Impact Resistance Study of Fiber–Metal Hybrid Composite Laminate Structures: Experiment and Simulation

Abstract

1. Introduction

2. Materials and Methods

2.1. Specimen Preparation

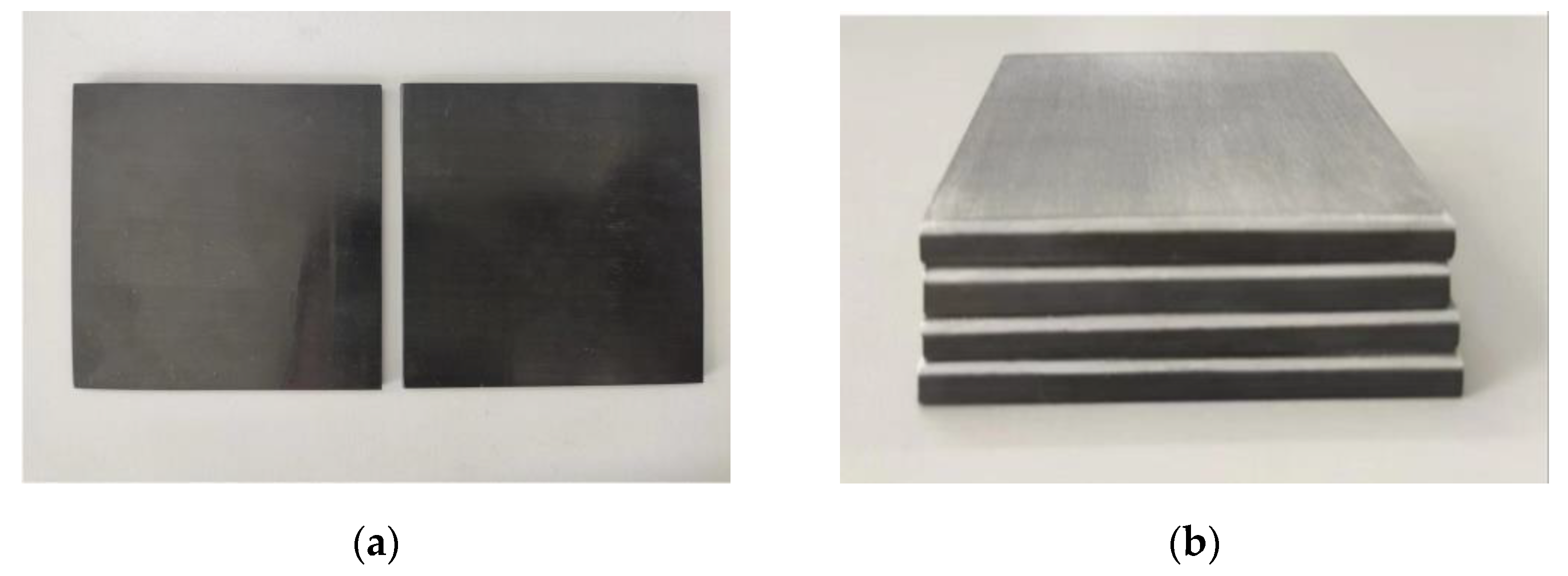

2.1.1. Test Materials and Pretreatment

2.1.2. Laminate Preparation Process

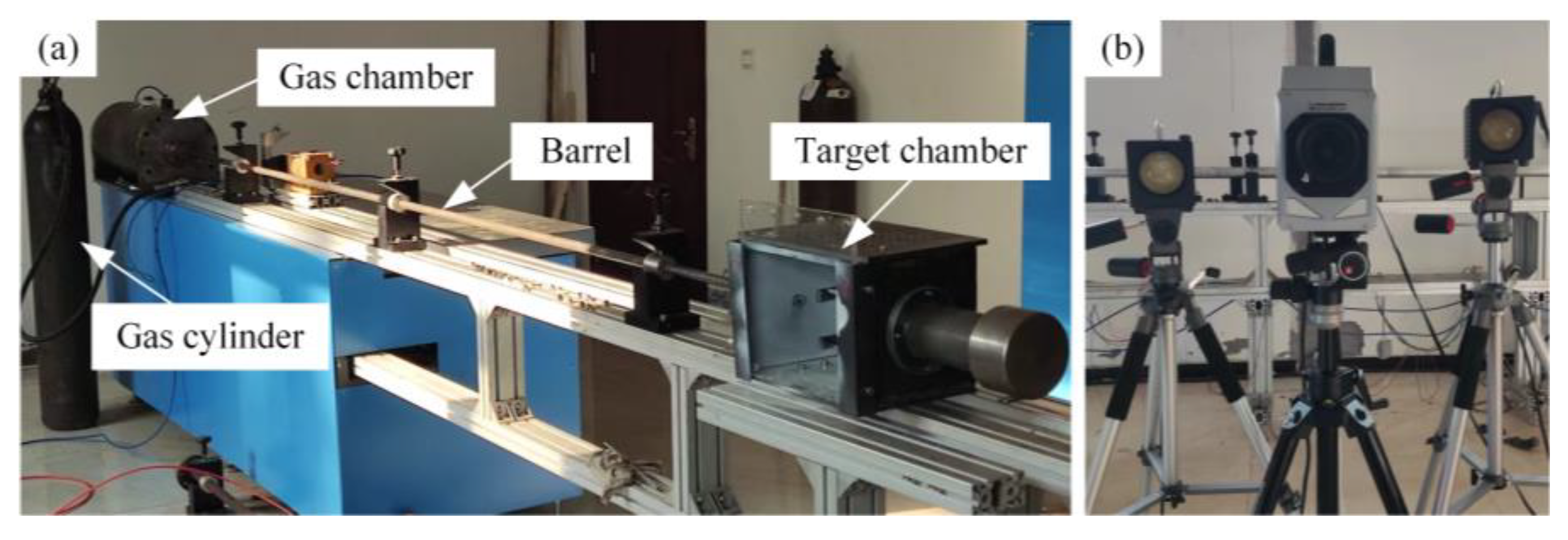

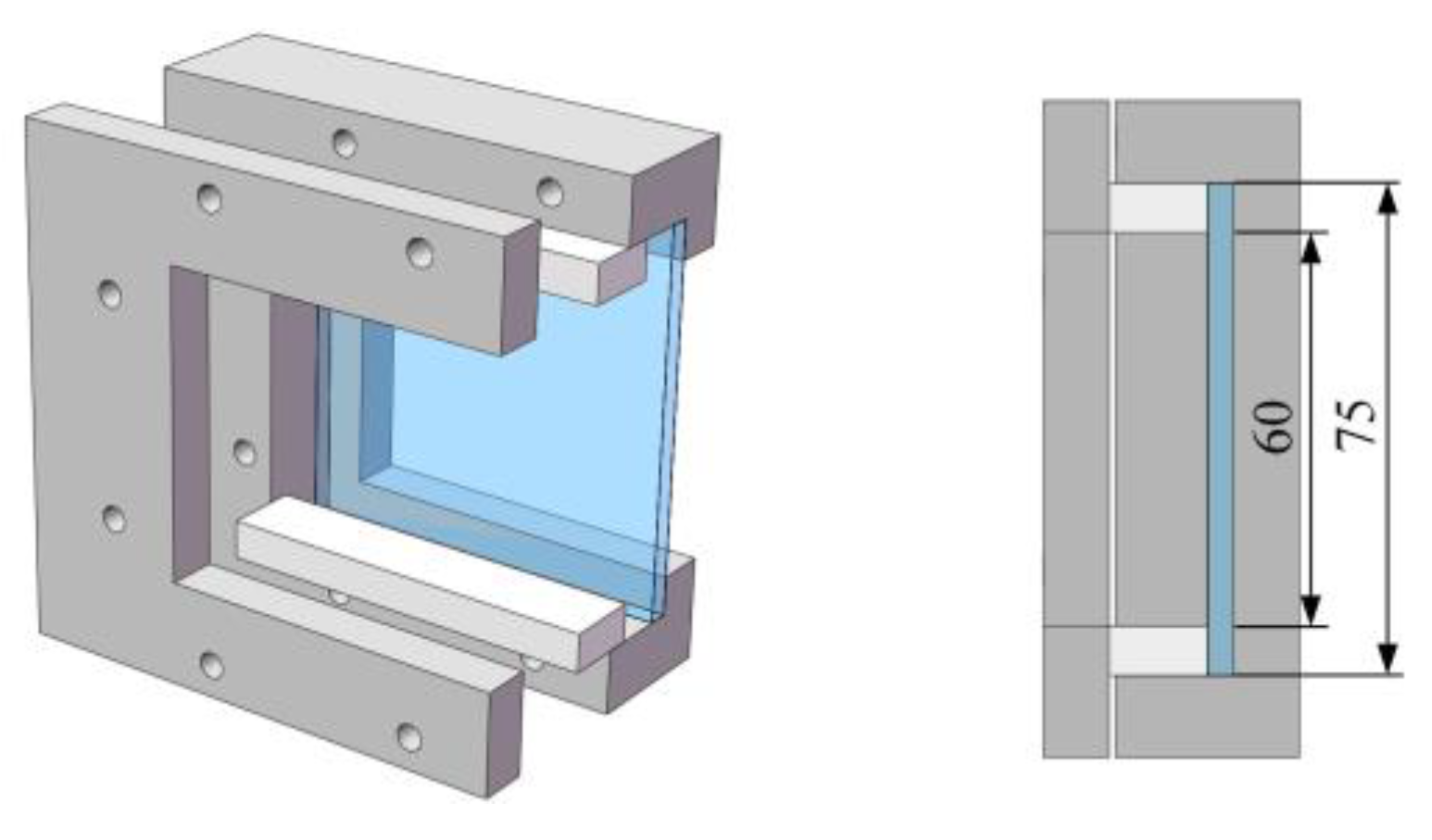

