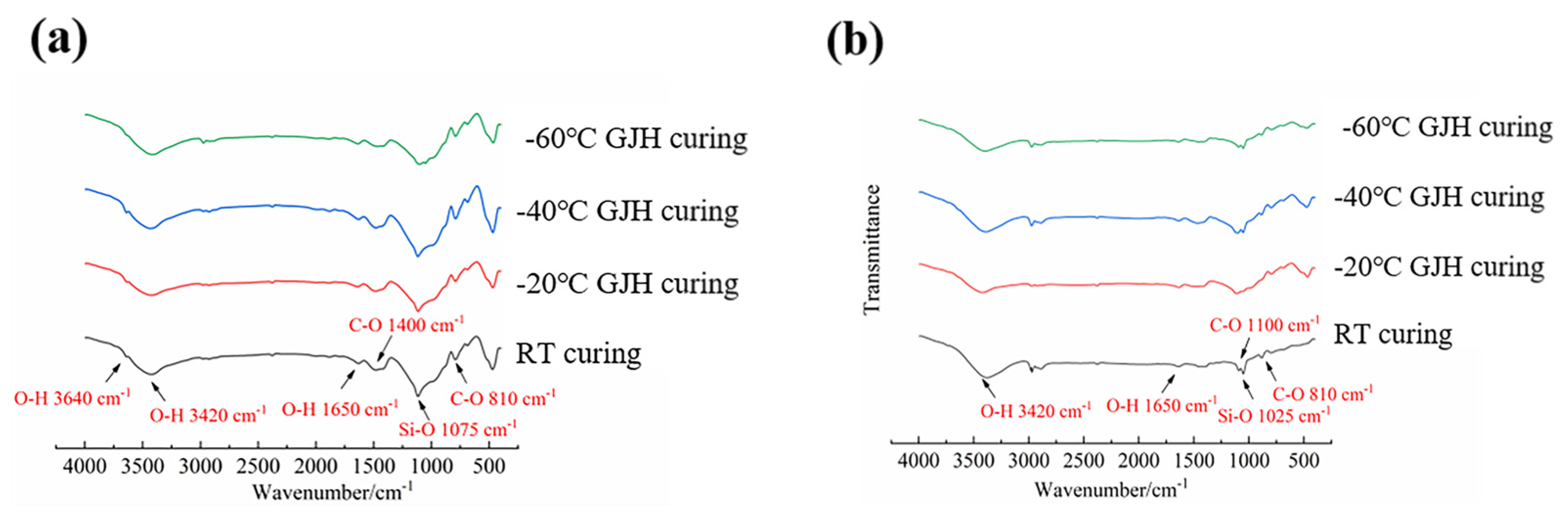

3.3.1. Fourier Transform Infrared (FT-IR) Spectroscopy

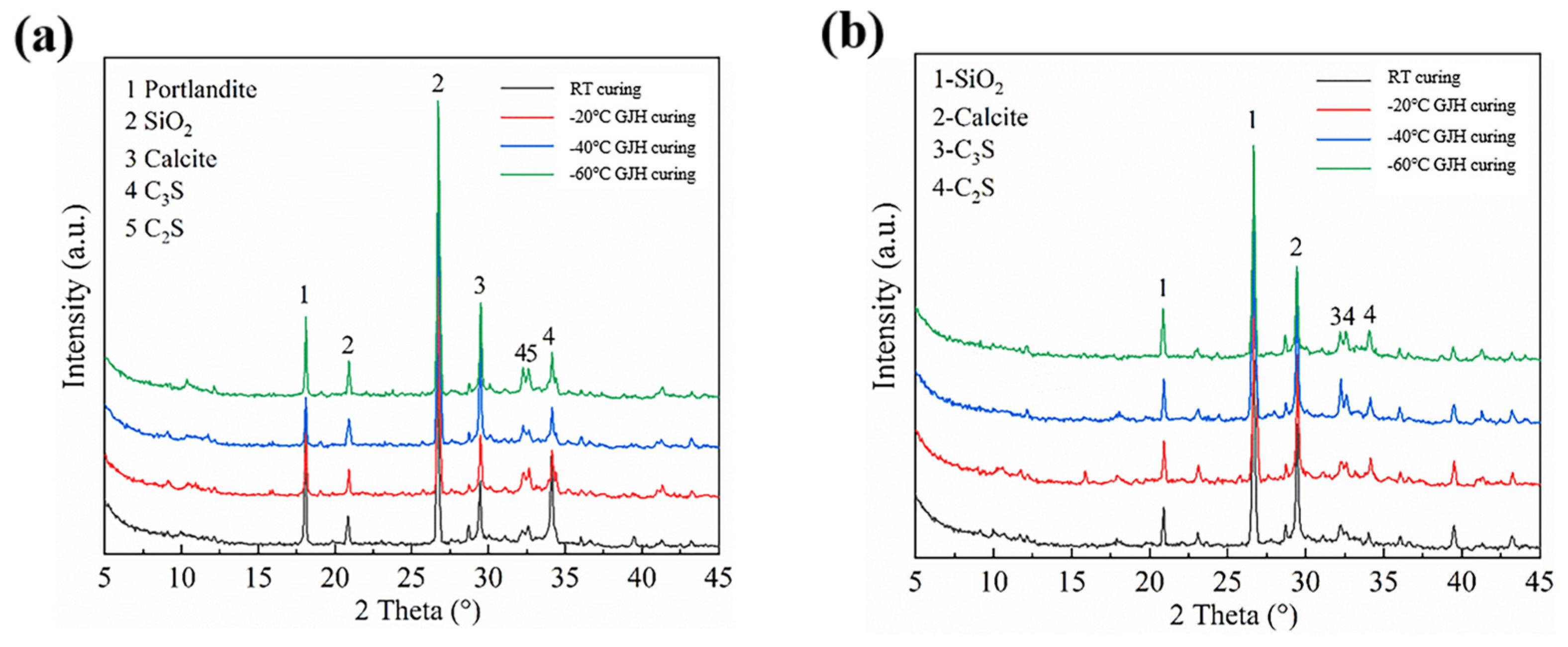

3.3.2. Phase Composition

3.4. Pore Structure Analysis

