Effect of Annealing on Vacancy-Type Defects and Heterogeneous Cu Precipitation Behavior in Fe60Cr12Mn8Cu15Mo3V2 Alloy

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Characterization

3. Research Results and Their Analysis

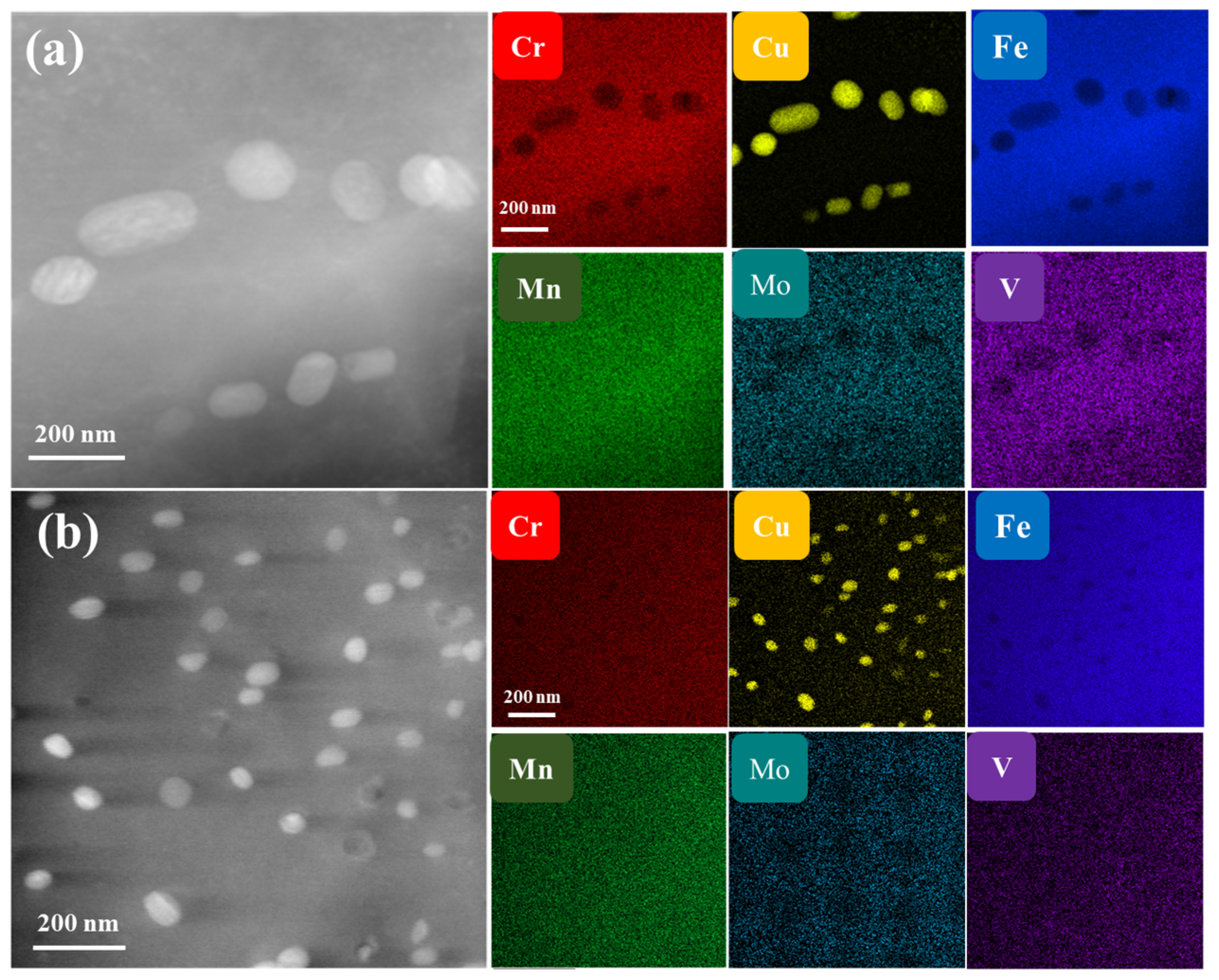

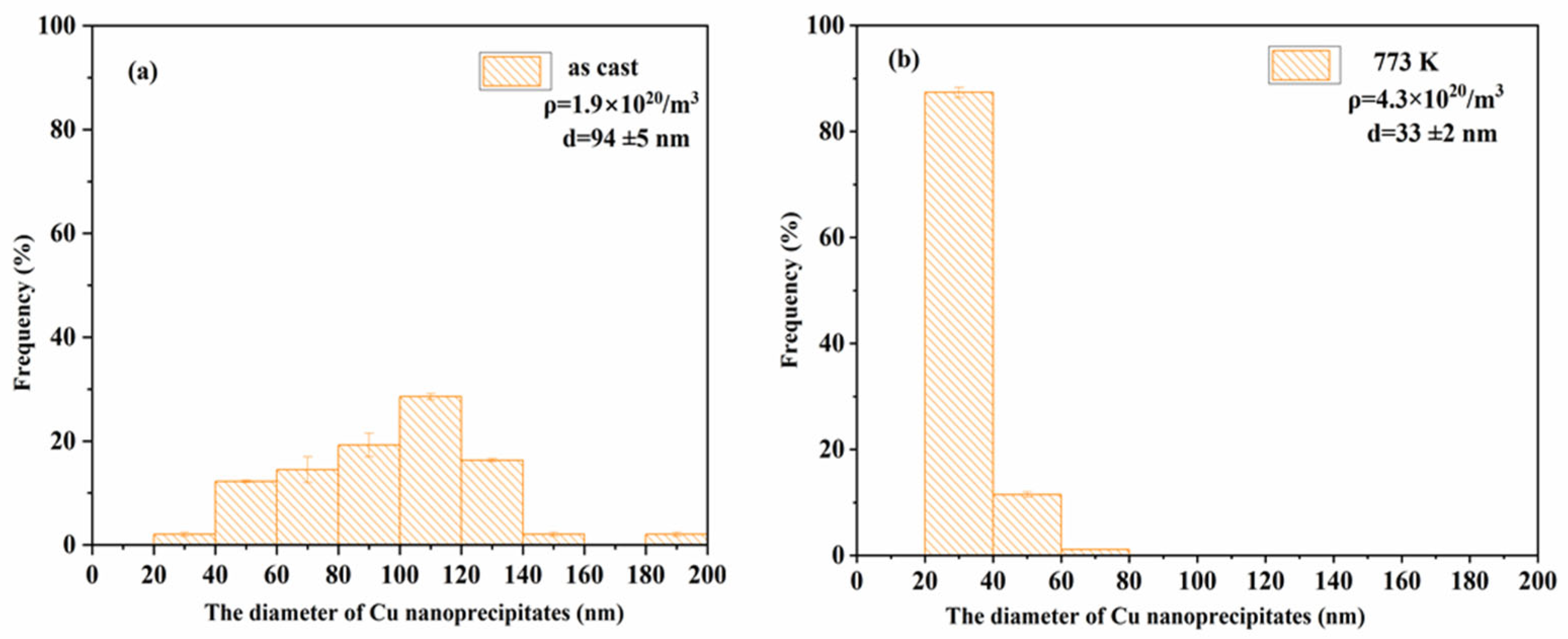

3.1. The Influence of Annealing on the Microstructure of Alloys

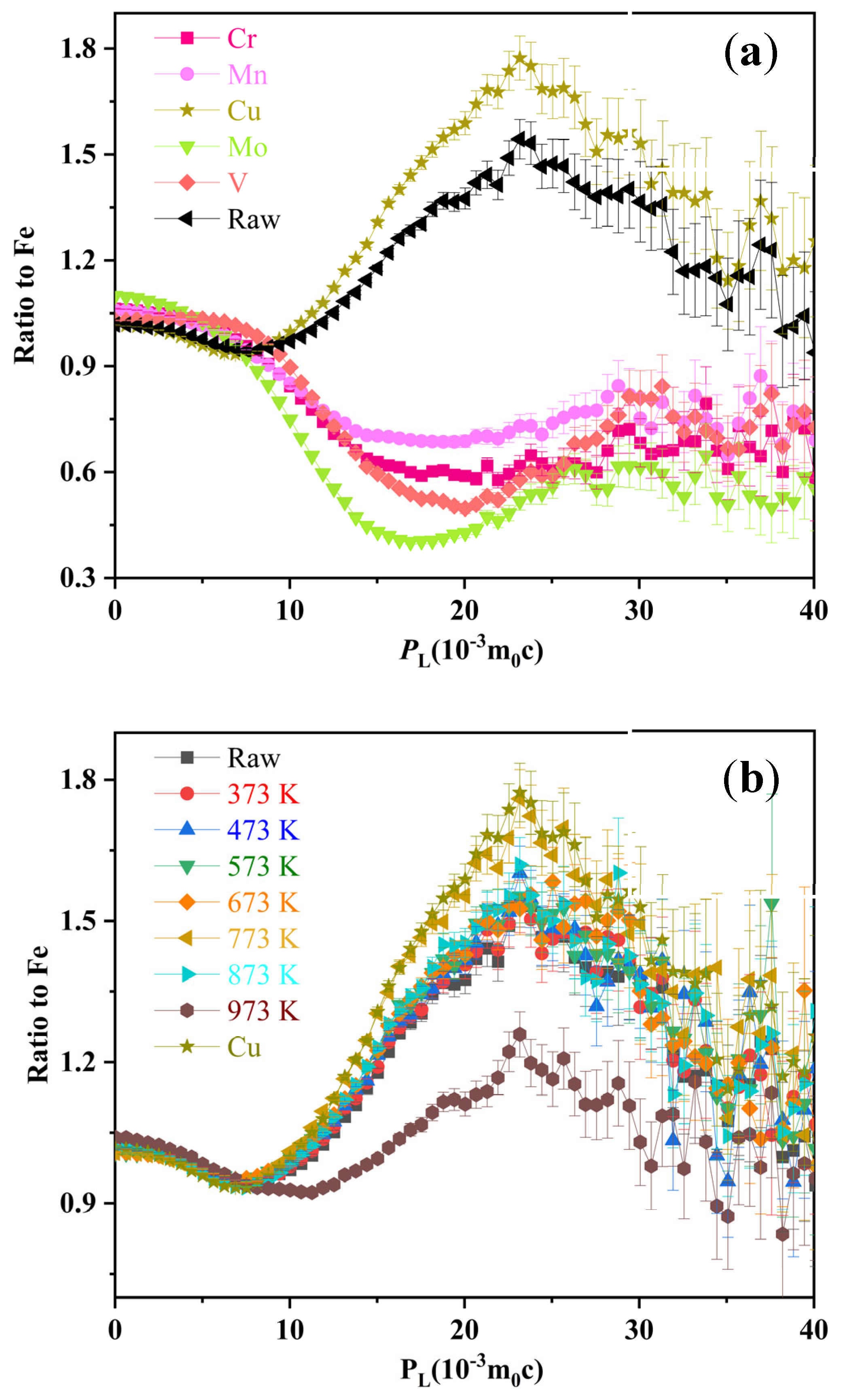

