Revealing the Influence of Material Properties of Shaped Charge Liner on Penetration Performance via Numerical Simulation and Machine Learning

Abstract

1. Introduction

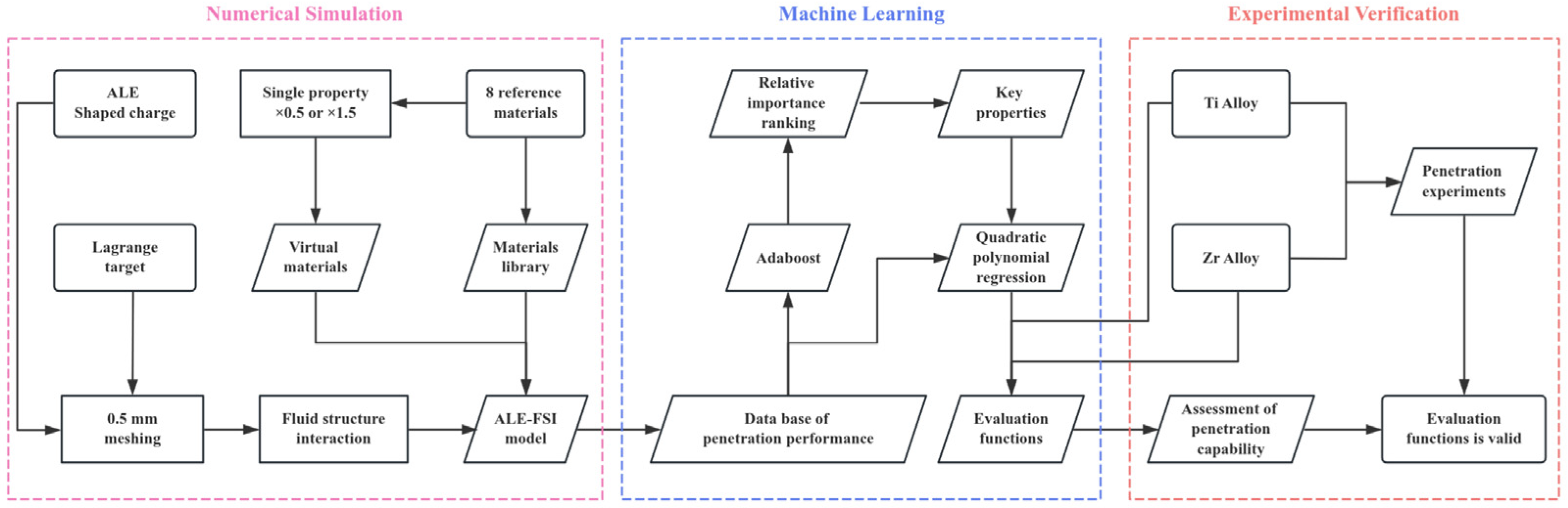

2. Research Methodology

2.1. Numerical Simulation Method

2.2. Machine Learning Method

2.3. Experimental Verification Method

3. Results of Simulation and Experiment

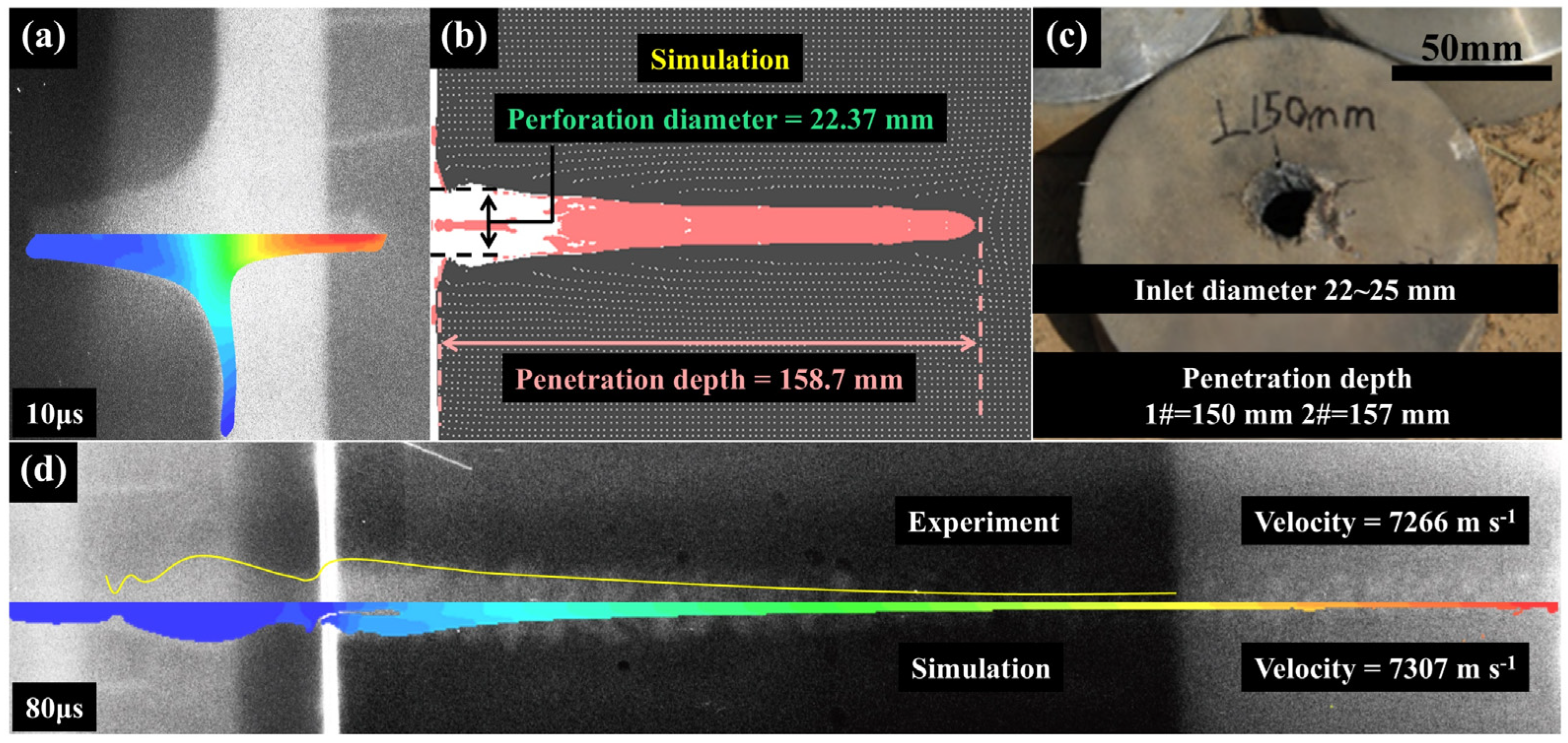

3.1. Simulation Model Verification

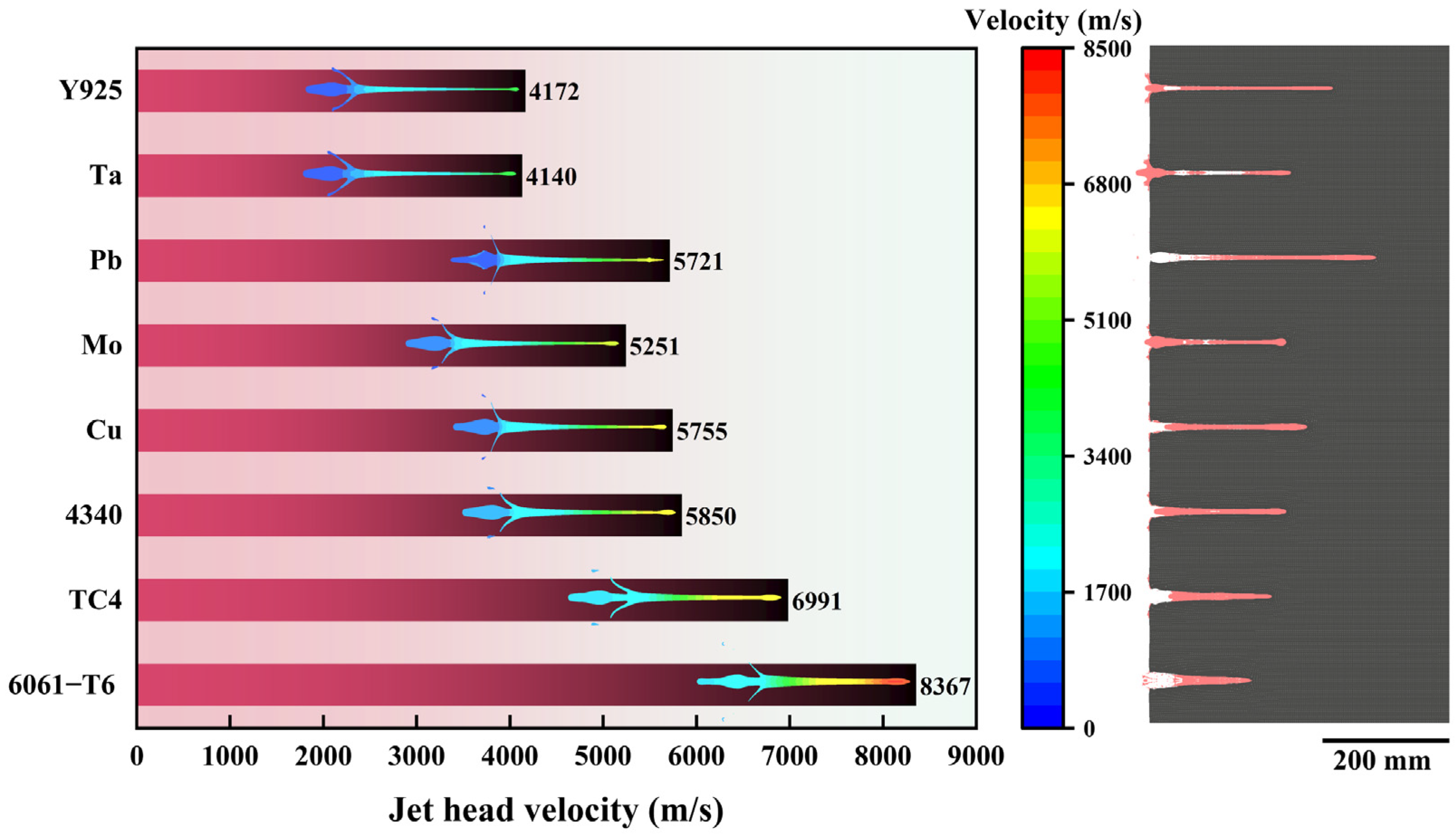

