Compressive Creep Performances of Dispersion Coated Particle Surrogate Fuel Pellets with ZrC–SiC Composite Matrix

Abstract

:1. Introduction

2. Experimental Methods

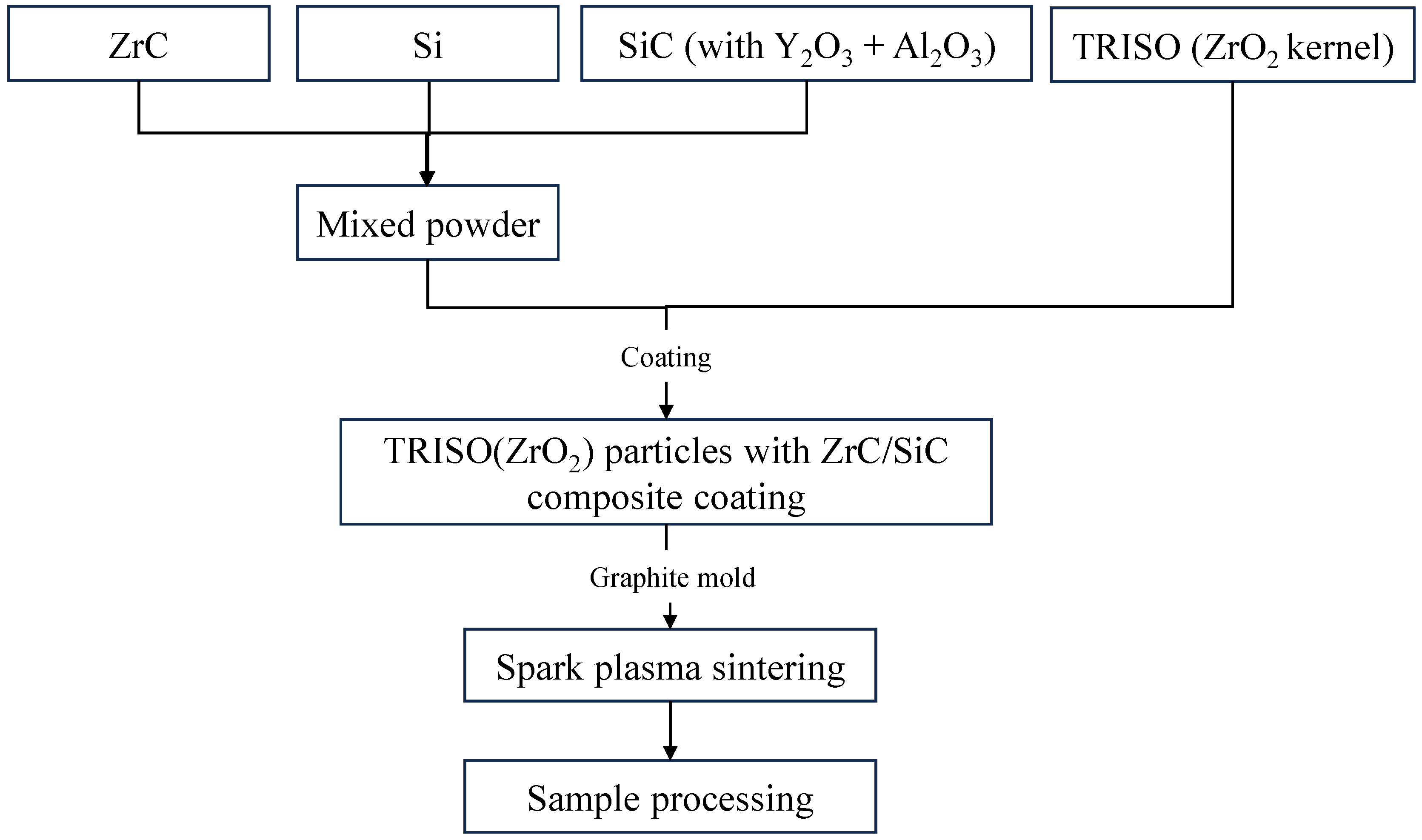

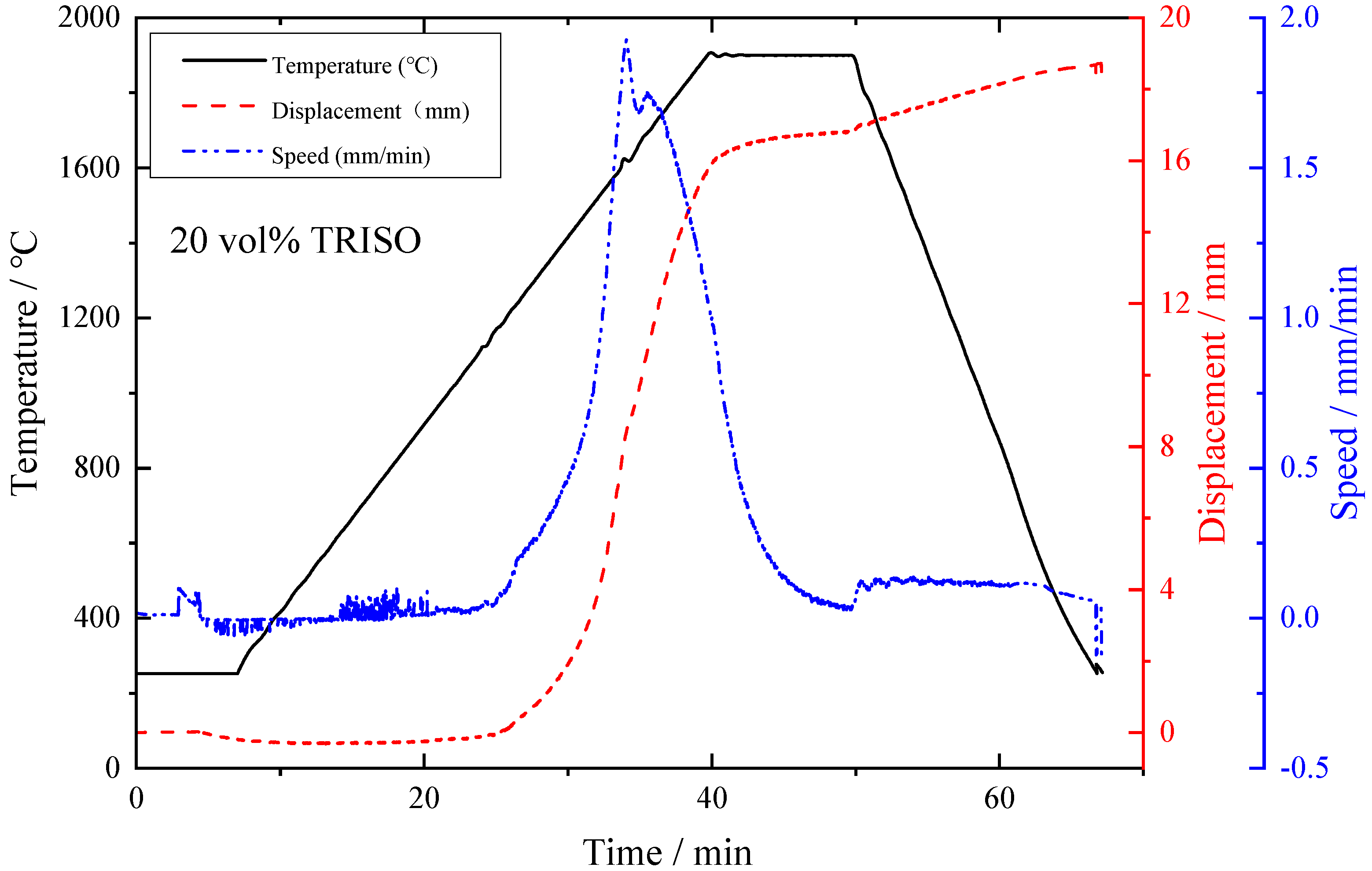

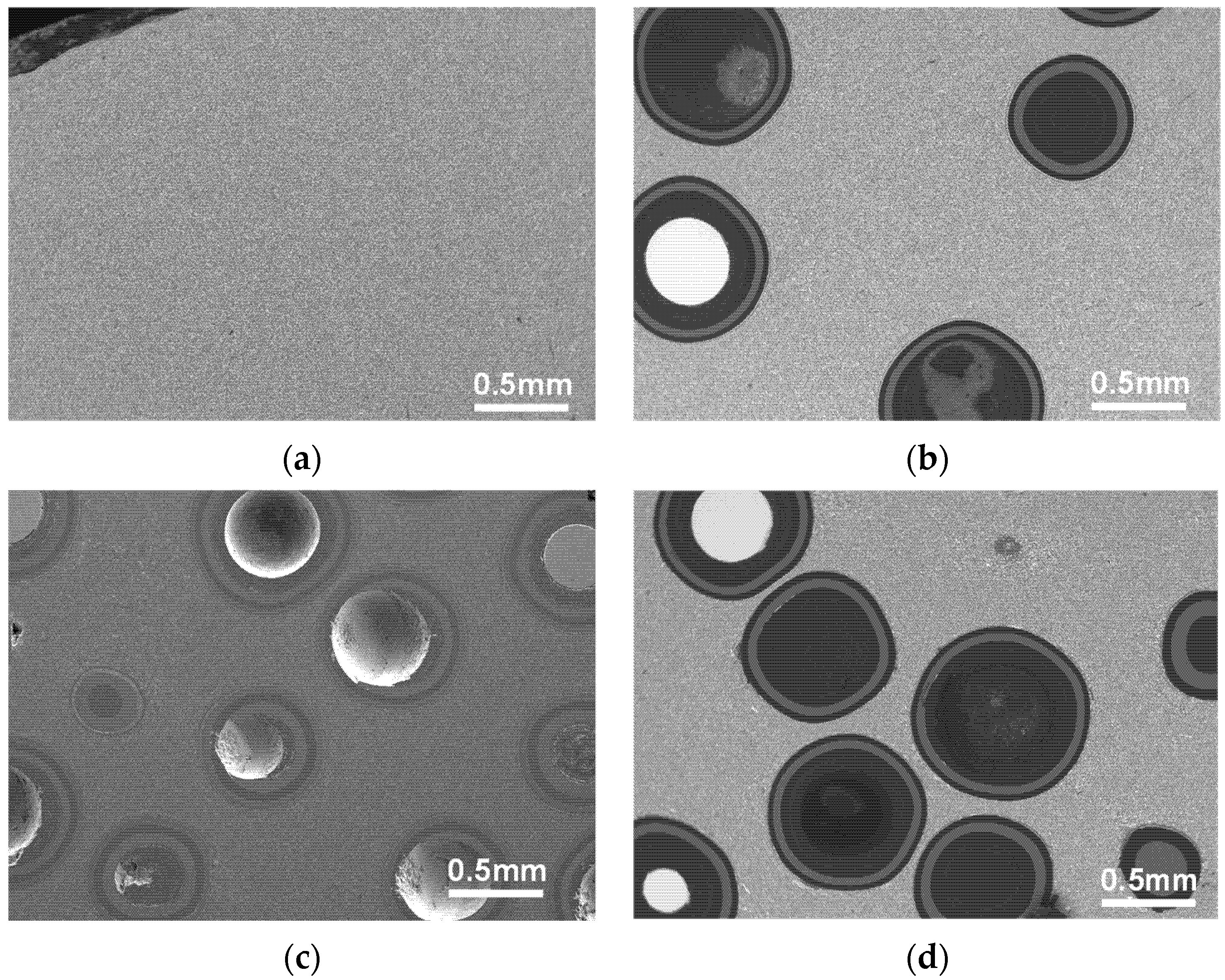

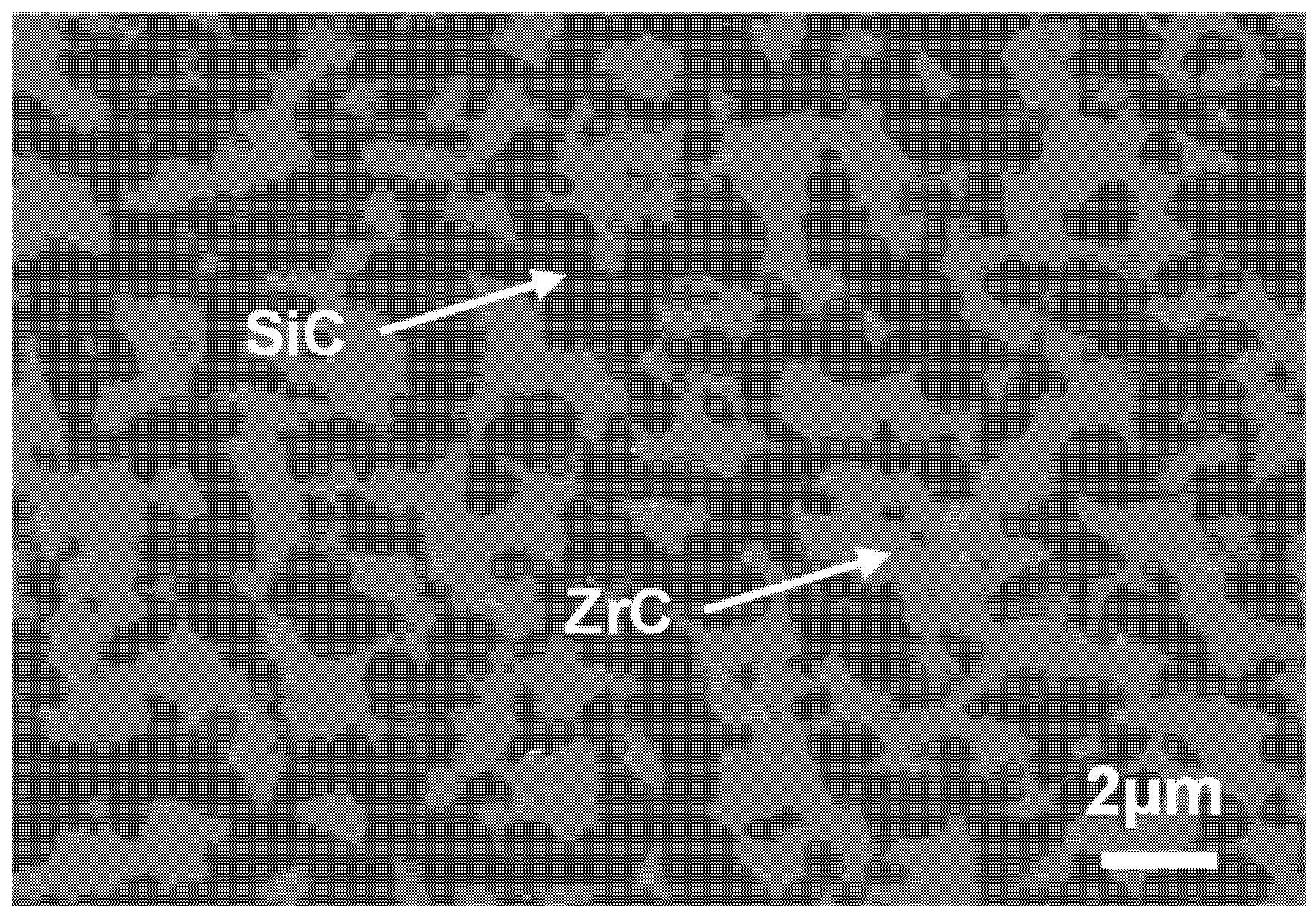