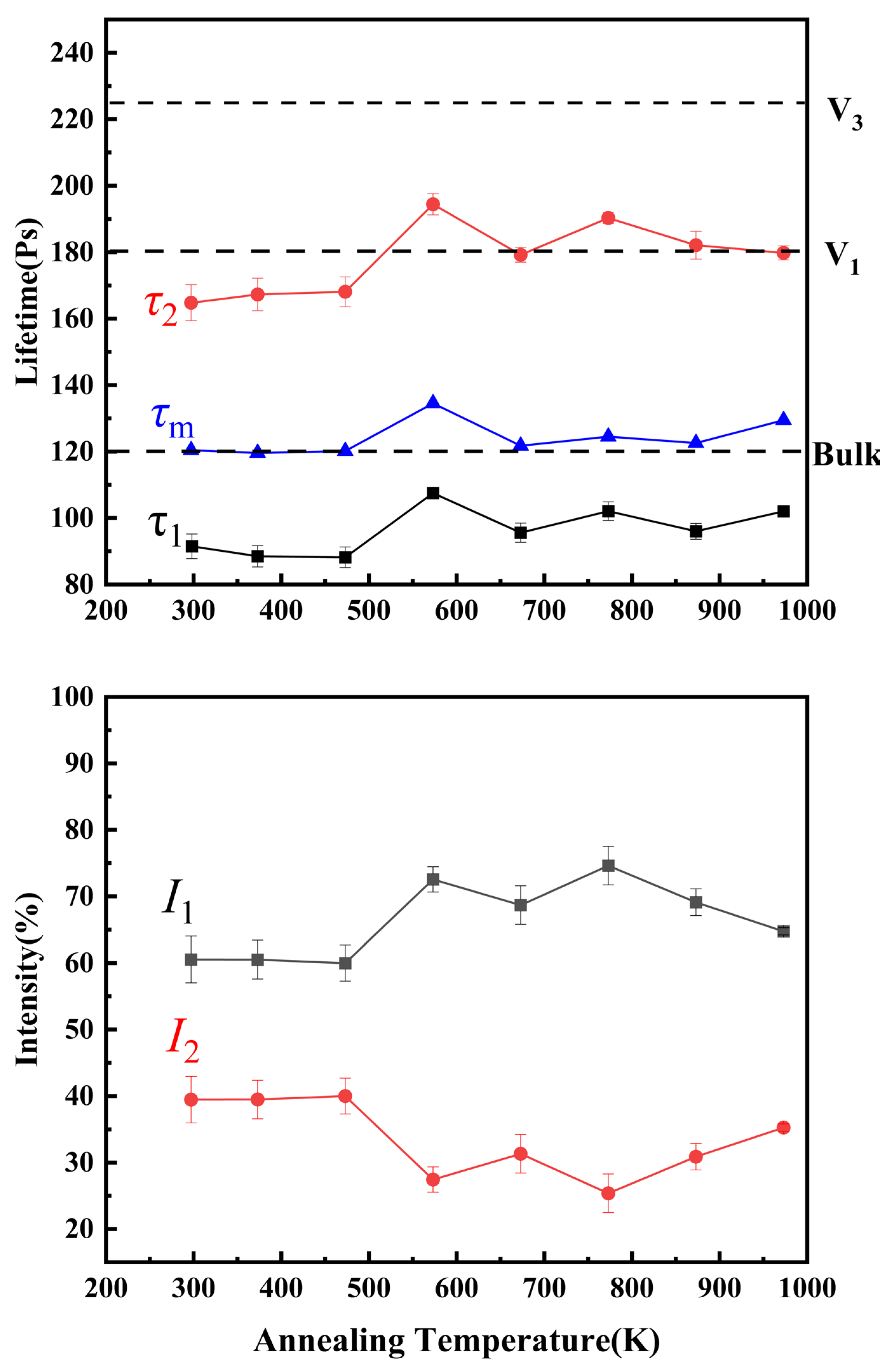

3.2. Effect of Annealing on Defects and Cu Precipitation Behavior

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Moschetti, M.; Burr, P.A.; Obbard, E.; Kruzic, J.J.; Hosemann, P.; Gludovatz, B. Design considerations for high entropy alloys in advanced nuclear applications. J. Nucl. Mater. 2022, 567, 153814. [Google Scholar] [CrossRef]

- Zhang, L.; Dou, Y.K.; Bai, B.; Yu, B.T.; He, X.F.; Yang, W. Research progress on creep resistance of high entropy alloys. J. Alloys Compd. 2024, 1011, 178280. [Google Scholar] [CrossRef]

- Rodríguez-López, A.; Savoini, B.; Monge, M.A.; Galatanu, A.; Galatanu, M. Evaluation of thermal properties of CuCrFeV (Ti, Ta, W, Mo) for nuclear fusion applications. Nucl. Mater. Energy 2024, 41, 101767. [Google Scholar] [CrossRef]

- Chu, S.; Majumdar, A. Opportunities and challenges for a sustainable energy future. Nature 2012, 488, 294–303. [Google Scholar] [CrossRef]

- Priyanka, A.D.; Abhijeet, D.; Hu, Z.H.; Dubey, M.; Shao, L.; Prabhakaran, R.; Mishra, R.S. Irradiation-induced shift in the thermodynamic stability of phases and the self-healing effect in transformative high entropy alloys. J. Nucl. Mater. 2024, 597, 155093. [Google Scholar]

