Modification of the Mechanical Properties of Photosensitive Resin by Using Biobased Fillers During Stereolithography (SLA) 3D Printing

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

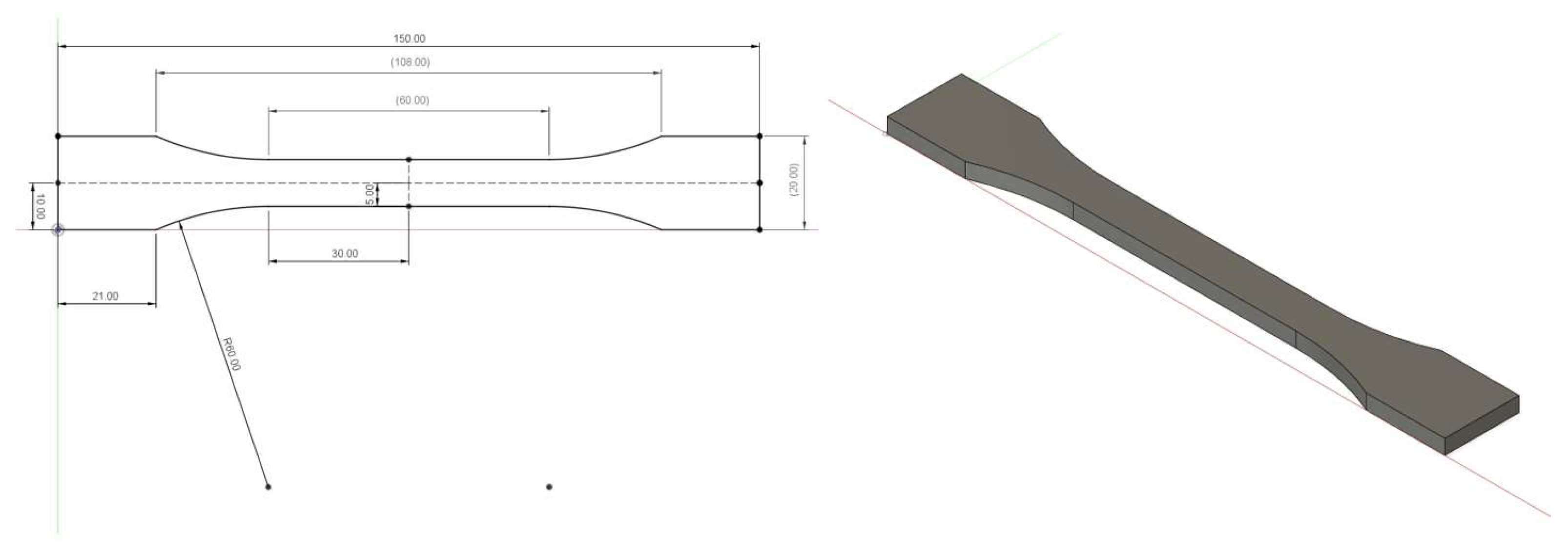

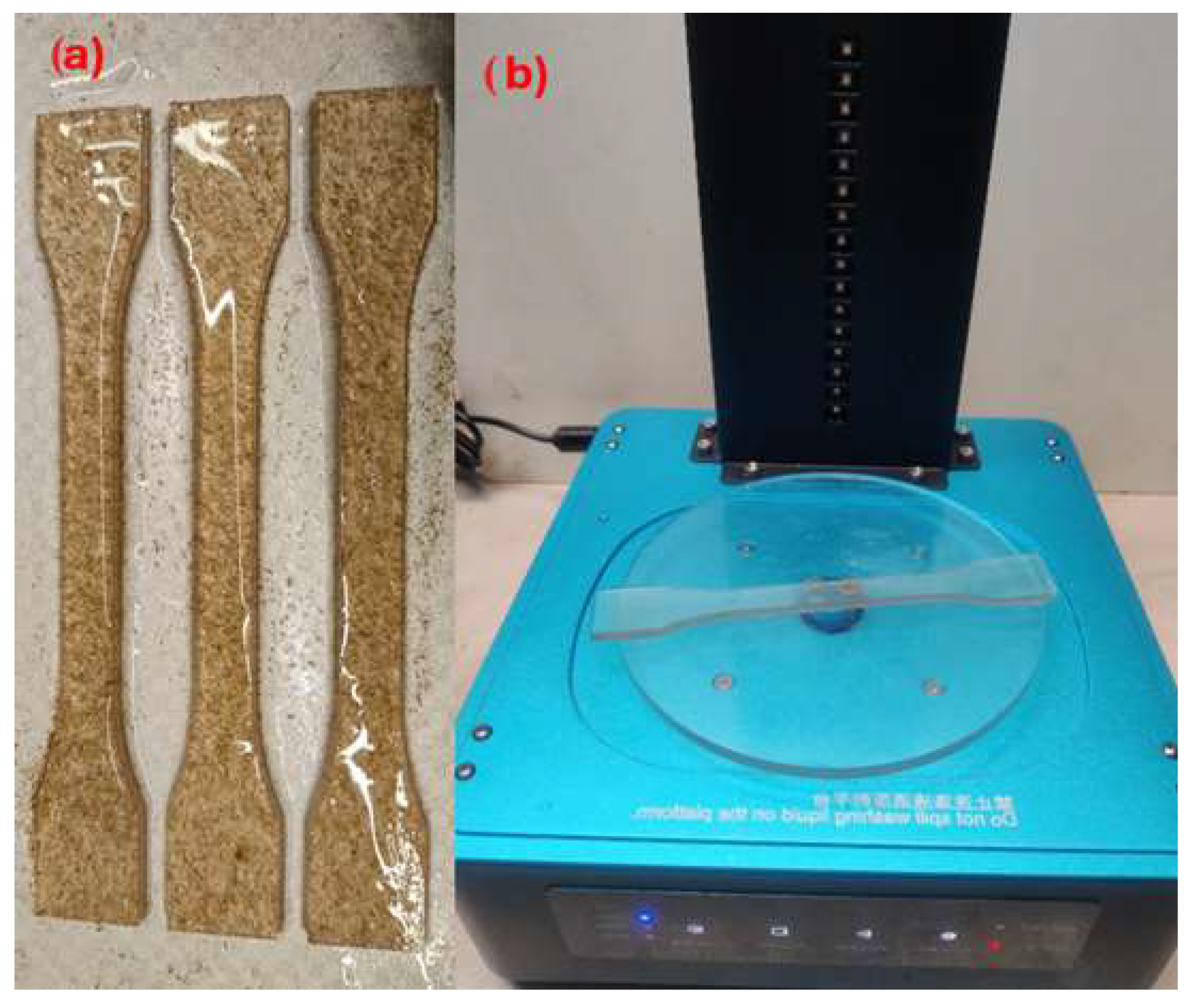

2.1.1. Test Body

2.1.2. Resin and Fillers

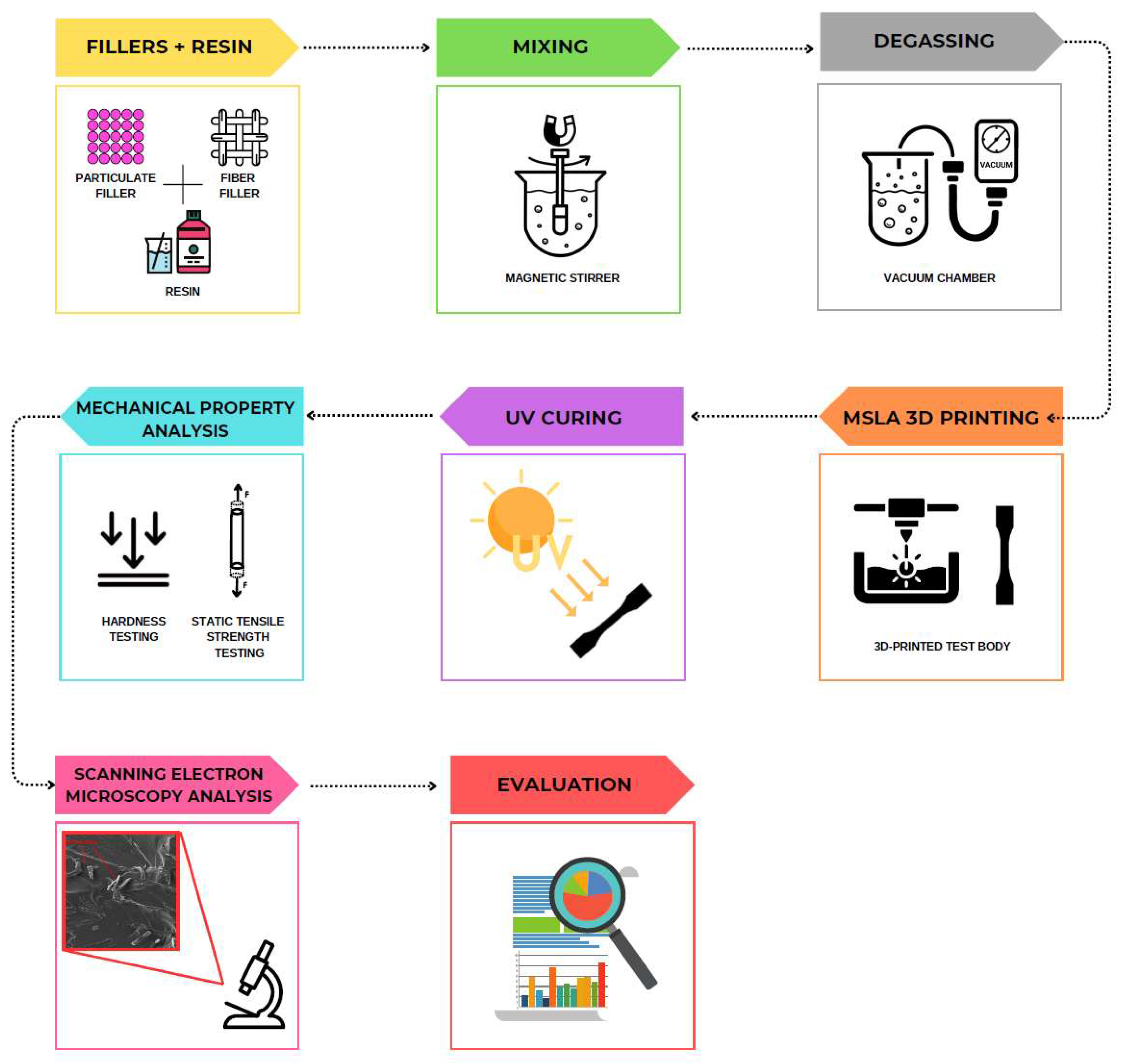

2.2. Methods

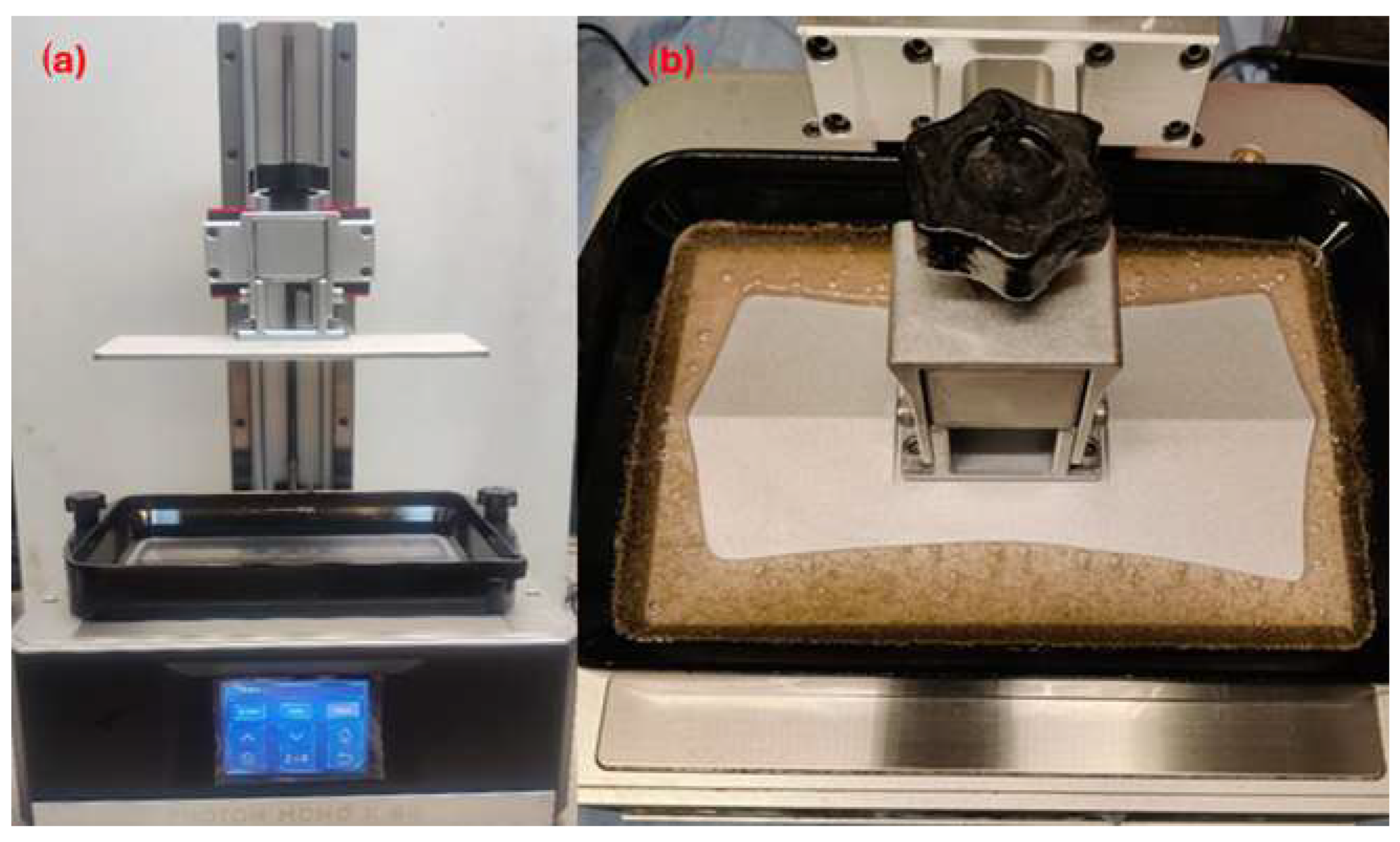

2.2.1. 3D Printer Device and Parameters of Printing

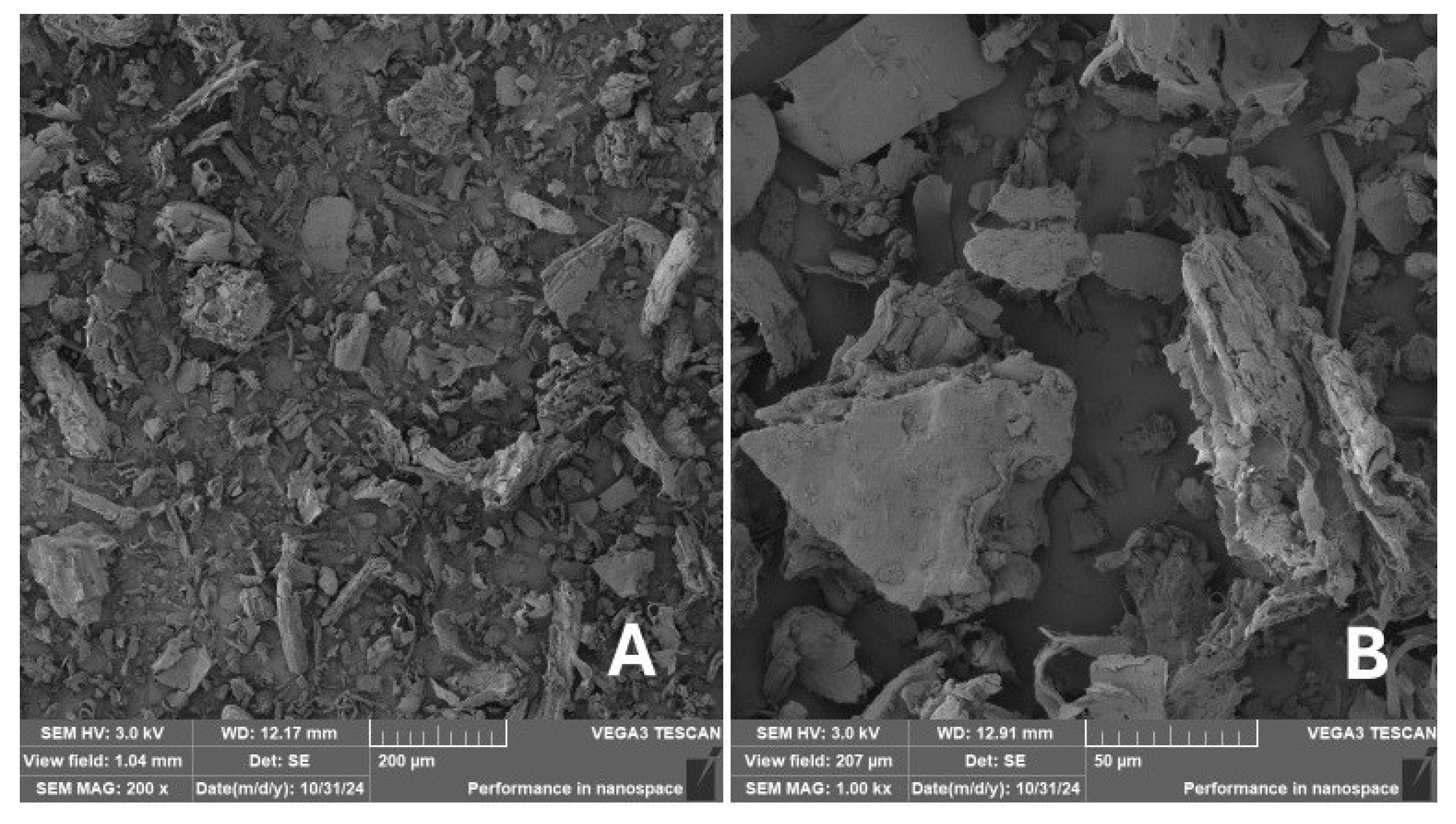

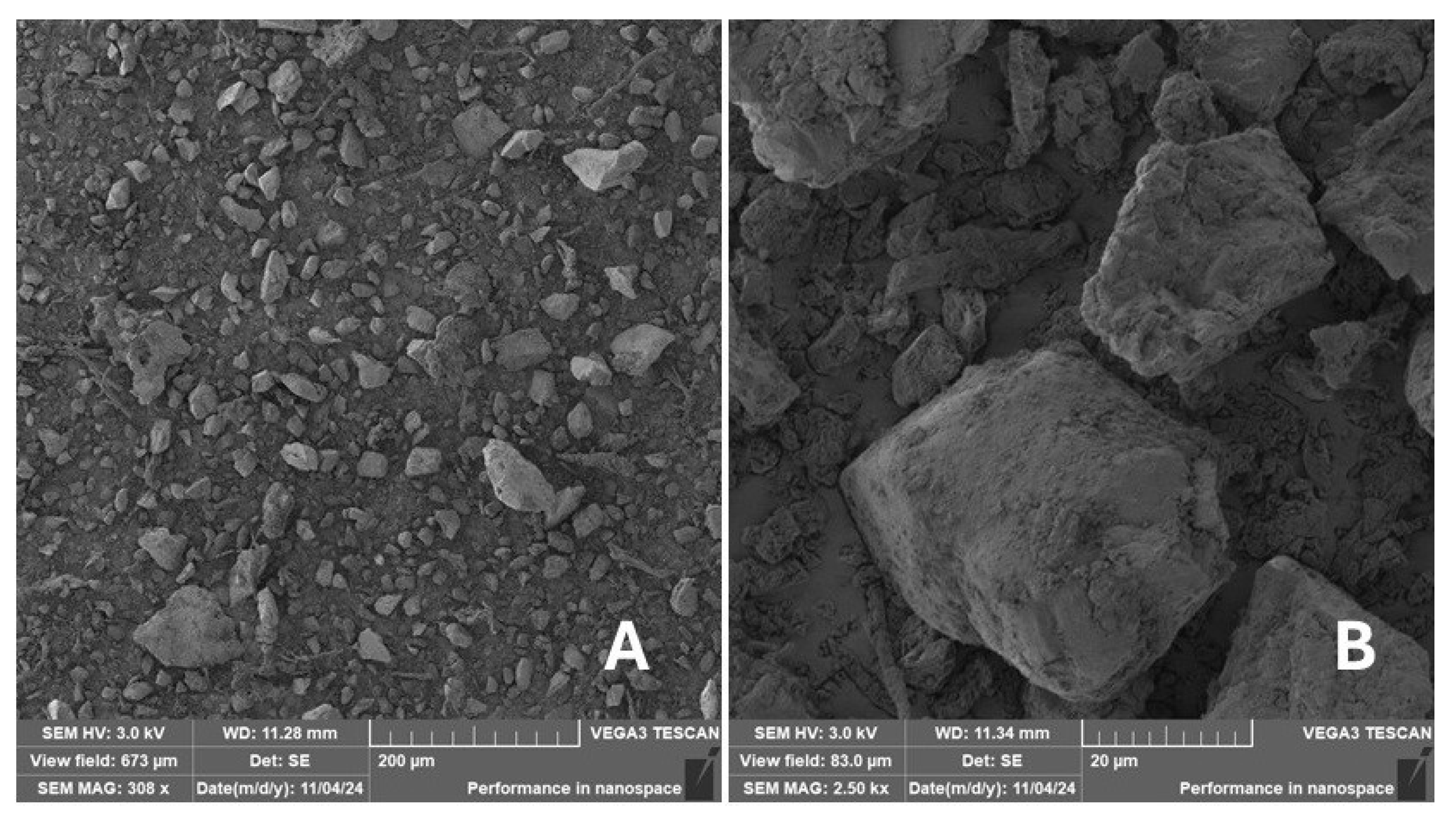

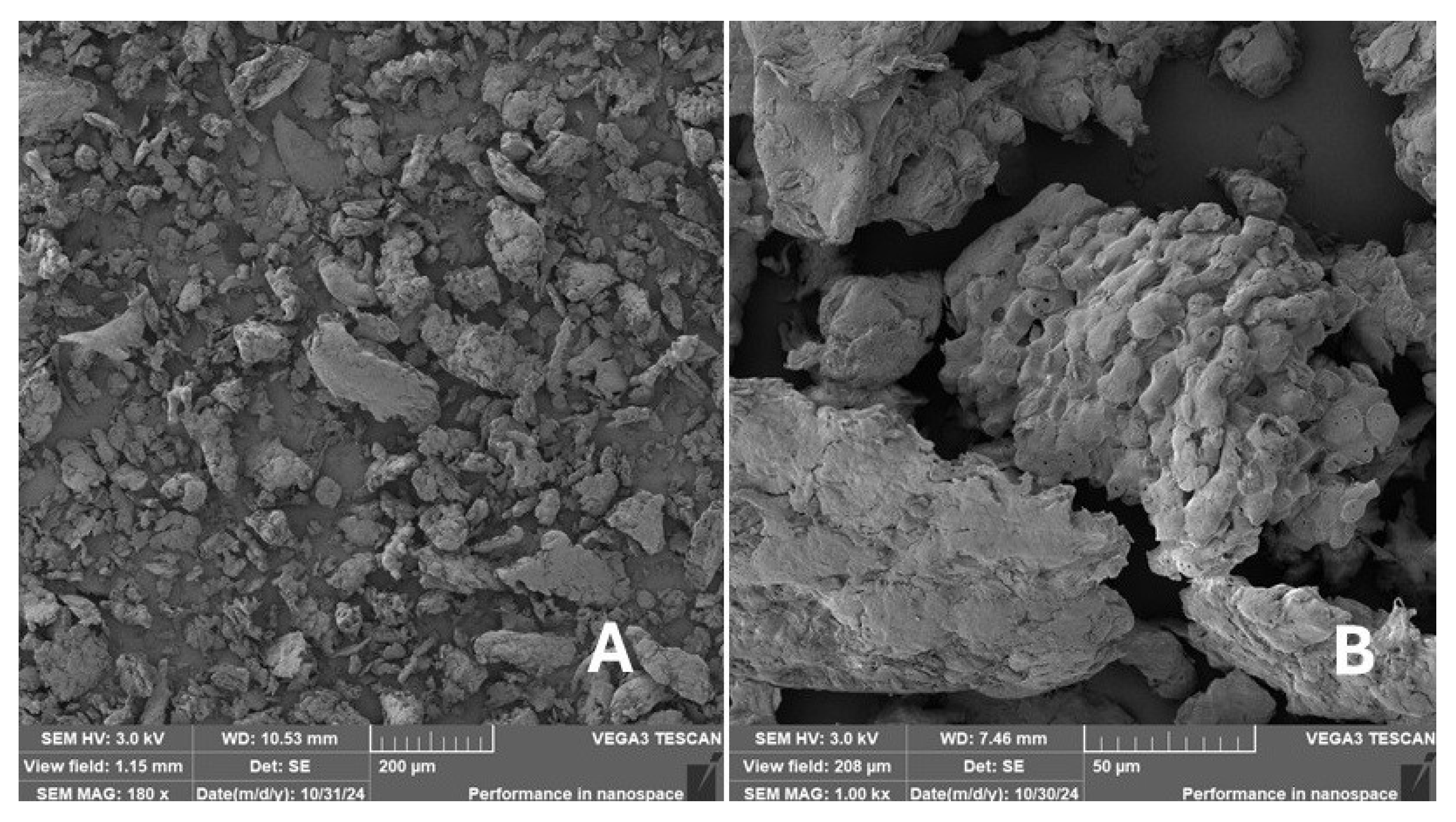

