A Constitutive Equation and Numerical Study on the Tensile Behavior of Reinforcing Steel Under Different Mass Loss Ratios

Abstract

1. Introduction

2. Experimental Program

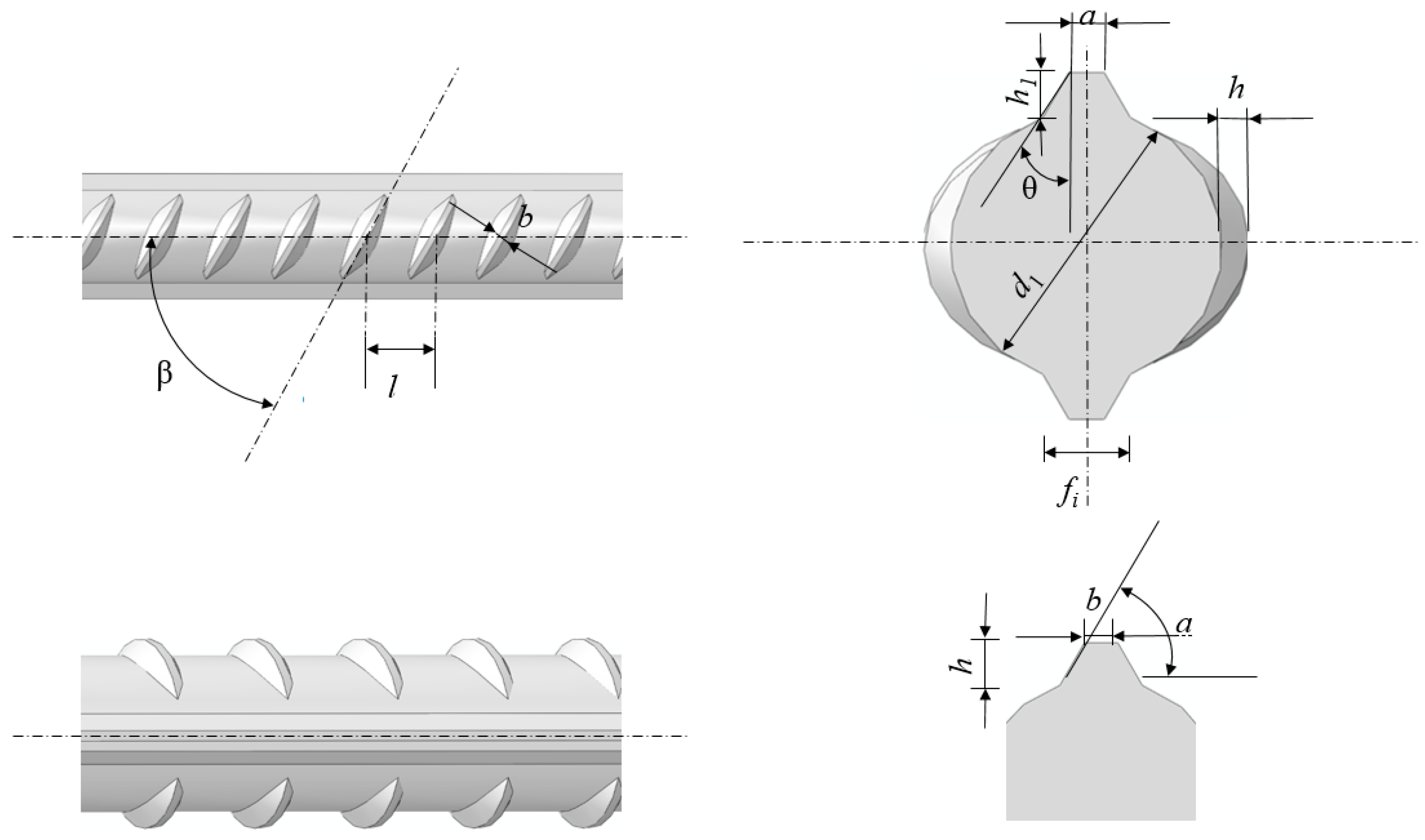

2.1. Specimen Design

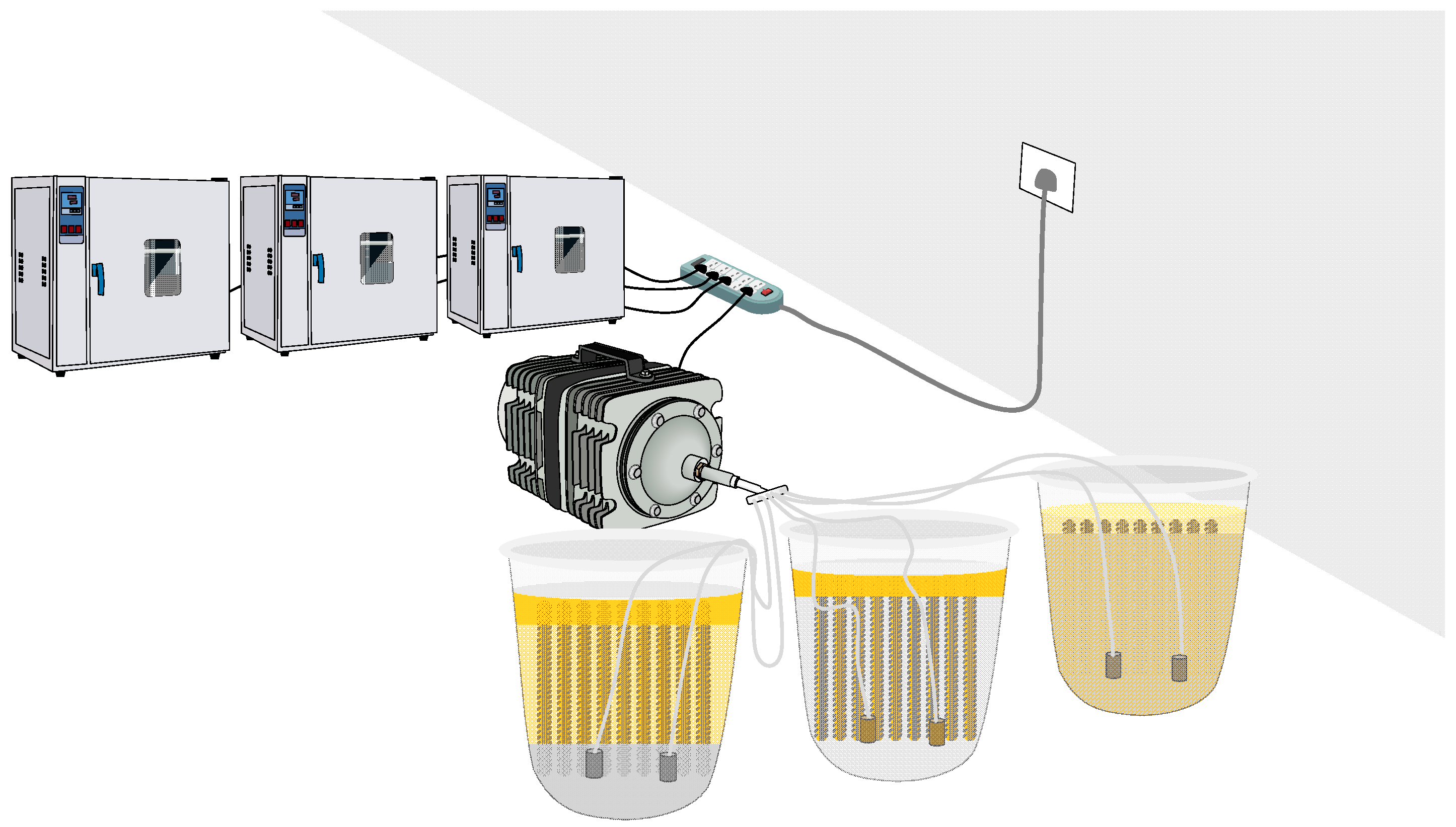

2.2. Corrosion Process

2.3. Loading Scheme of the Artificially Corroded Bar Reinforcement

3. Experimental Results and Analysis

3.1. Surface Topography

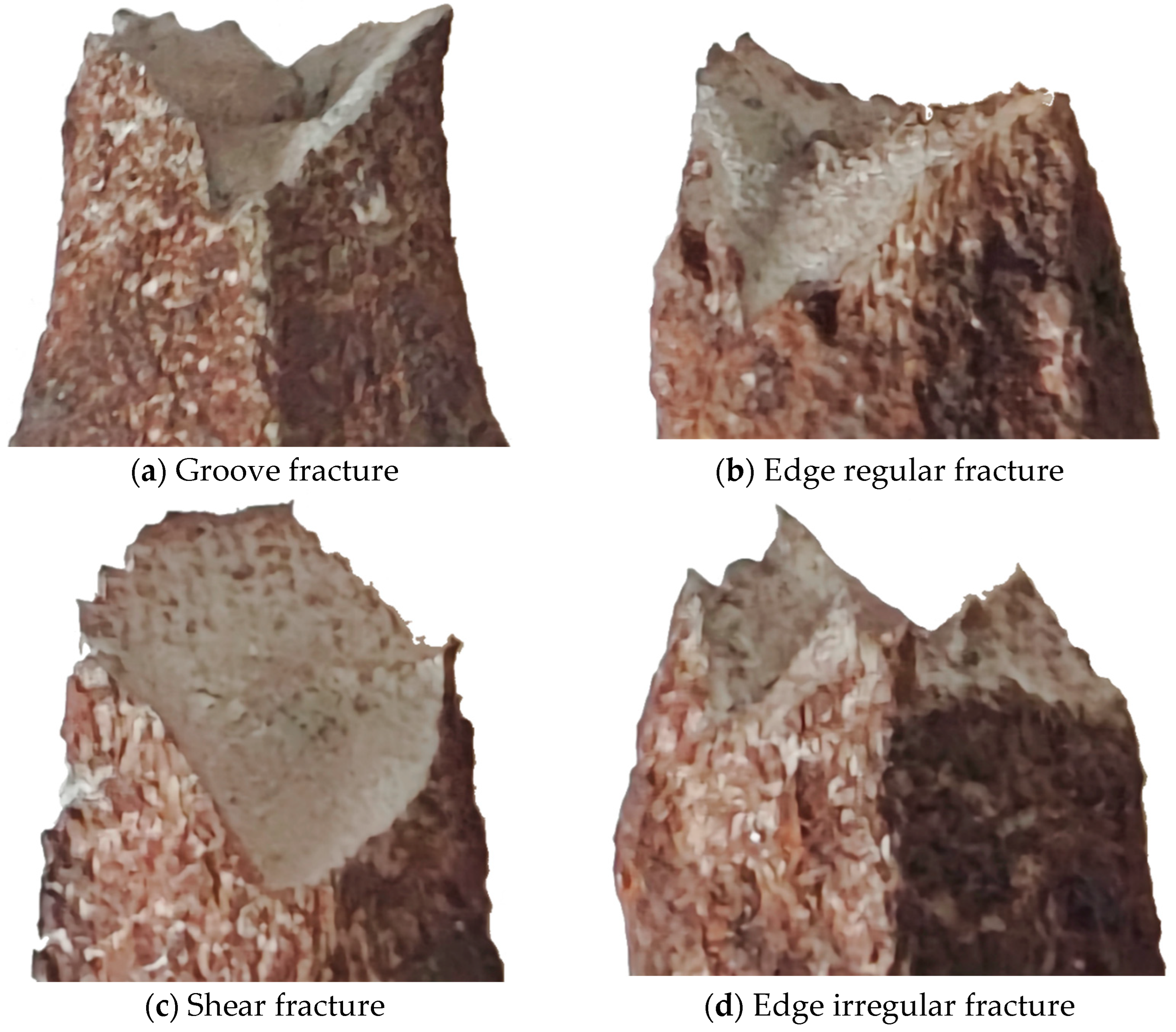

3.2. Tensile Failure Morphology

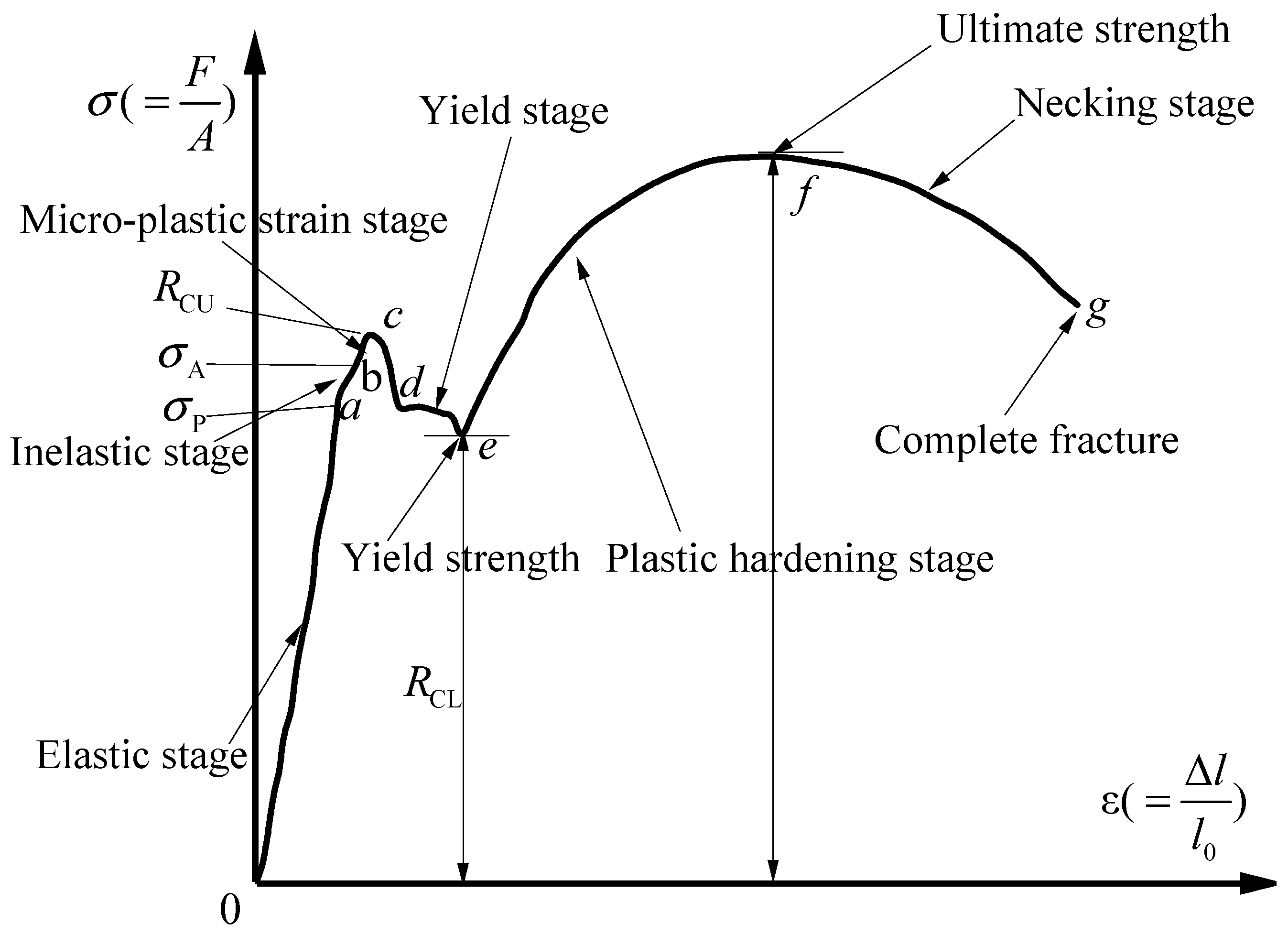

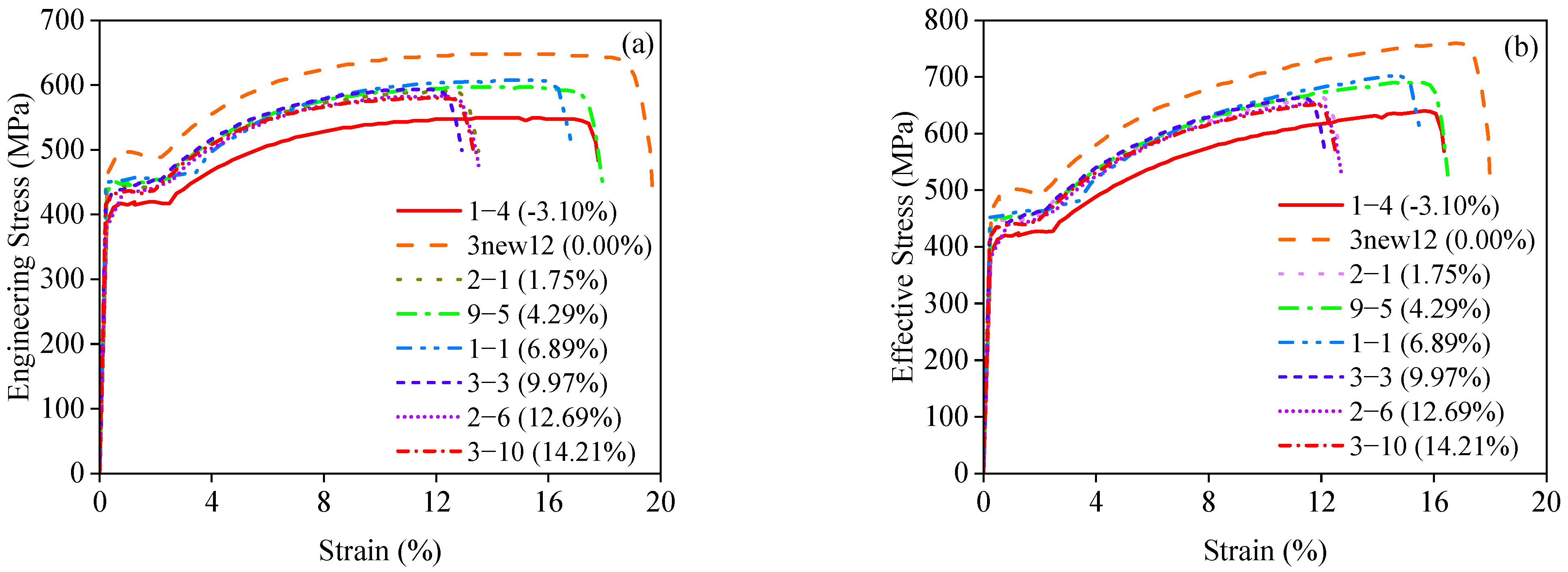

3.3. Tensile Stress–Strain Curves at Different Mass Loss Ratios

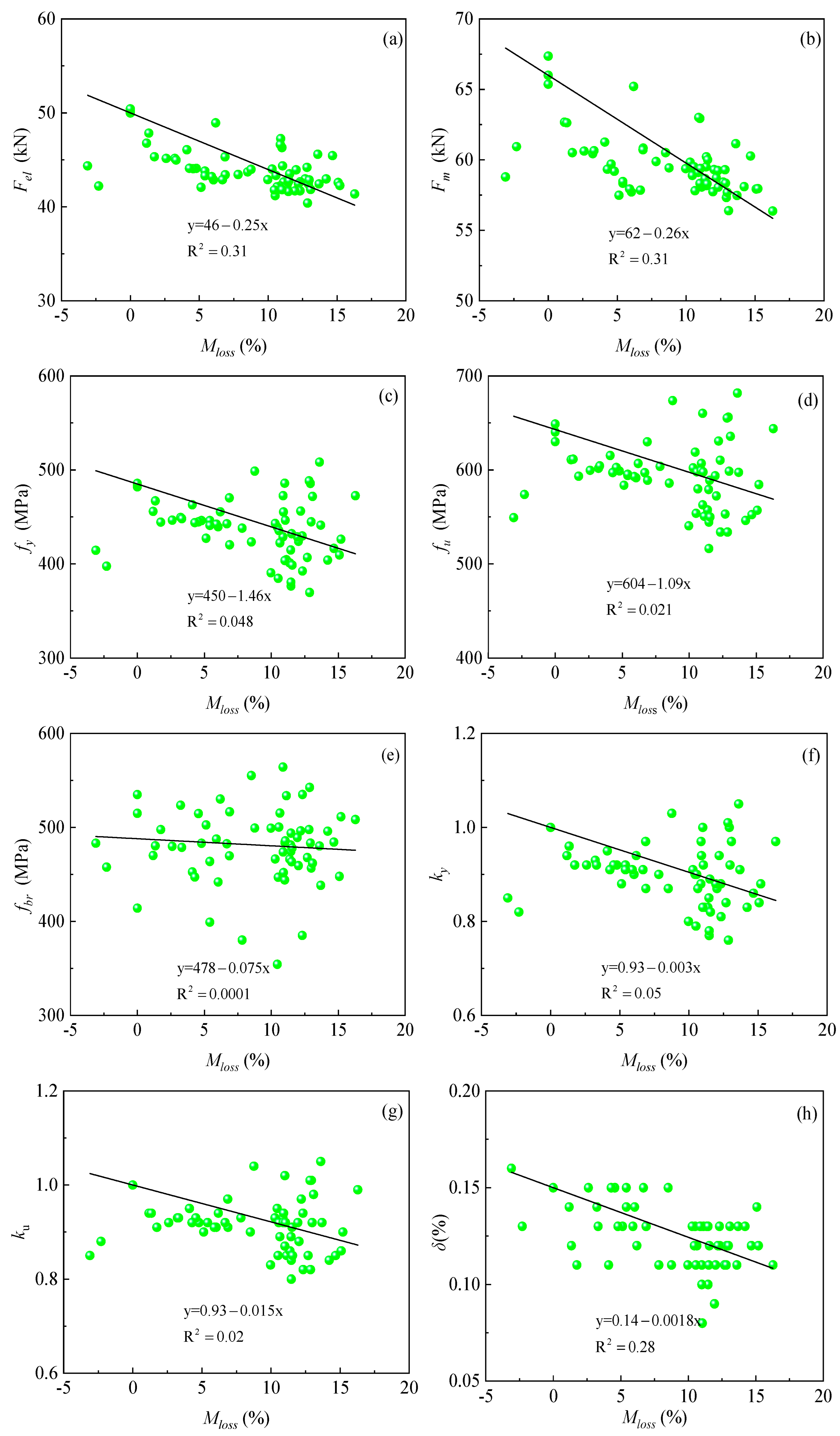

3.4. Effects of Mass Loss Ratios on Mechanical Properties

4. Mechanical Properties Degradation Model

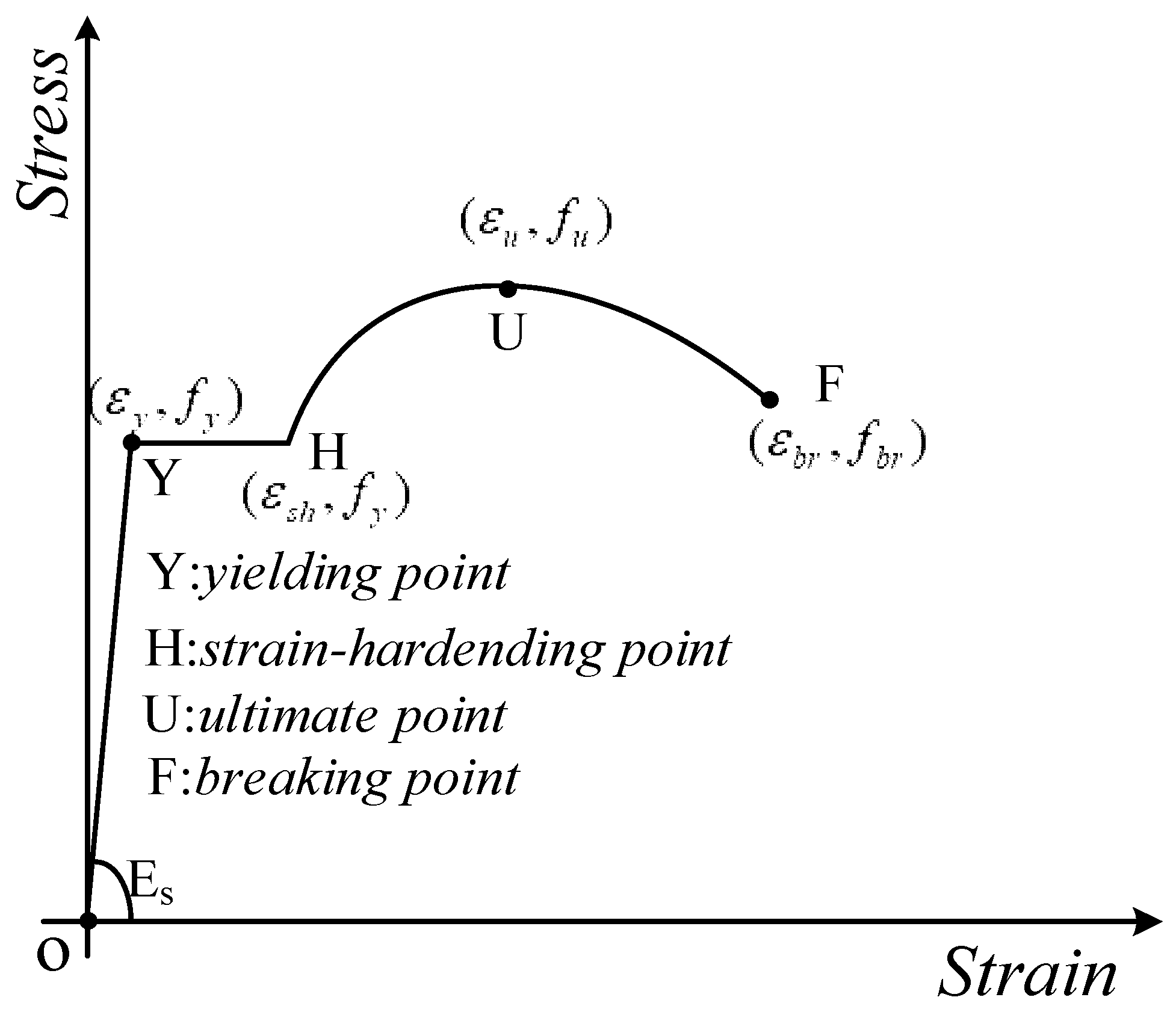

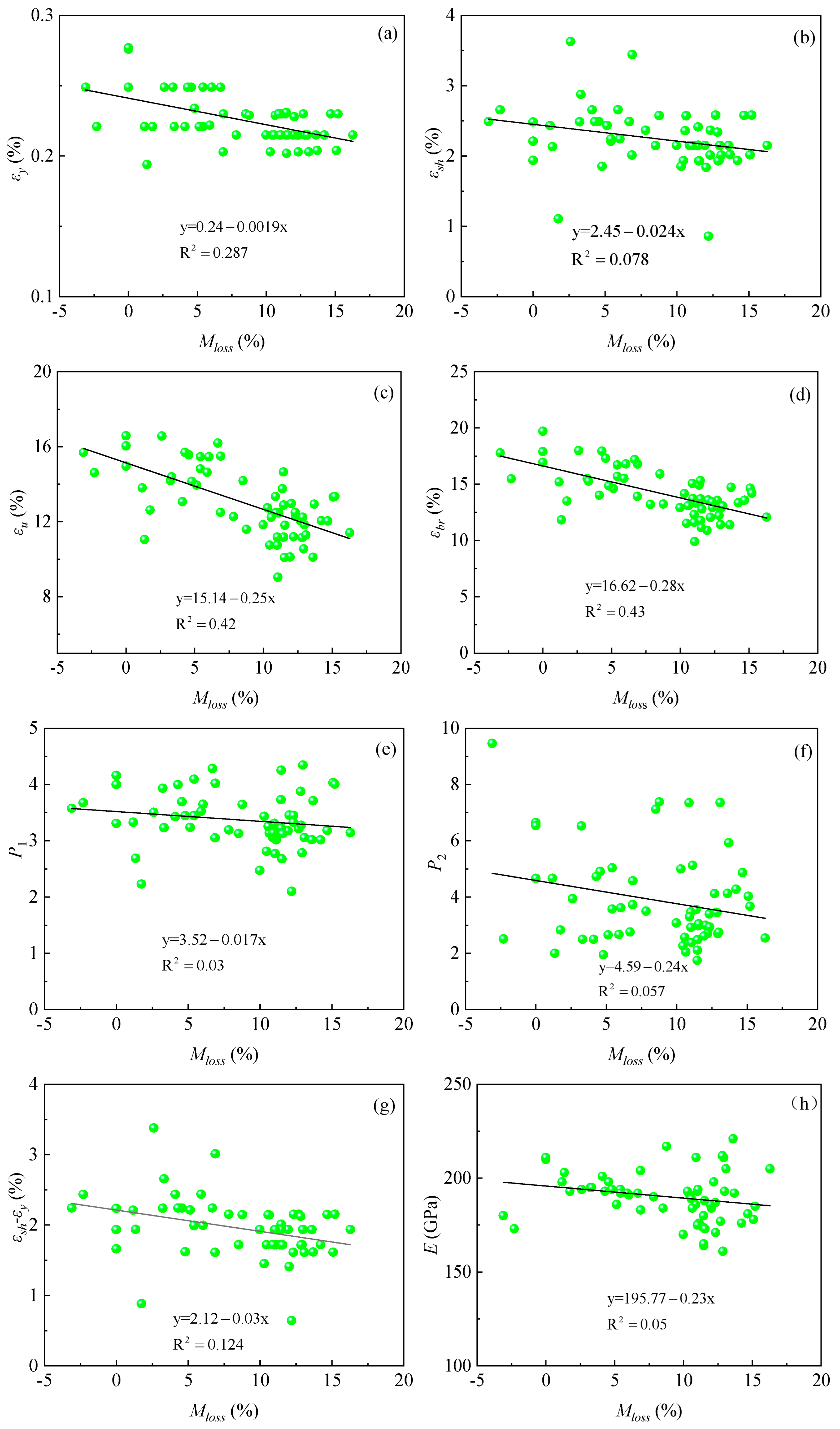

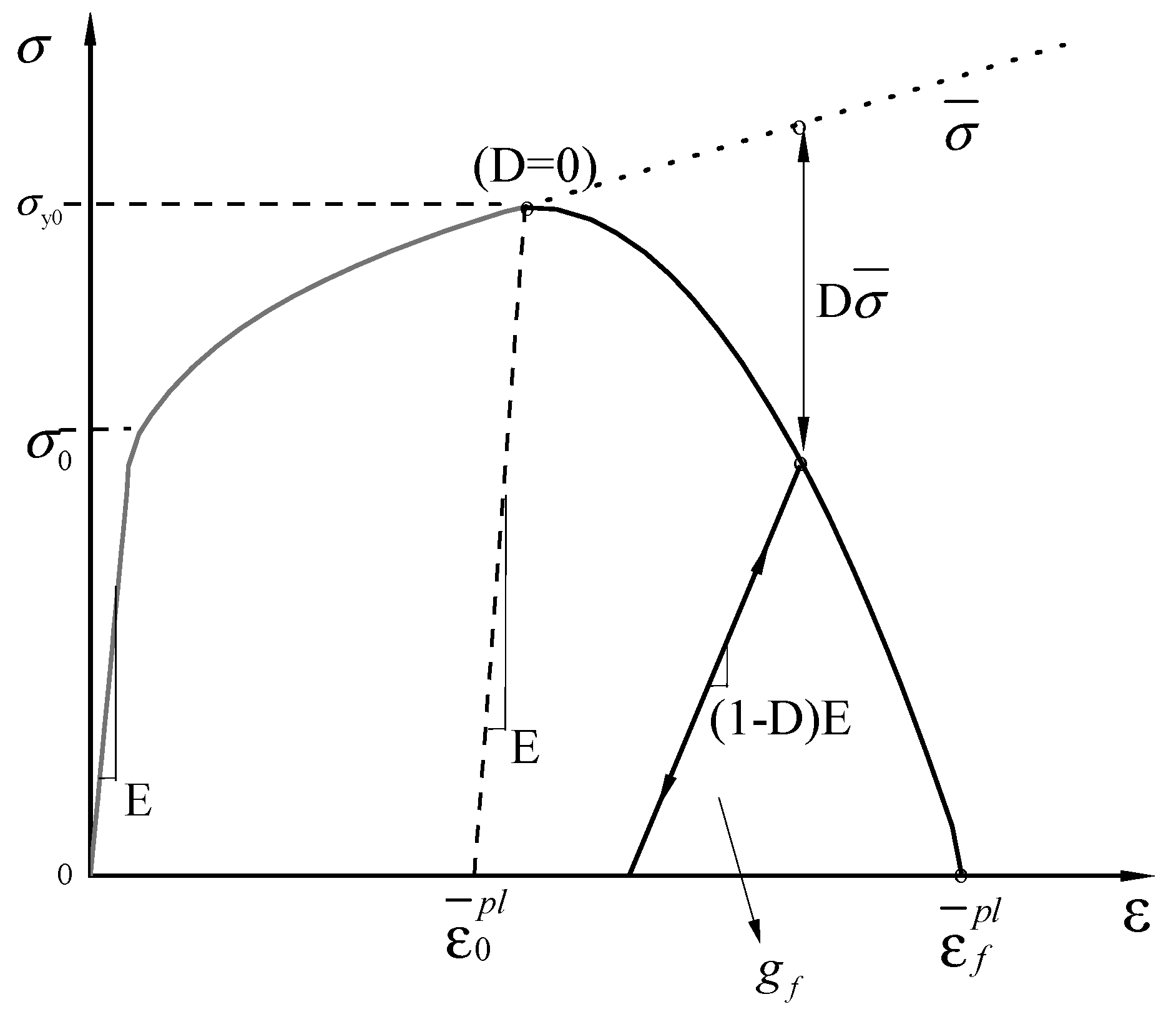

4.1. Constitutive Model

4.2. Comparison Between Experimental Model and Computational Model

4.3. Mechanical Degradation Model