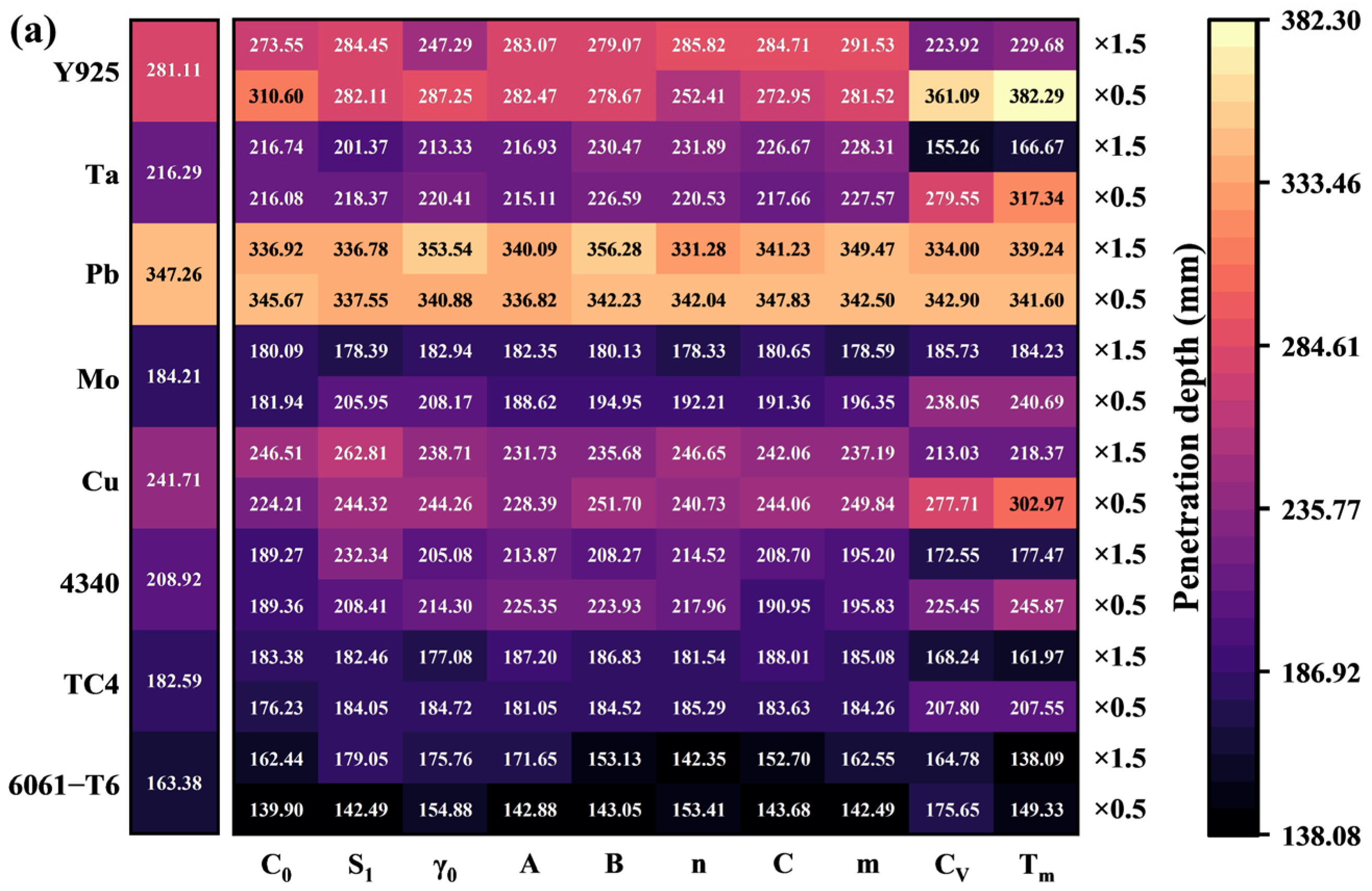

3.2. Simulation Results and Discussion

3.3. Results of Machine Learning Analysis

3.4. Experimental Verification

4. Analysis and Discussion

4.1. Influence Mechanism of Melting Point on Penetration Depth

4.2. Influence Mechanism of Specific Heat on Penetration Depth

4.3. Influence Mechanism of Density on Penetration Depth

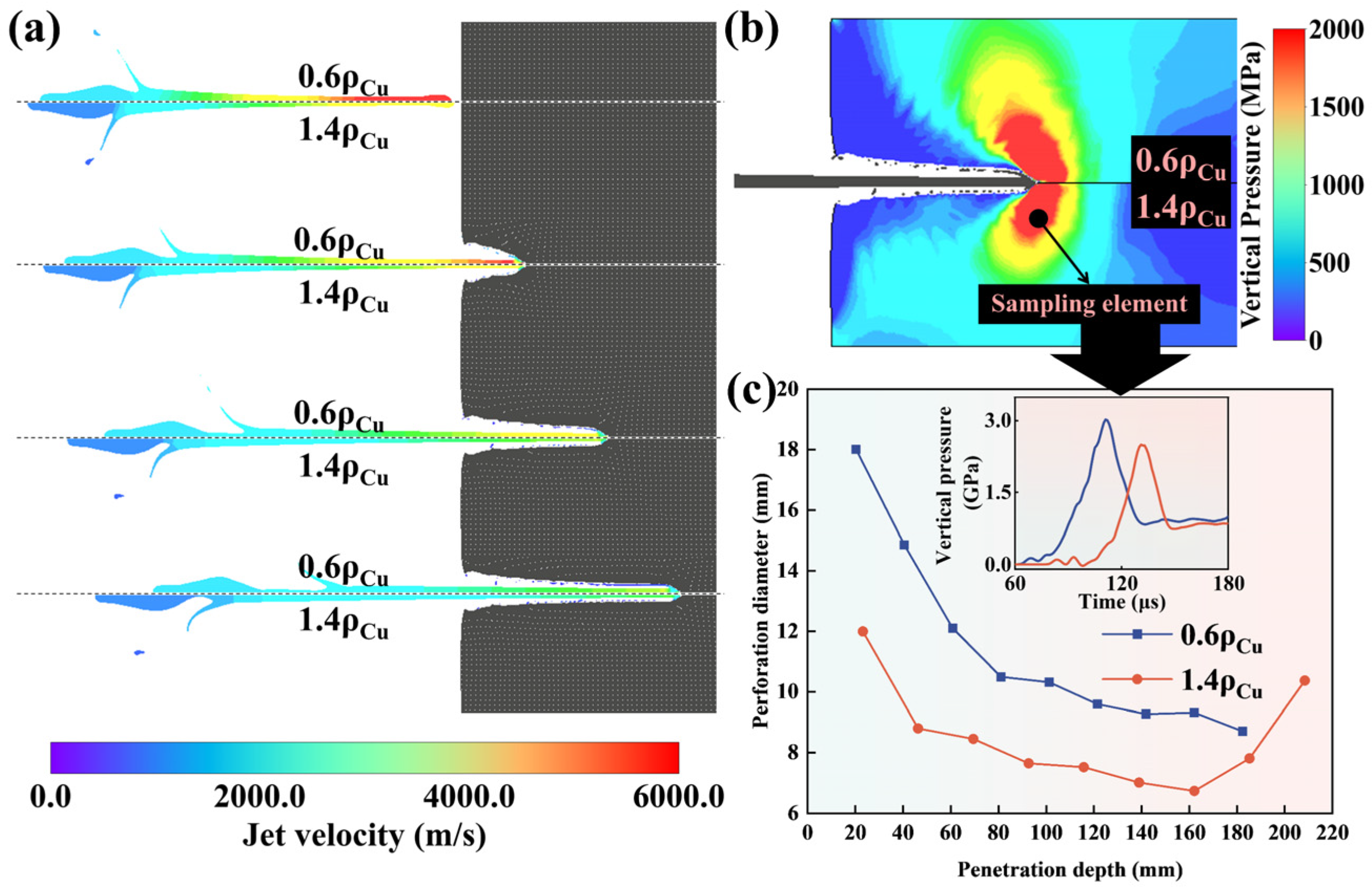

4.4. Influence Mechanism of Density on Perforation Diameter

5. Conclusions

- (1)

