Flexural Strengthening of Reinforced Concrete Beams Using Near-Surface Mounted (NSM) Carbon Fiber-Reinforced Polymer (CFRP) Strips with Additional Anchorage

Abstract

1. Introduction

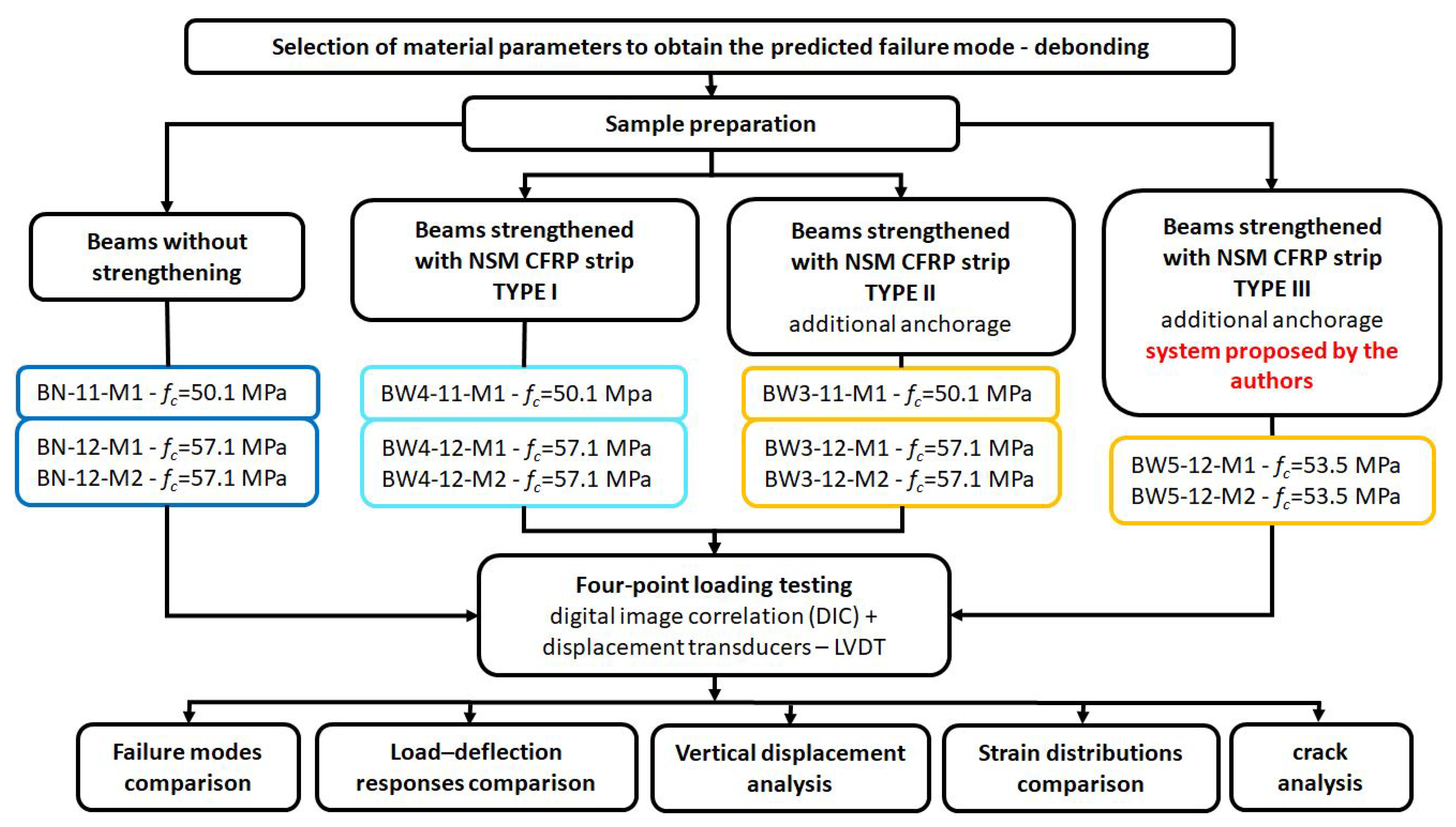

2. Materials and Methods

2.1. Materials Used to Prepare Specimens and Their Properties

- beams marked with the symbol 11 (BN-11-M1, BW3-11-M1, BW4-11-M1)—concrete average cylinder compressive strength fc = 50.1 MPa (12 samples).

