Abstract

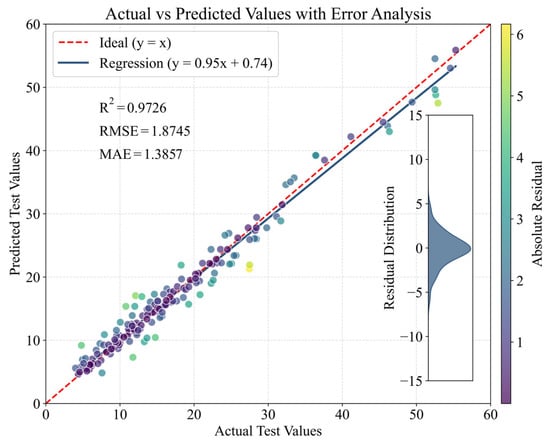

Accurate prediction of fiber-reinforced polymer (FRP)-concrete interfacial bond strength is critical for ensuring the safety of FRP-strengthened structures. This study proposes a predictive model based on extreme gradient boosting (XGBoost), which is enhanced via the Nevergrad optimization framework, to address the limited accuracy of traditional empirical approaches. By integrating seven optimizers from the Nevergrad platform, the model achieves global hyperparameter optimization, and a five-fold cross-validation strategy is employed to improve generalization. The prediction results based on 855 sets of single-lap shear test data demonstrate that the optimized model exhibits significantly superior performance on the test set (R2 = 0.9726, RMSE = 1.8745, MAE = 1.3857). Compared to the existing best-performing empirical model, the R2 is improved by 22.3%, while the RMSE and MAE are reduced by 63.4% and 61.8%, respectively. SHAP interpretability analysis indicates that the width, thickness, elastic modulus, and bond length of the FRP sheets are the main factors influencing the bond strength prediction. The predictive model developed in this study combines high accuracy with strong interpretability, providing a reliable, intelligent tool for designing FRP-strengthened structures.

1. Introduction

Fiber-reinforced polymers (FRP), which are composed of high-strength fibers and a polymer matrix, possess characteristics such as high strength, low weight, and excellent corrosion resistance []. As an advanced high-performance composite material, FRP has been widely adopted in civil engineering, particularly for strengthening and repairing reinforced-concrete structures [,]. In engineering practice, FRP is typically externally bonded to the surface of concrete, forming an FRP-concrete interface that serves as a critical zone for load transfer. The bond strength at this interface directly affects the composite action of the FRP strengthening system and its overall structural reliability. Therefore, accurately predicting the bond strength at the FRP-concrete interface is essential for engineering design and safety evaluation.

The academic community has systematically investigated the bonding mechanism of the FRP-concrete interface and proposed various bond strength prediction models (Table 1) [,,,,,,,,,,,,,,,,,,]. Specifically, the proposed approaches fall into three categories: empirical models derived from experimental data, semi-empirical models incorporating fracture mechanics theory, and models based on interfacial bond slip relationships. Early studies relied on single lap shear test data to derive empirical formulations [,,,]. These formulations typically use average bond shear stress methods to estimate interfacial performance. However, these models often fail to adequately account for critical parameters, such as the effective FRP bond length, material heterogeneity, and localized interfacial effects, resulting in significant deviations when applied to real-world engineering predictions. Subsequent advances in fracture mechanics have enabled the development of semi-empirical bond-strength models [,,,,,], in which parameters such as the effective bond length and stress-field distribution functions have been systematically incorporated. These models can capture the nonlinear bond behavior under load more accurately, thereby providing a more robust theoretical basis for the structural strengthening design. Although these models yield reasonable predictions under certain conditions, their development based on specific experimental datasets limits their applicability and fails to fully account for the complex nonlinear mechanical characteristics of the FRP-concrete interface [,,,].

Table 1.

Existing bond-strength models.

In recent years, fueled by the growth of big data and advances in machine learning, new approaches have been developed to address complex nonlinear problems. Recent studies have established diverse predictive models for the FRP–concrete interfacial bond strength using extensive experimental datasets [,,,,,,,]. For instance, Zhou et al. [] employed a backpropagation neural network (BPNN) to develop an explicit prediction model that outperforms most traditional models in terms of accuracy. Su et al. [] compared three machine learning methods and found that the support vector machine (SVM) exhibited the best performance, with prediction accuracy further enhanced by a stacking ensemble. Zhang et al. [] systematically evaluated six machine learning models based on a single-lap shear test database, and the results showed that the extreme gradient boosting (XGBoost) achieved a 54% reduction in coefficient of variation compared to optimal traditional models. These studies demonstrate that machine learning methods can substantially improve the accuracy of FRP-concrete interfacial bond strength predictions. However, the generalization ability and stability of these models still require improvement, and the selection of model hyperparameters significantly impacts the final prediction accuracy. Consequently, developing effective hyperparameter optimization frameworks to simultaneously improve prediction precision and enhance model interpretability remains a key research challenge.

This study proposes a Nevergrad-optimized XGBoost framework (Nevergrad-XGBoost) to improve the prediction accuracy and robustness of the FRP-concrete interfacial bond strength. By integrating seven built-in optimizers from Nevergrad for hyperparameter tuning of the XGBoost model, in conjunction with a 5-fold cross-validation mechanism, intelligent optimization of the model’s hyperparameters is achieved to construct the optimal predictive model. Furthermore, to improve model interpretability, the Shapley Additive exPlanations (SHAP) method was employed to quantitatively assess the contributions of different input features, thereby revealing the mechanisms influencing the bond strength at the FRP–concrete interface.