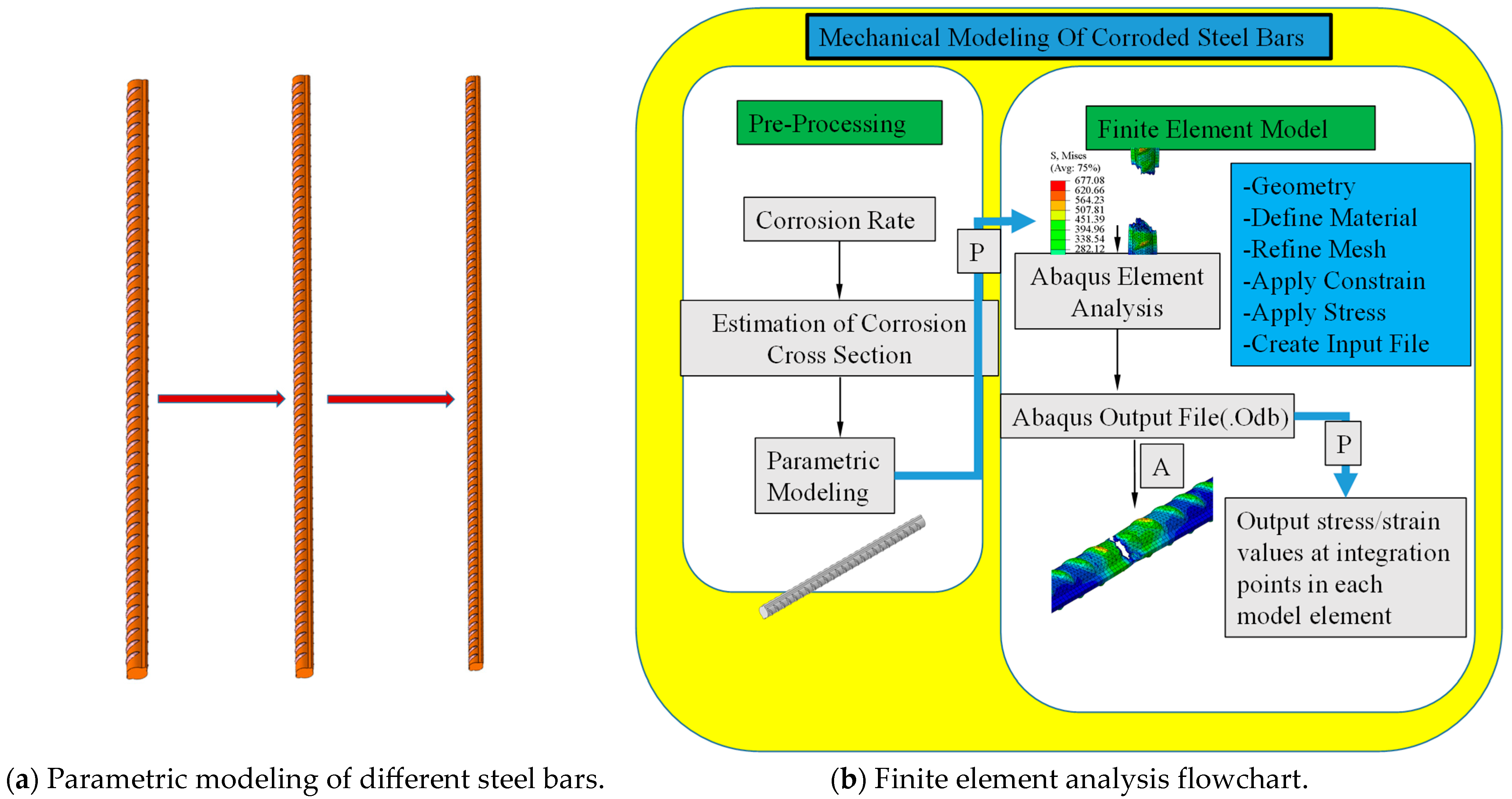

5. Numerical Simulation

5.1. HDD Guidelines

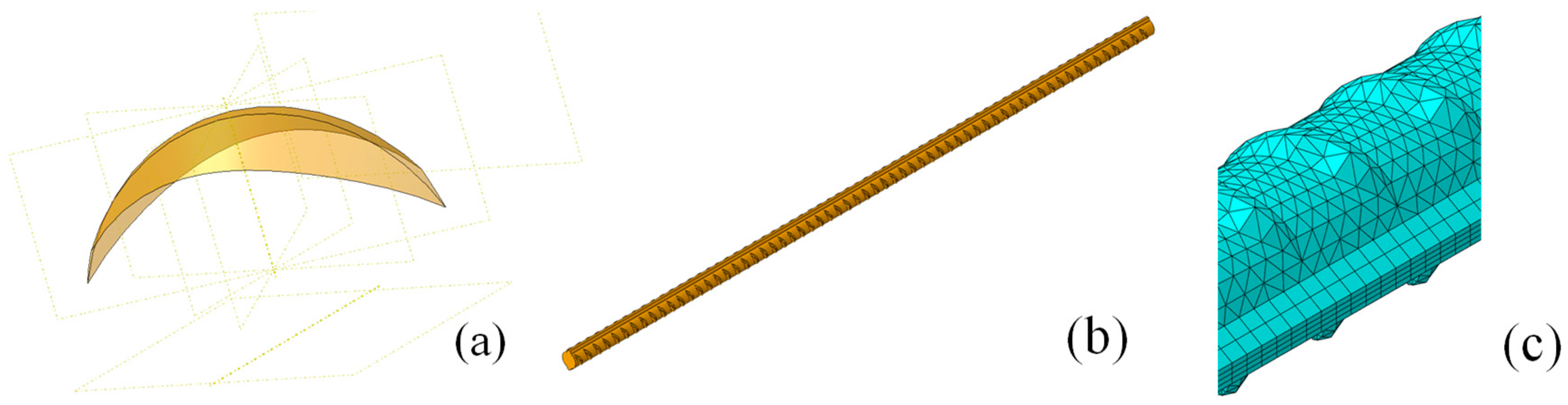

5.2. Finite Element Refinement Modeling and Analysis

5.2.1. Model Establishment and Grid Division

5.2.2. Loading Application and Boundary Conditions

5.2.3. Stress Distribution Analysis

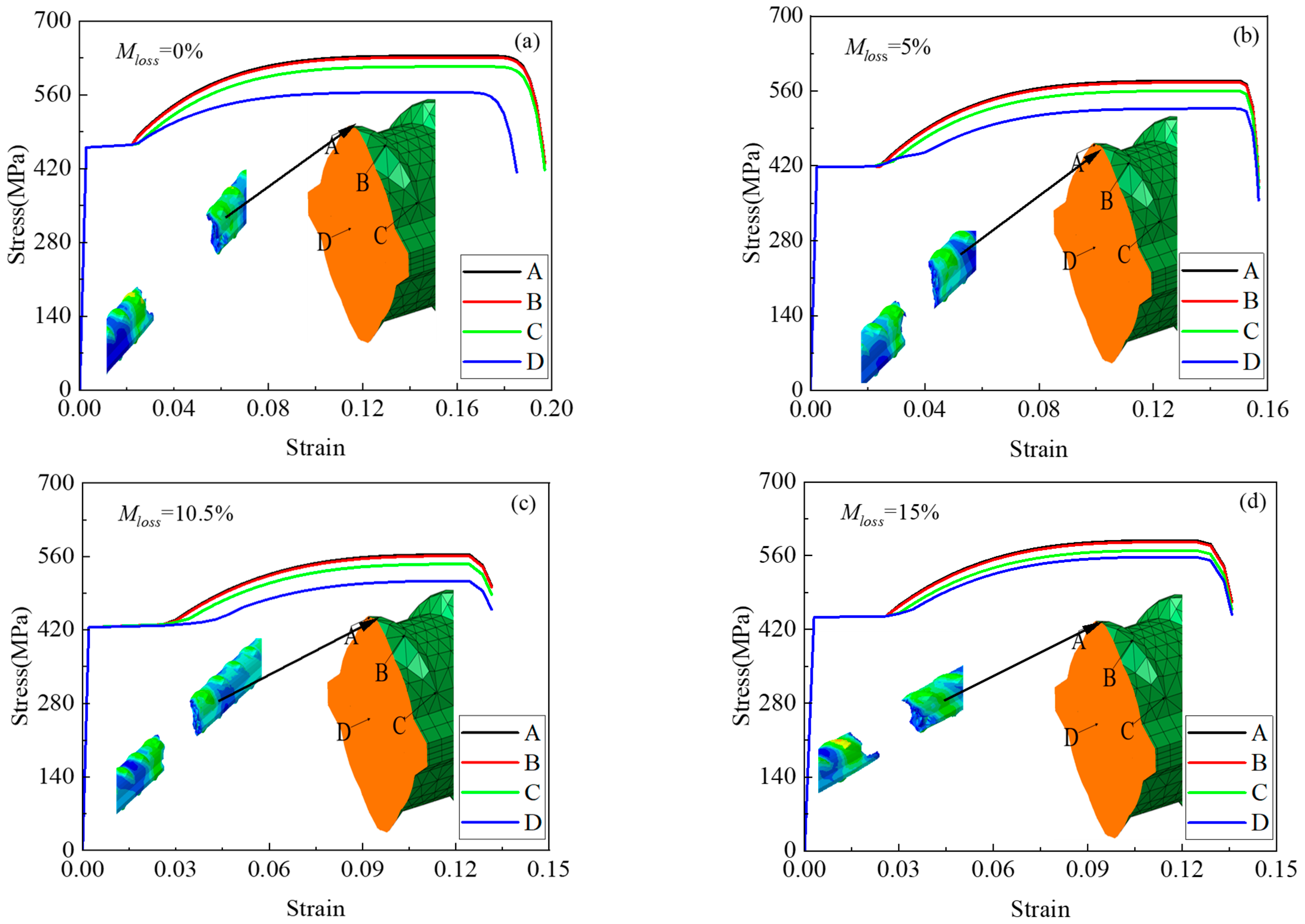

5.2.4. Contrastive Analysis of Stress–Strain Relationship

5.3. Models of Stress–Strain Relationship

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fernandez, I.; Bairán, J.M.; Marí, A.R. 3D FEM model development from 3D optical measurement technique applied to corroded steel bars. Constr. Build. Mater. 2016, 124, 519–532. [Google Scholar] [CrossRef]

- Caprili, S.; Salvatore, W. Cyclic behaviour of uncorroded and corroded steel reinforcing bars. Constr. Build. Mater. 2015, 76, 168–186. [Google Scholar] [CrossRef]

- Fernandez, I.; Bairán, J.M.; Marí, A.R. Corrosion effects on the mechanical properties of reinforcing steel bars. Fatigue and σ–ε behavior. Constr. Build. Mater. 2015, 101, 772–783. [Google Scholar] [CrossRef]

