Effect of Induction Heating Temperature on the Uniformity of Mechanical Properties of Bulb Flat Steel Sections in the Quenched State

Abstract

1. Introduction

2. Experimental

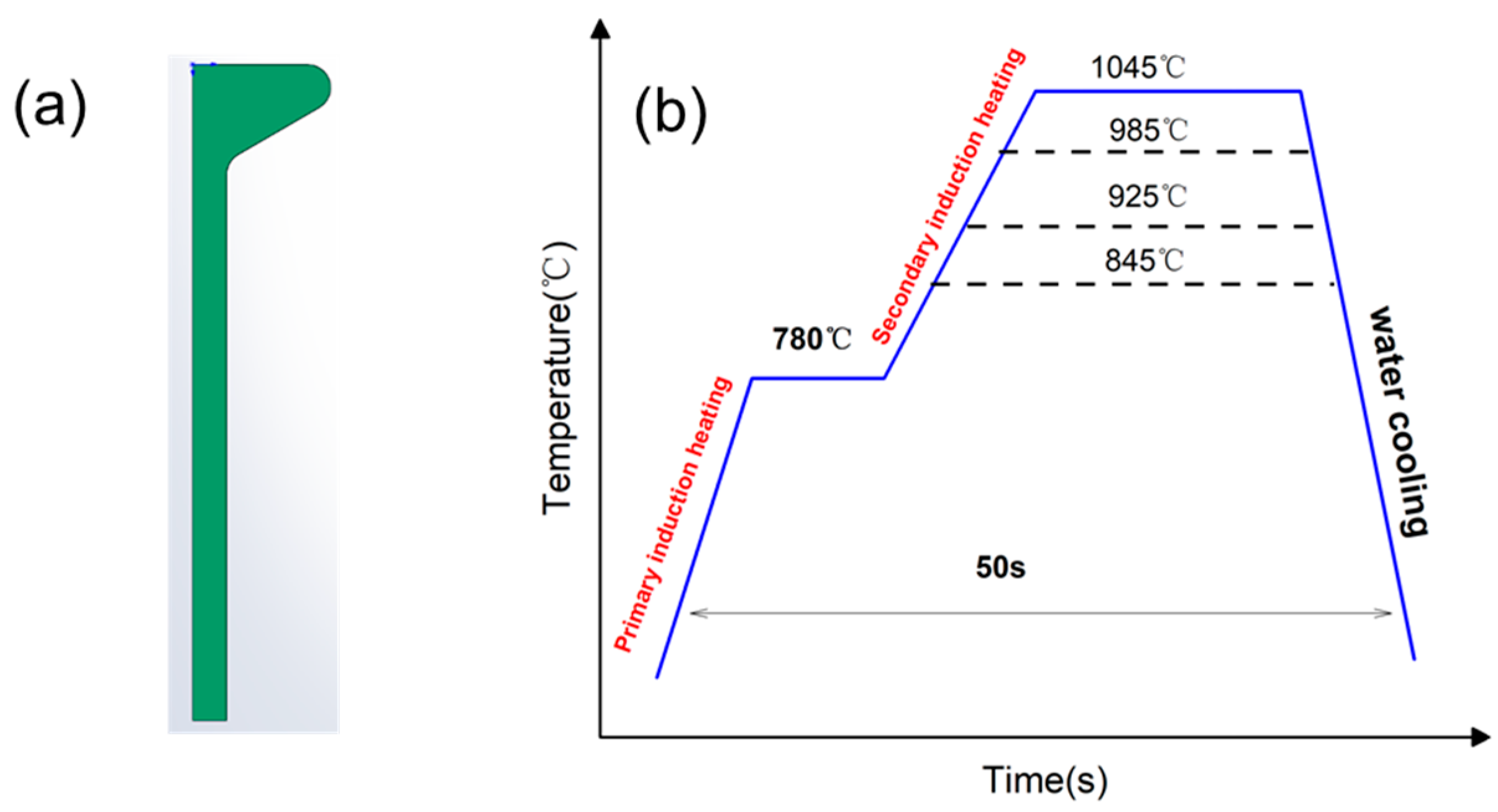

2.1. Starting Material and Thermo-Mechanical Processing

2.2. Microstructural Characterization

2.3. Mechanical Testing