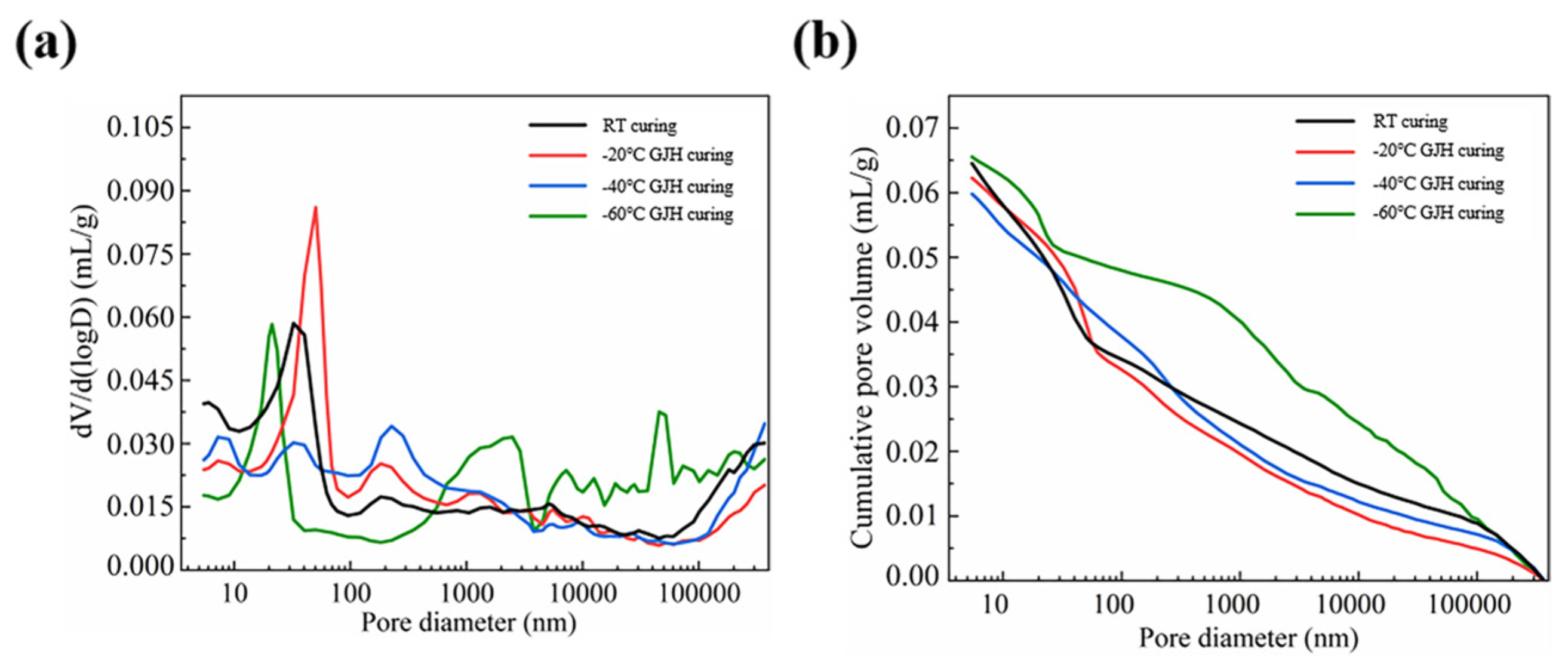

3.4.1. The Pore Distribution of the Specimens at Early Age

3.4.2. The Pore Distribution of the Specimens at 28 Days

4. Conclusions

- (1)

