Effects of Water-to-Cement and Sand-to-Binder Ratio on Mechanical and Drying Shrinkage Properties of Low-Carbon Mortar Containing Biochar Aggregate

Abstract

1. Introduction

2. Materials and Methods

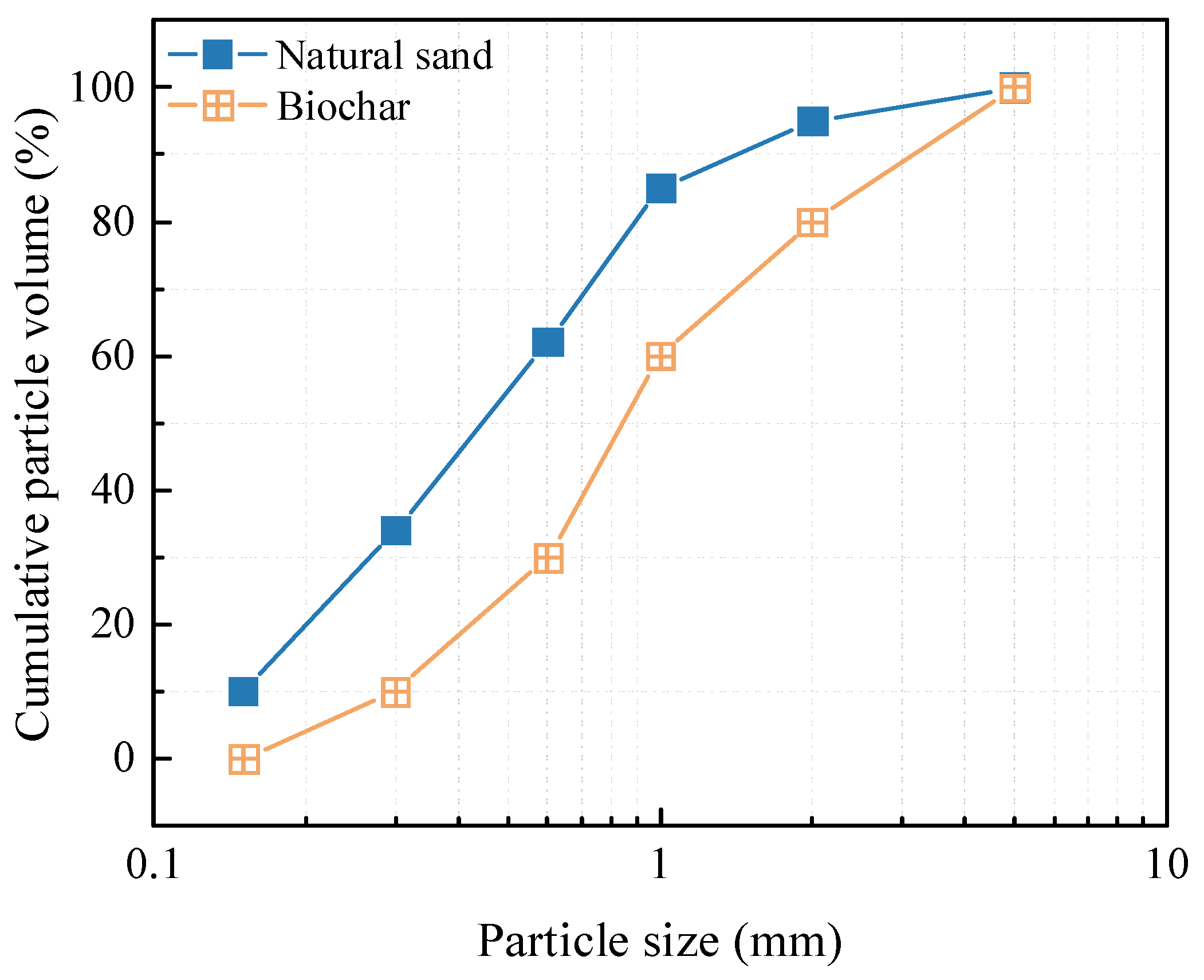

2.1. Materials

2.2. Mixture Design and Sample Preparation

2.2.1. Mixture Design

2.2.2. Specimens Preparation

2.3. Testing Methods

2.3.1. Mechanical Properties

2.3.2. Drying Shrinkage and Mass Loss

2.3.3. Water Transport Properties and Total Porosity

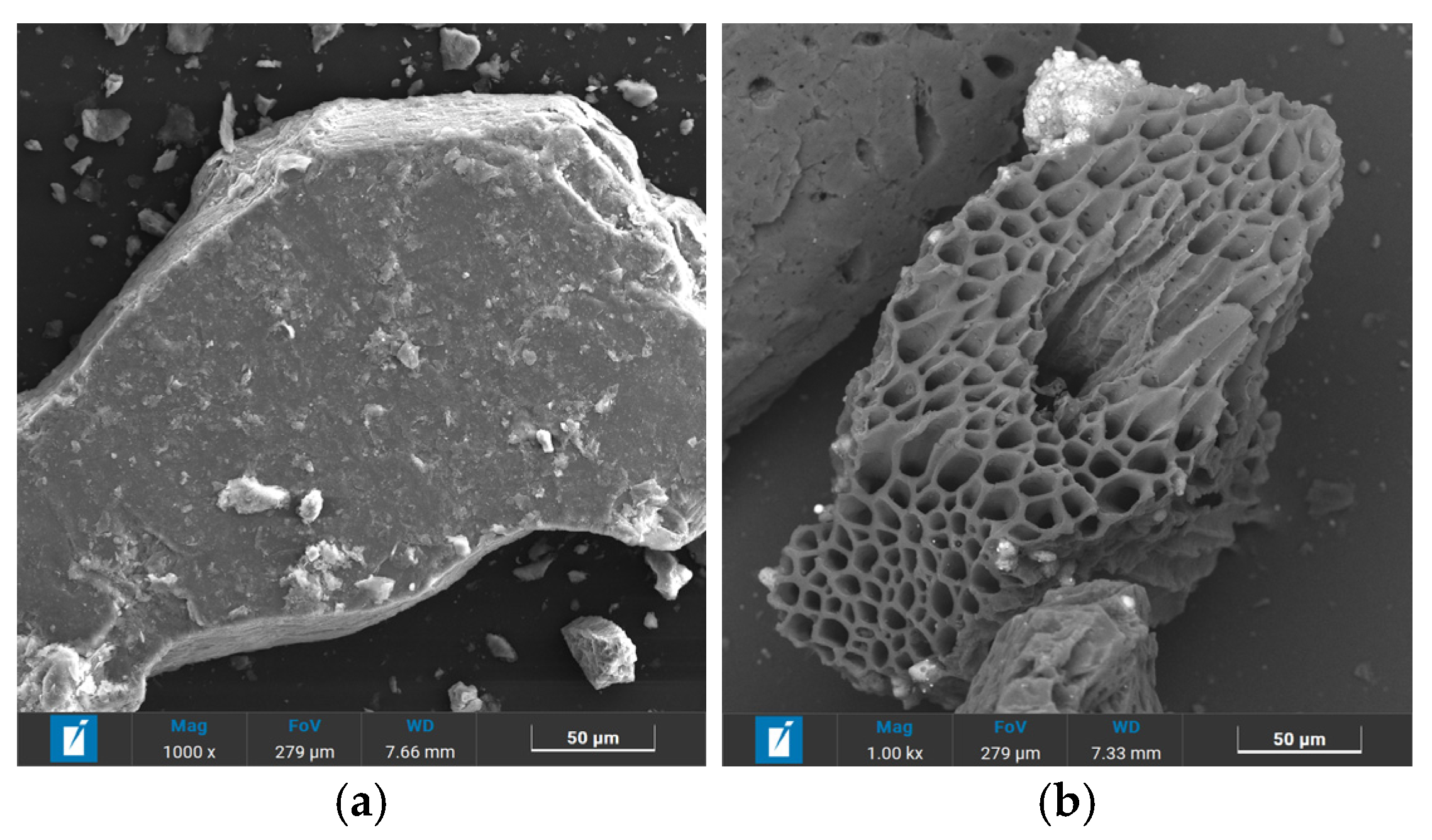

2.3.4. Microscopic Performance

3. Results and Discussion

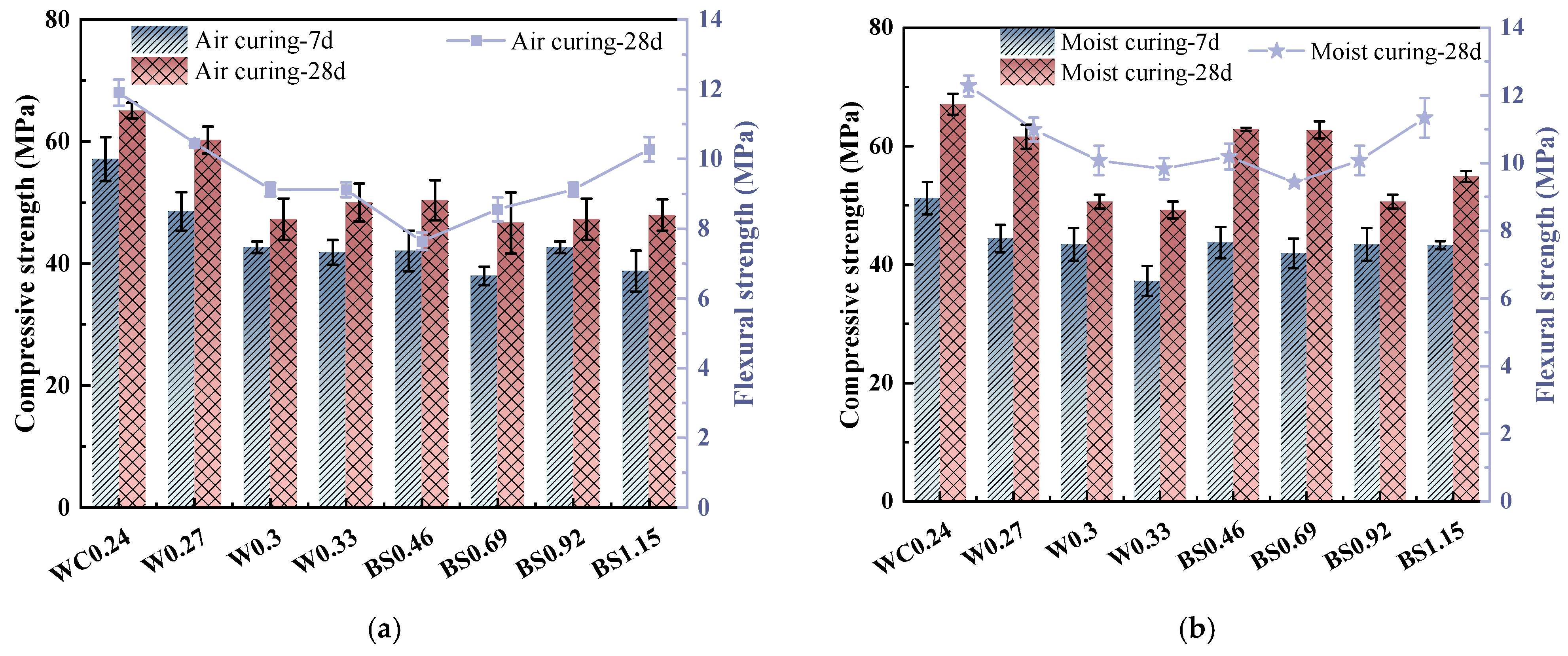

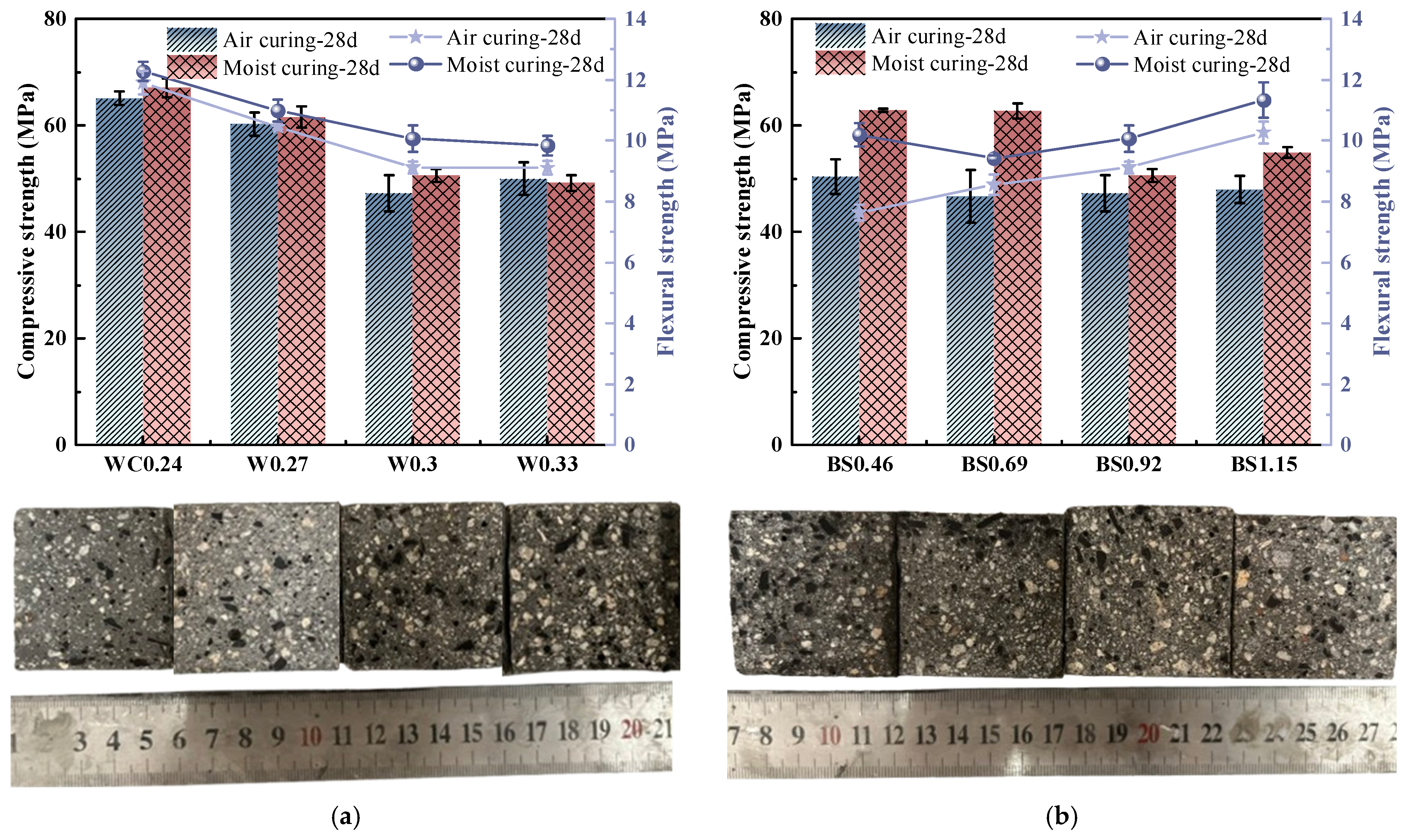

3.1. Mechanical Strengths

3.1.1. Effects of Different Conditions on Mechanical Strength

3.1.2. Compressive and Flexural Strengths

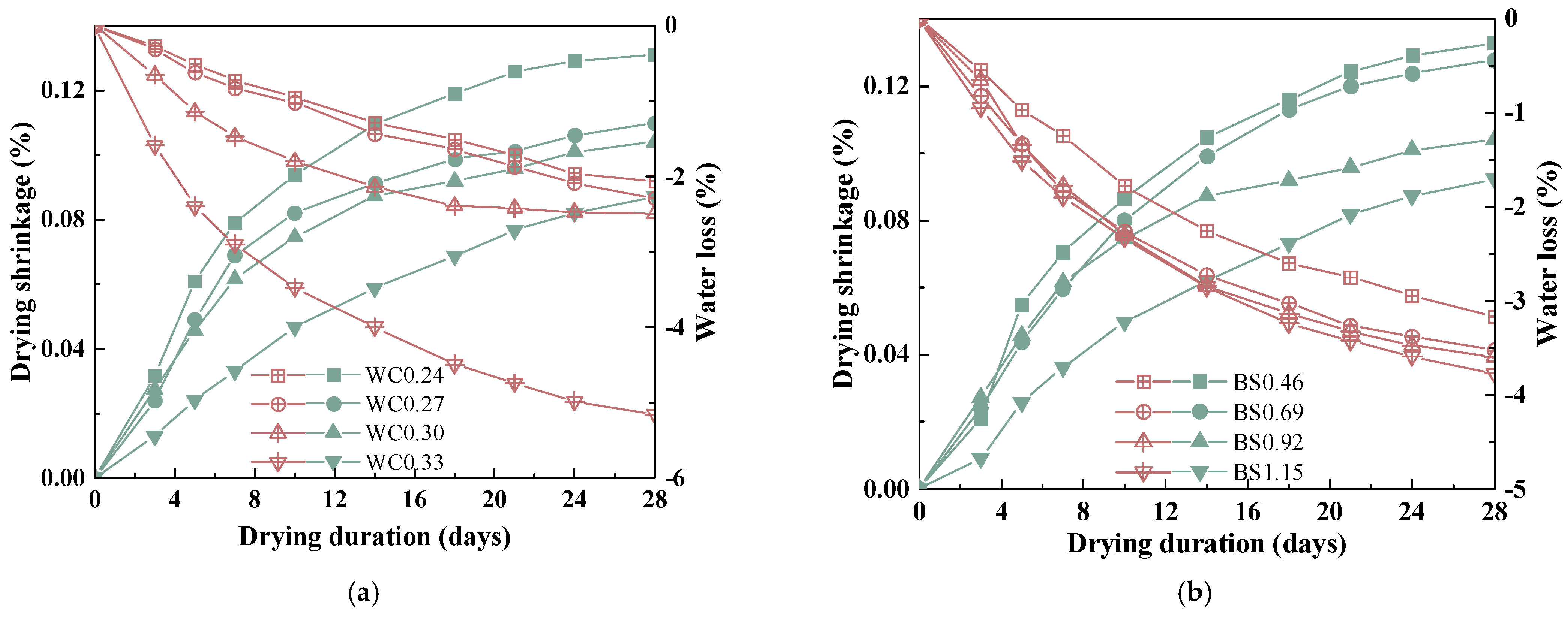

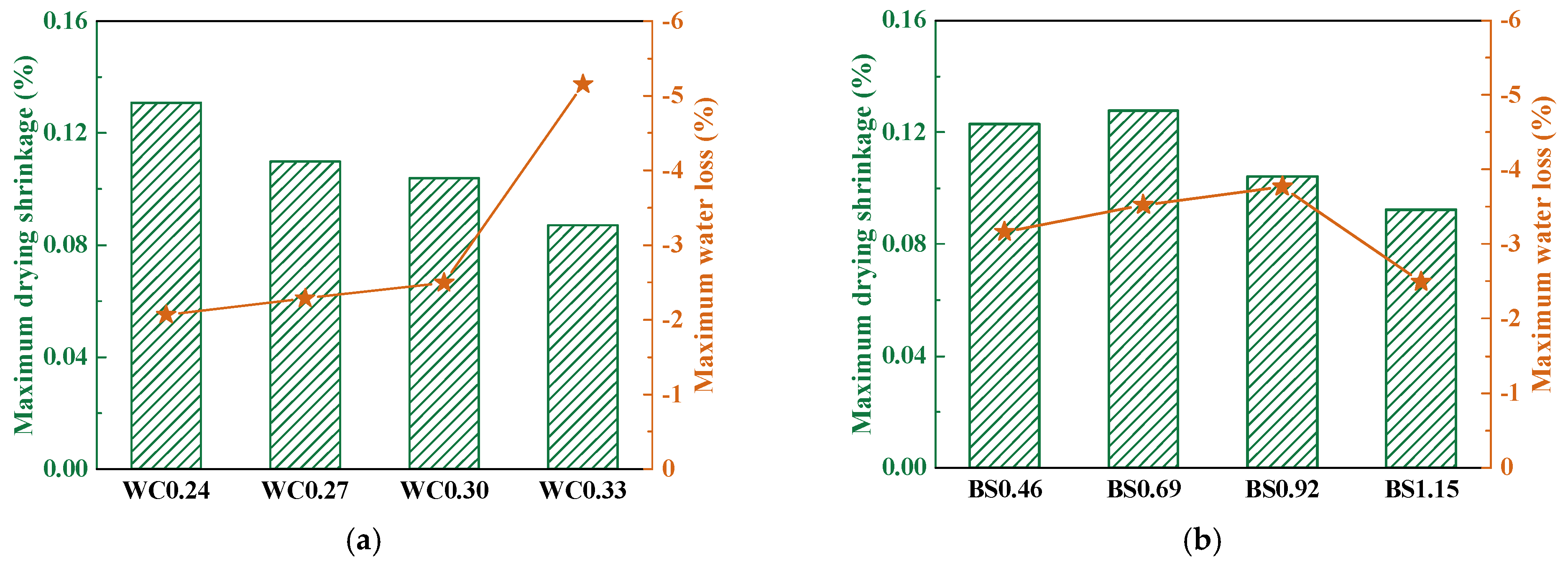

3.2. Drying Shrinkage and Water Loss Behavior

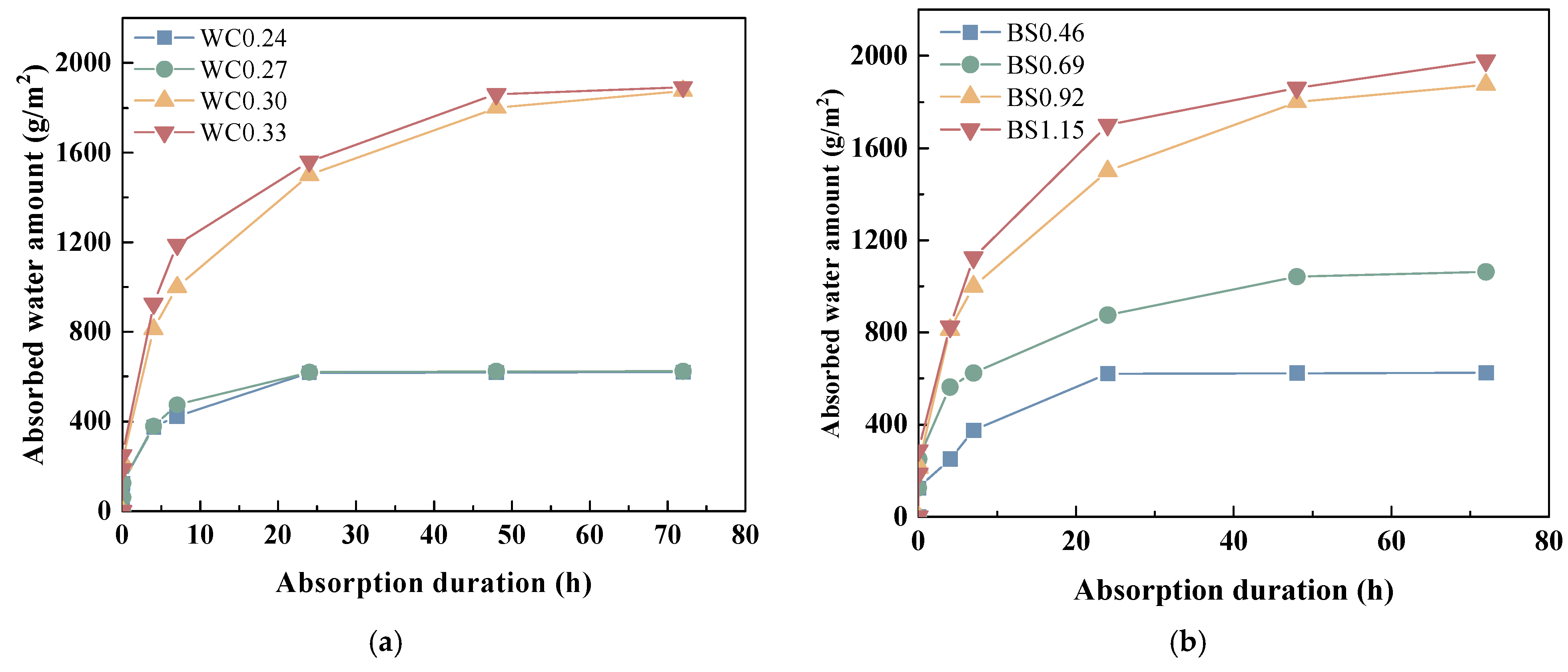

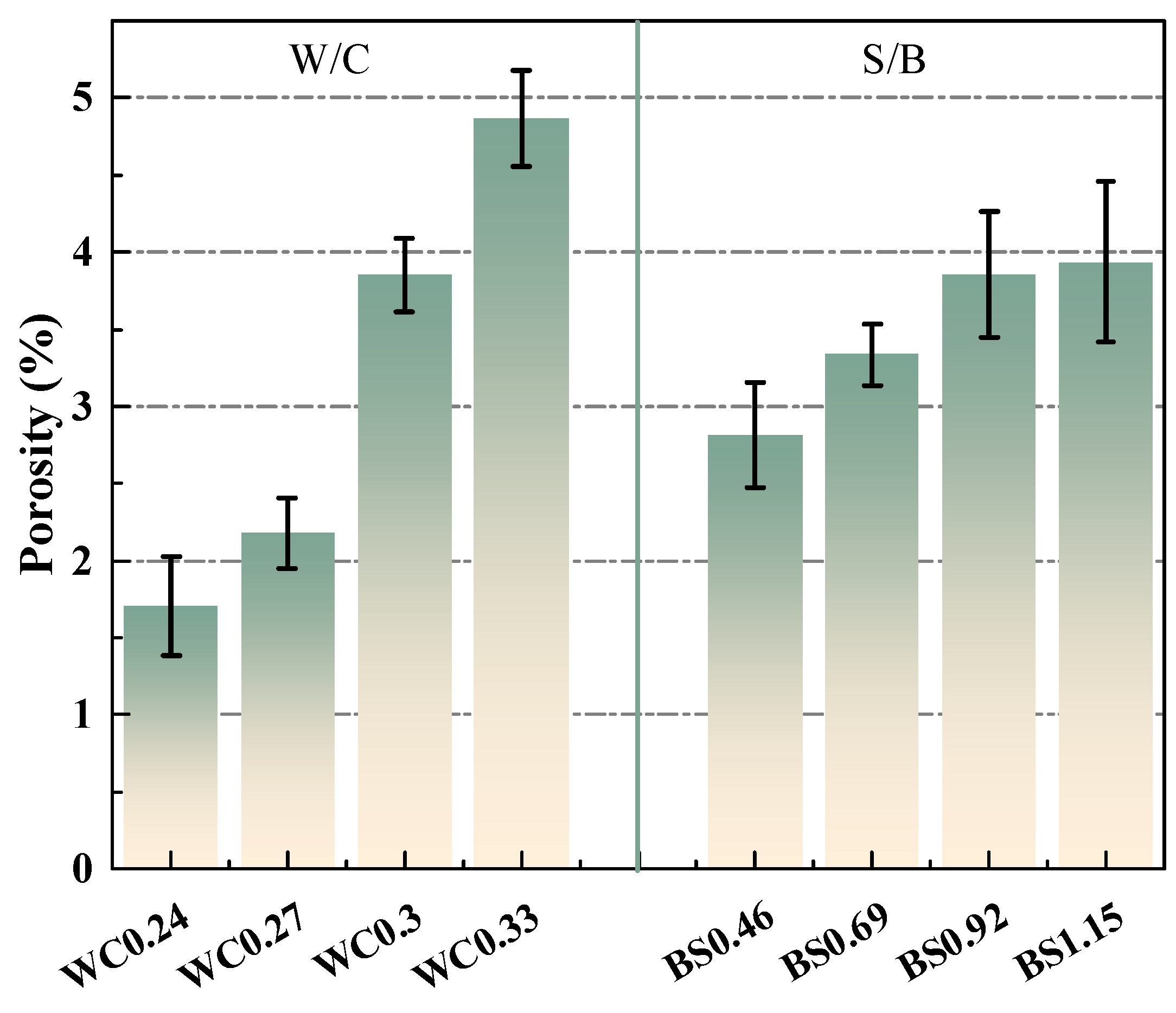

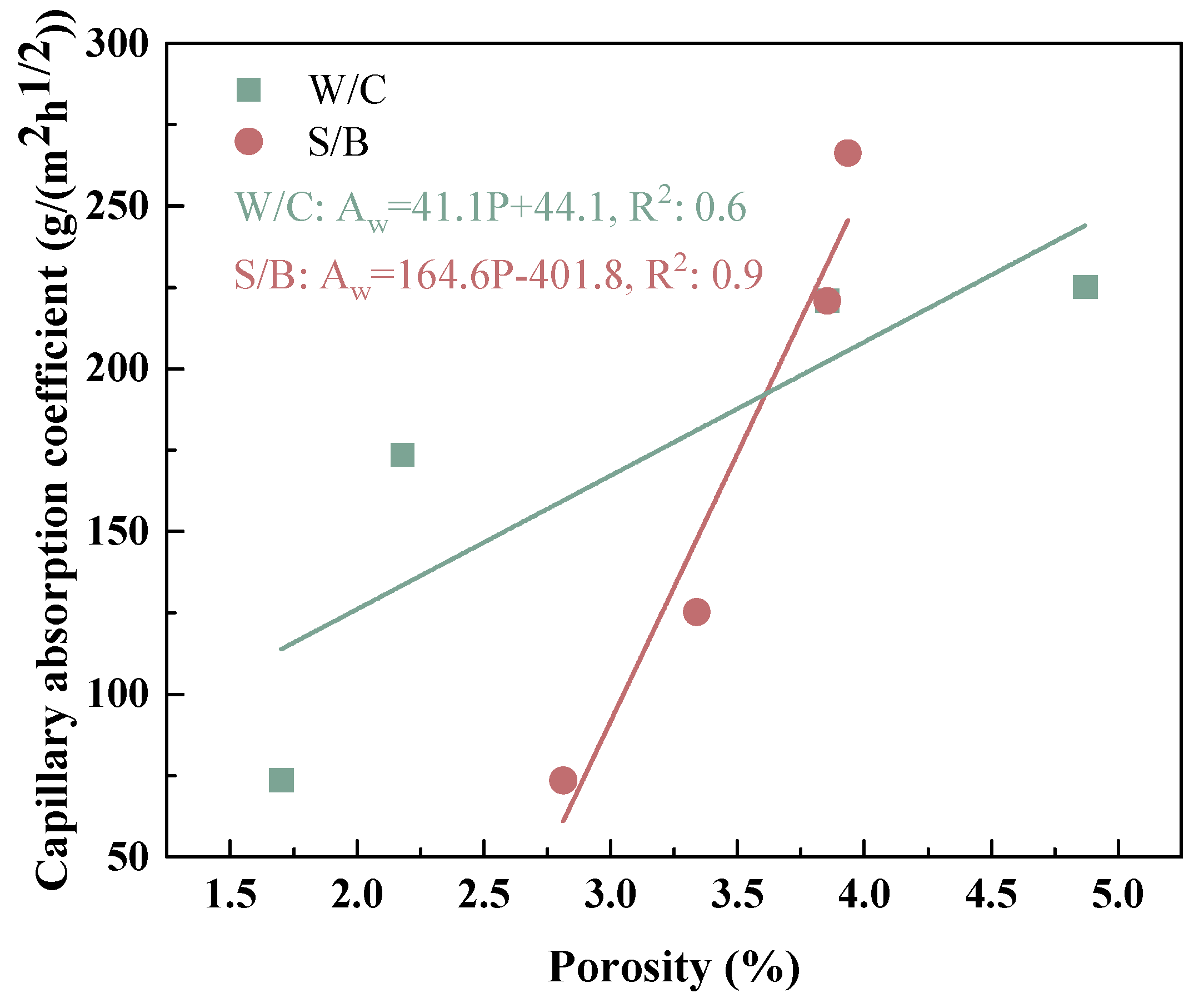

3.3. Water Transport Properties and Porosity