3. Results

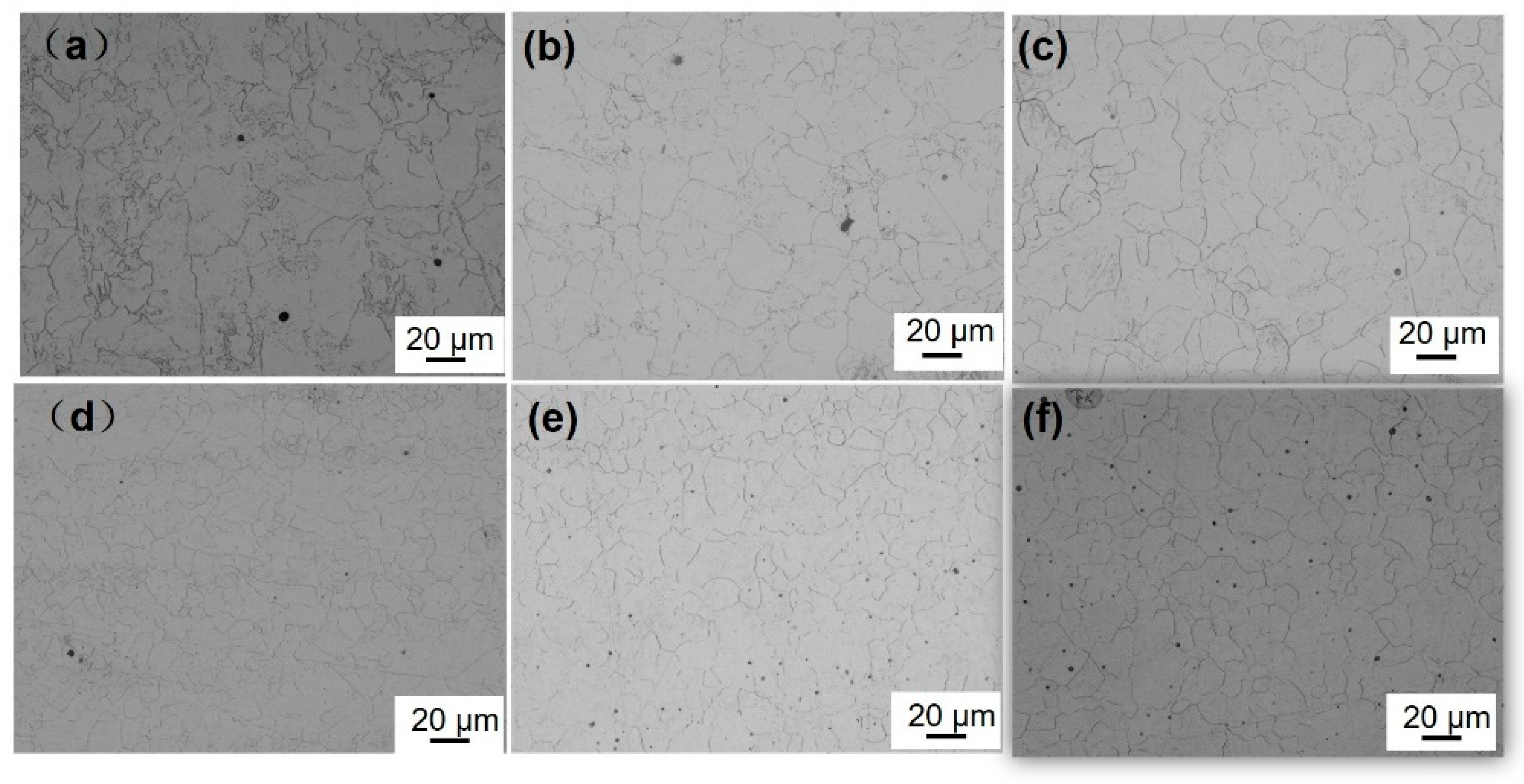

3.1. Prior Austenite Grains

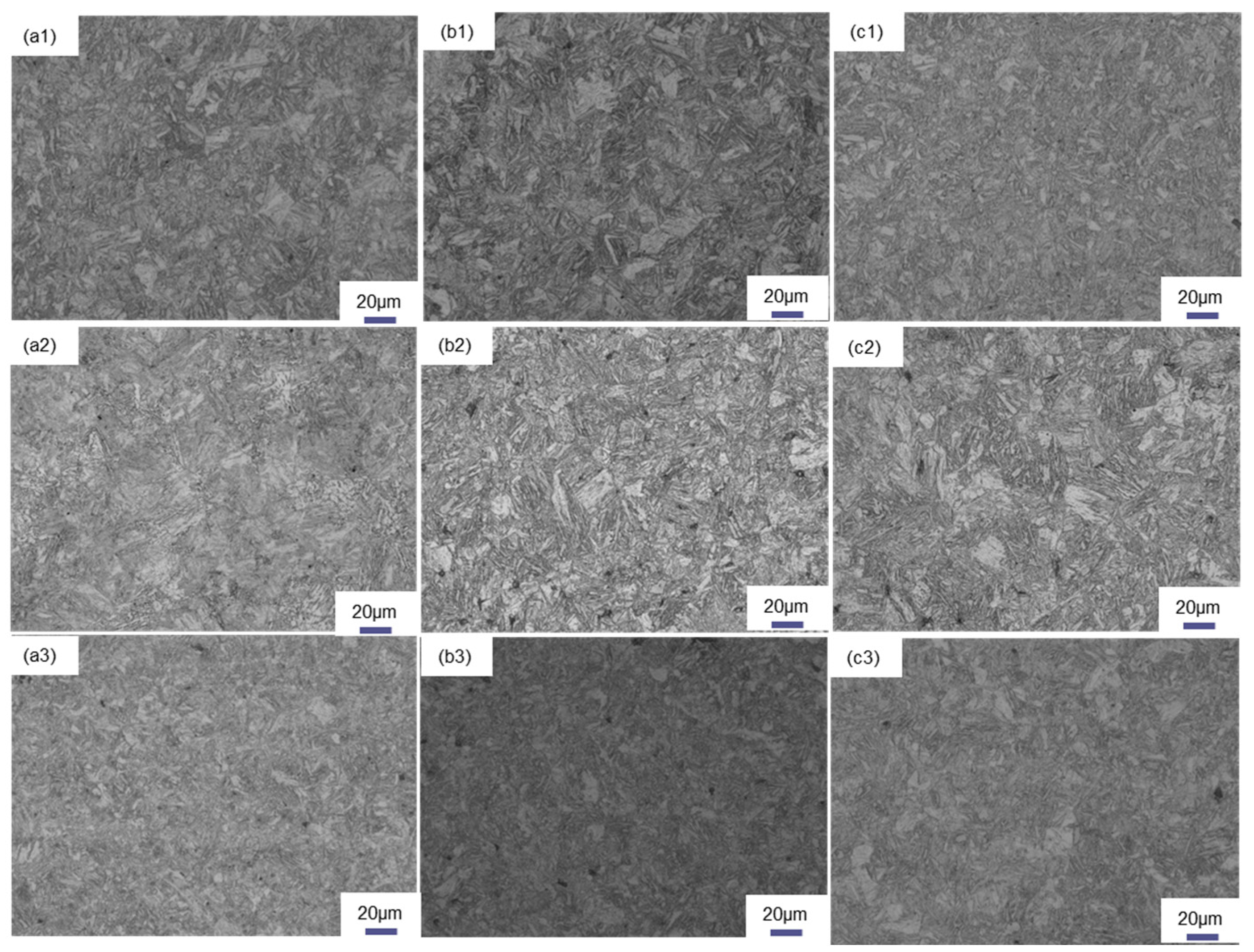

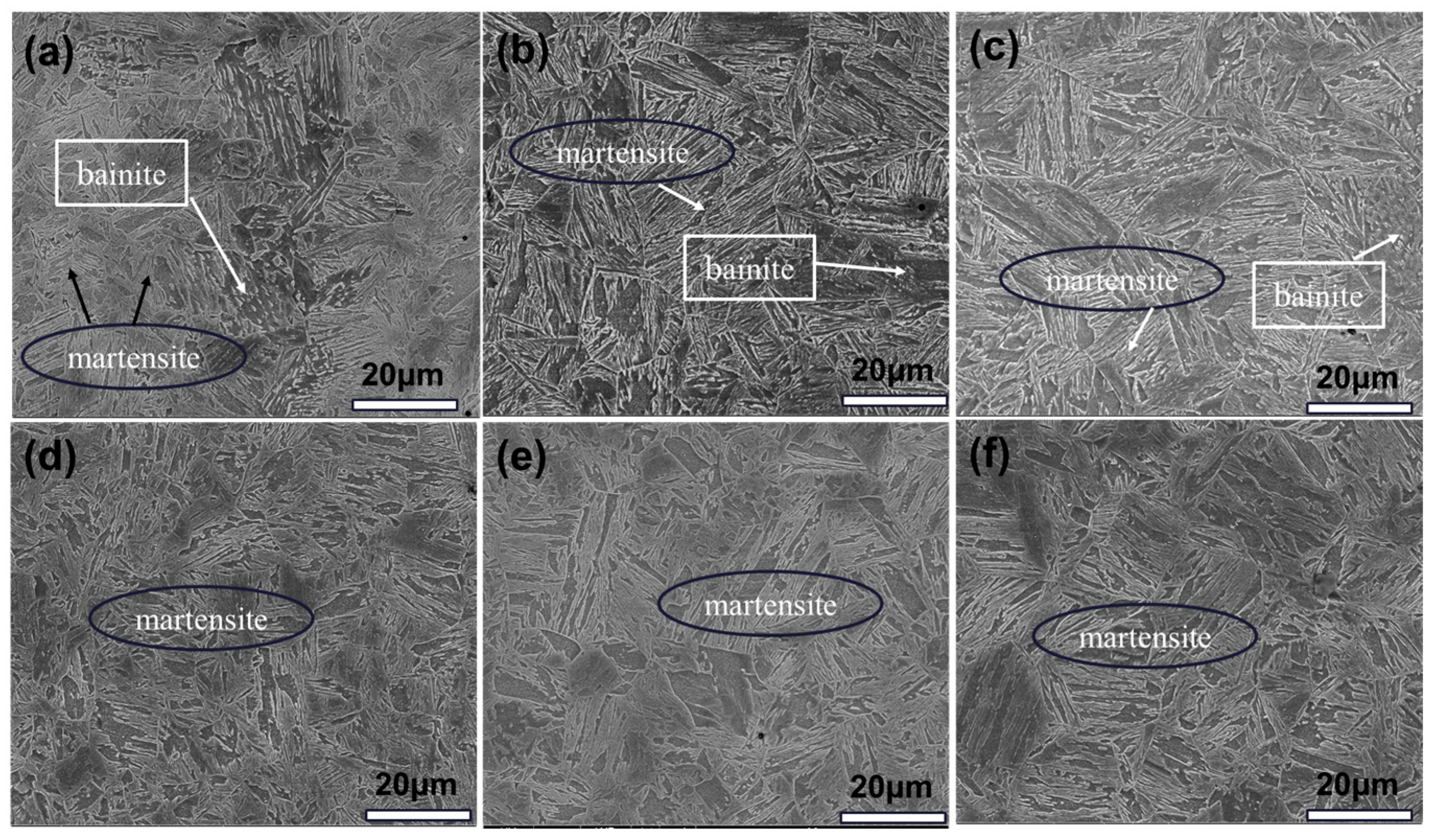

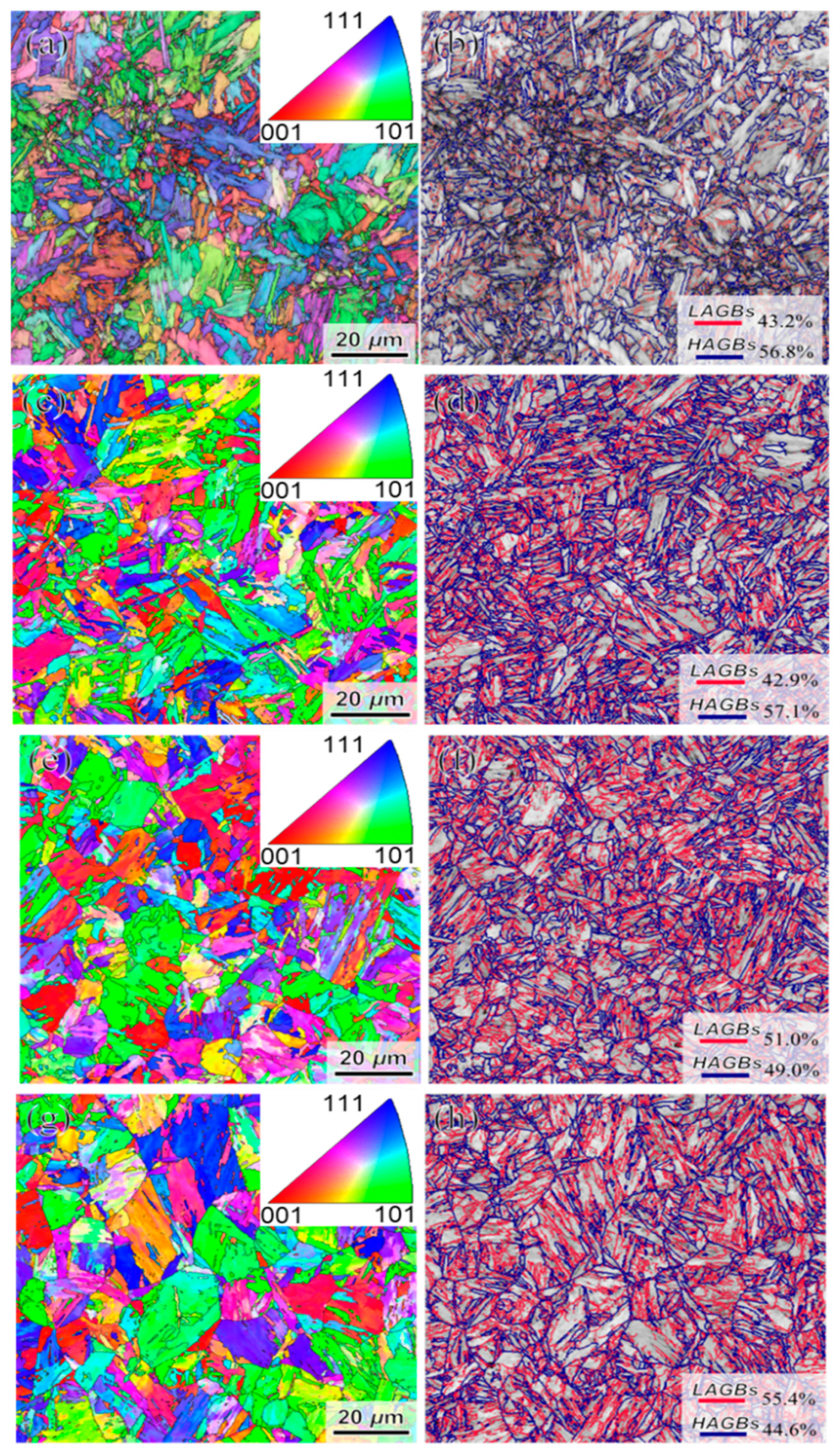

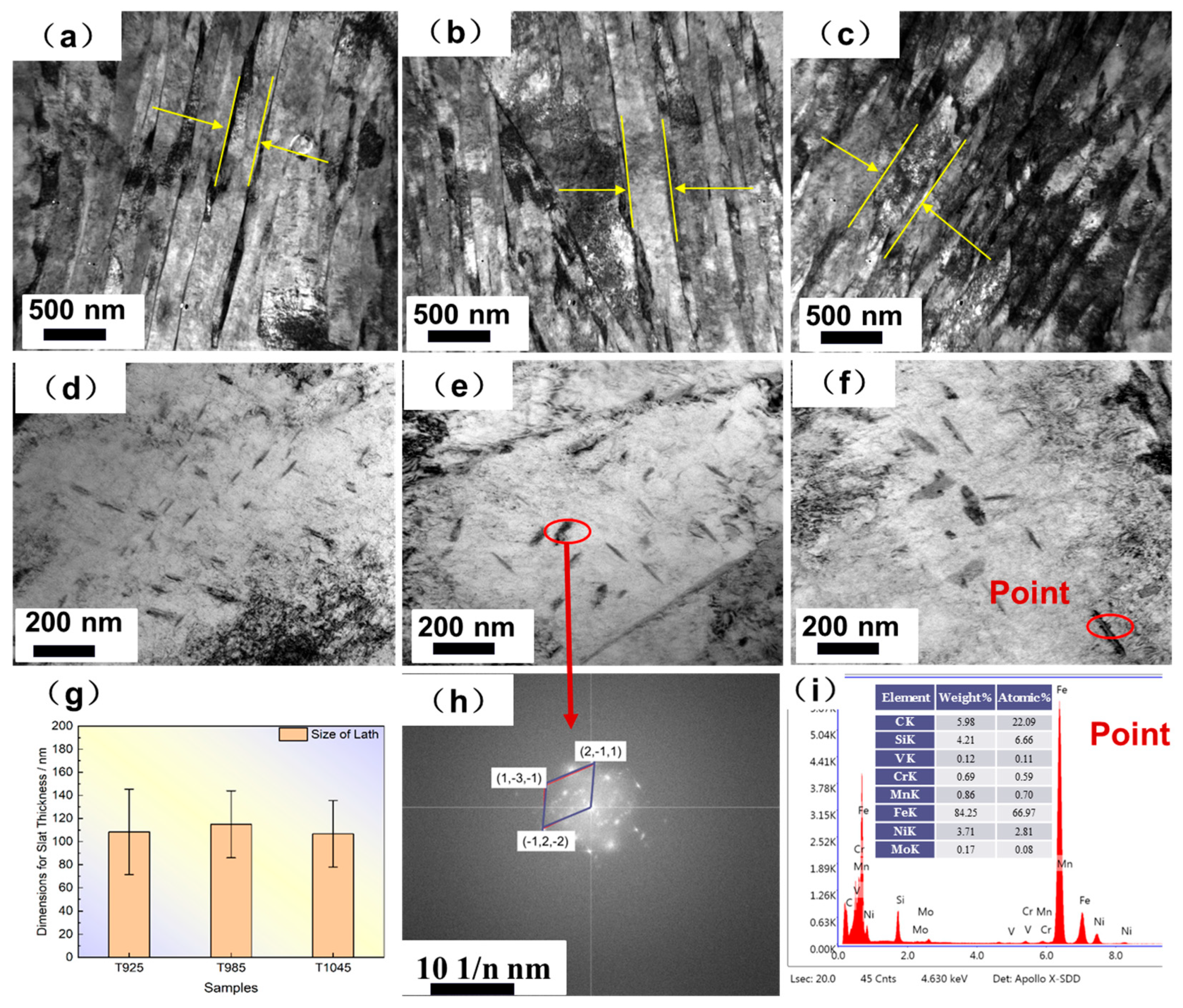

3.2. Microstructure

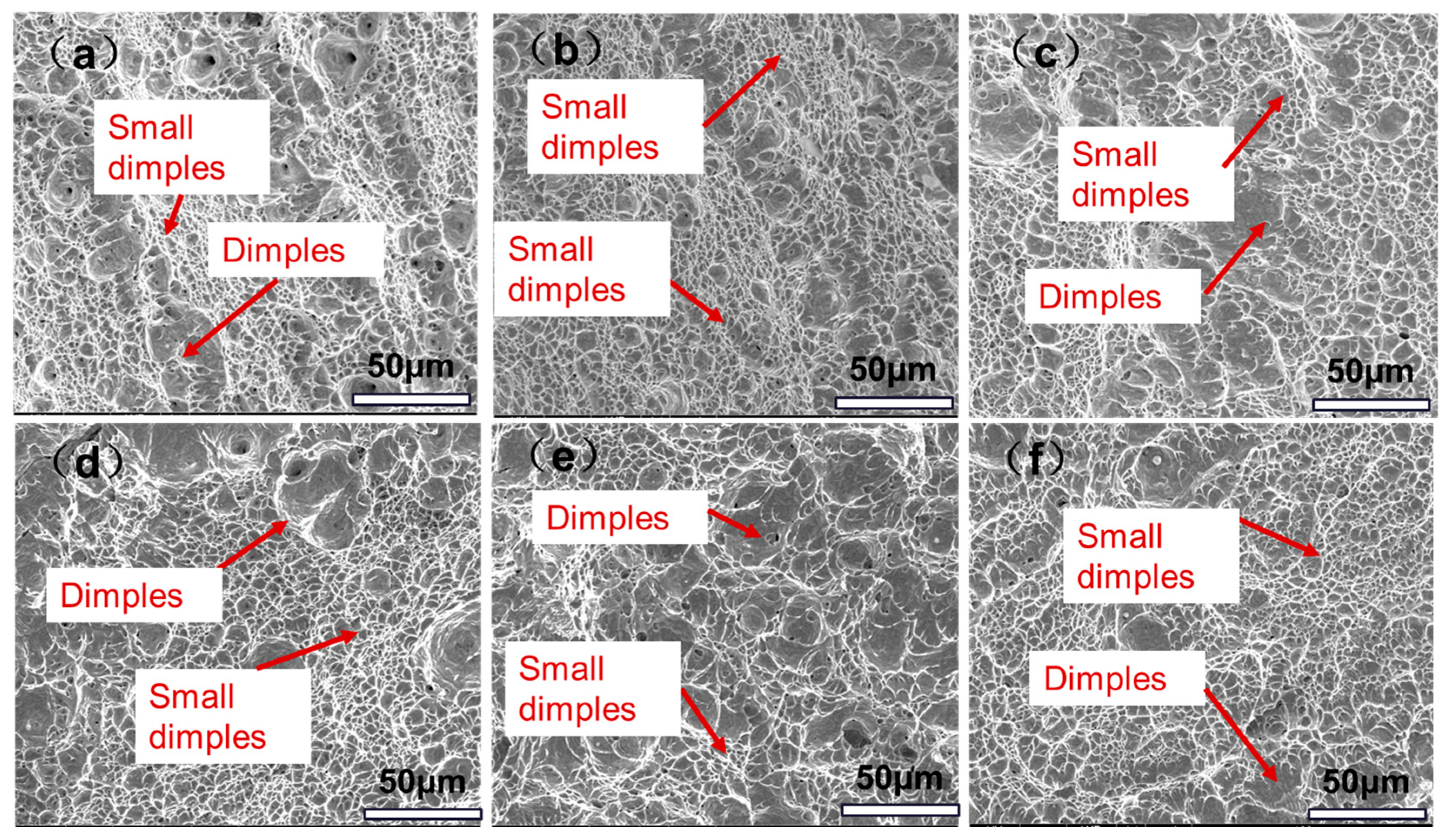