- Wan, H.; Su, Z.X.; Yan, X.; Yang, J.; Lu, Y.P.; Shi, T.; Lu, C.Y. Microstructures and hardening effects of refractory high entropy alloys irradiated by Proton & He ion dual beam. Mater. Charact. 2024, 209, 113741. [Google Scholar]

- Abid, H.; Dhaka, R.S.; Jin, R.H.; Kumar, S.S.; Kumar, K.P. A critical review on temperature dependent irradiation response of high entropy alloys. J. Alloys Compd. 2023, 948, 169624. [Google Scholar]

- Sadeghilaridjani, M.; Muskeri, S.; Pole, M.; Mukherjee, S. High-Temperature Nano-Indentation Creep of Reduced Activity High Entropy Alloys Based on 4-5-6 Elemental Palette. Entropy 2020, 22, 230. [Google Scholar] [CrossRef]

- Yu, Y.; Liu, X.; Wang, Q.Q.; Yang, Q.G.; Dong, Y.; Zhu, T.; Wang, B.Y.; Cao, X.Z. Enhanced irradiation swelling resistance in low activation Ti8VCrMnFeCu2 high entropy alloys: Exploring the role of heterogeneous nanoparticles. J. Mater. Res. Technol. 2025, 35, 344–352. [Google Scholar] [CrossRef]

- Amanzhulov, B.; Ivanov, I.; Uglov, V.; Zlotski, S.; Ryskulov, A.; Kurakhmedov, A.; Sapar, A.; Ungarbayev, Y.; Koloberdin, M.; Zdorovets, M. Radiation Resistance of High-Entropy Alloys CoCrFeNi and CoCrFeMnNi, Sequentially Irradiated with Kr and He Ions. Materials 2024, 19, 4751. [Google Scholar] [CrossRef]

- Li, J.; Zhu, Y.X.; Zhao, L.; Liang, S.; Huang, M.S.; Li, Z.H. Interactions between edge dislocation and irradiation dislocation loop in BCC refractory high entropy alloys and the lattice distortion effect on irradiation hardening behavior. J. Alloys Compd. 2024, 1002, 175286. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, L.; Huang, H.; Chen, S.; Jia, N.; Dong, Y.; Guo, X.; Jin, K.; Xue, Y. Radiation-enhanced precipitation and the impact on He bubble formation in V-Ti-based refractory alloys containing interstitial impurities. J. Nucl. Mater. 2024, 596, 155078. [Google Scholar] [CrossRef]

- Xu, Q.; Yuan, X.; Eckert, J.; Şopu, D. Crack-healing mechanisms in high-entropy alloys under ion irradiation. Acta Mater. 2024, 263, 119488. [Google Scholar] [CrossRef]

- Diao, S.Z.; Zhao, Q.; Wang, S.L.; Han, W.T.; Wang, Z.Q.; Liu, P.P.; Chen, Y.H.; Wan, F.R.; Zhan, Q. The microstructure evolution and irradiation hardening in 15Cr-ODS steel irradiated by helium ions. Mater. Charact. 2022, 184, 111699. [Google Scholar] [CrossRef]

- Feldmann, G.; Fichtner, P.F.P.; Zawislak, F.C. Investigation of the effects of He bubbles on the nucleation, growth and thermal stability of Al–Cu nanoprecipitates in ion implanted Al foils. Acta Mater. 2004, 52, 693–703. [Google Scholar] [CrossRef]

- Pu, G.; Lin, L.W.; Ang, R.; Zhang, K.; Li, B.; Liu, B.; Peng, T.; Liu, S.F.; Li, Q.R. Outstanding radiation tolerance and mechanical behavior in ultra-fine nanocrystalline Al1.5CoCrFeNi high entropy alloy films under He ion irradiation. Appl. Surf. Sci. 2020, 516, 146129. [Google Scholar] [CrossRef]

- Cheng, G.M.; Xu, W.Z.; Wang, Y.Q.; Misra, A.; Zhu, Y.T. Grain size effect on radiation tolerance of nanocrystalline Mo. Scr. Mater. 2016, 123, 90–94. [Google Scholar] [CrossRef]

- Fradera, J.; Cuesta-Lopez, S. Impact of nuclear irradiation on helium bubble nucleation at interfaces in liquid metals coupled to permeation through stainless steels. Fusion Eng. Des. 2014, 89, 16–24. [Google Scholar] [CrossRef][Green Version]

