Effects of Thermal Cycles on Mechanical Properties of RPECC: Static and Dynamic Compressive Performance

Abstract

1. Introduction

2. Experiment Program

2.1. Mix Proportions

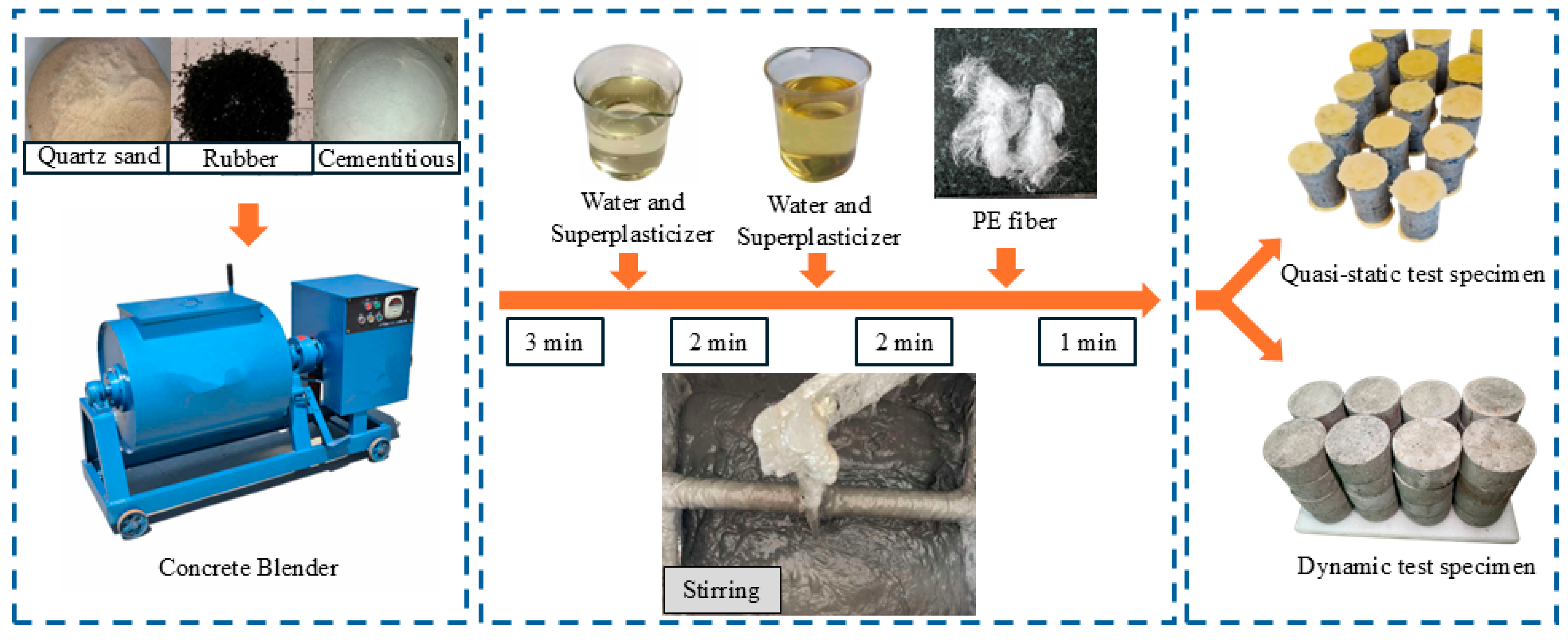

2.2. Specimen Preparation and Maintenance

2.3. Test Methods

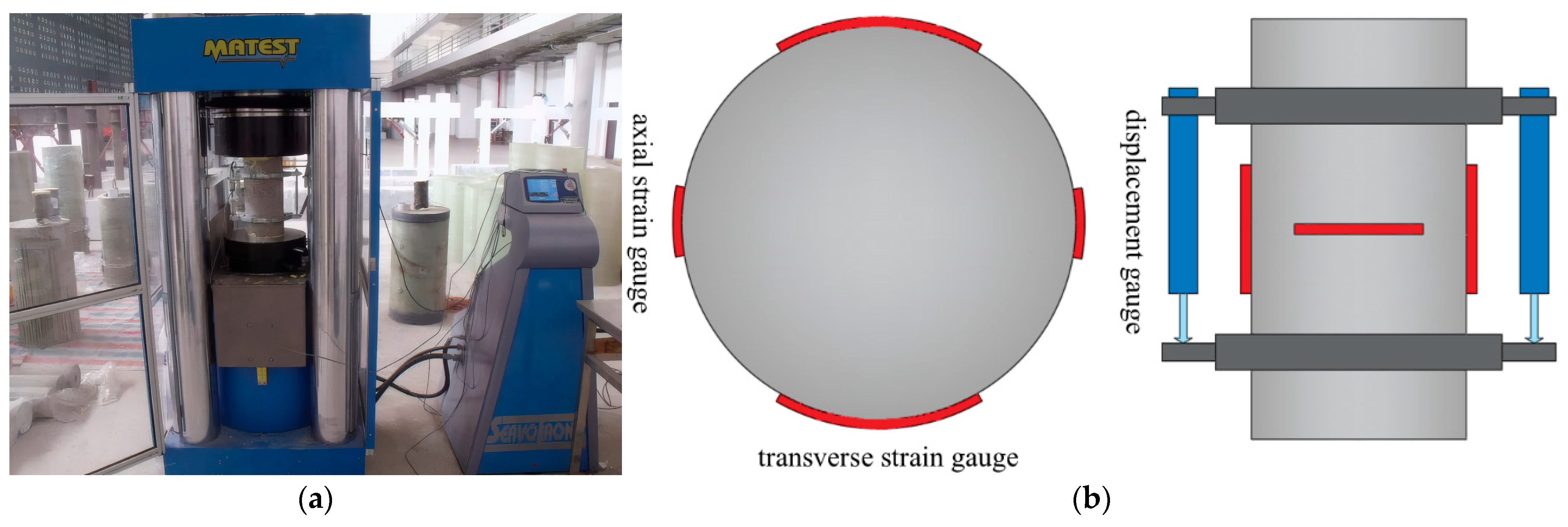

2.3.1. Static Compression Test

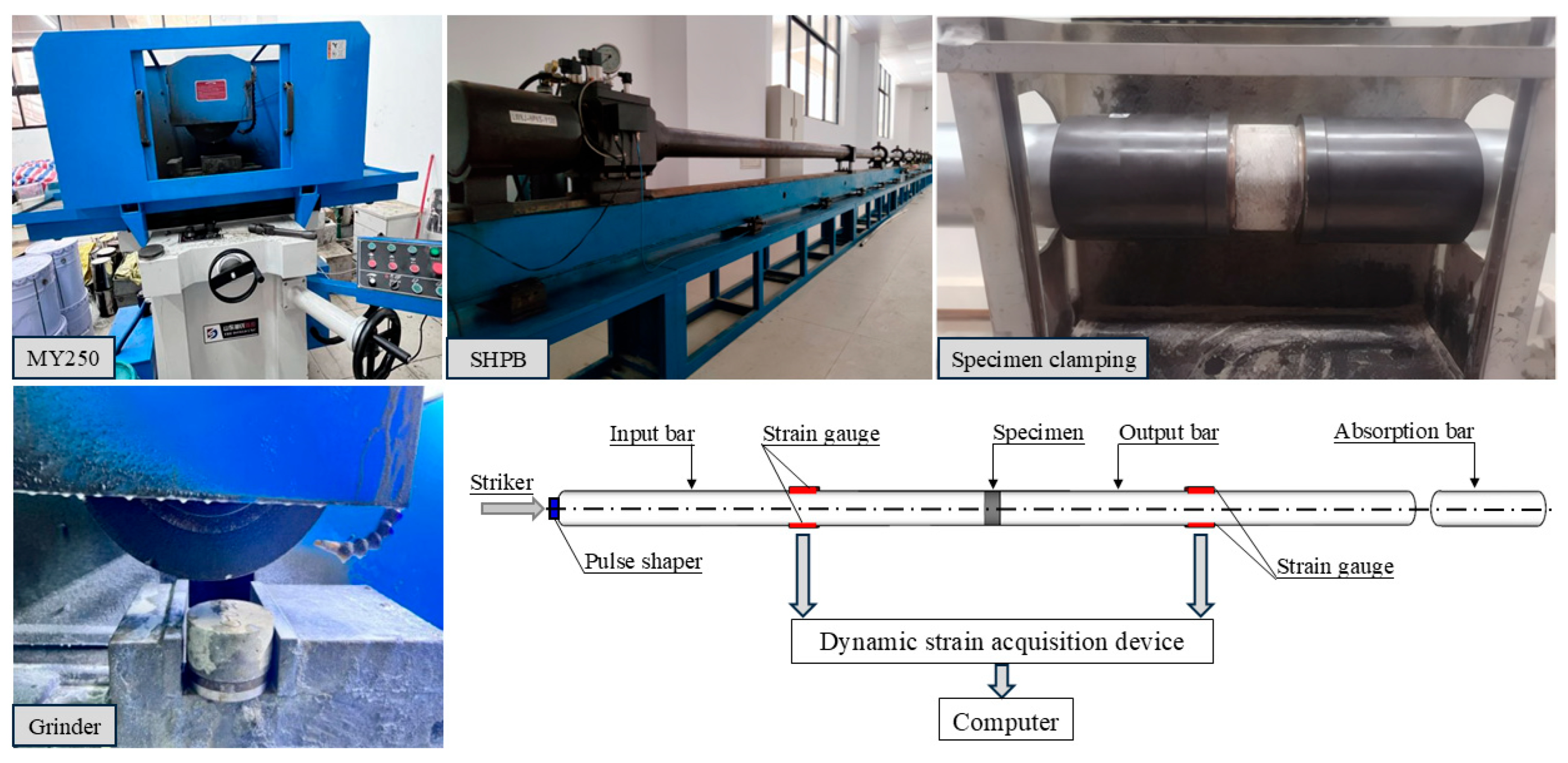

2.3.2. Dynamic Compression Test

2.3.3. Scanning Electron Microscopy

3. Results and Discussion

3.1. Quasi-Static Compressive Behavior

3.1.1. Failure Pattern of Static Compressive Samples

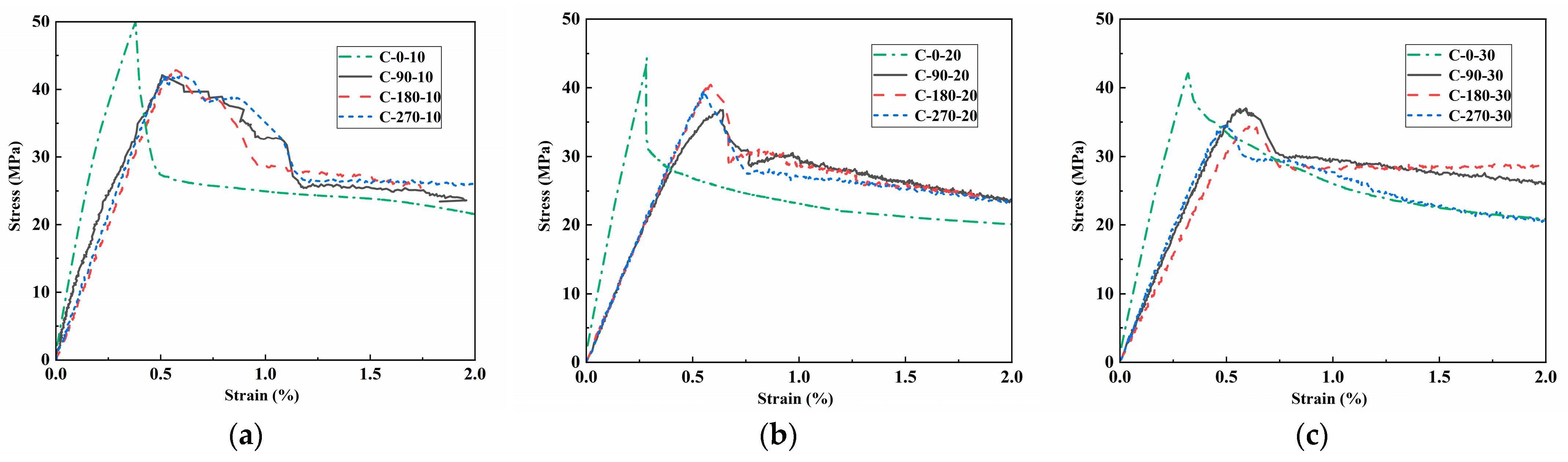

3.1.2. Static Compressive Stress vs. Strain Relationship

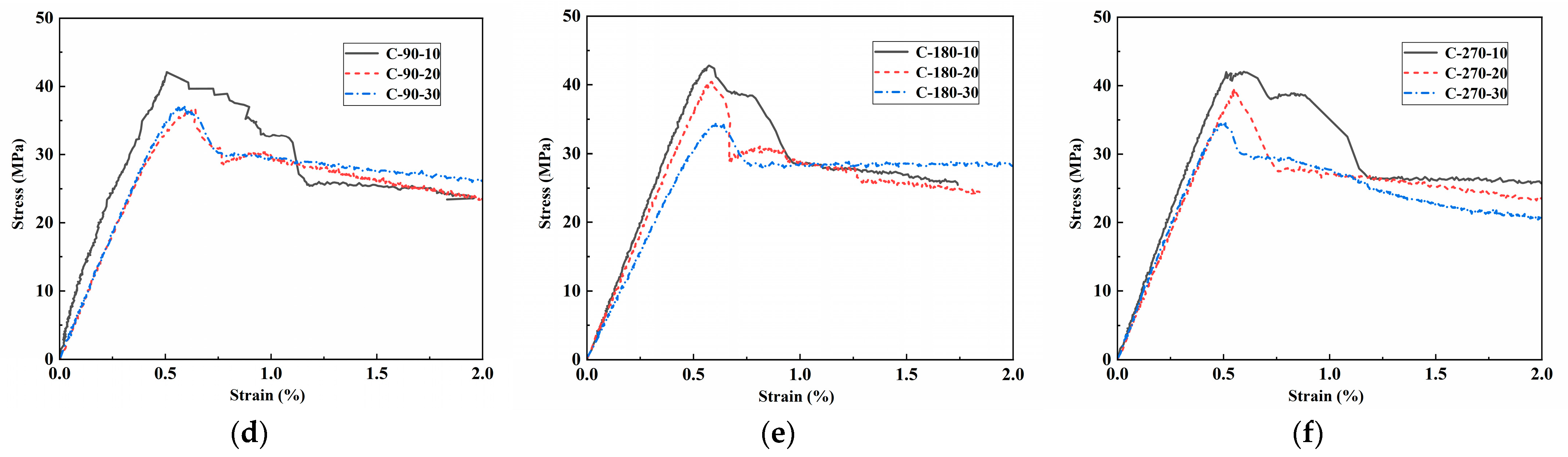

3.1.3. Quasi-Static Compressive Strength and Elastic Modulus

3.2. Dynamic Compressive Behavior

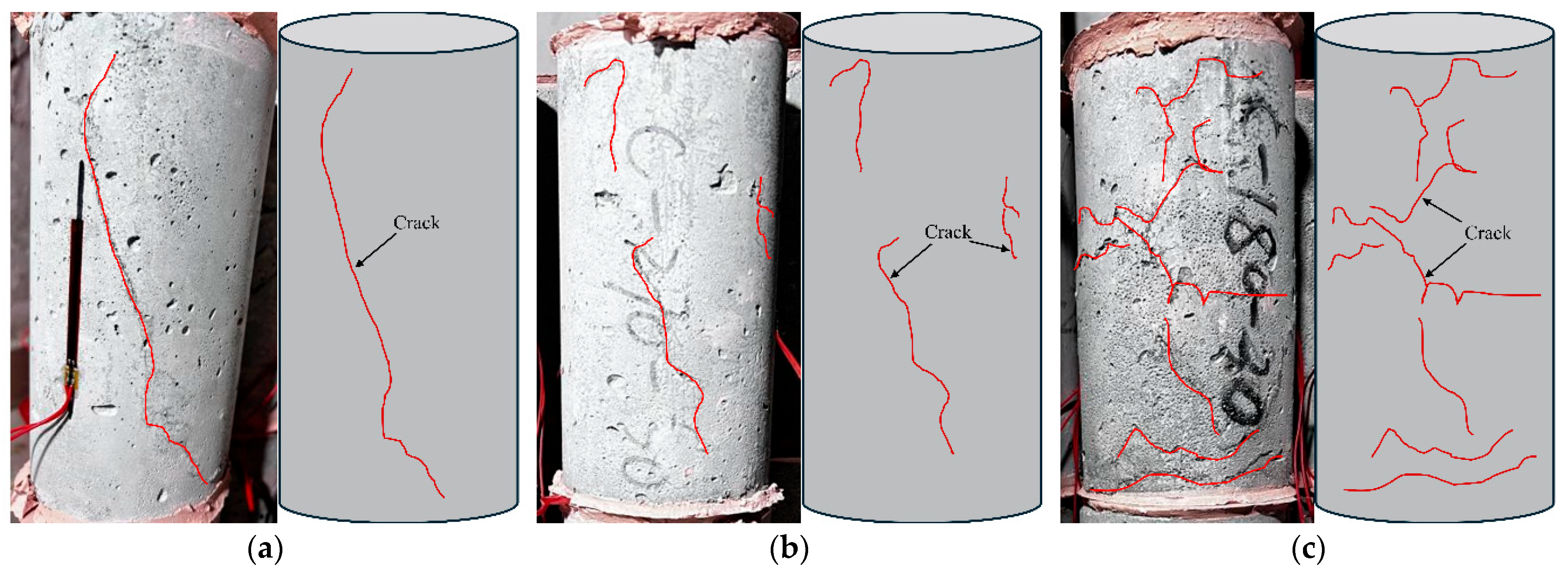

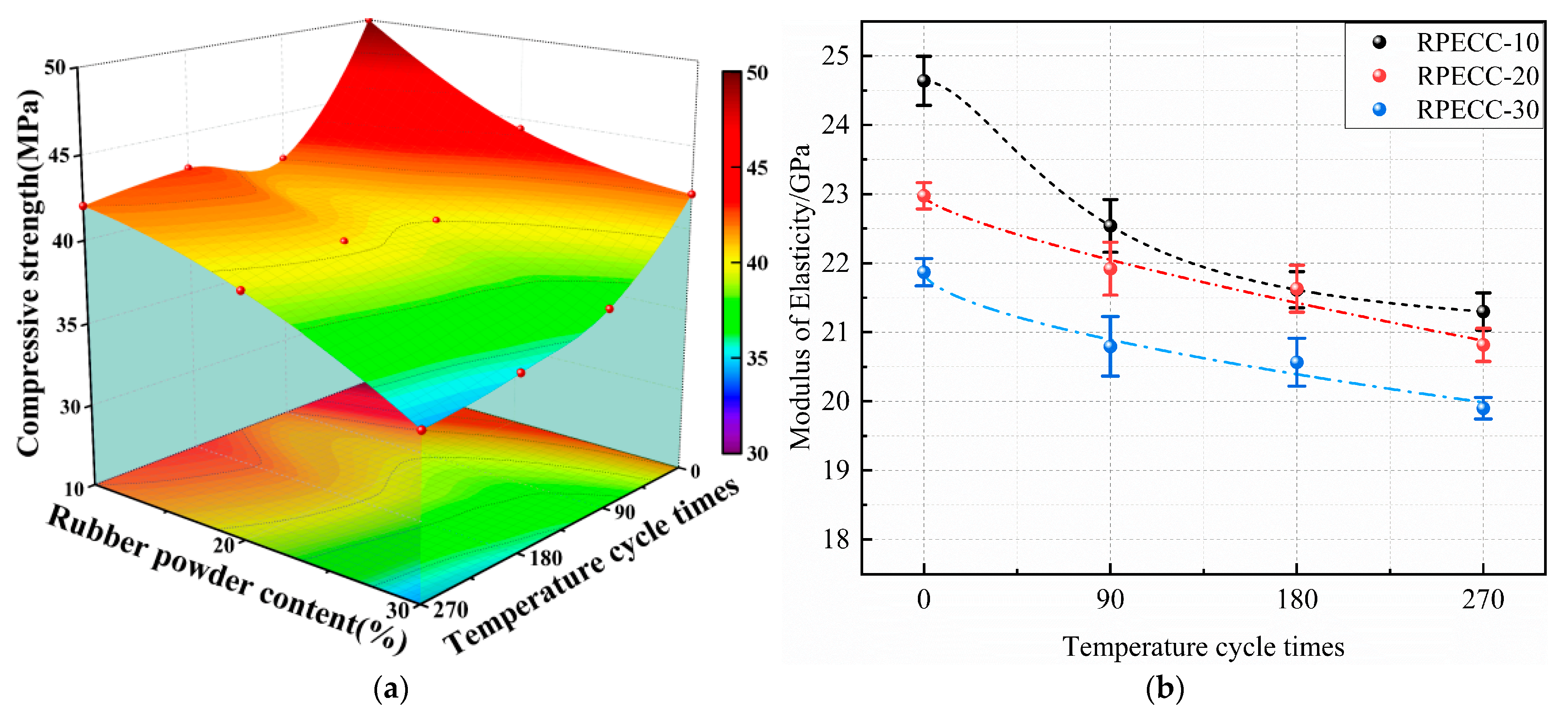

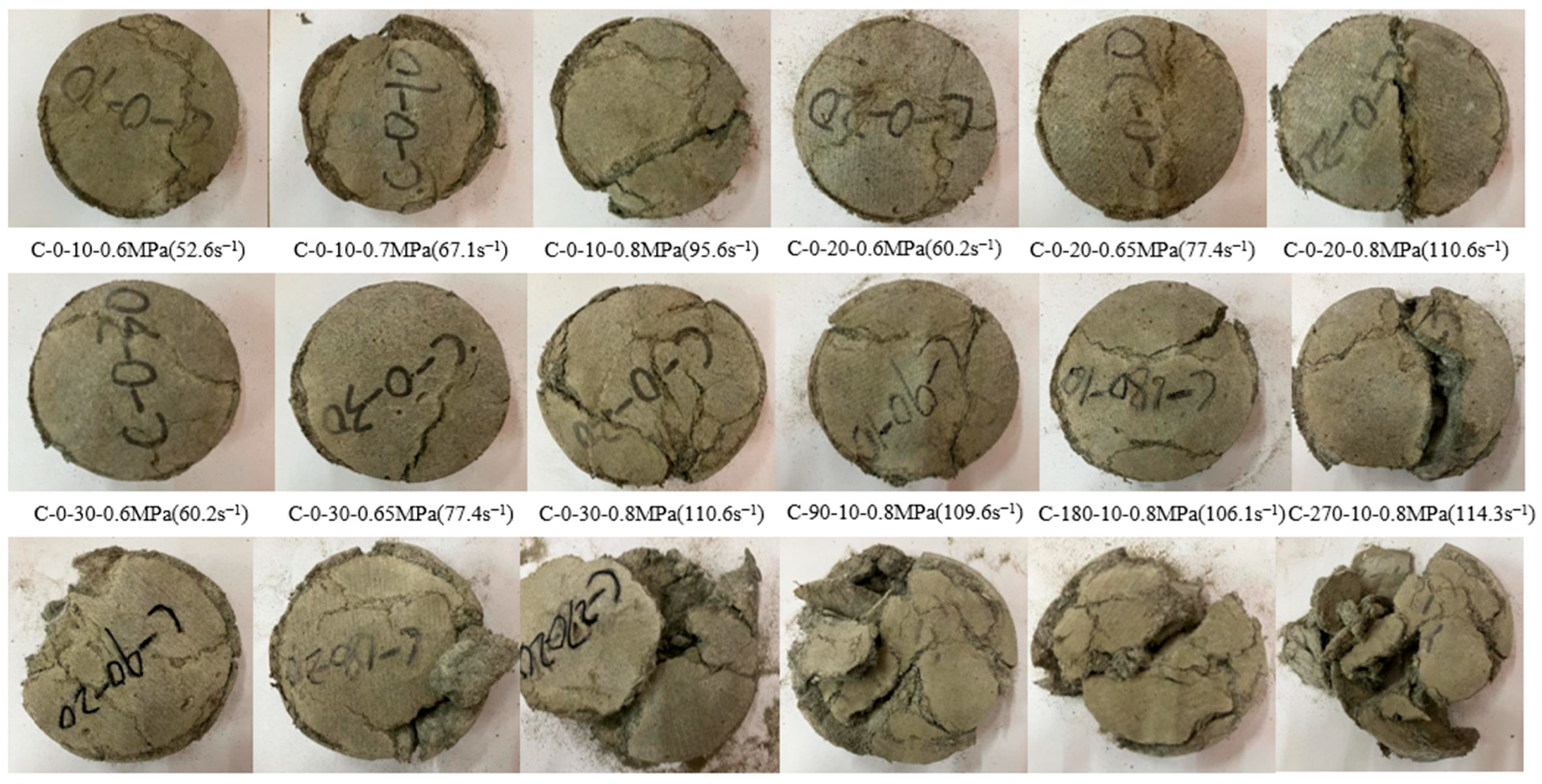

3.2.1. Failure Pattern Dynamic Compressive Samples