2. Database

2.1. Data Sources

The data used in this study are derived from a large-scale database established by Zhou et al. [], which includes 969 sets of FRP–concrete interface single-lap shear test results collected from 34 existing studies. The single-lap shear test is regarded as one of the most effective methods for investigating the bond performance between FRP and concrete interfaces []. These tests primarily focus on measuring the ultimate bond strength and encompass the key material properties and geometric parameters. To eliminate the influence of specimen size variations across different studies, the compressive and tensile strengths of the concrete are converted. Specifically, the tensile strength ft is converted using the formula ft = 0.395(fc)0.55, as specified in the Chinese concrete code GB 50010-2010 []. In addition, the concrete cube compressive strength fc is converted to the equivalent cylinder compressive strength fc′ using the relevant conversion coefficients, as detailed in Reference [].

To enhance the data quality, the original dataset was filtered based on a unified criterion. Specifically, in a set of data with the same test parameters, if the target value Pu of a certain data point differs from the others by more than 15%, while the differences among the remaining data points are within 15%, this data point is identified as an outlier and excluded; under the same test parameter group, if the difference between any two data points in the group exceeds 15%, the whole set of data is removed. After processing, 855 sets of high-quality experimental data were ultimately retained. The database includes the following parameters:

- The material properties: the compressive strength of a concrete cylinder (fc′) and the elastic modulus of the FRP sheets (Ef);

- The geometrical parameters: the thickness (tf), width (bf), and bond length (Lf) of the FRP sheets and the concrete substrate width (bc);

- The bond strength of the FRP-concrete interface (Pu).

2.2. Data Description

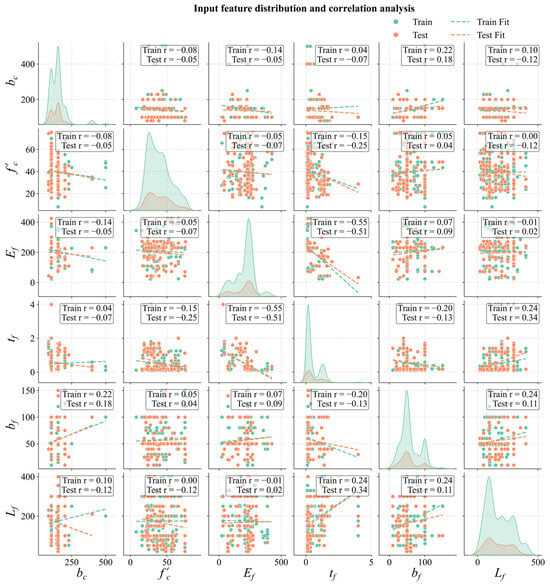

To develop the predictive model, this study selects material properties (fc′ and Ef) and geometric parameters (tf, bf, Lf, and bc) as input features, and Pu serves as the target variable. The statistical characteristics of these parameters, including the minimum, maximum, mean, and quartiles (Q1, Q3, etc.), are summarized in Table 2. The dataset is randomly divided into 80% for training and 20% for testing. Figure 1 illustrates the sample distributions in the training and test sets, as well as the correlation analysis of the input features. The results indicate that the training and test sets exhibit a similar distribution in the feature space, and no significant multicollinearity is detected among the input features.

Table 2.

Statistical information of the database.

Figure 1.

Data distribution and feature correlation analyses.

3. Methods

3.1. Nevergrad Optimization Library

Nevergrad is an open-source, gradient-free optimization library developed by Facebook [,]. It efficiently addresses optimization problems in continuous, discrete, or mixed parameter spaces and is well-suited for hyperparameter tuning in machine learning. The library supports multiple optimization algorithms. Seven of these algorithms were selected in this study to tune the hyperparameters of the XGBoost regression model.

- Covariance matrix adaptation evolution strategy (CMA): The CMA is an evolutionary optimization algorithm based on a multivariate Gaussian distribution []. It dynamically updates the mean vector, covariance matrix, and step size parameter to match the geometric characteristics of the objective function. In each iteration, candidate solutions are sampled, and their fitness is evaluated, with the mean updated via weighted recombination. The covariance matrix is refined using both the Rank-μ strategy (current generation information) and the Rank-1 strategy (historical path). An independent evolution path controls the step size scaling, thereby achieving efficient optimization of both the search direction and scale.

- Two-point differential evolution (TwoPointsDE): TwoPointsDE is a variant of differential evolution whose core innovation lies in replacing the classical binomial crossover with a two-point crossover mechanism []. The algorithm randomly selects two crossover points and replaces the parameter segment within the selected interval of the mutation-generated donor vector with the target individual. This design preserves the dependencies between adjacent parameters and reduces the disruption to potentially beneficial schemata, thus enhancing the global exploration capability of the algorithm.

- Particle swarm optimization (PSO): PSO is a swarm intelligence optimization algorithm that simulates the collective behavior of bird flocks and fish schools []. The algorithm is optimized by simulating particles moving through the search space. Each particle represents a potential solution and retains records of its personal best position and the global best position. The PSO dynamically adjusts each particle’s velocity and position based on individual memory and social collaboration, enabling the swarm to progressively converge toward the optimal solution.

- Random Search: Random Search identifies the optimal solution by performing uniform random sampling of candidate solutions within a predefined search space and evaluating their corresponding objective function values [].

- ScrHammersley: ScrHammersley is an optimization algorithm based on low-discrepancy sequences, specifically the Hammersley sequence, combined with scrambling techniques in a quasi-Monte Carlo framework [,]. It employs deterministic sampling points to achieve efficient and uniform exploration of parameter space. Compared with a pure random search, ScrHammersley mitigates sample clustering and uneven coverage issues, thereby enhancing the quality of the initial population.