- Beams with the symbol 12 (BN-12-M1, BW3-11-M1, BW3-11-M2, BW4-11-M1, BW4-11-M2)—concrete average cylinder compressive strength fc = 57.1 MPa (36 samples) and (BW5-11-M1, BW5-11-M2)—concrete average cylinder compressive strength fc = 53.5 MPa (24 samples).

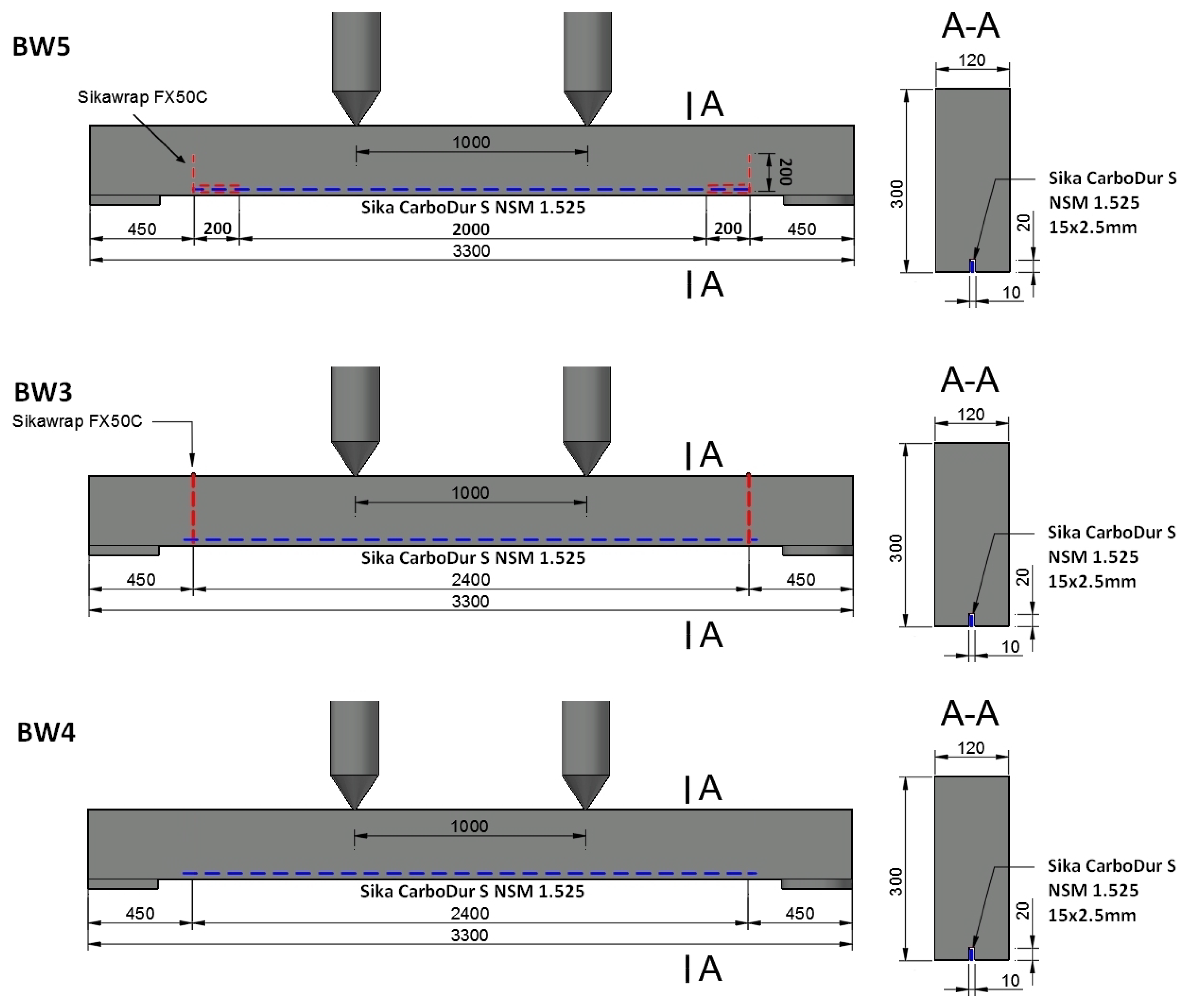

2.2. Strengthening of the Specimens

- Reference beams unreinforced BN—3 elements;