2.1. Sample Preparation

2.2. Compressive Creep Testing Protocol

3. Results and Discussion

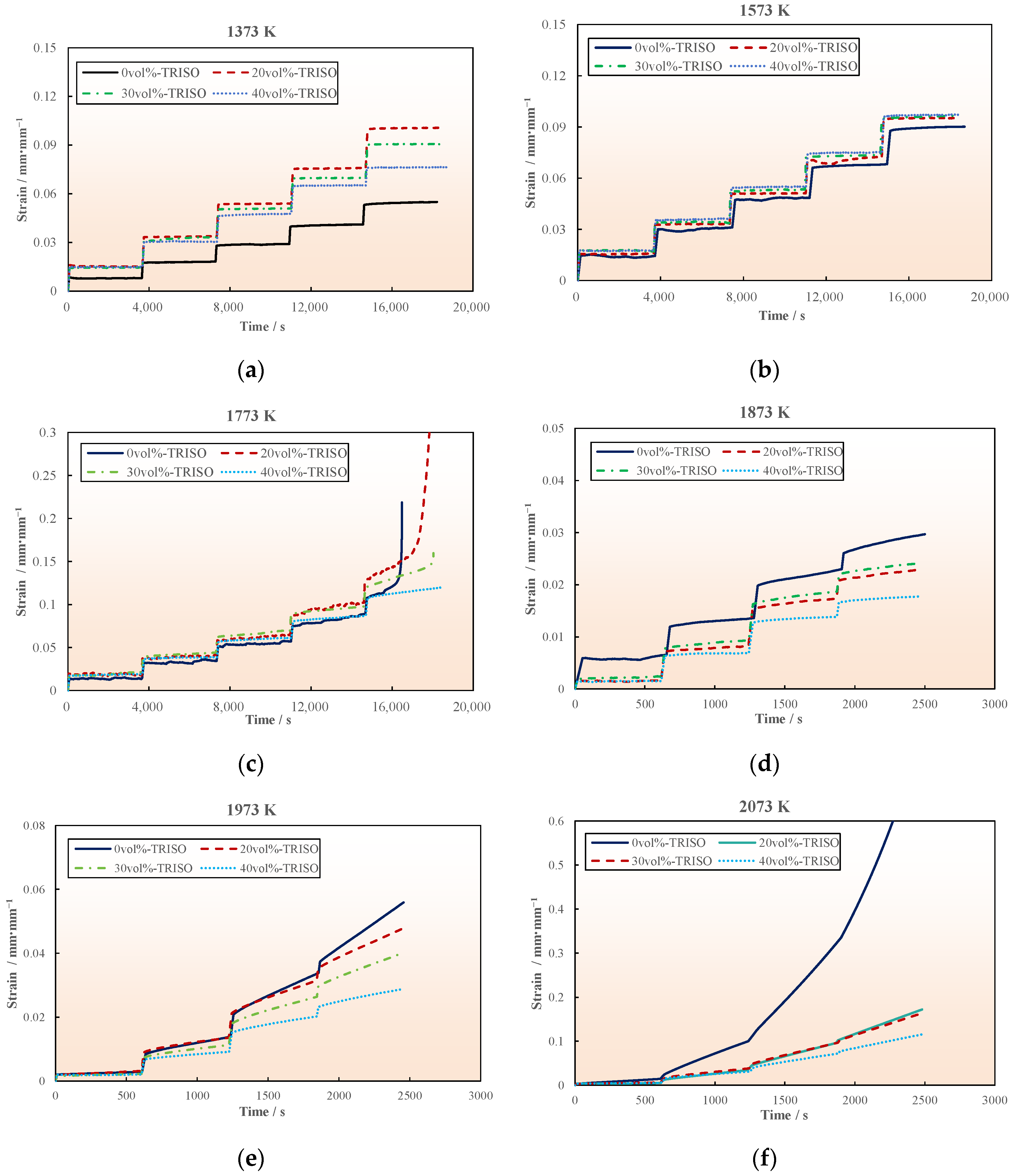

3.1. Creep Strain