- DiscreteOnePlusOne: This algorithm is a (1 + 1) evolution strategy variant tailored for discrete optimization within the Nevergrad framework [,,]. It operates through a single-individual iterative optimization mechanism, where each iteration maintains a parent solution and generates an offspring via probabilistic perturbation operators (e.g., discrete parameter flipping or categorical resets). A greedy selection mechanism determines whether the parent solution should be replaced. The algorithm implements an adaptive mutation strategy that dynamically adjusts the perturbation probabilities to maintain the exploration-exploitation balance.

- NGOpt: NGOpt is a general-purpose optimizer in the Nevergrad library based on dynamic multi-strategy collaboration [,]. It is designed to automatically adapt to problem characteristics and select the most suitable optimization strategies.

3.2. XGBoost

Extreme gradient boosting (XGBoost), proposed by Chen et al. [], is an ensemble method based on gradient-boosting decision trees and is widely applied across various domains. The core idea of XGBoost is to integrate multiple weak learners, typically decision trees, using the gradient boosting algorithm [,]. In each iteration, XGBoost adds a new tree to fit the residuals (i.e., the differences between the actual and predicted values) of the previous model. The algorithm then updates the model parameters by minimizing the regularized objective function. The objective function of XGBoost is presented in Equation (1).

where, represents the loss function, where is the predicted value, and is the actual value. denotes the regularization term, which is used to control the model complexity. represents the model of the k-th tree, T is the number of leaf nodes in the k-th tree and is the weight of the leaf nodes in the k-th tree. Additionally, represents the penalty regularization term for the leaf nodes, while is the penalty regularization term for the leaf weights.

3.3. Evaluation Metrics

To quantify the predictive performance of the model, this study employs the mean squared error (MSE), root mean squared error (RMSE), and coefficient of determination (R2) as evaluation metrics [,,,,,,,]. The formulas for these metrics are as follows:

where N represents the number of samples, denotes the actual values, represents the predicted values, and is the mean of the actual values.

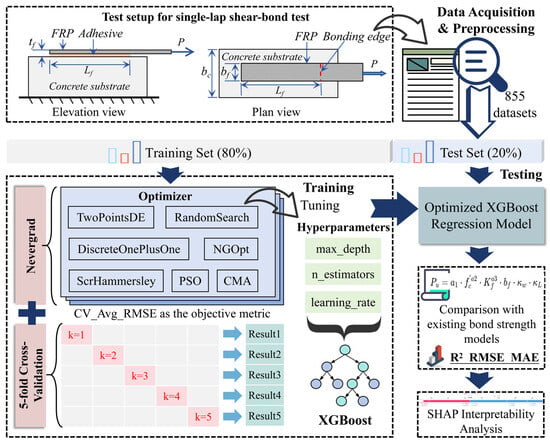

3.4. Model Construction

Figure 2 illustrates the framework for constructing the XGBoost bond strength prediction model based on multi-algorithm ensemble optimization. The dataset is randomly split into a training set (80%) and an independent test set (20%). The Nevergrad framework integrates seven optimization algorithms to search for optimal hyperparameters within a predefined search space, including n_estimators, learning_rate, and max_depth. The model uses the five-fold cross-validated average root-mean-square error (CV_Avg_RMSE) as its optimization objective, thereby ensuring robust hyperparameter selection. During optimization, the system records the convergence trajectories and evaluation metrics (R2, RMSE, and MAE) of each algorithm. A multi-dimensional algorithmic performance assessment is conducted based on the predictive accuracy of the validation subsets, ultimately selecting the optimal hyperparameter combination. The optimized parameters are then applied to XGBoost to construct a high-performance regression model, which is subsequently validated on an independent test set. A systematic comparison with existing bond strength models is conducted to ensure the superior performance of the constructed model. To further analyze the decision-making mechanism of the model, SHAP analysis is employed to quantitatively characterize the contribution of each input variable to the prediction outcomes.

Figure 2.

Structure of the XGBoost bond-strength prediction model.