- BW4 beams—3 elements. RC beams strengthened using the NSMR (near-surface mounted reinforcement) without additional anchoring;

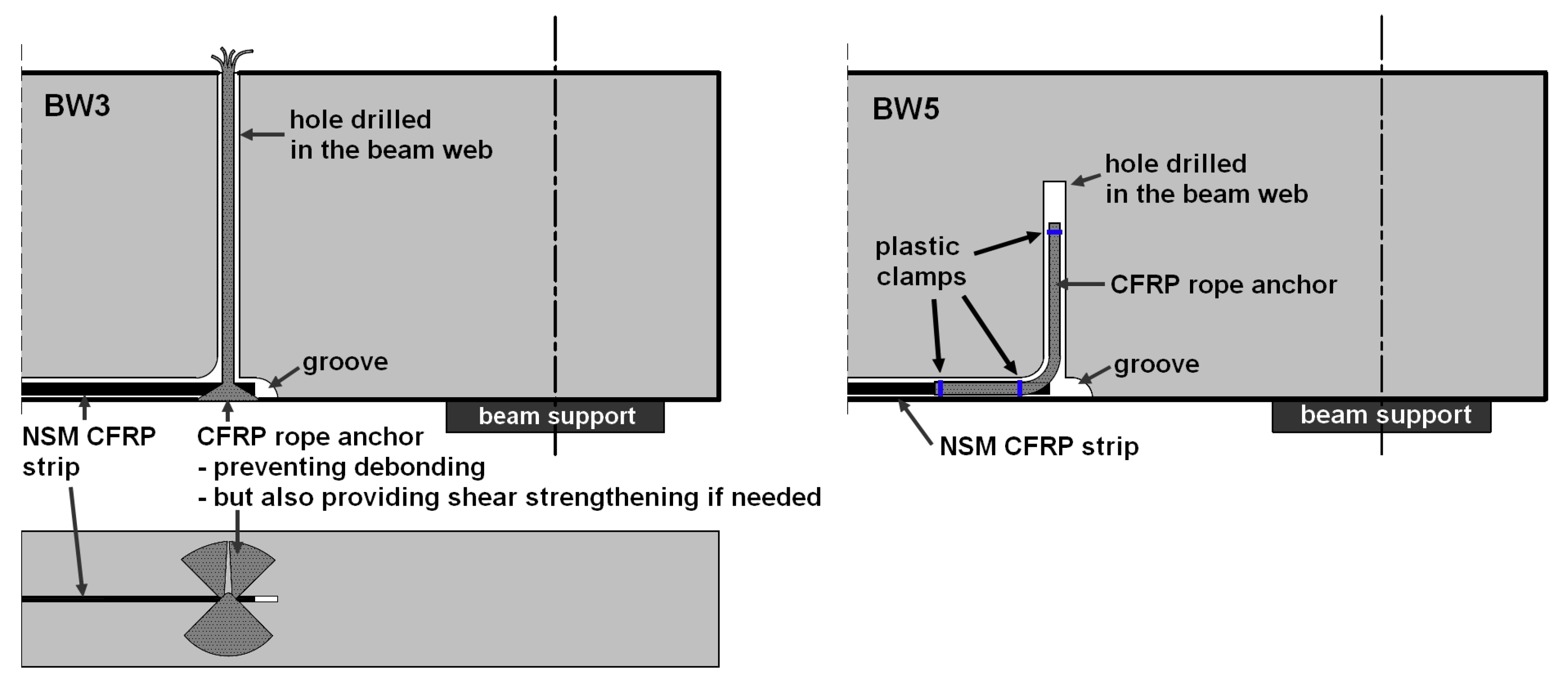

- BW3 beams—3 elements. RC beams strengthened using the NSMR method with additional anchoring in the near-support zone at the end of the strip—the fiber anchor wrapped around the CFRP strip end and fan-folded on the beam surface;

- BW5 beams—3 elements. RC beams strengthened using the NSMR method with additional anchoring in the support zone at the end of the strip—the fiber anchor connected to the strip with a 20 cm overlap.

- Cleaning the grooves and FRP surfaces.

- BW4 beams—strengthening followed Figure 5:

- Filling pre-cut groove with Sikadur-330 resin [43];

- Gluing Sika CarboDur S NSM 1.525 CFRP strip (dimensions of the tape cross-section: 15 mm × 2.5 mm);

- Refilling or removing excess resin.