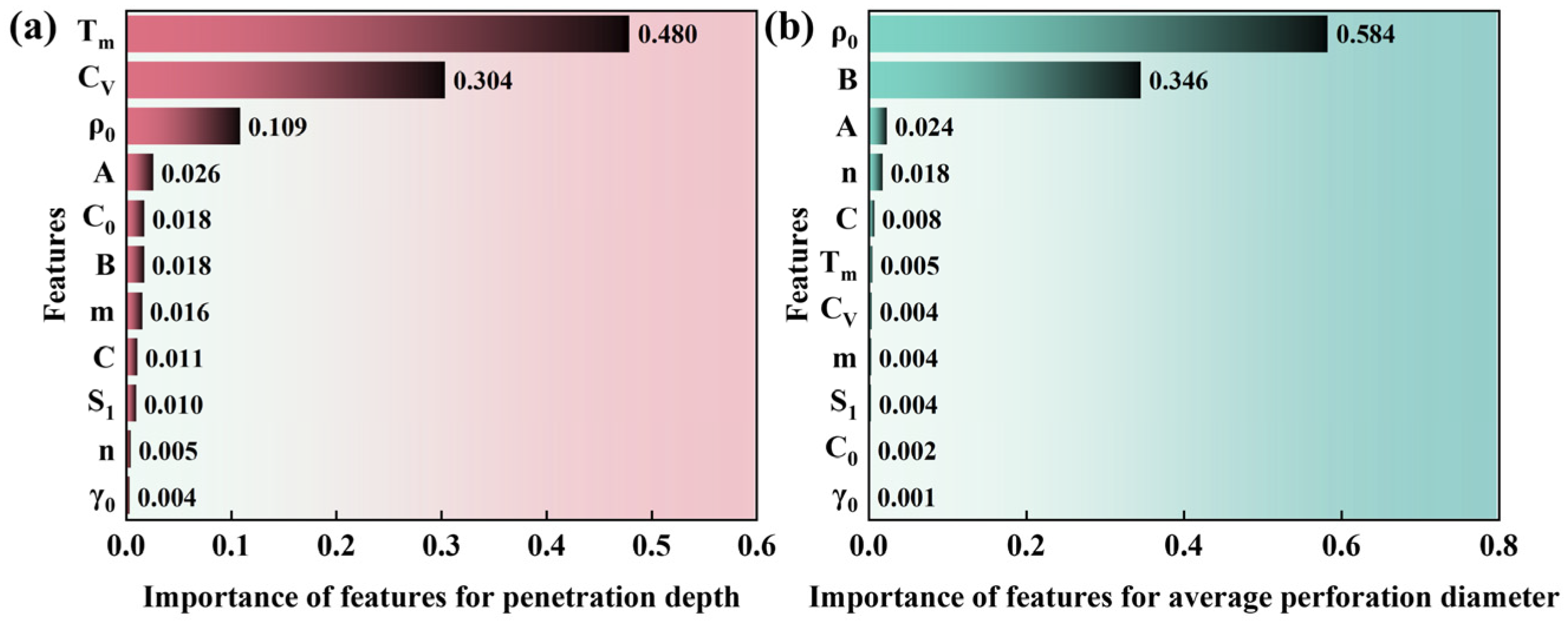

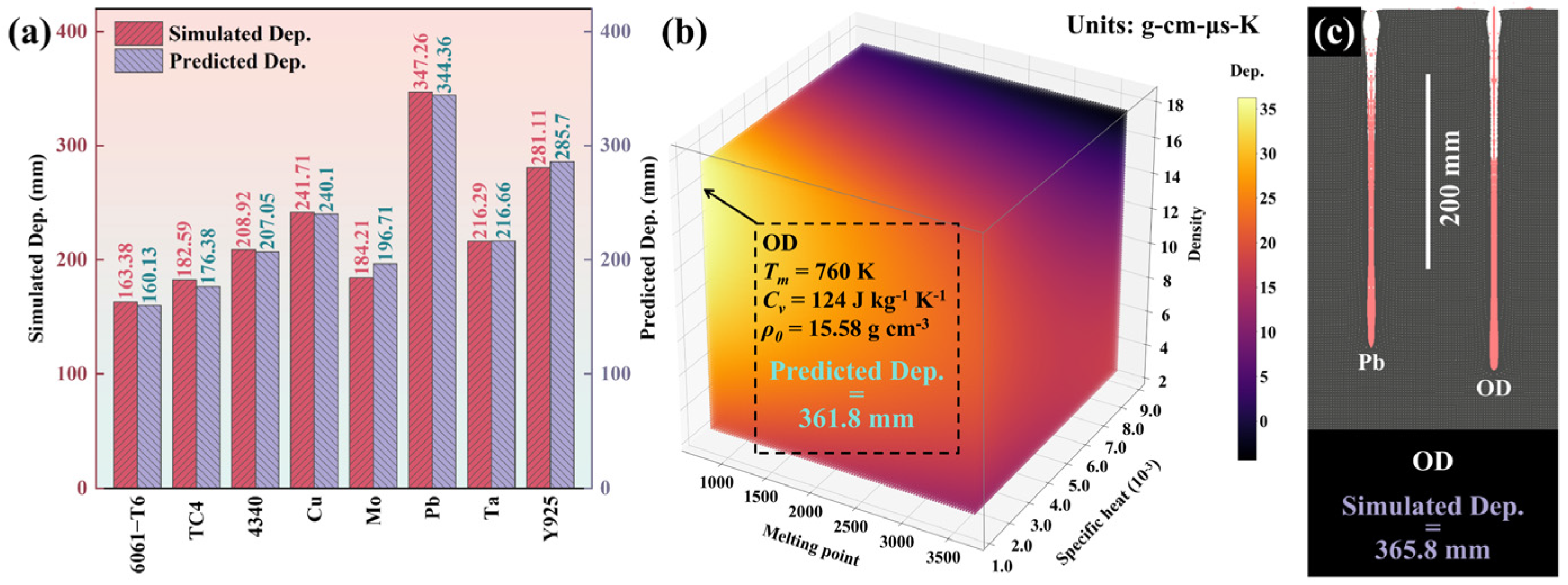

- Based on the virtual material method, the numerical simulation model for SCL penetration on an AISI 1045 target was established, and the depicted error of the penetration performance is less than 5%. The Adaboost algorithm based on a regression tree pointed out that, among the physical properties described by the J-C model and Mie–Grüneisen EOS, melting point, specific heat, and density have the greatest influence on the penetration depth of the SCL, and their relative importance is 0.4252, 0.3469, and 0.0651, respectively. The density and strain hardening coefficient have the greatest influence on the perforation diameter of the SCL, and the relative importance is 0.7883 and 0.0646, respectively.

- (2)

- The evaluation functions of the melting point, specific heat, and density of SCL materials on penetration depth and perforation diameter were obtained