1. Introduction

Mechanical metamaterials are a class of materials with specific mechanical properties that are produced by designing their internal microstructures. The unique properties of these materials are not derived from the materials they are composed of but rather from their structural design. These metamaterials exhibit many unique mechanical properties that do not exist in nature, achieved through the ingenious design of geometry, arrangement, and topology. The application scenarios of mechanical metamaterials are extensive. Progress has been made in the fields of mechanics [

1,

2,

3], acoustics [

4,

5,

6,

7], optics [

8,

9,

10,

11], energy absorption [

12,

13,

14], biomaterials [

15], robotics [

16,

17,

18,

19], and 3D material printing [

20,

21,

22]. These mechanical metamaterials have been applied for various purposes in these fields by using their negative Poisson’s ratio, large tensile strain, programmability, and other characteristics [

23].

Three-dimensional chiral metamaterials are a class of mechanical metamaterials with special properties, which have received widespread attention in recent years. Overall rotational motion of three-dimensional chiral mechanical metamaterials can be induced through internal deformation rather than external forces, and their global rotational effect can be optimized by adjusting their structural parameters [

1]. For example, the twisting behavior of three-dimensional chiral mechanical metamaterials can be adjusted by changing the geometric shape of the helix, which can achieve precise control of the helix structure’s parameters to regulate light transmission [

8]. The combination of chiral metamaterials and plasmonic nanostructures can significantly enhance the optical chiral signal of chiral molecules [

9]. In addition, as an auxiliary structure, by adjusting the design parameters of chiral metamaterials, negative three-dimensional Poisson’s ratio characteristics can be stably achieved over a large strain range [

18].

Coupled compression–torsion effects are attractive characteristics of three-dimensional chiral mechanical metamaterials, and the unique deformation mechanism behind them has attracted widespread attention from researchers. Tobias et al. [

11] designed a kind of three-dimensional compression–torsion metamaterial with a cubic unit cell composed of a tetrachiral lattice on each surface. The metamaterial twisted more than 2 degrees per unit axial strain. Zheng et al. [

24] proposed a novel three-dimensional tension-torsion metamaterial by connecting adjacent chiral honeycomb layers and inclined rods. This metamaterial exhibited significant changes in torsion angle at a tensile strain of 1% and maintained a high torsion angle even when the number of cells was large. Li et al. [

25] proposed a novel compression–torsion three-dimensional metamaterial design method based on the shear–compression coupling effect of two-dimensional materials; they found that infinite torsion angle per axial strain could be achieved through elaborate design, providing new ideas for designing three-dimensional structures with multifunctional applications. Zhong et al. [

26] also proposed a novel three-dimensional compression–torsion mechanical metamaterial by converting axial strain into torsional strain based on the inclined rod spiral mechanism. Compared with previously reported three-dimensional compression–torsion metamaterials, this material exhibited superior compression–torsion performance. The factors affecting the compression–torsion characteristics were also discussed in detail, providing guidance for designing three-dimensional metamaterials with excellent compression–torsion characteristics. Kumar et al. [

27] investigated the fabrication of a Cu/SiC surface composite via friction stir processing (FSP) for heat sink applications. By embedding SiC particles into a copper matrix using FSP—a solid-state technique—uniform particle distribution was achieved in the composite without defects like porosity or clustering. The material exhibited a 57% increase in hardness and a 13% improvement in tensile strength compared to pure copper, although ductility decreased due to grain refinement and reinforcement effects. The enhanced wear resistance was attributed to SiC’s hardness and homogeneous dispersion. The results highlight FSP’s potential for producing high-performance thermal materials with balanced mechanical and tribological properties. Fang X et al. [

28] presented a chiral mechanical metamaterial based on twist buckling, which significantly enhanced elastic energy storage density by coupling axial compression with torsional deformation through freely rotatable metacell structures. Compared to conventional non-chiral designs, this material achieved 5–10 -higher buckling strength and 2–160× greater energy density as well as supported recoverable strains up to 20% while maintaining high stiffness. The key mechanism was in storing additional energy via torsional deformation without substantially increasing local stress concentrations. Experimental validation using 3D-printed prototypes confirmed its superior performance, demonstrating potential applications in lightweight energy storage, impact-resistant structures, and low-frequency vibration isolation.

However, it should be noted that due to the complexity of geometric models and physical mechanisms, research on three-dimensional chiral mechanical metamaterials is still limited. Most studies have analyzed their quasi-static mechanical behavior and deformation process, and research on their dynamic characteristics deserves more attention. The coupled effects of compression–torsion under dynamic loading conditions are still unclear. In addition, the close relationship between the coupled compression–torsion effect and the size effect is significantly affected by the array number of unit cells. Therefore, investigating the dynamic influence mechanism of the size effect on compression–torsion deformation is also a very interesting scientific problem.

In this paper, the quasi-static and dynamic compression mechanical behavior of three-dimensional chiral mechanical metamaterials is investigated. The effects of geometric parameters and size on the coupled compression–torsion effect (i.e., twist angle per axial strain and effective modulus) are studied. The rest of this paper is organized as follows:

Section 2 describes the structural and computational model, and the simulation method is validated in

Section 3. The quasi-static compression behavior and dynamic compression behavior are discussed in

Section 4 and

Section 5, respectively. Finally, the key conclusions are summarized in

Section 6.