3.2.2. Dynamic Compressive Stress vs. Strain Relationship

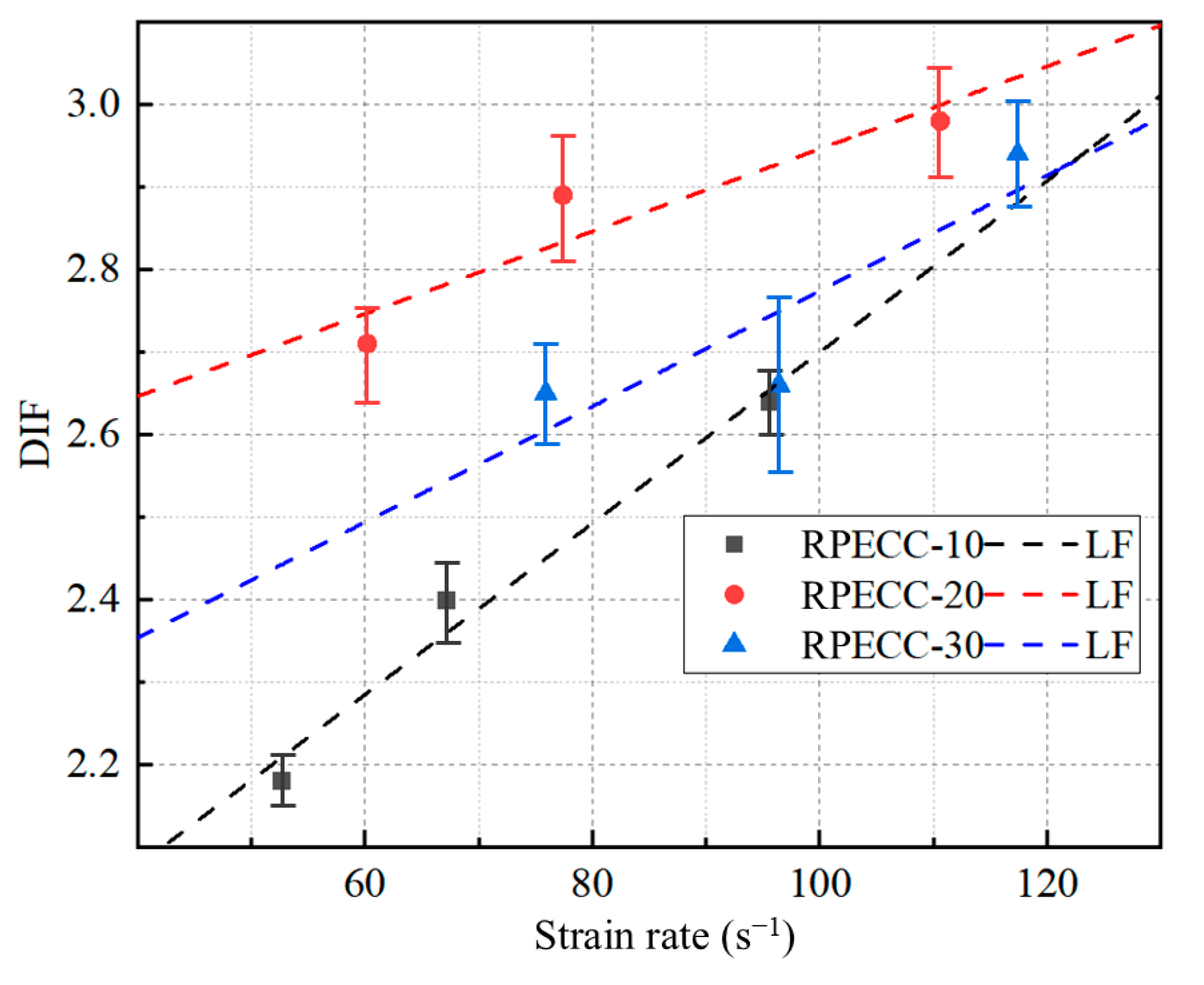

3.2.3. Dynamic Compressive Strength

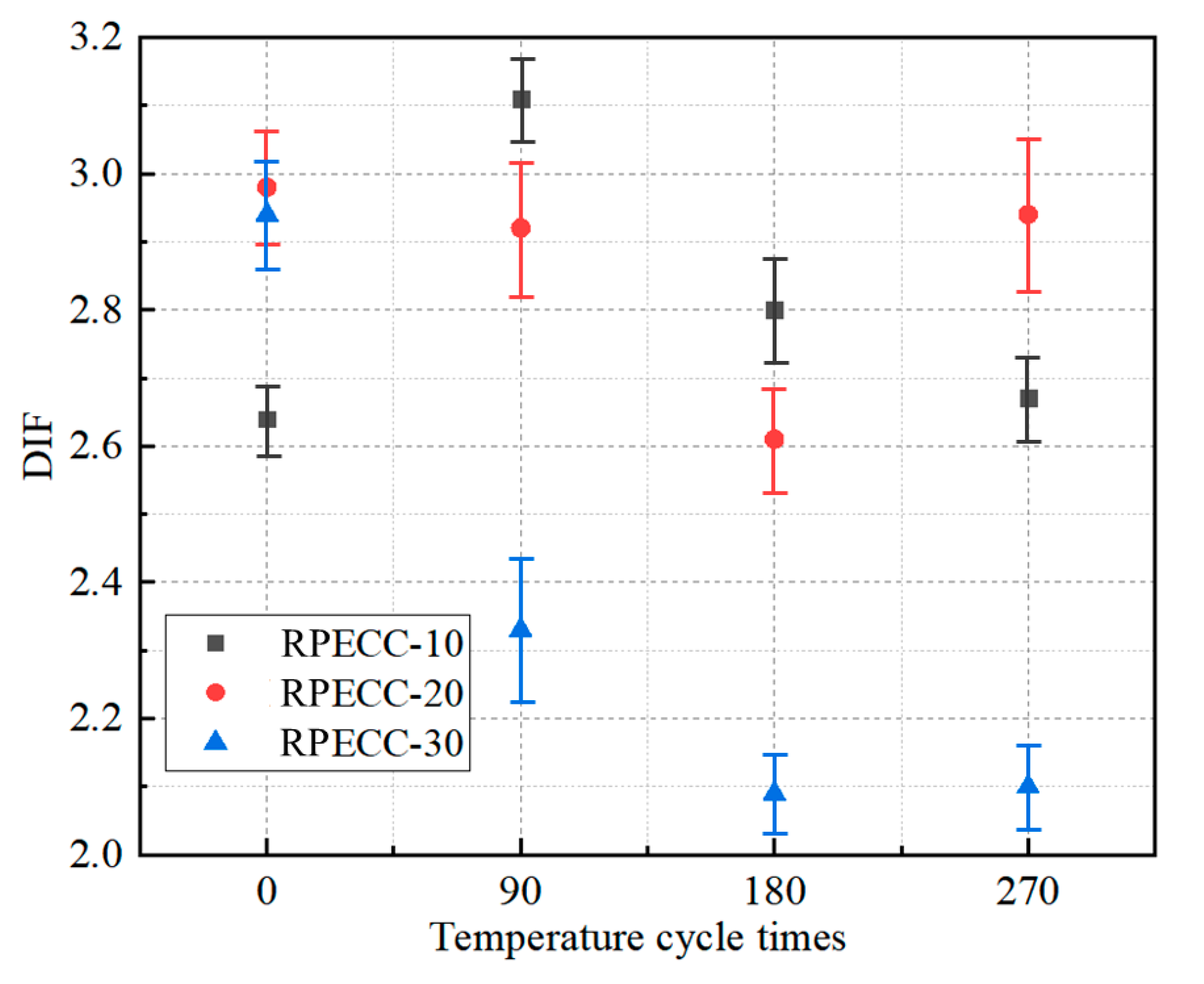

3.2.4. Dynamic Peak Stress

3.3. Microstructural Evolution

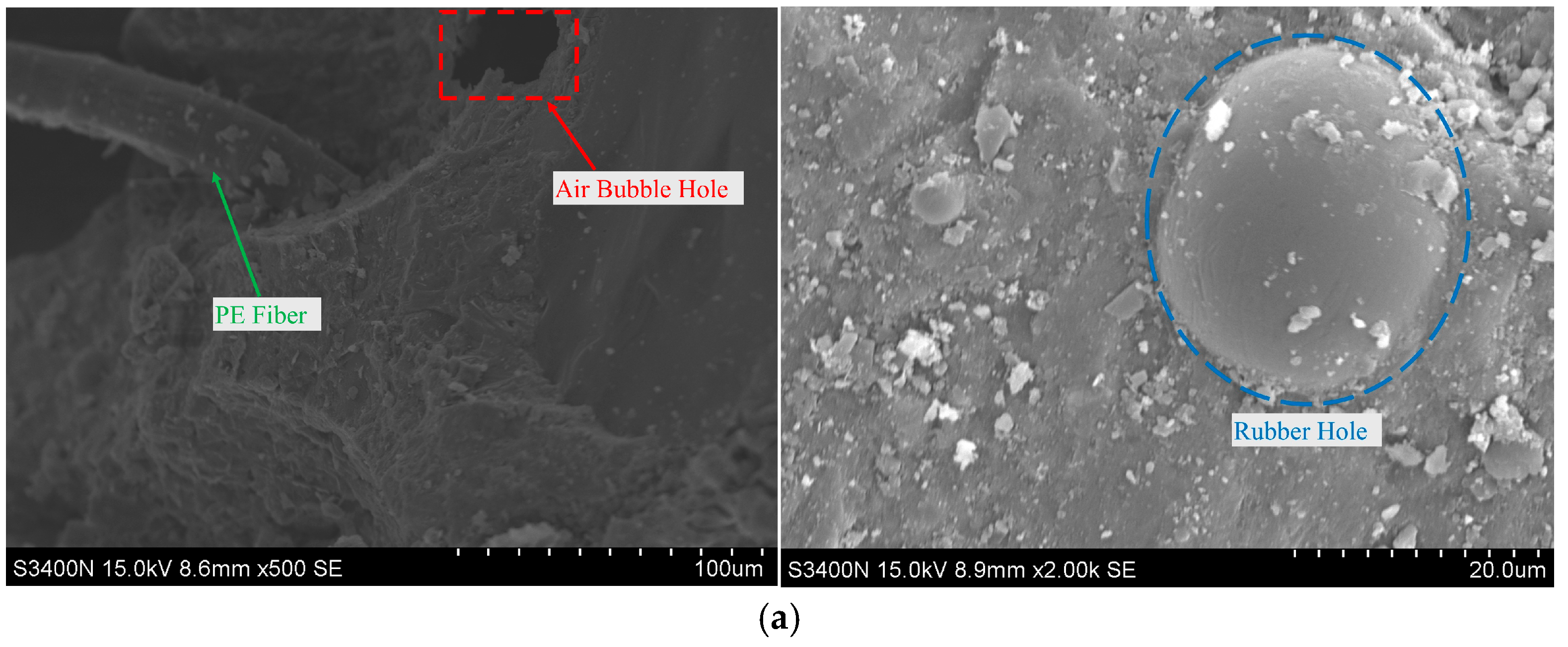

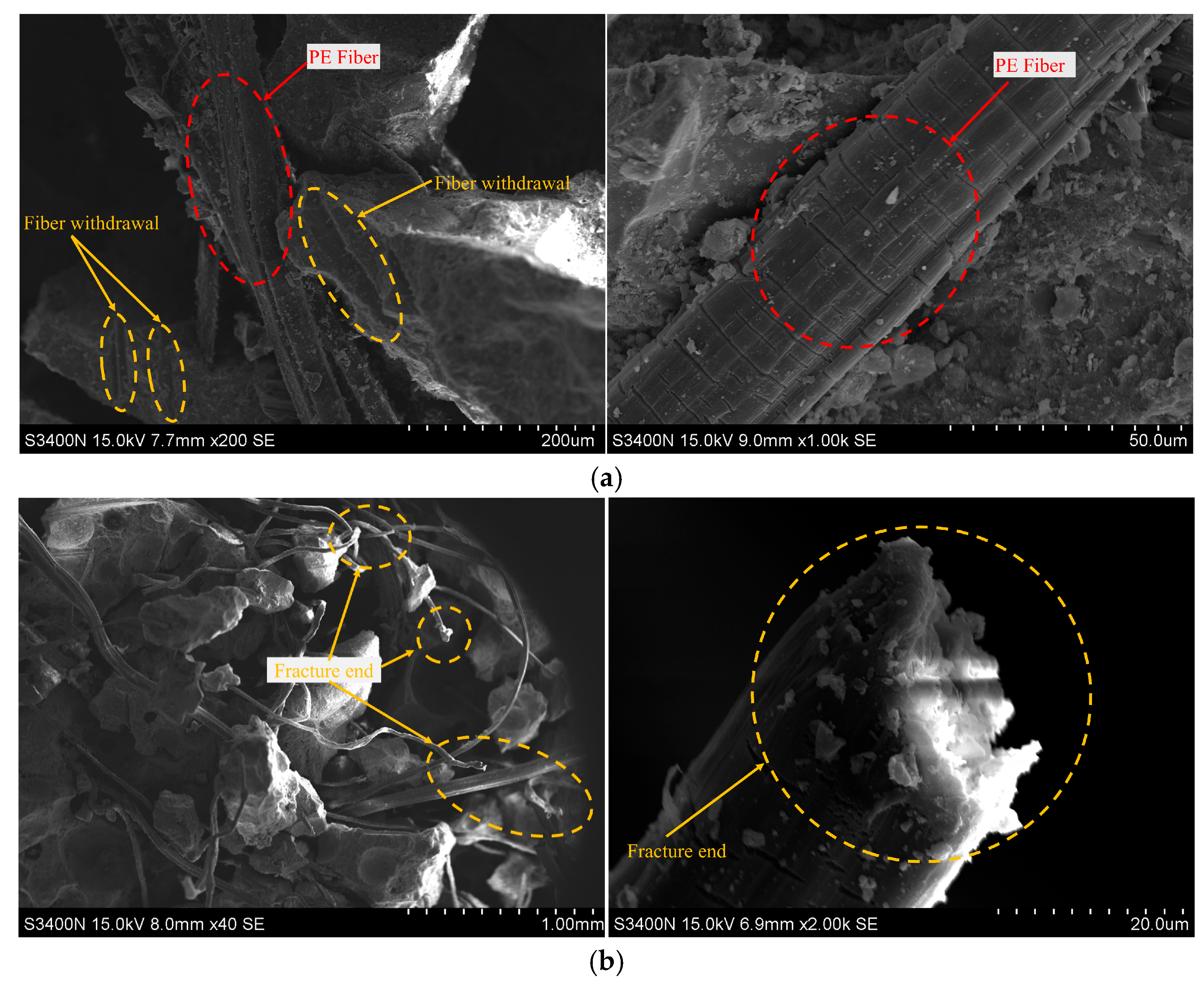

3.3.1. Microscopic Analysis of RPECC

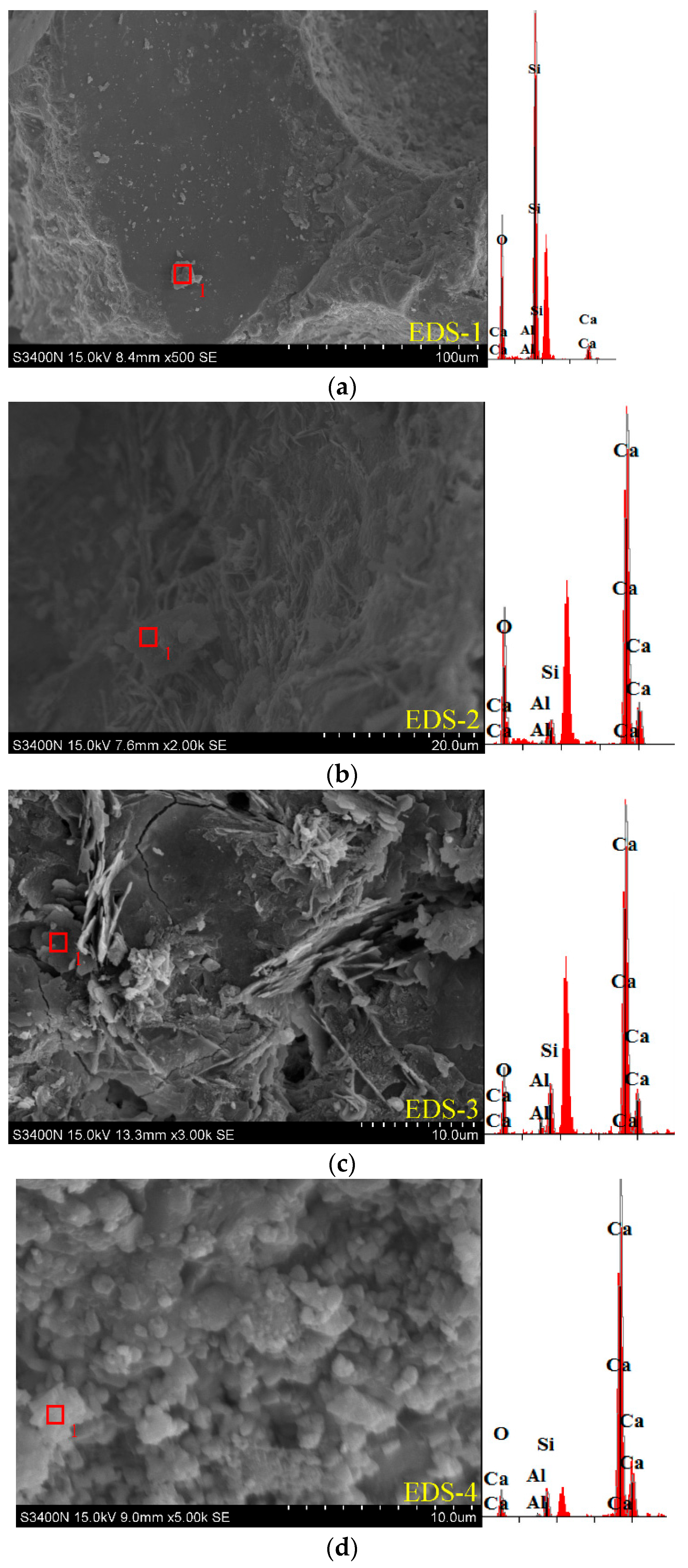

3.3.2. Energy-Dispersive X-Ray Spectroscopy (EDS) for Microstructural Analysis

4. Conclusions

- Failure mode of RPECC resembles that of rubber concrete, with damage mainly in peripheral areas. Larger fragments are held together by fibers, allowing some structural integrity under static compression. Under dynamic loads, increased strain rate, rubber particle content, and thermal-cycle frequency worsen the damage, showing the material’s high sensitivity to external conditions.

