1. Introduction

The pottery manufacturing techniques during the Neolithic period in China had already reached a high level of maturity, with diverse vessel forms and strong functional designs. As a representative culture of the Late Neolithic period in China, the Longshan Culture played a key role in developing both cultural evolution and pottery technology. The Longshan Culture in the Yongcheng District, as an important and distinctive regional type within the Longshan cultural system, has attracted significant attention from scholars both in China and abroad. In 1936, Li Jingdan conducted archeological surveys in the Shangqiu and Yongcheng areas in search of the origins of the Shang civilization. He discovered several Longshan Culture remains along both sides of the Huai River in Yongcheng and carried out small-scale excavations at the HeiguDui Site, the Zaolütai Site, and the Caoqiao Site, uncovering a collection of pottery, stone tools, and bone artifacts [

1]. In the late 1970s, to explore the social conditions in eastern Henan at the end of the primitive society, the Institute of Archaeology of the Chinese Academy of Social Sciences and the Shangqiu Cultural Relics Administration conducted three rounds of surveys in the counties of Shangqiu, discovering 17 Longshan Culture sites [

2] and carrying out excavations at the Wangyoufang Site [

3] and the Heigudui Site [

4] in Yongcheng. The Wangyoufang Site is considered the most representative, with thick cultural deposits and rich artifact types, and the Longshan Culture remains from this site are referred to as the Wangyoufang type. Subsequently, further discoveries of Longshan Culture remains have been made in eastern Henan, including at the Duanzhai Site in Dancheng, the Pingliangtai Site in Huaiyang, and the Luantai Site in Luyi, as well as the Qingliangshan Site in Xiayi and the Lutai Gang Site in Qixian, Kaifeng. These sites have all yielded Longshan Culture remains and are generally classified under the Wangyoufang type. In 1995, a Sino-American joint archeological team excavated the Shantaisi Site in Zhecheng, discovering a large number of Longshan cultural features and artifacts, such as large rammed-earth platforms and sacrificial cattle pits, confirming its central position in the Longshan Culture of eastern Henan [

5]. In 2002, the Department of Archaeology at Zhengzhou University surveyed 24 ancient cultural sites in Shangqiu, including four Longshan Culture sites in Yongcheng: the Hongfu Site, the Zhaozhuang Site, the Mingyangsi Site, and the Zaolütai Site [

6]. In 2022, to further clarify the distribution of cultural relics and settlement hierarchy of the Longshan Culture in the Huai River basin of Yongcheng, the Department of Archaeology at Zhengzhou University carried out a comprehensive systematic survey and exploration of the cultural remains in the region.

With the continuous publication of archeological excavation data from Longshan Culture sites, the study of Longshan Culture has produced abundant results. Traditional archeological research has primarily focused on the cultural chronology and origins, especially in classifying and forming regional types, such as the Wangyoufang type [

7] and the Wangwan type [

8] of the Longshan Culture. Secondly, studies have addressed the geographical distribution of the culture. Scholars such as Liang Sicheng [

9], An Zhimin [

10], and Yang Zifan [

11] have proposed different views on the extent of the Longshan Culture, with three prevailing opinions regarding the western boundary of the Haidai Longshan Culture distribution area [

12]. Thirdly, many specialized studies have been carried out on the nature and function of sites and have unearthed artifacts and features—especially tombs and typical pottery vessels. By conducting typological research on representative pottery, scholars have explored issues related to their distribution, manufacturing techniques, morphological evolution, functions, and social significance.

With the adoption of experimental archeological methods, Chinese researchers have increasingly employed techniques such as X-ray fluorescence spectroscopy (XRF), wavelength-dispersive X-ray fluorescence (WDXRF), and scanning electron microscopy–energy dispersive spectroscopy (SEM-EDS) to analyze the chemical composition and firing techniques of Longshan Culture pottery. These methods have facilitated deeper investigations into raw material sources, production processes, and technical strategies. For example, Li Minsheng and Huang Suying conducted chemical and physical analyses on pottery sherds from different periods at the Taosi Site, shedding light on ceramic manufacturing techniques during the Miaodigou Phase II and Longshan periods [

13]. Chen Qianqian and Yang Yuzhang used WDXRF to study Neolithic pottery from the Jiahu Site in Henan and the Xiaohuangshan Site in Zhejiang [

14]; Gao Shoulei applied XRF to analyze the composition of pottery from the Hongshan Culture at the Niuheliang Site [

15]. As pottery is one of prehistoric cultures’ most important material remains, its manufacturing technology and social function have become core issues in international archeological research [

16,

17,

18,

19,

20]. Internationally, scholars widely use techniques such as XRF, X-ray diffraction (XRD), SEM-EDS, and Raman spectroscopy to analyze the composition, mineral structure, and microstructure of pottery, revealing the technological development of ceramic production [

21,

22,

23,

24]. For example, Maja Gajić-Kvašćev used EDXRF to study the composition of pottery from the Velika Humska Čuka Site in Serbia, providing evidence of cultural exchange influences [

25]. Laura Teodorescu and colleagues combined XRD and SEM-EDS to analyze the raw materials and production techniques of Dacian pottery [

26]. Philippe Colomban and others applied XRF and Raman spectroscopy to detect different chemical compositions in ceramics, proving that as early as the 12th century CE, Islamic potters had mastered highly advanced ceramic techniques [

27]. These international research paradigms have provided important references for the scientific and systematic development of ceramic studies in China [

28,

29,

30,

31,

32].