- Balestra, C.E.T.; Lima, M.G.; Silva, A.R.; Medeiros-Junior, R.A. Corrosion Degree Effect on Nominal and Effective Strengths of Naturally Corroded Reinforcement. J. Mater. Civ. Eng. 2016, 28, 04016103. [Google Scholar] [CrossRef]

- Meda, A.; Mostosi, S.; Rinaldi, Z.; Riva, P. Experimental evaluation of the corrosion influence on the cyclic behaviour of RC columns. Eng. Struct. 2014, 76, 112–123. [Google Scholar] [CrossRef]

- Ou, Y.-C.; Susanto, Y.T.T.; Roh, H. Tensile behavior of naturally and artificially corroded steel bars. Constr. Build. Mater. 2016, 103, 93–104. [Google Scholar] [CrossRef]

- Papadopoulos, M.; Apostolopoulos, C.; Alexopoulos, N.; Pantelakis, S. Effect of salt spray corrosion exposure on the mechanical performance of different technical class reinforcing steel bars. Mater. Des. 2007, 28, 2318–2328. [Google Scholar] [CrossRef]

- Farhad, F.; Zhang, X.; Smyth-Boyle, D. Fatigue behaviour of corrosion pits in X65 steel pipelines. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2018, 233, 1771–1782. [Google Scholar] [CrossRef]