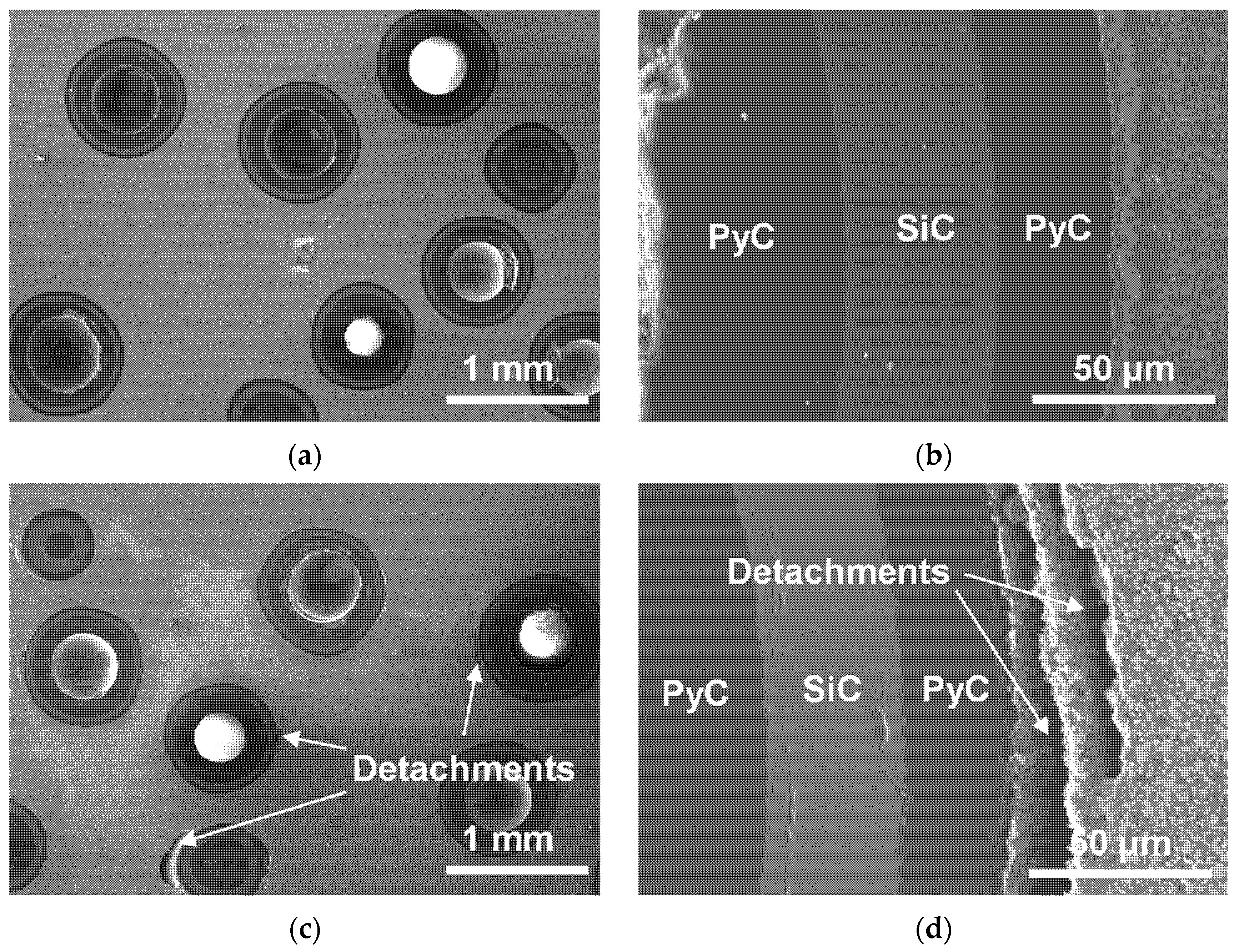

3.2. Post-Creep Microstructure

3.3. Creep Properties

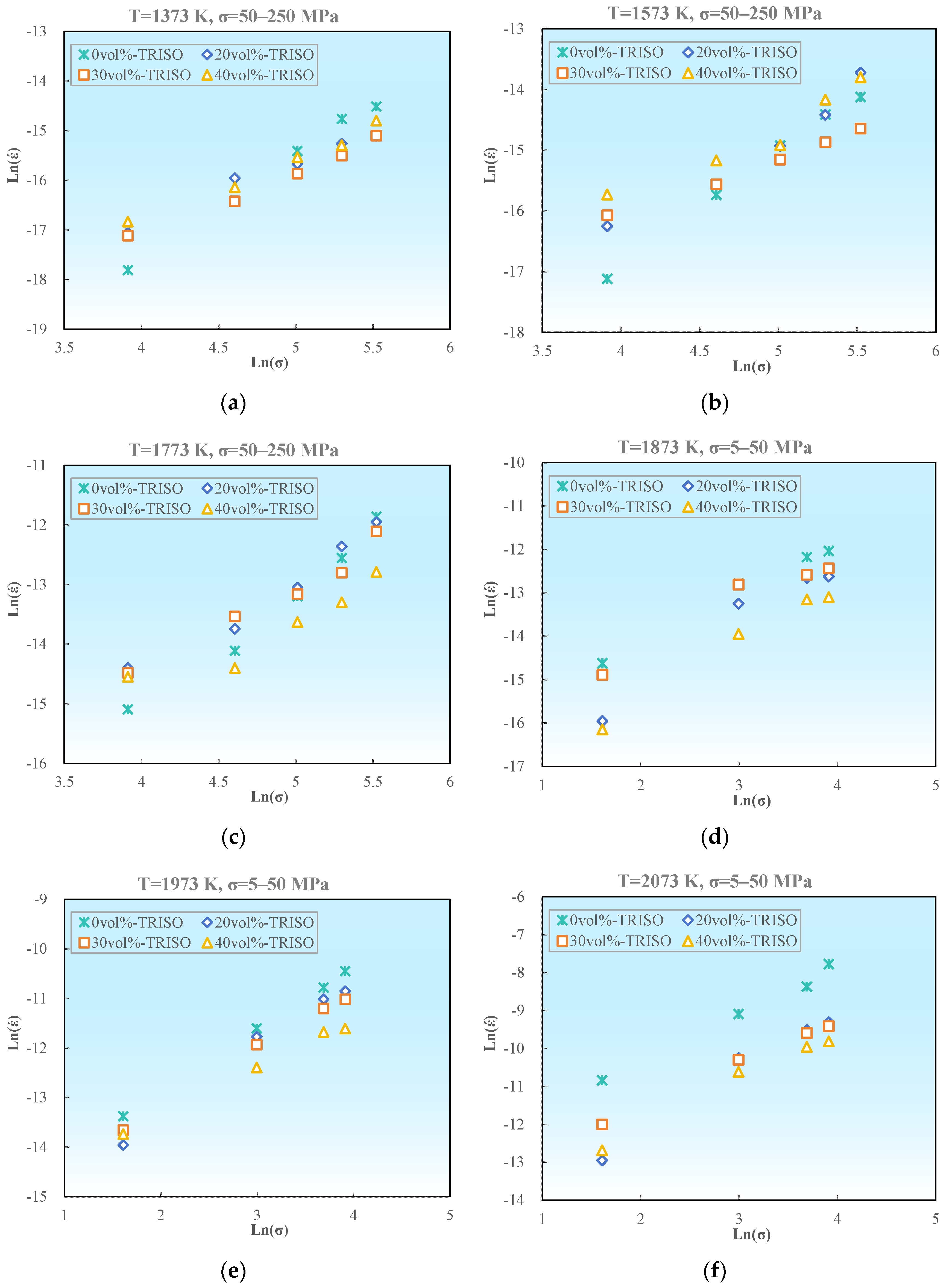

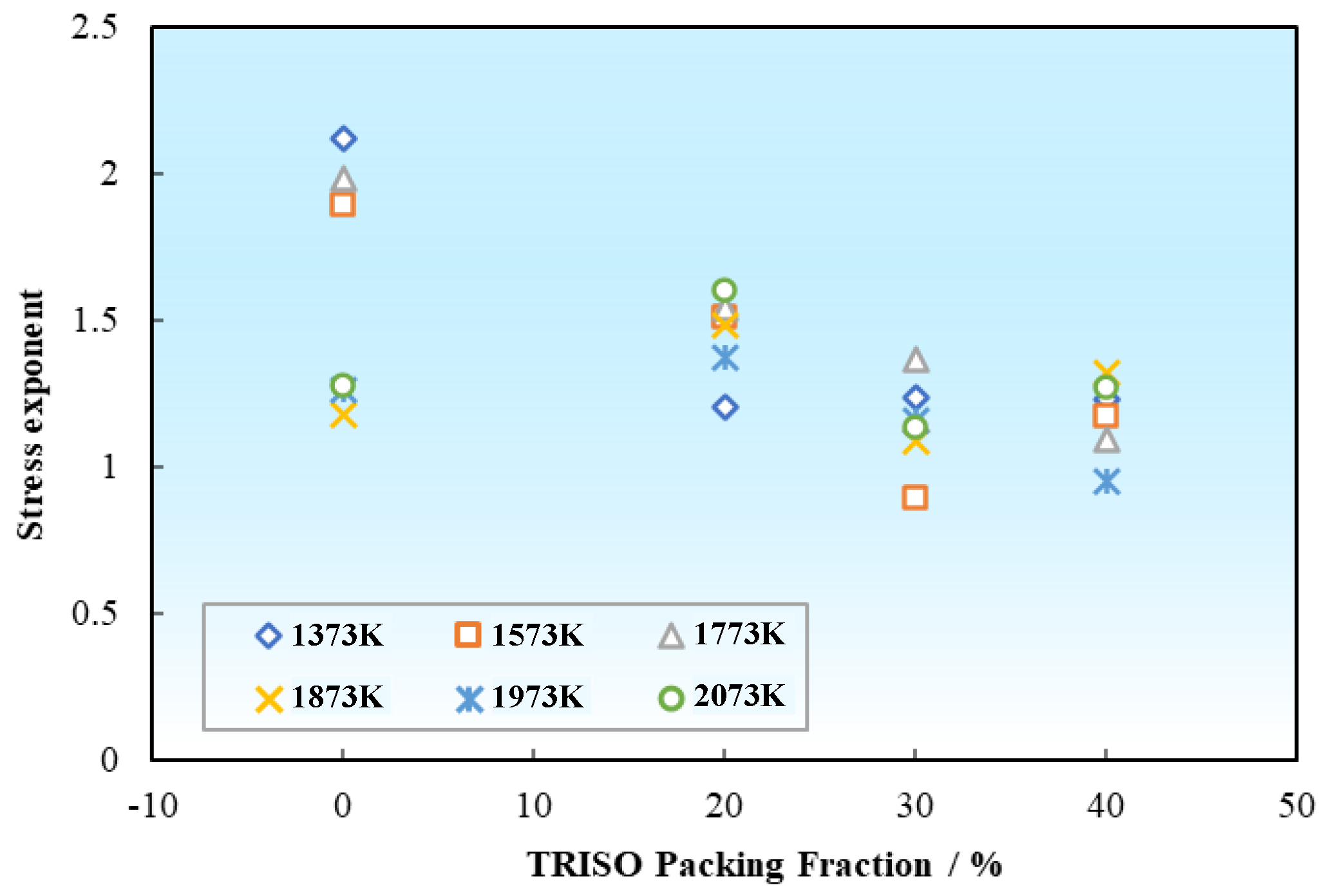