3.3. Mechanical Property

4. Discussion

4.1. Effect of Induction Heating Temperature on Prior-Austenitic Grains

4.2. Effect of Induction Heating Temperature on Microstructural Evolution of Bulb Flat Steel

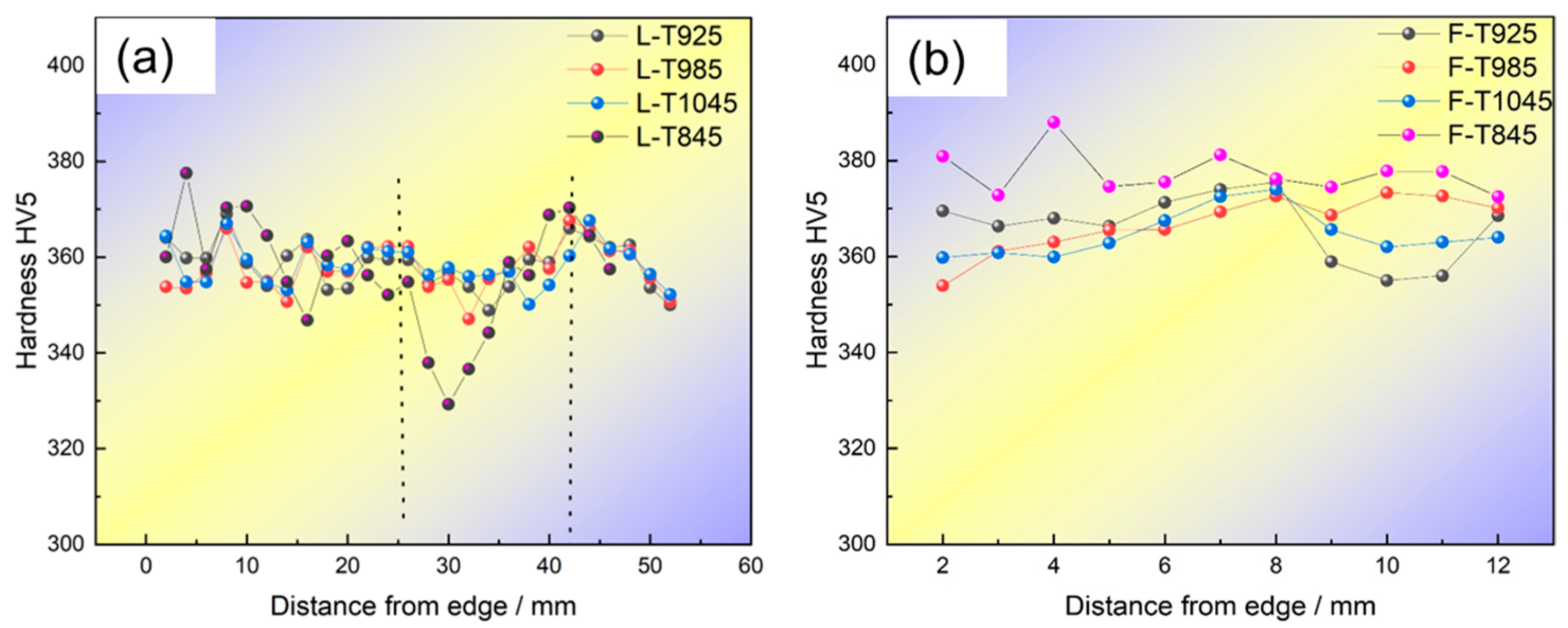

4.3. Analysis of Cross-Sectional Hardness Uniformity in Bulb Flats

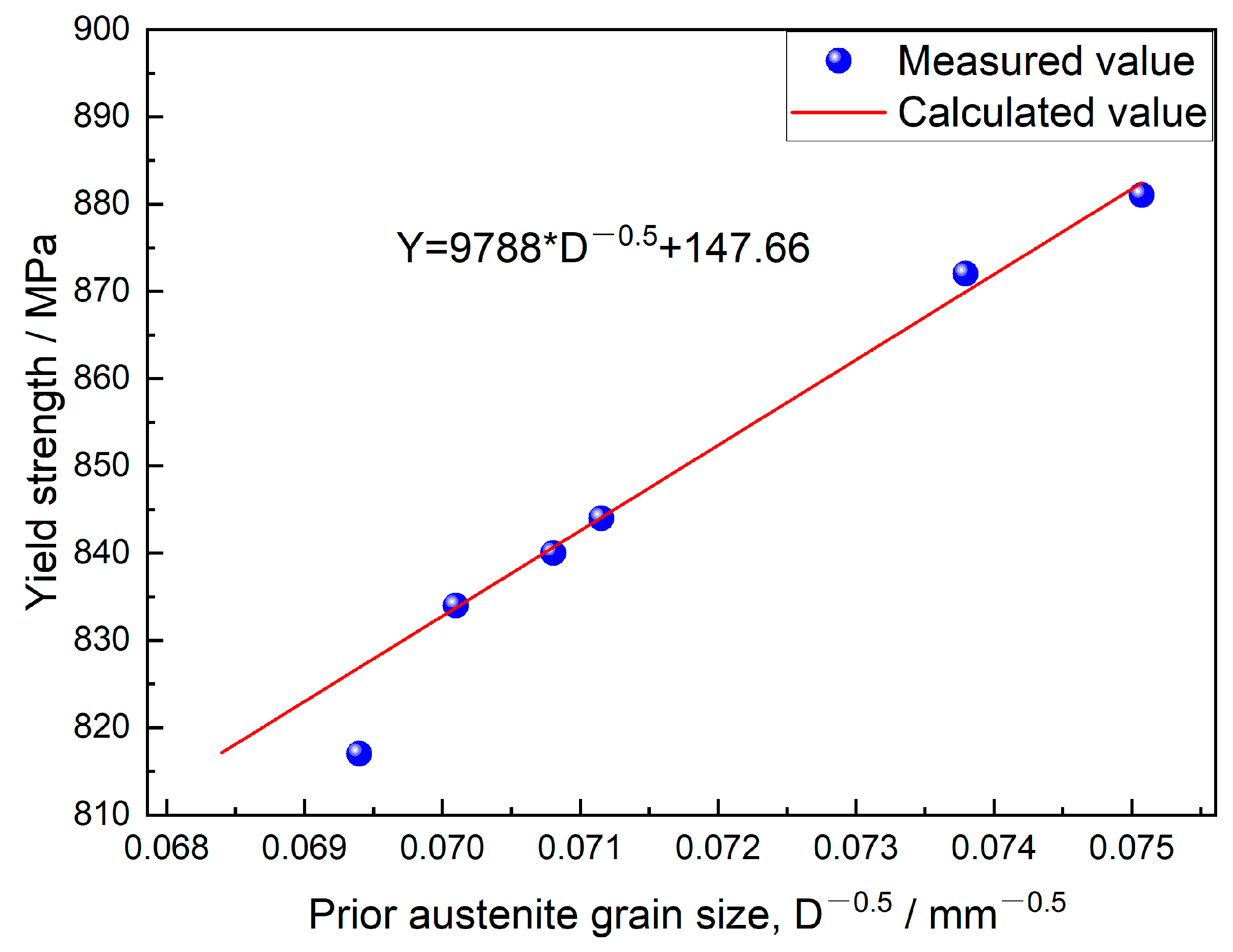

4.4. Effect of Induction Heating Temperature on Tensile Properties of Bulb Flat Steel Section

5. Conclusions

- With the increase in the induction heating temperature from 845 °C to 1045 °C, a significant coarsening phenomenon is observed in the prior austenite grain size of both the bulb and flat sections. Quantitative analysis reveals that the prior austenite grain size in the bulb center at 1045 °C exhibits a 15.3% increase in coarseness compared to that at 925 °C. Furthermore, the prior austenite grain size in the flat section demonstrates a more pronounced coarsening effect, with a 31.4% increase relative to the grain size at 845 °C.