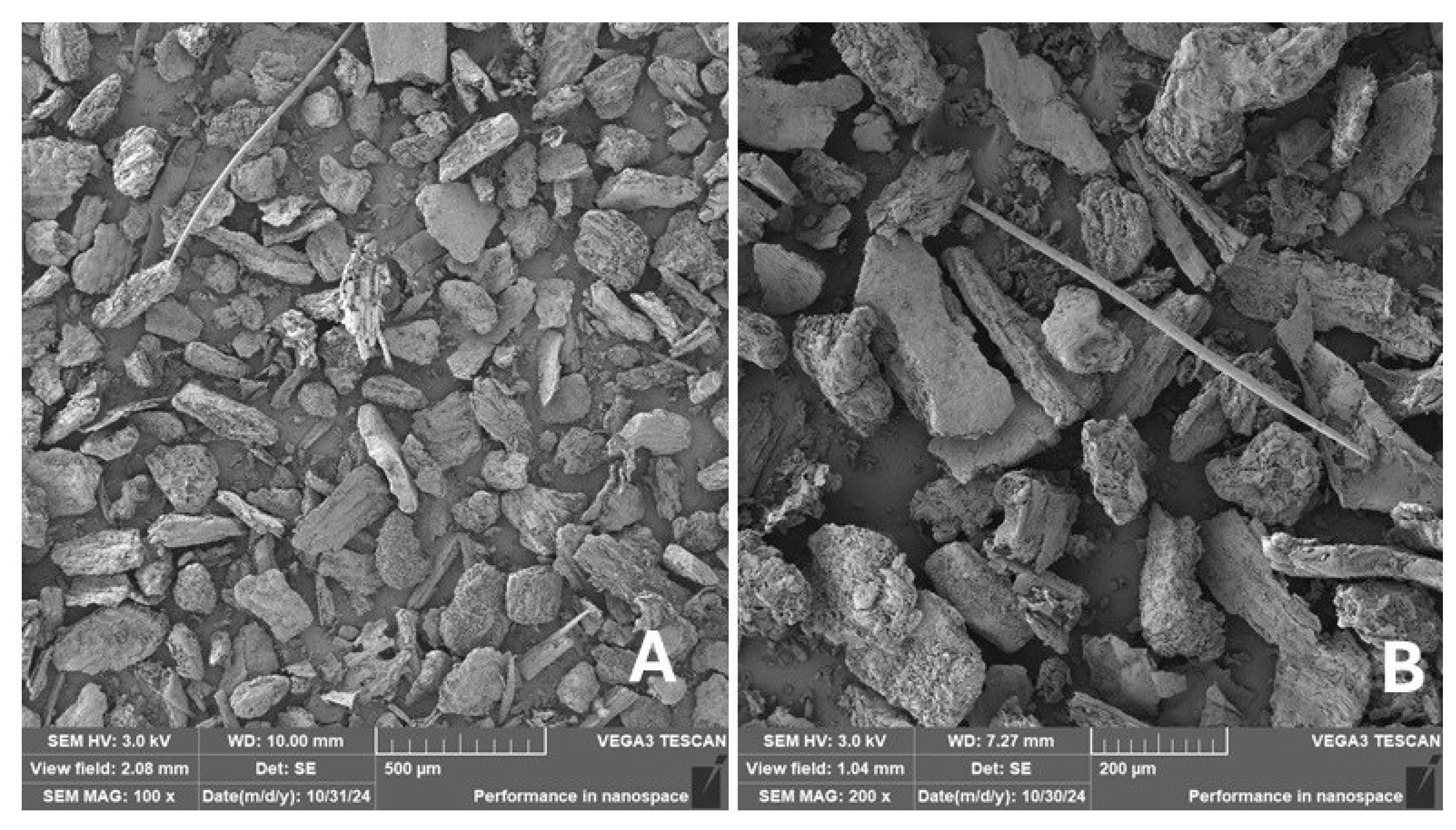

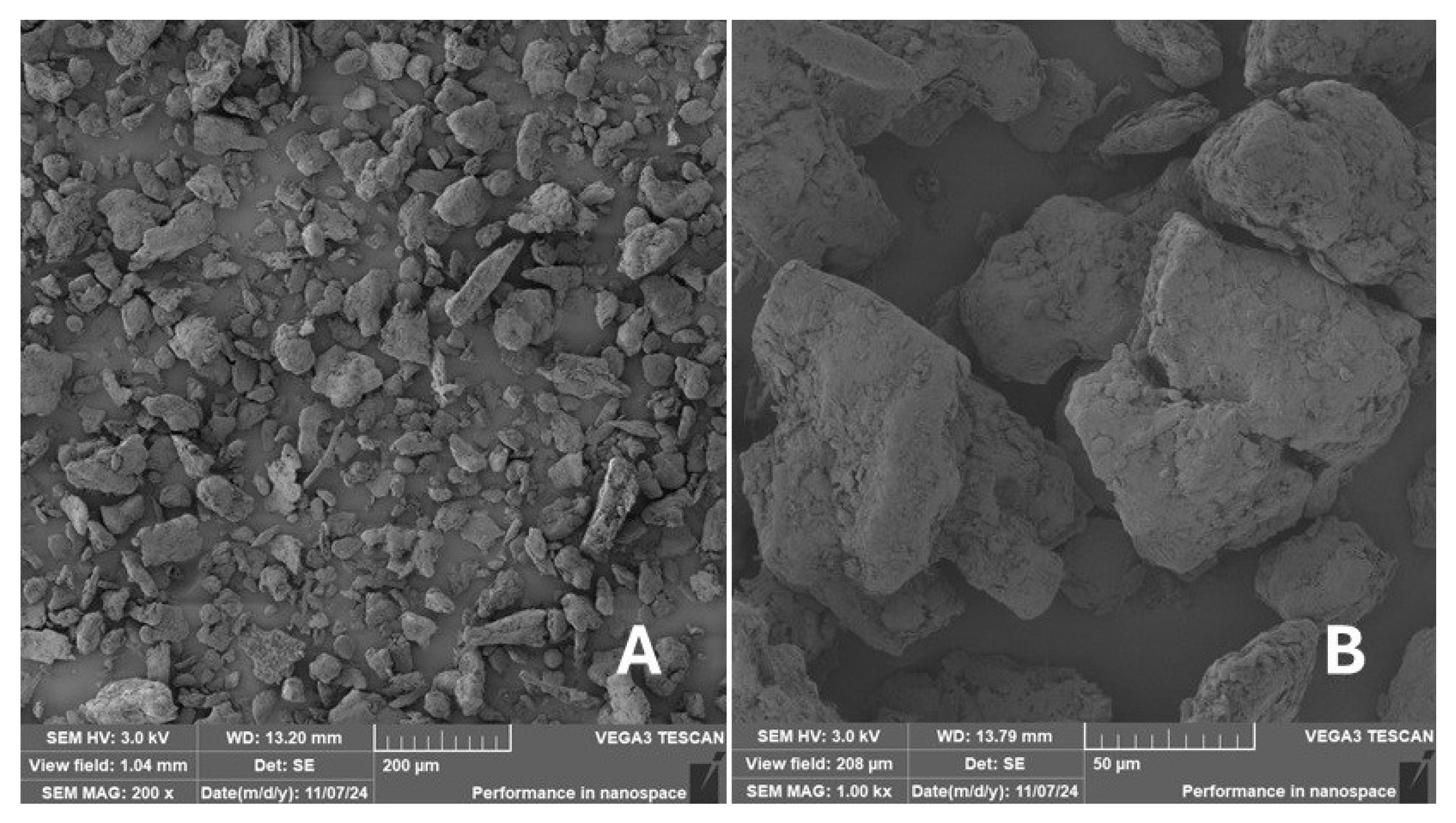

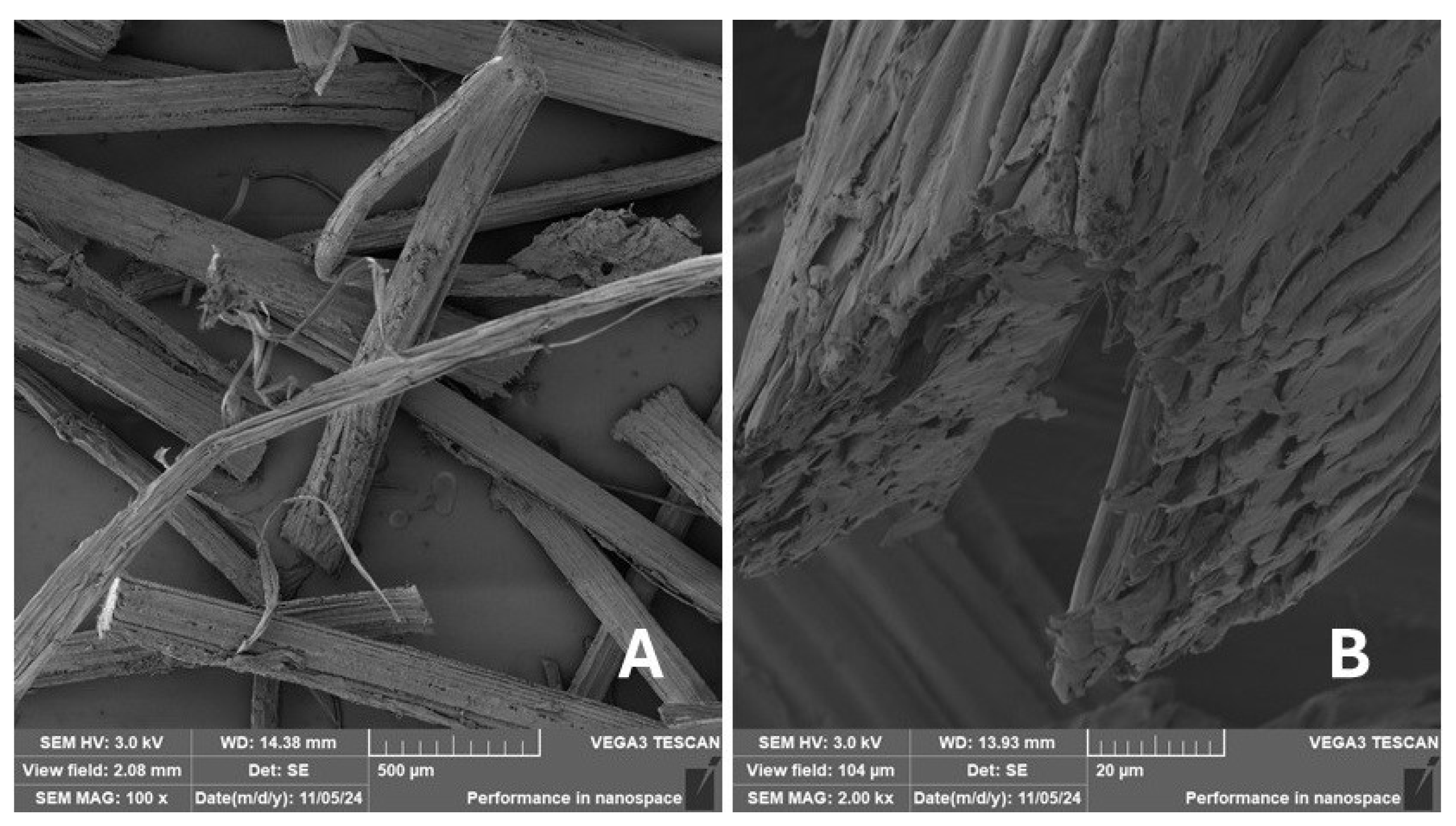

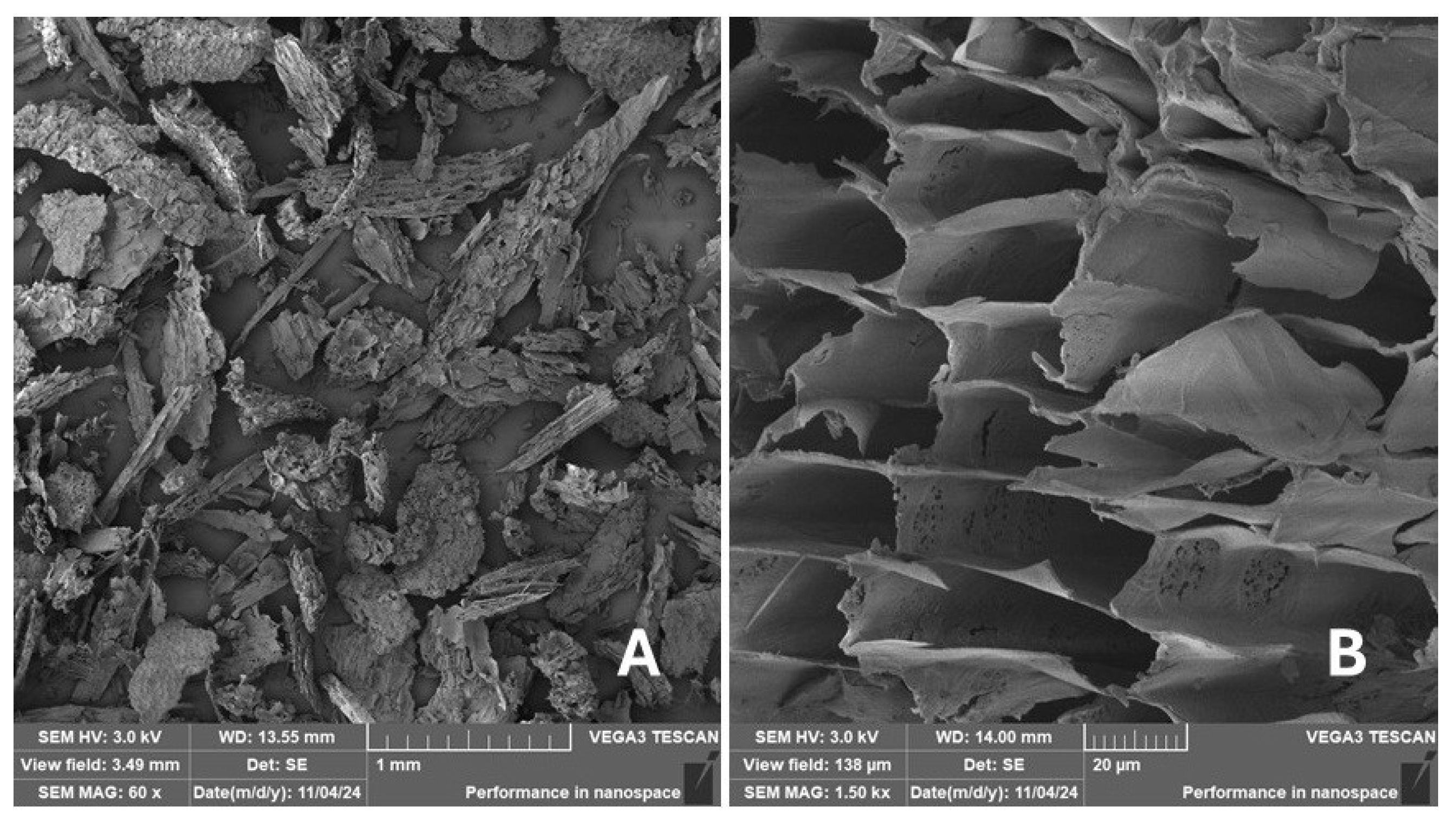

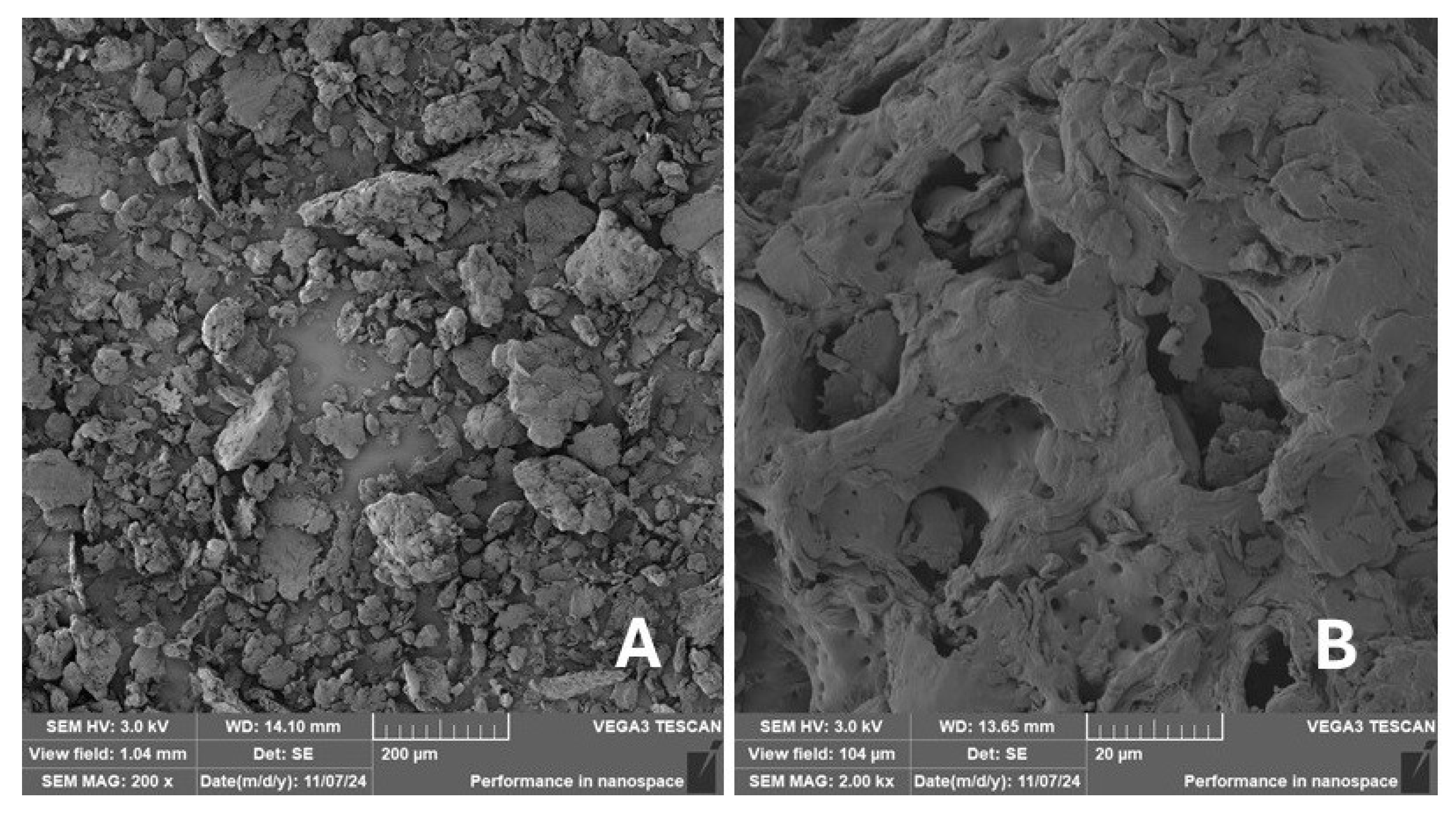

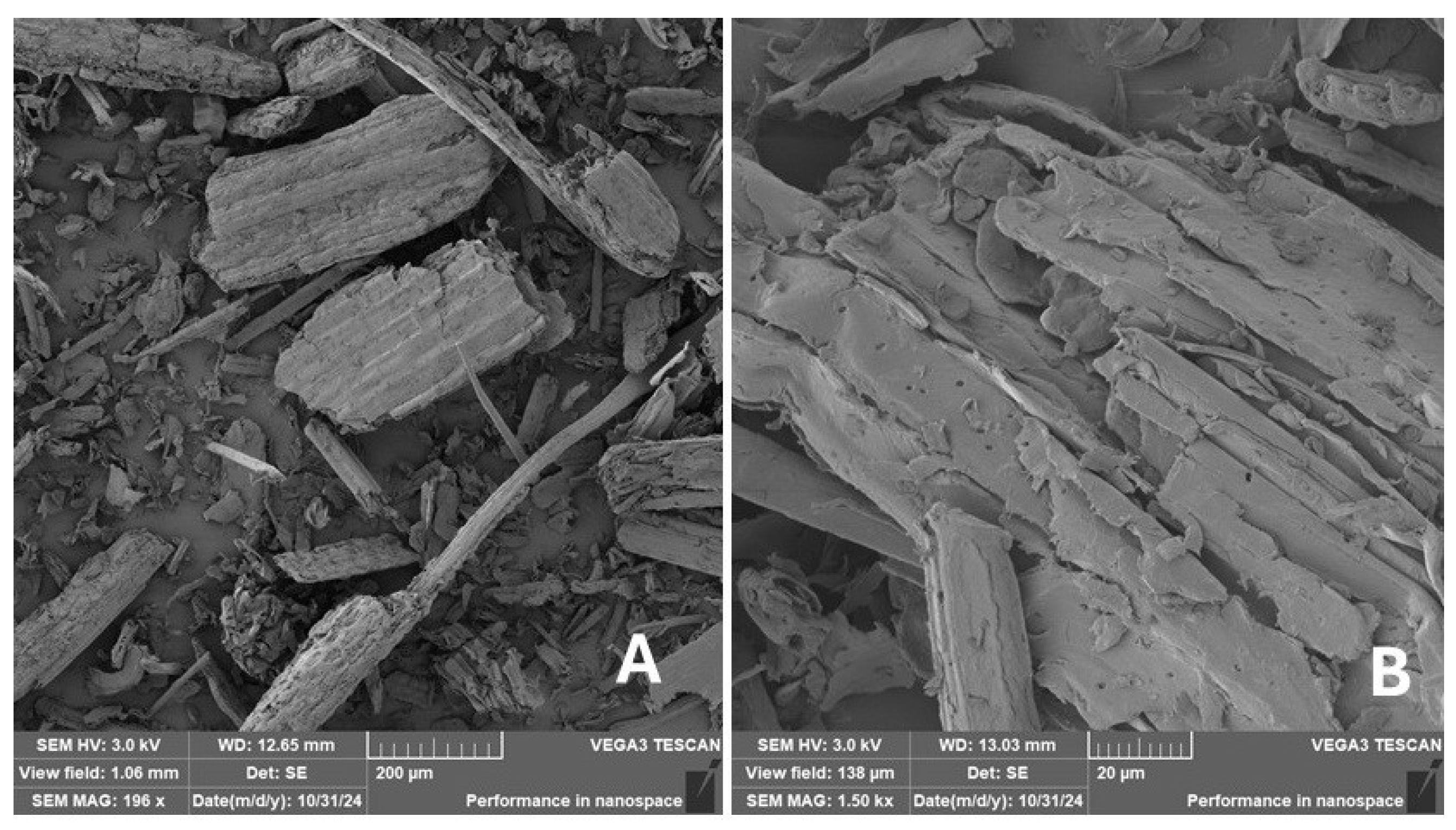

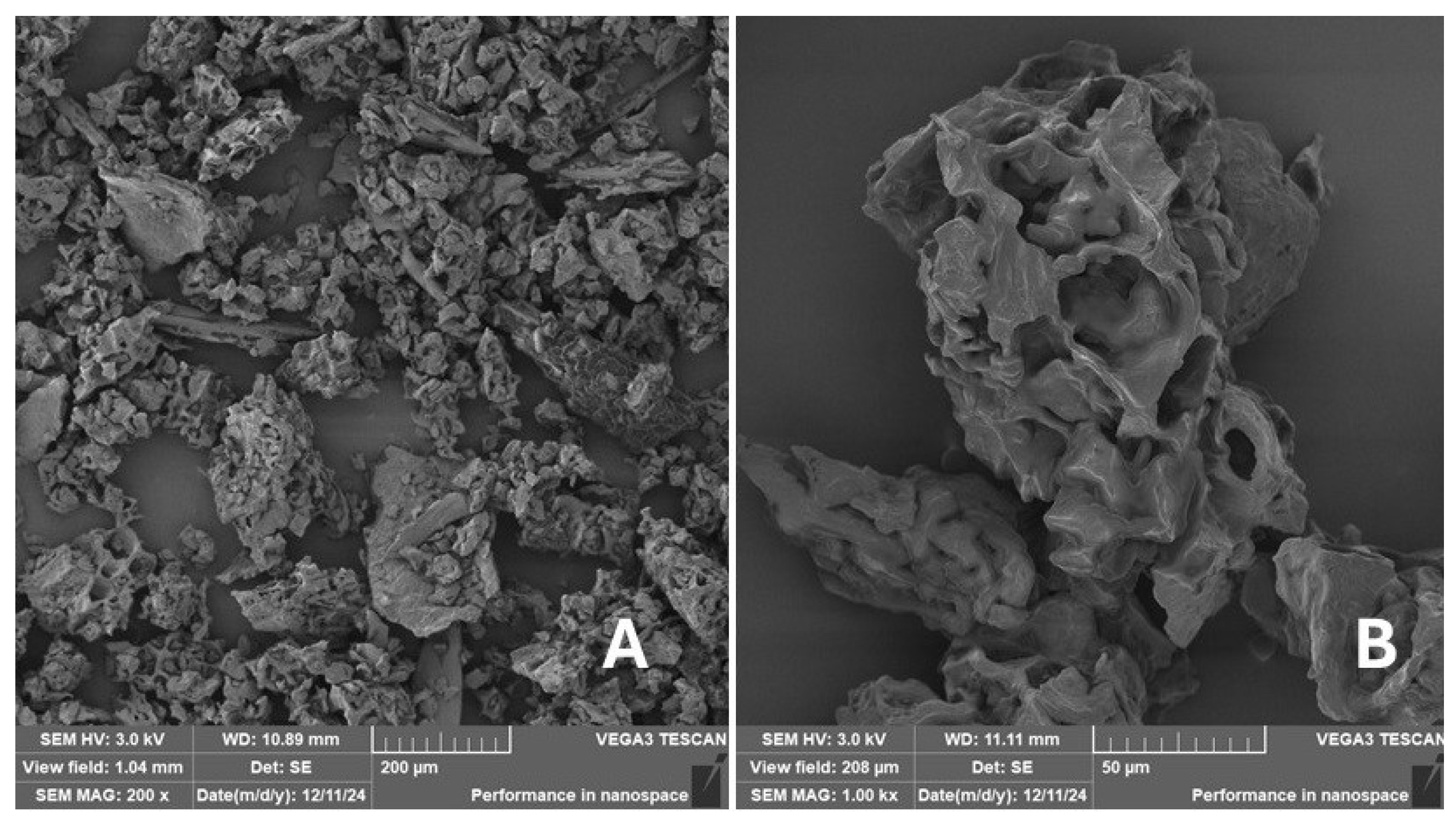

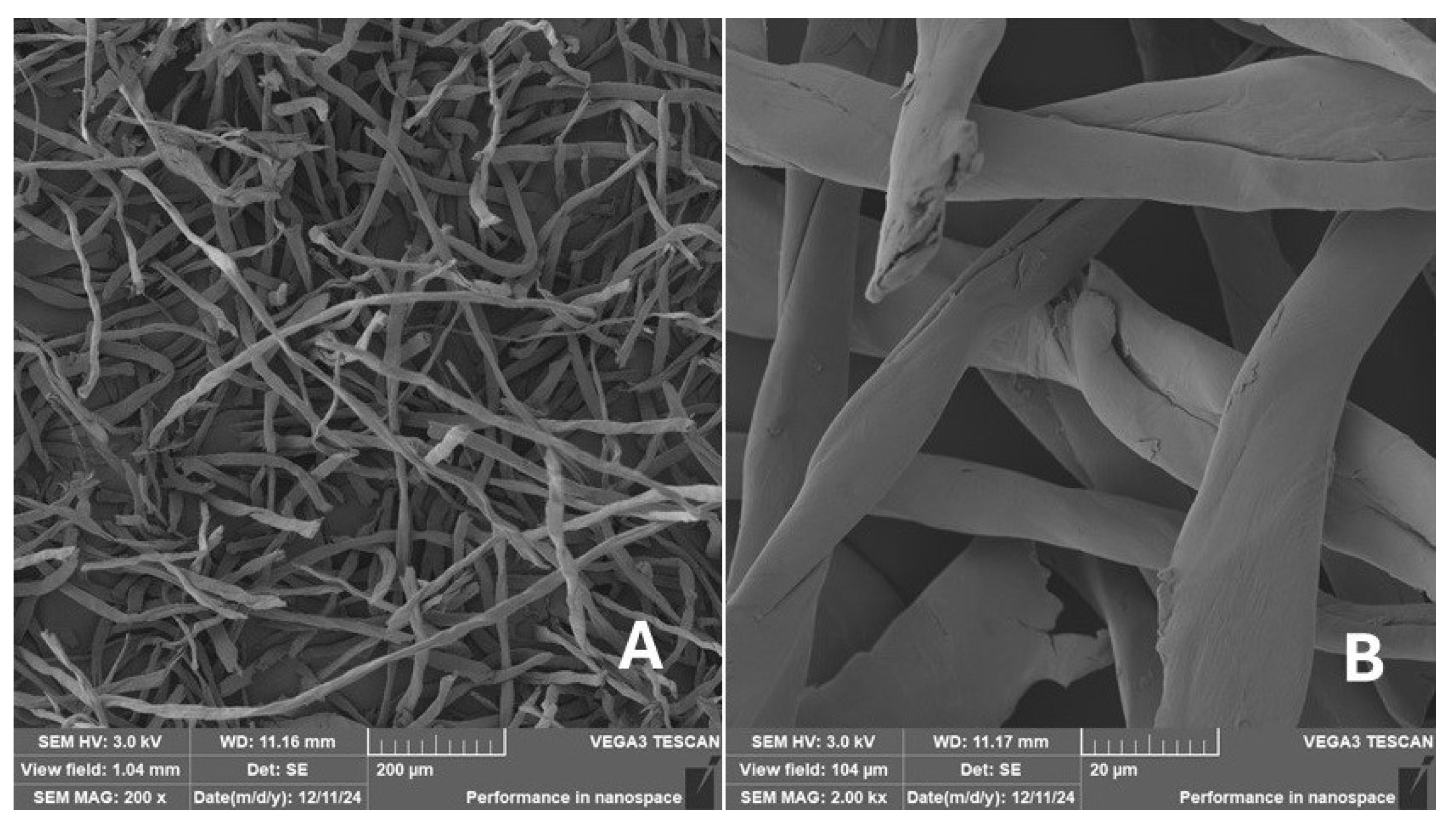

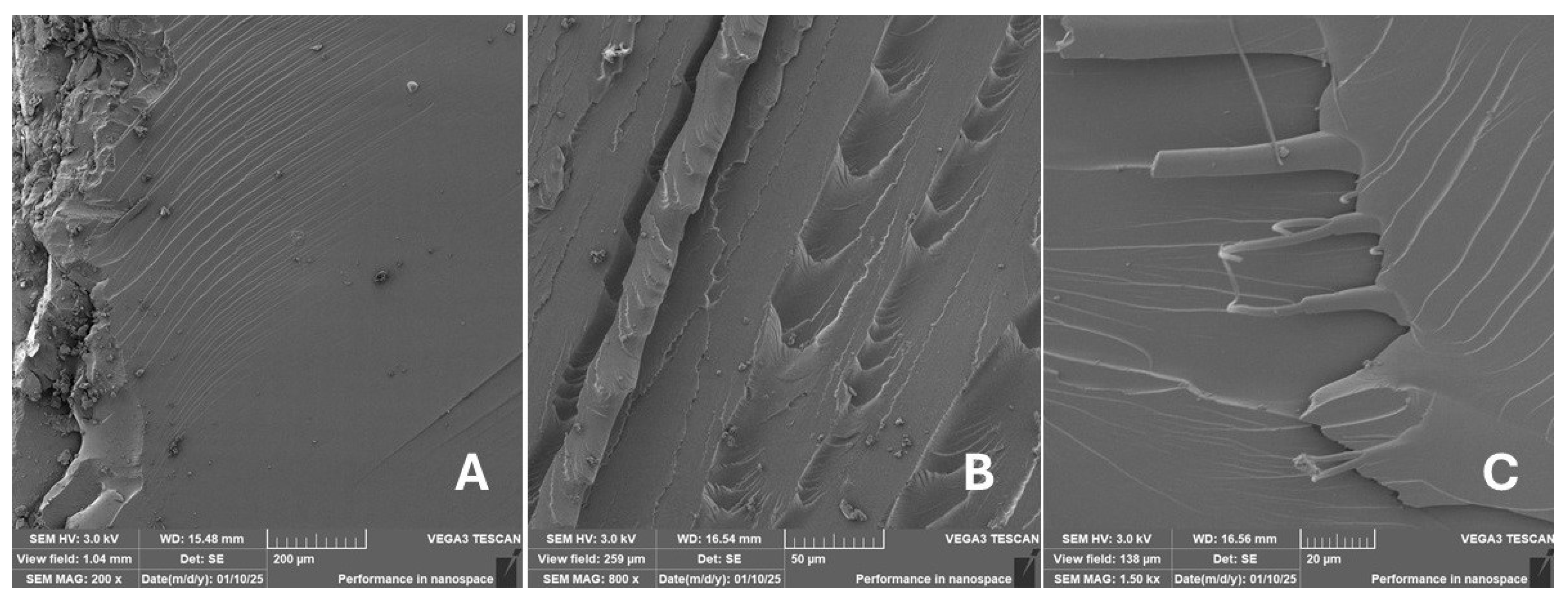

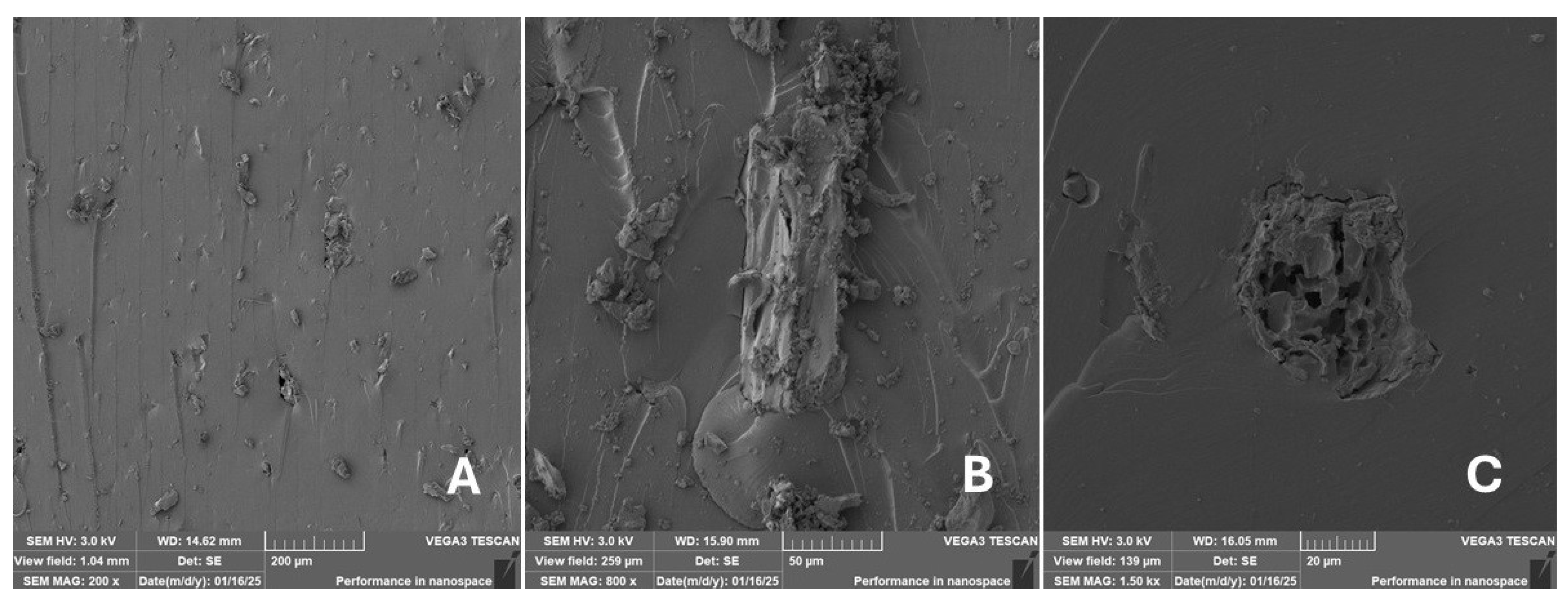

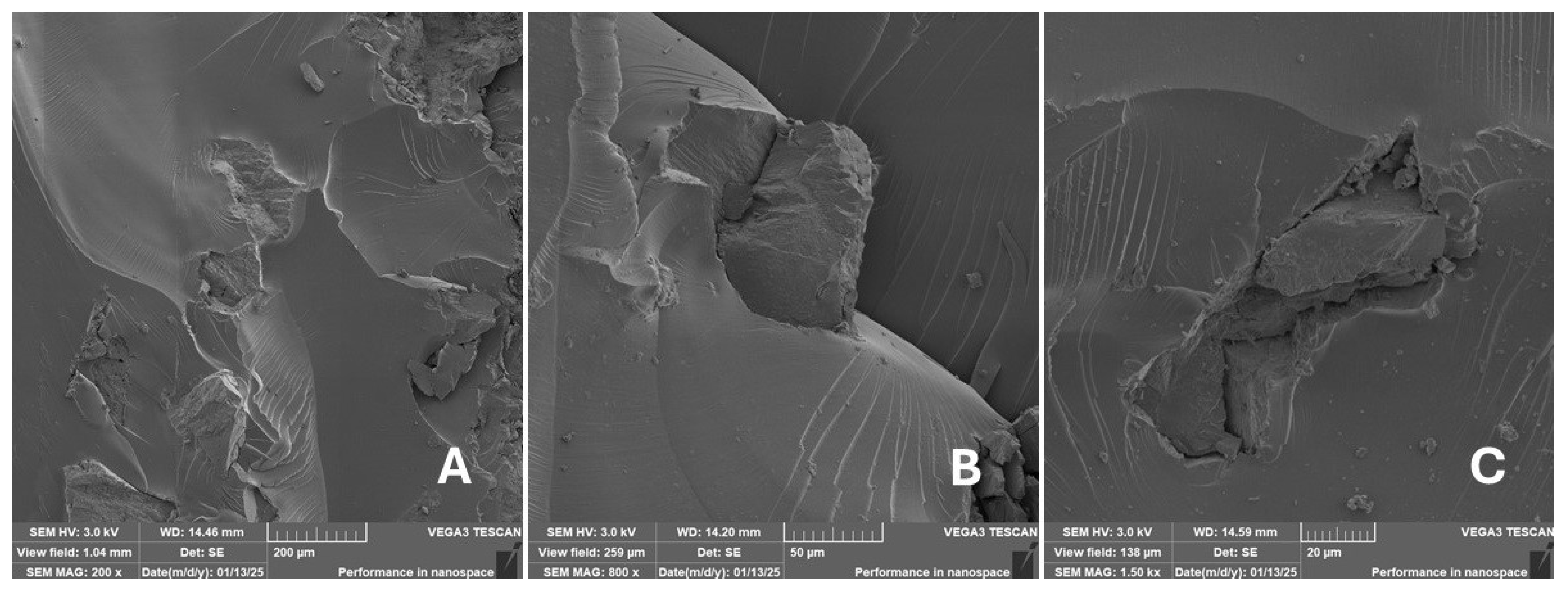

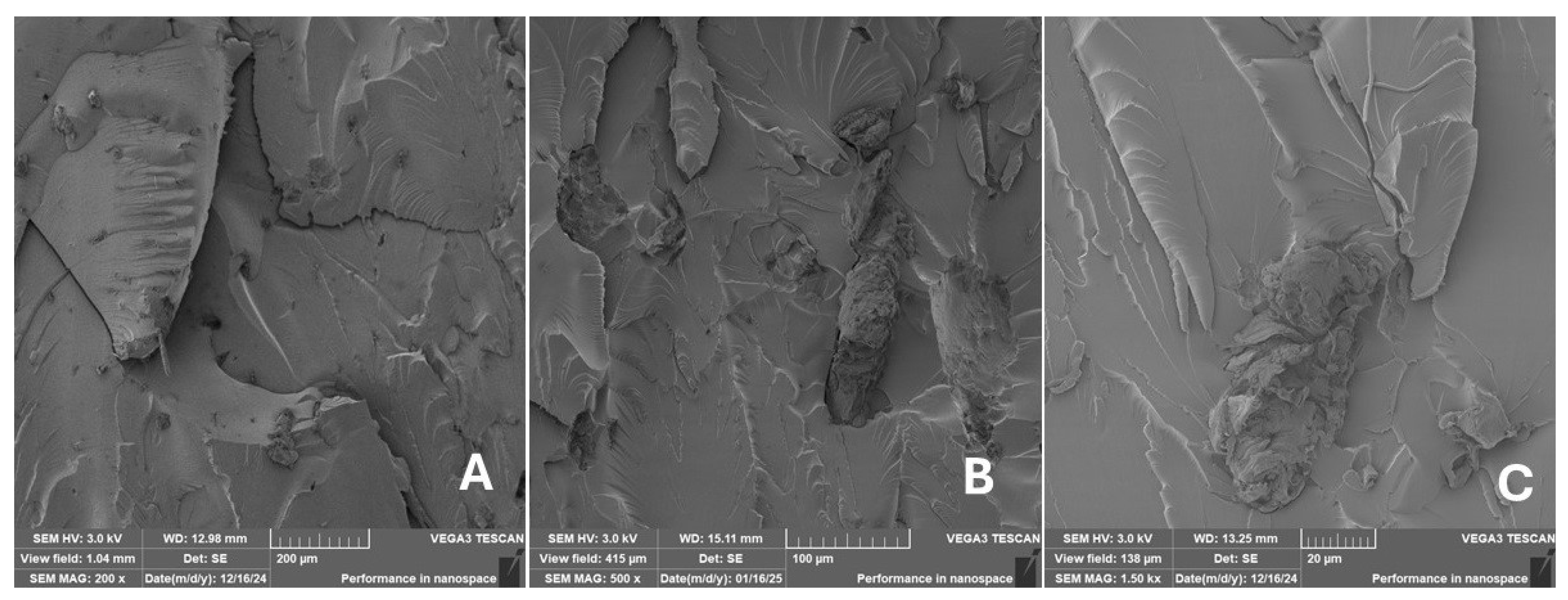

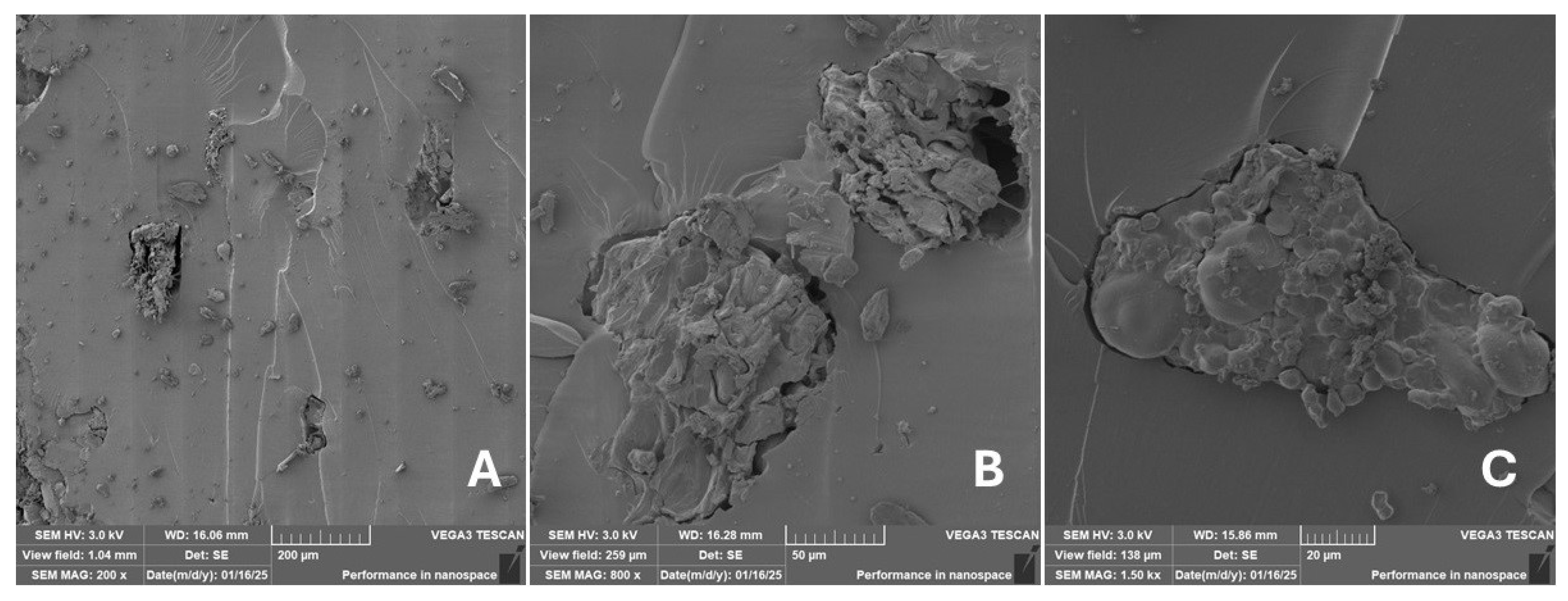

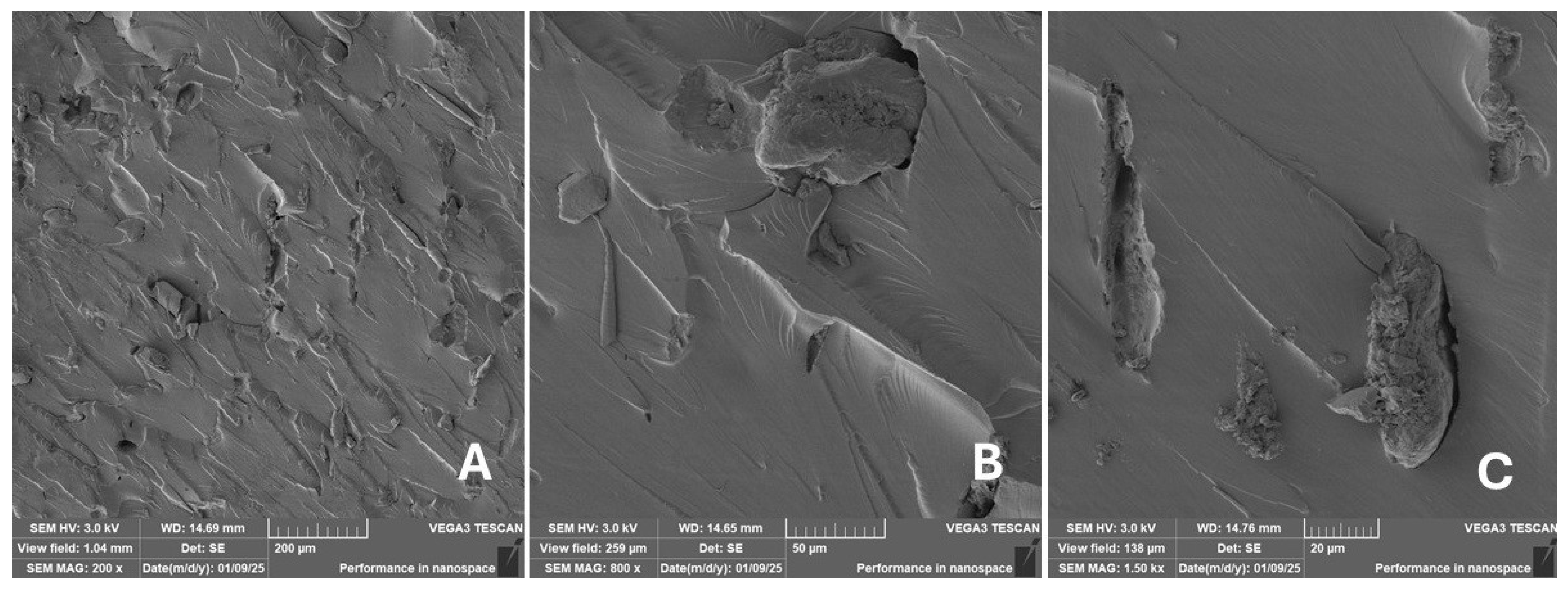