by a quadratic polynomial regression algorithm. An optimally designed SCL material with high penetration performance is given by the maximum point of the evaluation function, from which the key properties are the melting point of 760 K, specific heat capacity of 124 J·kg−1·K−1, and density of 15.58 g·cm−3, respectively. The numerical simulation proves that the SCL of this material can form a theoretical penetration depth of 365.8 cm, which is 51.3% higher than that of OFHC copper.

- (3)

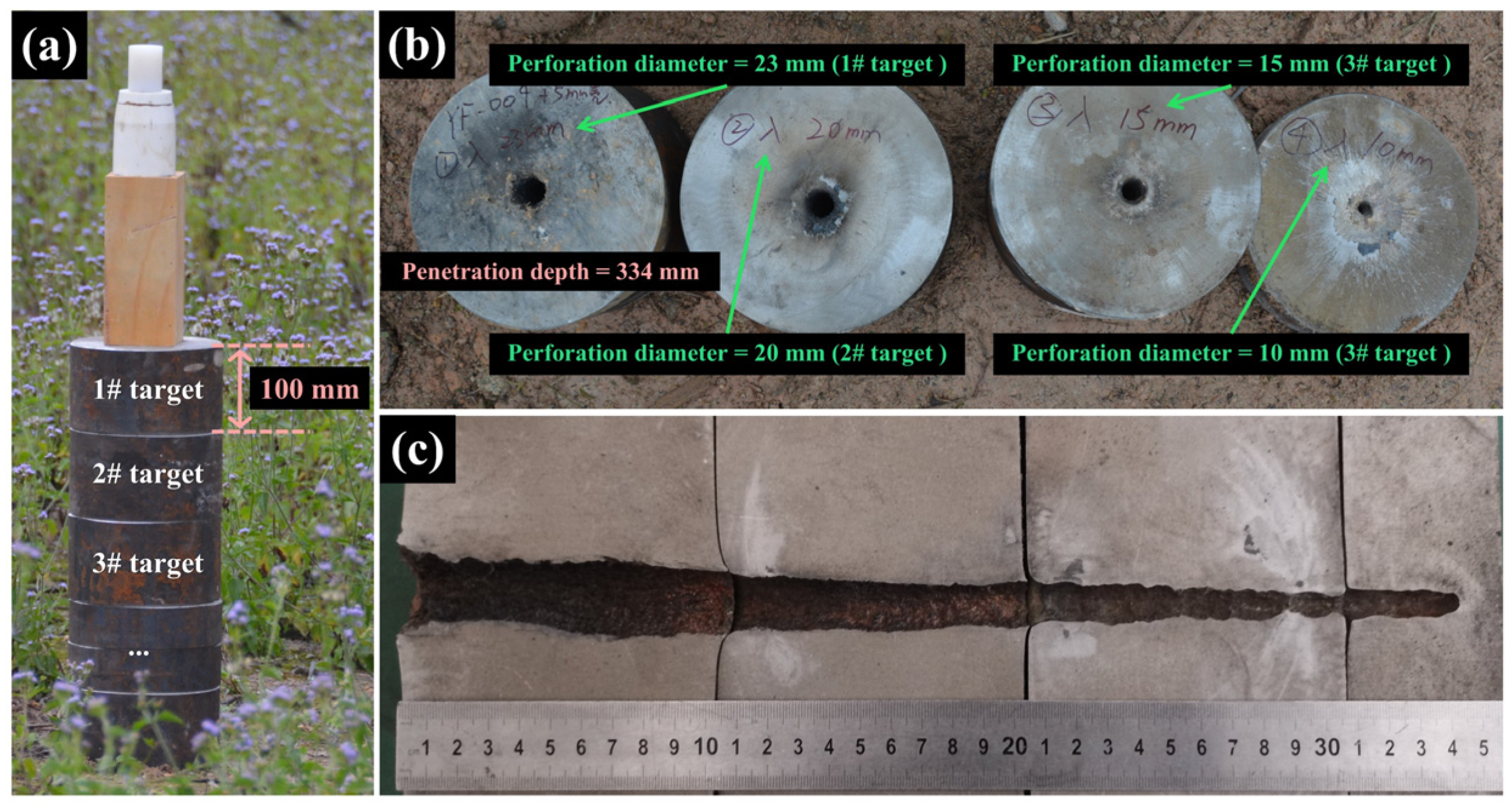

- SCL materials with both excellent penetration and perforation diameter can be found or designed based on the relative importance of the key properties and quantitative evaluation methods. This is proved by the experimental results of the Zr Alloy SCL and Ti Alloy SCL. The penetration depth of Zr Alloy SCL is increased by 114% compared to Ti Alloy SCL, while the inlet diameter is reduced by only about 4%.

- (4)