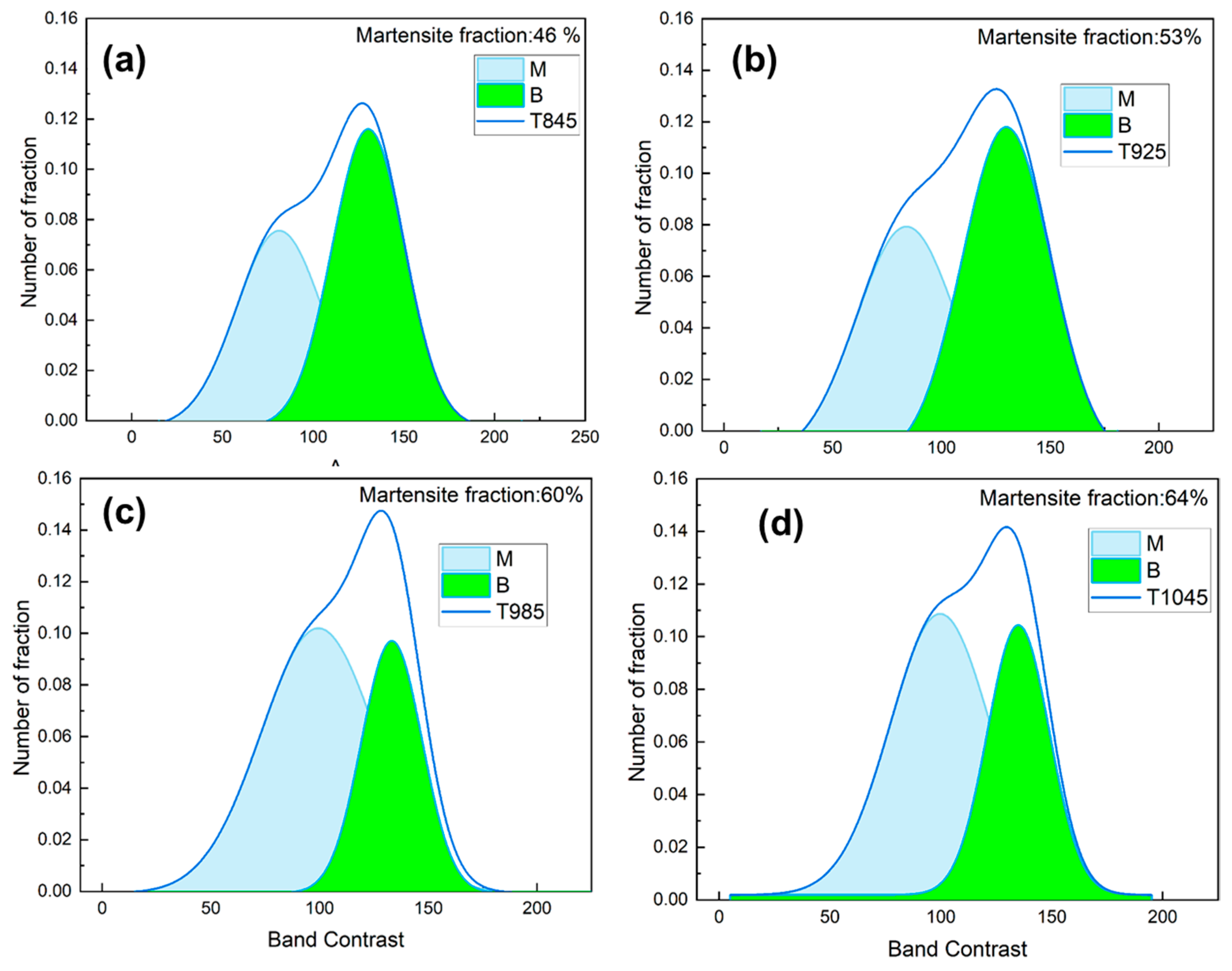

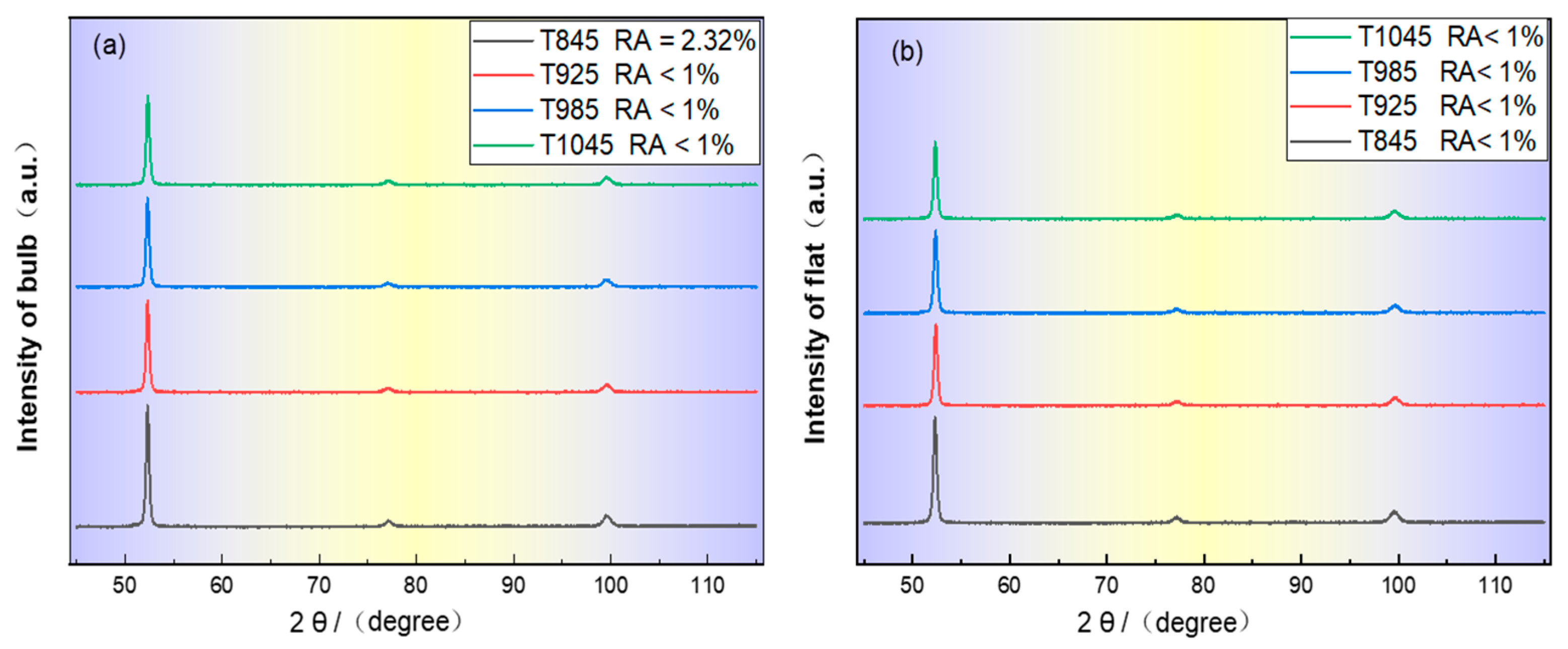

- As the induction heating temperature is elevated from 845 °C to 1045 °C, the martensite volume fraction in the steel matrix demonstrates a significant increase from 46% to 64%, accompanied by the predominant precipitation of M3C-type carbides.

- When the induction heating temperature ranges from 845 °C to 1045 °C, the strength of the quenched bulb exhibits an overall increasing trend, whereas the strength of the flat section demonstrates a gradual decrease with the rising temperature. Consequently, the yield strength differential between the bulb and flat sections is significantly reduced from 94 MPa to 6 MPa, resulting in a substantial enhancement in the mechanical uniformity across the bulb flat section.

- When the induction heating temperature ranges from 845 °C to 985 °C, the disparity in yield strength between the bulb and flat components is predominantly attributed to dislocation strengthening mechanisms. However, at an elevated temperature of 1045 °C, the strength differential becomes more closely associated with fine grain strengthening effects.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- An, F.; Zhao, S.; Xue, X.; Wang, J.; Yuan, G.; Liu, C. Incompleteness of bainite transformation in quenched and tempered steel under continuous cooling conditions. J. Mater. Res. Technol. 2020, 9, 8985–8996. [Google Scholar] [CrossRef]

- Liu, G.; Guo, H.; Wang, S.; Wu, H.; Ruan, X.; Huang, Y.; Li, X.; Mao, X. Unveiling the kinetics of interphase and random quaternary Nb-Ti precipitations, and strengthening mechanism of HSLA steel. Mater. Charact. 2024, 215, 114238. [Google Scholar] [CrossRef]

- Hong, S.; Song, J.; Kim, M.C.; Choi, K.J.; Lee, B.S. Effects of microstructural variation on Charpy impact properties in heavy-section Mn-Mo-Ni low alloy steel for reactor pressure vessel. Met. Mater. Int. 2016, 22, 196–203. [Google Scholar] [CrossRef]

- Luo, X.; Chen, X.; Wang, T.; Pan, S.; Wang, Z. Effect of morphologies of martensite–austenite constituents on impact toughness in intercritically reheated coarse-grained heat-affected zone of HSLA steel. Mater. Sci. Eng. A 2018, 710, 192–199. [Google Scholar] [CrossRef]