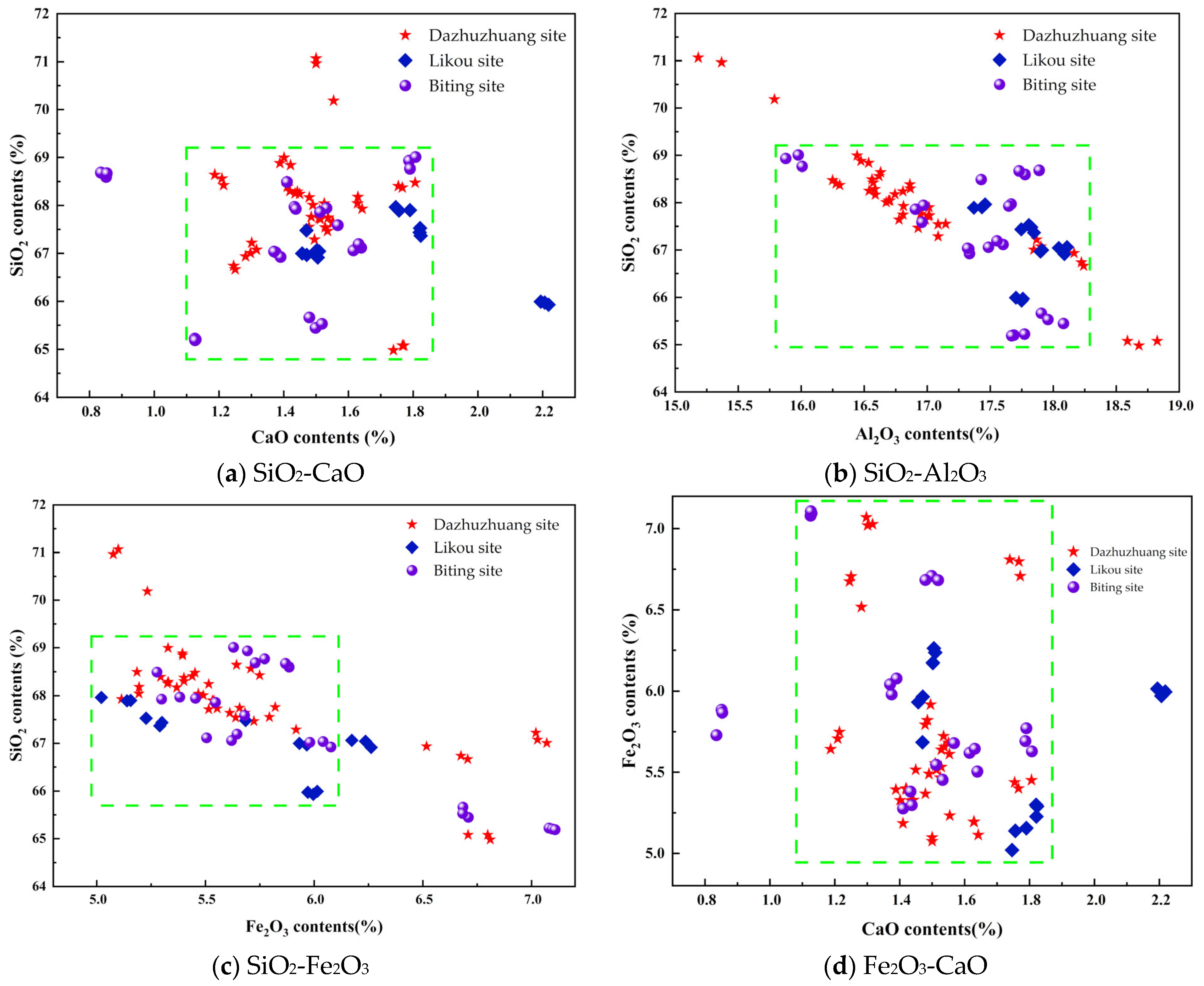

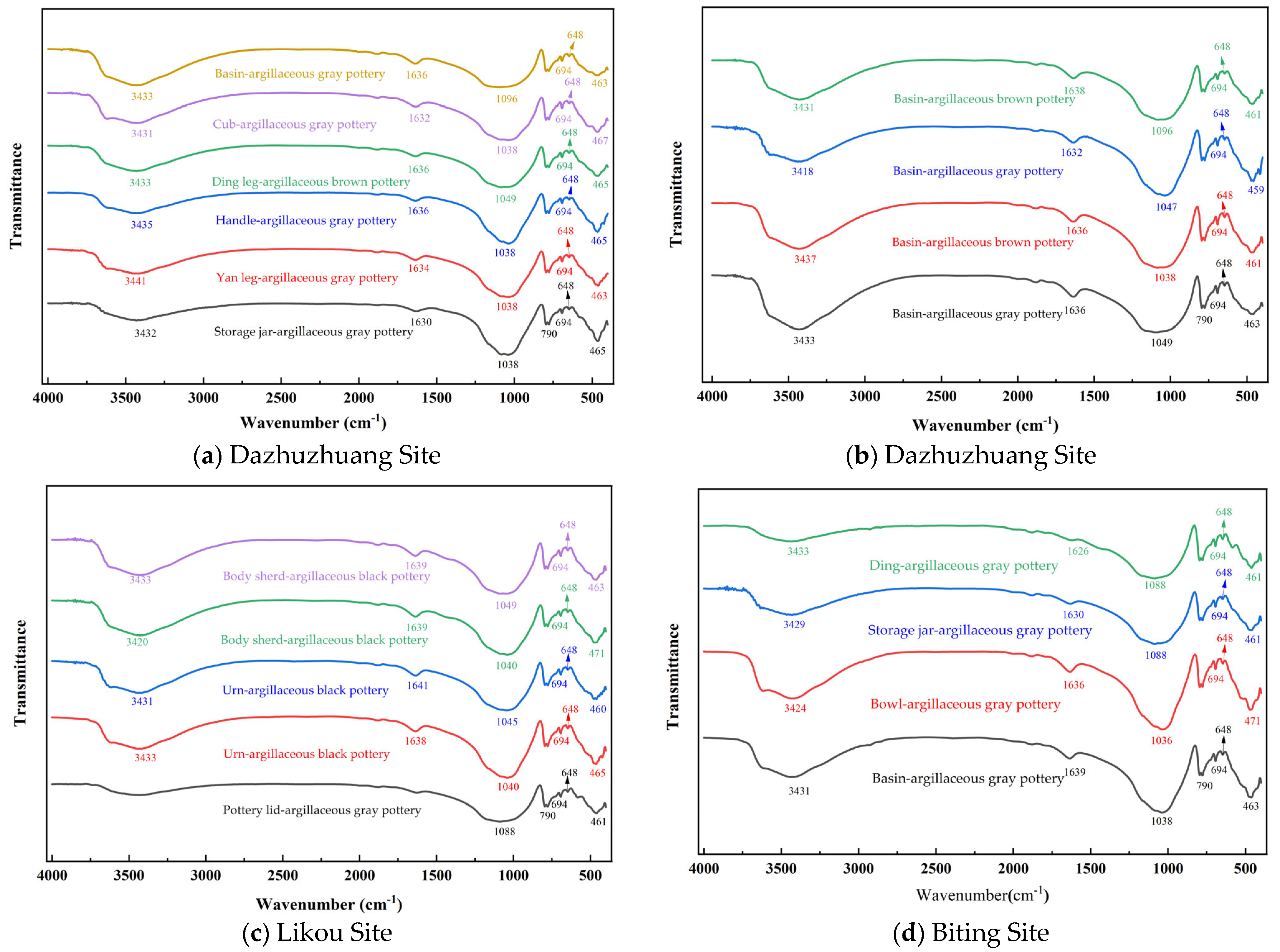

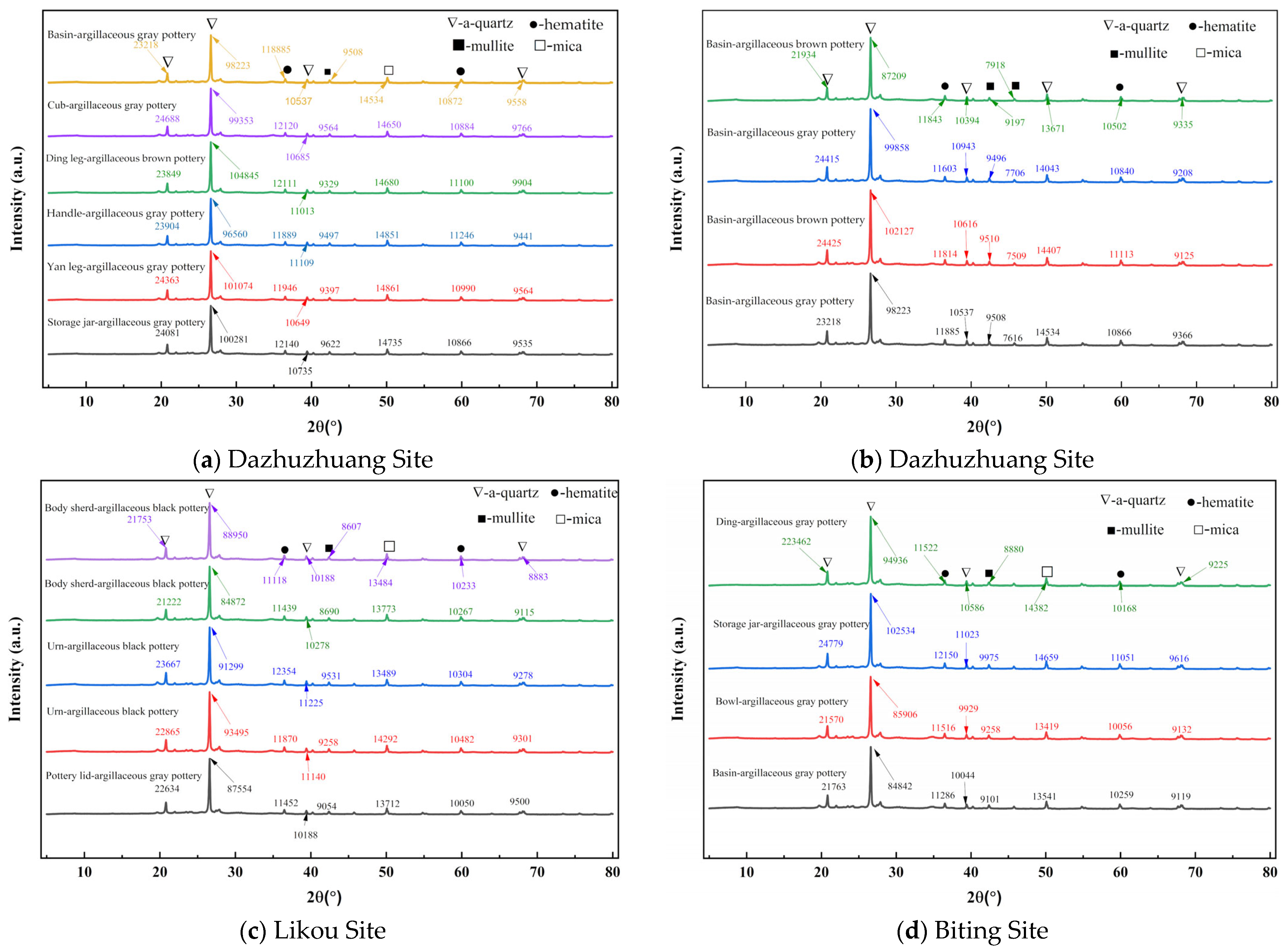

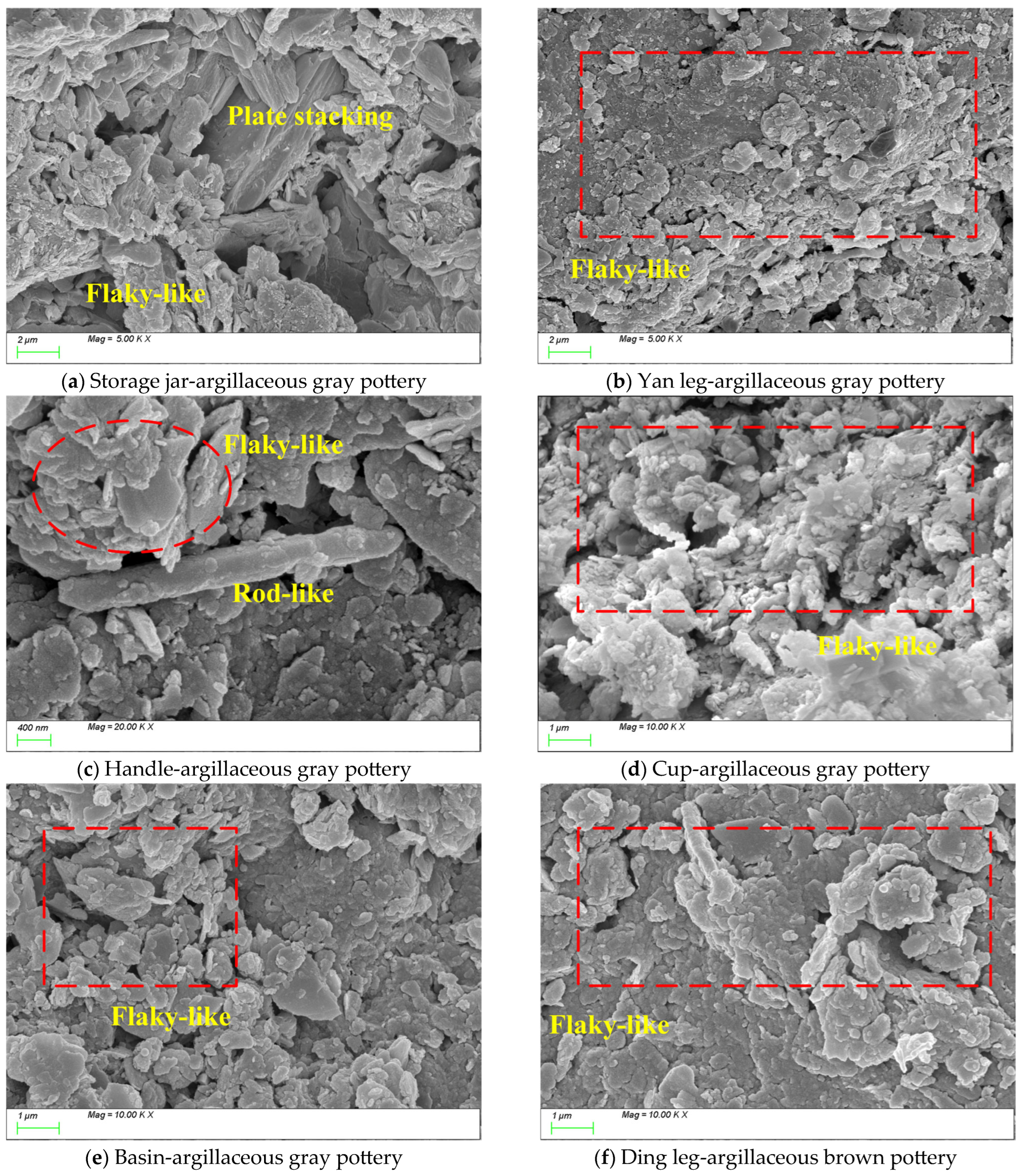

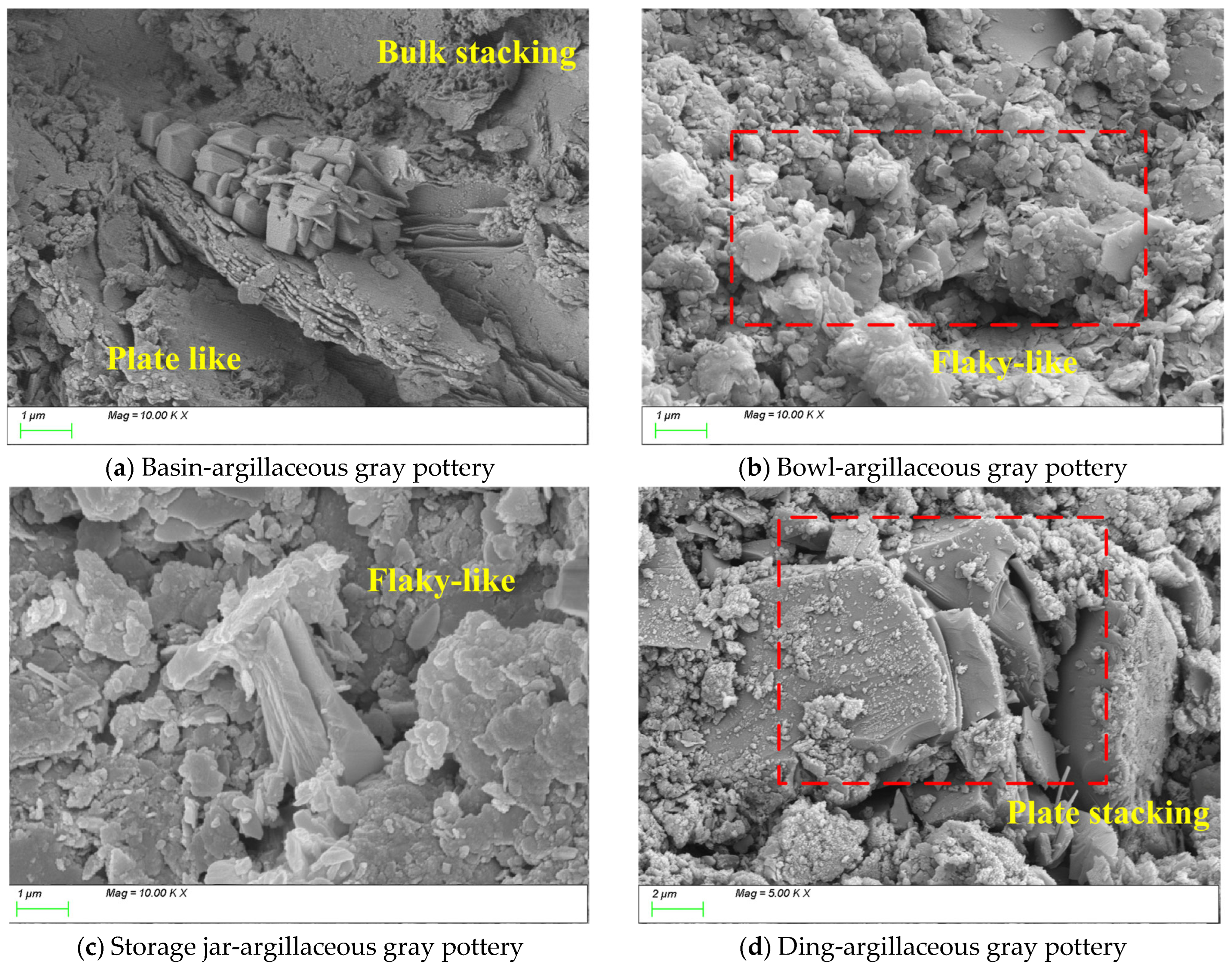

However, current scientific archeological research still faces challenges, such as limited analytical methods and lacking a comprehensive technical system that integrates multiple techniques and interdisciplinary approaches. This has hindered a full understanding of the complexity of pottery manufacturing techniques and the diversity of raw material sources. Based on this research context, the present study adopts an integrated approach combining traditional archeology and materials science. By applying both typological and scientific methods and using a combination of analytical techniques, including XRF [

33,

34,

35,

36], XRD, infrared spectroscopy (IR), and SEM-EDS, we aim to carry out systematic analysis at the levels of chemical composition, mineral structure, and microscopic morphology [

37,

38,

39,

40,

41]. This multi-technical approach overcomes the limitations of relying on single methods, providing more reliable data for identifying pottery composition and raw material sources.