2.2. High-Speed Impact Test System

3. Results and Discussion

3.1. Test Result Analysis

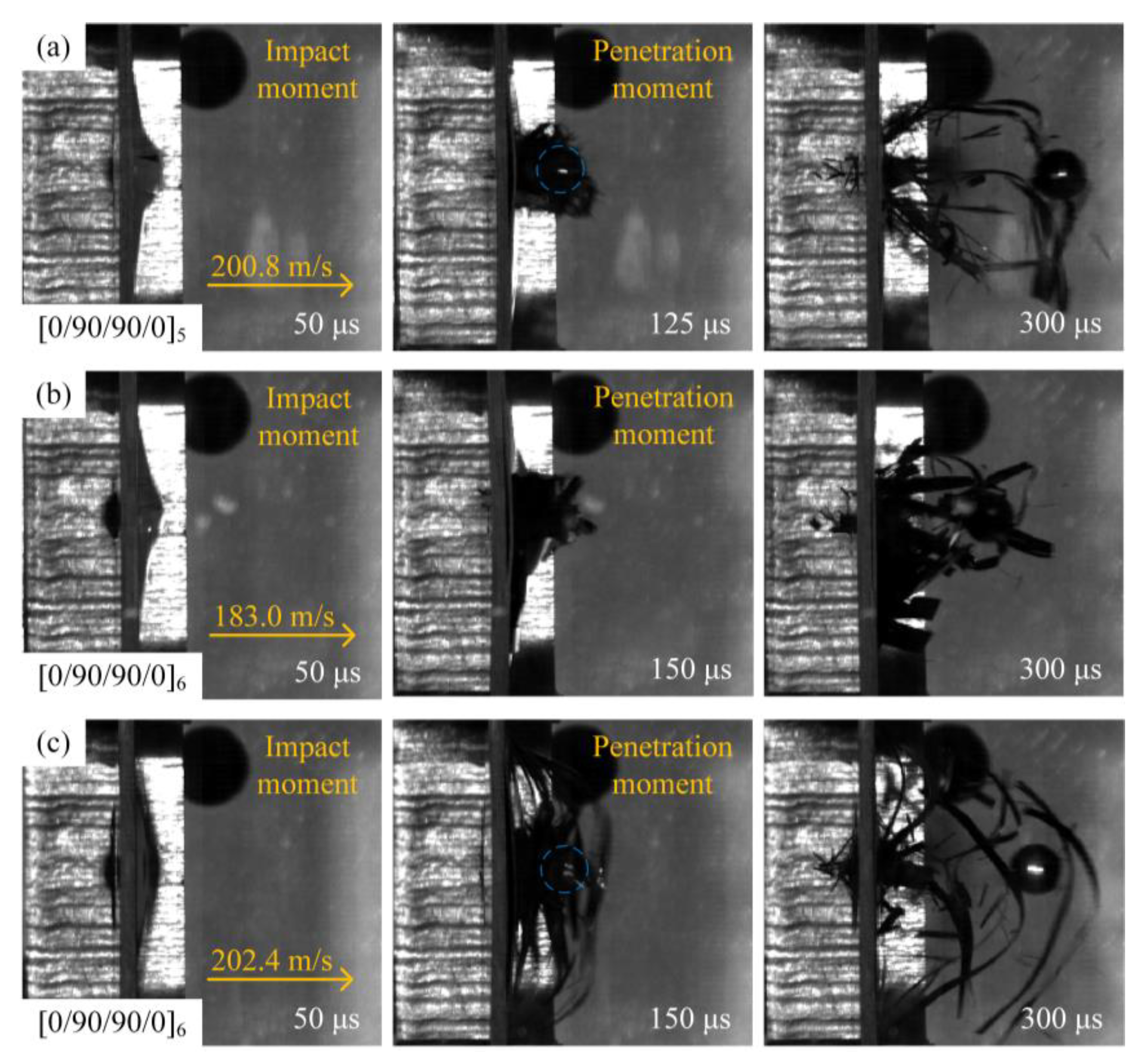

3.1.1. High-Speed Impact Test Results

- Total energy absorption :where is the projectile mass; is the impact velocity; and is the residual velocity.

- Specific energy absorption Q:where m is laminated quality.

- Energy absorption per unit thickness e:where h is the laminate thickness.