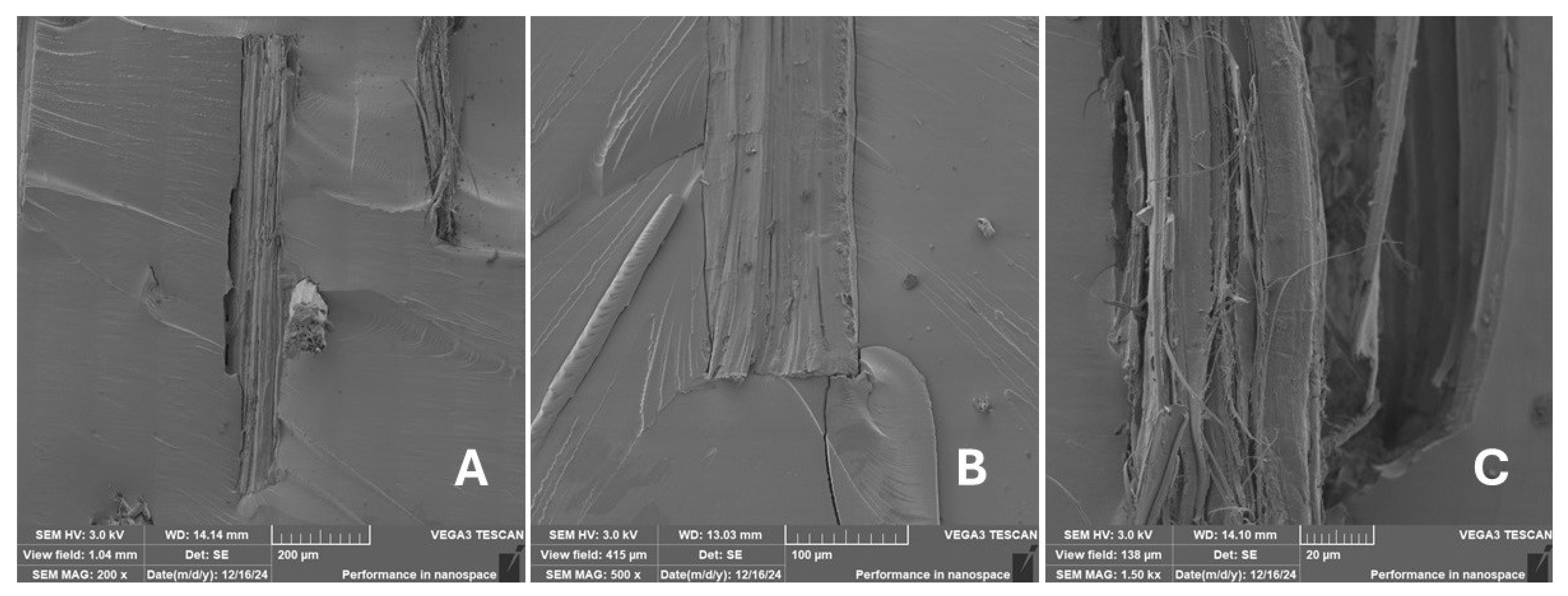

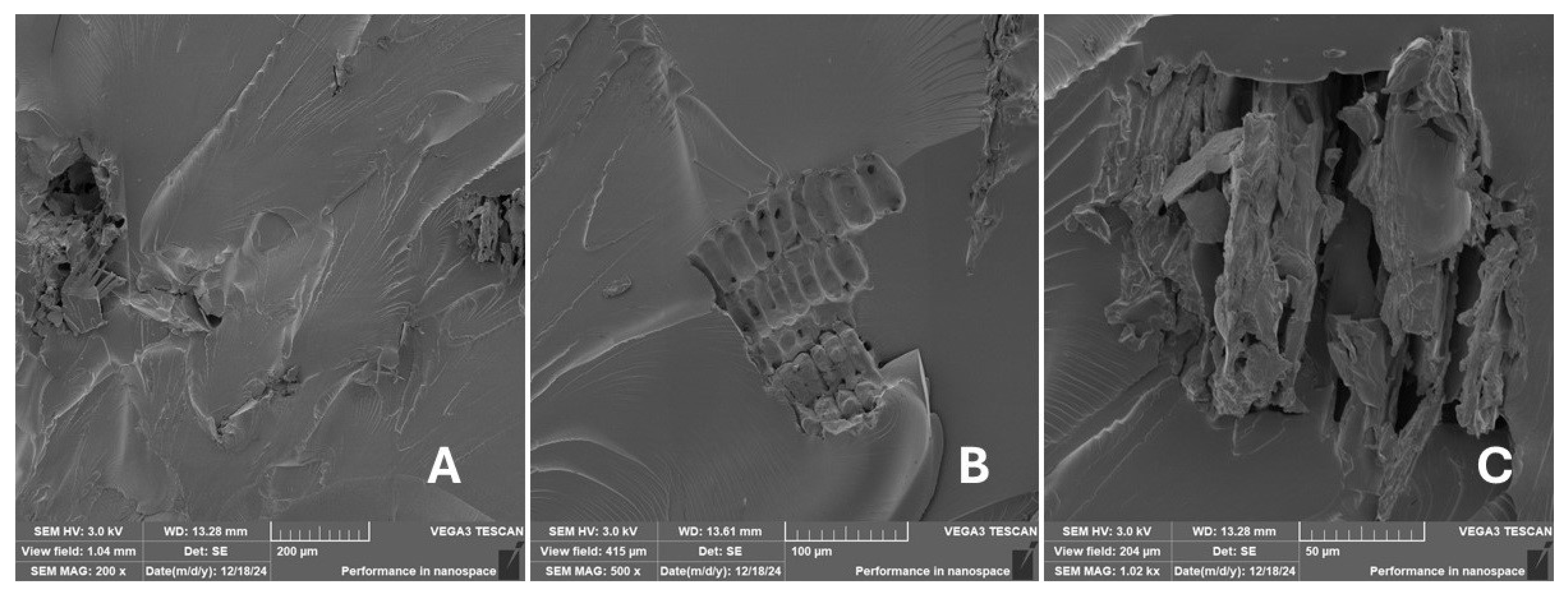

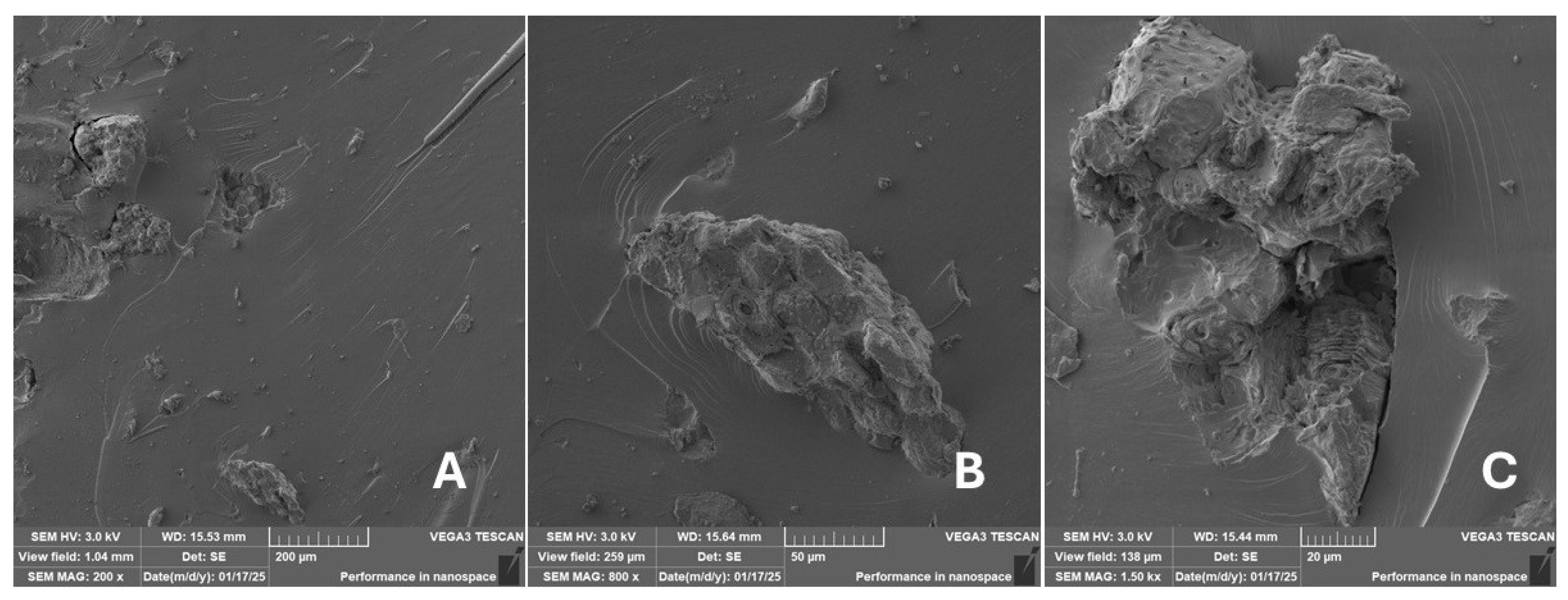

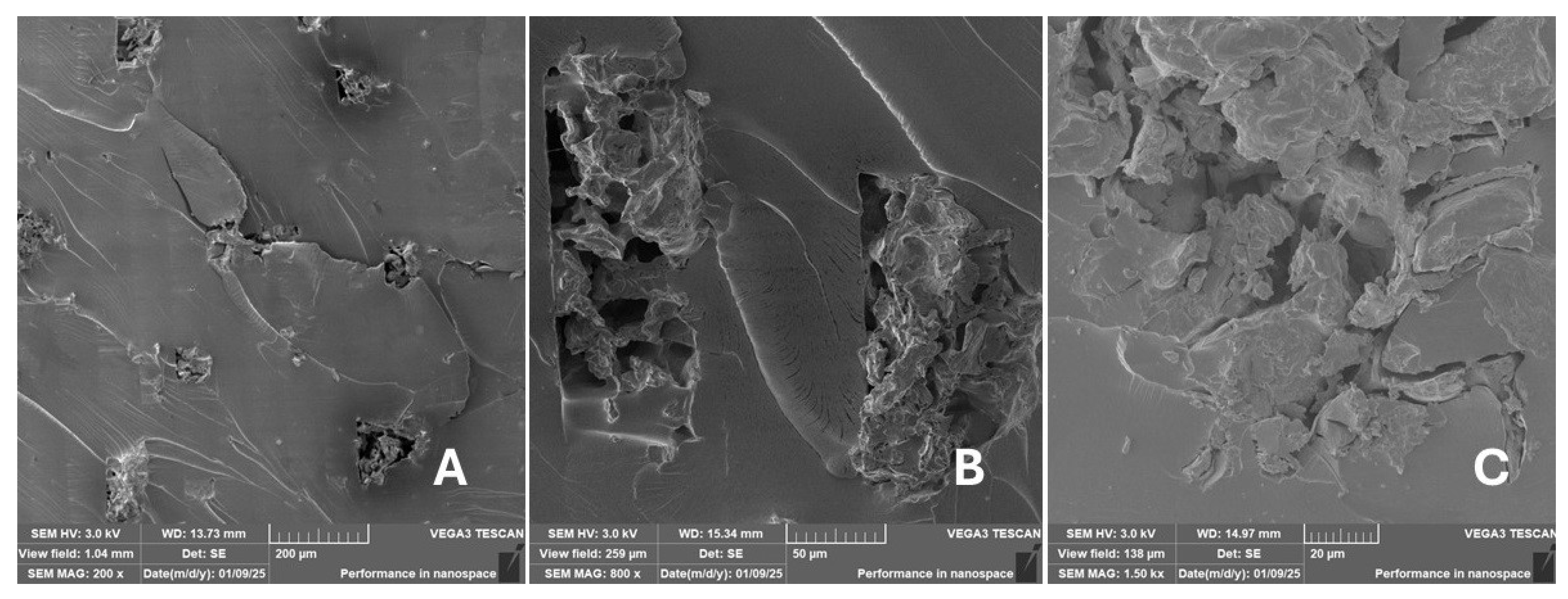

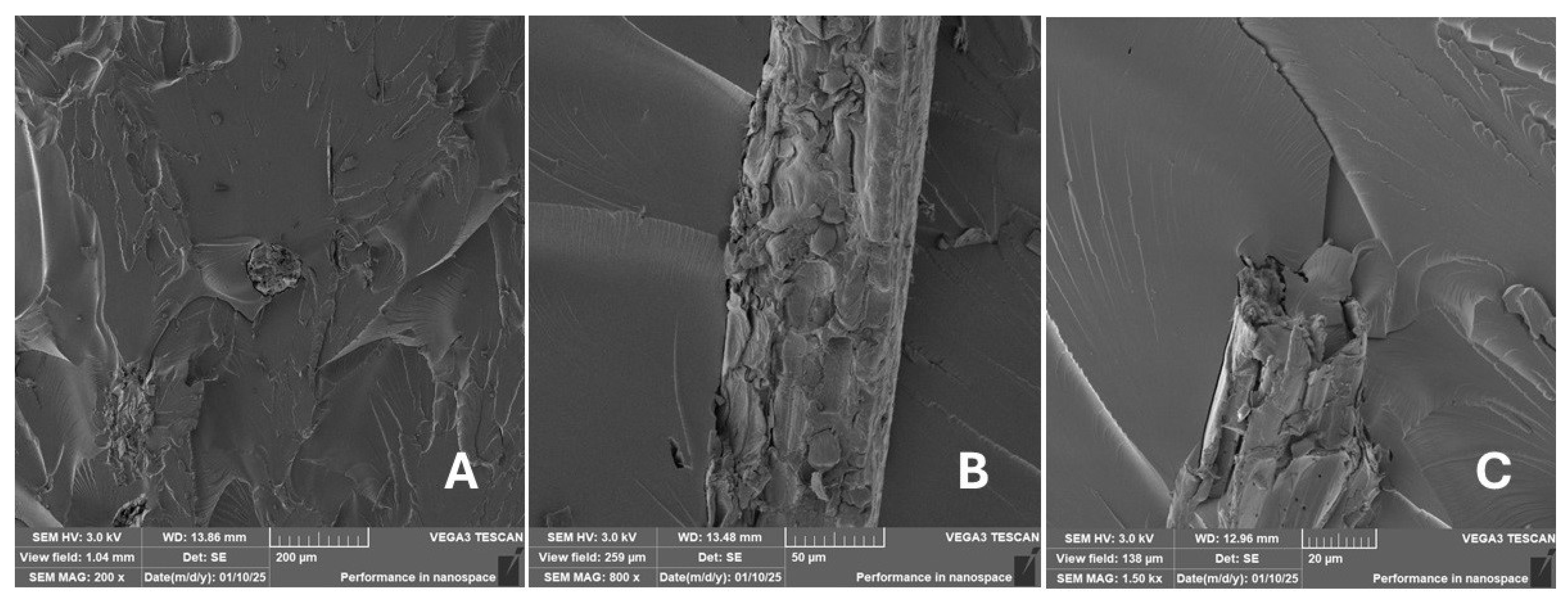

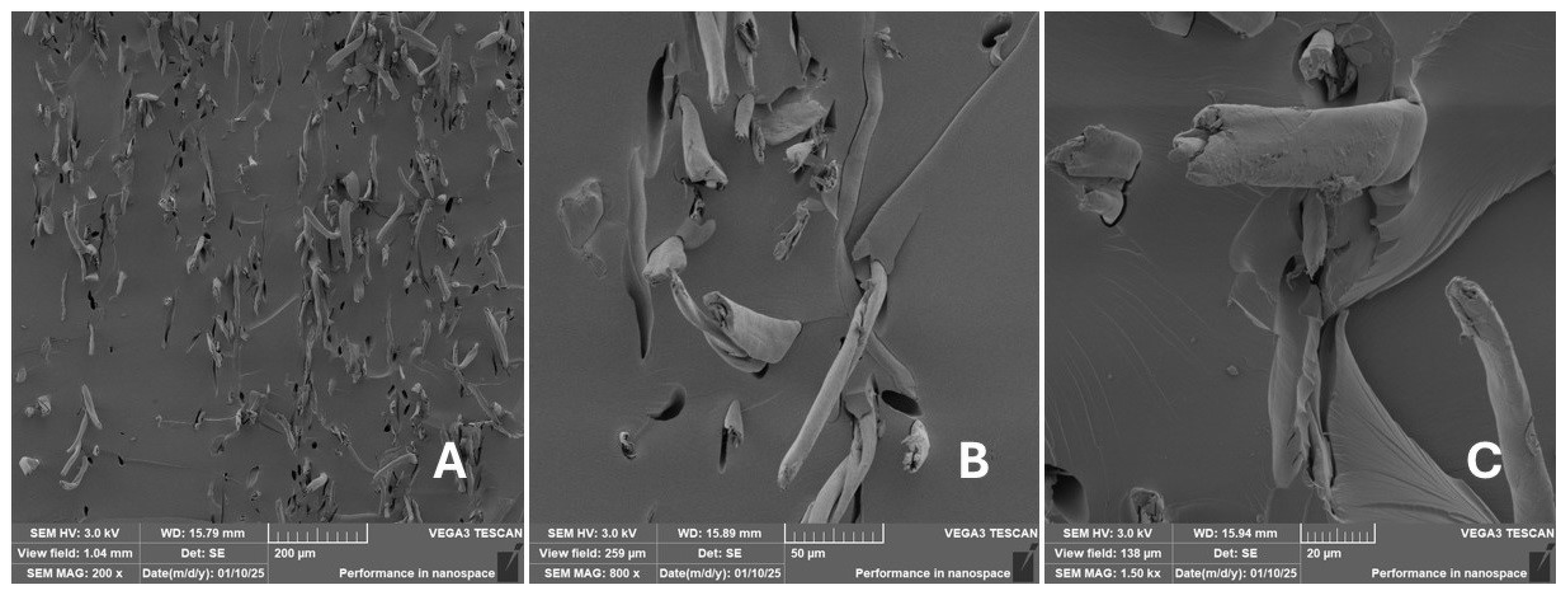

2.2.2. Scanning Electron Microscopy (SEM)

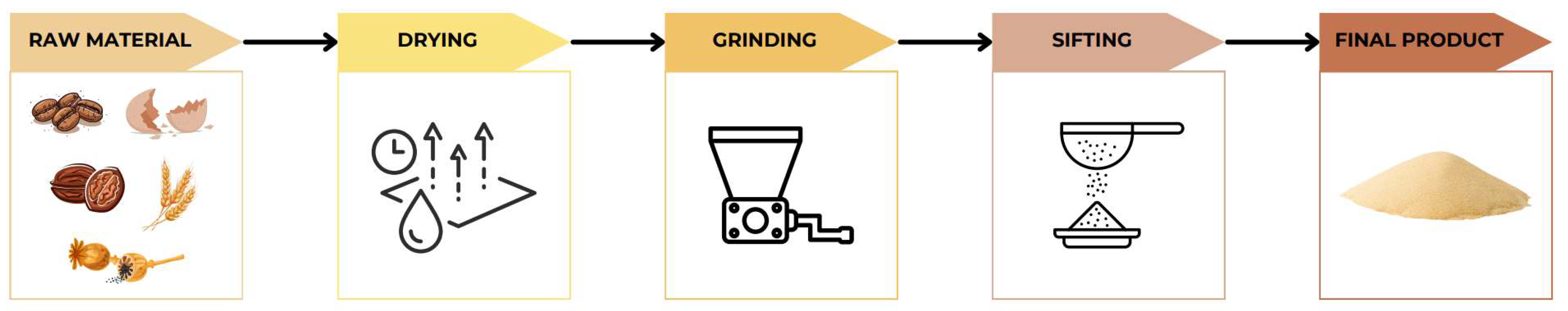

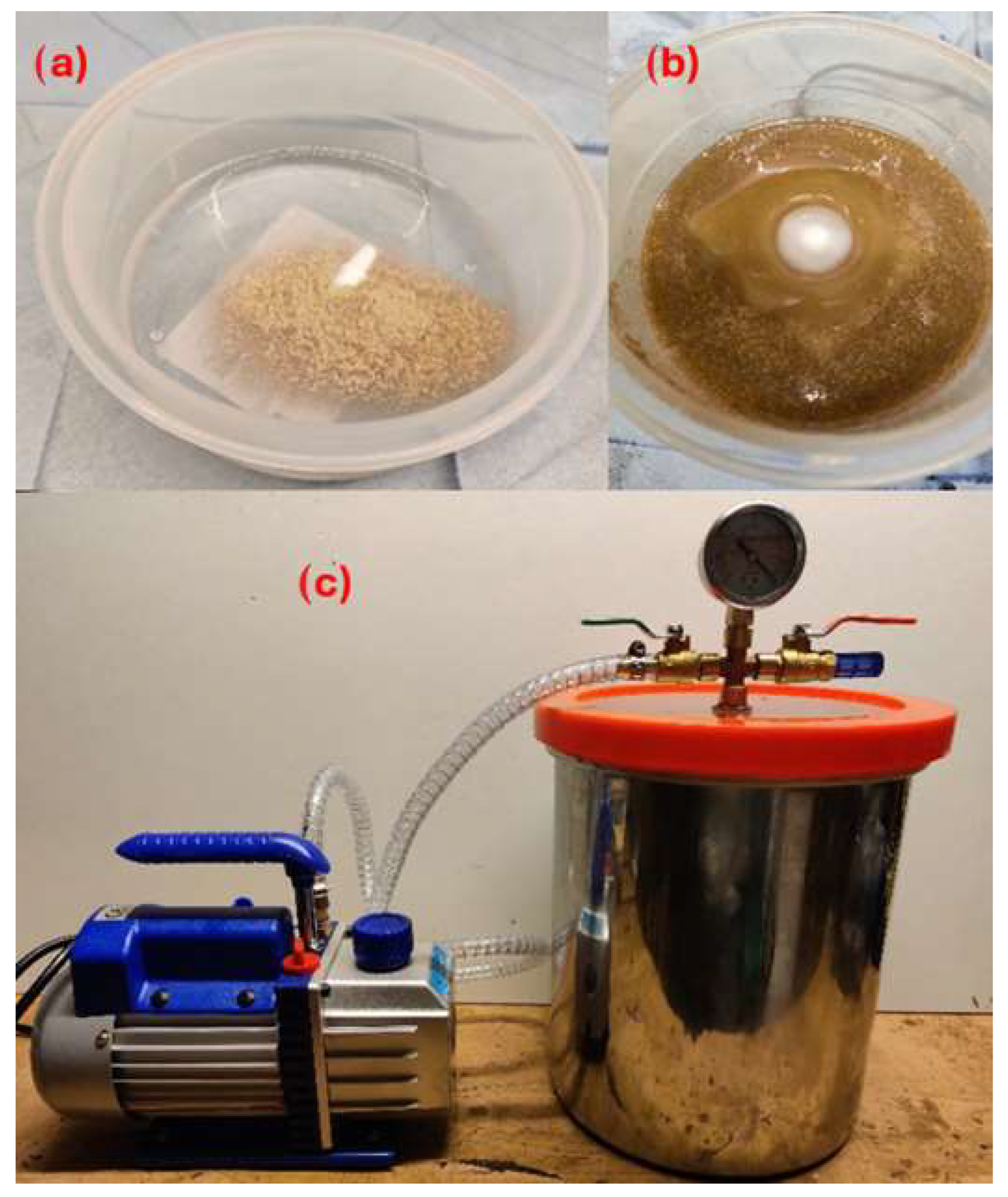

2.2.3. Preparation Process of the Composite Samples

2.2.4. Testing the Mechanical Properties

2.2.5. Scanning Electron Microscopy (SEM) Analysis

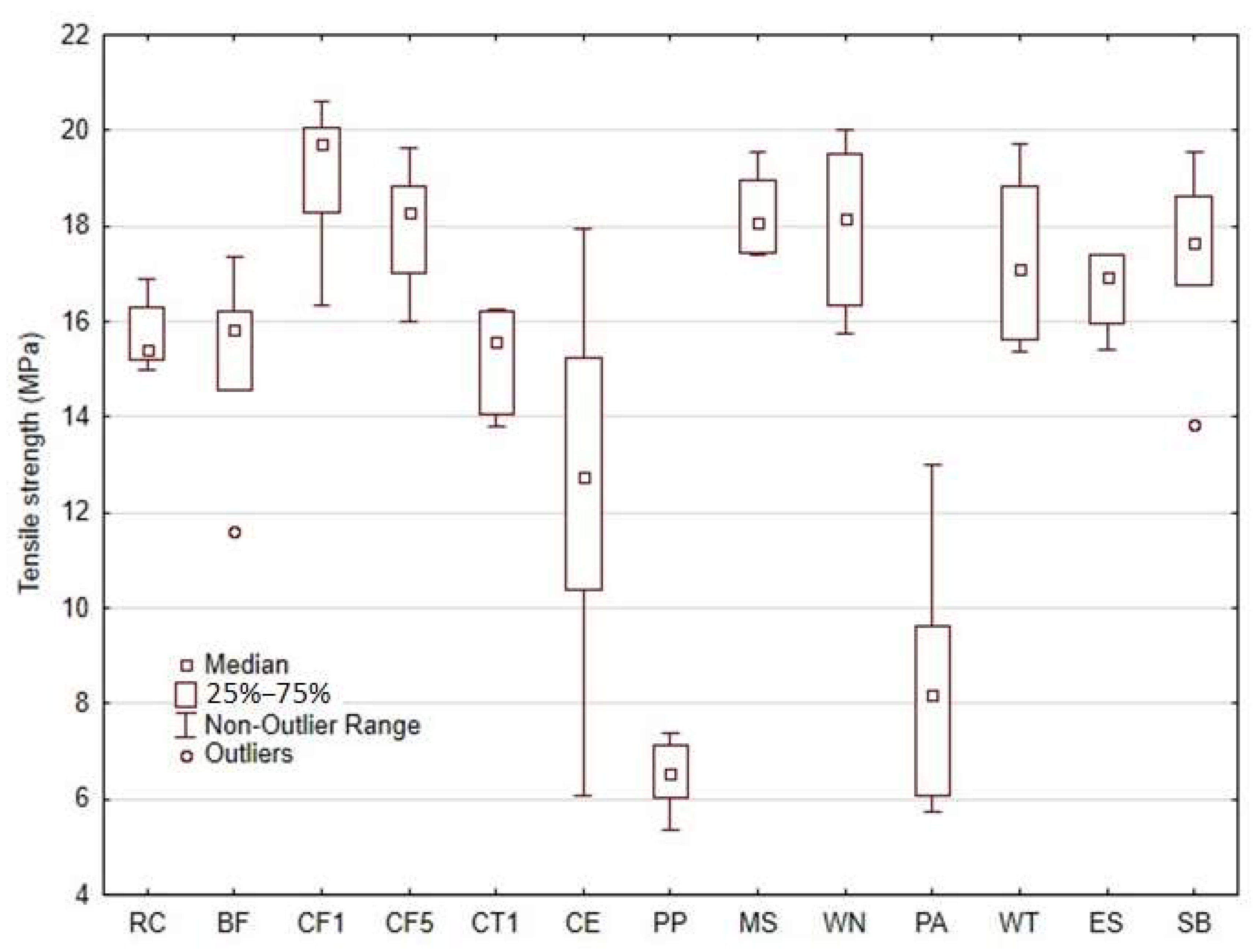

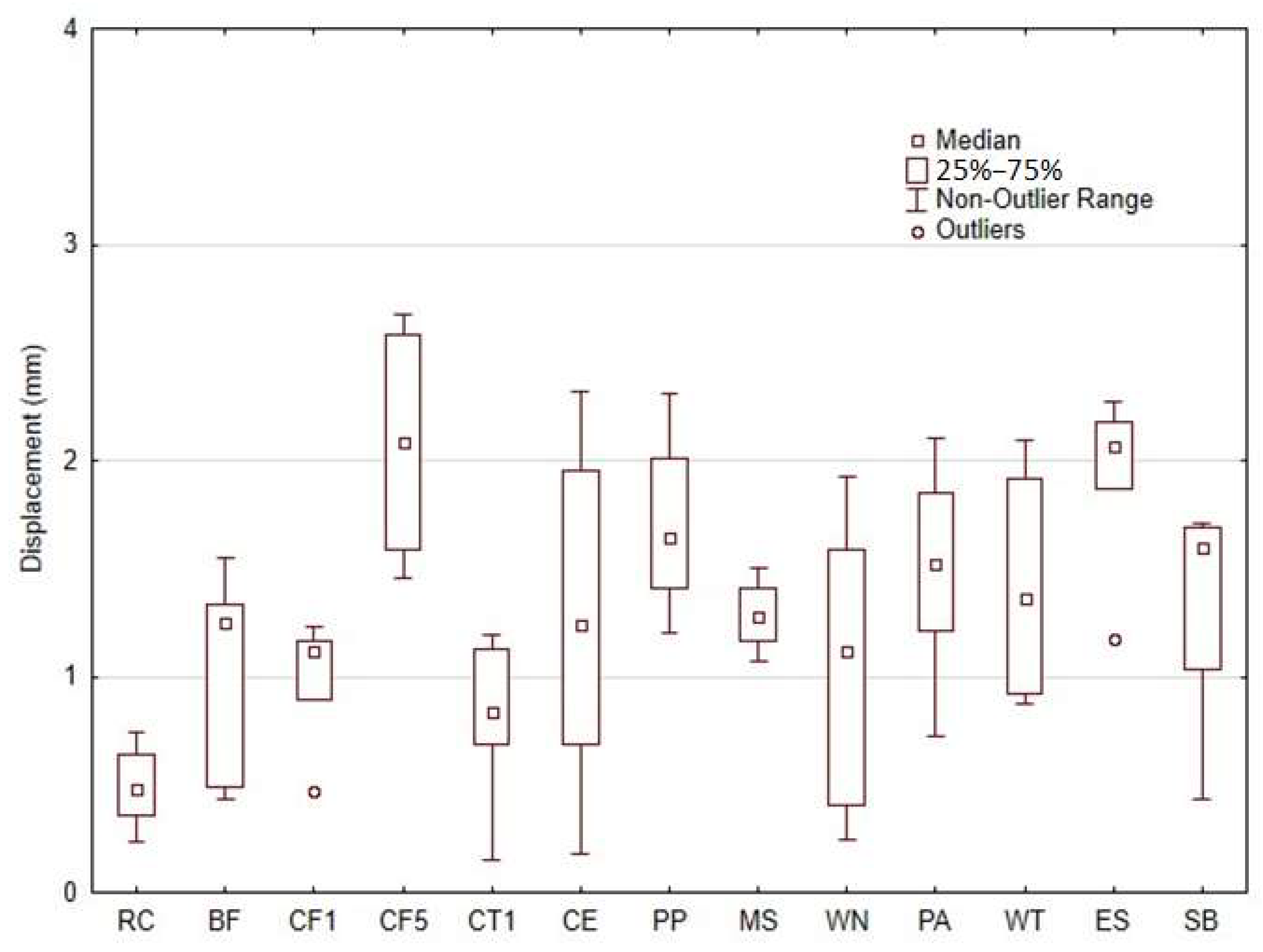