- Zhang, H.Z.; Wang, Q.Q.; Li, C.H.; Zhu, Z.B.; Huang, H.F.; Lu, Y.P. He-ion Irradiation Effects on the Microstructures and Mechanical Properties of the Ti-Zr-Hf-V-Ta Low-Activation High-Entropy Alloys. Materials 2023, 16, 5530. [Google Scholar] [CrossRef]

- Bauyrzhan, A.; Igor, I.; Vladimir, U.; Sergey, Z.; Azamat, R.; Alisher, K.; Maxim, Z. Composition and Structure of NiCoFeCr and NiCoFeCrMn High-Entropy Alloys Irradiated by Helium Ions. Materials 2023, 16, 3695. [Google Scholar]

- El Atwani, O.; Vo, H.T.; Tunes, M.A.; Lee, C.; Alvarado, A.; Krienke, N.; Poplawsky, J.D.; Kohnert, A.A.; Gigax, J.; Chen, W.Y.; et al. A quinary WTaCrVHf nanocrystalline refractory high-entropy alloy withholding extreme irradiation environments. Nat. Commun. 2023, 14, 2516. [Google Scholar] [CrossRef] [PubMed]

- El-Atwani, O.; Nathaniel, J.E.; Leff, A.C.; Muntifering, B.R.; Baldwin, J.K.; Hattar, K.; Taheri, M.L. The role of grain size in He bubble formation: Implications for swelling resistance. J. Nucl. Mater. 2017, 484, 236–244. [Google Scholar] [CrossRef]

- Li, Z.B.; Cao, Y.J.; Liu, W.; Wang, Y.G.; Sun, F.Y.; Chen, Z.; Zhang, Z.Y. Enhanced irradiation resistance and thermal conductivity of SiC induced by the addition of carbon under Au2+ ion irradiation. Ceram. Int. 2018, 44, 8521–8527. [Google Scholar] [CrossRef]

- Yvon, P.; Carre, F. Structural materials challenges for advanced reactor systems. J. Nucl. Mater. 2009, 385, 217–222. [Google Scholar] [CrossRef]

- Cao, P.P.; Wang, H.; He, J.Y.; Xu, C.; Jiang, S.H.; Du, J.L.; Cao, X.Z.; Fu, E.G.; Lu, Z.P. Effects of nanosized precipitates on irradiation behavior of CoCrFeNi high entropy alloys. J. Alloys Compd. 2021, 859, 158291. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, K.; Feng, Y.; Li, Y.S.; Tang, W.Q.; Wei, B.C. Evaluation of Radiation Response in CoCrFeCuNi High-Entropy Alloy. Entropy 2018, 20, 835. [Google Scholar] [CrossRef]

- Wang, Z.J.; Liu, C.T.; Dou, P. Thermodynamics of vacancies and clusters in high-entropy alloys. Phys. Rev. Mater. 2017, 1, 043601. [Google Scholar] [CrossRef]

- Lescoat, M.L.; Ribis, J.; Gentils, A.; Kaïtasov, O.; de Carlan, Y.; Legris, A. In situ TEM study of the stability of nano-oxides in ODS steels under ion-irradiation. J. Nucl. Mater. 2012, 428, 176–182. [Google Scholar] [CrossRef]

- Watanabe, H.; Yamasaki, K.; Higashijima, A.; Taguma, H.; Nagasaka, T.; Muroga, T. Microstructural changes of Y-doped V-4Cr-4Ti alloys after ion and neutron irradiation. Nucl. Mater. Energy 2016, 9, 447–450. [Google Scholar] [CrossRef]

- Jin, Y.N.; Jiang, Y.; Yang, L.T.; Lan, G.; Odette, G.R.; Yamamoto, T.; Shang, J.; Dang, Y. First principles assessment of helium trapping in Y2TiO5 in nano-featured ferritic alloys. J. Appl. Phys. 2014, 116, 143501. [Google Scholar] [CrossRef]

- Hadraba, H.; Chlup, Z.; Dlouhy, A.; Dobes, F.; Roupcova, P.; Vilemova, M.; Matejicek, J. Oxide dispersion strengthened CoCrFeNiMn high-entropy alloy. Mater. Sci. Eng. A 2017, 689, 252–256. [Google Scholar] [CrossRef]