4. Results

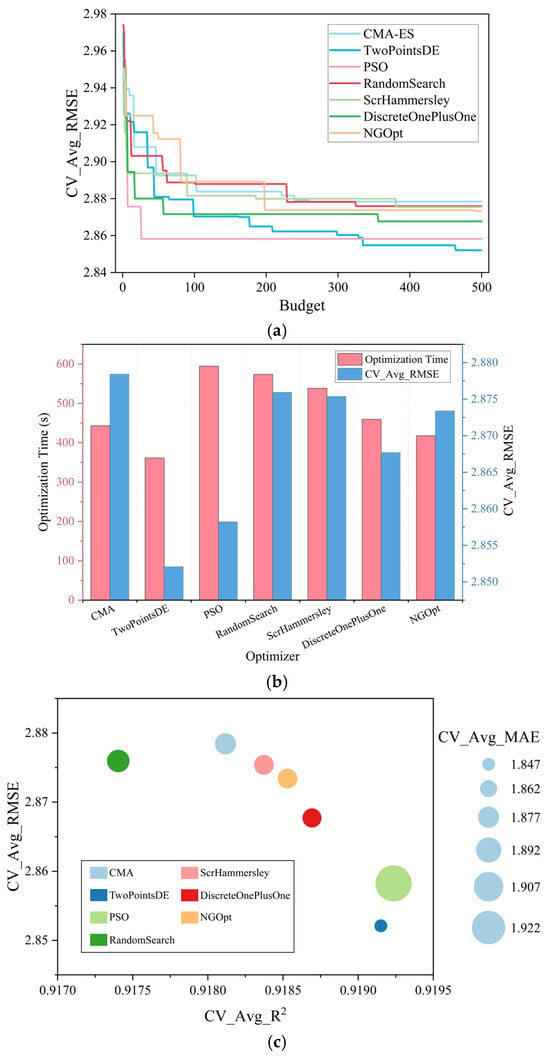

4.1. Hyperparameter Optimization

The predefined hyperparameter search space is presented in Table 3. Figure 3a presents the variation trend of the objective function value CV_Avg_RMSE with respect to the number of iterations (budget) during the optimization process. Figure 3b shows the best objective values obtained by the seven optimizers, along with their corresponding computational times. Among these optimizers, TwoPointsDE achieves the lowest CV_Avg_RMSE within the 500-iteration budget while requiring the least optimization time. Figure 3c presents a bubble chart that provides an intuitive comparison of the overall performance of the different optimization methods. The horizontal axis represents the cross-validation average R2 (CV_Avg_R2), and the vertical axis corresponds to CV_Avg_RMSE. The bubble size indicates the cross-validation average MAE (CV_Avg_MAE), and different colors distinguish the optimizers used. From Figure 3c, TwoPointsDE achieves lower CV_Avg_RMSE and CV_Avg_MAE values compared to the other optimizers, while its CV_Avg_R2 is second only to PSO, indicating that it exhibits the best overall performance.

Table 3.

Hyperparameter search space for XGBoost.

Figure 3.

Hyperparameter optimization process of the XGBoost model: (a) variation in the best CV_Avg RMSE, (b) optimization time of optimizers, (c) comprehensive comparison of optimizers’ predictive performance, (d) variation in the objective value during the TwoPointsDE optimization process, and (e) hyperparameter optimization path of TwoPointsDE (top 100 ranked sets).

Figure 3d,e provides a detailed visualization of the optimization process of TwoPointsDE, illustrating the evolution of the objective function value and the hyperparameter optimization trajectory. Ultimately, TwoPointsDE determines the optimal set of XGBoost hyperparameters as follows: n_estimators = 90, learning_rate = 0.12737845681247, and max_depth = 8. Further details regarding the optimization results for all the optimizers are presented in Table 4.

Table 4.

Detailed results of the optimizer hyperparameter optimization.

4.2. Comparison of Prediction Performance

The optimized XGBoost model is used to predict the test dataset, and the results are illustrated in Figure 4. The red dashed line represents the ideal scenario, where the predicted values equal the actual values (y = x), and the blue solid line denotes the regression fit of the model predictions. As shown in the figure, the model achieves an R2 of 0.9726, indicating a strong predictive capability. Furthermore, the RMSE and MAE are 1.8745 and 1.3857, respectively, demonstrating low prediction errors and high accuracies. The residual distribution plot on the right reveals that most residuals are symmetrically distributed around zero, with only a few extreme deviations, suggesting no significant systematic bias in the model predictions. The color bar represents the absolute values of the prediction residuals, where darker colors indicate smaller errors and lighter colors correspond to larger deviations. Overall, the optimized XGBoost model performs well on the test dataset, effectively capturing the actual data trends with high predictive accuracy.

Figure 4.

Test set prediction results of the Nevergrad-XGBoost model.

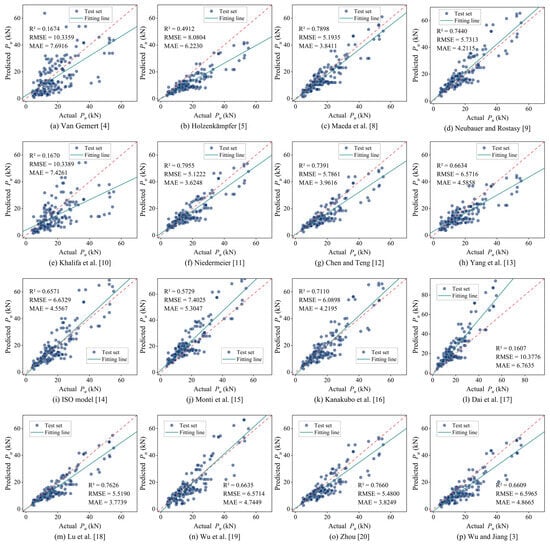

To further evaluate the model performance, existing strength prediction models were applied to the same test set, with their prediction results illustrated in Figure 5. The results demonstrate that among the existing models, the model proposed by Maeda et al. [] (R2 = 0.7898, RMSE = 5.1935, MAE = 3.8411), Niedermeier [] (R2 = 0.7955, RMSE = 5.1222, MAE = 3.6248), and Zhou [] (R2 = 0.7660, RMSE = 5.4800, MAE = 3.8249) exhibit relatively superior predictive performance. Additionally, the ANN model trained by Zhou et al. [] using the same database achieved prediction results of R2 = 0.928 and RMSE = 3.584 on the test set. The Nevergrad-XGBoost model developed in this study achieves an approximately 22.3% improvement in R2, a reduction of about 63.4% in RMSE, and a reduction of roughly 61.8% in MAE compared to the best-performing existing empirical model (Niedermeier []). Moreover, when compared with the ANN model proposed by Zhou et al. [], the Nevergrad-XGBoost model demonstrates an approximate 4.8% increase in R2 and a reduction of about 47.7% in RMSE (see Table 5 for details). These comparisons demonstrate that the proposed model offers markedly superior predictive accuracy and generalization performance.