In 2022, the Department of Archaeology at Zhengzhou University conducted a systematic survey and exploration in the Huai River basin of the Yongcheng District, identifying 17 archeological sites containing cultural remains from the Longshan Culture, as shown in

Figure 1. Among them, the Dazhuzhuang Site (16,800 m

2), the Biting Site (40,000 m

2), and the Likou Site (90,000 m

2) are located at the junction of Henan, Anhui, and Shandong Provinces. These sites serve as a crucial area for interaction between the Wangyoufang type of the Longshan Culture in eastern Henan and adjacent cultural regions. With well-defined hierarchical settlement structures, these sites yielded abundant pottery sherds from the Longshan period, featuring diverse types and representative vessel forms. For this reason, pottery from these three sites was selected as the focus of the present study. This research integrates domestic and international advances in pottery studies through the systematic sampling and analysis of typical pottery sherds unearthed from the Dazhuzhuang, Biting, and Likou Sites [

42,

43,

44,

45,

46]. It applies a multi-technical and interdisciplinary approach to investigate Longshan Culture pottery in the Yongcheng District comprehensively. The objective is to clarify the raw material sources and technological characteristics of these ceramics during the Longshan period, thereby uncovering the intrinsic relationship between ceramic manufacturing and regional cultural interaction. This study aims to provide new empirical evidence for understanding regional variation within the Longshan Culture and the pathways of ceramic technological transmission.

The specimens analyzed from the three sites are introduced as follows:

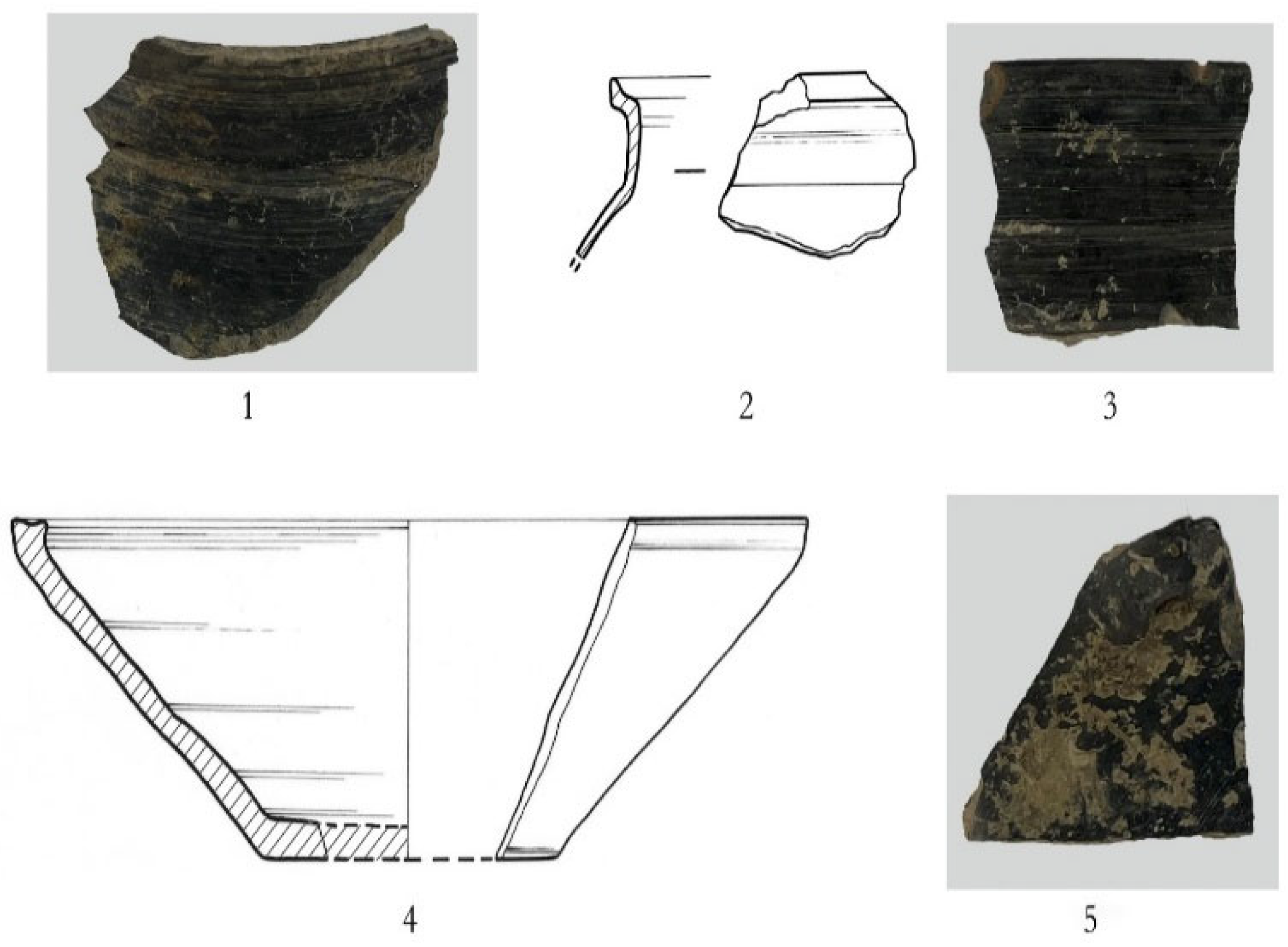

The Dazhuzhuang Site is on the northwest side of Dazhuzhuang Village, Peiqiao Town, Yongcheng District. It is approximately 120 m wide from north to south and 140 m long from east to west, covering an area of about 16,800 square meters. The cultural deposits are 0.8–2.1 m thick. Collected artifacts are mainly pottery sherds, with a few shells and animal bone remains. The pottery primarily dates back to the Longshan culture and Han periods. Pottery from the Longshan Culture is mainly argillaceous gray pottery, followed by argillaceous brown pottery and argillaceous black pottery. Decorations are primarily cord marks and plain surfaces, followed by basket patterns, along with a few string patterns and grid patterns. Vessel types include storage jars (ceramic containers for liquids or food), the Yan (a cooking vessel functionally similar to a modern steamer, comprising an upper zeng for holding food and a lower li for water, separated by a perforated grate to allow for steam circulation), the Ding (tripod or quadripod cooking vessels with handles, typically round with three legs and two ears, though rectangular versions exist), the Dou (food-serving vessels with tall ring feet), urns (storage vessels with a narrow mouth and bulging belly), bowls (round concave dishes for food), and cups.