- Drilling vertical holes (20 mm in diameter) in the beam web 30 cm from the support axis, through the entire height of the beam cross-section;

- Filling pre-cut groove and drilled hole with Sikadur-330 resin;

- Impregnating SikaWrap FX-50C Sika CFRP anchors along their entire length with Sikadur-52 resin [44];

- Gluing the fiber anchor into the drilled holes leaving a 6 cm section outside the hole;

- Dividing the protruding part of the fiber anchor into two parts;

- Gluing the CarboDur S NSM 1.525 CFRP strip in the pre-cut groove;

- Wrapping the strip end on both sides with the part of the anchor left outside the hole to obtain a 5 cm overlap;

- Spreading the fiber anchor on the beam surface;

- Refilling or removing excess resin.

- Widening the groove (dimensions of the widened groove: 16 mm × 20 mm) in the section of the planned strip and fiber anchor connection;

- Drilling vertical holes (20 mm in diameter; hole depth: 25 cm [45]) in the beam web 30 cm from the support axis;

- Filling pre-cut groove and drilled hole with Sikadur-330 resin;

- Impregnating SikaWrap FX-50C Sika CFRP anchors along their entire length with Sikadur-52 resin;

- Connecting the anchor with an overlap (20 cm) with CarboDur S NSM 1.525 CFRP strip using plastic clamps;

- Gluing the strip into the pre-cut groove and the anchor into the drilled hole using a wire hooked to a plastic clamp installed at the end of the anchor fibers;

- Refilling or removing excess resin.

- In order to make pre-cut grooves and holes, a wall chaser (Bosch GNF 35CA) and a hammer drill were used. The adopted method of preparing beams for gluing the composite from the point of view of practical application does not differ in the degree of complexity from other construction works.