Figure 5.

Scatter plot of the prediction results of the existing bond strength models on the test set [,,,,,,,,,,,,,,,].

Table 5.

Comparison of the prediction performance of bond strength models.

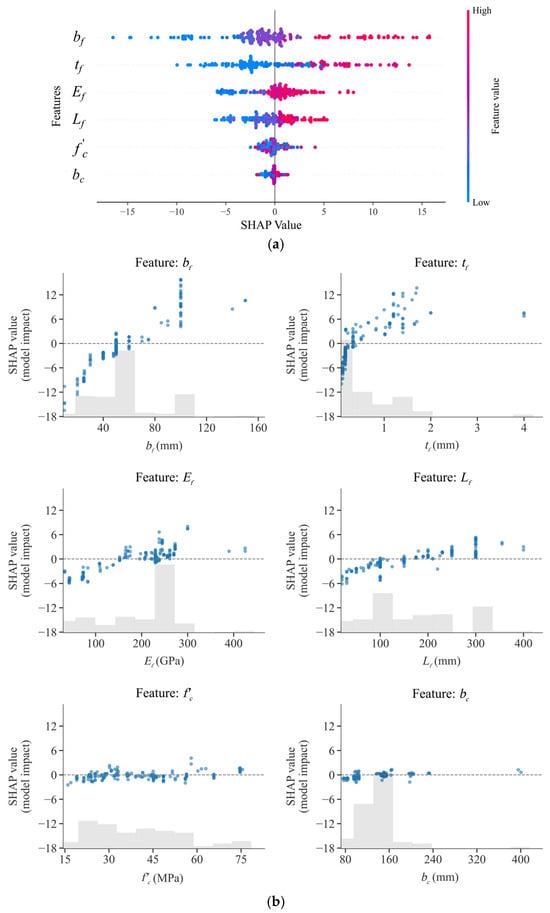

4.3. Interpretability Analysis

This study employs the Shapley Additive exPlanations (SHAP) interpretability analysis method, which is based on cooperative game theory [,], to quantitatively assess the feature contributions in the Nevergrad-XGBoost model. By computing the marginal contributions of different feature combinations to the prediction results, this study systematically evaluates the influence mechanisms of various input parameters on the prediction of the bond strength at the FRP-concrete interface. The sign of the SHAP value indicates the directional impact of a feature on the prediction: a SHAP value greater than zero signifies a positive contribution to the prediction outcome, whereas a SHAP value less than zero indicates a suppressive effect.

As shown in the SHAP summary plot in Figure 6a, bf, tf, and Ef are the three features contributing most to the model output, which is broadly consistent with the feature importance analyses reported by Zhang et al. [] and Su et al. []. Further analysis of the SHAP scatter plots in Figure 6b suggests that the SHAP values of bf, tf, Ef, and Lf are generally positively correlated with their respective feature values. Specifically, the pronounced influence of bf may have arisen from the expansion of the interaction area between the FRP sheet and concrete over a larger surface. An increase in bf implies an enlarged bond interface area and a more uniform stress distribution, thereby enhancing bond strength. For relatively small tf values, the SHAP values are negative. This is due to an excessively low tf causing insufficient axial stiffness (Eftf) of the FRP, localized stress concentrations, and weakened interfacial friction, ultimately reducing the bond strength. Although Lf also exhibited a positive correlation with the SHAP values, its SHAP contributions were mostly confined within the range of [−6, 6]. This may be attributed to the fact that once Lf exceeds the effective bond length, further increasing Lf no longer significantly improves the bond strength. It is noteworthy that numerous studies have demonstrated the significant effect of bf on bond strength; however, due to differences in interpretability methods, experimental protocols, FRP material types, and adhesive layer properties, the relative importance of each feature may also vary across the literature.

Figure 6.

SHAP global explanation: (a) SHAP summary plot and (b) SHAP scatter plot.

Figure 7 presents the SHAP force plot, which intuitively illustrates the specific contributions of individual input features to the final prediction for a particular sample in the test set. According to Table 6, the feature values of this sample are as follows: bc = 150 mm, fc′ = 74.67 MPa, Ef = 73 GPa, tf = 0.169 mm, bf = 100 mm, and Lf = 100 mm. Based on these feature values, the model’s baseline prediction (i.e., the initial prediction value in the absence of any feature contributions) is 17.7713. For this particular sample, bf exhibits the highest positive contribution to the prediction, with a SHAP value of 4.8879. In contrast, Ef has the highest negative contribution, with a SHAP value of −4.4544. After aggregating the positive and negative contributions of all features, the final predicted value of the model for this sample is 14.5847 kN. The actual bond strength for this sample is 15.14 kN, demonstrating close agreement between the predicted and actual values. This result validates the effectiveness of the model in predicting the bond strength of the FRP-concrete interface.

Figure 7.

Shap force plot.

Table 6.

SHAP explanation details for a single sample.

SHAP analysis effectively elucidates the influence mechanisms of different features on model prediction outcomes, providing data-driven support for an in-depth understanding of the predictive mechanisms governing the FRP-concrete interfacial bond strength.

5. Conclusions

This study proposes a Nevergrad-optimized XGBoost model (Nevergrad-XGBoost) for predicting the bond strength of FRP-concrete interfaces. By integrating seven built-in Nevergrad optimization algorithms with a 5-fold cross-validation mechanism, intelligent hyperparameter search and optimization for XGBoost are achieved, resulting in a high-performance predictive model. The principal findings are summarized as follows:

- By comparing the hyperparameter optimization results of the seven built-in Nevergrad optimizers, it was found that the TwoPointsDE algorithm achieved the lowest CV_Avg_RMSE (2.85207) within 500 iterations while requiring the shortest computational time (361.25 s), demonstrating an excellent balance between exploration and exploitation. The optimized hyperparameter combination (n_estimators = 90, learning_rate = 0.12737845681247, max_depth = 8) significantly enhanced the predictive performance of the model.