- Ledermueller, C.; Pratiwi, H.I.; Webster, R.F.; Eizadjou, M.; Ringer, S.P.; Primig, S. Microalloying effects of Mo versus Cr in HSLA steels with ultrafine-grained ferrite microstructures. Mater. Des. 2020, 185, 108278. [Google Scholar] [CrossRef]

- Wang, K.; Han, J.; Yu, H. Research on strength and toughness matching of 1.3GPa ultralow temperature resistant bulb flat steel. Mater. Des. 2024, 239, 112771. [Google Scholar] [CrossRef]

- Danielson, D.A.; Wilmer, A. Buckling of stiffened plates with bulb flat flanges. Int. J. Solids Struct. 2004, 41, 6407–6427. [Google Scholar] [CrossRef]

- Li, Y.; Jiang, Z.; Wang, P.; Li, D. Effect of Austenitizing Temperature on Isothermal Quenching Microstructure and Mechanical Properties of 52100 Bearing Steel. Mater. Sci. Eng. A 2024, 892, 146051. [Google Scholar] [CrossRef]

- Liang, F.; Zhou, D.; Wang, T.; Xiu, G.; Yang, Y. Finite element simulation and process optimizing of induction heating for high strength bulb flats steel. China Metall. 2019, 29, 45–51. [Google Scholar]

- Kaiser, D.; Damon, J.; Mühl, J.; Graaff, F.; de Kiefer, B.; Dietrich, S.; Schulze, V. Experimental investigation and finite-element modeling of the short-time induction quench-and-temper process of AISI 4140. J. Mater. Process Technol. 2020, 279, 116485. [Google Scholar] [CrossRef]

- Díaz, M.J.M.; Vázquez, C.G.; Montesinos, M.G.; Gallego, F.O. Analysis and numerical simulation of an induction–conduction model arising in steel heat treating. J. Comput. Appl. Math. 2012, 236, 3007–3015. [Google Scholar] [CrossRef]

- Cho, K. Coupled electro-magneto-thermal model for induction heating process of a moving billet. Int. J. Therm. Sci. 2012, 60, 195–204. [Google Scholar] [CrossRef]

- Han, Y.; Xiao, Y.; Yu, E.; Wang, L. Electromagnetic heating and motion mechanism for contact welded pipes based on a node sequential number method. Appl. Therm. Eng. 2018, 137, 822–835. [Google Scholar] [CrossRef]

- Song, M.; Moon, Y. Coupled electromagnetic and thermal analysis of induction heating for the forging of marine crankshafts. Appl. Therm. Eng. 2016, 98, 98–109. [Google Scholar] [CrossRef]

- Kawaguchi, H.; Enokizono, M.; Todaka, T. Thermal and magnetic field analysis of induction heating problems. J. Mater. Process Technol. 2005, 161, 193–198. [Google Scholar] [CrossRef]

- Xie, Z.; Fang, Y.; Han, G.; Guo, H.; Misra, R.D.K.; Shang, C. Structure–property relationship in a 960 MPa grade ultrahigh strength low carbon niobium–vanadium microalloyed steel: The significance of high frequency induction tempering. Mater. Sci. Eng. A 2014, 618, 112–117. [Google Scholar] [CrossRef]

- Yan, W.; Luo, X.; Xu, G.; Wang, H.; Wang, Z.; Chen, X. Significant improvement in CGHAZ toughness of HSLA steel via welding with trailing mechanical treatment. J. Mater. Res. Technol. 2022, 11, 142725. [Google Scholar] [CrossRef]

- Jin, L.; Zhang, K.; Zhu, M.L.; Xuan, F.Z. Evolution of carbides and Charpy toughness in a low alloy bainitic steel during step-up aging process. Npj Mater. Degrad. 2024, 8, 107. [Google Scholar] [CrossRef]

- Shi, J.; Pang, Q.; Li, W.; Xiang, Z.; Qi, H. Evolution of inclusions in DH36 grade ship plate steel during high heat input welding. Sci. Rep. 2024, 14, 18921. [Google Scholar] [CrossRef]

- Ji, G.; Ma, L.; Wu, L. Effect of the gas layer evolution on electrolytic plasma polishing of stainless steel. Sci. Rep. 2024, 14, 22099. [Google Scholar] [CrossRef]

- Mioković, T.; Schulze, V.; Vöhringer, O.; Löhe, D. Prediction of phase transformations during laser surface hardening of AISI 4140 including the effects of inhomogeneous austenite formation. Mater. Sci. Eng. A 2006, 428, 141–147. [Google Scholar] [CrossRef]

- Sun, J.; Li, S.; Qiu, C.; Peng, Y. Numerical and experimental investigation of induction heating process of heavy cylinder. Appl. Therm. Eng. 2018, 134, 341–352. [Google Scholar] [CrossRef]

- Damon, J.; Schüßler, P.; Mühl, F.; Dietrich, S.; Schulze, V. Short-time induction heat treatment of high speed steel AISI M2: Laboratory proof of concept and application-related component tests. Mater. Des. 2023, 230, 111991. [Google Scholar] [CrossRef]

- Zhang, X.; Li, G.; Zhao, H.; Gao, J. Evolution of microstructure and mechanical properties along the thickness direction of 500 MPa HSLA steel heavy plates. Mater. Sci. Eng. A 2024, 913, 147097. [Google Scholar] [CrossRef]

- Sun, X.; Yuan, S.; Xie, Z.; Dong, L.; Shang, C.J.; Misra, R.D.K. Microstructure-property relationship in a high strength-high toughness combination ultra-heavy gauge offshore plate steel: The significance of multiphase microstructure. Mater. Sci. Eng. A 2017, 689, 212–219. [Google Scholar] [CrossRef]

- Zhang, X.; Li, G.; Zhao, H.; Gao, J.; Wu, H.; Zhang, C.; Wu, G.; Wang, S. Effect of vanadium microalloying on phase transformation and strengthening mechanism of 1000 MPa low carbon bainitic steel. Mater. Sci. Eng. A 2023, 884, 145578. [Google Scholar] [CrossRef]

- Chen, X.; Yang, C.; Qian, Z.; Su, H. Study on Section Homogeneity of V-N Microalloyed High Strength Flat Bulb Steel. Iron Steel 2010, 45, 45–51. [Google Scholar]

- Su, Y.; Chuang, T.; Huang, C.; Wu, C.; Liao, K. Retained austenite amount determination comparison in JIS SKD11 steel using quantitative metallography and X-ray diffraction methods. Adv. Mater. Res. 2012, 482, 1165–1168. [Google Scholar] [CrossRef]

- GB/T 228.1-2021; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. Standardization Administration of China: Beijing, China, 2021.

- GB/T 229-2020; Metallic Materials—Charpy Pendulum Impact Test Method. Standardization Administration of China: Beijing, China, 2020.