- Shu, S.; Almirall, N.; Wells, P.B.; Yamamoto, T.; Odette, G.R.; Morgan, D.D. Precipitation in Fe-Cu and Fe-Cu-Mn model alloys under irradiation: Dose rate effects. Acta Mater. 2018, 157, 72–82. [Google Scholar] [CrossRef]

- Barashev, A.V.; Golubov, S.I.; Bacon, D.J.; Flewitt, P.E.J.; Lewis, T.A. Copper precipitation in Fe–Cu alloys under electron and neutron irradiation. Acta Mater. 2004, 52, 877–886. [Google Scholar] [CrossRef]

- Zhang, S.; Yao, Z.; Zhang, Z.; Oleksandr, M. Irradiation damage and mechanical properties in Fe-Au and Fe-Cu model alloys under helium ion irradiation. Appl. Surf. Sci. 2020, 504, 144383. [Google Scholar] [CrossRef]

- Jin, S.X.; Cao, X.Z.; Cheng, G.D.; Lian, X.Y.; Zhu, T.; Zhang, P.; Yu, R.S.; Wang, B.Y. Thermally promoted evolution of open-volume defects and Cu precipitates in the deformed FeCu alloys. J. Nucl. Mater. 2018, 501, 293–301. [Google Scholar] [CrossRef]

- Ye, F.J.; Zhu, T.; Wang, Q.Q.; Song, Y.M.; Zhang, H.Q.; Zhang, P.; Kuang, P.; Yu, R.S.; Cao, X.Z.; Wang, B.Y. Positron annihilation study of open volume defects and Cr segregation in deformed CoCrFeMnNi alloy. Intermetallics 2022, 149, 107670. [Google Scholar] [CrossRef]

- Ye, F.J.; Zhu, T.; Song, Y.M.; Wang, Q.Q.; Zhang, P.; Kuang, P.; Liu, F.Y.; Yu, R.S.; Xu, Q.; Wang, B.Y.; et al. Irradiation swelling resistance characteristics of heterogeneous nanoparticles in an iron-based multi-principal alloy. J. Alloys Compd. 2021, 939, 168643. [Google Scholar] [CrossRef]

- Zhang, R.G.; Wang, B.Y.; Zhang, H.; Wei, L. Influence of sulfidation ambience on the properties of nanocrystalline ZnS films prepared by sulfurizing the as-sputtered ZnO films. Appl. Surf. Sci. 2005, 245, 340–345. [Google Scholar] [CrossRef]

- Zhu, T.; Cao, X.Z. Research progress of hydrogen/helium effects in metal materials by positron annihilation spectroscopy. Acta Phys. Sin. 2020, 69, 177801. [Google Scholar] [CrossRef]

- Ye, F.J.; Zhu, T.; Mori, K.; Xu, Q.; Song, Y.M.; Wang, Q.Q.; Yu, R.S.; Wang, B.Y.; Cao, X.Z. Effects of dislocations and hydrogen concentration on hydrogen embrittlement of austenitic 316 stainless steels. J. Alloys Compd. 2021, 876, 160134. [Google Scholar] [CrossRef]

- Abhaya, S.; Rajaraman, R.; Kalavathi, S.; Amarendra, G. Positron annihilation studies on FeCrCoNi high entropy alloy. J. Alloys Compd. 2015, 620, 277–282. [Google Scholar] [CrossRef]

- Brusa, R.S.; Deng, W.; Karwasz, G.P.; Zecca, A. Doppler-broadening measurements of positron annihilation with high-momentum electrons in pure elements. Nucl. Instrum. Meth. B 2002, 194, 519–531. [Google Scholar] [CrossRef]

- He, S.M.; Brandhoff, P.N.; Schut, H.; He, S.M.; Brandhoff, P.N.; Schut, H.; van der Zwaag, S.; van Dijk, N.H. Positron annihilation study on repeated deformation/precipitation aging in Fe–Cu–B–N alloys. J. Mater. Sci. 2013, 48, 6150–6156. [Google Scholar] [CrossRef]