- Thermal cycles significantly reduce the compressive strength of RPECC, with a pronounced decline as cycles increase. After 270 cycles, static compressive strength drops by 18.0%, while dynamic compressive strength falls by 41.2%. The dynamic strength of RPECC rises with higher strain rates, demonstrating a strain-rate sensitivity similar to that of conventional concrete.

- Adding rubber to RPECC reduces static compressive strength, decreasing by 17.9% at 30% rubber content and by only 11.3% at 20% rubber content. However, an optimal rubber proportion (20%) exists for enhancing strain-rate sensitivity under dynamic loading. Beyond this threshold, the material’s dynamic performance may deteriorate. Moreover, the stress–strain response of the 20% rubber specimens is more elastic with higher peak strain values, achieving a balance between ductility and strength loss.

- SEM images indicate that PE fibers primarily fail through fracture and pull-out slip, with the addition of rubber shifting the failure mechanism towards pull-out slip. EDS analysis shows that thermal fatigue and hydration promote the formation of hydration products, especially calcium hydroxide (CH), which significantly reduces the dynamic compressive strength of RPECC after thermal cycles. Furthermore, thermal cycling affects RPECC properties in two ways: (i) the CTE difference between rubber and matrix triggers interfacial microcracks, and high temperature accelerates the aging of rubber, weakening its stress dispersion ability; (ii) the interfacial bond between PE fibers and matrix is degraded by thermal cycling, and the fiber-bridging effect is reduced, which, together with the formation of the hydration product CH, results in the deterioration of the mechanical properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Singh, M.; Saini, B.; Chalak, H.D. Performance and composition analysis of engineered cementitious composite (ECC)–A review. J. Build. Eng. 2019, 26, 100851. [Google Scholar] [CrossRef]