- Lolla, T.; Cola, G.; Narayanan, B.; Alexandrov, B.; Babu, S.S. Development of rapid heating and cooling (flash processing) process to produce advanced high strength steel microstructures. Mater. Sci. Technol. 2011, 27, 863–875. [Google Scholar] [CrossRef]

- Zhan, Z.; Liu, W.; Yang, Y.; Chai, F.; Luo, X.; Shi, Z.; Wang, Z. Effects of temperature on the microstructural evolution and mechanical properties of copper-bearing medium manganese steel during tempering. Mater. Des. 2024, 245, 113273. [Google Scholar] [CrossRef]

- Slama, B.H.M.; Yedra, L.; Heripre, E.; Upadhyay, M.V. Insight on Precipitate Evolution During Additive Manufacturing of Stainless Steels via In-Situ Heating-Cooling Experiments in a Transmission Electron Microscope. Materialia 2022, 21, 101368. [Google Scholar] [CrossRef]

- Li, K.; Qian, H.; Wei, C.; Yu, W. Effect of Prior Austenite Grain Size on Austenite Reversion, Bainite Transformation, and Mechanical Properties of Fe-2Mn-0.2C Steel. Materials 2024, 215, 114134. [Google Scholar] [CrossRef]

- Godon, A.; Creus, J.; Cohendoz, S.; Conforto, E.; Feaugas, X.; Girault, P.; Savall, C. Effects of grain orientation on the Hall–Petch relationship in electrodeposited nickel with nanocrystalline grains. Scr. Mater. 2010, 62, 403–406. [Google Scholar] [CrossRef]

- Wang, Y.; Hua, J.; Kong, M.; Zeng, Y.; Liu, J.; Liu, Z. Quantitative analysis of martensite and bainite microstructures using electron backscatter diffraction. Microsc. Res. Tech. 2016, 79, 814–819. [Google Scholar] [CrossRef]

- Miyamoto, G.; Takayama, N.; Furuhara, T. Accurate measurement of the orientation relationship of lath martensite and bainite by electron backscatter diffraction analysis. Scr. Mater. 2009, 60, 1113–1116. [Google Scholar] [CrossRef]

- Wu, B.; Wang, Z.; Wang, X.; Zhao, J.; Shang, C.; Misra, R.D.K. Relationship between high angle grain boundaries and hardness after γ→α transformation. Mater. Sci. Technol. 2019, 35, 1803–1814. [Google Scholar] [CrossRef]

- He, B.; Hu, B.; Yen, H.; Cheng, G.; Wang, G.; Luo, H.; Huang, M. High dislocation density–induced large ductility in deformed and partitioned steels. Science. 2017, 357, 1029–1032. [Google Scholar] [CrossRef]

- Bai, P.; Shang, C.; Wu, H.; Ma, G.; Wang, S.; Wu, G. A review on the advance of low-temperature toughness in pipeline steels. J. Mater. Res. Technol. 2023, 25, 6949–6964. [Google Scholar] [CrossRef]

- Liu, G.; Li, Y.; Liao, T.; Wang, S.; Lv, B.; Guo, H. Revealing the precipitation kinetics and strengthening mechanisms of a 450 MPa grade Nb-bearing HSLA steel. Mater. Sci. Eng. A 2023, 884, 145578. [Google Scholar] [CrossRef]

- Mao, X.; Huo, X.; Sun, X.; Chai, Y. Strengthening mechanisms of a new 700MPa hot rolled Ti-microalloyed steel produced by compact strip production. J. Mater. Process Technol. 2010, 210, 1660–1666. [Google Scholar] [CrossRef]

- Rancel, L.; Gomez, M.; Medina, S.; Gutierrez, I. Measurement of bainite packet size and its influence on cleavage fracture in a medium carbon bainitic steel. Mater. Sci. Eng. A 2011, 530, 21–27. [Google Scholar] [CrossRef]

- Riaz, T.; Shyamal, S.; Shee, T.K.; Karjalainen, L.P.; Sahu, P. X-ray line profile analysis on the deformation microstructure of Al-bearing high-Mn steels. Mater. Charact. 2023, 196, 112567. [Google Scholar] [CrossRef]

| C | Si | Mn | P | S | Ni + Cr + Mo | V | Fe |

|---|---|---|---|---|---|---|---|

| 0.10 | 0.23 | 0.54 | 0.006 | 0.0025 | <6.0 | 0.06 | Balance |

| Secondary Coil Power Setting Ratio | 70% | 80% | 90% | 95% |

|---|---|---|---|---|

| temperature/°C | 845 ± 5 | 925 ± 9 | 985 ± 6 | 1045 ± 13 |

| Type of Sample | Method of Preparation |

|---|---|

| optical microscopy | Sanding, mechanical polishing, etching with 4% nitric acid and 96% alcohol solution. |

| SEM | Sanding, mechanical polishing, etching with 4% nitric acid and 96% alcohol solution. |

| EBSD | Sanding, mechanical polishing, etching with 10% perchloric acid and 90% alcohol solution. |

| XRD | Sanding, mechanical polishing, etching with 10% perchloric acid and 90% alcohol solution. |

| Tensile of bulb | Machined, dimensions M16 × 110 mm |

| Tensile of flat | Machined, dog-bone shaped, size 220 × 30 × 13 mm |

| Charpy V-notch impact | Machined, dimensions 10 × 10 × 55 mm |

| Samples | Bulb (cm−2) | Flat (cm−2) |

|---|---|---|

| T845 | 3.2 × 1011 | 4.7 × 1011 |

| T925 | 4.1 × 1011 | 5.9 × 1011 |

| T985 | 4.2 × 1011 | 4.8 × 1011 |

| T1045 | 3.5 × 1010 | 3.8 × 1011 |

| Samples | Position | (MPa) | Yield Strength (MPa) | |

|---|---|---|---|---|

| T845 | bulb | 143 | 404 | 796 |

| flat | 147 | 489 | 890 | |

| Difference in strength(MPa) | - | −4 | −85 | −94 |

| T925 | bulb | 155 | 457 | 817 |

| flat | 172 | 548 | 881 | |

| Difference in strength(MPa) | - | −17 | −91 | −64 |

| T985 | bulb | 121 | 465 | 844 |

| flat | 168 | 498 | 872 | |

| Difference in strength(MPa) | - | −47 | −26 | −28 |

| T1045 | bulb | 144 | 425 | 840 |

| flat | 135 | 439 | 834 | |

| Difference in strength(MPa) | - | 9 | −12 | 6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qi, Z.; Luo, X.; Liang, F.; Chai, F.; Ge, Q.; Zhan, Z.; Wang, C.; Fan, W.; Yang, H.; Liu, Y. Effect of Induction Heating Temperature on the Uniformity of Mechanical Properties of Bulb Flat Steel Sections in the Quenched State. Materials 2025, 18, 2626. https://doi.org/10.3390/ma18112626

Qi Z, Luo X, Liang F, Chai F, Ge Q, Zhan Z, Wang C, Fan W, Yang H, Liu Y. Effect of Induction Heating Temperature on the Uniformity of Mechanical Properties of Bulb Flat Steel Sections in the Quenched State. Materials. 2025; 18(11):2626. https://doi.org/10.3390/ma18112626

Chicago/Turabian StyleQi, Zhen, Xiaobing Luo, Fengrui Liang, Feng Chai, Qilu Ge, Zhide Zhan, Chunfang Wang, Wei Fan, Hong Yang, and Yitong Liu. 2025. "Effect of Induction Heating Temperature on the Uniformity of Mechanical Properties of Bulb Flat Steel Sections in the Quenched State" Materials 18, no. 11: 2626. https://doi.org/10.3390/ma18112626

APA StyleQi, Z., Luo, X., Liang, F., Chai, F., Ge, Q., Zhan, Z., Wang, C., Fan, W., Yang, H., & Liu, Y. (2025). Effect of Induction Heating Temperature on the Uniformity of Mechanical Properties of Bulb Flat Steel Sections in the Quenched State. Materials, 18(11), 2626. https://doi.org/10.3390/ma18112626