3.4. Microproperties of Cement Paste

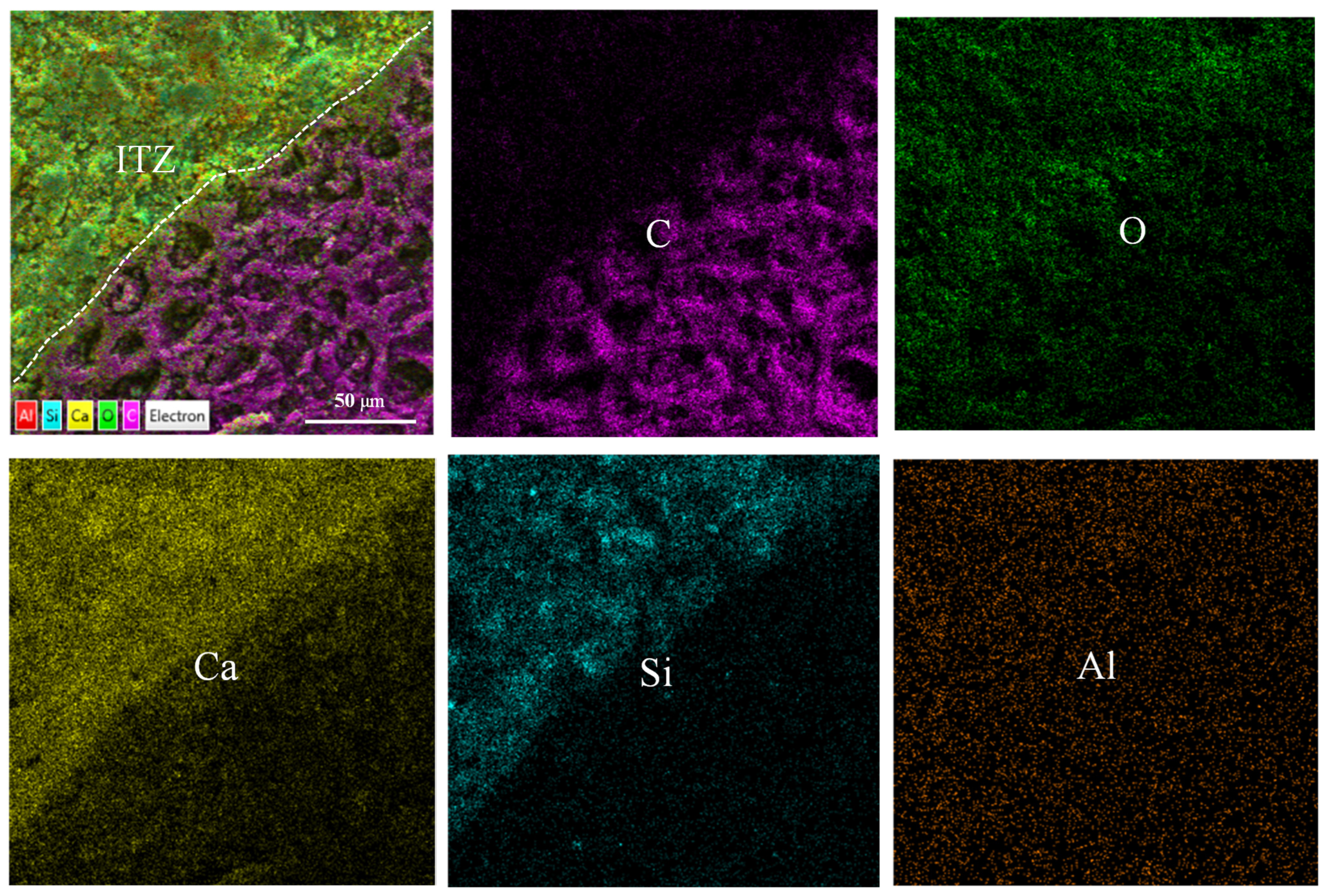

Partial Bonding Mechanisms

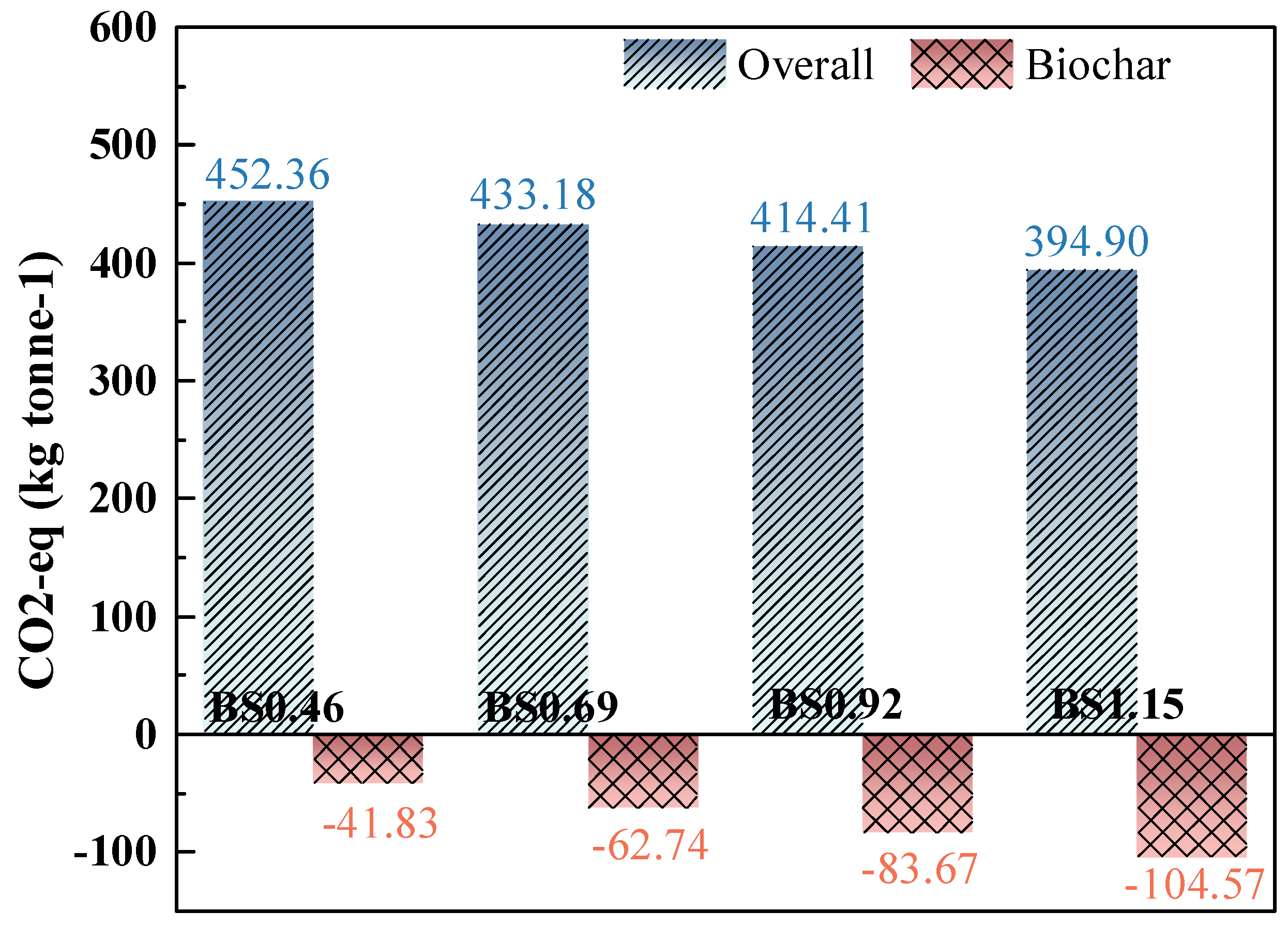

3.5. CO2 Footprint Performance of Biochar Mortar

4. Conclusions

- The mechanical strength decreases with an increasing W/C ratio. And the compressive strength of the mortar decreases gradually with increases in the S/B ratio, while its flexural strength increases gradually with increases in the S/B ratio. Although biochar is more sustainable for the development of cementitious materials, the excessive addition of biochar aggregate leads to reductions in mechanical strength.

- The percentage of mass loss exhibits a similar trend alongside drying shrinkage value. Due to the additional water required to achieve the saturated surface drying of the BC before the preparation of biochar mortar, the ever-increasing S/B ratio causes a rise in free water content. Thus, compared to natural mortar, biochar mortar has a mitigating effect on drying shrinkage due to early water absorption in the pores of the biochar and the subsequent desorption during drying shrinkage.