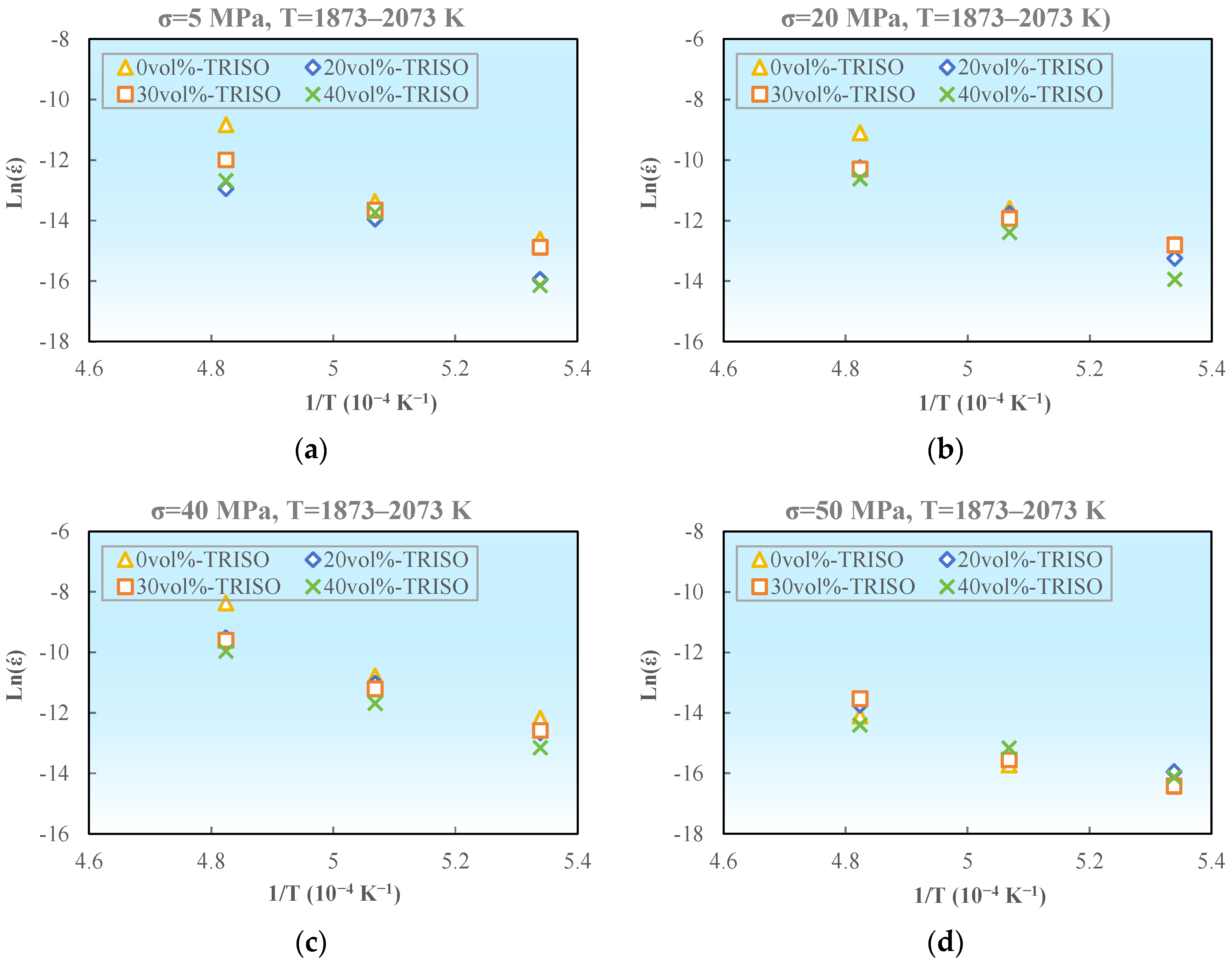

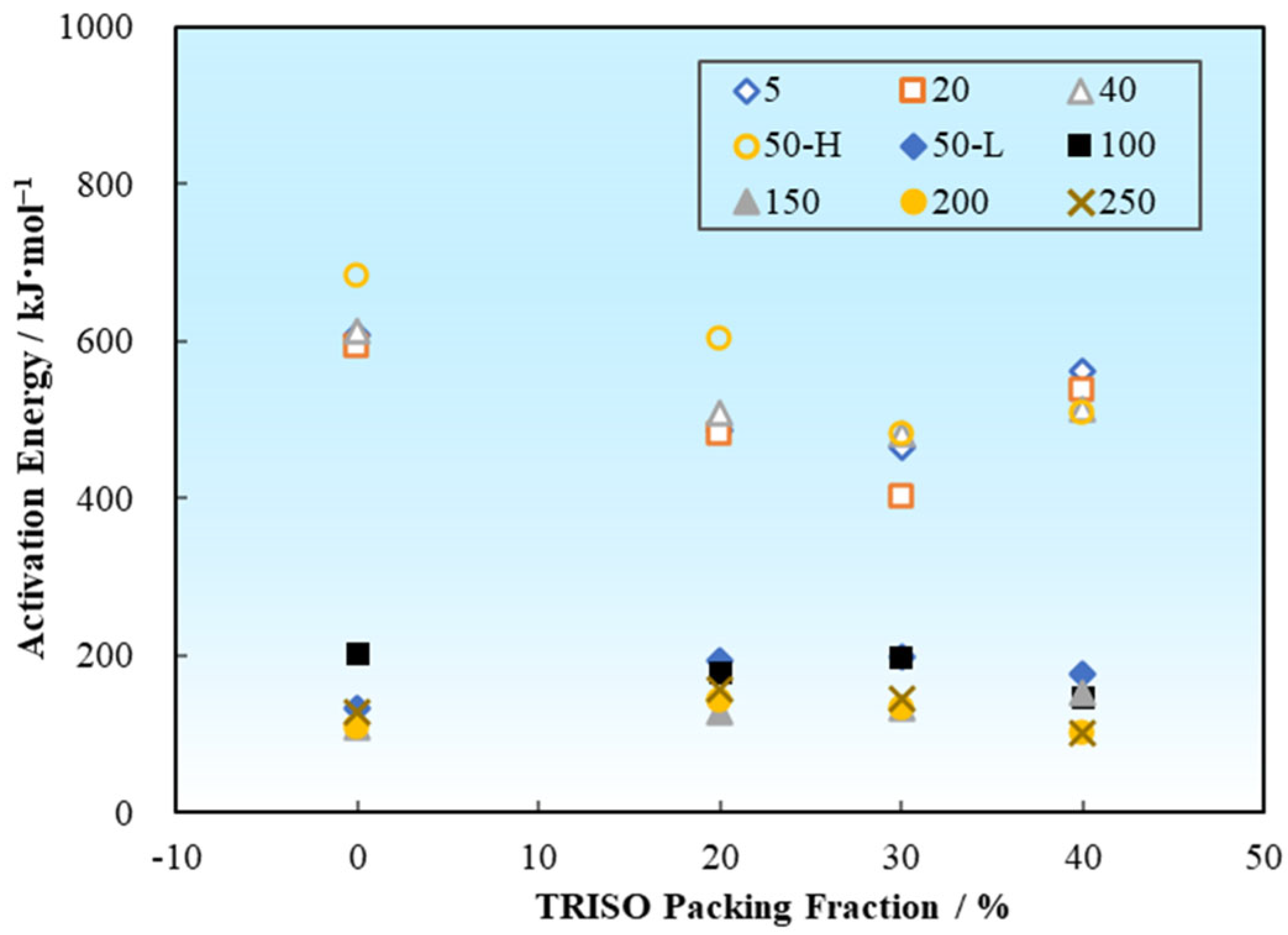

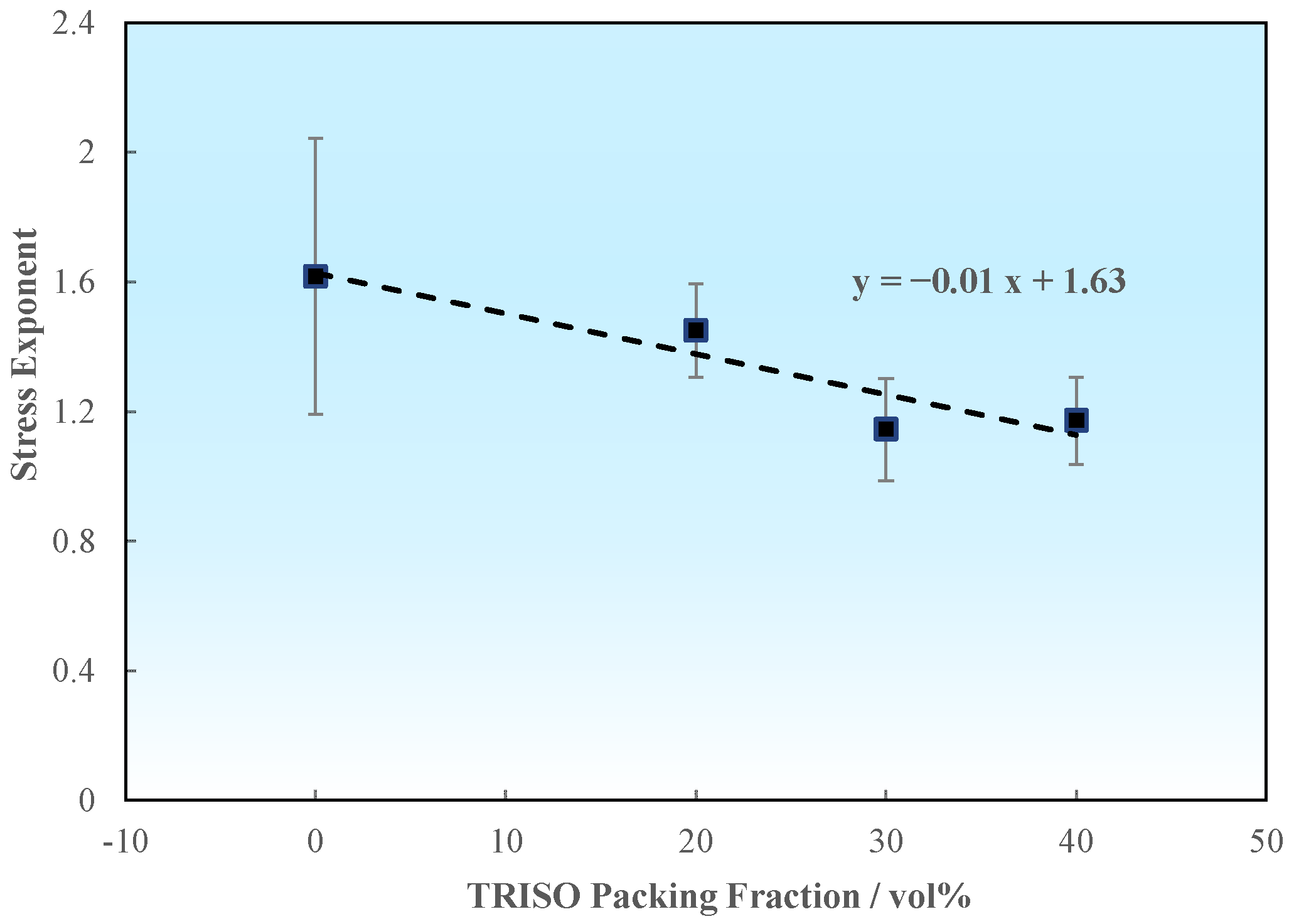

3.3.1. Stress Exponents