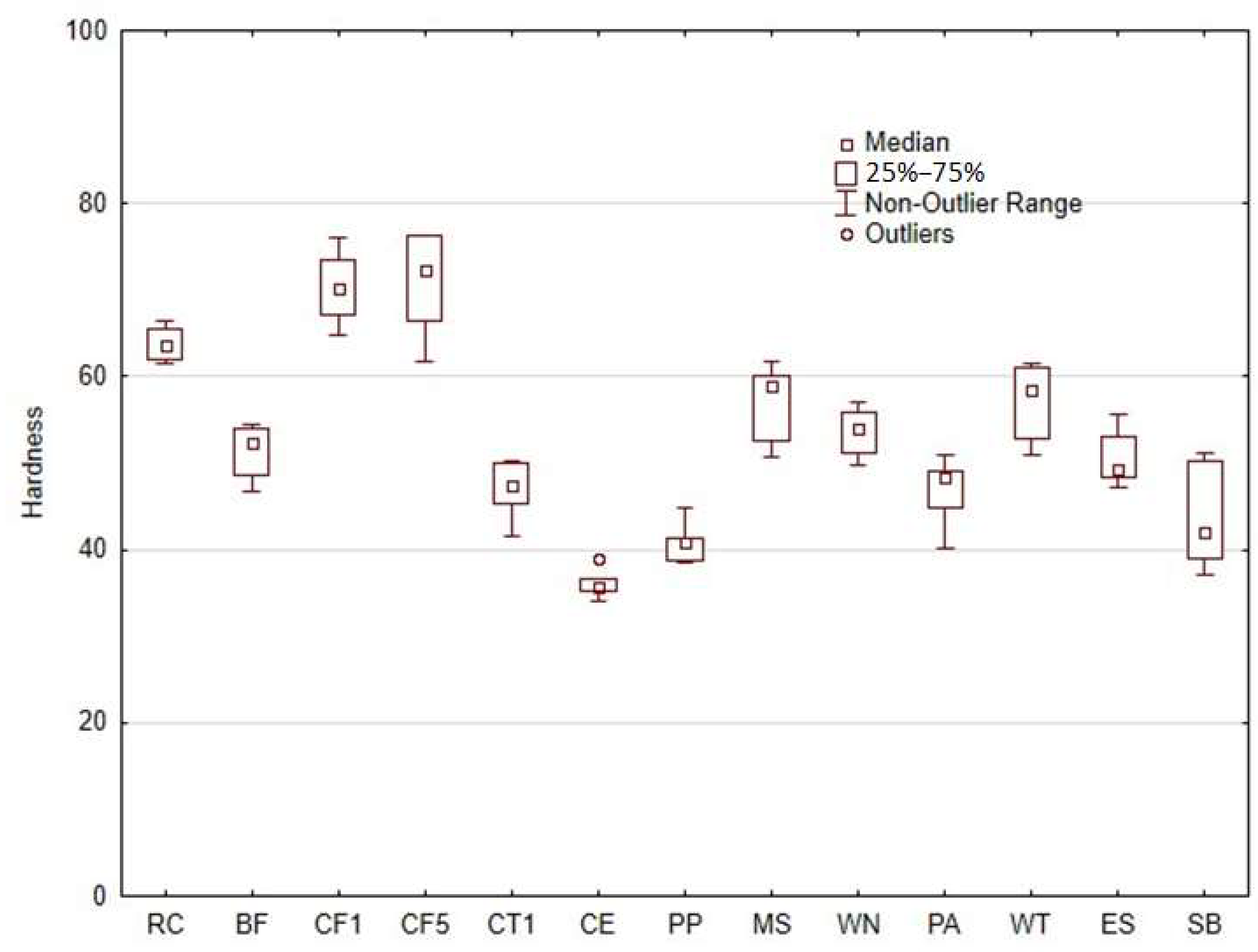

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Memarzadeh, A.; Safaei, B.; Tabak, A.; Sahmani, S.; Kizilors, C. Advancements in additive manufacturing of polymer matrix composites: A systematic review of techniques and properties. Mater. Today Commun. 2023, 36, 106449. [Google Scholar] [CrossRef]

- Jirků, P.; Urban, J.; Müller, M.; Kolář, V.; Chandan, V.; Svobodová, J.; Mishra, R.K.; Jamshaid, H. Evaluation of Mechanical Properties and Filler Interaction in the Field of SLA Polymeric Additive Manufacturing. Materials 2023, 16, 4955. [Google Scholar] [CrossRef] [PubMed]