- Pogrebnjak, A.D. Structure and Properties of Nanostructured (Ti-Hf-Zr-V-Nb)N Coatings. J. Nanomater. 2013, 2013, 780125. [Google Scholar] [CrossRef]

- Zhong, Z.H.; Xu, Q.; Mori, K.; Tokitani, M. Thermal stability of microstructures and mechanical properties in a Fe-based Fe-Cr-Mn-Cu-Mo multi-component alloy. Philos. Mag. 2019, 99, 1515–1527. [Google Scholar] [CrossRef]

- Liu, M.W.; Zheng, R.X.; Li, H.X.; Wei, Q.W.; Ma, C.L.; Tsuji, N. Phase decomposition behavior and its impact on mechanical properties in bulk nanostructured Cu-20 at.% Fe supersaturated solid solution. J. Mater. Sci. Technol. 2024, 185, 207–220. [Google Scholar] [CrossRef]

- Liang, C.; Han, J.N.; Zhou, B.W.; Xue, Y.Y.; Jia, F.; Zhang, X.G. Effects of rolling and annealing on microstructures and properties of Cu–Mg–Te–Y alloy. Trans. Nonferrous Met. Soc. China 2014, 24, 1046–1052. [Google Scholar]

- Ma, Q.D.; Zhang, Y.B.; Yue, S.P.; Chen, J.L.; Li, Y.J. Microstructure and property evolution of Cu-Fe alloys during cryogenic rolling and aging treatment. Metal Heat Treat. 2024, 49, 48–54. [Google Scholar]

- Pogrebnjak, A.D.; Bakharev, O.G.; Pogrebnjak, N.A.; Tsvintarnaya, Y.V.; Shablja, V.T.; Sandrik, R.; Zecca, A. Certain features of high-dose and intensive implantation of Al ions in iron. Phys. Lett. A 2000, 265, 225–232. [Google Scholar] [CrossRef]

- Dai, H.Y.; Ye, F.J.; Li, T.; Chen, Z.P.; Cao, X.Z.; Wang, B.Y. Impact of Li doping on the microstructure, defects, and physical properties of CuFeO2 multiferroic ceramics. Ceram. Int. 2019, 45, 24570–24577. [Google Scholar] [CrossRef]

- Nagai, Y.; Takadate, K.; Tang, Z.H.; Ohkubo, H.; Sunaga, H.; Takizawa, H.; Hasegawa, M. Positron annihilation study of vacancy-solute complex evolution in Fe-based alloys. Phys. Rev. B 2003, 67, 224202. [Google Scholar] [CrossRef]

- Xu, Q.; Yoshiie, T.; Sato, K. Formation of Cu precipitates and vacancy clusters in neutron-irradiated Fe-Cu alloys. Philos. Mag. Lett. 2008, 88, 353–362. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ye, F.; Zhu, T.; Zhang, P.; Kuang, P.; Wu, H.; Cao, X. Effect of Annealing on Vacancy-Type Defects and Heterogeneous Cu Precipitation Behavior in Fe60Cr12Mn8Cu15Mo3V2 Alloy. Materials 2025, 18, 2613. https://doi.org/10.3390/ma18112613

Ye F, Zhu T, Zhang P, Kuang P, Wu H, Cao X. Effect of Annealing on Vacancy-Type Defects and Heterogeneous Cu Precipitation Behavior in Fe60Cr12Mn8Cu15Mo3V2 Alloy. Materials. 2025; 18(11):2613. https://doi.org/10.3390/ma18112613

Chicago/Turabian StyleYe, Fengjiao, Te Zhu, Peng Zhang, Peng Kuang, Haibiao Wu, and Xingzhong Cao. 2025. "Effect of Annealing on Vacancy-Type Defects and Heterogeneous Cu Precipitation Behavior in Fe60Cr12Mn8Cu15Mo3V2 Alloy" Materials 18, no. 11: 2613. https://doi.org/10.3390/ma18112613

APA StyleYe, F., Zhu, T., Zhang, P., Kuang, P., Wu, H., & Cao, X. (2025). Effect of Annealing on Vacancy-Type Defects and Heterogeneous Cu Precipitation Behavior in Fe60Cr12Mn8Cu15Mo3V2 Alloy. Materials, 18(11), 2613. https://doi.org/10.3390/ma18112613