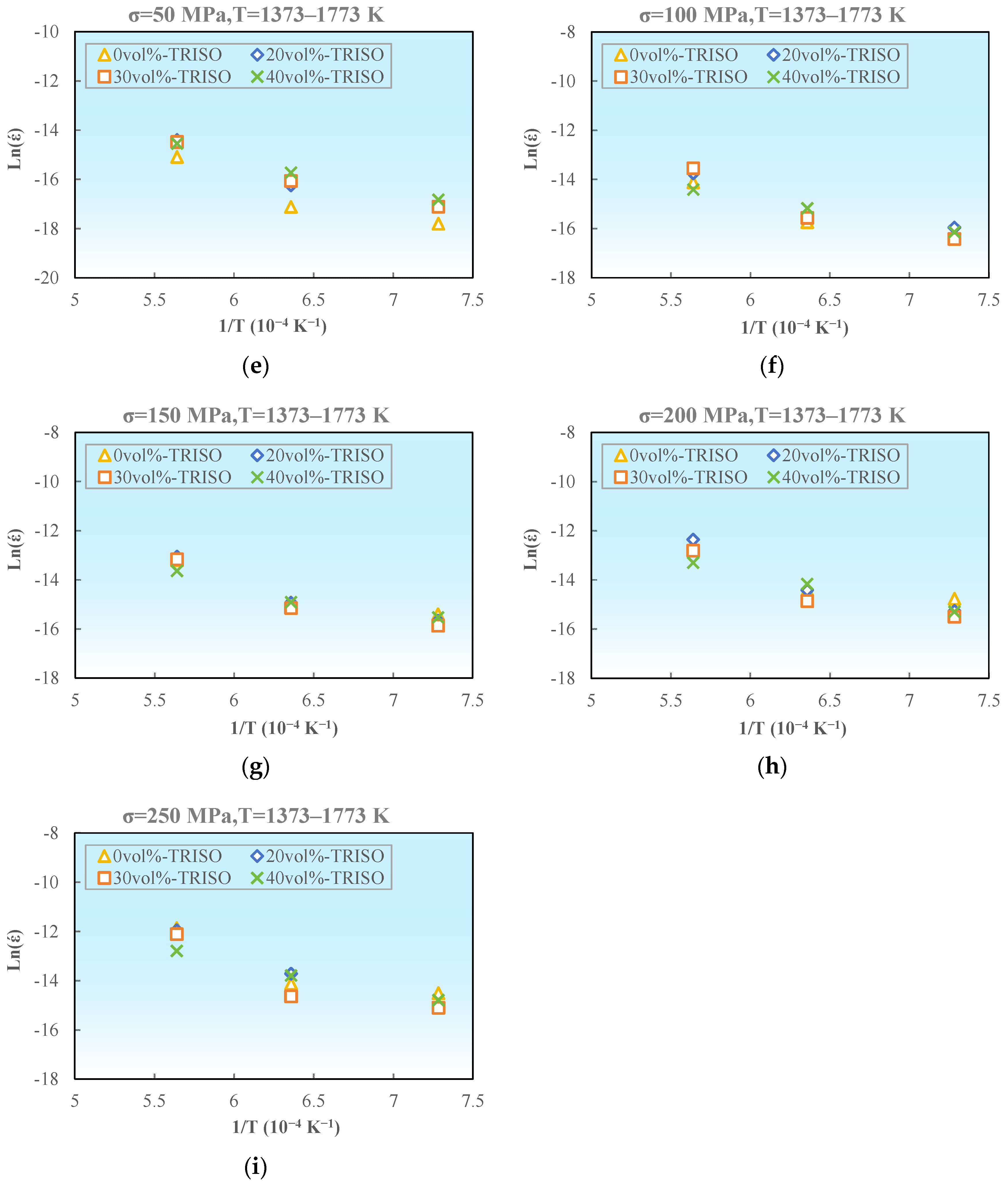

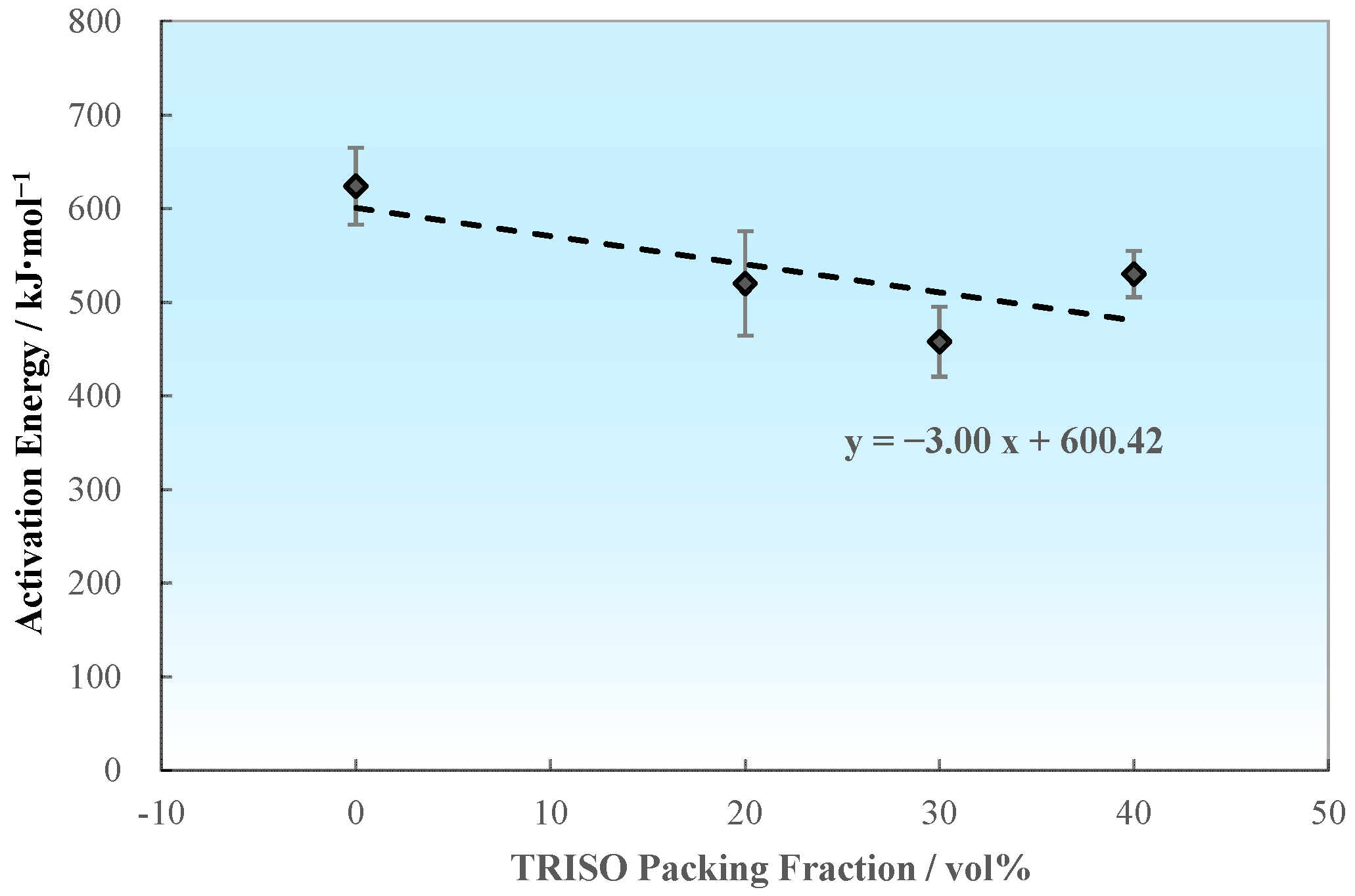

3.3.2. Activation Energy

3.4. Creep Modelling

4. Conclusions

- (1)