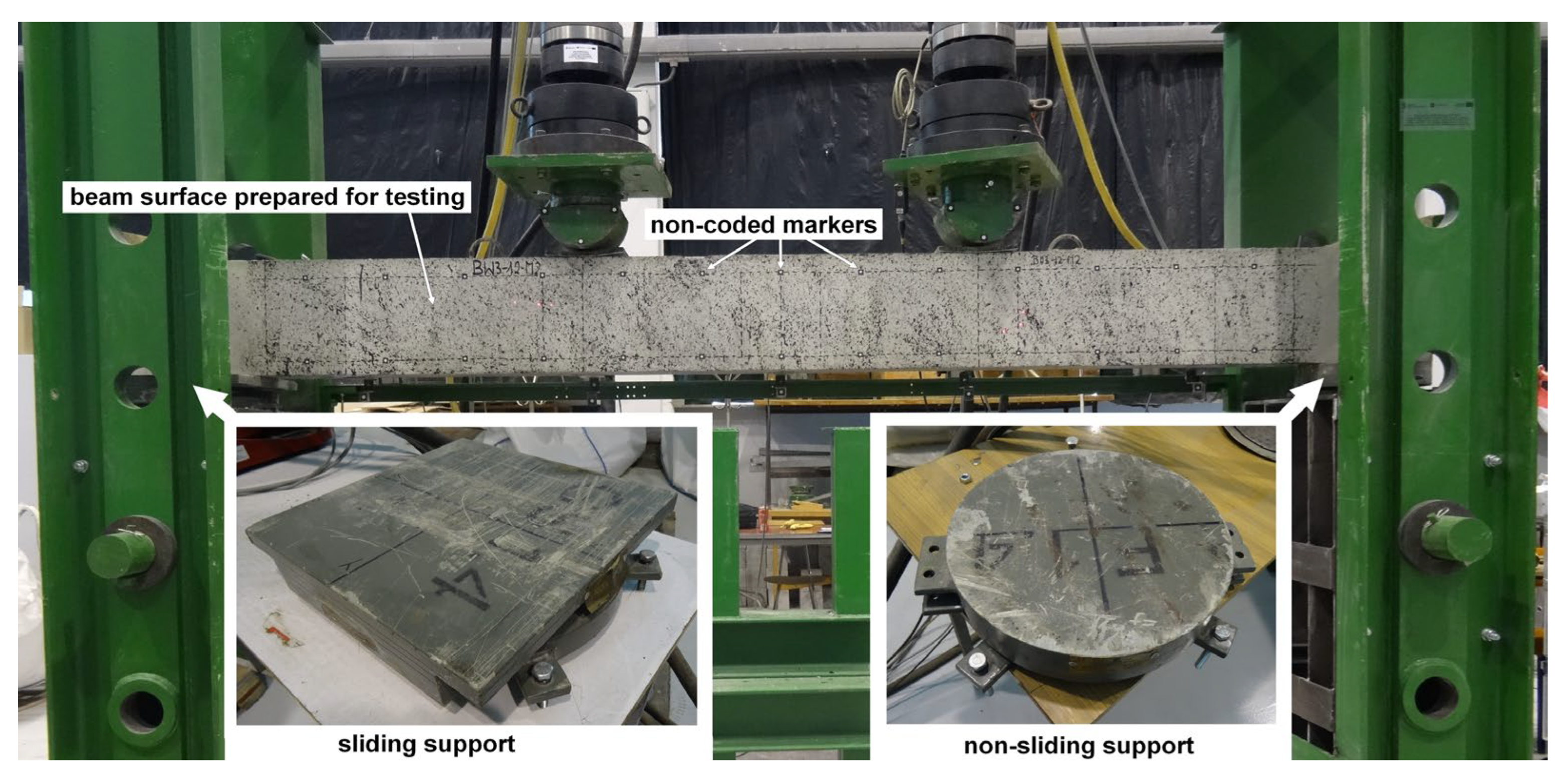

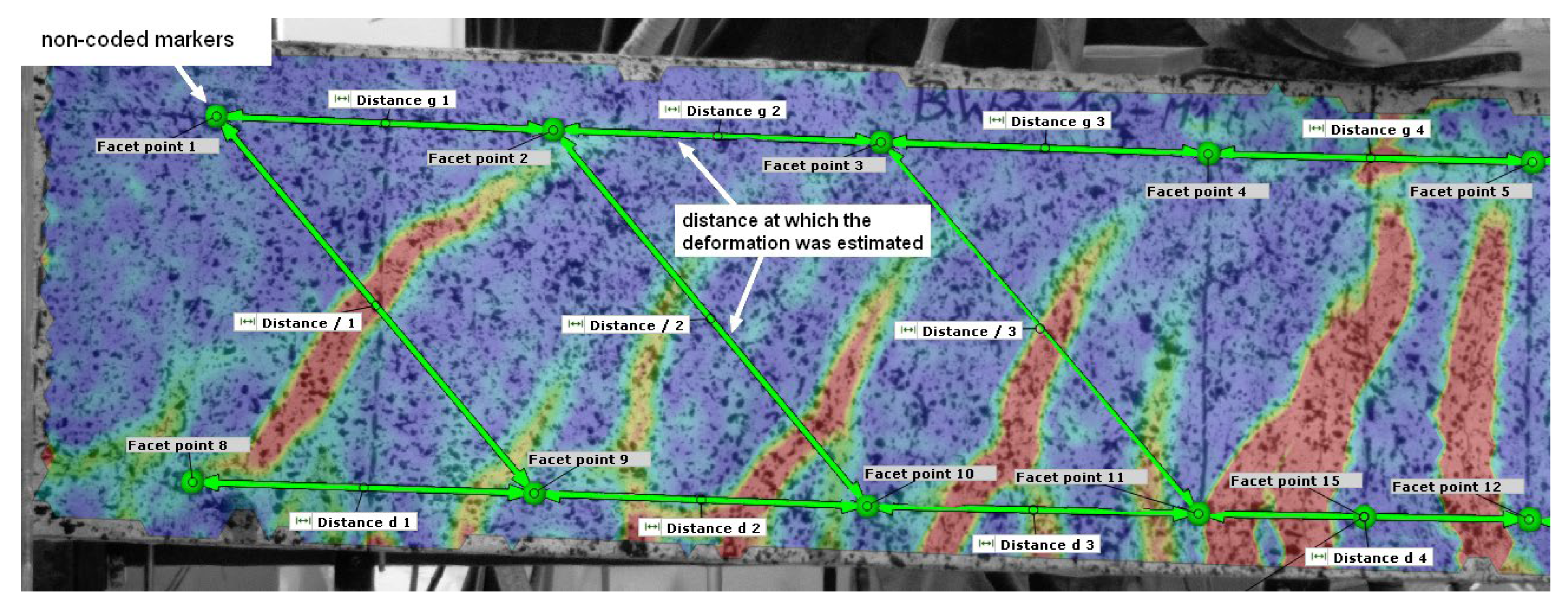

- digital image correlation (DIC)—to measure deflections at selected points, strains, location, and width of cracks on the beam surface observed by cameras;

- five displacement transducers, LVDTs, used for measuring beam deflections;

- the moment of failure of each beam was recorded by a camera placed on a tripod on the other side of the beam relative to the one recorded by the DIC system.