2. Materials and Methods

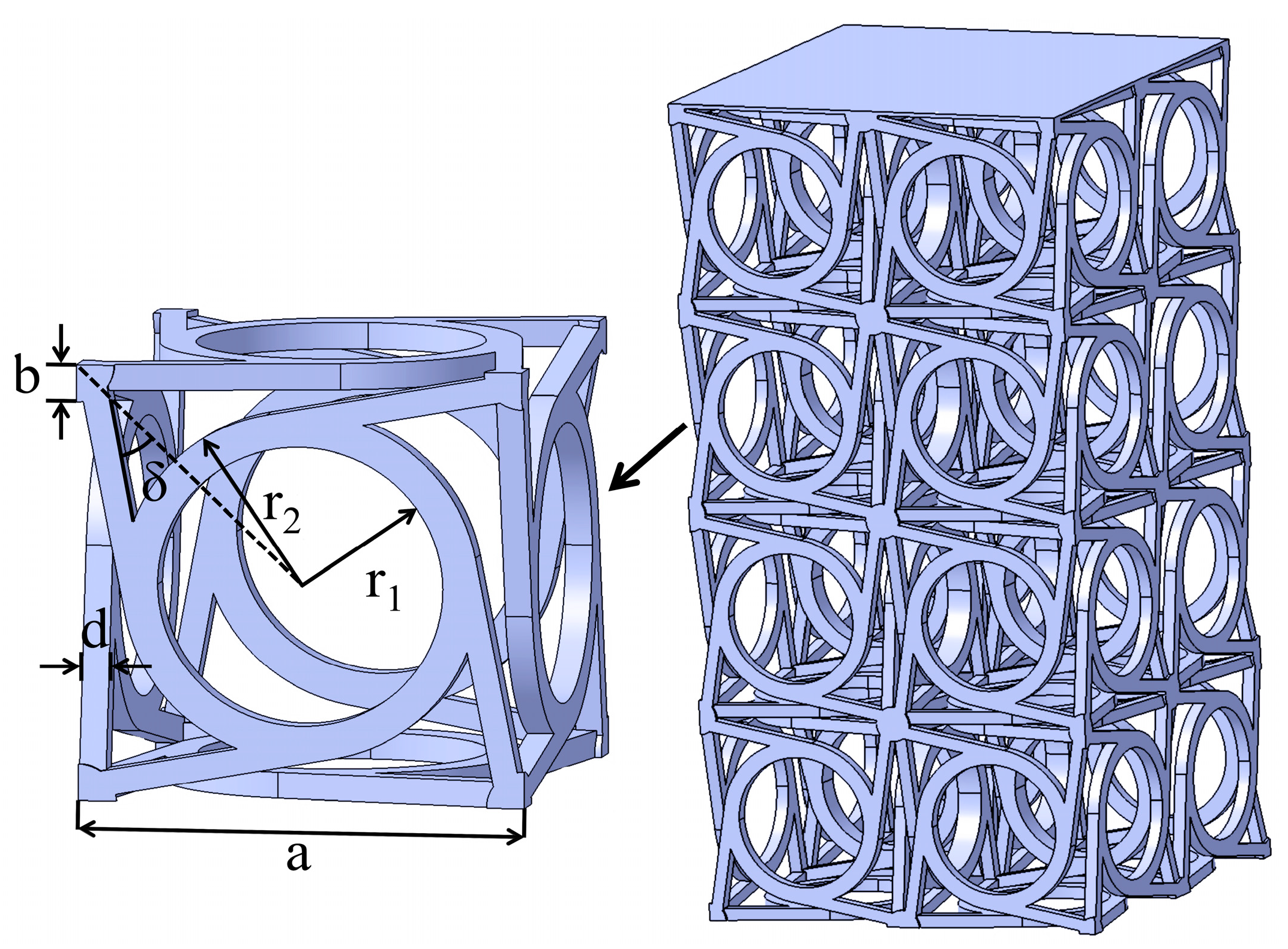

In

Figure 1, the unit cell configuration as well as structural pattern of the three-dimensional chiral mechanical metamaterials are illustrated. This paper is based on the linear elasticity eigenstructure model (

) and explicit kinetic equations (

) that model the dynamic compression process. The unit cell configuration and equations were proposed in [

11], where the target structure was generated by arraying the corresponding unit cell in three orthogonal directions. Geometric parameters, including the unit cell size a, the angle δ, the inner radius r

1, the outer radius r

2, the corner width b, and the ligament width d, are also all indicated in the figure. It should be noted that

, where

N is the number of arrays.

To simulate its dynamic compression mechanical behavior and gain insight into the effects of size, commercial finite element software ABAQUS 2020/Explicit (Dassault Systèmes, France) was utilized. The linear elastic–plastic mechanical behavior of the constituent material was assumed [

11], which was used to simplify the calculation, and the impact of simplification was ignored particularly for the dynamic behavior, with a density of 1.15 g/cm

3, Young’s modulus of 2.6 GPa, Poisson’s ratio of 0.4, and yield stress of 69 MPa. To ensure the degrees of freedom in rotational deformation, the number of arrays in the Z direction was set as 2N. The bottom side of the specimen was fixed on a rigid substrate, and the top side, made of the same constituent material, was connected to a square plate with a thickness of 10 µm. General contact with a penalty friction coefficient of 0.3 was applied between the target structure and the rigid plates. The structural pattern was meshed using modified quadratic tetrahedral elements (C3D10M) with an element size of 0.015 mm, and the reliability of the calculated results was ensured through mesh convergence analysis. The boundary between quasi-static and dynamic compression was delineated by the strain rate, which ranged from 10

−5 to 10 s

−1 for quasi-static compression to 10–10

3 s

−1 for low-speed dynamic compression. This paper focuses on the study of three-dimensional chiral mechanical metamaterials under quasi-static and low-speed dynamic compression. In order to simulate the mechanical behavior of three-dimensional chiral metamaterials under static and dynamic compressive loading, the quasi-static mechanical behavior simulation loading method was used to control the displacement loading method, and the dynamic mechanical behavior simulation loading method was used to control the velocity loading method. The calculation time of the simulation was 0.01 s, and the dynamic loading rate was equal to the total strain/time period. The strain rate for quasi-static compression was 10

−1 s

−1. Depending on the amount of deformation, the speed of dynamic loading was 15 mm/s, 30 mm/s, 45 mm/s, 60 mm/s, or 75 mm/s.

3. Simulation Method Validation

To validate the accuracy of the computational model, the numerical results were compared with the experimental data and the displacement vector field from [

11]. As shown in

Figure 2, the twist angle per axial strain and effective compression modulus versus the applied axial strain of the target structure with N = 1 and N = 2 were both analyzed. It can be observed that the variations in the simulated curves obtained in this article were consistent with the experimental data points. Additionally, the simulated displacement vector field also matched well with the calculation results from the chiral micropolar continuum mechanics [

11]. The comparisons of the data points and distribution of the displacement field demonstrated the effectiveness of the calculation results in this study. It should be noted in particular that this study ignored the nonlinear behavior of the material (e.g., plasticity and viscoelasticity), a simplification that reduced computational complexity but could have led to biased predictions of local stress concentrations or energy dissipation mechanisms under dynamic loading. Although actual materials may yield at larger strains, the results in this paper are only applicable to mechanical behavior in the elastic range. Future work is needed to verify the critical conditions at the elastic–plastic boundary in conjunction with experiments (

Figure 2).