- Wang, J.; Yuan, Y.; Xu, Q.; Qin, H. Prediction of Corrosion-Induced Longitudinal Cracking Time of Concrete Cover Surface of Reinforced Concrete Structures under Load. Materials 2022, 15, 7395. [Google Scholar] [CrossRef]

- Wang, X.; Ba, M.; Yi, B.; Liu, J. Experimental and numerical investigation on the effect of cracks on chloride diffusion and steel corrosion in concrete. J. Build. Eng. 2024, 86, 108521. [Google Scholar] [CrossRef]

- Sola, E.; Ožbolt, J.; Balabanić, G.; Mir, Z. Experimental and numerical study of accelerated corrosion of steel reinforcement in concrete: Transport of corrosion products. Cem. Concr. Res. 2019, 120, 119–131. [Google Scholar] [CrossRef]

- Qin, G.-C.; Xu, S.-H.; Yao, D.-Q.; Zhang, Z.-X. Study on the degradation of mechanical properties of corroded steel plates based on surface topography. J. Constr. Steel Res. 2016, 125, 205–217. [Google Scholar] [CrossRef]

- Li, D.; Xiong, C.; Huang, T.; Wei, R.; Han, N.; Xing, F. A simplified constitutive model for corroded steel bars. Constr. Build. Mater. 2018, 186, 11–19. [Google Scholar] [CrossRef]