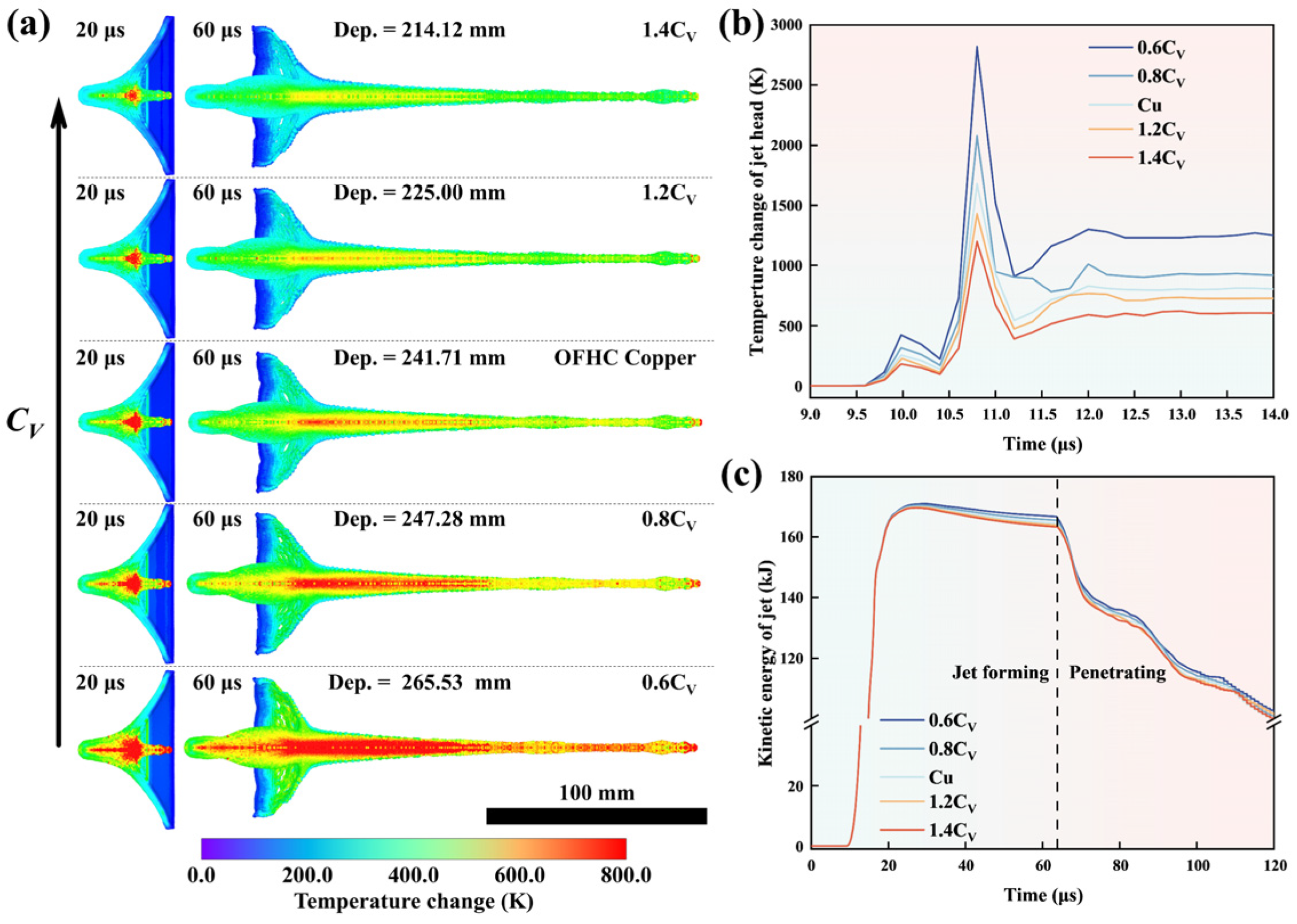

- The influence mechanisms of the key material properties—density, specific heat, and melting point—on the penetration performace of the SCL were disclosed by tracing the penetration process of the metal jets. Both low specific heat and low melting point can increase the thermal softening effect to reduce the internal work of the SCL under formation and penetration precesses of the metal jet, but low specific heat can also reduce the self-penetrating consumption of the jet during the latter process. Density affects the jet penetration process through influencing dynamic pressure. The penetration depth is significantly increased with density in the SCL of low-density materials, but it is less affected by the density in the high-density materials.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Borkowski, J.; Wilk, Z.; Koslik, P.; Szymanczyk, L.; Zygmunt, B. Application of sintered liners for explosively formed projectile charges. Int. J. Impact Eng. 2018, 118, 91–97. [Google Scholar] [CrossRef]

- Xu, H.; Liu, J.; Cai, Q.; Xue, X.; Li, S. Significantly improved penetration performance of intermetallic-compound-contained Ti-Al-Nb alloy shaped charge liner against reinforced concrete targets. Mater. Des. 2022, 221, 110997. [Google Scholar] [CrossRef]

- Ma, B.; Huang, Z.; Guan, Z.; Jia, X.; Xiao, Q.; Zu, X. Theoretical analysis of the acceleration effect of the magnetic field on the shaped charge jet. Int. J. Mech. Sci. 2017, 133, 283–287. [Google Scholar] [CrossRef]

- Fedorov, S.V.; Kolpakov, V.I.; Vinogradova, E.P.; Bolotina, I.A. Combined shaped-charge liners for explosion formation of aluminum particles with velocities up to 16 km/s. Acta Astronaut. 2022, 190, 231–240. [Google Scholar] [CrossRef]

- Selivanov, V.V.; Ladov, S.V.; Silnikov, M.V.; Nikol’skaya, Y.M. Combined hemisphere-cylinder shaped-charge liner optimization for high-velocity metal fragments formation in anti-meteoroid resistance tests. Acta Astronaut. 2021, 180, 149–154. [Google Scholar] [CrossRef]

- Żochowski, P.; Warchoł, R. Experimental and numerical study on the influence of shaped charge liner cavity filing on jet penetration characteristics in steel targets. Def. Technol. 2023, 23, 60–74. [Google Scholar] [CrossRef]

- Sun, T.; Wang, H.; Wang, S.; Ge, C.; Hu, D.; Chen, P.; Zheng, Y. Formation behaviors of rod-like reactive shaped charge penetrator and their effects on damage capability. Def. Technol. 2023, 32, 242–253. [Google Scholar] [CrossRef]

- Peng, J.; Jiang, J.; Men, J.; Li, J.; Zhou, D.; Hu, Y. The Penetration–Explosion Effects of Differently Distributed Inactive/Active Composite Shaped Charge Jets. Materials 2022, 15, 344. [Google Scholar] [CrossRef]

- Warchol, R.; Zochowski, P.; Salacinski, G.T. Influence of a non-Explosive Filling Included in the Conical Liner Cavity of a Shaped Charge on its Penetrative Capability. Cent. Eur. J. Energ. Mater. 2023, 20, 400–416. [Google Scholar] [CrossRef]

- Xiao, J.; Zhang, X.; Wang, Y.; Xu, F.; Wang, H. Demolition Mechanism and Behavior of Shaped Charge with Reactive Liner. Propellants Explos. Pyrotech. 2016, 41, 612–617. [Google Scholar] [CrossRef]

- Xu, W.; Wang, C.; Chen, D. The jet formation and penetration capability of hypervelocity shaped charges. Int. J. Impact Eng. 2019, 132, 103337. [Google Scholar] [CrossRef]

- Hong, B.; Li, W.; Li, Y.; Guo, Z.; Yan, B. Jet formation and penetration performance of a double-layer charge liner with chemically-deposited tungsten as the inner liner. Def. Technol. 2023, 33, 374–385. [Google Scholar] [CrossRef]

- Fan, Y.-Q.; Wang, J.; Zhu, J.-J. Jet formation and initiation study of double-layer shaped charge. J. Energ. Mater. 2021, 39, 170–181. [Google Scholar] [CrossRef]

- Sun, S.; Jiang, J.; Wang, S.; Men, J.; Li, M. Structural design of the fluted shaped charge liner using multi-section optimization method. Def. Technol. 2023, 25, 249–262. [Google Scholar] [CrossRef]

- Elshenawy, T.; Li, Q.; Elbeih, A. Experimental and numerical investigation of zirconium jet performance with different liner shapes design. Def. Technol. 2022, 18, 12–26. [Google Scholar] [CrossRef]

- Zhan, H.; Shu, D.; Wu, H.; Chen, Q.; Yu, M.; Xia, X.; Chen, M.; Du, C. Cold extrusion of a shaped charge liner preform with hyperboloid structure: Simulation and experiment. Int. J. Adv. Manuf. Technol. 2024, 130, 933–944. [Google Scholar] [CrossRef]

- Voitenko, Y.; Sydorenko, Y.; Zakusylo, R.; Goshovskii, S.; Zaychenko, S.; Boyko, V. On the Influence of the Liner Shape and Charge Detonation Scheme on the Kinetic Characteristics of Shaped Charge Jets and Explosively Formed Penetrators. Cent. Eur. J. Energ. Mater. 2023, 20, 417–441. [Google Scholar] [CrossRef]