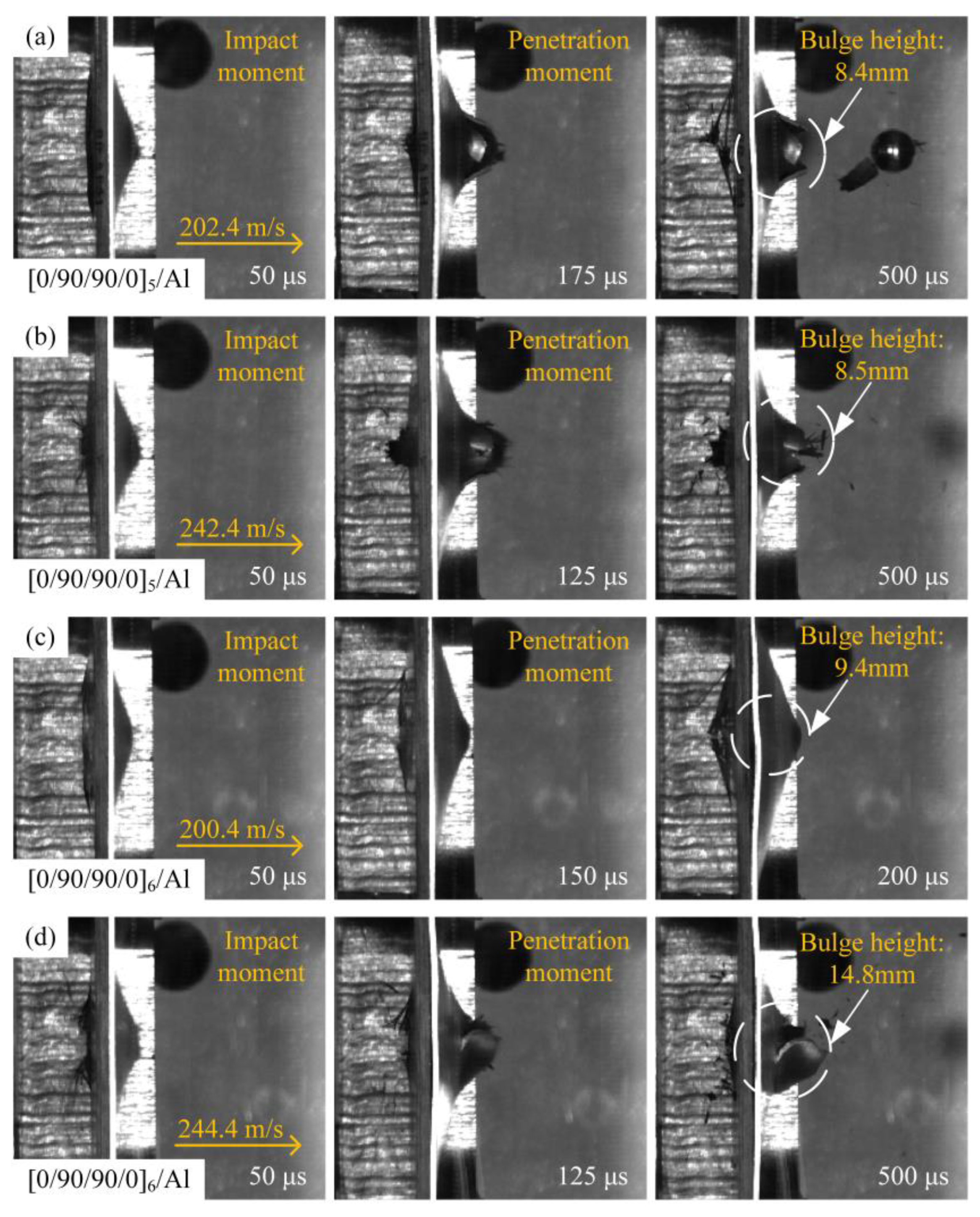

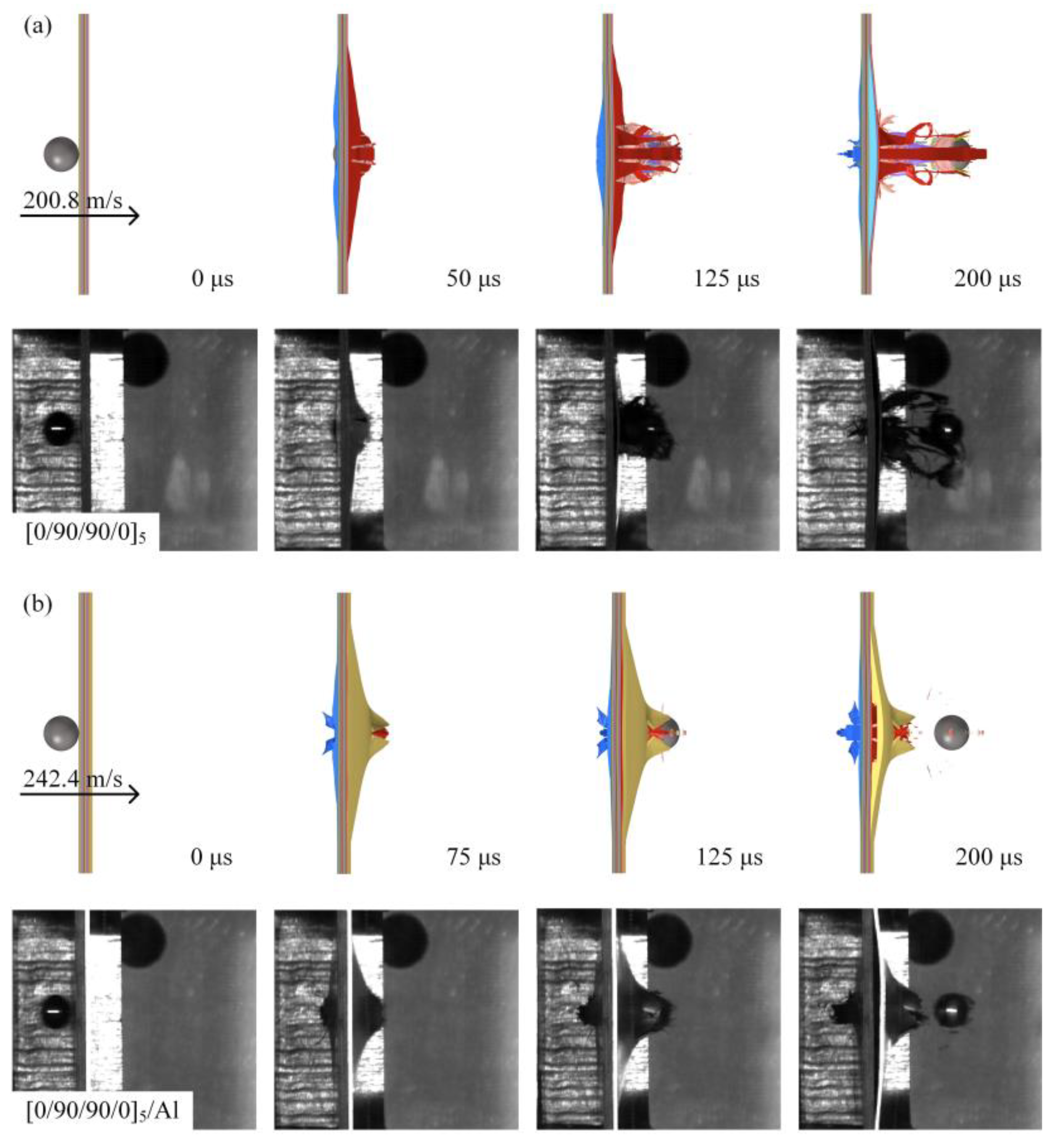

3.1.2. Dynamic Response Analysis

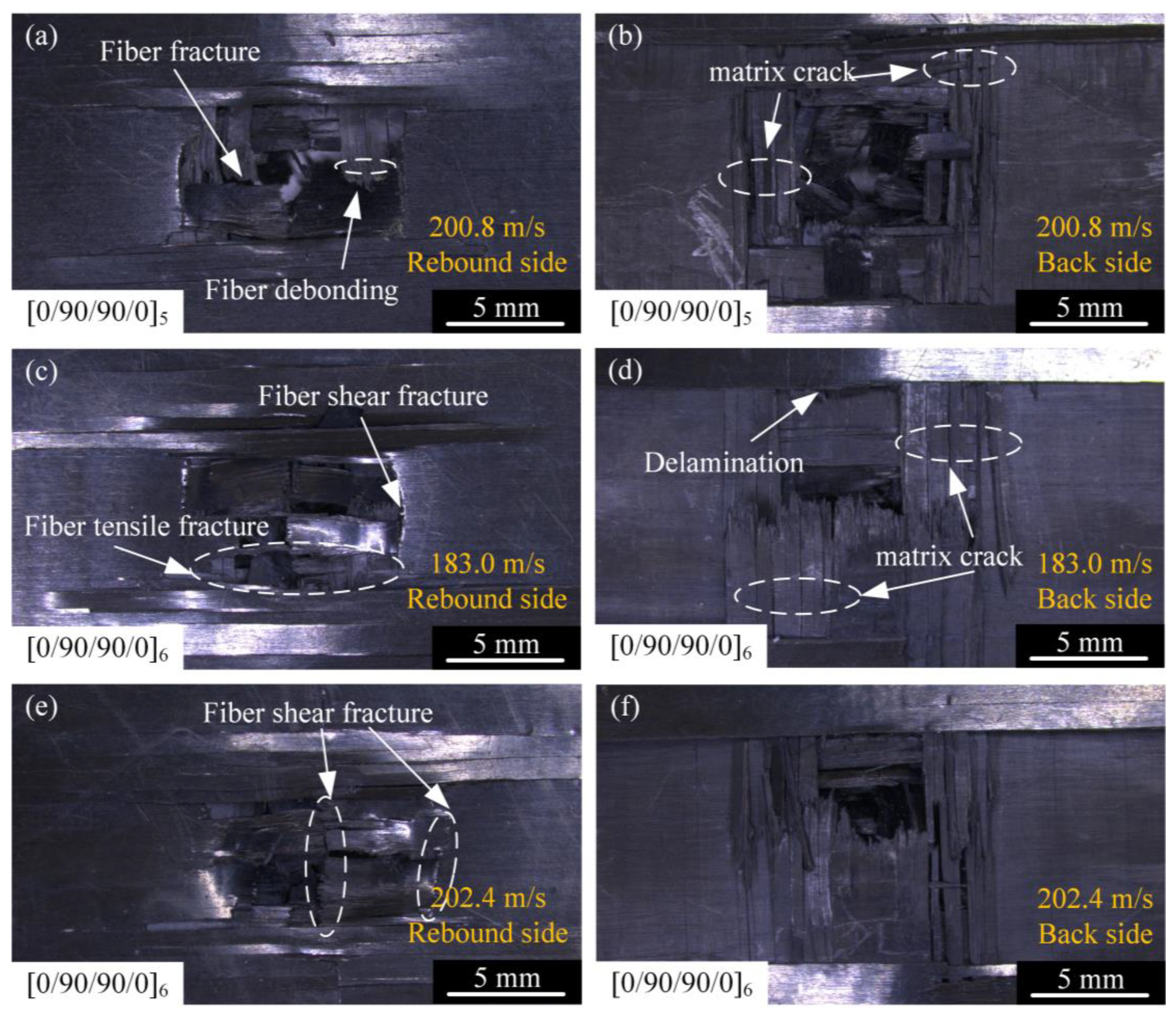

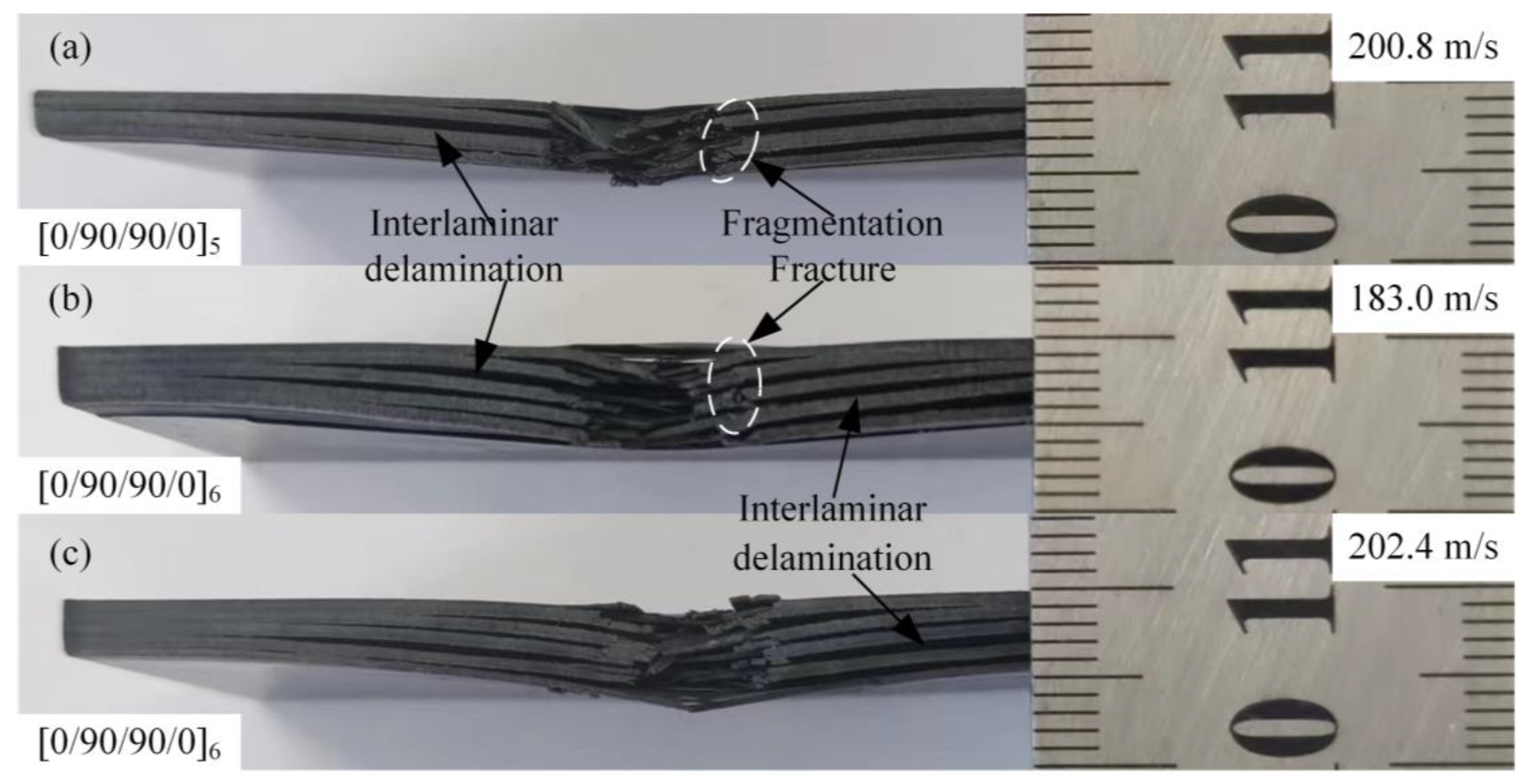

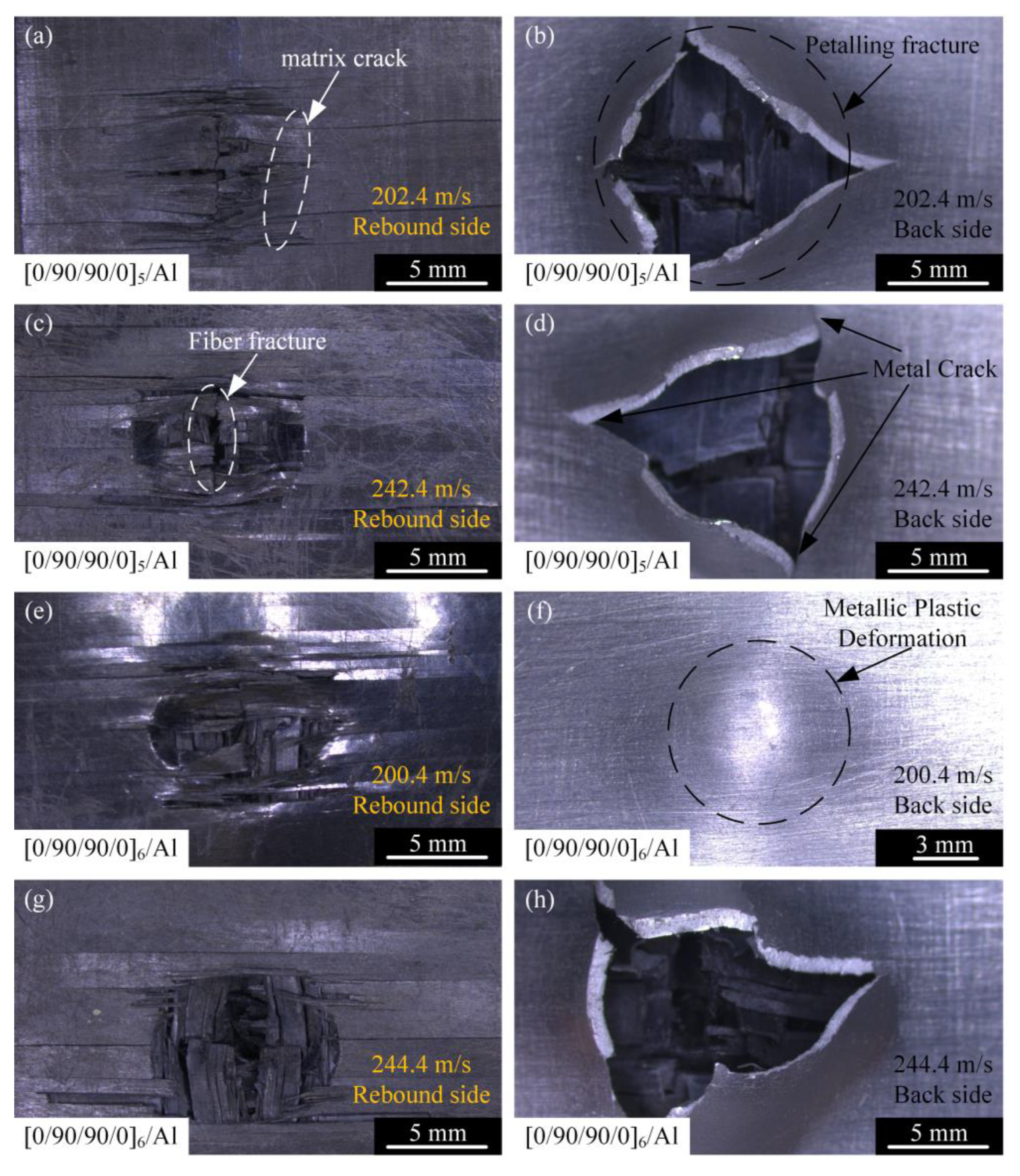

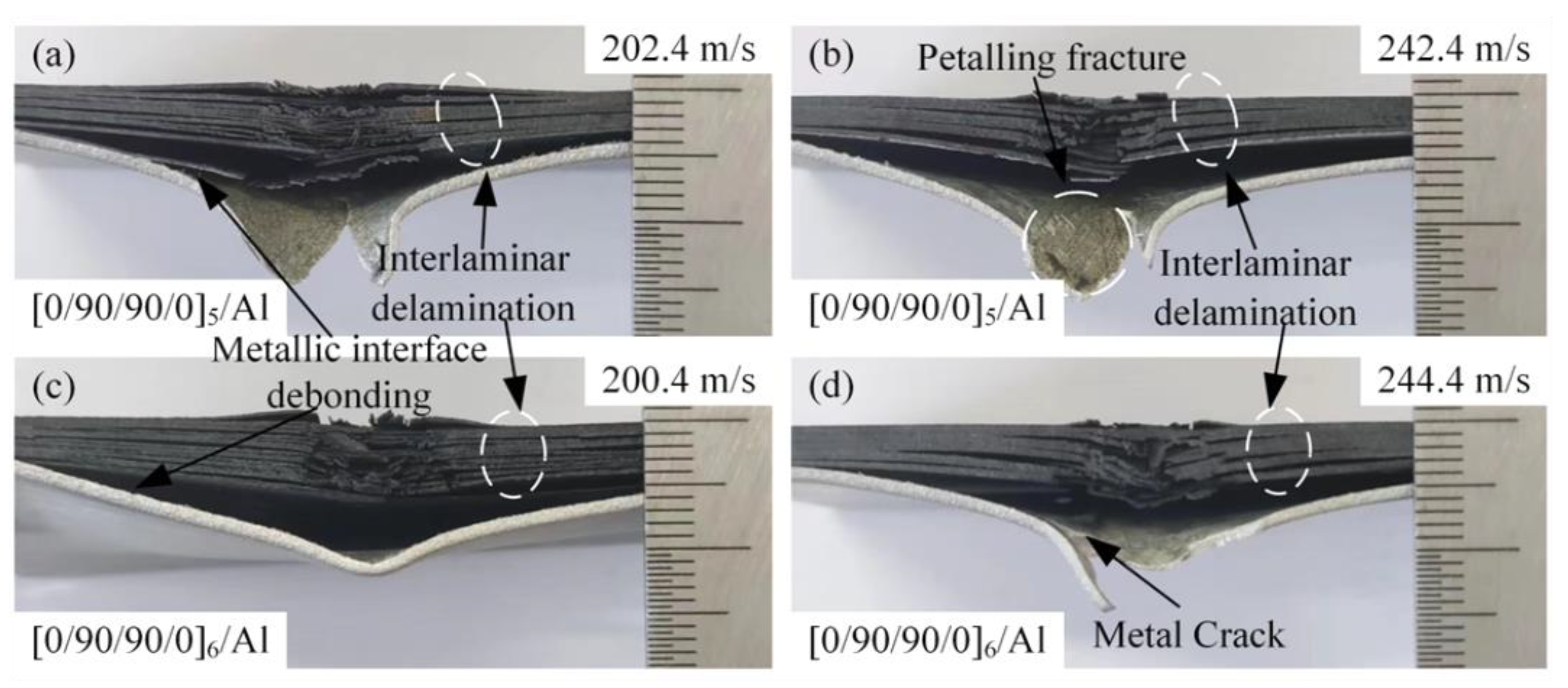

3.1.3. Failure Morphology Analysis

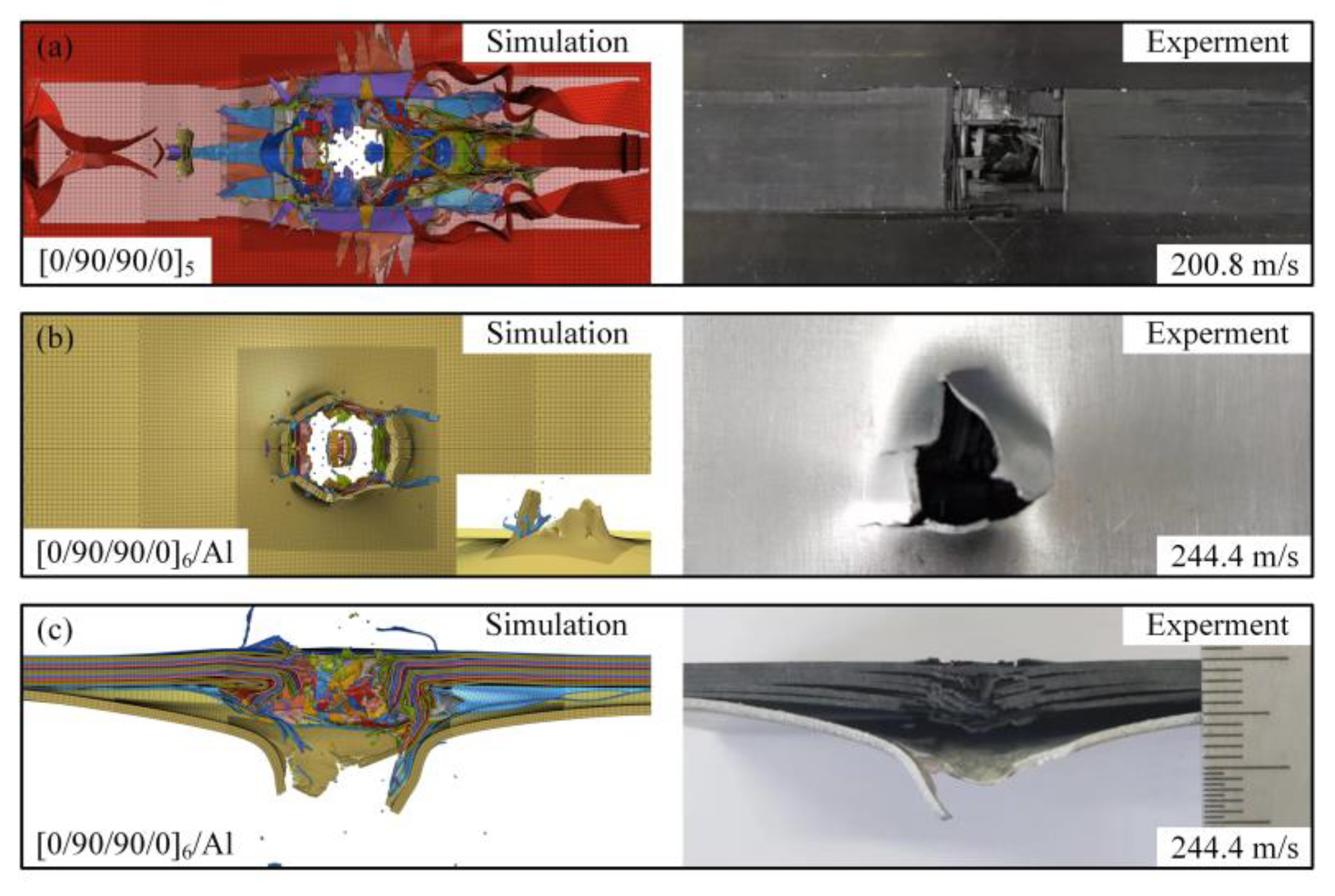

3.2. Numerical Model Validation

3.2.1. Constitutive Relationship and Failure Model for Metal Materials

3.2.2. Constitutive Relationship and Failure Model for Composite Materials