- The creep deformation of coated particle dispersed fuel pellets was mainly activated by the ZrC–SiC matrix, while the TRISO particle structure remained basically unchanged. The introduction of TRISO particles enhanced the creep performance of the pellets.

- (2)

- Creep stress exponents of the dispersed pellet ranged from 0.89 to 2.12, creep activation energies ranged from 457.81 to 623.77 kJ/mol for the high temperature low stress cases (1873–2073 K, 5–50 MPa), and from 135.14 to 161.59 kJ/mol for the low temperature high stress cases (1373–1773 K, 50–250 MPa). The creep stress exponents and creep activation energy of the dispersed pellet changed slightly with TRISO packing fraction.

- (3)

- Based on the experimental results, a steady-state creep strain rate calculation model for dispersed fuels is established, providing a valuable reference tool for the research and deployment of ceramic matrix dispersed coated particle fuels.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zinkle, S.J.; Terrani, K.A.; Gehin, J.C.; Ott, L.J.; Snead, L.L. Accident tolerant fuels for LWRs: A perspective. J. Nucl. Mater. 2014, 448, 374–379. [Google Scholar] [CrossRef]

- Was, G.S.; Petti, D.; Ukai, S.; Zinkle, S. Materials for future nuclear energy systems. J. Nucl. Mater. 2019, 527, 151837. [Google Scholar] [CrossRef]

- Ott, L.J.; Robb, K.R.; Wang, D. Preliminary assessment of accident-tolerant fuels on LWR performance during normal operation and under DB and BDB accident conditions. J. Nucl. Mater. 2014, 448, 520–533. [Google Scholar] [CrossRef]

- Ang, C.; Snead, L.; Kato, Y. A logical approach for zero-rupture fully ceramic microencapsulated (FCM) fuels via pressure-assisted sintering route. J. Nucl. Mater. 2020, 531, 151987. [Google Scholar] [CrossRef]

- Huang, J.; Li, N.; Zhang, Y.; Guo, Q.; Zhang, J. The safety analysis of a small pressurized water reactor utilizing fully ceramic microencapsulated fuel. Nucl. Eng. Des. 2017, 320, 250–257. [Google Scholar] [CrossRef]

- Chun, J.H.; Lim, S.W.; Chung, B.D.; Lee, W.L. Safety evaluation of accident-tolerant FCM fueled core with SiC-coated zircalloy cladding for design-basis-accidents and beyond DBAs. Nucl. Eng. Des. 2015, 289, 287–295. [Google Scholar] [CrossRef]

- Schappel, D.; Terrani, K.; Powers, J.J.; Snead, L.L.; Wirth, B.D. Modeling the performance of TRISO-based fully ceramic matrix (FCM) fuel in an LWR environment using BISON. Nucl. Eng. Des. 2018, 335, 116–127. [Google Scholar] [CrossRef]

- Yang, Z.; Li, B.; Zhang, P.; Chu, M.; Bai, B.; Tang, H.; Zhong, Y.; Liu, X.; Gao, R.; Liu, T.; et al. Microstructure and thermal physical properties of SiC matrix microencapsulated composites at temperature up to 1900 °C. Ceram. Int. 2020, 46, 5159–5167. [Google Scholar] [CrossRef]

- Brown, N.R. A review of in-pile fuel safety tests of TRISO fuel forms and future testing opportunities in non-HTGR applications. J. Nucl. Mater. 2020, 534, 152139. [Google Scholar] [CrossRef]

- Snead, L.L.; Venneri, F.; Kim, Y.; Terrani, K.A.; Tulenko, J.E.; Forsberg, C.W.; Peterson, P.F.; Lahoda, E.J. Fully Ceramic Microencapsulated Fuels: A Transformational Technology for Present and Next Generation Reactors—Properties and Fabrication of FCM fuel. Trans. Am. Nucl. Soc. 2011, 104, 668–670. [Google Scholar]

- Terrani, K.A.; Snead, L.L.; Gehin, J.C. Microencapsulated fuel technology for commercial light water and advanced reactor application. J. Nucl. Mater. 2012, 427, 209–224. [Google Scholar] [CrossRef]

- Demkowicz, P.A.; Liu, B.; Hunn, J.D. Coated particle fuel: Historical perspectives and current progress. J. Nucl. Mater. 2019, 515, 434–450. [Google Scholar] [CrossRef]

- Terrani, K.A.; Kiggans, J.O.; Silva, C.M.; Shih, C.; Katoh, Y.; Snead, L.L. Progress on matrix SiC processing and properties for fully ceramic microencapsulated fuel form. J. Nucl. Mater. 2015, 457, 9–17. [Google Scholar] [CrossRef]

- Liu, C.; Huang, R.; Tan, J.; Lin, H.T.; Liu, M.; Liu, B.; Liu, R. Fully ceramic microencapsulated fuels fabricated by tape casting. J. Nucl. Mater. 2022, 564, 153675. [Google Scholar] [CrossRef]

- Kim, H.J.; Kang, E.S.; Kim, Y.W.; Lim, K.Y.; Lee, S.J. Effects of starting powder on microstructure and thermal conductivity of pressureless-sintered fully ceramic microencapsulated fuels. J. Eur. Ceram. Soc. 2023, 43, 783–791. [Google Scholar] [CrossRef]

- Kim, H.M.; Kang, E.S.; Kim, Y.W.; Lim, K.Y.; Lee, S.J. Pressureless sintering of fully ceramic microencapsulated fuels. J. Eur. Ceram. Soc. 2020, 15, 5180–5185. [Google Scholar] [CrossRef]

- Terrani, K.A.; Kiggans, J.O.; Katoh, Y.; Shimoda, K.; Montgomery, F.C.; Armstrong, B.L.; Parish, C.M.; Hinoki, T.; Hunn, J.D.; Snead, L.L. Fabrication and characterization of fully ceramic microencapsulated fuels. J. Nucl. Mater. 2012, 426, 268–276. [Google Scholar] [CrossRef]

- Kim, G.D.; Kim, Y.W. Processing of fully ceramic microencapsulated fuels with a small amount of additives by hot-pressing. J. Eur. Ceram. Soc. 2021, 41, 3980–3990. [Google Scholar] [CrossRef]

- Tan, J.; Huang, R.; Lin, H.T.; Liu, M.; Liu, B.; Liu, R. Fully ceramic microencapsulated fuels with high TRISO particles loading capacity fabricated by gel-casting. J. Nucl. Mater. 2023, 581, 154449. [Google Scholar] [CrossRef]

- Fu, L.; Huang, R.; Liu, R.; Liu, C.; Lin, H.T.; Liu, M.; Liu, B. Pressureless sintering of large sized fully ceramic microencapsulated fuel pellets. J. Nucl. Mater. 2024, 589, 154870. [Google Scholar] [CrossRef]

- Terrani, K.A.; Kiggans, J.O.; Lance, L. Snead. Fabrication and preliminary evaluation of metal matrix microencapsulated fuels. J. Nucl. Mater. 2012, 427, 79–86. [Google Scholar] [CrossRef]