- He, S.H.; Zhong, H.Q.; Chen, Z.L.; Chen, H.W.; Chen, J.C.; Yu, Z.T. Effects of thermal cycles on mechanical properties of RPECC: Static and dynamic splitting tensile performance. Materials 2025, 18, 994. [Google Scholar] [CrossRef] [PubMed]

- Lepech, M.D.; Li, V.C. Sustainable pavement overlays using engineered cementitious composites. Int. J. Pavement Res. Technol. 2010, 3, 241–250. [Google Scholar]

- He, S.H.; Zhou, D.F.; Bai, B.S.; Liu, C.X.; Dong, Y. Experimental study on shear performance of prefabricated HSS-UHPC composite beam with perfobond strip connectors. Eng. Struct. 2025, 324, 119318. [Google Scholar] [CrossRef]

- Li, V.C.; Yang, E.H.; Li, M. Field Demonstration of Durable Link Slabs for Jointless Bridge Decks Based on Strain-Hardening Cementitious Composites-Phase 3: Shrinkage Control; Michigan Department of Transportation: Lansing, MI, USA, 2008. [Google Scholar]

- Al-Tayyib, A.J.; Baluch, M.H.; Sharif, A.F.M.; Mahamud, M.M. The effect of thermal cycling on the durability of concrete made from local materials in the Arabian Gulf countries. Cem. Concr. Res. 1989, 19, 131–142. [Google Scholar] [CrossRef]

- Li, Z.W.; Xu, J.Y.; Bai, E.L. Static and dynamic mechanical properties of concrete after high temperature exposure. Mater. Sci. Eng. A 2012, 544, 27–32. [Google Scholar] [CrossRef]

- Ahmad, F.; Rawat, S.; Yang, R.C.; Zhang, L.; Zhang, Y.X. Fire resistance and thermal performance of hybrid fibre-reinforced magnesium oxychloride cement-based composites. Constr. Build. Mater. 2025, 472, 140867. [Google Scholar] [CrossRef]

- Bu, C.M.; Zhu, D.X.; Liu, L.; Lu, X.Y.; Sun, Y.; Yu, L.W.; OuYang, Y.H.; Cao, X.M.; Wang, F.X. Research progress on rubber concrete properties: A review. J. Rubber Res. 2022, 25, 105–125. [Google Scholar] [CrossRef]

- Ahmad, F.; Jamal, A.; Mazher, K.M.; Umer, W.; Iqbal, M. Performance evaluation of plastic concrete modified with e-waste plastic as a partial replacement of coarse aggregate. Materials 2021, 15, 175. [Google Scholar] [CrossRef]