- Meda, A.; Mostosi, S.; Rinaldi, Z.; Riva, P. Corroded RC columns repair and strengthening with high performance fiber reinforced concrete jacket. Mater. Struct. 2015, 49, 1967–1978. [Google Scholar] [CrossRef]

- di Carlo, F.; Meda, A.; Rinaldi, Z. Numerical Modelling of Corroded RC Columns Repaired with High Performance Fiber Reinforced Concrete Jacket. Key Eng. Mater. 2016, 711, 1004–1011. [Google Scholar] [CrossRef]

- Yu, L.; François, R.; Dang, V.H.; L’hostis, V.; Gagné, R. Distribution of corrosion and pitting factor of steel in corroded RC beams. Constr. Build. Mater. 2015, 95, 384–392. [Google Scholar] [CrossRef]

- Fu, C.; Jin, N.; Ye, H.; Jin, X.; Dai, W. Corrosion characteristics of a 4-year naturally corroded reinforced concrete beam with load-induced transverse cracks. Corros. Sci. 2017, 117, 11–23. [Google Scholar] [CrossRef]

- Wang, J.; Su, H.; Du, J.-S. Corrosion Characteristics of Steel Bars Embedded in Recycled Concrete Beams under Static Loads. J. Mater. Civ. Eng. 2020, 32, 04020263. [Google Scholar] [CrossRef]