- GJH curing can effectively promise the mechanical strength development of SFR-HPC in subzero environments while ensuring favorable long-term performance development. The specimens cured at −20 °C, −30 °C, −40 °C, and −50 °C for 2 days exhibited compressive strengths of 75.8 MPa, 79.2 MPa, 77.6 MPa, and 75.4 MPa, respectively, and flexural strengths of 15.4 MPa, 15.1 MPa, 14.8 MPa, and 14.5 MPa, respectively. These results were comparable to those subjected to RT curing for 3 days (compressive strength: 84.3 MPa; flexural strength: 16.6 MPa). At −60 °C, the mechanical properties exhibited a declining trend but still exceeded 60 MPa and 13 GPa, confirming the feasibility and effectiveness of GJH curing.

- (2)

- GJH curing does not adversely affect the formation of hydration products in SFR-HPC. FTIR and XRD analyses confirmed that the hydration products under GJH curing remained consistent with those under RT curing across all temperatures, demonstrating the stability of GJH curing.

- (3)

- As the environment temperature decreased, the pore structure of SFR-HPC cured by GJH curing showed obvious deterioration at early age, while specimens at −20 °C exhibited a more refined pore structure than RT-cured specimens, and those at −40 °C and −60 °C displayed inferior porosity. To be specific, the pore size distributions (>1000 nm) of the cured specimens under RT curing, −20 °C, −40 °C, and −60 °C were 37.4%, 32.0%, 36.8%, and 60.7%, respectively. However, the differences in pore structure diminished with prolonged curing duration; the most probable pore size of the specimens cured at −60 °C for 28 days decreased to ~226 nm.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lu, J.X.; Shen, P.; Ali, H.A.; Poon, C.S. Mix Design and Performance of Lightweight Ultra High-Performance Concrete. Mater. Des. 2022, 216, 110553. [Google Scholar] [CrossRef]

- Azmee, N.M.; Shafiq, N. Ultra-High Performance Concrete: From Fundamental to Applications. Case Stud. Constr. Mater. 2018, 9, e00197. [Google Scholar] [CrossRef]

- Meng, C.; Li, W.; Cai, L.; Shi, X.; Jiang, C. Experimental Research on Durability of High-Performance Synthetic Fibers Reinforced Concrete: Resistance to Sulfate Attack and Freezing-Thawing. Constr. Build. Mater. 2020, 262, 120055. [Google Scholar] [CrossRef]

- Shi, C.; Wu, Z.; Xiao, J.; Wang, D.; Huang, Z.; Fang, Z. A Review on Ultra High Performance Concrete: Part I. Raw Materials and Mixture Design. Constr. Build. Mater. 2015, 101, 741–751. [Google Scholar] [CrossRef]

- Liu, Y.; Fu, S.; Gao, J.; Yang, Y. Prediction for Temperature Evolution and Compressive Strength of Non-Mass Concrete with Thermal Insulation Curing in Cold Weather. J. Build. Eng. 2020, 32, 101737. [Google Scholar] [CrossRef]

- Çullu, M.; Arslan, M. The Effects of Antifreeze Use on Physical and Mechanical Properties of Concrete Produced in Cold Weather. Compos. Part B Eng. 2013, 50, 202–209. [Google Scholar] [CrossRef]

- Liu, Y.; Tian, W.; Ma, G. Electric Activation Curing Behaviour of Reinforced Concrete Beam under Severely-Cold Environment: Breakthrough of Rapid Concrete Manufacturing at Cold Region. Constr. Build. Mater. 2023, 384, 131443. [Google Scholar] [CrossRef]

- Ouyang, M.; Tian, W.; Liu, Y.; Wang, W. Gradient Power Modified Ohmic Heating Curing to Prepare Hybrid Carbon Fibers/High Performance Concrete under Deep-Freeze Low Temperature. Constr. Build. Mater. 2022, 330, 127279. [Google Scholar] [CrossRef]