- Ang, C.; Snead, L.; Benensky, K. Niobium carbide as a technology demonstrator of ultra-high temperature ceramics for fully ceramic microencapsulated fuels. Int. J. Ceram. Eng. Sci. 2019, 1, 92–102. [Google Scholar] [CrossRef]

- Katoh, Y.; Vasudevamurthy, G.; Nozawa, T.; Snead, L.L. Properties of zirconium carbide for nuclear fuel applications. J. Nucl. Mater. 2013, 441, 718–742. [Google Scholar] [CrossRef]

- Wei, B.; Wang, D.; Wang, Y.; Zhang, H.; Peng, S.; Xu, C.; Song, G.; Zhou, Y. Corrosion kinetics and mechanisms of ZrC1-x ceramics in high temperature water vapor. RSC Adv. 2018, 8, 18163–18174. [Google Scholar] [CrossRef]

- Pizon, D.; Charpentier, L.; Lucas, R.; Foucaud, S.; Maitre, A.; Balat-Pichelin, M. Oxidation behavior of spark plasma sintered ZrC-SiC composites obtained from the polymer-derived ceramics route. Ceram. Int. 2014, 40, 5025–5031. [Google Scholar] [CrossRef]

- Fahrenholtz, W.G.; Hilmas, G.E. Ultra-high temperature ceramics: Materials for extreme environments. Scr. Mater. 2017, 129, 94–99. [Google Scholar] [CrossRef]

- Gong, B.; Zhao, D.; Broussard, A.; Harp, J.; Nelson, A.T.; Lian, J. High-temperature compressive creep tests of U3Si2 with spark plasma sintering: Experiments and finite element modeling. J. Nucl. Mater. 2022, 561, 153568. [Google Scholar] [CrossRef]

- Snead, L.; Nozawa, T.; Katoh, Y. Handbook of SiC properties for fuel performance modeling. J. Nucl. Mater. 2007, 371, 329–377. [Google Scholar] [CrossRef]

- Antou, G.; Ohin, M.D.; Lucas, R.; Trolliard, G.; Clegg, W.J.; Foucaud, S.; Maître, A. Thermomechanical properties of a spark plasma sintered ZrC–SiC composite obtained by a precursor derived ceramic route. Mat. Sci. Eng A 2015, 643, 1–11. [Google Scholar] [CrossRef]

- Connor, B.; Ang, C. Analysis of initial stage densification kinetics of zirconium carbide (ZrC) powders. J. Eur. Ceram. Soc. 2025, 45, 117114. [Google Scholar] [CrossRef]

- Bird, M.W.; Aune, R.P.; Yu, F.; Becher, P.F.; White, K.W. Creep behavi.or of a zirconium diboride–silicon carbide composite. J. Eur. Ceram. Soc. 2013, 33, 2407–2420. [Google Scholar] [CrossRef]

- Guo, H.; Zou, W.; Moskovskikh, D.; Yudin, S.; Cheng, Z.; Volodko, S.; Zhang, C. High creep resistance of (Hf0.2Ta0.2Ti0.2Nb0.2Zr0.2)C high entropy ceramics prepared by spark plasma sintering of the self-propagating high temperature synthesized powders. Ceram. Int. 2025, 51, 5148–5158. [Google Scholar] [CrossRef]

- Han, X.; Girman, V.; Sedlak, R.; Dusza, J.; Castle, E.G.; Wang, Y.; Reece, M.; Zhang, C. Improved creep resistance of high entropy transition metal carbides. J. Eur. Ceram. Soc. 2020, 40, 2709–2715. [Google Scholar] [CrossRef]

- Šajgalík, P.; Cheng, Z.; Han, X.; Zhang, C.; Hanzel, O.; Sedláček, J.; Orlova, T.; Zhukovskyi, M.; Mukasyan, A.S. Ultra-high creep resistant SiC ceramics prepared by rapid hot pressing. J. Eur. Ceram. Soc. 2022, 42, 820–829. [Google Scholar] [CrossRef]

| TRISO Packing Fraction, vol% | Density, g/cm3 | Theoretical Density, g/cm3 | Relative Density, % | TRISO Packing Fraction, vol% |

|---|---|---|---|---|

| 0 | 4.30 | 4.32 | 99.5 | 0 |

| 20 | 3.92 | 3.96 | 99.0 | 20 |

| 30 | 3.62 | 3.78 | 95.8 | 30 |

| 40 | 3.51 | 3.60 | 97.5 | 40 |

| Samples | Stress/MPa | Temperature/K | |||||

|---|---|---|---|---|---|---|---|

| 1373 | 1573 | 1773 | 1873 | 1973 | 2073 | ||

| Holding Time ~60 min | Holding Time ~10 min | ||||||

| TRISO packing fraction 0 vol%, 20 vol%, 30 vol%, and 40 vol% | 5 | √ | √ | √ | |||

| 20 | √ | √ | √ | ||||

| 40 | √ | √ | √ | ||||

| 50 | √ | √ | √ | √ | √ | √ | |

| 100 | √ | √ | √ | ||||

| 150 | √ | √ | √ | ||||

| 200 | √ | √ | √ | ||||

| 250 | √ | √ | √ | ||||

| Temperature | 1373 K | 1573 K | 1773 K | 1873 K | 1973 K | 2073 K | |

|---|---|---|---|---|---|---|---|

| TRISO Content | |||||||

| 0 vol% | 2.12 | 1.89 | 1.98 | 1.14 | 1.26 | 1.27 | |

| 20 vol% | 1.20 | 1.51 | 1.54 | 1.49 | 1.37 | 1.60 | |

| 30 vol% | 1.24 | 0.89 | 1.36 | 1.07 | 1.16 | 1.13 | |

| 40 vol% | 1.23 | 1.17 | 1.09 | 1.36 | 0.95 | 1.27 | |

| Stress | 5 MPa | 20 MPa | 40 MPa | 50 MPa | Average (Std. Deviation) | |

|---|---|---|---|---|---|---|

| TRISO Content | ||||||

| 0 vol% | 606.85 | 592.17 | 612.14 | 683.91 | 623.77 (40.97) | |

| 20 vol% | 487.40 | 482.50 | 507.84 | 602.15 | 519.97 (55.88) | |

| 30 vol% | 465.15 | 402.83 | 481.59 | 481.67 | 457.81 (37.47) | |

| 40 vol% | 561.88 | 536.60 | 513.85 | 507.60 | 529.98 (24.65) | |

| Stress | 50 MPa | 100 MPa | 150 MPa | 200 MPa | 250 MPa | Average (Std. Deviation) | |

|---|---|---|---|---|---|---|---|

| TRISO Content | |||||||

| 0 vol% | 133.50 | 202.81 | 108.50 | 107.70 | 129.15 | 136.33 (38.96) | |

| 20 vol% | 193.87 | 178.17 | 128.91 | 143.23 | 157.64 | 160.36 (26.13) | |

| 30 vol% | 197.80 | 198.20 | 133.14 | 132.85 | 145.94 | 161.59 (33.66) | |

| 40 vol% | 175.82 | 147.07 | 151.82 | 100.43 | 100.58 | 135.14 (33.45) | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, Q.; Liu, Y.; Fang, R.; Wu, L.; Liu, W. Compressive Creep Performances of Dispersion Coated Particle Surrogate Fuel Pellets with ZrC–SiC Composite Matrix. Materials 2025, 18, 2659. https://doi.org/10.3390/ma18112659

Ren Q, Liu Y, Fang R, Wu L, Liu W. Compressive Creep Performances of Dispersion Coated Particle Surrogate Fuel Pellets with ZrC–SiC Composite Matrix. Materials. 2025; 18(11):2659. https://doi.org/10.3390/ma18112659

Chicago/Turabian StyleRen, Qisen, Yang Liu, Runjie Fang, Lixiang Wu, and Weiqiang Liu. 2025. "Compressive Creep Performances of Dispersion Coated Particle Surrogate Fuel Pellets with ZrC–SiC Composite Matrix" Materials 18, no. 11: 2659. https://doi.org/10.3390/ma18112659

APA StyleRen, Q., Liu, Y., Fang, R., Wu, L., & Liu, W. (2025). Compressive Creep Performances of Dispersion Coated Particle Surrogate Fuel Pellets with ZrC–SiC Composite Matrix. Materials, 18(11), 2659. https://doi.org/10.3390/ma18112659