- Wang, J.; Xu, Q. The combined effect of load and corrosion on the flexural performance of recycled aggregate concrete beams. Struct. Concr. 2022, 24, 359–373. [Google Scholar] [CrossRef]

- Van Nguyen, C.; Bui, Q.H.; Lambert, P. Experimental and numerical evaluation of the structural performance of corroded reinforced concrete beams under different corrosion schemes. Structures 2022, 45, 2318–2331. [Google Scholar] [CrossRef]

- Zeng, C.; Zhu, J.-H.; Xiong, C.; Li, Y.; Li, D.; Walraven, J. Analytical model for the prediction of the tensile behaviour of corroded steel bars. Constr. Build. Mater. 2020, 258, 120290. [Google Scholar] [CrossRef]

- Imperatore, S.; Rinaldi, Z.; Drago, C. Degradation relationships for the mechanical properties of corroded steel rebars. Constr. Build. Mater. 2017, 148, 219–230. [Google Scholar] [CrossRef]

- Gao, X.; Pan, Y.; Ren, X. Probabilistic model of the minimum effective cross-section area of non-uniform corroded steel bars. Constr. Build. Mater. 2019, 216, 227–238. [Google Scholar] [CrossRef]

- Liu, Y.; Yuan, H.; Miao, Z.; Geng, X.; Shao, X.; Lu, Y. Tensile behaviour of pitting corroded steel bars: Laboratory investigation and probabilistic-based analysis. Constr. Build. Mater. 2023, 411, 134502. [Google Scholar] [CrossRef]

- Apostolopoulos, A.; Matikas, T.E. Corrosion of bare and embedded in concrete steel bar—Impact on mechanical behavior. Int. J. Struct. Integr. 2016, 7, 240–259. [Google Scholar] [CrossRef]

- Xu, Q.; Wang, J.; Tian, Z.; Song, J.; Chen, B. Experimental Study on the Flexural Performance of Composite Beams with Corrugated Steel Webs under the Coupled Effect of Chloride Ion Erosion and Sustained Load. Buildings 2023, 13, 2611. [Google Scholar] [CrossRef]

- Castorena-González, J.H.; Martin, U.; Gaona-Tiburcio, C.; Núñez-Jáquez, R.E.; Almeraya-Calderón, F.M.; Bastidas, J.M.; Bastidas, D.M. Modeling Steel Corrosion Failure in Reinforced Concrete by Cover Crack Width 3D FEM Analysis. Front. Mater. 2020, 7, 00041. [Google Scholar] [CrossRef]

- Vera, R.; Valverde, B.; Olave, E.; Sánchez, R.; Díaz-Gómez, A.; Muñoz, L.; Rojas, P. Atmospheric corrosion and impact toughness of steels: Case study in steels with and without galvanizing, exposed for 3 years in Rapa Nui Island. Heliyon 2023, 9, e17811. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Guo, X.; Zhao, H.; Hu, D.; Gu, X.; Li, R. A probabilistic stress-strain relationship model for steel bars including the non-uniform corrosion effects in chloride environments. Case Stud. Constr. Mater. 2025, 22, e04262. [Google Scholar] [CrossRef]

- Wood, R.; Walker, J.; Harvey, T.; Wang, S.; Rajahram, S. Influence of microstructure on the erosion and erosion–corrosion characteristics of 316 stainless steel. Wear 2013, 306, 254–262. [Google Scholar] [CrossRef]

- Wang, Y.; Wharton, J.A.; Shenoi, R.A. Ultimate strength analysis of aged steel-plated structures exposed to marine corrosion damage: A review. Corros. Sci. 2014, 86, 42–60. [Google Scholar] [CrossRef]

- Chen, Z.; Yu, Q.; Zhao, L.; Zhang, C.; Gu, M.; Wang, Q.; Wang, G. Insight into the role of Si on corrosion resistance of weathering steel in a simulated industrial atmosphere. J. Mater. Res. Technol. 2023, 26, 487–503. [Google Scholar] [CrossRef]

- Dai, K.; Li, S.; Hu, P.; Jiang, N.; Wang, D. Effect of outer rust layer on cathodic protection and corrosion behavior of high-strength wire hangers with sheath crack in marine rainfall environment. Case Stud. Constr. Mater. 2023, 18, e02043. [Google Scholar] [CrossRef]

- Zhu, W.; Yu, Z.; Yang, C.; Dong, F.; Ren, Z.; Zhang, K. Spatial Distribution of Corrosion Products Influenced by the Initial Defects and Corrosion-Induced Cracking of the Concrete. J. Test. Eval. 2023, 51, 2582–2597. [Google Scholar] [CrossRef]

- Zhao, L.; Wang, J.; Gao, P.; Yuan, Y. Experimental study on the corrosion characteristics of steel bars in concrete considering the effects of multiple factors. Case Stud. Constr. Mater. 2023, 20, e02706. [Google Scholar] [CrossRef]

- ISO/FDIS 15630-1; Steel for the Reinforcement and Prestressing of Concrete—Test Methods—Part 1: Reinforcing Bars, Wire Rod and Wire. International Organization for Standardization: Geneva, Switzerland, 2002.

- Dang, V.H.; François, R. Influence of long-term corrosion in chloride environment on mechanical behaviour of RC beam. Eng. Struct. 2013, 48, 558–568. [Google Scholar] [CrossRef]

- Zhu, W.; Yang, C.; Yu, Z.; Xiao, J.; Xu, Y. Impact of Defects in Steel-Concrete Interface on the Corrosion-Induced Cracking Propagation of the Reinforced Concrete. KSCE J. Civ. Eng. 2023, 27, 2621–2628. [Google Scholar] [CrossRef]

- Gu, X.-L.; Dong, Z.; Yuan, Q.; Zhang, W.-P. Corrosion of Stirrups under Different Relative Humidity Conditions in Concrete Exposed to Chloride Environment. J. Mater. Civ. Eng. 2020, 32, 04019329. [Google Scholar] [CrossRef]

- Zhang, W.; François, R.; Cai, Y.; Charron, J.-P.; Yu, L. Influence of artificial cracks and interfacial defects on the corrosion behavior of steel in concrete during corrosion initiation under a chloride environment. Constr. Build. Mater. 2020, 253, 119165. [Google Scholar] [CrossRef]

- Zhang, R.; Castel, A.; François, R. The corrosion pattern of reinforcement and its influence on serviceability of reinforced concrete members in chloride environment. Cem. Concr. Res. 2009, 39, 1077–1086. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, Q.; Chen, H.; Huang, Y. Understanding the interaction between erosion and corrosion of pipeline steel in acid solution of different pH. J. Mater. Res. Technol. 2023, 25, 6550–6566. [Google Scholar] [CrossRef]

- EN 1990:2002; Eurocode—Basis of Structural Design. European Committee for Standardization (CEN): Brussels, Belgium, 2002.

- Pratama, A.A.; Prabowo, A.R.; Muttaqie, T.; Muhayat, N.; Ridwan, R.; Cao, B.; Laksono, F.B. Hollow tube structures subjected to compressive loading: Implementation of the pitting corrosion effect in nonlinear FE analysis. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 143–165. [Google Scholar] [CrossRef]

- Wu, W.; Thomson, R. Compatibility between passenger vehicles and road barriers during oblique collisions. Int. J. Crashworthiness 2004, 9, 245–253. [Google Scholar] [CrossRef]

| Grade | Chemical Composition % | |||||

|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Other | |

| HRB400 | 0.25 | 0.8 | 1.6 | 0.045 | 0.045 | 0.54 |

| d | dl | h | h1: (≤) | b | a | l | Max End Clearance of Transverse Rib (10% of Nominal Perimeter) | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Nominal Size | Allowable Deviation | Nominal Size | Allowable Deviation | Nominal Size | Allowable Deviation | |||||

| 12 | 11.5 | ±0.4 | 1.2 | ±0.1 | 1.6 | 0.7 | 1.5 | 8 | ±0.5 | 3.7 |

| Labels | Mloss /% | Fel/kN | Fm/kN | fy/MPa | fu/MPa | fbr/MPa | fy/fu | ky | ku | δ /% |

|---|---|---|---|---|---|---|---|---|---|---|

| 1-1 | 6.89 | 43.41 | 60.83 | 420.33 | 589.01 | 516.58 | 0.71 | 0.87 | 0.91 | 0.13 |

| 1-3 | 8.51 | 43.72 | 60.51 | 423.33 | 585.91 | 555.17 | 0.72 | 0.87 | 0.90 | 0.15 |

| 1-4 | −3.10 | 44.36 | 58.79 | 414.43 | 549.24 | 483.15 | 0.75 | 0.85 | 0.85 | 0.16 |

| 1-5 | 6.68 | 42.89 | 57.85 | 442.70 | 597.11 | 482.60 | 0.74 | 0.91 | 0.92 | 0.15 |

| 1-6 | 11.13 | 42.65 | 58.07 | 404.47 | 550.70 | 533.72 | 0.73 | 0.83 | 0.85 | 0.13 |

| 1-10 | 10.87 | 42.22 | 59.15 | 428.76 | 600.69 | 564.18 | 0.71 | 0.88 | 0.93 | 0.13 |

| 1-11 | 10.51 | 41.19 | 59.31 | 384.62 | 553.83 | 446.93 | 0.69 | 0.79 | 0.85 | 0.13 |

| 2-1 | 1.75 | 45.33 | 60.51 | 444.44 | 593.27 | 497.66 | 0.75 | 0.92 | 0.91 | 0.11 |

| 2-2 | 8.76 | 43.99 | 59.43 | 498.74 | 673.79 | 499.32 | 0.74 | 1.03 | 1.04 | 0.11 |

| 2-4 | 5.41 | 43.81 | 58.34 | 446.11 | 594.07 | 399.15 | 0.75 | 0.92 | 0.92 | 0.14 |