- The water absorption of the biochar mortar increases with the W/C and S/B ratios. We also display the water ingress depth in biochar mortar, and the water ingress depth in mortar obviously increased with increases in W/C and S/B ratio. Moreover, the Cw of the different mortars differed significantly only in the first few hours, and their final coefficients and water ingress depth were similar.

- Biochar can provide nucleation sites for hydration products, allowing a unique binding mechanism between them and the cement matrix, i.e., through CH or a layer of C-S-H gel. When the S/B ratio reaches 1.15, the biochar can result in a reduction 104.57 kg of CO2eq, and biochar mortar shows good potential for CO2eq sequestration.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nakano, Y.; Akimoto, K.; Sano, F.; Oda, J.; Kanaboshi, H. Climate change mitigation measures for global net-zero emissions and the roles of CO2 capture and utilization and direct air capture. Energy Clim. Change 2021, 2, 100057. [Google Scholar] [CrossRef]

- Wang, C.; Bu, J.; Wu, W.-Y.; Tao, L.; Lee, J.J.C.; Soo, X.Y.D.; Zhu, Q. Advancements in CO2 capture by absorption and adsorption: A comprehensive review. J. CO2 Util. 2024, 81, 102727. [Google Scholar] [CrossRef]

- Lehmann, J.; Street-Perrott, F.A.; Amonette, J.E.; Joseph, S.; Woolf, D. Sustainable biochar to mitigate global climate change. Nat. Commun. 2010, 1, 56. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.S.; Mishra, G.; Danoglidis, P.A.; Shah, S.P. Carbon capture and storage potential of biochar-enriched cementitious systems. Cem. Concr. Compos. 2023, 140, 105078. [Google Scholar] [CrossRef]

- Kanavaris, F.; Das, B.B.; Barbhuiya, S. Biochar-concrete: A comprehensive review of properties, production and sustainability. Case Stud. Constr. Mater. 2024, 20, e02859. [Google Scholar] [CrossRef]

- Pang, S.D.; Kua, H.W.; Gupta, S. Biochar-mortar composite: Manufacturing, evaluation of physical properties and economic viability. Constr. Build. Mater. 2018, 167, 874–889. [Google Scholar] [CrossRef]

- Tang, Y.; Wu, H.; Leung, C.K.; Li, G.; Qin, S.; Wang, T. Sustainable and mechanical properties of Engineered Cementitious Composites with biochar: Integrating micro- and macro-mechanical insight. Cem. Concr. Compos. 2025, 155, 105813. [Google Scholar] [CrossRef]