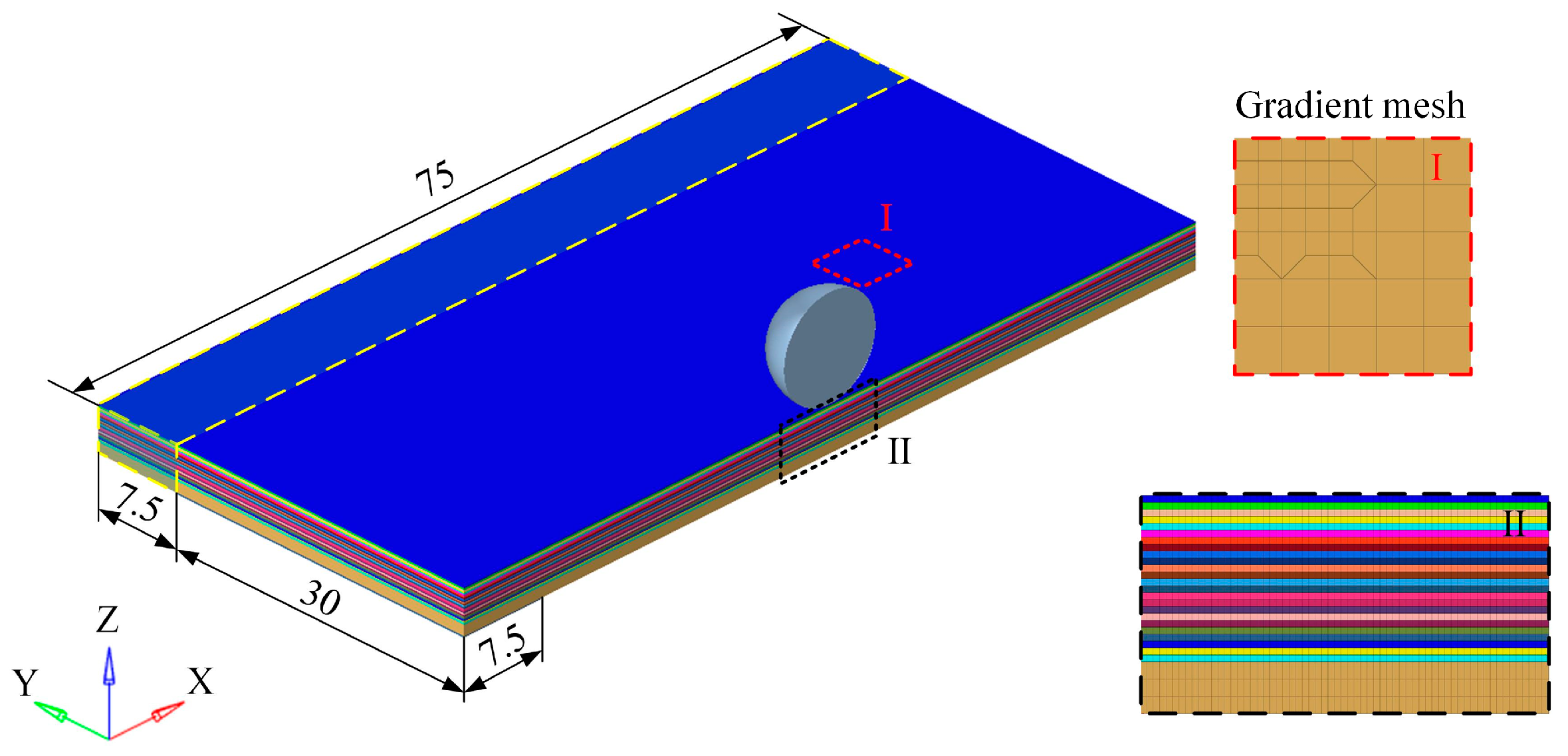

3.2.3. Establishment of Nonlinear Finite Element Model

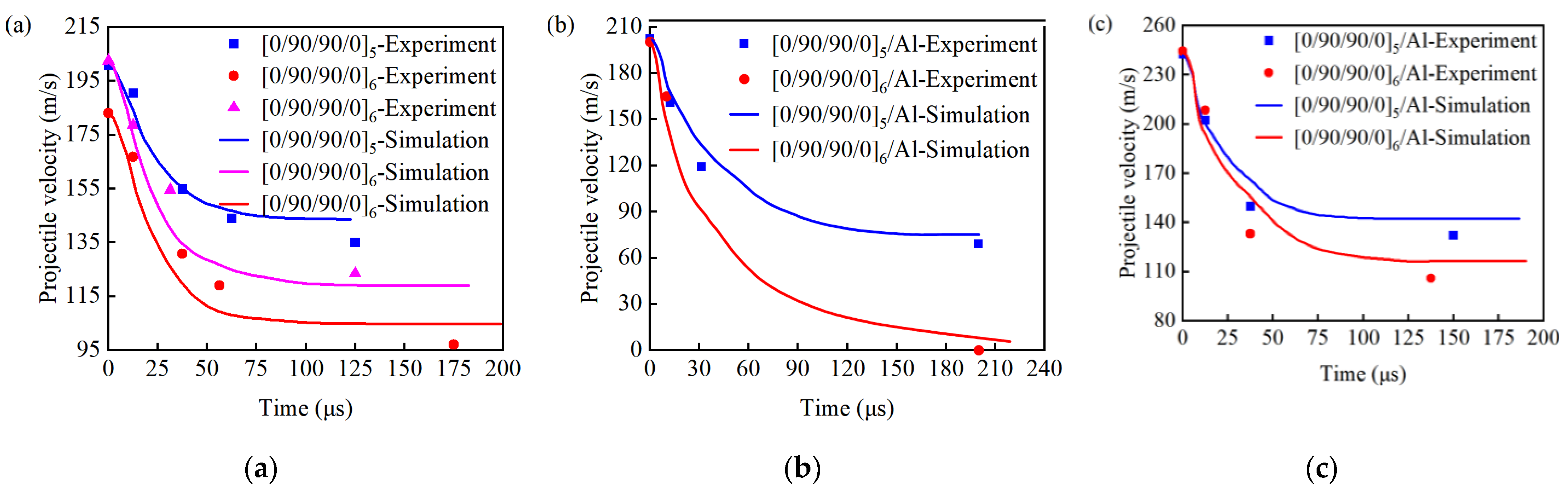

3.2.4. Finite Element Model Verification

4. Conclusions

- According to the processing technology of thermoplastic carbon fiber/aluminum alloy hybrid composite laminates, thermoplastic carbon fiber-reinforced composite laminates and thermoplastic carbon fiber/aluminum alloy hybrid composite laminates were fabricated using a hot-die pressing machine. The process processes are mainly preheating, heating up, pressurizing, and holding pressure cooling.

- A first-stage light gas gun test system was used to carry out high-speed impact tests on the specimens, and it was found that within the speed range of 200 m/s, the specific energy absorption and energy absorption per unit thickness of [0/90/90/0]6 and [0/90/90/0]5 had a small difference. The [0/90/90/0]5/Al ratio and [0/90/90/0]5 specific energy absorption increased by 3.7%, and unit thickness energy absorption increased by 24.4%, suggesting that the use of fiber and metal hybrids could improve the impact resistance of composite materials.

- The main failure modes of thermoplastic carbon fiber-reinforced composite laminates are fiber debonding, fiber fracture, and matrix cracks along the fiber direction. The failure modes of thermoplastic carbon fiber/aluminum alloy hybrid composite laminates, in addition to fiber debonding, fiber fracture, matrix cracks along the fiber direction, and interlaminar delamination of the composite also include fiber–metal interfacial delamination, metal plastic deformation, and petal-shaped fracture.