- Liu, Z.; Zhai, J.; Su, S. Numerical Simulation on Conical Shaped Charge with Copper Liner in Several Typical Shapes. Mater. Res. Proc. 2019, 13, 7–12. [Google Scholar]

- Wang, C.; Huang, F.; Ning, J. Jet formation and penetration mechanism of W typed shaped charge. Acta Mech. Sin. 2009, 25, 107–120. [Google Scholar] [CrossRef]

- Xue, X. Characterization of slugs for self-designed Ti-alloy shaped charge liner after penetrating reinforced concrete and steel target. J. Phys. Conf. Ser. 2024, 2819, 012027. [Google Scholar] [CrossRef]

- Guo, H.; Zheng, Y.; Yu, Q.; Ge, C.; Wang, H. Penetration behavior of reactive liner shaped charge jet impacting thick steel plates. Int. J. Impact Eng. 2019, 126, 76–84. [Google Scholar] [CrossRef]

- Shan, Y.; Xin, C.; Liu, J.; Li, G.; Zhai, C.; Li, Y. On Aftereffects of Shaped Charge Comprised of Reactive Material Liner. J. Phys. Conf. Ser. 2023, 2478, 072059. [Google Scholar] [CrossRef]

- Guo, H.; Xie, J.; Wang, H.; Yu, Q.; Zheng, Y. Penetration Behavior of High-Density Reactive Material Liner Shaped Charge. Materials 2019, 12, 3486. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.-F.; Zhu, H.-R. Copper-Tungsten Shaped Charge Liner and its Jet. Propellants Explos. Pyrotech. 1996, 21, 193–195. [Google Scholar] [CrossRef]

- He, H.; Jia, S. Direct Electrodeposition of Cu-Ni-W Alloys for the Liners for Shaped Charges. J. Mater. Sci. Technol. 2010, 26, 429–432. [Google Scholar] [CrossRef]

- Elshenawy, T.; Elbeih, A.; Li, Q. A Modified Penetration Model for Copper-Tungsten Shaped Charge Jet with Non-Uniform Density Distribution. Cent. Eur. J. Energ. Mater. 2016, 13, 927–943. [Google Scholar] [CrossRef]

- Li, R.X.; Ding, J.B.; Zhao, Y.Y.; Tian, Q.W.; Zhong, X.T.; Wang, R.Q.; Song, J.X.; Huang, J.Y.; Wu, J.X.; Li, Y.C. Preliminary study on the dynamic deformation mechanism of CoCrFeNi high-entropy alloy and its application in the shaped charge liner. J. Alloys Compd. 2024, 999, 175083. [Google Scholar] [CrossRef]

- Liu, S.; Liu, X.; Xie, R.; Feng, X.; He, C.; Liu, J. Mechanism and influence factors on energy-release capacity under the high-velocity impact fragmentation of Zr-Nb alloys. J. Alloys Compd. 2023, 935, 168022. [Google Scholar] [CrossRef]

- Si, S.; Fan, B.; Liu, X.; Zhou, T.; He, C.; Song, D.; Liu, J. Study on strengthening effects of Zr-Ti-Nb-O alloys via high throughput powder metallurgy and data-driven machine learning. Mater. Des. 2021, 206, 109777. [Google Scholar] [CrossRef]

- Han, H.; Chen, F.; Gan, L.; Chu, Z. The Application of Tungsten as Shaped Charge Liner Material. China Tungsten Ind. 2004, 19, 26–28. [Google Scholar]

- Wang, C.; Ding, J.; Zhao, H. Numerical Simulation on Jet Formation of Shaped Charge with Different Liner Materials. Def. Sci. J. 2015, 65, 279–286. [Google Scholar] [CrossRef]

- Elshenawy, T.; Elbeih, A.; Li, Q.M. Influence of target strength on the penetration depth of shaped charge jets into RHA targets. Int. J. Mech. Sci. 2018, 136, 234–242. [Google Scholar] [CrossRef]

- Gu, Y.; Wang, J.; Li, H.; Tang, K.; Liu, L. Formation characteristics and penetration performance of an underwater shaped charge jet. Ocean Eng. 2022, 258, 111695. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, L.; Yang, S.; Zong, Z.; Zhang, Z. Efficient Cutting of Submarine Pipelines by Linear-Shaped Charge. In Computational and Experimental Simulations in Engineering; Zhou, K., Ed.; Springer Nature: Cham, Switzerland, 2024; Volume 168, pp. 433–445. ISBN 978-3-031-68774-7. [Google Scholar] [CrossRef]

- Hu, F.; Wu, H.; Fang, Q.; Liu, J.C.; Liang, B.; Kong, X.Z. Impact performance of explosively formed projectile (EFP) into concrete targets. Int. J. Impact Eng. 2017, 109, 150–166. [Google Scholar] [CrossRef]

- Chen, J.-Y.; Feng, D.-L.; Sun, Q.-Y.; Peng, C.; Zhu, Y.-H.; Yu, S.-Y. Numerical modeling of shaped charge jet penetration into ceramic–metal double-layered medium using smoothed particle hydrodynamics. Int. J. Impact Eng. 2023, 175, 104526. [Google Scholar] [CrossRef]

- Katayama, M.; Kibe, S.; Yamamoto, T. Numerical and experimental study on the shaped charge for space debris assessment. Acta Astronaut. 2001, 48, 363–372. [Google Scholar] [CrossRef]

- Yao, Z.; Zhou, T.; Shen, Z.; Ren, H.; Jia, H.; Zeng, Z.; Ren, X. Numerical simulation of applying shaped charge cutting technology to Explosive Switch. In Proceedings of the 2010 International Conference on Computer Application and System Modeling (ICCASM 2010), Taiyuan, China, 22–24 October 2010; pp. V8-102–V8-106. [Google Scholar] [CrossRef]

- Xiong, S.; Yang, T.; Wu, Y.; Wang, J.; Li, Y.; Wen, Y. Numerical simulation of radiated noise during combustion of energetic materials in a closed bomb. Def. Technol. 2022, 18, 1167–1178. [Google Scholar] [CrossRef]

- Ye, G.; Meng, K. Constitutive parameters for powder liner in shaped charge: An inversion study. Exp. Technol. Manag. 2024, 41, 92–100. [Google Scholar]

- Sterbentz, D.M.; Jekel, C.F.; White, D.A.; Rieben, R.N.; Belof, J.L. Linear shaped-charge jet optimization using machine learning methods. J. Appl. Phys. 2023, 134, 045102. [Google Scholar] [CrossRef]

- Zhao, Z.; Li, T.; Sheng, D.; Chen, J.; Yan, A.; Chen, Y.; Wang, H.; Chen, X.; Dai, L. Machine learning optimization strategy of shaped charge liner structure based on jet penetration efficiency. Def. Technol. 2024, 39, 23–41. [Google Scholar] [CrossRef]

- Nations, S.; Nandi, T.; Ramazani, S.D. Metal hydride composition-derived parameters as machine learning features for material design and H2 storage. J. Energy Storage 2023, 70, 107980. [Google Scholar] [CrossRef]

- Chan, C.H.; Sun, M.; Huang, B. Application of machine learning for advanced material prediction and design. EcoMat 2022, 4, e12194. [Google Scholar] [CrossRef]

- Zhu, M.; Dong, Y.; Shen, B.; Yu, H.; Jiang, L.; Cai, H. Three Dimensional Metal-Surface Processing Parameter Generation Through Machine Learning-Based Nonlinear Mapping. Tsinghua Sci. Technol. 2023, 28, 754–768. [Google Scholar] [CrossRef]

- Dou, J.-H.; Jia, X.; Huang, Z.-X.; Gu, X.-H.; Xia, M.; Zheng, Y.-M.; Bin, M. Theoretical and experimental study on jet formation and penetration of the liner loaded by electromagnetic force. Int. J. Mech. Sci. 2020, 186, 105883. [Google Scholar] [CrossRef]