- Niendorf, K.; Raeymaekers, B. Quantifying macro- and microscale alignment of carbon microfibers in polymer-matrix composite materials fabricated using ultrasound directed self-assembly and 3D-printing. Compos. Part A Appl. Sci. Manuf. 2020, 29, 105713. [Google Scholar] [CrossRef]

- Müller, M.; Valášek, P.; Kolář, V.; Šleger, V.; Gürdil, G.A.K.; Hromasová, M.; Hloch, S.; Moravec, J.; Pexa, M. Material Utilization of Cotton Post-Harvest Line Residues in Polymeric Composites. Polymers 2019, 11, 1106. [Google Scholar] [CrossRef]

- Dizon, J.R.C.; Espera, A.H., Jr.; Chen, Q.; Advincula, R.C. Mechanical characterization of 3D-printed polymers. Addit. Manuf. 2018, 20, 44–67. [Google Scholar] [CrossRef]

- Eng, H.; Maleksaeedi, S.; Yu, S.; Choong, Y.; Wiria, F.; Tan, C.; Su, P.; Wei, J. 3D Stereolithography of Polymer Composites Reinforced with Orientated Nanoclay. Procedia Eng. 2017, 216, 1–7. [Google Scholar] [CrossRef]

- Kabir, A.; Chowdhury, M.A.; Hossain, N.; Islam, M.A.; Aoyon, H.; Rana, M. Graphene reinforced 3D printed polymer nanocomposites for diverse applications. Results Chem. 2023, 6, 101197. [Google Scholar] [CrossRef]

- Nakamoto, T.; Kojima, S. Layered Thin Film Micro Parts Reinforced with Aligned Short Fibers in Laser Stereolithography by Applying Magnetic Field. J. Adv. Mech. Design., Syst. Manuf. 2012, 6, 849–858. [Google Scholar] [CrossRef]

- Islam, M.A.; Mobarak, M.H.; Rimon, M.I.H.; Al Mahmud, M.Z.; Ghosh, J.; Ahmed, M.M.S.; Hossain, N. Additive manufacturing in polymer research: Advances, synthesis, and applications. Polym. Test. 2024, 132, 108364. [Google Scholar] [CrossRef]

- Melentiev, R.; Melentieva, M.; Yu, N. Top 10 directions in lithography 3D printing. Bioprinting 2024, 40, e00343. [Google Scholar] [CrossRef]