- Khan, J.; Santha Kumar, G. Influence of Binary Antifreeze Admixtures on Strength Performance of Concrete under Cold Weather Conditions. J. Build. Eng. 2021, 34, 102055. [Google Scholar] [CrossRef]

- Barna, L.A.; Seman, P.M.; Korhonen, C.J. Energy-Efficient Approach to Cold-Weather Concreting. J. Mater. Civ. Eng. 2011, 23, 1544–1551. [Google Scholar] [CrossRef]

- Nmai, C.K. Cold Weather Concreting. Cem. Concr. Compos. 1998, 20, 121–128. [Google Scholar] [CrossRef]

- ACI Committee 306. Cold Weather Concreting. In Proceedings of the American Concrete Institute; Elsevier Ltd.: Amsterdam, The Netherlands, 2010. [Google Scholar]

- ACI 306.1-90; Standard Specification for Cold Weather Concreting. American Concrete Institute: Farmington Hills, MI, USA, 2002; pp. 1–5.

- Tian, W.; Liu, Y.; Wang, W. Enhanced Ohmic Heating and Chloride Adsorption Efficiency of Conductive Seawater Cementitious Composite: Effect of Non-Conductive Nano-Silica. Compos. Part B Eng. 2022, 236, 109854. [Google Scholar] [CrossRef]

- Tian, W.; Liu, X.; Wang, X.; Zou, F.; Xu, Y.; Liu, Y.; Lu, J.X.; Xu, L.; Wang, W. Improving Electrical-Thermal-Mechanical Functional Performance of Intelligent Conductive Cementitious Composites: Through Fiber Orientation by Magnetic Field. J. Build. Eng. 2025, 104, 112374. [Google Scholar] [CrossRef]

- Kovtun, M.; Ziolkowski, M.; Shekhovtsova, J.; Kearsley, E. Direct Electric Curing of Alkali-Activated Fly Ash Concretes: A Tool for Wider Utilization of Fly Ashes. J. Clean. Prod. 2016, 133, 220–227. [Google Scholar] [CrossRef]

- Ziolkowski, M.; Kovtun, M. Confined-Direct Electric Curing of NaOH-Activated Fly Ash Based Brick Mixtures under Free Drainage Conditions: Part 1. Factorial Experimental Design. Constr. Build. Mater. 2017, 155, 1050–1062. [Google Scholar] [CrossRef]

- Han, B.; Yu, X.; Kwon, E. A Self-Sensing Carbon Nanotube/Cement Composite for Traffic Monitoring. Nanotechnology 2009, 20, 445501. [Google Scholar] [CrossRef]

- Dong, S.; Han, B.; Yu, X.; Ou, J. Constitutive Model and Reinforcing Mechanisms of Uniaxial Compressive Property for Reactive Powder Concrete with Super-Fine Stainless Wire. Compos. Part B Eng. 2019, 166, 298–309. [Google Scholar] [CrossRef]

- Liu, Y.; Tian, W.; Wang, M.; Qi, B.; Wang, W. Rapid Strength Formation of On-Site Carbon Fiber Reinforced High-Performance Concrete Cured by Ohmic Heating. Constr. Build. Mater. 2020, 244, 118344. [Google Scholar] [CrossRef]

- Tian, W.; Liu, Y.; Wang, W. Multi-Structural Evolution of Conductive Reactive Powder Concrete Manufactured by Enhanced Ohmic Heating Curing. Cem. Concr. Compos. 2021, 123, 104199. [Google Scholar] [CrossRef]

- Tian, W.; Wang, M.; Liu, Y.; Wang, W. Ohmic Heating Curing of High Content Fly Ash Blended Cement-Based Composites towards Sustainable Green Construction Materials Used in Severe Cold Region. J. Clean. Prod. 2020, 276, 123300. [Google Scholar] [CrossRef]

- Tian, W.; Qi, B.; Liu, Y.; Liu, K.; Wang, W. Early Frost Resistance and Permeability Properties of Carbon Fiber/Cement-Based Composite Cured by Ohmic Heating under Ultra-Low Temperature. Constr. Build. Mater. 2021, 282, 122729. [Google Scholar] [CrossRef]

- Zhang, L.; Ouyang, M.; Tian, W.; Liu, Y.; Fu, Q.; Wang, W. Internal Structural Evolution of Conductive Cementitious Composites Subjected to Multi-Step Ohmic Heating Curing Strategy under Severely Cold Temperature. J. Build. Eng. 2023, 80, 108101. [Google Scholar] [CrossRef]