- Zheng, Y.; Su, C.; Guo, H.; Yu, Q.; Wang, H. Chain damage effects of multi-spaced plates by reactive jet impact. Def. Technol. 2021, 17, 393–404. [Google Scholar] [CrossRef]

- Liang, S.-C.; Li, Y.; Chen, H.; Huang, J.; Liu, S. Research on the technique of identifying debris and obtaining characteristic parameters of large-scale 3D point set. Int. J. Impact Eng. 2013, 56, 27–31. [Google Scholar] [CrossRef]

- He, Q.-G.; Chen, X.; Chen, J.-F. Finite element-smoothed particle hydrodynamics adaptive method in simulating debris cloud. Acta Astronaut. 2020, 175, 99–117. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, J.; Sun, S.; Men, J.; Wang, S. Investigation on the spatial distribution characteristics of behind-armor debris formed by the perforation of EFP through steel target. Def. Technol. 2020, 16, 119–135. [Google Scholar] [CrossRef]

- Wen, K.; Chen, X.-W. Failure evolution in hypervelocity impact of Al spheres onto thin Al plates. Int. J. Impact Eng. 2021, 147, 103727. [Google Scholar] [CrossRef]

- Shi, J. Experimental and numerical investigation of jet performance based on Johnson-Cook model of liner material. Int. J. Impact Eng. 2022, 170, 104343. [Google Scholar] [CrossRef]

- O’Toole, L.; Haridas, R.S.; Mishra, R.S.; Fang, F. Determination of Johnson-Cook plasticity model parameters for CoCrMo alloy. Mater. Today Commun. 2023, 34, 105128. [Google Scholar] [CrossRef]

- Molinari, J.F. Finite element simulation of shaped charges. Finite Elem. Anal. Des. 2002, 38, 921–936. [Google Scholar] [CrossRef]

- Chen, J.; Chen, W.; Chen, S.; Zhou, G.; Zhang, T. Shock Hugoniot and Mie-Grüneisen EOS of TiAl alloy: A molecular dynamics approach. Comput. Mater. Sci. 2020, 174, 109495. [Google Scholar] [CrossRef]

- Carpenter, A.J.; Chocron, S.; Anderson, C.E. Linking the equation of state for fiber-reinforced composites to those of the individual fiber and matrix constituents. Procedia Eng. 2017, 204, 383–389. [Google Scholar] [CrossRef]

- Bian, Y.L.; Liu, Q.; Feng, Z.D.; Hua, J.Y.; Xie, H.L.; Chen, S.; Cai, Y.; Yao, X.H.; Luo, S.N. High-speed penetration dynamics of polycarbonate. Int. J. Mech. Sci. 2022, 223, 107250. [Google Scholar] [CrossRef]

- Wu, J.; Liu, J.; Du, Y. Experimental and numerical study on the flight and penetration properties of explosively-formed projectile. Int. J. Impact Eng. 2007, 34, 1147–1162. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, H.; Zhang, J.; Wang, L.; Zhang, G.; Zong, Z. Characterization of Underwater Explosive Loads of Blasting and Shaped Charges. J. Mar. Sci. Appl. 2024, 23, 302–315. [Google Scholar] [CrossRef]

- Yan, Q.-L.; Zeman, S.; Elbeih, A. The Influence of the Semtex Matrix on the Thermal Behavior and Decomposition Kinetics of Cyclic Nitramines. Cent. Eur. J. Energ. Mater. 2013, 10, 509–528. [Google Scholar]

- Elek, P.; Dzingalasevic, V.; Jaramaz, S.; Mickovic, D. Determination of detonation products equation of state from cylinder test: Analytical model and numerical analysis. Therm. Sci. 2015, 19, 35–48. [Google Scholar] [CrossRef]

- Khoei, A.R.; Biabanaki, S.O.R.; Parvaneh, S.M. Dynamic modeling of powder compaction processes via a simple contact algorithm. Int. J. Mech. Sci. 2012, 64, 196–210. [Google Scholar] [CrossRef]

- Elshenawy, T. Determination of the Velocity Difference between Jet Fragments for a Range of Copper Liners with Different Small Grain Sizes. Propellants Explos. Pyrotech. 2016, 41, 69–75. [Google Scholar] [CrossRef]

- Helte, A.; Lundgren, J.; Candle, J. The interaction between a shaped charge jet and a single moving plate. Def. Technol. 2023, 31, 1–13. [Google Scholar] [CrossRef]

- Chen, G.; Chen, Z.F.; Tao, J.L.; Niu, W.; Huang, X.C. Investigation and validation on plastic constitutive parameters of 45 steel. Explos. Shock Waves 2005, 25, 451–456. [Google Scholar]

- Hao, Z.; Wang, Z.; Xu, Y.; Duan, C.; Wang, Y. Study on the detonation wave propagation of shaped charge with three-layer liner and its driving characteristics to liner. Sci. Rep. 2024, 14, 8778. [Google Scholar] [CrossRef]

- Milani, A.S.; Dabboussi, W.; Nemes, J.A.; Abeyaratne, R.C. An improved multi-objective identification of Johnson–Cook material parameters. Int. J. Impact Eng. 2009, 36, 294–302. [Google Scholar] [CrossRef]

- Robbins, J.R.; Ding, J.L.; Gupta, Y.M. Load spreading and penetration resistance of layered structures—A numerical study. Int. J. Impact Eng. 2004, 30, 593–615. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures. Eng. Fract. Mech. 1983, 21, 541–548. [Google Scholar]

- Steinberg, D.J.; Cochran, S.G.; Guinan, M.W. A constitutive model for metals applicable at high-strain rate. J. Appl. Phys. 1980, 51, 1498–1504. [Google Scholar] [CrossRef]

- Quan, X.; Clegg, R.A.; Cowler, M.S.; Birnbaum, N.K.; Hayhurst, C.J. Numerical simulation of long rods impacting silicon carbide targets using JH-1 model. Int. J. Impact Eng. 2006, 33, 634–644. [Google Scholar] [CrossRef]

- Saleh, M.; Edwards, L. Evaluation of a hydrocode in modelling NATO threats against steel armour. In Proceedings of the 25th International Symposium on Ballistics, Beijing, China, 17–21 May 2010. [Google Scholar]

- Vahedi, K.; Khazraiyan, N. Numerical Modeling of Ballistic Penetration of Long Rods into Ceramic/Metal Armors. In Proceedings of the 8th International LS-DYNA Users Conference, Detroit, MI, USA, 8–10 June 2004. [Google Scholar]

- Lundberg, P.; Renström, R.; Lundberg, B. Impact of conical tungsten projectiles on flat silicon carbide targets: Transition from interface defeat to penetration. Int. J. Impact Eng. 2006, 32, 1842–1856. [Google Scholar] [CrossRef]

- Pappu, S. Hydrocode and Microstructural Analysis of Explosively Formed Penetrators. Ph.D. Thesis, The University of Texas at El Paso, El Paso, TX, USA, 2000. [Google Scholar]

- Wang, X.; Shi, J. Validation of Johnson-Cook plasticity and damage model using impact experiment. Int. J. Impact Eng. 2013, 60, 67–75. [Google Scholar] [CrossRef]

- Pan, K.; Liu, X.; Wang, B.; Gao, S.; Wu, S.; Li, N. The rapid densification behavior of powder metallurgy Ti alloys by induction heating sintering. J. Mater. Sci. Technol. 2024, 181, 152–164. [Google Scholar] [CrossRef]

- Littlefield, D.L.; Anderson, C.E.; Partom, Y.; Bless, S.J. The penetration of steel targets finite in radial extent. Int. J. Impact Eng. 1997, 19, 49–62. [Google Scholar] [CrossRef]