A total of 15 specimens were selected for testing, including vessel types such as storage jars, basins (wide-mouthed, narrow-based containers for liquids, food, or washing), cups (liquid-holding vessels), Ding legs, Yan legs, and handles (lateral protrusions for grasping). The majority are argillaceous gray pottery, with a few argillaceous brown pottery pieces. Decorations are mainly grid patterns and plain surfaces.

Seven storage jars were examined, including six argillaceous gray pottery specimens and one argillaceous brown pottery specimen. The six argillaceous gray pottery pieces exhibit flared rims, folded rims, square lips, contracted necks, and sloping shoulders. Specimen 2023YPDH1:1 features a globular body and is preserved below the belly. The surface is plain (

Figure 2(1)). Specimen 2023YPDH1:4 is preserved below the shoulder, which is decorated with grid patterns (

Figure 2(6)). Specimen 2023YPDH1:5 has a round lip and is preserved below the shoulder. The shoulder is decorated with diamond-shaped grid patterns (

Figure 2(7)). Specimen 2023YPDH1:16 has a square lip with a circumferential groove on the lip surface and is preserved below the shoulder. The shoulder is decorated with grid patterns (

Figure 3(1)). Specimen 2023YPDH2:1 has a grid pattern decoration on the shoulder. Specimen 2023YPDH2:5 features a round lip and a curved body, with the lower belly preserved. The exterior is decorated with medium-sized cord marks (

Figure 3(3)).

Specimen 2023YPDH1:9 is an argillaceous brown pottery storage jar. It features a flared rim, a folded rim, a square lip with a circumferential groove on the inner edge, a contracted neck, sloping shoulders, and a curved body. The portion below the belly is preserved. The exterior has diamond-shaped grid patterns (

Figure 2(5)).

Four basins were examined, including three made of argillaceous gray pottery. These basins have open mouths, round lips, and obliquely straight bodies, with parts preserved below the belly. The surfaces are plain. Specimens include 2023YPDH1:13 (

Figure 2(9)), 2023YPDH1:11 (

Figure 2(11)), and 2023YPDH2:12.

One specimen is made of argillaceous brown pottery, featuring an open mouth, a round lip, an obliquely straight body, and preservation below the belly. The surface is plain (Specimen 2023YPDH1:12) (

Figure 2(10)).

One cup was identified. Specimen 2023YPDH1:19 is an argillaceous gray pottery piece with an open mouth, a square lip, a circumferential groove on the inner edge of the rim, a shallow body, and a flat base. The surface is plain (

Figure 2(8)).

One Ding leg was found. Specimen 2023YPDH1:21 is an argillaceous brown pottery piece. It has a side-triangular flat leg with a solid root. There are six depressions on the outer side of the leg root. The surface is plain (

Figure 2(4)).

One Yan leg was recovered. Specimen 2023YPDH1:23 is made of argillaceous gray pottery and features a pouch-shaped leg with a tall, tapered, solid root. The surface is plain (

Figure 2(2)).

One handle was documented. Specimen 2023YPDH1:17 is an argillaceous gray pottery piece with a bridge-shaped handle. The surface is plain (

Figure 2(3)).

- 2.

Biting Site

The Biting Site is located southeast of Bianzhuang Village, Xinqiao Town, Yongcheng District. The central, western, and northern parts of the site are overlain by the town’s grain storage facility. The site is irregular in shape and covers an area of approximately 40,000 square meters. Collected artifacts mainly date back to the Longshan and Shang culture periods. Pottery sherds from the Longshan Culture period are primarily composed of argillaceous gray and argillaceous gray-black pottery, along with some argillaceous polished black pottery and argillaceous brown pottery. There are also small quantities of sand-tempered gray/brown pottery and shell-tempered brown/gray pottery. Decorative patterns are dominated by basket patterns, square patterns, and plain surfaces, followed by cord-marked patterns and a few string patterns. Common vessel types include storage jars, basins, bowls, and Ding.

A total of eight specimens were selected for testing, including storage jars, basins, bowls, and Ding legs. Most are made of argillaceous gray pottery, with decorative patterns mainly featuring square patterns, cord marks, and plain surfaces.

Five storage jars, all made of argillaceous gray pottery, have flaring mouths, folded rims, and square lips (Specimen 2023YXBP⑤:7: argillaceous gray pottery). A groove is present inside the lip, and it has a contracted neck and a sloping shoulder but is missing below the shoulder. The shoulder is decorated with a square pattern (

Figure 4(3)) (Specimen 2023YXBP⑤:21: argillaceous gray pottery). It has a contracted neck and a sloping shoulder but is missing below the shoulder. The shoulder is decorated with a cord-marked pattern (

Figure 4(4)) (Specimen 2023YXBP⑤:13: argillaceous gray pottery). A groove is present inside the lip, and it has a contracted neck, a sloping shoulder, and a plain surface but is missing below the shoulder (

Figure 4(5)) (Specimen 2023YXBP⑤:8: argillaceous gray pottery). A groove is present inside the lip, and it has a contracted neck and a sloping shoulder but is missing below the shoulder. The shoulder is decorated with a square pattern (

Figure 4(6)) (Specimen 2023YXBP⑤:14: argillaceous gray pottery). A groove is present on the surface of the square lip, and it has a contracted neck, a round shoulder, and a plain surface; it is missing below the shoulder (

Figure 4(7)).