- Huang, X.Y.; Ranade, R.; Ni, W.; Li, V.C. On the use of recycled tire rubber to develop low E-modulus ECC for durable concrete repairs. Constr. Build. Mater. 2013, 46, 134–141. [Google Scholar] [CrossRef]

- Zhang, Z.G.; Ma, H.; Qian, S.Z. Investigation on properties of ECC incorporating crumb rubber of different sizes. J. Adv. Concr. Technol. 2015, 13, 241–251. [Google Scholar] [CrossRef]

- Ismail, M.K.; Sherir, M.A.; Siad, H.; Hassan, A.A.; Lachemi, M. Properties of self-consolidating engineered cementitious composite modified with rubber. J. Mater. Civ. Eng. 2018, 30, 04018031. [Google Scholar] [CrossRef]

- Abdulkadir, I.; Mohammed, B.S.; Liew, M.S.; Wahab, M.M.B.A.; Zawawi, N.A.W.A.; As’ad, S. A review of the effect of waste tire rubber on the properties of ECC. Intern. J. Adv. Appl. Sci. 2020, 7, 105–116. [Google Scholar]

- He, S.H.; Chen, H.W.; Jiang, Z.; Yu, Z.T. Static and impact properties of polyethylene fiber-reinforced engineered cementitious composites with crumb rubber powder. J. Civ. Envir. Eng. 2024, 46, 167–174. (In Chinese) [Google Scholar]

- JGJ/T70-2009; Standard for Basic Performance Test of Building Mortar. MOHURD (Ministry of Housing and Urban-Rural Development of the People’s Republic of China). China Architecture & Building Press: Beijing, China, 2009.

- ASTM International Committee C09 on Concrete and Concrete Aggregates. Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression1; ASTM International: West Concord, PA, USA, 2014. [Google Scholar]

- Li, L.J.; Ruan, S.H.; Zeng, L. Mechanical properties and constitutive equations of concrete containing a low volume of tire rubber particles. Constr. Build. Mater. 2014, 70, 291–308. [Google Scholar] [CrossRef]

- Guo, Y.C.; Xie, J.H.; Zhao, J.B.; Zuo, K.X. Utilization of unprocessed steel slag as fine aggregate in normal-and high-strength concrete. Constr. Build. Mater. 2019, 204, 41–49. [Google Scholar] [CrossRef]

- Wang, L.-L. Elementary theory of one-dimensional stress waves in bars. In Foundations of Stress Waves; Elsevier: Oxford, UK, 2007; pp. 7–55. [Google Scholar]

- Fang, X.F. A one-dimensional stress wave model for analytical design and optimization of oscillation-free force measurement in high-speed tensile test specimens. Int. J. Impact Eng. 2021, 149, 103770. [Google Scholar] [CrossRef]

- Lindholm, U.S. Some experiments with the split hopkinson pressure bar∗. J. Mech. Phys. Solids 1964, 12, 317–335. [Google Scholar] [CrossRef]

- Feng, Y.; Niu, Z.J.; Zhao, C.; Li, L.J. Compressive test investigation and numerical simulation of polyvinyl-alcohol (PVA)-Fiber-Reinforced rubber concrete. Buildings 2023, 13, 431. [Google Scholar] [CrossRef]

- Khaloo, A.R.; Dehestani, M.; Rahmatabadi, P. Mechanical properties of concrete containing a high volume of tire–rubber particles. Waste Manag. 2008, 28, 2472–2482. [Google Scholar] [CrossRef]

- Liu, F.; Zheng, W.H.; Li, L.J.; Feng, W.X.; Ning, G.F. Mechanical and fatigue performance of rubber concrete. Constr. Build. Mater. 2013, 47, 711–719. [Google Scholar] [CrossRef]

- Zheng, L.; Huo, X.S.; Yuan, Y. Strength, modulus of elasticity, and brittleness index of rubberized concrete. J. Mater. Civ. Eng. 2008, 20, 692–699. [Google Scholar] [CrossRef]

- Najim, K.B. Determination and Enhancement of Mechanical and Thermo-Physical Behaviour of Crumb Rubber-Modified Structural Concrete. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 2012. [Google Scholar]

- Yang, R.Z.; Xu, Y.; Chen, P.Y.; Wang, J. Experimental study on dynamic mechanics and energy evolution of rubber concrete under cyclic impact loading and dynamic splitting tension. Constr. Build. Mater. 2020, 262, 120071. [Google Scholar] [CrossRef]

- Al-Fakih, A.; Mohammed, B.S.; Liew, M.S. On rubberized engineered cementitious composites (R-ECC): A review of the constituent material. Case Stud. Constr. Mater. 2021, 14, e00536. [Google Scholar] [CrossRef]

- Xie, J.H.; Huang, L.; Guo, Y.C.; Li, Z.J.; Fang, C.; Li, L.J.; Wang, J.J. Experimental study on the compressive and flexural behaviour of recycled aggregate concrete modified with silica fume and fibres. Constr. Build. Mater. 2018, 178, 612–623. [Google Scholar] [CrossRef]

- Feng, L.; Chen, X.D.; Zhang, J.H.; Chen, C.L. Experimental and mesoscopic investigation of self-compacting rubberized concrete under dynamic splitting tension. J. Build. Eng. 2022, 57, 104942. [Google Scholar] [CrossRef]

- Zhong, H.Q.; Chen, Z.L.; Liu, C.X.; He, S.H.; Wan, Z.Y.; Yu, Z.T. Fatigue shear failure mechanism and prediction method for UHPC-NC bond interfaces. Eng. Struct. 2025, 336, 120455. [Google Scholar] [CrossRef]

- Chen, X.D.; Xu, L.Y.; Wu, S.X. Influence of pore structure on mechanical behavior of concrete under high strain rates. J. Mater. Civ. Eng. 2016, 28, 04015110. [Google Scholar] [CrossRef]

- Grote, D.L.; Park, S.W.; Zhou, M. Dynamic behavior of concrete at high strain rates and pressures: I. experimental characterization. Int. J. Impact Eng. 2001, 25, 869–886. [Google Scholar] [CrossRef]

- He, S.H.; Zhong, H.Q.; Huang, X.; Xu, Y.M.; Mosallam, A. Experimental investigation on shear fatigue behavior of perfobond strip connectors made of high strength steel and ultra-high performance concrete. Eng. Struct. 2025, 322, 119181. [Google Scholar] [CrossRef]

- Ross, C.A.; Tedesco, J.W.; Kuennen, S.T. Effects of strain rate on concrete strength. Mater. J. 1995, 92, 37–47. [Google Scholar]

- Chen, B.; Chen, J.L.; Chen, X.D.; Qiang, S.; Zheng, Y.J. Experimental study on compressive strength and frost resistance of steam cured concrete with mineral admixtures. Constr. Build. Mater. 2022, 325, 126725. [Google Scholar] [CrossRef]

- Xu, X.B.; Jin, Z.Q.; Yu, Y.; Li, N. Impact properties of Ultra High Performance Concrete (UHPC) cured by steam curing and standard curing. Case Stud. Constr. Mater. 2022, 17, e01321. [Google Scholar] [CrossRef]

- Ahmad, F.; Jamal, A.; Iqbal, M.; Alqurashi, M.; Almoshaogeh, M.; Al-Ahmadi, H.M.; Hussein, E.E. Performance Evaluation of Cementitious Composites Incorporating Nano Graphite Platelets as Additive Carbon Material. Materials 2022, 15, 290. [Google Scholar] [CrossRef]

- Amjad, H.; Khushnood, R.A.; Ahmad, F. Enhanced fracture and durability resilience using bio-intriggered sisal fibers in concrete. J. Build. Eng. 2023, 76, 107008. [Google Scholar] [CrossRef]

- Kai, M.F.; Xiao, Y.; Shuai, X.L.; Ye, G. Compressive behavior of engineered cementitious composites under high strain-rate loading. J. Mater. Civ. Eng. 2017, 29, 04016254. [Google Scholar] [CrossRef]