- Pang, S.D.; Dixit, A.; Verma, A. Dual waste utilization in ultra-high performance concrete using biochar and marine clay. Cem. Concr. Compos. 2021, 120, 104049. [Google Scholar] [CrossRef]

- Berruti, F.; Briens, C.; Berardi, U.; Cuthbertson, D. Biochar from residual biomass as a concrete filler for improved thermal and acoustic properties. Biomass Bioenergy 2019, 120, 77–83. [Google Scholar] [CrossRef]

- Kua, H.W.; Gupta, S. Factors Determining the Potential of Biochar as a Carbon Capturing and Sequestering Construction Material: Critical Review. J. Mater. Civ. Eng. 2017, 29, 04017086. [Google Scholar] [CrossRef]

- Jagdale, P.; Tulliani, J.-M.; Ferro, G.A.; Khushnood, R.A.; Ahmad, S. High performance self-consolidating cementitious composites by using micro carbonized bamboo particles. Mater. Des. 2015, 76, 223–229. [Google Scholar] [CrossRef]

- Belletti, B.; Malcevschi, A.; Bernardi, P.; Moretti, E.; Domenichelli, I.; Fornoni, P.; Dalcanale, E.; Sirico, A. Mechanical characterization of cement-based materials containing biochar from gasification. Constr. Build. Mater. 2020, 246, 118490. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W. Effect of water entrainment by pre-soaked biochar particles on strength and permeability of cement mortar. Constr. Build. Mater. 2018, 159, 107–125. [Google Scholar] [CrossRef]

- Pan, P.; Han, J.; Ye, B.; Zhang, Y. Effect of water to binder ratio and sand to binder ratio on shrinkage and mechanical properties of High-strength Engineered Cementitious Composite. Constr. Build. Mater. 2019, 226, 899–909. [Google Scholar] [CrossRef]

- Lu, J.-X.; Poon, C.S.; Xiao, J.; Zou, S.; Leung, L.M.; Sham, M.L. Biochar-enabled carbon negative aggregate designed by core-shell structure: A novel biochar utilizing method in concrete. Constr. Build. Mater. 2024, 449, 138507. [Google Scholar] [CrossRef]

- Qiu, J.; Yuan, L.; Jia, Y.; Zhao, M.; Xie, C. Experimental study on the vegetation characteristics of biochar-modified vegetation concrete. Constr. Build. Mater. 2019, 206, 321–328. [Google Scholar] [CrossRef]

- GB 175-2007; Common Portland Cement. China National Standardization Administration Committee: Beijing, China, 2007.