- The Nevergrad-XGBoost model demonstrates outstanding predictive capability on the test set, with performance metrics of R2 = 0.9726, RMSE = 1.8745, and MAE = 1.3857. Compared with the best-performing empirical model, the R2 of Nevergrad-XGBoost improves by 22.3%, while the RMSE and MAE decrease by 63.4% and 61.8%, respectively. When compared with the ANN model, the R2 increases by 4.8%, and the RMSE decreases by 47.7%, confirming its significant advantages in both predictive accuracy and generalization ability.

- The SHAP-based interpretability analysis reveals that the contribution of features to the prediction results, from highest to lowest, is as follows: bf, tf, Ef, Lf, fc′, and bc. The feature values of bf, tf, Ef, and Lf show a generally positive correlation with the SHAP values. The global and local interpretation results support the model’s interpretability requirements for engineering applications.

In summary, the XGBoost model optimized by Nevergrad can accurately predict the bond strength at the FRP–concrete interface, providing a new approach for the cost-effective optimization of FRP strengthening parameters. When combined with field monitoring data, the model can support the dynamic evaluation of the residual load-bearing capacity of structures. Moreover, the core algorithmic architecture and interpretability analysis framework employed in this study can be extended to predict the performance of other composite material–concrete interfaces.

Author Contributions

Y.C.: Methodology, Validation, Resources, Visualization, Software, Writing—original draft; Y.Z.: Visualization, Writing—review & editing; C.L.: Investigation, Writing—review & editing; J.Z.: Conceptualization, Methodology, Validation, Investigation, Visualization, Writing—review & editing, Supervision, Funding acquisition. All authors have read and agreed to the published version of the manuscript.

Funding

This research is partially supported by the Outstanding Youth Project of the Hunan Provincial Department of Education (23B0008), and the Zhumadian Key R&D Special Project (ZMDSZDZX2023006).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Bank, L.C. Composites for Construction: Structural Design with FRP Materials; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Teng, J.G.; Chen, J.F.; Smith, S.T.; Lam, L. FRP Strengthened RC Structures; John Wiley & Sons: Chichester, UK, 2002. [Google Scholar]

- Wu, Y.F.; Jiang, C. Quantification of bond-slip relationship for externally bonded FRP-to-concrete joints. J. Compos. Constr. 2013, 17, 673–686. [Google Scholar] [CrossRef]

- Van Gemert, D. Force transfer in epoxy bonded steel/concrete joints. Int. J. Adhes. Adhes. 1980, 1, 67–72. [Google Scholar] [CrossRef]

- Holzenkämpfer, P. IngenieurmModelle des Verbunds Geklebter Bewehrung für Betonbauteile; IBMB: Braunschweig, Germany, 1994. [Google Scholar]

- Tanaka, T. Shear Resisting Mechanism of Reinforced Concrete Beams with CFS as Shear Reinforcement. Ph.D. Thesis, Hokkaido University, Sapporo, Japan, 1996. [Google Scholar]

- Yoshizawa, H. Analysis of debonding fracture properties of CFS strengthened RC member subject to tension. In Proceedings of the 3rd International Symposium on Non-Metallic (FRP) Reinforcement for Concrete Structures, Sapporo, Japan, 14–16 October 1997; Japan Concrete Institute: Tokyo, Japan, 1997; pp. 287–294. [Google Scholar]

- Maeda, T.; Asano, Y.; Sato, Y.; Ueda, T.; Kakuta, Y. A study on bond mechanism of carbon fiber sheet. In Proceedings of the 3rd International Symposium on Non-Metallic (FRP) Reinforcement for Concrete Structures, Sapporo, Japan, 14–16 October 1997; Japan Concrete Institute: Tokyo, Japan, 1997; Volume 1, pp. 285–297. [Google Scholar]

- Neubauer, U.; Rostasy, F.S. Design aspects of concrete structures strengthened with externally bonded CFRP-plates. In Proceedings of the Seventh International Conference on Structural Faults and Repair, London, UK, 8–10 July 1997; Engineering Technics Press: Edinburgh, UK, 1997; Volume 2, pp. 109–118. [Google Scholar]

- Khalifa, A.; Gold, W.J.; Nanni, A.; MI, A.A. Contribution of externally bonded FRP to shear capacity of RC flexural members. J. Compos. Constr. 1998, 2, 195–202. [Google Scholar] [CrossRef]

- Niedermeier, R. Envelope Line of Tensile Forces While Using Externally Bonded Reinforcement. Ph.D. Thesis, Technical University of Munich, Munich, Germany, 2000. [Google Scholar]

- Chen, J.F.; Teng, J.G. Anchorage strength models for FRP and steel plates bonded to concrete. J. Struct. Eng. 2001, 127, 784–791. [Google Scholar] [CrossRef]

- Yang, Y.X.; Yue, Q.R.; Hu, Y.C. Experimental study on bond performance between carbon fiber sheets and concrete. J. Build. Struct. 2001, 22, 36–42. (In Chinese) [Google Scholar]

- Japan Concrete Institute (JCI). Technical Report of Technical Committee on Retrofit Technology. In Proceedings of the International Symposium on the Latest Achievement of Technology and Research on Retrofitting Concrete Structures; Japan Concrete Institute (JCI): Tokyo, Japan, 2003. [Google Scholar]