One basin: Specimen 2023YXBP⑤:1: argillaceous gray pottery: It has a flaring mouth, a folded rim, a round lip with an inner groove, an oblique straight belly, and a plain surface but is missing below the belly (

Figure 4(1)). One bowl: Specimen 2023YXBP⑤:10: argillaceous gray pottery: It has an open mouth, a square lip with a groove on the lip surface, an oblique belly, and a plain surface but is missing below the belly (

Figure 4(2)). One ding leg: Argillaceous gray pottery: It has a side-triangular flat leg with a solid foot root. The tip of the foot is broken. A depression is visible on the upper part of the outer side of the leg (

Figure 4(8)).

- 3.

Likou Site

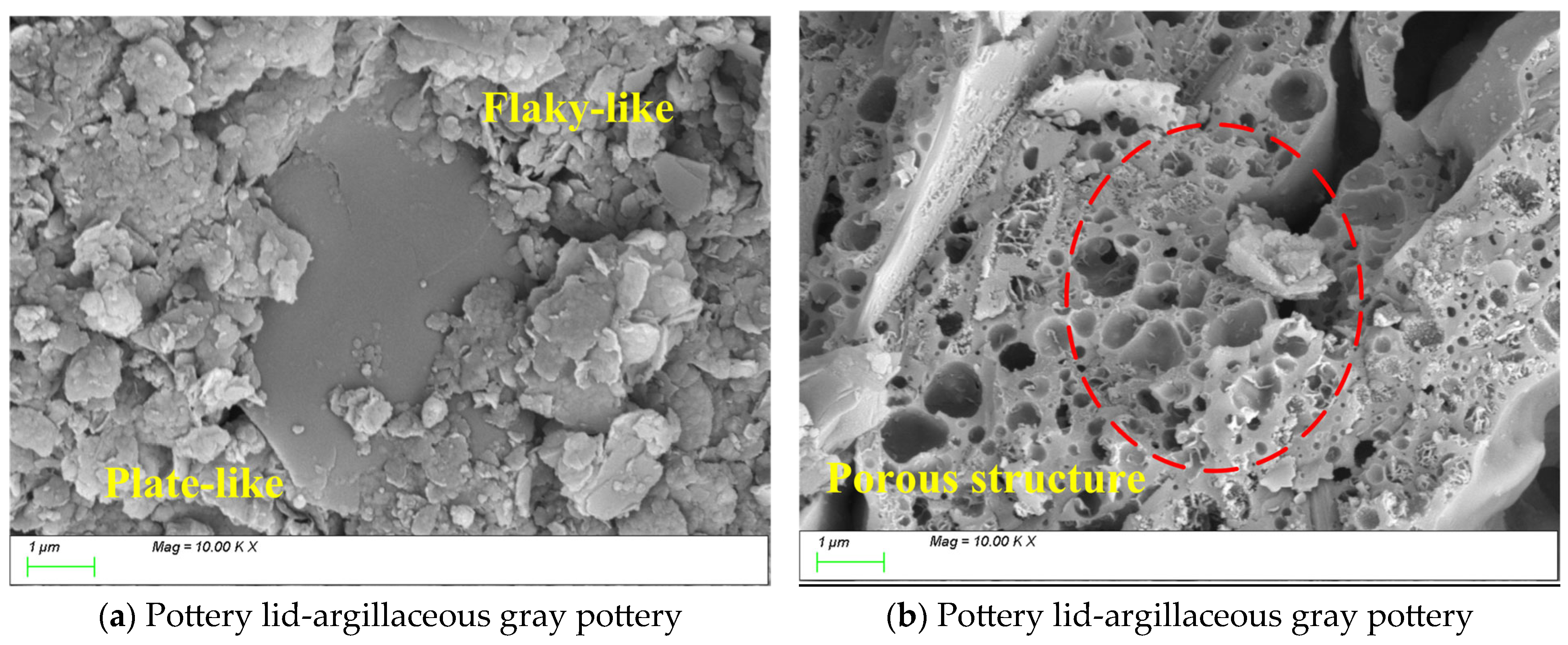

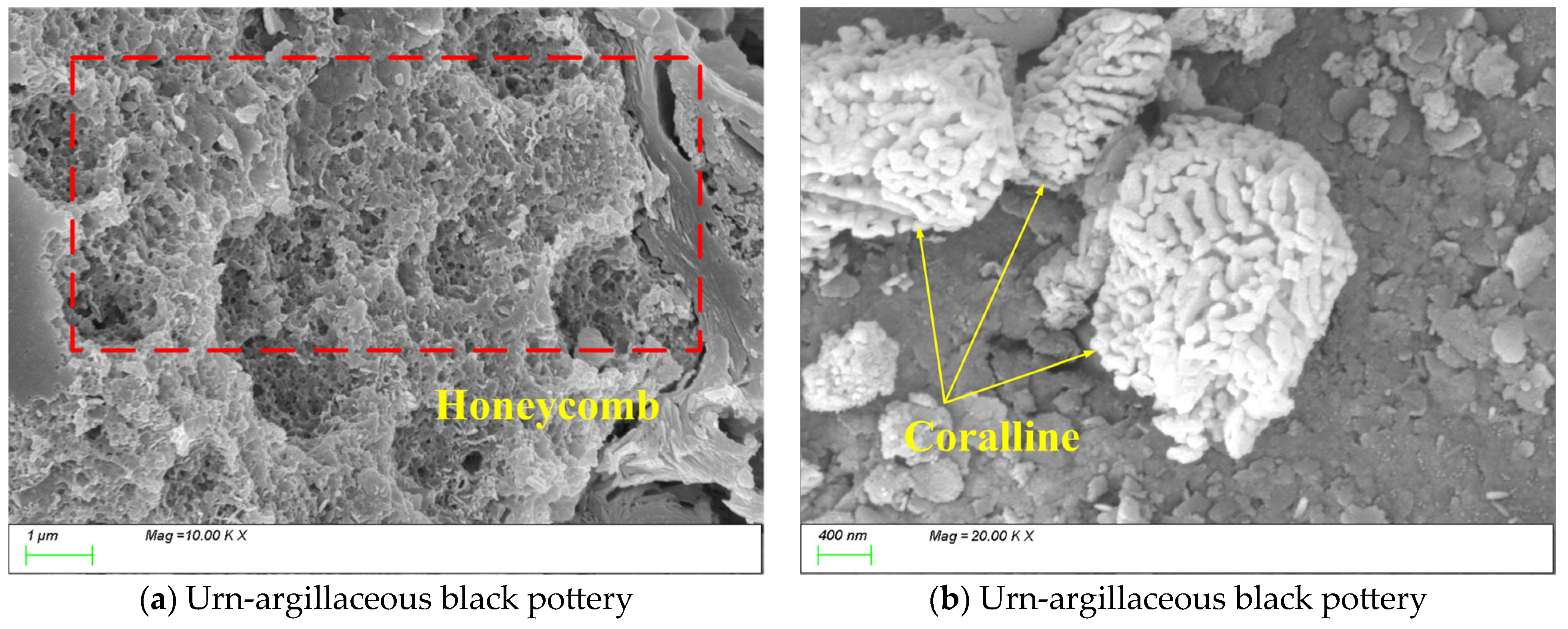

The Likou Site is located in Likou Village, Houling Community. The Huai River lies to the south, a village to the west, and the northern and eastern areas border the Huaibei City of Anhui Province. It is situated on a high terrace surrounded by water on two sides. The site measures about 300 m in length and width, covering an area of approximately 90,000 square meters, with cultural deposits ranging from 0.3 to 3.8 m thick. Collected artifacts include pottery sherds, stone tools, shells, deer antlers, and animal bones. Pottery sherds mainly date back to the Yangshao, Longshan, and Shang cultures. Pottery from the Longshan Culture period is primarily argillaceous gray pottery, along with polished black