4. Discussion

4.1. Investigation of Geometric Parameters

The unit cell is an important constituent element of structural materials, and its mechanical properties can be affected by geometric dimensions. Thus, exploring the effects of key geometric parameters on the mechanical behavior of the unit cell is of great significance. Compared to Zhong et al., our study showcases the effect of geometric parameters including the outer radius and corner width on the coupled compression–torsion effects on the three-dimensional chiral mechanical metamaterial in [

11]. This section mainly focuses on the effects of the outer radius

and corner width

on the twist angle per axial strain and effective modulus. The effects of the other parameters are not critical, and thus they are not considered in this article.

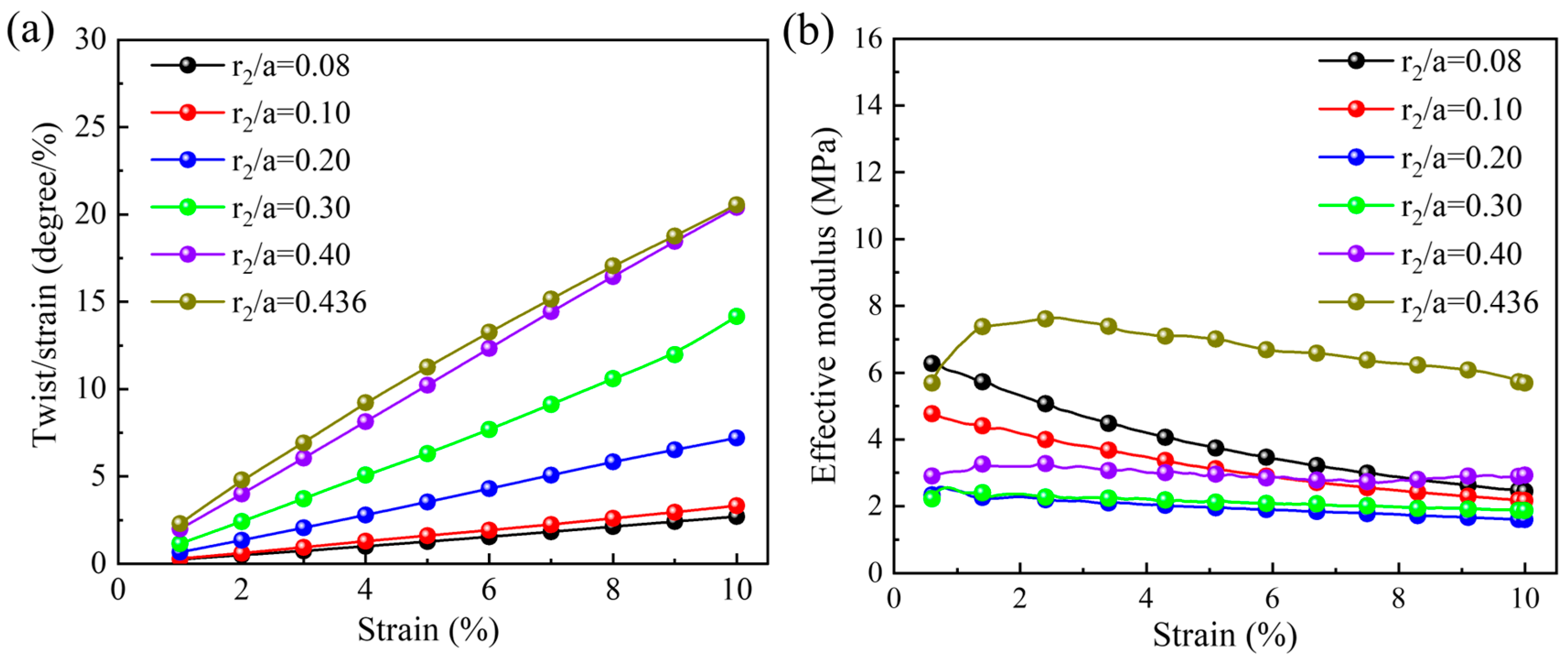

4.1.1. The Effect of the Ratio of the Outer Radius on the Unit Cell Size

In

Figure 3a, the relationship between the quasi-static compression twist angle per axial strain and the applied axial strain under different

values is plotted. Herein,

corresponds to a limit state of the three-dimensional chiral mechanical metamaterials, where the central ring and the ligament are in contact and tangent with each other. It can be observed that the twist angle per axial strain increases with the increase in the applied axial strain, almost in a linear growth trend. Additionally, when the specific axial compression strain is considered, the twist angle per axial strain also increases with the increase in the ratio of the outer radius to the unit cell size. Particularly, when the axial compression strain is 0.1, the twist angle per axial strain is

degrees per unit strain for the

pattern and is

degrees per unit strain for

. The corresponding relationship between the effective modulus and the applied axial strain is given in

Figure 3b. As the applied axial strain increases, the effective modulus shows a slow decreasing trend. However, different from the variation in the twist angle, the effective modulus shows a trend of first decreasing and then increasing with the increase in

. The maximum value of the effective modulus of 7.61 MPa can be attained when

. The possible reason why the effective modulus increases at higher

is that the central ring and the ligament are in contact and tangent with each other.