- Monti, G.; Renzelli, M.; Luciani, P. FRP adhesion in uncracked and cracked concrete zones. In Proceedings of the 6th International Symposium on FRP Reinforcement for Concrete Structures (FRPRCS-6), Singapore, 8–10 July 2003; pp. 183–192. [Google Scholar] [CrossRef]

- Kanakubo, T.; Furuta, T.; Fukuyama, H. Bond strength between fiber-reinforced polymer laminates and concrete. In Proceedings of the 6th International Symposium on FRP Reinforcement for Concrete Structures (FRPRCS-6), Singapore, 8–10 July 2003; pp. 133–142. [Google Scholar] [CrossRef]

- Dai, J.; Ueda, T.; Sato, Y. Development of the Nonlinear Bond Stress–Slip Model of Fiber Reinforced Plastics Sheet–Concrete Interfaces with a Simple Method. J. Compos. Constr. 2005, 9, 52–62. [Google Scholar] [CrossRef]

- Lu, X.Z.; Teng, J.G.; Ye, L.P.; Jiang, J.J. Bond–slip models for FRP sheets/plates bonded to concrete. Eng. Struct. 2005, 27, 920–937. [Google Scholar] [CrossRef]

- Wu, Z.; Islam, S.M.; Said, H. A three-parameter bond strength model for FRP-concrete interface. J. Reinf. Plast. Compos. 2009, 28, 2309–2323. [Google Scholar] [CrossRef]

- Zhou, Y.W. Analytical and Experimental Study on the Strength and Ductility of FRP-Reinforced High Strength Concrete Beam. Ph.D. Thesis, Dalian University of Technology, Dalian, China, 2009. [Google Scholar]

- Lin, J.P.; Wu, Y.F.; Smith, S.T. Width factor for externally bonded FRP-to-concrete joints. Constr. Build. Mater. 2017, 155, 818–829. [Google Scholar] [CrossRef]

- Lu, X.; Ye, L.; Teng, J.; Zhuang, J. Bond-slip model for FRP-to-concrete interface. Jianzhu Jiegou Xuebao J. Build. Struct. 2005, 26, 10–18. [Google Scholar]

- Zhou, Y.; Zheng, S.; Huang, Z.; Sui, L.; Chen, Y. Explicit Neural Network Model for Predicting FRP-Concrete Interfacial Bond Strength Based on a Large Database. Compos. Struct. 2020, 240, 111998. [Google Scholar] [CrossRef]

- Chen, S.Z.; Zhang, S.Y.; Han, W.S.; Wu, G. Ensemble learning based approach for FRP-concrete bond strength prediction. Constr. Build. Mater. 2021, 302, 124230. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, C.; Liu, J.; Zou, X.; Sneed, L.H.; Bao, Y.; Wang, L. Prediction of FRP-concrete interfacial bond strength based on machine learning. Eng. Struct. 2023, 274, 115156. [Google Scholar] [CrossRef]

- Su, M.; Zhong, Q.; Peng, H.; Li, S. Selected machine learning approaches for predicting the interfacial bond strength between FRPs and concrete. Constr. Build. Mater. 2021, 270, 121456. [Google Scholar] [CrossRef]

- Vu, D.T.; Hoang, N.D. Punching shear capacity estimation of FRP-reinforced concrete slabs using a hybrid machine learning approach. Struct. Infrastruct. Eng. 2016, 12, 1153–1161. [Google Scholar] [CrossRef]

- Jahangir, H.; Eidgahee, D.R. A new and robust hybrid artificial bee colony algorithm–ANN model for FRP-concrete bond strength evaluation. Compos. Struct. 2021, 257, 113160. [Google Scholar] [CrossRef]

- Mahjoubi, S.; Meng, W.; Bao, Y. Logic-guided neural network for predicting steel-concrete interfacial behaviors. Expert Syst. Appl. 2022, 198, 116820. [Google Scholar] [CrossRef]

- Kim, B.; Lee, D.E.; Hu, G.; Natarajan, Y.; Preethaa, S.; Rathinakumar, A.P. Ensemble machine learning-based approach for predicting of FRP–concrete interfacial bonding. Mathematics 2022, 10, 231. [Google Scholar] [CrossRef]

- Mukhtar, F.M.; Faysal, R.M. A review of test methods for studying the FRP-concrete interfacial bond behavior. Constr. Build. Mater. 2018, 169, 877–887. [Google Scholar] [CrossRef]

- GB 50010-2010; Code for design of concrete structures. China Architecture & Building Press: Beijing, China, 2010.

- Nevergrad—A gradient-Free Optimization Platform. Available online: https://facebookresearch.github.io/nevergrad/ (accessed on 26 March 2025).