pottery, argillaceous brown pottery, and small quantities of sand-tempered gray/brown pottery and shell-tempered gray/brown pottery. The decorations include basket, square, and cord-marked patterns, with minor plain surfaces and scattered string patterns. Vessel types include storage jars, urns, basins, bowls, pottery lids (a cover for containers), and Ding.

A total of five specimens were selected for testing, including urns, storage jars, and a pottery lid.

Two urns, both made of argillaceous black pottery, have straight mouths and sharp lips. Specimen 2023YHL⑥:1: The outer side of the rim has two raised ridges. It has a short neck and a sloping shoulder but is missing below the shoulder. The surface is plain and polished (

Figure 5(1)). Specimen 2023YHL⑥:2: The inner side of the rim has a groove; it has a tall neck and a sloping shoulder but is missing below the shoulder (

Figure 5(2)).

One pottery lid: Specimen 2023YHLH2:2: argillaceous gray pottery: It has an open mouth with a slightly constricted rim, a square lip with a groove on the lip surface, an oblique straight belly, and a flat base, along with wheel marks on the inside and a plain surface (

Figure 5(4)).

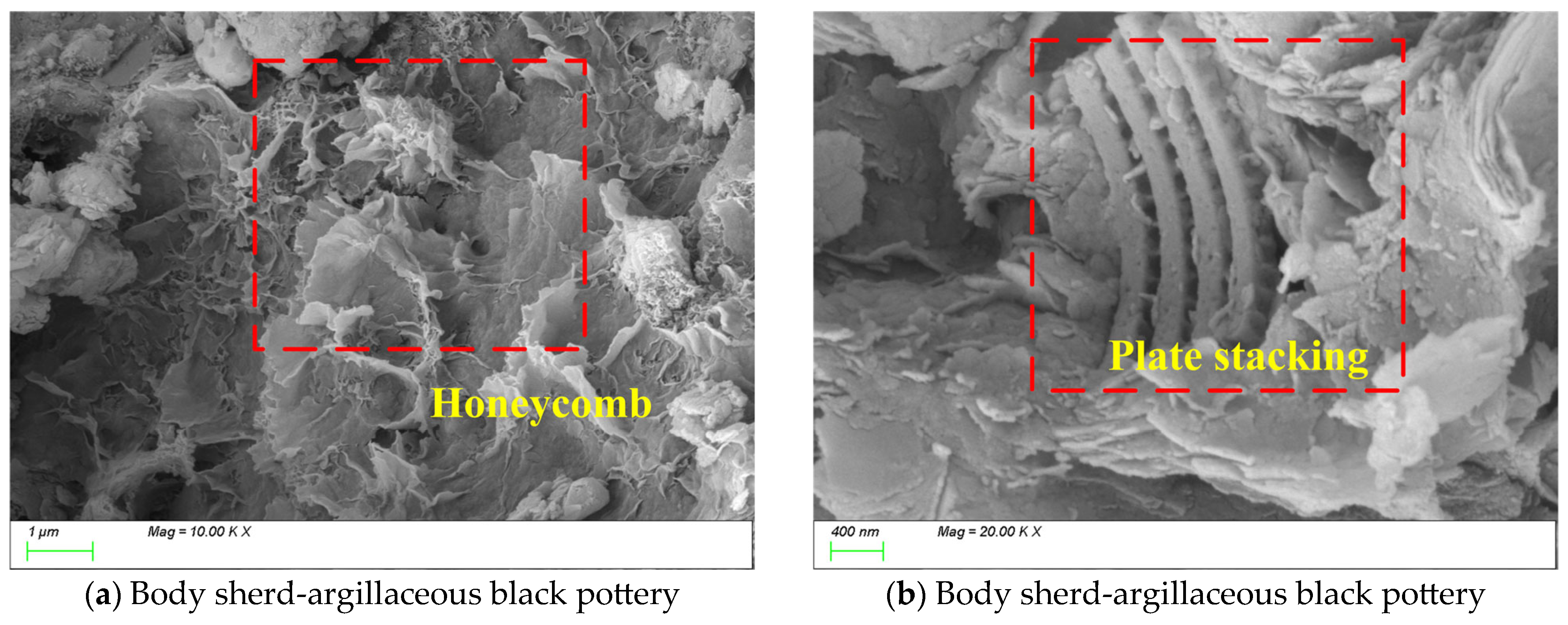

Two storage jars are made of argillaceous black pottery with plain polished surfaces: Specimen B6:3: a body sherd (

Figure 5(5)). Specimen B6:4: a flaring mouth, a rounded sharp lip, a contracted neck, and missing below the neck (

Figure 5(3)).