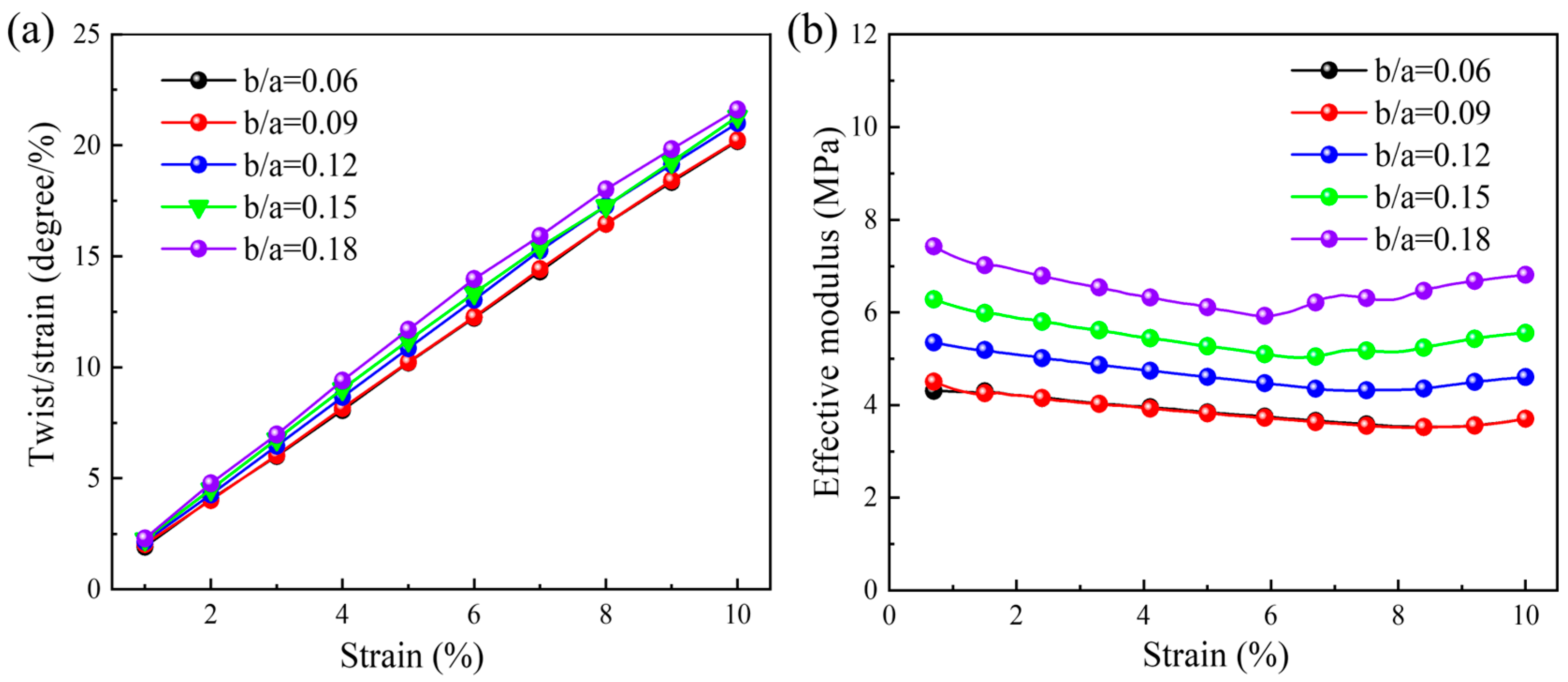

4.1.2. The Effect of the Ratio of Corner Width to the Unit Cell Size

Figure 4a shows the quasi-static compression relationship between the twist angle per axial strain and the applied axial strain. It can be seen that the quasi-static compression twist angle per axial strain increases with the applied axial strain for all

values. When

ranges from 0.06 to 0.18, the twist angle per axial strain also shows a gradually increasing trend, but the growth rate is very small. When the quasi-static compression strain is 0.1, the maximum twist angle per axial strain is

degrees per unit strain, and the minimum value is

degrees per unit strain. The quasi-static relationship between the effective modulus and the applied axial strain is indicated in

Figure 4b. Overall, the effective modulus decreases slightly with the increase in the axial strain. The maximum effective modulus of 7.43 MPa is achieved when

, and the minimum effective modulus of 3.69 MPa is obtained when

.

4.2. Investigation of Size Effect

Size has a significant effect on the mechanical properties and deformation behavior of cellular materials, and exploring the underlying rules is an interesting topic. Different from Zhong et al. and Frenzel et al., our research expanded the stacking method of unit cells and analyzed the influence of size on the coupled compression–torsion effect of three-dimensional chiral metamaterials in more detail.

Herein, the effects of the cell stacking method and size on the quasi-static coupled compression–torsion characteristics and effective elastic modulus were investigated. A basic structure with characteristic dimensions of , unit cell size , ligament width , corner width , inner radius , and outer radius , was selected and considered.