- Considering the flexibility in laminate structural design and complex practical engineering environments, this study has limitations: the high-velocity impact speed range is confined to 200–244.4 m/s. Furthermore, laminates in practical applications are subjected to impacts from projectiles of varying geometries at diverse incident angles. Comparative investigations on the impact resistance of laminates under multiple impact scenarios warrant further exploration. Future work could also integrate optimization design methods to conduct multi-objective optimization for laminates with additional stacking sequences, enabling comprehensive analysis of impact resistance across different layup configurations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Asundi, A.; Choi, A.Y. Fiber metal laminates: An advanced material for future aircraft. J. Mater. Process. Technol. 1997, 63, 384–394. [Google Scholar] [CrossRef]

- Vogelesang, L.B.; Vlot, A. Development of fibre metal laminates for advanced aerospace structures. J. Mater. Res. Technol. 2000, 103, 1–5. [Google Scholar] [CrossRef]

- Sun, J.; Xu, S.; Lu, G.; Wang, Q.; Gong, A. Ballistic impact experiments of titanium-based carbon-fibre/epoxy laminates. Thin-Walled Struct. 2022, 179, 109709. [Google Scholar] [CrossRef]

- Corderley, G.; Mostert, F.; Krüger, J.J. Failure modes in a carbon/titanium fibre metal laminate under hyper-velocity impact. Int. J. Impact Eng. 2019, 125, 180–187. [Google Scholar] [CrossRef]

- Zhu, Z.; Li, X.; Yang, R.; Xie, W.; Zhang, D. The energy dissipation mechanism of bi-metal Kevlar\titanium fiber metal laminate under high-velocity impact. Eur. J. Mech.—A/Solids 2023, 100, 104956. [Google Scholar] [CrossRef]

- Ali, A.; Pan, L.; Duan, L.; Zheng, Z.; Sapkota, B. Characterization of seawater hygrothermal conditioning effects on the properties of titanium-based fiber-metal laminates for marine applications. Compos. Struct. 2016, 158, 199–207. [Google Scholar] [CrossRef]

- Song, Z.; Ming, S.; Du, K.; Zhou, C.; Wang, Y.; Xu, S.; Wang, B. Energy absorption of metal-composite hybrid tubes with a diamond origami pattern. Thin-Walled Struct. 2022, 180, 109824. [Google Scholar] [CrossRef]

- Wu, G.Q.; Pan, Y.C.; Zhang, Z.K. Research progress on ultra-light fiber metal laminates. Aeronaut. Manuf. Technol. 2016, 25, 133–136. [Google Scholar]

- Rekatsinas, C.S.; Siorikis, D.K.; Nastos, C.V.; Chrysochoidis, N.A.; Theodosiou, T.C.; Yigit, A.S.; Christoforou, A.P.; Saravanos, D.A. An efficient computational framework for hailstone impacts on composite plates utilizing a semi-empirical viscoplastic contact law. Int. J. Impact Eng. 2023, 178, 104628. [Google Scholar] [CrossRef]

- Zhang, F.Q.; Luo, G.; Zhang, H.Y.; Cong, P.; Liu, L.; Chen, W. Experimental and numerical analysis study on the low and medium speed bird strike. Eng. Fail. Anal. 2024, 156, 107766. [Google Scholar] [CrossRef]

- Abdullah, M.R.; Cantwell, W.J. The high-velocity impact response of thermoplastic-matrix fibre-metal laminates. J. Strain Anal. Eng. Des. 2012, 47, 432–443. [Google Scholar] [CrossRef]

- Ferrante, L.; Sarasini, F.; Tirillò, J.; Lampani, L.; Valente, T.; Gaudenzi, P. Low velocity impact response of basalt-aluminium fibre metal laminates. Mater. Des. 2016, 98, 98–107. [Google Scholar] [CrossRef]

- Fatt, S.M.H.; Lin, C.; Revilock, M.D.; Hopkins, D.A. Ballistic impact of GLARE™ fiber-metal laminates. Compos. Struct. 2003, 61, 73–88. [Google Scholar] [CrossRef]

- Li, X.; Zhang, X.; Guo, Y.; Shim, V.; Yang, J.; Chai, G.B. Influence of fiber type on the impact response of titanium-based fiber-metal laminates. Int. J. Impact Eng. 2018, 114, 32–42. [Google Scholar] [CrossRef]

- Gao, Y.; Shi, L.; Lu, T.; Xie, W.; Cai, X. Ballistic and delamination mechanism of CFRP/aluminum laminates subjected to high velocity impact. Eng. Fract. Mech. 2024, 295, 109797. [Google Scholar] [CrossRef]

- Li, H.; Li, Z.; Xiao, Z.; Wang, X.; Xiong, J.; Zhou, J.; Guan, Z. Development of an integrated model for prediction of impact and vibration response of hybrid fiber metal laminates with a viscoelastic layer. Int. J. Mech. Sci. 2021, 197, 106298. [Google Scholar] [CrossRef]

- Yang, Z.X.; Wang, D.K.; Zhang, C. Prediction and failure analysis of high-speed bird impact damage in fiber metal laminates. J. Mater. Sci. Eng. 2024, 42, 593–601. [Google Scholar]

- Yaghoubi, A.S.; Liaw, B. Thickness influence on ballistic impact behaviors of GLARE 5 fiber-metal laminated beams: Experimental and numerical studies. Compos. Struct. 2012, 94, 2585–2598. [Google Scholar] [CrossRef]

- Zhang, L.; Xie, M.X.; Zhang, L.J.; Zhang, J.X. Research progress on interface regulation of fiber reinforced thermoplastic composites/metal connections. Welded Pipe Tube 2024, 47, 1–10. [Google Scholar]

- Sheng, L.Y.; Lai, C.; Xu, Z.F.; Jiao, J.K. Effect of the surface texture on laser joining of a carbon fiber-reinforced thermosetting plastic and stainless steel. Strength Mater. 2019, 51, 122–129. [Google Scholar] [CrossRef]

- ISO 11357-6:2018; Plastics-Differential Scanning Calorimetry (DSC)-Part 6: Determination of Specific Heat Capacity. ISO: Geneva, Switzerland, 2018.

- ISO 11357-2:2021; Plastics-Differential Scanning Calorimetry (DSC)-Part 2: Determination of Glass Transition Temperature. ISO: Geneva, Switzerland, 2021.

- ASTM D792-23; Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement. ASTM International: West Conshohocken, PA, USA, 2023.

- ISO 10352-6:2017; Fibre-Reinforced Plastics—Moulding Compounds and Prepregs—Part 6: Determination of the Fibre Mass Content by Ignition Method. ISO: Geneva, Switzerland, 2017.

- ASTM D3171-22; Standard Test Methods for Constituent Content of Composite Materials. ASTM International: West Conshohocken, PA, USA, 2022.

- GB/T 1447-2005; Fiber-Reinforced Plastics Composites—Determination of Tensile Properties. Standardization Administration of China: Beijing, China, 2005.

- GB/T 1449-2005; Fibre-Reinforced Plastic Composites—Determination of Flexural Properties. Standardization Administration of China: Beijing, China, 2005.

- JC/T 773-2010; Fibre-Reinforced Plastics Composites. Determination of Apparent Interlaminar Shear Strength by Short-Beam Method. Standardization Administration of China: Beijing, China, 2010.