| 2-5 | 11.37 | 42.22 | 58.67 | 401.08 | 557.35 | 466.18 | 0.72 | 0.83 | 0.86 | 0.13 |

| 2-6 | 12.69 | 42.97 | 58.42 | 406.80 | 553.06 | 467.89 | 0.74 | 0.84 | 0.85 | 0.11 |

| 2-9 | 12.03 | 43.94 | 59.31 | 423.98 | 572.29 | 459.36 | 0.74 | 0.87 | 0.88 | 0.11 |

| 2-11 | 10.64 | 42.12 | 57.81 | 422.45 | 579.81 | 515.23 | 0.73 | 0.87 | 0.89 | 0.12 |

| 3-1 | 7.82 | 43.44 | 59.88 | 438.01 | 603.78 | 380.21 | 0.73 | 0.90 | 0.93 | 0.11 |

| 3-2 | 1.18 | 46.77 | 62.67 | 455.89 | 610.88 | 470.11 | 0.75 | 0.94 | 0.94 | 0.14 |

| 3-3 | 9.97 | 42.90 | 59.38 | 390.50 | 540.51 | 499.19 | 0.72 | 0.80 | 0.83 | 0.11 |

| 3-5 | 12.92 | 42.43 | 57.33 | 485.62 | 656.16 | 483.37 | 0.74 | 1.00 | 1.01 | 0.12 |

| 3-6 | 6.03 | 42.88 | 57.72 | 439.52 | 591.63 | 441.96 | 0.74 | 0.90 | 0.91 | 0.14 |

| 3-9 | 12.33 | 42.67 | 58.06 | 392.37 | 533.89 | 535.03 | 0.73 | 0.81 | 0.82 | 0.12 |

| 3-10 | 14.21 | 42.97 | 58.10 | 404.01 | 546.26 | 496.01 | 0.74 | 0.83 | 0.84 | 0.13 |

| 4-1 | −2.30 | 42.22 | 60.94 | 397.54 | 573.80 | 457.71 | 0.69 | 0.82 | 0.88 | 0.13 |

| 4-2 | 10.45 | 41.79 | 58.89 | 439.17 | 618.87 | 354.39 | 0.71 | 0.90 | 0.95 | 0.12 |

| 4-3 | 12.19 | 42.47 | 58.72 | 456.20 | 630.75 | 496.32 | 0.72 | 0.94 | 0.97 | 0.12 |

| 4-4 | 11.45 | 42.61 | 59.50 | 414.75 | 579.16 | 481.24 | 0.72 | 0.85 | 0.89 | 0.13 |

| 4-5 | 5.90 | 43.21 | 57.93 | 442.30 | 592.97 | 487.59 | 0.75 | 0.91 | 0.91 | 0.13 |

| 4-9 | 12.86 | 40.40 | 58.35 | 369.61 | 533.84 | 542.52 | 0.69 | 0.76 | 0.82 | 0.12 |

| 4-11 | 12.31 | 41.71 | 59.24 | 429.70 | 610.29 | 385.06 | 0.70 | 0.88 | 0.94 | 0.13 |

| 5-2 | 11.94 | 41.70 | 57.74 | 428.82 | 593.77 | 489.31 | 0.72 | 0.88 | 0.92 | 0.09 |

| 5-3 | 12.82 | 44.20 | 59.30 | 488.37 | 655.21 | 497.64 | 0.75 | 1.01 | 1.01 | 0.11 |

| 5-4 | 12.98 | 42.86 | 57.69 | 444.74 | 598.62 | 456.72 | 0.74 | 0.92 | 0.92 | 0.12 |

| 5-5 | 5.13 | 42.08 | 57.49 | 427.24 | 583.70 | 502.56 | 0.73 | 0.88 | 0.90 | 0.13 |

| 5-6 | 16.28 | 41.37 | 56.37 | 472.59 | 643.95 | 508.36 | 0.73 | 0.97 | 0.99 | 0.11 |

| 5-9 | 13.08 | 41.85 | 56.39 | 471.80 | 635.72 | 461.89 | 0.74 | 0.97 | 0.98 | 0.13 |

| 5-11 | 3.23 | 45.15 | 60.44 | 449.43 | 601.63 | 523.52 | 0.75 | 0.93 | 0.93 | 0.14 |

| 6-1 | 6.87 | 45.32 | 60.71 | 470.26 | 629.96 | 469.73 | 0.75 | 0.97 | 0.97 | 0.13 |

| 6-2 | 10.29 | 44.02 | 59.83 | 443.07 | 602.20 | 466.36 | 0.74 | 0.91 | 0.93 | 0.13 |

| 6-4 | 4.79 | 44.09 | 59.19 | 446.07 | 598.83 | 483.06 | 0.74 | 0.92 | 0.92 | 0.13 |

| 6-5 | 13.69 | 42.44 | 57.47 | 441.17 | 597.42 | 438.34 | 0.74 | 0.91 | 0.92 | 0.13 |

| 6-11 | 3.32 | 44.98 | 60.65 | 448.15 | 604.28 | 478.76 | 0.74 | 0.92 | 0.93 | 0.13 |

| 7-2 | 11.47 | 41.63 | 60.22 | 376.39 | 544.46 | 474.42 | 0.69 | 0.77 | 0.84 | 0.13 |

| 7-4 | 2.60 | 45.15 | 60.62 | 446.51 | 599.51 | 479.85 | 0.74 | 0.92 | 0.92 | 0.15 |

| 7-5 | 5.41 | 43.30 | 58.46 | 440.94 | 595.32 | 463.74 | 0.74 | 0.91 | 0.92 | 0.15 |

| 7-6 | 15.08 | 42.59 | 57.93 | 409.53 | 557.04 | 447.90 | 0.74 | 0.84 | 0.86 | 0.14 |

| 7-9 | 11.47 | 42.87 | 58.17 | 380.51 | 516.32 | 493.89 | 0.74 | 0.78 | 0.80 | 0.10 |

| 7-10 | 11.01 | 41.83 | 58.33 | 403.63 | 562.84 | 483.92 | 0.72 | 0.83 | 0.87 | 0.11 |

| 7-11 | 13.60 | 45.59 | 61.15 | 508.27 | 681.75 | 480.22 | 0.75 | 1.05 | 1.05 | 0.11 |

| 8-1 | 6.19 | 48.94 | 65.21 | 455.43 | 606.84 | 530.18 | 0.75 | 0.94 | 0.94 | 0.12 |

| 8-2 | 4.56 | 44.06 | 59.70 | 444.70 | 602.56 | 514.76 | 0.74 | 0.92 | 0.93 | 0.15 |

| 8-3 | 11.00 | 46.31 | 62.94 | 485.78 | 660.23 | 444.12 | 0.74 | 1.00 | 1.02 | 0.10 |

| 8-4 | 10.91 | 47.26 | 63.01 | 455.23 | 606.94 | 451.92 | 0.75 | 0.94 | 0.94 | 0.13 |

| 8-5 | 4.10 | 46.08 | 61.26 | 462.86 | 615.34 | 452.64 | 0.75 | 0.95 | 0.95 | 0.11 |

| 8-6 | 14.67 | 45.45 | 60.27 | 416.52 | 552.34 | 484.37 | 0.75 | 0.86 | 0.85 | 0.12 |

| 8-11 | 11.52 | 42.78 | 58.30 | 432.13 | 588.90 | 463.49 | 0.73 | 0.89 | 0.91 | 0.11 |

| 9-1 | 11.56 | 43.51 | 60.01 | 398.74 | 549.95 | 478.12 | 0.73 | 0.82 | 0.85 | 0.12 |

| 9-2 | 10.57 | 43.34 | 59.51 | 435.45 | 597.92 | 500.28 | 0.73 | 0.90 | 0.92 | 0.11 |

| 9-4 | 10.88 | 46.62 | 59.11 | 472.60 | 599.21 | 473.80 | 0.79 | 0.97 | 0.92 | 0.13 |

| 9-5 | 4.29 | 44.10 | 59.33 | 443.85 | 597.14 | 447.24 | 0.74 | 0.91 | 0.92 | 0.15 |

| 9-6 | 15.20 | 42.27 | 57.96 | 426.22 | 584.42 | 511.32 | 0.73 | 0.88 | 0.90 | 0.12 |

| 9-9 | 1.34 | 47.84 | 62.63 | 467.06 | 611.45 | 480.50 | 0.76 | 0.96 | 0.94 | 0.12 |

| 9-11 | 11.05 | 44.36 | 59.39 | 446.50 | 597.78 | 485.76 | 0.75 | 0.92 | 0.92 | 0.08 |

| 1new12 | 0.00 | 49.98 | 65.37 | 482.00 | 630.12 | 534.96 | 0.76 | 1.00 | 1.00 | 0.15 |

| 2new12 | 0.00 | 50.12 | 66.00 | 484.00 | 640.34 | 414.07 | 0.76 | 1.00 | 1.00 | 0.15 |

| 3new12 | 0.00 | 50.42 | 67.36 | 485.67 | 648.84 | 515.03 | 0.75 | 1.00 | 1.00 | 0.15 |