- Gorfain, J.E.; Key, C.T. Damage prediction of rib-stiffened composite structures subjected to ballistic impact. Int. J. Impact Eng. 2013, 57, 159–172. [Google Scholar] [CrossRef]

- Aslam, T.D.; Bdzil, J.B. Numerical and theoretical investigations on detonation-inert confinement interactions. In Proceedings of the 12th International Symposium on Detonation, San Diego, CA, USA, 11–16 August 2002. [Google Scholar]

- Chen, S.R.; Gray, G.T. Constitutive behavior of tantalum and tantalum-tungsten alloys. Metall. Mater. Trans. A 1996, 27, 2994–3006. [Google Scholar] [CrossRef]

- Woodward, R.L. Penetration of semi-infinite metal targets by deforming projectiles. Int. J. Mech. Sci. 1982, 24, 73–87. [Google Scholar] [CrossRef]

- Lü, C.; Liu, J.; Li, S.; Guo, W.; Bai, X. Penetration Performance of W-Ni-Fe Alloy Shaped Charge Liner. Rare Met. Mater. Eng. 2013, 42, 2337–2340. [Google Scholar]

- Wen, L. Predicting the deformation behaviour of concrete face rockfill dams by combining support vector machine and AdaBoost ensemble algorithm. Comput. Geotech. 2018, 161, 105611. [Google Scholar] [CrossRef]

- Hao, C.; Sui, Y.; Yuan, Y.; Li, P.; Jin, H.; Jiang, A. Composition optimization design and high temperature mechanical properties of cast heat-resistant aluminum alloy via machine learning. Mater. Des. 2025, 250, 113587. [Google Scholar] [CrossRef]

- Cumming, A.S. Collaboration on Pressable Explosives for Shaped Charges—A European Success Story. Propellants Explos. Pyrotech. 1999, 24, 46–49. [Google Scholar] [CrossRef]

- Fernando, P.L.N.; Mohotti, D.; Remennikov, A. Behaviour of explosively welded impedance-graded multi-metal composite plates under near-field blast loads. Int. J. Mech. Sci. 2019, 163, 105124. [Google Scholar] [CrossRef]

- Liu, J.; Li, S.; Zhou, X.; Wang, Y.; Yang, J. Dynamic Recrystallization in the Shear Bands of Tungsten Heavy Alloy Processed by Hot-Hydrostatic Extrusion and Hot Torsion. Rare Met. Mater. Eng. 2011, 40, 957–960. [Google Scholar] [CrossRef]

- Guan, X.R.; Chen, Q.; Qu, S.J.; Cao, G.J.; Wang, H.; Feng, A.H.; Chen, D.L. Adiabatic shear instability in a titanium alloy: Extreme deformation-induced phase transformation, nanotwinning, and grain refinement. J. Mater. Sci. Technol. 2023, 150, 104–113. [Google Scholar] [CrossRef]

- Selivanov, V.V.; Fedorov, S.V.; Babkin, A.V.; Bolotina, I.A. Using shaped charges with a “magnetic cut-off” for testing anti-meteoroid shields. Acta Astronaut. 2021, 180, 170–175. [Google Scholar] [CrossRef]

- Yang, H. Analysis on mass loss of different sized projectiles penetrating into concrete targets. Int. J. Mech. Sci. 2017, 131, 683–692. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, L.; Silberschmidt, V.V.; Wang, S. SPH-FEM simulation of shaped-charge jet penetration into double hull: A comparison study for steel and SPS. Compos. Struct. 2016, 155, 135–144. [Google Scholar] [CrossRef]

- Zhang, H.; Zheng, Y.; Yu, Q.; Ge, C.; Su, C.; Wang, H. Penetration and internal blast behavior of reactive liner enhanced shaped charge against concrete space. Def. Technol. 2022, 18, 952–962. [Google Scholar] [CrossRef]

| Material | ρ0 (kg m−3) | D (m s−1) | A (GPa) | B (GPa) | r1 | r2 | Pcj (GPa) | E (kJ m−3) | ω |

|---|---|---|---|---|---|---|---|---|---|

| RDX | 1700 | 8318 | 854.5 | 20.5 | 4.6 | 1.35 | 29.5 | 8.5 × 106 | 0.25 |

| Material | A (MPa) | B (MPa) | n | C | (S−1) | m | CV (J kg−1 K−1) | Tm (K) |

|---|---|---|---|---|---|---|---|---|

| Ti Alloy | 915 | 497 | 0.89 | 0.012 | 0.001 | 0.65 | 1281 | 1900 |

| Material | ρ0 (kg m−3) | C0 (m s−1) | S1 | γ0 |

|---|---|---|---|---|

| Ti Alloy | 4700 | 5130 | 1.03 | 1.23 |

| Material | A (MPa) | B (MPa) | n | C | (S−1) | m | CV (J kg−1 K−1) | Tm (K) |

|---|---|---|---|---|---|---|---|---|

| AISI 1045 | 507 | 320 | 0.28 | 0.064 | 1 | 1.06 | 477 | 1723 |

| Material | ρ0 (kg m−3) | C0 (m s−1) | S1 | γ0 |

|---|---|---|---|---|

| AISI 1045 | 7800 | 4610 | 1.73 | 1.67 |

| MAT | ρ0 (103) | C0 (103) | S1 | γ0 | A (106) | B (106) | n | C | m | CV | Tm |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 6061-T6 Aluminum Alloy | 2.70 | 5.2 | 1.4 | 2.0 | 324 | 114 | 0.4 | 0.002 | 1.3 | 876 | 878 |

| TC4 Titanium Alloy | 4.43 | 5.1 | 1.0 | 1.2 | 1135 | 250 | 0.2 | 0.032 | 1.1 | 580 | 1878 |

| AISI 4340 Steel | 7.83 | 4.6 | 1.5 | 2.2 | 792 | 510 | 0.3 | 0.014 | 1.0 | 477 | 1793 |

| OFHC Copper | 8.96 | 3.9 | 1.5 | 2.0 | 90 | 292 | 0.3 | 0.025 | 1.1 | 383 | 1381 |

| Molybdenum | 10.20 | 5.1 | 1.3 | 1.6 | 425 | 398 | 0.6 | 0.095 | 0.4 | 251 | 3660 |

| Lead | 11.27 | 2.0 | 1.6 | 2.8 | 24 | 300 | 1.0 | 0.100 | 1.0 | 124 | 760 |

| Tantalum | 16.65 | 3.4 | 1.2 | 1.6 | 204 | 1470 | 0.8 | 0.093 | 0.4 | 140 | 3269 |

| Y925 Tungsten Alloy | 17.70 | 4.0 | 1.2 | 1.5 | 631 | 1258 | 0.1 | 0.014 | 0.9 | 150 | 1723 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Liu, J.; Liu, X.; Feng, X.; Du, Y.; Cao, J. Revealing the Influence of Material Properties of Shaped Charge Liner on Penetration Performance via Numerical Simulation and Machine Learning. Materials 2025, 18, 2742. https://doi.org/10.3390/ma18122742

Wang Y, Liu J, Liu X, Feng X, Du Y, Cao J. Revealing the Influence of Material Properties of Shaped Charge Liner on Penetration Performance via Numerical Simulation and Machine Learning. Materials. 2025; 18(12):2742. https://doi.org/10.3390/ma18122742

Chicago/Turabian StyleWang, Yan, Jinxu Liu, Xingwei Liu, Xinya Feng, Yifan Du, and Jie Cao. 2025. "Revealing the Influence of Material Properties of Shaped Charge Liner on Penetration Performance via Numerical Simulation and Machine Learning" Materials 18, no. 12: 2742. https://doi.org/10.3390/ma18122742

APA StyleWang, Y., Liu, J., Liu, X., Feng, X., Du, Y., & Cao, J. (2025). Revealing the Influence of Material Properties of Shaped Charge Liner on Penetration Performance via Numerical Simulation and Machine Learning. Materials, 18(12), 2742. https://doi.org/10.3390/ma18122742