- Khalil, E.; Abd-Elmohsen, M.; Anwar, A.M. Impact resistance of rubberized self-compacting concrete. Water Sci. 2015, 29, 45–53. [Google Scholar] [CrossRef]

- Ahmad, F.; Rawat, S.; Yang, R.; Zhang, L.; Guo, Y.; Fanna, D.J.; Zhang, Y.X. Effect of hybrid fibres on mechanical behaviour of magnesium oxychloride cement-based composites. Constr. Build. Mater. 2024, 424, 135937. [Google Scholar] [CrossRef]

| Code | Cement | Fly Ash | Blast Furnace Slag | Sand | Water | Superplasticizer /% | PE Fiber /% | Cycles | Rubber Content /% |

|---|---|---|---|---|---|---|---|---|---|

| C-0-10 | 0.75 | 0.1 | 0.15 | 0.45 | 0.25 | 1.0 | 2 | 0 | 10 |

| C-0-20 | 0.40 | 20 | |||||||

| C-0-30 | 0.35 | 30 | |||||||

| C-90-10 | 0.45 | 90 | 10 | ||||||

| C-90-20 | 0.40 | 20 | |||||||

| C-90-30 | 0.35 | 30 | |||||||

| C-180-10 | 0.45 | 180 | 10 | ||||||

| C-180-20 | 0.40 | 20 | |||||||

| C-180-30 | 0.35 | 30 | |||||||

| C-270-10 | 0.45 | 270 | 10 | ||||||

| C-270-20 | 0.40 | 20 | |||||||

| C-270-30 | 0.35 | 30 |

| Length/mm | Diameter/µm | Elongation at Break/% | Tensile modulus/MPa | Tensile Strength/MPa | Density/(g/cm3) |

|---|---|---|---|---|---|

| 18 | 24 | 2 | 116 × 103 | 3000 | 0.97–0.98 |

| Specimen Code | Peak Stress/MPa | Average Value/MPa | Standard Deviation | Modulus of Elasticity/GPa | Average Value/GPa | Standard Deviation | |

|---|---|---|---|---|---|---|---|

| C-0-10 | a | 52.10 | 50.01 | 2.16 | 25.01 | 24.61 | 0.41 |

| b | 47.91 | 24.20 | |||||

| C-0-20 | a | 44.54 | 44.37 | 0.67 | 23.11 | 22.97 | 0.14 |

| b | 43.20 | 22.83 | |||||

| C-0-30 | a | 41.10 | 42.11 | 1.01 | 21.73 | 21.87 | 0.14 |

| b | 43.12 | 22.01 | |||||

| C-90-10 | a | 43.11 | 42.06 | 1.05 | 22.81 | 22.54 | 0.27 |

| b | 41.01 | 22.27 | |||||

| C-90-20 | a | 40.34 | 40.05 | 0.29 | 22.19 | 21.92 | 0.27 |

| b | 39.76 | 21.65 | |||||

| C-90-30 | a | 38.14 | 37.00 | 1.14 | 21.10 | 20.79 | 0.31 |

| b | 35.86 | 20.48 | |||||

| C-180-10 | a | 43.39 | 42.83 | 0.56 | 21.80 | 21.61 | 0.19 |

| b | 42.27 | 21.42 | |||||

| C-180-20 | a | 39.79 | 40.41 | 0.62 | 21.39 | 21.63 | 0.24 |

| b | 41.03 | 21.87 | |||||

| C-180-30 | a | 34.95 | 35.39 | 0.44 | 20.81 | 20.56 | 0.25 |

| b | 35.83 | 20.31 | |||||

| C-270-10 | a | 42.61 | 42.03 | 0.58 | 21.49 | 21.30 | 0.19 |

| b | 41.45 | 21.11 | |||||

| C-270-20 | a | 40.61 | 39.38 | 1.12 | 21.09 | 20.81 | 0.28 |

| b | 38.38 | 20.53 | |||||

| C-270-30 | a | 34.85 | 34.52 | 0.33 | 19.79 | 19.90 | 0.11 |

| b | 34.19 | 20.01 | |||||

| Specimen Code | Dynamic Compressive Strength/MPa | Strain Rate/s−1 | DIF | Dynamic Toughness/(MJ/m3) | Energy Absorption Rate Strength/% |

|---|---|---|---|---|---|

| C-10-0.6 | 109.18 | 52.6 | 2.18 | 1.11 | 1.017 |

| C-10-0.7 | 120.13 | 67.1 | 2.40 | 1.46 | 1.215 |

| C-10-0.8 | 132.02 | 95.6 | 2.64 | 2.45 | 1.856 |

| C-20-0.65 | 120.13 | 60.2 | 2.71 | 1.46 | 1.215 |

| C-20-0.7 | 128.37 | 77.4 | 2.89 | 1.29 | 1.005 |

| C-20-0.8 | 132.03 | 110.6 | 2.98 | 2.01 | 1.522 |

| C-30-0.6 | 111.40 | 75.9 | 2.65 | 2.08 | 1.867 |

| C-30-0.7 | 112.04 | 96.4 | 2.66 | 1.86 | 1.660 |

| C-30-0.8 | 123.62 | 117.4 | 2.94 | 2.21 | 1.788 |

| Specimen Code | Dynamic Compressive Strength/MPa | Strain Rate/s−1 | DIF | Dynamic Toughness/(MJ/m3) | Energy Absorption Rate Strength/% |

|---|---|---|---|---|---|

| C-0-10 | 132.02 | 95.6 | 2.64 | 2.45 | 1.856 |

| C-0-20 | 132.03 | 110.6 | 2.98 | 2.01 | 1.522 |

| C-0-30 | 123.62 | 117.4 | 2.94 | 2.21 | 1.788 |

| C-90-10 | 130.66 | 109.6 | 3.11 | 1.45 | 1.110 |

| C-90-20 | 116.80 | 113.6 | 2.92 | 1.81 | 1.550 |

| C-90-30 | 86.03 | 131.6 | 2.33 | 1.14 | 1.325 |

| C-180-10 | 119.76 | 106.1 | 2.80 | 2.03 | 1.695 |

| C-180-20 | 105.43 | 120.3 | 2.61 | 1.16 | 1.100 |

| C-180-30 | 73.85 | 141.1 | 2.09 | 0.93 | 1.259 |

| C-270-10 | 112.11 | 114.3 | 2.67 | 1.93 | 1.722 |

| C-270-20 | 115.73 | 124.1 | 2.94 | 1.75 | 1.512 |

| C-270-30 | 72.66 | 129.2 | 2.10 | 0.96 | 1.321 |

| Specimen Code | Element Content/% | |||

|---|---|---|---|---|

| O | Al | Si | Ca | |

| C-0-20 | 61.883 | 0.287 | 35.599 | 2.231 |

| C-90-20 | 49.635 | 0.302 | 1.922 | 48.141 |

| C-180-20 | 35.598 | 1.500 | 4.820 | 58.083 |

| C-270-20 | 22.589 | 0.366 | 2.956 | 74.090 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, S.; Chen, Z.; Liu, C.; Chen, J.; Chen, H.; Yu, Z. Effects of Thermal Cycles on Mechanical Properties of RPECC: Static and Dynamic Compressive Performance. Materials 2025, 18, 2846. https://doi.org/10.3390/ma18122846

He S, Chen Z, Liu C, Chen J, Chen H, Yu Z. Effects of Thermal Cycles on Mechanical Properties of RPECC: Static and Dynamic Compressive Performance. Materials. 2025; 18(12):2846. https://doi.org/10.3390/ma18122846

Chicago/Turabian StyleHe, Shaohua, Zhiliang Chen, Changxi Liu, Jincai Chen, Huanwei Chen, and Zhitao Yu. 2025. "Effects of Thermal Cycles on Mechanical Properties of RPECC: Static and Dynamic Compressive Performance" Materials 18, no. 12: 2846. https://doi.org/10.3390/ma18122846

APA StyleHe, S., Chen, Z., Liu, C., Chen, J., Chen, H., & Yu, Z. (2025). Effects of Thermal Cycles on Mechanical Properties of RPECC: Static and Dynamic Compressive Performance. Materials, 18(12), 2846. https://doi.org/10.3390/ma18122846