| Labels | Mloss/% | εy/% | εsh/% | εu/% | εbr/% | P1 | P2 | E/GPa |

|---|---|---|---|---|---|---|---|---|

| 1-1 | 6.89 | 0.23 | 3.444 | 15.497 | 16.789 | 4.021 | 4.579 | 183 |

| 1-3 | 8.51 | 0.23 | 2.15 | 14.187 | 15.906 | 3.13 | 7.123 | 184 |

| 1-4 | −3.10 | 0.249 | 2.491 | 15.692 | 17.779 | 3.577 | 9.465 | 180 |

| 1-5 | 6.68 | 0.249 | 2.491 | 16.191 | 17.187 | 4.286 | 2.76 | 192 |

| 1-6 | 11.13 | 0.23 | 2.15 | 12.467 | 13.327 | 3.019 | 5.13 | 176 |

| 1-10 | 10.87 | 0.23 | 2.152 | 13.345 | 15.067 | 3.062 | 7.352 | 186 |

| 2-1 | 1.75 | 0.221 | 1.107 | 12.62 | 13.506 | 2.231 | 2.831 | 193 |

| 2-2 | 8.76 | 0.229 | 2.576 | 11.592 | 13.237 | 3.645 | 7.384 | 217 |

| 2-4 | 5.41 | 0.221 | 2.212 | 14.818 | 15.686 | 4.095 | 5.041 | 194 |

| 2-5 | 11.37 | 0.23 | 2.15 | 13.757 | 14.918 | 3.236 | 3.555 | 174 |

| 2-6 | 12.69 | 0.23 | 2.583 | 12.054 | 13.55 | 3.215 | 4.123 | 177 |

| 2-9 | 12.03 | 0.228 | 1.839 | 12.972 | 13.599 | 3.458 | 3.00 | 184 |

| 2-11 | 10.64 | 0.229 | 2.573 | 12.434 | 13.155 | 3.136 | 2.048 | 184 |

| 3-1 | 7.82 | 0.215 | 2.368 | 12.269 | 13.208 | 3.193 | 3.50 | 190 |

| 3-2 | 1.18 | 0.221 | 2.433 | 13.801 | 15.201 | 3.33 | 4.67 | 198 |

| 3-3 | 9.97 | 0.215 | 2.152 | 11.838 | 12.917 | 2.474 | 3.08 | 170 |

| 3-5 | 12.92 | 0.215 | 1.937 | 10.547 | 11.408 | 2.787 | 2.70 | 211 |

| 3-6 | 6.03 | 0.249 | 2.244 | 15.46 | 16.801 | 3.65 | 3.62 | 191 |

| 3-9 | 12.33 | 0.215 | 2.368 | 12.269 | 12.915 | 3.452 | 2.938 | 171 |

| 3-10 | 14.21 | 0.215 | 1.937 | 12.054 | 13.345 | 3.017 | 4.282 | 176 |

| 4-1 | −2.30 | 0.221 | 2.657 | 14.613 | 15.477 | 3.676 | 2.512 | 173 |

| 4-2 | 10.45 | 0.215 | 1.935 | 10.748 | 11.516 | 2.814 | 2.27 | 191 |

| 4-3 | 12.19 | 0.215 | 0.861 | 11.193 | 12.053 | 2.103 | 2.70 | 198 |

| 4-4 | 11.45 | 0.231 | 2.154 | 14.655 | 15.316 | 3.732 | 1.75 | 180 |

| 4-5 | 5.90 | 0.222 | 2.66 | 14.629 | 15.516 | 3.525 | 2.669 | 192 |

| 4-9 | 12.86 | 0.215 | 1.932 | 12.236 | 12.88 | 3.278 | 3.45 | 161 |

| 4-11 | 12.31 | 0.203 | 2.015 | 12.494 | 13.431 | 3.33 | 3.402 | 187 |

| 5-2 | 11.94 | 0.215 | 2.152 | 10.116 | 10.898 | 3.18 | 2.615 | 186 |

| 5-3 | 12.82 | 0.215 | 2.34 | 11.153 | 12.227 | 3.878 | 3.46 | 212 |

| 5-4 | 12.98 | 0.215 | 2.152 | 11.838 | 12.915 | 4.345 | 2.75 | 193 |

| 5-5 | 5.13 | 0.221 | 2.435 | 13.949 | 14.613 | 3.239 | 2.655 | 186 |

| 5-6 | 16.28 | 0.215 | 2.152 | 11.408 | 12.072 | 3.144 | 2.546 | 205 |

| 5-9 | 13.08 | 0.203 | 2.015 | 11.285 | 13.063 | 3.056 | 7.36 | 205 |

| 5-11 | 3.23 | 0.249 | 2.488 | 14.182 | 15.494 | 3.934 | 6.531 | 195 |

| 6-1 | 6.87 | 0.203 | 2.015 | 12.494 | 13.921 | 3.053 | 3.732 | 204 |

| 6-2 | 10.29 | 0.203 | 1.854 | 12.736 | 14.159 | 3.435 | 5.00 | 193 |

| 6-4 | 4.79 | 0.234 | 1.854 | 14.151 | 14.853 | 3.447 | 1.95 | 194 |

| 6-5 | 13.69 | 0.204 | 2.021 | 12.932 | 14.721 | 3.713 | 5.931 | 192 |

| 6-11 | 3.32 | 0.221 | 2.878 | 14.392 | 15.277 | 3.234 | 2.50 | 195 |

| 7-2 | 11.47 | 0.202 | 2.415 | 12.88 | 13.685 | 4.255 | 2.484 | 164 |

| 7-4 | 2.60 | 0.249 | 3.629 | 16.568 | 17.984 | 3.507 | 3.94 | 194 |

| 7-5 | 5.41 | 0.249 | 2.244 | 15.46 | 16.707 | 3.449 | 3.576 | 192 |

| 7-6 | 15.08 | 0.204 | 2.018 | 13.318 | 14.643 | 4.034 | 4.03 | 178 |

| 7-9 | 11.47 | 0.215 | 2.15 | 11.178 | 11.772 | 3.227 | 2.116 | 165 |

| 7-10 | 11.01 | 0.215 | 2.15 | 10.748 | 11.607 | 3.167 | 2.923 | 175 |

| 7-11 | 13.6 | 0.215 | 2.15 | 10.103 | 11.393 | 3.02 | 4.131 | 221 |

| 8-2 | 4.56 | 0.249 | 2.491 | 15.568 | 17.311 | 3.695 | 4.911 | 198 |

| 8-3 | 11.00 | 0.23 | 2.15 | 11.178 | 12.301 | 3.31 | 3.47 | 193 |

| 8-4 | 10.91 | 0.23 | 2.152 | 12.484 | 13.718 | 3.145 | 3.30 | 211 |

| 8-5 | 4.10 | 0.221 | 2.657 | 13.063 | 14.018 | 3.429 | 2.50 | 201 |

| 8-6 | 14.67 | 0.23 | 2.579 | 12.037 | 13.577 | 3.184 | 4.871 | 181 |

| 8-11 | 11.52 | 0.215 | 1.932 | 10.089 | 11.141 | 2.679 | 2.98 | 188 |

| 9-1 | 11.56 | 0.215 | 1.932 | 11.807 | 12.807 | 3.123 | 3.05 | 173 |

| 9-2 | 10.57 | 0.215 | 2.361 | 12.236 | 13.095 | 3.257 | 2.57 | 189 |

| 9-5 | 4.29 | 0.249 | 2.491 | 15.692 | 17.934 | 3.999 | 4.73 | 193 |

| 9-6 | 15.2 | 0.23 | 2.583 | 13.345 | 14.206 | 4.006 | 3.672 | 185 |

| 9-9 | 1.34 | 0.194 | 2.133 | 11.055 | 11.831 | 2.69 | 2.00 | 203 |

| 9-11 | 11.05 | 0.215 | 2.152 | 9.040 | 9.901 | 2.771 | 2.386 | 194 |

| 1new12 | 0.00 | 0.249 | 2.485 | 16.043 | 17.895 | 4.00 | 4.667 | 210 |

| 2new12 | 0.00 | 0.276 | 2.212 | 16.587 | 19.708 | 4.161 | 6.65 | 210 |

| 3new12 | 0.00 | 0.277 | 1.939 | 14.962 | 16.937 | 3.309 | 6.54 | 211 |

| Density, ρ (kg/m3) | 7800 |

| Young’s modulus, E (GPa) | 210 |

| Poisson’s ratios, ν | 0.28 |

| Yield strength, σy0 (MPa) | 440 |

| Tensile strength, σu (MPa) | 560 |

| Fracture strain, eu (%) | 25 |

| Failure displacement (mm) | 0.14 |

| Labels | Mloss/% | E/GPa | εy/% | εsh/% | εu/% | εbr/% | P1 | P2 | fy | fu | fbr |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 2new12 | 0 | 195.77 | 0.24 | 2.45 | 15.14 | 16.62 | 3.52 | 4.59 | 604 | 450 | 478 |

| 2-4 | 5 | 194.62 | 0.2305 | 2.33 | 13.89 | 15.22 | 3.435 | 3.39 | 599 | 442 | 399 |

| 2-11 | 10.5 | 193 | 0.22005 | 2.198 | 12.515 | 13.68 | 3.3415 | 2.07 | 592 | 435 | 477 |

| 8-6 | 15 | 192.32 | 0.2115 | 2.09 | 11.39 | 12.42 | 3.265 | 0.99 | 587 | 428 | 476 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Long, Z.; Liu, X. A Constitutive Equation and Numerical Study on the Tensile Behavior of Reinforcing Steel Under Different Mass Loss Ratios. Materials 2025, 18, 2640. https://doi.org/10.3390/ma18112640

Zhang W, Long Z, Liu X. A Constitutive Equation and Numerical Study on the Tensile Behavior of Reinforcing Steel Under Different Mass Loss Ratios. Materials. 2025; 18(11):2640. https://doi.org/10.3390/ma18112640

Chicago/Turabian StyleZhang, Wei, Zhilin Long, and Xiaowei Liu. 2025. "A Constitutive Equation and Numerical Study on the Tensile Behavior of Reinforcing Steel Under Different Mass Loss Ratios" Materials 18, no. 11: 2640. https://doi.org/10.3390/ma18112640

APA StyleZhang, W., Long, Z., & Liu, X. (2025). A Constitutive Equation and Numerical Study on the Tensile Behavior of Reinforcing Steel Under Different Mass Loss Ratios. Materials, 18(11), 2640. https://doi.org/10.3390/ma18112640