- Tian, W.; Liu, Y.; Wang, M.; Liu, H.; Yu, K.; Xia, Y.; Wang, W.; Li, R. Improved Chloride Binding Capacity in Sustainable Metakaolin Blended Seawater Cement Mortar: Effect of External Alternative Electric Field. J. Build. Eng. 2024, 98, 111454. [Google Scholar] [CrossRef]

- Tian, W.; Liu, Y.; Liu, H.; Wang, W. Performance Evolution and Chloride Adsorption Efficiency of Seawater Mixed Cement-Based Materials Subjected to Ohmic Heating Curing under a Severely Cold Environment. J. Mater. Civ. Eng. 2023, 35, 04023459. [Google Scholar] [CrossRef]

- Kahanji, C.; Ali, F.; Nadjai, A.; Alam, N. Effect of Curing Temperature on the Behaviour of UHPFRC at Elevated Temperatures. Constr. Build. Mater. 2018, 182, 670–681. [Google Scholar] [CrossRef]

- Ylmén, R.; Jäglid, U.; Panas, I. Monitoring Early Hydration of Cement by Ex Situ and In Situ ATR-FTIR—A Comparative Study. J. Am. Ceram. Soc. 2014, 97, 3669–3675. [Google Scholar] [CrossRef]

- Sáez Del Bosque, I.F.; Martínez-Ramírez, S.; Blanco-Varela, M.T. FTIR Study of the Effect of Temperature and Nanosilica on the Nano Structure of C-S-H Gel Formed by Hydrating Tricalcium Silicate. Constr. Build. Mater. 2014, 52, 314–323. [Google Scholar] [CrossRef]

- Li, B.; Huo, B.; Cao, R.; Wang, S.; Zhang, Y. Sulfate Resistance of Steam Cured Ferronickel Slag Blended Cement Mortar. Cem. Concr. Compos. 2019, 96, 204–211. [Google Scholar] [CrossRef]

| Materials | SiO2 | Al2O3 | Fe2O3 | MgO | CaO | SO3 |

|---|---|---|---|---|---|---|

| Cement | 20.86 | 5.47 | 3.94 | 1.73 | 62.23 | 2.66 |

| Silica fume | 95.8 | 0.8 | 0.2 | 0.2 | 0.5 | - |

| Silica Fume (wt%) | Sand-to-Binder Ratio | Water-to-Binder Ratio | Steel Fiber Content (vol%) | PCE-SP (wt%) |

|---|---|---|---|---|

| 20 | 1:1 | 0.20 | 2.5 | 2.5 |

| Specimen | Pore Size Distribution (%) | |||

|---|---|---|---|---|

| <20 nm | 20~100 nm | 100~1000 nm | >1000 nm | |

| RT-cured | 21.8 | 27.7 | 13.1 | 37.4 |

| −20 °C GJH-cured | 15.5 | 32.8 | 19.7 | 32.0 |

| −40 °C GJH-cured | 16.2 | 24.2 | 22.8 | 36.8 |

| −60 °C GJH-cured | 15.7 | 12.5 | 11.1 | 60.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Wang, J.; Zhou, Z.; Zhang, L.; Fu, Q. Gradient Joule Heating Curing Performance of Steel-Fiber-Reinforced High-Performance Concrete in Severe Cold Environments: A Preliminary Attempt for Deep-Cold Concrete Construction. Materials 2025, 18, 2909. https://doi.org/10.3390/ma18122909

Liu X, Wang J, Zhou Z, Zhang L, Fu Q. Gradient Joule Heating Curing Performance of Steel-Fiber-Reinforced High-Performance Concrete in Severe Cold Environments: A Preliminary Attempt for Deep-Cold Concrete Construction. Materials. 2025; 18(12):2909. https://doi.org/10.3390/ma18122909

Chicago/Turabian StyleLiu, Xinyu, Jinghui Wang, Zheng Zhou, Lei Zhang, and Qiang Fu. 2025. "Gradient Joule Heating Curing Performance of Steel-Fiber-Reinforced High-Performance Concrete in Severe Cold Environments: A Preliminary Attempt for Deep-Cold Concrete Construction" Materials 18, no. 12: 2909. https://doi.org/10.3390/ma18122909

APA StyleLiu, X., Wang, J., Zhou, Z., Zhang, L., & Fu, Q. (2025). Gradient Joule Heating Curing Performance of Steel-Fiber-Reinforced High-Performance Concrete in Severe Cold Environments: A Preliminary Attempt for Deep-Cold Concrete Construction. Materials, 18(12), 2909. https://doi.org/10.3390/ma18122909