- Gupta, S.; Kua, H.W.; Low, C.Y. Use of biochar as carbon sequestering additive in cement mortar. Cem. Concr. Compos. 2018, 87, 110–129. [Google Scholar] [CrossRef]

- GB/T14684-2022; Sand for Construction. China National Standardization Administration Committee: Beijing, China, 2022.

- Zhang, J.; Zhang, H.; Xiao, J.; Zhang, M.; Wang, D.; Tang, Y. Effect of accelerated carbonation of fully recycled aggregates on fracture behaviour of concrete. Cem. Concr. Compos. 2024, 148, 105442. [Google Scholar] [CrossRef]

- Wu, H.; Shen, J.; Wang, C.; Ma, Z. Characterization of sustainable mortar containing high-quality recycled manufactured sand crushed from recycled coarse aggregate. Cem. Concr. Compos. 2022, 132, 104629. [Google Scholar] [CrossRef]

- Ibrahim, M.S.; Nasr, M.S.; Shubbar, A.A.; Abed, Z.A.-A.R. Properties of eco-friendly cement mortar contained recycled materials from different sources. J. Build. Eng. 2020, 31, 101444. [Google Scholar] [CrossRef]

- JTG 3420-2020; Testing Methods of Cement and Concrete for Highway Engineering. Chinese Standard: Beijing, China, 2020.

- Han, S.; Bao, J.; Xue, S.; Wang, J.; He, L.; Zhang, P. Influences of thermal damage on water transport in heat-treated cement mortar: Experimental and theoretical analyses. Constr. Build. Mater. 2021, 288, 123100. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J.D. Water absorption and electrical resistivity of concrete with recycled concrete aggregates and fly ash. Cem. Concr. Compos. 2019, 95, 169–182. [Google Scholar] [CrossRef]

- Vogel, M.; Wittmann, F.H.; Zhao, T.; Müller, H.S.; Zhang, P. Influence of freeze-thaw cycles on capillary absorption and chloride penetration into concrete. Cem. Concr. Res. 2017, 100, 60–67. [Google Scholar] [CrossRef]

- del Bosque, I.S.; de Rojas, M.S.; De Belie, N.; Velardo, P.; Medina, C. Design and evaluation of physical, mechanical and micro-structural properties of eco-friendly binary-blended mortars using biomass bottom ash or construction and demolition waste powder. Cem. Concr. Compos. 2023, 143, 105252. [Google Scholar] [CrossRef]

- Chen, X.; Wu, F.; Yu, Q. Unleashing the potential of bio-based concrete: Investigating its long-term mechanical strength and drying shrinkage in real climatic environments. Cem. Concr. Compos. 2023, 143, 105237. [Google Scholar] [CrossRef]

- Chen, T.; Li, L.; Jiang, Y.; Gao, X. Porous biochar-assisted aqueous carbonation of steel slag as an adsorptive crystallization modifier for value-added cement applications. Cem. Concr. Compos. 2025, 159, 106002. [Google Scholar] [CrossRef]

- van Riessen, A.; MacKenzie, K.; Temuujin, J. Preparation and characterisation of fly ash based geopolymer mortars. Constr. Build. Mater. 2010, 24, 1906–1910. [Google Scholar] [CrossRef]

- Deng, X.; Chu, S.; Unluer, C.; Khan, M. Bio-inspired self-prestressing concrete (SPC) involving basalt fibers and expansive agent. Cem. Concr. Res. 2022, 155, 106735. [Google Scholar] [CrossRef]

- Chen, J.; Mechtcherine, V.; Li, H.; Ruan, S.; Tsang, D.C.; Zhang, Y.; Yang, J.; Chen, L.; Wang, L. Biochar-augmented carbon-negative concrete. Chem. Eng. J. 2022, 431, 133946. [Google Scholar] [CrossRef]

- Lu, D.; Zhan, B.; Chen, Y.; Li, J.; Ma, P.; Yu, Q.; Wang, C.; Gao, P.; Wang, L.; Guo, B.; et al. Investigation of the properties and sustainability of modified biochar-doped cement-based composite. Cem. Concr. Compos. 2024, 153, 105684. [Google Scholar] [CrossRef]

- Belletti, B.; Milanese, D.; Malcevschi, A.; Bernardi, P.; Sciancalepore, C.; Vecchi, F.; Sirico, A. Biochar from wood waste as additive for structural concrete. Constr. Build. Mater. 2021, 303, 124500. [Google Scholar] [CrossRef]

- Wang, L.; Chen, L.; Tsang, D.C.; Guo, B.; Yang, J.; Shen, Z.; Hou, D.; Ok, Y.S.; Poon, C.S. Biochar as green additives in cement-based composites with carbon dioxide curing. J. Clean. Prod. 2020, 258, 120678. [Google Scholar] [CrossRef]

- Wang, S.; Wang, J. Preparation, modification and environmental application of biochar: A review. J. Clean. Prod. 2019, 227, 1002–1022. [Google Scholar] [CrossRef]

- Dong, B.; Castel, A.; Zhang, S.; Deng, Z.; Zhang, X.; Lin, X.; Li, W. Effect of crystalline admixtures on shrinkage and alkali-silica reaction of biochar-cementitious composites. Dev. Built Environ. 2024, 18, 100456. [Google Scholar] [CrossRef]

- Duan, Z.; Poon, C.-S.; Zhang, H.; Tang, Y.; Xiao, J. Long-term shrinkage and mechanical properties of fully recycled aggregate concrete: Testing and modelling. Cem. Concr. Compos. 2022, 130, 104527. [Google Scholar] [CrossRef]

- Shi, C.; Wang, H.; Zhang, Z.; Farzadnia, N.; Wu, L. Autogenous shrinkage of high performance concrete: A review. Constr. Build. Mater. 2017, 149, 62–75. [Google Scholar] [CrossRef]

- Marinković, S.; de la Fuente, A.; Tošić, N. Shrinkage of recycled aggregate concrete: Experimental database and application of fib Model Code 2010. Mater. Struct. 2018, 51, 126. [Google Scholar] [CrossRef]

- Sirivivatnanon, V.; Homwuttiwong, S.; Chindaprasirt, P. Influence of fly ash fineness on strength, drying shrinkage and sulfate resistance of blended cement mortar. Cem. Concr. Res. 2004, 34, 1087–1092. [Google Scholar] [CrossRef]

- Xu, S.; Li, K.; Liu, W. Utilizing bamboo biochar in cement mortar as a bio-modifier to improve the compressive strength and crack-resistance fracture ability. Constr. Build. Mater. 2022, 327, 126917. [Google Scholar] [CrossRef]