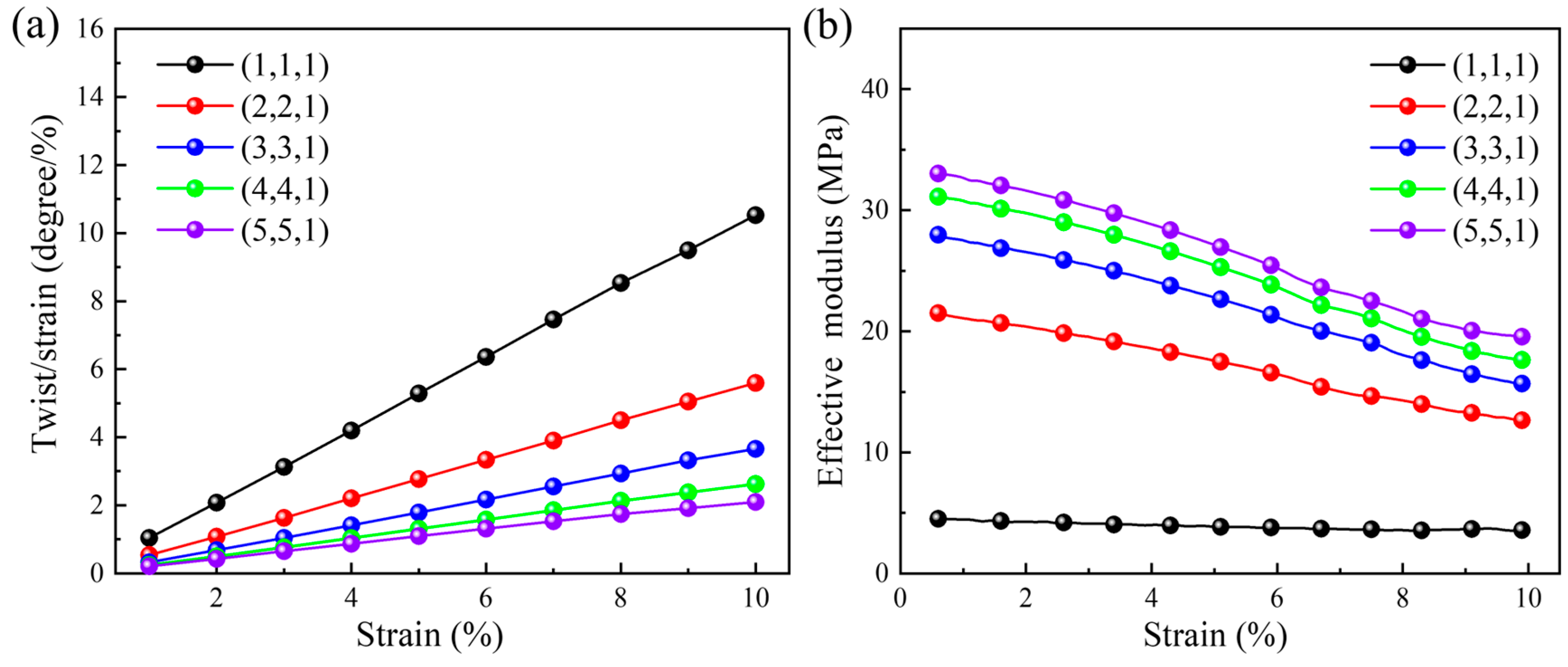

4.2.1. The Effect of the Number of Arrays in the X and Y Directions

Figure 5a illustrates the variation between the quasi-static compression twist angle per axial strain and the applied axial strain under different number of arrays in the X and Y directions. It should be noted that, when exploring the effects of the number of arrays in the X and Y directions, the number of arrays in the Z direction remains unchanged (i.e., kept as 1) and is annotated in the legend. The quasi-static compression twist angle per axial strain increases with the increase in the applied axial strain. However, a smaller twist angle per axial strain is obtained for a higher array number in the X and Y directions. The reason for this phenomenon is the size effect. The larger the array number in the X and Y directions, the stronger the ability of three-dimensional chiral mechanical metamaterials to resist torsion, and the corresponding twist angle per axial strain is smaller. When the axial compression strain is 0.1, the maximum twist angle per axial strain is

degrees per unit strain for the structural pattern with one horizontal array, and the minimum twist angle per axial strain is

degrees per unit strain for five horizontal arrays. Correspondingly, the relationship between the quasi-static compression effective modulus and the applied axial strain under different number of arrays in the X and Y directions is given in

Figure 5b. As the compression progresses, effective modulus exhibits a gradual downward trend. A higher effective modulus, i.e., higher stiffness or a stronger ability to resist deformation, is obtained with larger array numbers in the X and Y directions. Thus, the twist angle per axial strain exhibits a downward trend, which is consistent with those shown in

Figure 5a. When the compression strain is 0.1, the maximum and minimum moduli are 19.52 MPa and 3.59 MPa, respectively.

4.2.2. The Effect of the Number of Arrays in the Z Direction

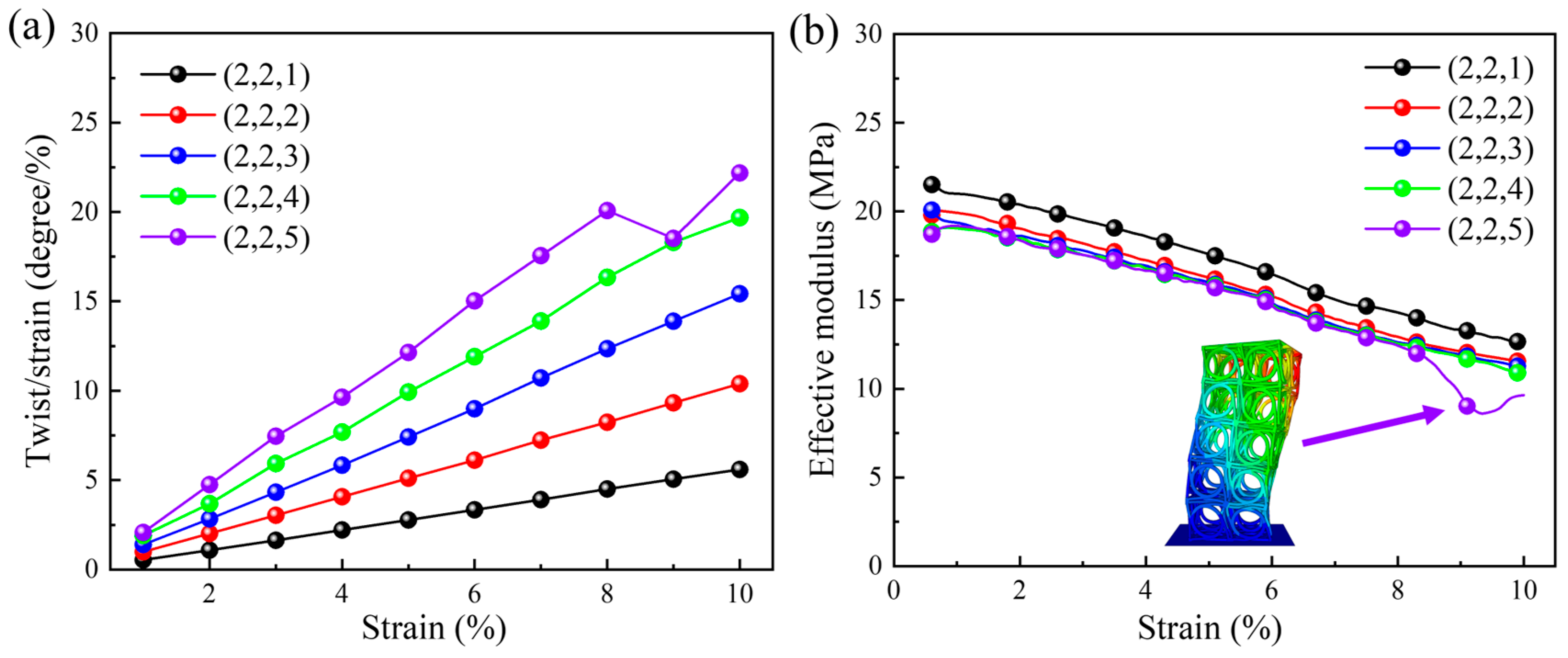

The relationship between the quasi-static compression twist angle per axial strain and the applied axial strain for different numbers of arrays in the Z direction is plotted in

Figure 6a. The number of unit cells in the X and Y directions remains constant (i.e., kept as two), while the number of unit cells in the Z direction varies between one and five. When the applied axial strain increases, the twist angle per axial strain also shows an increasing trend. The quasi-static compression twist angle per axial strain increases with the increase in the number of arrays in the Z direction, owing to the decrease in the ability to the resist torsion caused by the size effect. When the compression strain is 0.1, the maximum twist angle per axial strain is

degrees per unit strain, and the minimum value is

degrees per unit strain. On the contrary, when the number of arrays in the Z direction is five, a sudden drop emerges under large compressive strain. It results from the instability in the structural materials during compression. The variation in effective modulus is shown in

Figure 6b, where a decreasing trend can be observed as the array number in the Z direction increases. Similarly, when the array number in the Z direction is five, a sudden drop is also observed in the effective modulus, which is consistent with the phenomenon shown in

Figure 6a. In this case, effective modulus is only 8.29 MPa, which is caused by the instability of the three-dimensional chiral mechanical metamaterials due to the shift in the center of gravity (see the instability deformation diagram in

Figure 6b).