- Dong, H.M.; Yi, X.S.; An, X.F.; Zhang, C.Q.; Yan, L.; Deng, H. Research progress on interlayer toughening of fiber reinforced thermosetting polymer matrix composites. J. Compos. Mater. 2014, 31, 273–285. [Google Scholar]

- Yun, N.G.; Won, Y.G.; Kim, S.C. Toughening of carbon fiber/epoxy composite by inserting polysulfone film to form morphology spectrum. Polymer 2004, 45, 6953–6958. [Google Scholar] [CrossRef]

- Livingston, R.; Koohbor, B. Characterizing fiber-matrix debond and fiber interaction mechanisms by full-field measurements. Compos. Part C Open Access 2022, 7, 100229. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures. In Proceedings of the 7th International Symposium on Ballistics, The Hague, The Netherlands, 19–21 April 1983; pp. 541–547. [Google Scholar]

- Zakeri, M.; Mansoori, H.; Sadeghian, M.; Guagliano, M. Impact response of fiber metal laminates based on aluminum and UHMWPE composite: Numerical simulation. Thin-Walled Struct. 2022, 172, 108796. [Google Scholar] [CrossRef]

- Han, J.; Shi, Y.; Ma, Q.; Vershinin, V.V.; Chen, X.; Xiao, X.; Jia, B. Experimental and numerical investigation on the ballistic resistance of 2024-T351 aluminum alloy plates with various thicknesses struck by blunt projectiles. Int. J. Impact Eng. 2022, 163, 104182. [Google Scholar] [CrossRef]

- Cheng, J.C.; Zhang, S.; Liu, Q.; Ye, S.; Luo, S.; Cai, Y.; Huang, J. Ballistic impact experiments and modeling on impact cratering, deformation and damage of 2024-T4 aluminum alloy. Int. J. Mech. Sci. 2022, 224, 107312. [Google Scholar] [CrossRef]

- Kollár, L.P.; Springer, G.S. Mechanics of Composite Structure; Cambridge University Press: New York, NY, USA, 2003. [Google Scholar]

- Hastie, J.C.; Guz, I.A.; Kashtalyan, M. Effects of thermal gradient on failure of a thermoplastic composite pipe (TCP) riser leg. Int. J. Press. Vessel. Pip. 2019, 172, 90–99. [Google Scholar] [CrossRef]

- Cherniaev, A.; Telichev, I. Meso-scale modeling of hypervelocity impact damage in composite laminates. Compos. Part B Eng. 2015, 74, 95–103. [Google Scholar] [CrossRef]

- Liu, H.B.; Liu, J.; Kaboglu, C.; Zhou, J.; Kong, X.; Blackman, B.R.; Kinloch, A.J.; Dear, J.P. The behaviour of fibre-reinforced composites subjected to a soft impact-loading: An experimental and numerical study. Eng. Fail. Anal. 2020, 111, 104448. [Google Scholar] [CrossRef]

- Santiago, R.; Cantwell, W.; Jones, N.; Alves, M. The modelling of impact loading on thermoplastic fibre-metal laminates. Compos. Struct. 2018, 189, 228–238. [Google Scholar] [CrossRef]

- Li, Z.-Y.; Xue, Y.-S.; Sun, B.-Z.; Gu, B.-H. Ballistic penetration damages of hybrid plain-woven laminates with carbon, Kevlar and UHMWPE fibers in different stacking sequences. Def. Technol. 2023, 26, 23–38. [Google Scholar] [CrossRef]

- Shen, Z.; Hu, D.; Zhang, Y.; Cai, Q.; Han, X. Continuous twice-impacts analysis of UHMWPE laminate fixed with bolted joints. Int. J. Impact Eng. 2017, 109, 293–301. [Google Scholar] [CrossRef]

| Physical Property | Unit | Test Criteria | Test Result |

|---|---|---|---|

| Melting point of resin | °C | ISO 11357 [21] | 343 |

| Glass transition temperature of resin | °C | ISO 11357 [22] | 143 |

| Density | g/cm3 | ASTM D792 [23] | 1.62 |

| Fiber surface density | g/cm2 | ISO 10352 [24] | 220 |

| Fiber mass fraction | % | ASTM D3171 [25] | 60 |

| 0° tensile strength | MPa | GB/T 1447-2005 [26] | 2000 |

| 0° tensile modulus | GPa | GB/T 1447-2005 | 130 |

| 0° bending strength | MPa | GB/T 1449-2005 [27] | 1600 |

| 0° bending modulus | GPa | GB/T 1449-2005 | 120 |

| Interlaminar shear strength | MPa | JC/T 773-2010 [28] | 120 |

| Specimen Types | Thickness (mm) |

|---|---|

| [0/90/90/0]5 | 2.6 |

| [0/90/90/0]6 | 3.12 |

| [0/90/90/0]5/Al | 3.6 |

| [0/90/90/0]6/Al | 4.12 |

| Specimen Types | Impact Speed (m/s) | Impact Energy (J) | Residual Velocity (m/s) | Residual Energy (J) | Energy Absorption (J) | Specific Energy Absorption (J·kg−1) | Energy Absorption per Unit Thickness (J·m−1) |

|---|---|---|---|---|---|---|---|

| [0/90/90/0]5 | 200.8 | 70.6 | 138.9 | 33.8 | 36.8 | 1553.1 | 14,153.1 |

| [0/90/90/0]6 | 183.0 | 58.6 | 97.0 | 16.5 | 42.1 | 1482.2 | 13,506.4 |

| [0/90/90/0]6 | 202.4 | 71.7 | 125.2 | 27.4 | 44.3 | 1556.7 | 14,185.5 |

| [0/90/90/0]5/Al | 202.4 | 71.7 | 69.0 | 7.1 | 64.5 | 1610.9 | 17,599.5 |

| [0/90/90/0]5/Al | 242.4 | 102.8 | 132.1 | 30.5 | 72.3 | 1838.0 | 20,080.0 |

| [0/90/90/0]6/Al | 200.4 | 70.3 | - | - | - | - | - |

| [0/90/90/0]6/Al | 244.4 | 104.5 | 106.0 | 19.7 | 84.9 | 1925.8 | 20,598.8 |

| Material Parameter | Quantitative Value | Model Parameter | Quantitative Value |

|---|---|---|---|

| (g/cm3) | 2.78 | n | 0.301 |

| (GPa) | 73 | m | 1 |

| 0.31 | 0.034 | ||

| (K) | 293 | 0.664 | |

| (K) | 775 | −1.5 | |

| (MPa) | 310 | 0.011 | |

| (MPa) | 456.4 | 0 |

| Material Parameter | Quantitative Value | Material Parameter | Quantitative Value |

|---|---|---|---|

| (g/cm3) | 1.62 | (GPa) | 3.6 |

| (GPa) | 130 | (MPa) | 2000 |

| (GPa) | 9.6 | (MPa) | 1360 |

| 0.37 | (MPa) | 79 | |

| 0.33 | (MPa) | 176 | |

| (GPa) | 5.7 | (MPa) | 130 |

| Specimen Type | Impact Speed (m/s) | Simulation Result (m/s) | Simulated Energy Absorption (J/kg) | Error (%) | RMSE |

|---|---|---|---|---|---|

| [0/90/90/0]5 | 200.8 | 143.7 | 34.5 | 3.5 | 4.2 |

| [0/90/90/0]6 | 183.0 | 104.8 | 39.4 | 8.0 | 8.2 |

| [0/90/90/0]6 | 202.4 | 119.1 | 46.9 | 4.9 | 5.3 |

| [0/90/90/0]5/Al | 202.4 | 75.2 | 61.8 | 9.0 | 7.0 |

| [0/90/90/0]5/Al | 242.4 | 142.3 | 67.4 | 7.7 | 8.1 |

| [0/90/90/0]6/Al | 244.4 | 115.8 | 81 | 9.2 | 7.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Guo, H.; Lan, Y.; Zhao, L. Impact Resistance Study of Fiber–Metal Hybrid Composite Laminate Structures: Experiment and Simulation. Materials 2025, 18, 2906. https://doi.org/10.3390/ma18122906

Zhang Z, Guo H, Lan Y, Zhao L. Impact Resistance Study of Fiber–Metal Hybrid Composite Laminate Structures: Experiment and Simulation. Materials. 2025; 18(12):2906. https://doi.org/10.3390/ma18122906

Chicago/Turabian StyleZhang, Zheyi, Haotian Guo, Yang Lan, and Libin Zhao. 2025. "Impact Resistance Study of Fiber–Metal Hybrid Composite Laminate Structures: Experiment and Simulation" Materials 18, no. 12: 2906. https://doi.org/10.3390/ma18122906

APA StyleZhang, Z., Guo, H., Lan, Y., & Zhao, L. (2025). Impact Resistance Study of Fiber–Metal Hybrid Composite Laminate Structures: Experiment and Simulation. Materials, 18(12), 2906. https://doi.org/10.3390/ma18122906