- Zarzycki, B.; Piasta, W. The effect of cement paste volume and w/c ratio on shrinkage strain, water absorption and compressive strength of high performance concrete. Constr. Build. Mater. 2017, 140, 395–402. [Google Scholar] [CrossRef]

- Ghafari, E.; Ghahari, S.A.; Durães, L.; Júlio, E.; Costa, H.; Portugal, A. Effect of supplementary cementitious materials on autogenous shrinkage of ultra-high performance concrete. Constr. Build. Mater. 2016, 127, 43–48. [Google Scholar] [CrossRef]

- Fang, C.; Ali, M.M.; Visintin, P.; Xie, T. Characterizations of autogenous and drying shrinkage of ultra-high performance concrete (UHPC): An experimental study. Cem. Concr. Compos. 2018, 91, 156–173. [Google Scholar] [CrossRef]

- Xu, W.; Su, Y.; Tsang, D.C.; Wang, L.; Zhu, X.; Zhang, Y. Using waste to improve the weak: Recycled seashell as an ideal way to regulate the interfacial transition zone in biochar-cement composites. Constr. Build. Mater. 2024, 444, 137765. [Google Scholar] [CrossRef]

- Ok, Y.S.; Kim, S.; Hou, D.; Kua, H.W.; Gupta, S.; Senadheera, S.S.; Tsang, D.C. Application of biochar in concrete–A review. Cem. Concr. Compos. 2023, 143, 105204. [Google Scholar] [CrossRef]

- Shi, X.; Li, Z. Towards sustainable industrial application of carbon-negative concrete: Synergistic carbon-capture by concrete washout water and biochar. Mater. Lett. 2023, 342, 134368. [Google Scholar] [CrossRef]

- Scrivener, K.; Rossen, J. Optimization of SEM-EDS to determine the C–A–S–H composition in matured cement paste samples. Mater. Charact. 2017, 123, 294–306. [Google Scholar] [CrossRef]

- Poon, C.S.; Zhang, Y.; Ma, B.; Chen, L.; Wang, L.; Tsang, D.C.; Zhu, X.; Li, J. Bonding mechanisms and micro-mechanical properties of the interfacial transition zone (ITZ) between biochar and paste in carbon-sink cement-based composites. Cem. Concr. Compos. 2023, 139, 105004. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, Y.; Yu, K.; Liu, C.; Li, L.; Tian, W. Carbon-negative heat-stored limestone calcined clay cement mortar containing form-stable phase change materials. J. Clean. Prod. 2024, 437, 140703. [Google Scholar] [CrossRef]

- Ran, B.; Xiong, Y.; Wu, T.; Zhou, X.; Wang, J.; Xu, L.; Hu, X. Physical performance, durability, and carbon emissions of recycled cement concrete and fully recycled concrete. Constr. Build. Mater. 2024, 447, 138128. [Google Scholar] [CrossRef]

- GB/T 51336–2019; Standard for Carbon Emission Calculation. China National Standardization Administration Committee: Beijing, China, 2019.

- Turner, L.K.; Collins, F.G. Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete. Constr. Build. Mater. 2013, 43, 125–130. [Google Scholar] [CrossRef]

- Hammond, J.; Shackley, S.; Ibarrola, R. Pyrolysis biochar systems for recovering biodegradable materials: A life cycle carbon assessment. Waste Manag. 2012, 32, 859–868. [Google Scholar] [CrossRef]

| Type | Apparent Density (kg/m3) | Water Absorption (%) | Fineness Modulus | Moisture Content (%) |

|---|---|---|---|---|

| NS | 2630 | 1.1 | 3.2 | 0.5 |

| BC | 1540 | 63 | 2.8 | 5.9 |

| Mix | Material Composition (kg/m3) | Slumps (mm) | ||||||

|---|---|---|---|---|---|---|---|---|

| Cement | NS | Biochar | W-m | W-a | SP | |||

| W/C | WC0.24 | 667.6 | 534.1 | 78.2 | 160.2 | 0 | 2.3 | 190 |

| WC0.27 | 667.6 | 534.1 | 78.2 | 180.3 | 14.8 | 2.3 | 210 | |

| WC0.3 | 667.6 | 534.1 | 78.2 | 200.3 | 14.8 | 2.3 | 225 | |

| WC0.33 | 667.6 | 534.1 | 78.2 | 220.3 | 14.8 | 2.3 | 235 | |

| S/B | BS0.46 | 667.6 | 267.0 | 39.1 | 200.3 | 7.4 | 2.3 | 225 |

| BS0.69 | 667.6 | 400.6 | 58.6 | 200.3 | 11.1 | 2.3 | 235 | |

| BS0.92 | 667.6 | 534.1 | 78.2 | 200.3 | 14.8 | 2.3 | 220 | |

| BS1.15 | 667.6 | 667.6 | 97.7 | 200.3 | 18.5 | 2.3 | 220 | |

| Information | Testing and Determinations | ||||

|---|---|---|---|---|---|

| Compressive Strength (Air Curing) | Compressive Strength (Moist Curing) | Flexural Strength | Drying Shrinkage | Water Absorption | |

| Size (mm) | 40 × 40 × 40 | 40 × 40 × 40 | 40 × 40 × 160 | 40 × 40 × 160 | 40 × 40 × 40 |

| Number | 6 samples | 6 samples | 6 samples | 3 samples | 3 samples |

| Mix | 7d fcu (MPa) | S.D. (MPa) | 28d fcu (MPa) | S.D. (MPa) | 28d ff (MPa) | S.D. (MPa) |

|---|---|---|---|---|---|---|

| WC0.24 | 57.13 | 1.28 | 65.08 | 3.63 | 11.91 | 0.38 |

| W0.27 | 48.54 | 2.19 | 60.25 | 3.15 | 10.45 | 0.07 |

| W0.3 | 42.67 | 3.39 | 47.27 | 0.92 | 9.125 | 0.20 |

| W0.33 | 41.83 | 3.10 | 50.02 | 2.03 | 9.12 | 0.21 |

| BS0.46 | 42.06 | 3.26 | 50.40 | 3.31 | 7.64 | 0.25 |

| BS0.69 | 37.98 | 4.99 | 46.67 | 1.53 | 8.55 | 0.34 |

| BS0.92 | 42.67 | 3.39 | 47.27 | 0.92 | 9.13 | 0.20 |

| BS1.15 | 38.75 | 2.58 | 47.94 | 3.36 | 10.27 | 0.35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, S.; Zhang, J.; Yang, H. Effects of Water-to-Cement and Sand-to-Binder Ratio on Mechanical and Drying Shrinkage Properties of Low-Carbon Mortar Containing Biochar Aggregate. Materials 2025, 18, 2750. https://doi.org/10.3390/ma18122750

Chen S, Zhang J, Yang H. Effects of Water-to-Cement and Sand-to-Binder Ratio on Mechanical and Drying Shrinkage Properties of Low-Carbon Mortar Containing Biochar Aggregate. Materials. 2025; 18(12):2750. https://doi.org/10.3390/ma18122750

Chicago/Turabian StyleChen, Shasha, Junhui Zhang, and Hao Yang. 2025. "Effects of Water-to-Cement and Sand-to-Binder Ratio on Mechanical and Drying Shrinkage Properties of Low-Carbon Mortar Containing Biochar Aggregate" Materials 18, no. 12: 2750. https://doi.org/10.3390/ma18122750

APA StyleChen, S., Zhang, J., & Yang, H. (2025). Effects of Water-to-Cement and Sand-to-Binder Ratio on Mechanical and Drying Shrinkage Properties of Low-Carbon Mortar Containing Biochar Aggregate. Materials, 18(12), 2750. https://doi.org/10.3390/ma18122750