5. Dynamic Compression Behavior

The above sections discussed the effects of the geometric parameters and size on the quasi-static compression behavior of three-dimensional chiral mechanical metamaterials. The insight into the effects of size on the dynamic mechanical behavior is more complex and interesting. Thus, in the following section, the effects of size (i.e., the array number in the horizontal and vertical directions) on the dynamic coupled compression–torsion characteristics and effective elastic modulus are investigated.

5.1. Size Effects in the X and Y Directions

In

Figure 7a, the relationship between the dynamic compression twist angle per axial strain and the applied axial strain under different number of arrays in the X and Y directions is illustrated. When the number of arrays in the X and Y directions increases, the ability of three-dimensional chiral mechanical metamaterials to resist torsion also increases, and the corresponding twist angle per axial strain shows a decreasing trend. When the array number in the X and Y directions is four or five, the dynamic compression twist angle per axial strain increases first and then decreases. This is due to the mutual strain between ligaments during the twist of the unit cells, which hinders the freedom of rotation. When the dynamic compression strain is 0.3, the maximum twist angle per axial strain is

degrees per unit strain, and the minimum value is

degrees per unit strain. Correspondingly, the dynamic compression effective modulus exhibits an increasing trend as the array number in the X and Y directions increases (see

Figure 7b), indicating an increase in the structural stiffness, which is also consistent with the results shown in

Figure 7a. When the compression strain is 0.3, the maximum and minimum dynamic compression effective moduli are 4.30 MPa and 2.70 MPa, respectively.

Furthermore, we compare the dynamic compression results with those obtained under quasi-static loading conditions for different numbers of arrays in the X and Y directions. Under specific axial compression strain, the values of the twist angle per axial strain under static and dynamic compression are almost the same, but the effective modulus decreases more sharply under the dynamic loading condition. From another perspective, it can be seen that under the dynamic loading condition, even if the effective modulus decreases more, the twist angle per axial strain under the same compressive strain remains almost unchanged, which may be due to inertia.

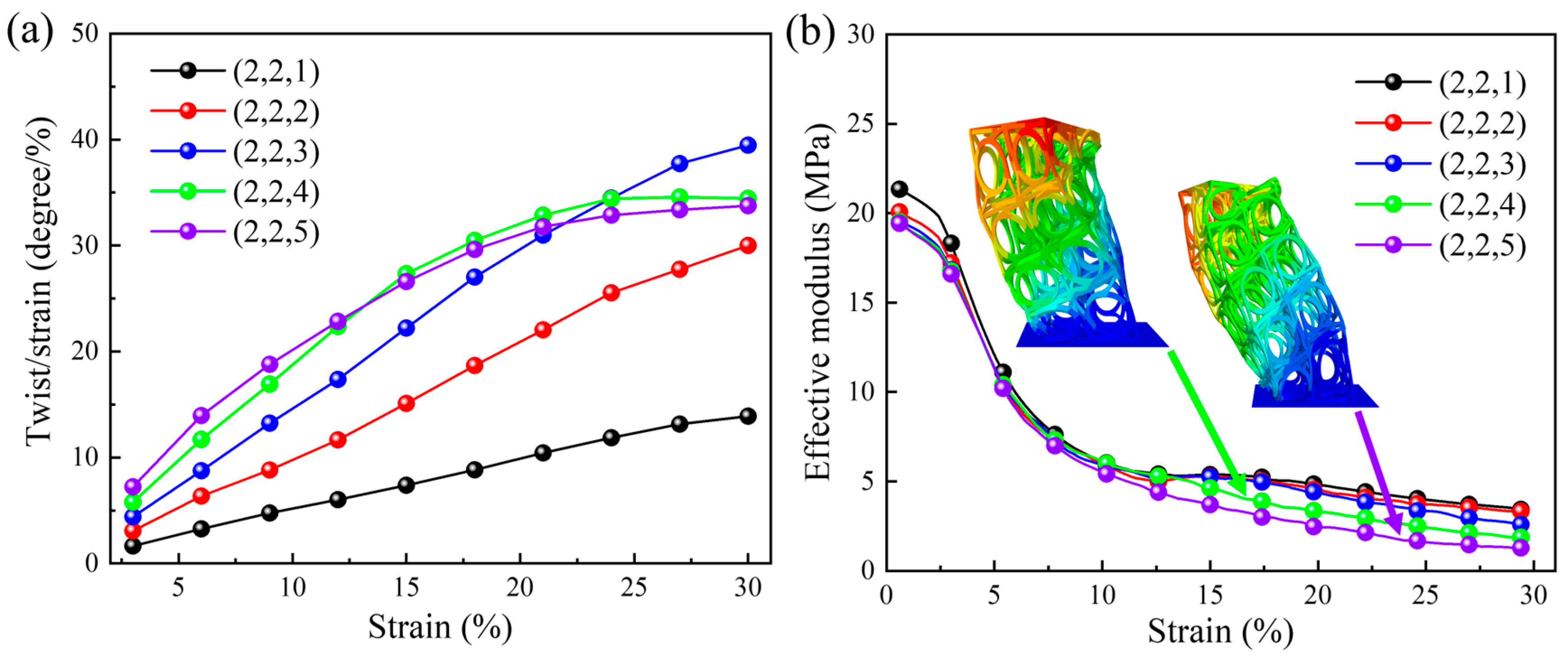

5.2. Size Effects in the Z Direction

Figure 8a illustrates the relationship between the dynamic compression twist angle per axial strain and the applied axial strain for different numbers of arrays in the Z direction. As the applied dynamic compression axial strain increases, the overall twist angle per axial strain shows an increasing trend. Additionally, a larger twist angle per axial strain can be obtained with a larger array number in the Z direction. The ability of structural materials to resist torsion decreases as the array number in the Z direction increases. However, when the number of arrays is four or five, buckling instability occurs during the dynamic compression process, resulting in a slower increase in the twist angle per axial strain. When the dynamic compression strain is 0.3, the twist angle per axial strain is

degrees per unit strain for the structural pattern with five vertical arrays and is

degrees per unit strain for the structural pattern with one vertical array.