- Bennet, P.; Doerr, C.; Moreau, A.; Rapin, J.; Teytaud, F.; Teytaud, O. Nevergrad: Black-box optimization platform. ACM SIGEVOlution 2021, 14, 8–15. [Google Scholar] [CrossRef]

- Hansen, N.; Ostermeier, A. Completely Derandomized Self-Adaptation in Evolution Strategies. Evol. Comput. 2001, 9, 159–195. [Google Scholar] [CrossRef] [PubMed]

- Storn, R.; Price, K. Differential Evolution—A Simple and Efficient Heuristic for Global Optimization over Continuous Spaces. J. Glob. Optim. 1997, 11, 341–359. [Google Scholar] [CrossRef]

- Kennedy, J.; Eberhart, R. Particle Swarm Optimization. In Proceedings of the IEEE International Conference on Neural Networks (ICNN’95), Perth, WA, Australia, 27 November–1 December 1995. [Google Scholar] [CrossRef]

- Bergstra, J.; Bengio, Y. Random Search for Hyper-Parameter Optimization. J. Mach. Learn. Res. 2012, 13, 281–305. [Google Scholar]

- Lemieux, C. Financial Applications. In Monte Carlo and Quasi-Monte Carlo Sampling; Springer Series in Statistics; Springer: New York, NY, USA, 2009; pp. 1–54. [Google Scholar] [CrossRef]

- Cauwet, M.-L.; Couprie, C.; Dehos, J.; Luc, P.; Rapin, J.; Riviere, M.; Teytaud, F.; Teytaud, O.; Usunier, N. Fully Parallel Hyperparameter Search: Reshaped Space-Filling. In Proceedings of the 37th International Conference on Machine Learning, PMLR, Online, 13–18 July 2020; Volume 119, pp. 1338–1348. Available online: https://proceedings.mlr.press/v119/cauwet20a.html (accessed on 18 March 2025).

- Rapin, J.; Gallagher, M.; Kerschke, P.; Preuss, M.; Teytaud, O. Exploring the MLDA benchmark on the nevergrad platform. In Proceedings of the Genetic and Evolutionary Computation Conference Companion, Prague, Czech Republic, 13–17 July 2019; pp. 1888–1896. [Google Scholar] [CrossRef]

- Raponi, E.; Rakotonirina Carraz, N.; Rapin, J.; Doerr, C.; Teytaud, O. Optimizing with Low Budgets: A Comparison on the Black-box Optimization Benchmarking Suite and OpenAI Gym. IEEE Trans. Evol. Comput. 2025, 29, 91–101. [Google Scholar] [CrossRef]

- Chen, T.; Guestrin, C. XGBoost: A Scalable Tree Boosting System. In Proceedings of the 22nd ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, San Francisco, CA, USA, 13–17 August 2016; pp. 785–794. [Google Scholar] [CrossRef]

- Zhou, X.; Duan, F.; Liu, W.; Shi, C.; Xie, B.; Yao, Z. Research on Prediction of Rheological Properties of Steel-Polypropylene Fiber UHPC Mortar Based on Ensemble Machine Learning. Constr. Build. Mater. 2025, 472, 140833. [Google Scholar] [CrossRef]

- Zhou, J.; Qiu, Y.; Zhu, S.; Armaghani, D.J.; Khandelwal, M.; Mohamad, E.T. Estimation of the TBM Advance Rate under Hard Rock Conditions Using XGBoost and Bayesian Optimization. Undergr. Space 2021, 6, 506–515. [Google Scholar] [CrossRef]

- Le, L.T.; Nguyen, H.; Zhou, J.; Dou, J.; Moayedi, H. Estimating the Heating Load of Buildings for Smart City Planning Using a Novel Artificial Intelligence Technique PSO-XGBoost. Appl. Sci. 2019, 9, 2714. [Google Scholar] [CrossRef]

- Zhou, J.; Qiu, Y.; Zhu, S.; Armaghani, D.J.; Li, C.; Nguyen, H.; Yagiz, S. Optimization of Support Vector Machine through the Use of Metaheuristic Algorithms in Forecasting TBM Advance Rate. Eng. Appl. Artif. Intell. 2021, 97, 104015. [Google Scholar] [CrossRef]

- Chen, Y.; Khandelwal, M.; Onifade, M.; Zhou, J.; Lawal, A.I.; Bada, S.O.; Genc, B. Predicting the Hardgrove Grindability Index Using Interpretable Decision Tree-Based Machine Learning Models. Fuel 2025, 384, 133953. [Google Scholar] [CrossRef]

- Zhou, J.; Chen, Y.; Li, C.; Qiu, Y.; Huang, S.; Tao, M. Machine Learning Models to Predict the Tunnel Wall Convergence. Transp. Geotech. 2023, 41, 101022. [Google Scholar] [CrossRef]

- Li, E.; Zhang, N.; Xi, B.; Zhou, J.; Gao, X. Compressive Strength Prediction and Optimization Design of Sustainable Concrete Based on Squirrel Search Algorithm-Extreme Gradient Boosting Technique. Front. Struct. Civ. Eng. 2023, 17, 1310–1325. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, R.; Qiu, Y.; Khandelwal, M. A True Triaxial Strength Criterion for Rocks by Gene Expression Programming. J. Rock Mech. Geotech. Eng. 2023, 15, 2508–2520. [Google Scholar] [CrossRef]

- Zhang, R.; Zhou, J. Predicting the Minimum Horizontal Principal Stress Using Genetic Expression Programming and Borehole Breakout Data. J. Rock Mech. Geotech. Eng. 2024, in press. [CrossRef]

- Zhang, Y.L.; Qiu, Y.G.; Armaghani, D.J.; Monjezi, M.; Zhou, J. Enhancing Rock Fragmentation Prediction in Mining Operations: A Hybrid GWO-RF Model with SHAP Interpretability. J. Cent. S. Univ. 2024, 31, 2916–2929. [Google Scholar] [CrossRef]

- Shapley, L.S. Stochastic Games. Proc. Natl. Acad. Sci. USA 1953, 39, 1095–1100. [Google Scholar] [CrossRef]

- Antwarg, L.; Miller, R.M.; Shapira, B.; Rokach, L. Explaining Anomalies Detected by Autoencoders Using Shapley Additive Explanations. Expert Syst. Appl. 2021, 186, 115736. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).