- Shahar, F.S.; Sultan, M.T.H.; Safri, S.N.A.; Jawaid, M.; Abu Talib, A.R.; Basri, A.A.; Shah, A.U.M. Fatigue and impact properties of 3D printed PLA reinforced with kenaf particles. J. Mater. Res. Technol. 2022, 16, 461–470. [Google Scholar] [CrossRef]

- Bhagia, S.; Bornani, K.; Agrawal, R.; Satlewal, A.; Ďurkovič, J.; Lagaňa, R.; Bhagia, M.; Yoo, C.G.; Zhao, X.; Kunc, V.; et al. Critical review of FDM 3D printing of PLA biocomposites filled with biomass resources, characterization, biodegradability, upcycling and opportunities for biorefineries. Appl. Mater. Today 2021, 24, 101078. [Google Scholar] [CrossRef]

- Ayrilmis, N. Effect of layer thickness on surface properties of 3D printed materials produced from wood flour/PLA filament. Polym. Test. 2018, 71, 163–166. [Google Scholar] [CrossRef]

- Sagias, V.D.; Giannakopoulos, K.L.; Stergiou, C. Mechanical properties of 3D printed polymer specimens. Procedia Struct. Integr. 2018, 10, 85–90. [Google Scholar] [CrossRef]

- Wu, H.; Fahy, W.P.; Kim, S.; Kim, H.; Zhao, N.; Pilato, L.; Kafi, A.; Bateman, S.; Koo, J. Recent developments in polymers/polymer nanocomposites for additive manufacturing. Prog. Mater. Sci. 2020, 111, 100638. [Google Scholar] [CrossRef]

- Zhang, S.; Bhagia, S.; Li, M.; Meng, X.; Ragauskas, A.J. Wood-reinforced composites by stereolithography with the stress whitening behavior. Mater. Des. 2021, 206, 109773. [Google Scholar] [CrossRef]

- Quan, H.; Zhang, T.; Xu, H.; Luo, S.; Nie, J.; Zhu, X. Photo-curing 3D printing technique and its challenges. Bioact. Mater. 2020, 5, 110–115. [Google Scholar] [CrossRef]

- Mukhtarkhanov, M.; Perveen, A.; Talamona, D. Application of Stereolithography Based 3D Printing Technology in Investment Casting. Micromachines 2020, 11, 946. [Google Scholar] [CrossRef]

- Nagaraju, D.S.; Krupakaran, R.L.; Sripadh, C.; Nitin, G.; Emmanuel, G.J.J. Mechanical properties of 3D printed specimen using FDM (Fused deposition modelling) and SLA (Stereolithography) technologies. Mater. Today Proc. 2023, 1–15. [Google Scholar] [CrossRef]

- Shah, D.M.; Morris, J.; Plaisted, T.A.; Amirkhizi, A.V.; Hansen, C.J. Highly filled resins for DLP-based printing of low density, high modulus materials. Addit. Manuf. 2021, 37, 101736. [Google Scholar] [CrossRef]

- Zhang, X.; Jiang, X.N.; Sun, C. Micro-stereolithography of polymeric and ceramic microstructures. Sens. Actuators A Phys. 1999, 77, 149–156. [Google Scholar] [CrossRef]

- Moumen, A.E.; Tarfaoui, M.; Lafdi, K. Additive manufacturing of polymer composites: Processing and modeling approaches. Compos.Part B. Eng. 2019, 171, 166–182. [Google Scholar] [CrossRef]

- Roques-Carmes, T.; Marchal, P.; Gigante, A.; Corbel, S. Stereolithography fabrication and characterization of syntactic foams containing hollow glass microspheres. Russ. Chem. Rev. 2009, 78, 375–386. [Google Scholar] [CrossRef]

- Arora, N.; Dua, S.; Singh, V.K.; Singh, S.K.; Senthilkumar, T. A comprehensive review on fillers and mechanical properties of 3D printed polymer composites. Mater. Today Commun. 2024, 40, 109617. [Google Scholar] [CrossRef]

- Yang, T.; Xiong, X.; Venkataraman, M.; Mishra, R.; Novák, J.; Militký, J. Investigation on sound absorption properties of aerogel/polymer nonwovens. J. Text. Inst. 2018, 110, 196–201. [Google Scholar] [CrossRef]

- Palacio, A.; Baniasadi, M.; Kardel, K. Investigating Mechanical Properties of Fabricated Carbon-Fiber-Reinforced Composites via LCD Additive Manufacturing. Polymers 2023, 15, 4556. [Google Scholar] [CrossRef] [PubMed]

- Lu, L.; Zhang, Z.; Xu, J.; Pan, Y. 3D-printed polymer composites with acoustically assembled multidimensional filler networks for accelerated heat dissipation. Compos.Part B Eng. 2019, 174, 106991. [Google Scholar] [CrossRef]

- Orji, B.O.; Thie, C.; Baker, K.; Maughan, M.R.; McDonald, A.G. Wood fiber-sodium silicate mixtures for additive manufacturing of composite materials. Eur. J. Wood Wood Prod. 2023, 81, 45–58. [Google Scholar] [CrossRef]

- Taylor, A.A.; Freeman, E.; Ploeg, M. Regulatory developments and their impacts to the nano-industry: A case study for nano-additives in 3D printing. Ecotoxicol. Environ. Saf. 2021, 207, 111458. [Google Scholar] [CrossRef]

- Romero-Ocaña, I.; Delgado, N.; Molina, S.I. Biomass waste from rice and wheat straw for developing composites by stereolithography additive manufacturing. Ind. Crops Prod. 2022, 189, 115832. [Google Scholar] [CrossRef]

- Boey, J.Y.; Lee, C.K.; Tay, G.S. Factors Affecting Mechanical Properties of Reinforced Bioplastics: A Review. Polymers 2022, 14, 3737. [Google Scholar] [CrossRef]

- Romero-Ocaña, I.; Molina, S.I. Cork photocurable resin composite for stereolithography (SLA): Influence of cork particle size on mechanical and thermal properties. Add. Manuf. 2022, 51, 102586. [Google Scholar] [CrossRef]

- Quagliato, L.; Kim, S.Y.; Ryu, S.C. Quasi-ductile to brittle transitional behavior and material properties gradient for additively manufactured SLA acrylate. Mater. Lett. 2022, 329, 133121. [Google Scholar] [CrossRef]

- Vázquez-Hernández, C.; Ramos-Galicia, L.; Velasco-Santos, C.; Bertolacci, L.; Zahid, M.; Yañez-Limón, J.M.; Perotto, G.; Martinez-Hernandez, A.L. Effect of keratin-rich fibers from rabbit hair in two polymers processed using additive manufacturing: FDM and SLA. J. Manuf. Process. 2024, 120, 1104–1114. [Google Scholar] [CrossRef]

- Manapat, J.Z.; Chen, Q.; Ye, P.; Advincula, R.C. 3D Printing of Polymer Nanocomposites via Stereolithography. Macromol. Mater. Eng. 2017, 302, 1600553. [Google Scholar] [CrossRef]

- Miturska-Barańska, I.; Rudawska, A.; Sobotova, L.; Badida, M.; Olewnik-Kruszkowska, E.; Müller, M.; Hromasová, M. Analysis of Acoustic Absorption Coefficients and Characterization of Epoxy Adhesive Compositions Based on the Reaction Product of Bisphenol A with Epichlorohydrin Modified with Fillers. Materials 2024, 17, 4452. [Google Scholar] [CrossRef]

- Kariz, M.; Sernek, M.; Obućina, M.; Kuzman, M.K. Effect of wood content in FDM filament on properties of 3D printed parts. Mater. Today Commun. 2018, 14, 135–140. [Google Scholar] [CrossRef]

- Palaganas, N.B.; Mangadlao, J.D.; de Leon, A.C.C.; Palaganas, J.O.; Pangilinan, K.D.; Lee, Y.J.; Advincula, R.C. 3D Printing of Photocurable Cellulose Nanocrystal Composite for Fabrication of Complex Architectures via Stereolithography. ACS Appl. Mater. Interfaces 2017, 9, 34314–34324. [Google Scholar] [CrossRef]

- Feng, X.; Yang, Z.; Chmely, S.; Wang, Q.; Wang, S.; Xie, Y. Lignin-coated cellulose nanocrystal filled methacrylate composites prepared via 3D stereolithography printing: Mechanical reinforcement and thermal stabilization. Carbohydr. Polym. 2017, 169, 272–281. [Google Scholar] [CrossRef]

- Zhang, S.; Li, M.; Hao, N.; Ragauskas, A.J. Stereolithography 3D Printing of Lignin-Reinforced Composites with Enhanced Mechanical Properties. ACS Omega 2019, 4, 20197–201204. [Google Scholar] [CrossRef]

- Mallick, P.K. Particulate Filled and Short Fiber Reinforced Polymer Composites. In Comprehensive Composite Materials II; Elsevier: Amsterdam, The Netherlands, 2018; pp. 360–400. [Google Scholar] [CrossRef]

- Debnath, S.; Ranade, R.; Wunder, S.; Mccool, J.; Boberick, K.; Baran, G. Interface effects on mechanical properties of particle-reinforced composites. Dent. Mater. 2004, 20, 677–686. [Google Scholar] [CrossRef] [PubMed]

- Ruggiero, A.; Valášek, P.; Müller, M.; D’Amato, R. Tribological investigation of epoxy/seed particle composite obtained from residues of processing Jatropha Curcas L. Fruits. Compos. Part B Eng. 2019, 167, 654–667. [Google Scholar] [CrossRef]

- Muller, M.; Choteborsky, R.; Valasek, P.; Hloch, S. Unusual possibility of wear resistence increase research in the sphere of soil cultivation. Tech. Vjesn.-Tech. Gaz. 2013, 20, 641–646. [Google Scholar]

- Roy, M.; Tran, P.; Dickens, T.; Quaife, B.D. Effects of geometry constraints and fiber orientation in field assisted extrusion-based processing. Addit. Manuf. 2020, 32, 101022. [Google Scholar] [CrossRef]

- Jamshaid, H.; Mishra, R.; Basra, S.; Rajput, A.W.; Hassan, T.; Petru, M.; Choteborsky, R.; Muller, M. Lignocellulosic Natural Fiber Reinforced Bisphenol F Epoxy Based Bio-composites: Characterization of Mechanical Electrical Performance. J. Natur. Fibers 2022, 19, 3317–3332. [Google Scholar] [CrossRef]

- Kalia, S.; Kaith, B.S.; Kaur, I. Pretreatments of natural fibers and their application as reinforcing material in polymer composites—A review. Polym. Eng. Sci. 2009, 49, 1253–1272. [Google Scholar] [CrossRef]

- Cai, M.; Takagi, H.; Nakagaito, A.N.; Katoh, M.; Ueki, T.; Waterhouse, G.I.; Li, Y. Influence of alkali treatment on internal microstructure and tensile properties of abaca fibers. Ind. Crops Prod. 2015, 65, 27–35. [Google Scholar] [CrossRef]

- Agarwal, B.; Broutman, L.; Chandrashekhara, K. Analysis and Performance of Fiber Composites, 3rd ed; Wiley: New Delhi, India, 2006. [Google Scholar]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Cha, J.; Jun, G.H.; Park, J.K.; Kim, J.C.; Ryu, H.J.; Hong, S.H. Improvement of modulus, strength and fracture toughness of CNT/Epoxy nanocomposites through the functionalization of carbon nanotubes. Compos. Part B Eng. 2017, 129, 169–179. [Google Scholar] [CrossRef]

- Yadollahi, A.; Shamsaei, N. Additive manufacturing of fatigue resistant materials: Challenges and opportunities. Int. J. Fatigue 2017, 98, 14–31. [Google Scholar] [CrossRef]

- Hasanah, U.; Setiaji, B.; Triyono, T.; Anwar, C. The Chemical Composition and Physical Properties of the Light and Heavy Tar Resulted from Coconut Shell Pyrolysis. J. Pure Appl. Chem. Res. 2012, 1, 26–32. [Google Scholar] [CrossRef]

- Markandan, K.; Lai, C.Q. Enhanced mechanical properties of 3D printed graphene-polymer composite lattices at very low graphene concentrations. Compos. Part A Appl. Sci. Manuf. 2020, 129, 105726. [Google Scholar] [CrossRef]

- Hassan, T.; Jamshaid, H.; Mishra, R.; Khan, M.Q.; Petru, M.; Tichy, M.; Muller, M. Factors Affecting Acoustic Properties of Natural-Fiber-Based Materials and Composites: A Review. Textiles 2021, 1, 55–85. [Google Scholar] [CrossRef]

| Matrix | Type of Filler | Proportion of Filler to Matrix [%wt.] | Specimen ID |

|---|---|---|---|

| Clear UV resin | - | - | RC |

| Clear UV resin | Cotton | 1.4 | CT1 |

| Clear UV resin | Eggshells | 3.0 | ES |

| Clear UV resin | Wheat | 3.0 | WT |

| Clear UV resin | Poppy | 3.0 | PP |

| Clear UV resin | Palm | 3.0 | PA |

| Clear UV resin | Banana | 2.0 | BF |

| Clear UV resin | Spruce tree | 1.3 | SB |

| Clear UV resin | Walnut | 1.3 | WN |

| Clear UV resin | Miscanthus | 1.3 | MS |

| Clear UV resin | Coffee grounds | 1.3 | CE |

| Clear UV resin | Cotton flakes | 5.0 | CF5 |

| Clear UV resin | Cotton flakes | 1.0 | CF1 |

| Printing Parameters | Value |

|---|---|

| Height of layer | 0.05 mm |

| Time of exposure | 2 s |

| Antialiasing | 1 |

| Distance of lifting | 8 mm |

| Speed of lifting | 2 mm/s |

| Time of bottom exposure | 23 s |

| Count of bottom layer | 6 |

| Distance of retract | 8 mm |

| Speed of restarting | 3 mm/s |

| Filler Designation | Filler Type | Arithmetic Mean (µm) | Median (µm) | Mode (µm) |

|---|---|---|---|---|

| CT—Cotton | Particle | 25.0 | 18.0 | 15.0 |

| ES—Eggshells | Particle | 254.0 | 8.4 | 7.8 |

| WT—Wheat | Particle | 45.4 | 43.0 | 32.0 |

| PP—Poppy | Particle | 106.9 | 87.0 | 43.0 |

| PA—Palm | Particle | 32.1 | 28.0 | 23.0 |

| BF-L—Banana | Short fibres | 1449.6 | 1535.0 | 1807.0 |

| BF-D—Banana | Particle | 127.0 | 121.0 | 90.0 |

| SB—Spruce tree | Particle | 254.0 | 199.0 | 71.0 |

| WN—Walnut | Particle | 33.8 | 30.0 | 30.0 |

| MS—Miscanthus | Particle | 128.0 | 79.5 | 42.0 |

| CE—Coffee grounds | Particle | 59.2 | 52.0 | 52.0 |

| CF-L—Cotton flakes | Short fibres | 342.2 | 318.5 | 307.0 |

| CF-D—Cotton flakes | Short fibres | 14.9 | 15.0 | 19.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Müller, M.; Urban, J.; Svobodová, J.; Mishra, R.K. Modification of the Mechanical Properties of Photosensitive Resin by Using Biobased Fillers During Stereolithography (SLA) 3D Printing. Materials 2025, 18, 2699. https://doi.org/10.3390/ma18122699

Müller M, Urban J, Svobodová J, Mishra RK. Modification of the Mechanical Properties of Photosensitive Resin by Using Biobased Fillers During Stereolithography (SLA) 3D Printing. Materials. 2025; 18(12):2699. https://doi.org/10.3390/ma18122699

Chicago/Turabian StyleMüller, Miroslav, Jiří Urban, Jaroslava Svobodová, and Rajesh Kumar Mishra. 2025. "Modification of the Mechanical Properties of Photosensitive Resin by Using Biobased Fillers During Stereolithography (SLA) 3D Printing" Materials 18, no. 12: 2699. https://doi.org/10.3390/ma18122699

APA StyleMüller, M., Urban, J., Svobodová, J., & Mishra, R. K. (2025). Modification of the Mechanical Properties of Photosensitive Resin by Using Biobased Fillers During Stereolithography (SLA) 3D Printing. Materials, 18(12), 2699. https://doi.org/10.3390/ma18122699