Figure 8b shows the relationship between the dynamic compression effective modulus and the applied axial strain. When the array number in the Z direction increases, the stiffness, i.e., the effective elastic modulus, of the structural material decreases. Thus, structures with fewer arrays in the vertical direction have a higher effective modulus, and the corresponding twist angle per axial strain is smaller. When the dynamic compressive strain is 0.3, the maximum and minimum effective moduli are 3.4 MPa and 1.26 MPa, respectively. The effective modulus of structures with four or five arrays in the Z direction is significantly lower than that of structures with other numbers of arrays. This results from the buckling instability of the struts (see the instability deformation diagram in

Figure 8b).

The static and dynamic results under different numbers of arrays in the Z direction are analyzed and compared. Similar patterns are shown in

Section 5.1. The values of the twist angle per axial strain under static and dynamic compression are almost the same, but the effective modulus decreases more sharply under the dynamic loading condition. The reason for this phenomenon may be inertia.

6. Conclusions

In this paper, the quasi-static and dynamic compression mechanical behavior of three-dimensional chiral mechanical metamaterials was investigated. The effects of geometric parameters and size on the twist angle per axial strain and effective modulus were discussed. The key conclusions gained from this study were as follows:

(1) Under the quasi-static compression loading condition, the twist angle per axial strain increases with the increase in the applied axial strain, while the effective modulus shows a decreasing trend. The twist angle per axial strain increases with the increase in the ratio of the outer radius to the unit cell size or the ratio of the corner width to the unit cell size.

(2) Under the quasi-static compression loading condition, a smaller twist angle per axial strain and a higher effective modulus can be obtained with larger array number in the X and Y directions. When the array number in the Z direction increases, the twist angle per axial strain exhibits an increasing trend, while a decreasing trend is observed in the effective modulus.

(3) Under the dynamic compression loading condition, when the number of arrays in the X and Y directions increases, the twist angle per axial strain shows a decreasing trend, while the effective modulus under dynamic compression exhibits an increasing trend. A larger twist angle per axial strain and a lower effective elastic modulus can be obtained with larger array numbers in the Z direction.

(4) Comparing the quasi-static and dynamic compression results shows that the effective modulus and twist angle per axial strain are not linearly related to the strain, and the effective modulus decreases more drastically under the dynamic loading condition, which may be due to inertia.

This study systematically revealed the mechanical behavior of 3D chiral mechanical metamaterials under quasi-static and dynamic compressive loading and its key regulatory mechanisms. The significant influences of the geometrical parameters and size on the properties of compression–torsion coupling were clarified through numerical simulations, and the dominant role of inertia on the effective modulus under dynamic loading was elucidated. It was found that the effective modulus decreases drastically under dynamic compression due to the effects of inertia, while the torsion angle is more consistent with the quasi-static results, which extends the traditional quasi-static theory and provides new insights for structural design under dynamic loading. In addition, an increase in the number of arrays in the X/Y directions suppresses torsional deformation and enhances stiffness, while the opposite occurs in the Z direction, revealing the anisotropic characteristics of the size effect. The results fill the knowledge gap regarding the dynamic compression–torsion coupling mechanism and provide theoretical support for engineering applications such as energy absorption and flexible sensing through providing a parametric design framework. Future research can focus on the following directions: (1) analyzing high-strain-rate experiments and microscopic inertia mechanisms in depth; (2) optimizing the performance of multi-material systems and additive manufacturing processes; (3) cross-scale modeling of coupled thermal–force–electrical multi-field behaviors; and (4) developing prediction methods for dynamic failure thresholds and non-equilibrium state responses.

Author Contributions

S.Q.: writing—original draft, methodology, investigation, conceptualization; Z.H.: software, methodology, investigation; W.C.: investigation, software; X.C.: conceptualization, validation, supervision; Y.L.: funding acquisition, validation, supervision. All authors have read and agreed to the published version of this manuscript.

Funding

The authors would like to thank the National Natural Science Foundation of China (No. 12302482), the Wuhan Natural Science Foundation Exploration Program (Morning Light Program), and the General Project of Hubei Provincial Natural Science Foundation for their support. The authors also thank the Open Foundation of Hubei Key Laboratory of Engineering Structural Analysis and Safety Assessment in Huazhong University of Science and Technology for providing funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data will be made available upon request.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Dudek, K.K. New Type of Rotation of Chiral Mechanical Metamaterials. Smart Mater. Struct. 2020, 29, 115027. [Google Scholar] [CrossRef]

- Karathanasopoulos, N.; Dos Reis, F.; Diamantopoulou, M.; Ganghoffer, J.-F. Mechanics of Beams Made from Chiral Metamaterials: Tuning Deflections through Normal-Shear Strain Couplings. Mater. Des. 2020, 189, 108520. [Google Scholar] [CrossRef]

- Fernandez-Corbaton, I.; Rockstuhl, C.; Ziemke, P.; Gumbsch, P.; Albiez, A.; Schwaiger, R.; Frenzel, T.; Kadic, M.; Wegener, M. New Twists of 3D Chiral Metamaterials. Adv. Mater. 2019, 31, 1807742. [Google Scholar] [CrossRef] [PubMed]

- Frenzel, T.; Köpfler, J.; Jung, E.; Kadic, M.; Wegener, M. Ultrasound Experiments on Acoustical Activity in Chiral Mechanical Metamaterials. Nat. Commun. 2019, 10, 3384. [Google Scholar] [CrossRef] [PubMed]

- Fei, X.; Jin, L.; Zhang, X.; Li, X.; Lu, M. Three-Dimensional Anti-Chiral Auxetic Metamaterial with Tunable Phononic Bandgap. Appl. Phys. Lett. 2020, 116, 021902. [Google Scholar] [CrossRef]

- An, X.; Lai, C.; He, W.; Fan, H. Three-Dimensional Chiral Meta-Plate Lattice Structures for Broad Band Vibration Suppression and Sound Absorption. Compos. Part B Eng. 2021, 224, 109232. [Google Scholar] [CrossRef]

- Chen, Y.; Li, T.; Scarpa, F.; Wang, L. Lattice Metamaterials with Mechanically Tunable Poisson’s Ratio for Vibration Control. Phys. Rev. Appl. 2017, 7, 024012. [Google Scholar] [CrossRef]

- Forte, A.E.; Melancon, D.; Zanati, M.; De Giorgi, M.; Bertoldi, K. Chiral Mechanical Metamaterials for Tunable Optical Transmittance. Adv. Funct. Mater. 2023, 33, 2214897. [Google Scholar] [CrossRef]

- Yoo, S.; Park, Q.-H. Metamaterials and Chiral Sensing: A Review of Fundamentals and Applications. Nanophotonics 2019, 8, 249–261. [Google Scholar] [CrossRef]

- Lee, Y.Y.; Kim, R.M.; Im, S.W.; Balamurugan, M.; Nam, K.T. Plasmonic Metamaterials for Chiral Sensing Applications. Nanoscale 2020, 12, 58–66. [Google Scholar] [CrossRef]

- Frenzel, T.; Kadic, M.; Wegener, M. Three-Dimensional Mechanical Metamaterials with a Twist. Science 2017, 358, 1072–1074. [Google Scholar] [CrossRef] [PubMed]

- Park, J.; Lee, G.; Kwon, H.; Kim, M.; Rho, J. All-Polarized Elastic Wave Attenuation and Harvesting via Chiral Mechanical Metamaterials. Adv. Funct. Mater. 2024, 34, 2403550. [Google Scholar] [CrossRef]

- Wang, Q.; Li, Z.; Zhang, Y.; Cui, S.; Yang, Z.; Lu, Z. Ultra-Low Density Architectured Metamaterial with Superior Mechanical Properties and Energy Absorption Capability. Compos. Part B Eng. 2020, 202, 108379. [Google Scholar] [CrossRef]

- Chen, B.; Jia, Y.; Narita, F.; Wang, C.; Shi, Y. Multifunctional Cellular Sandwich Structures with Optimised Core Topologies for Improved Mechanical Properties and Energy Harvesting Performance. Compos. Part B Eng. 2022, 238, 109899. [Google Scholar] [CrossRef]

- Xin, X.; Liu, L.; Liu, Y.; Leng, J. 4D Printing Auxetic Metamaterials with Tunable, Programmable, and Reconfigurable Mechanical Properties. Adv. Funct. Mater. 2020, 30, 2004226. [Google Scholar] [CrossRef]

- Janbaz, S.; Bobbert, F.S.L.; Mirzaali, M.J.; Zadpoor, A.A. Ultra-Programmable Buckling-Driven Soft Cellular Mechanisms. Mater. Horiz. 2019, 6, 1138–1147. [Google Scholar] [CrossRef]

- Mei, T.; Meng, Z.; Zhao, K.; Chen, C.Q. A Mechanical Metamaterial with Reprogrammable Logical Functions. Nat. Commun. 2021, 12, 7234. [Google Scholar] [CrossRef]

- Liu, B.; Feng, J.; Yu, K.; Li, J.; Hu, Q.; Lin, Z.; Fu, J. Three-Dimensional Auxetic Structure Design Methods Based on Bulking-Induced Deformation and the Application in Soft Crawling Robot. Compos. Part B Eng. 2022, 244, 110146. [Google Scholar] [CrossRef]

- Hu, X.; Tan, T.; Wang, B.; Yan, Z. A Reprogrammable Mechanical Metamaterial with Origami Functional-Group Transformation and Ring Reconfiguration. Nat. Commun. 2023, 14, 6709. [Google Scholar] [CrossRef]

- Dudek, K.K.; Martínez, J.A.I.; Ulliac, G.; Kadic, M. Micro-Scale Auxetic Hierarchical Mechanical Metamaterials for Shape Morphing. Adv. Mater. 2022, 34, 2110115. [Google Scholar] [CrossRef]

- Li, X.; Peng, W.; Wu, W.; Xiong, J.; Lu, Y. Auxetic Mechanical Metamaterials: From Soft to Stiff. Int. J. Extreme Manuf. 2023, 5, 042003. [Google Scholar] [CrossRef]

- Meng, Z.; Yan, H.; Liu, M.; Qin, W.; Genin, G.M.; Chen, C.Q. Encoding and Storage of Information in Mechanical Metamaterials. Adv. Sci. 2023, 10, 2301581. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Guo, D.; Hu, G. Tailored Mechanical Metamaterials with Programmable Quasi-Zero-Stiffness Features for Full-Band Vibration Isolation. Adv. Funct. Mater. 2021, 31, 2101428. [Google Scholar] [CrossRef]

- Zheng, B.-B.; Zhong, R.-C.; Chen, X.; Fu, M.-H.; Hu, L.-L. A Novel Metamaterial with Tension-Torsion Coupling Effect. Mater. Des. 2019, 171, 107700. [Google Scholar] [CrossRef]

- Li, X.; Yang, Z.; Lu, Z. Design 3D Metamaterials with Compression-Induced-Twisting Characteristics Using Shear–Compression Coupling Effects. Extreme Mech. Lett. 2019, 29, 100471. [Google Scholar] [CrossRef]

- Zhong, R.; Fu, M.; Chen, X.; Zheng, B.; Hu, L. A Novel Three-Dimensional Mechanical Metamaterial with Compression-Torsion Properties. Compos. Struct. 2019, 226, 111232. [Google Scholar] [CrossRef]

- Kumar, H.; Agarwal, A.; Kalenga, M.K.W.; Prasad, R.; Kumar, P.; Chilakamarri, L.A.; Yelamasetti, B. Fabrication of Cu/SiC Surface Composite via Thermo-Mechanical Process (Friction Stir Processing) for Heat Sink Application. Materials 2025, 18, 1179. [Google Scholar] [CrossRef]

- Fang, X.; Yu, D.; Wen, J.; Dai, Y.; Begley, M.R.; Gao, H.; Gumbsch, P. Large recoverable elastic energy in chiral metamaterials via twist buckling. Nature 2025, 639, 639–645. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).