3. Results

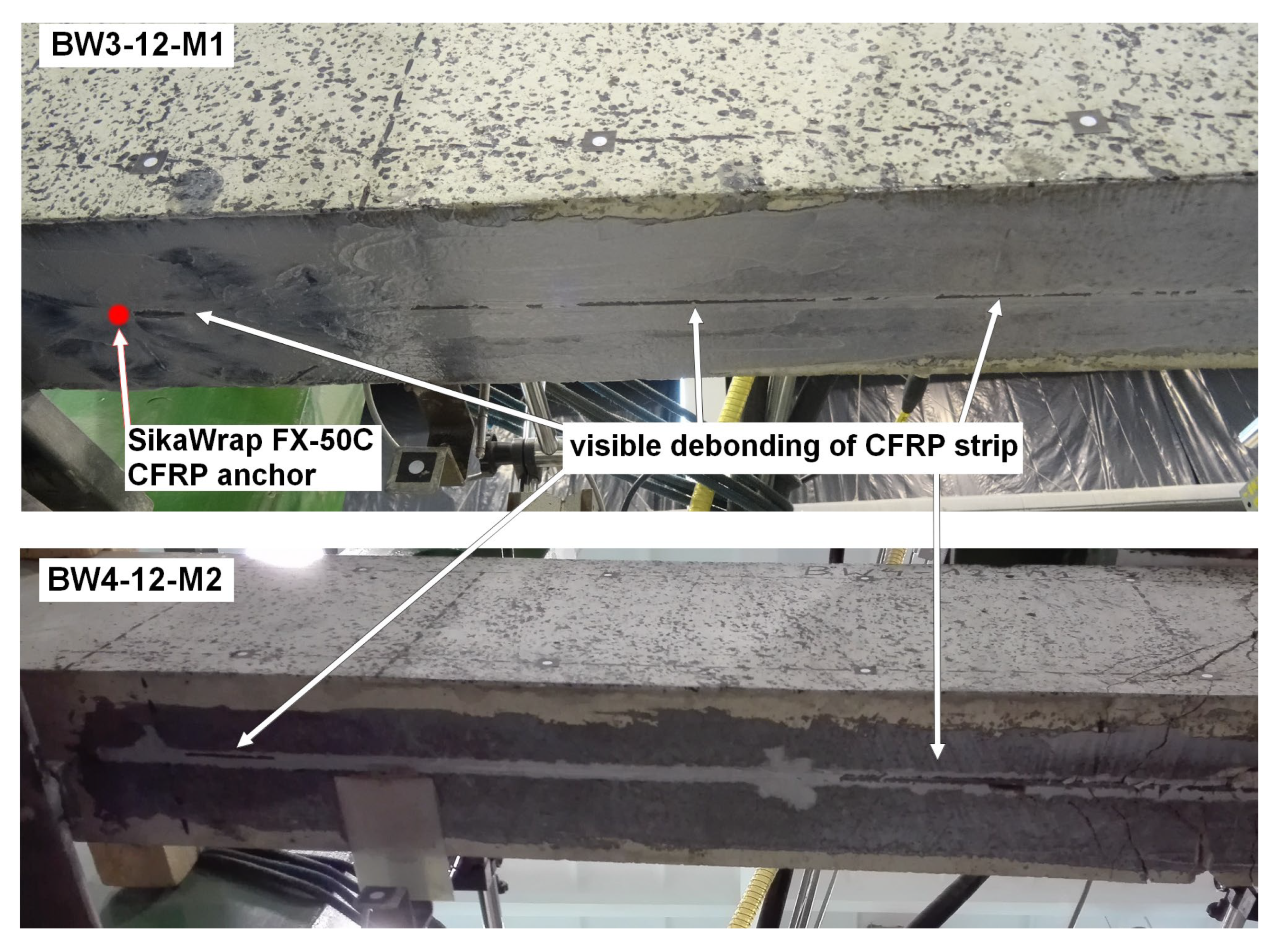

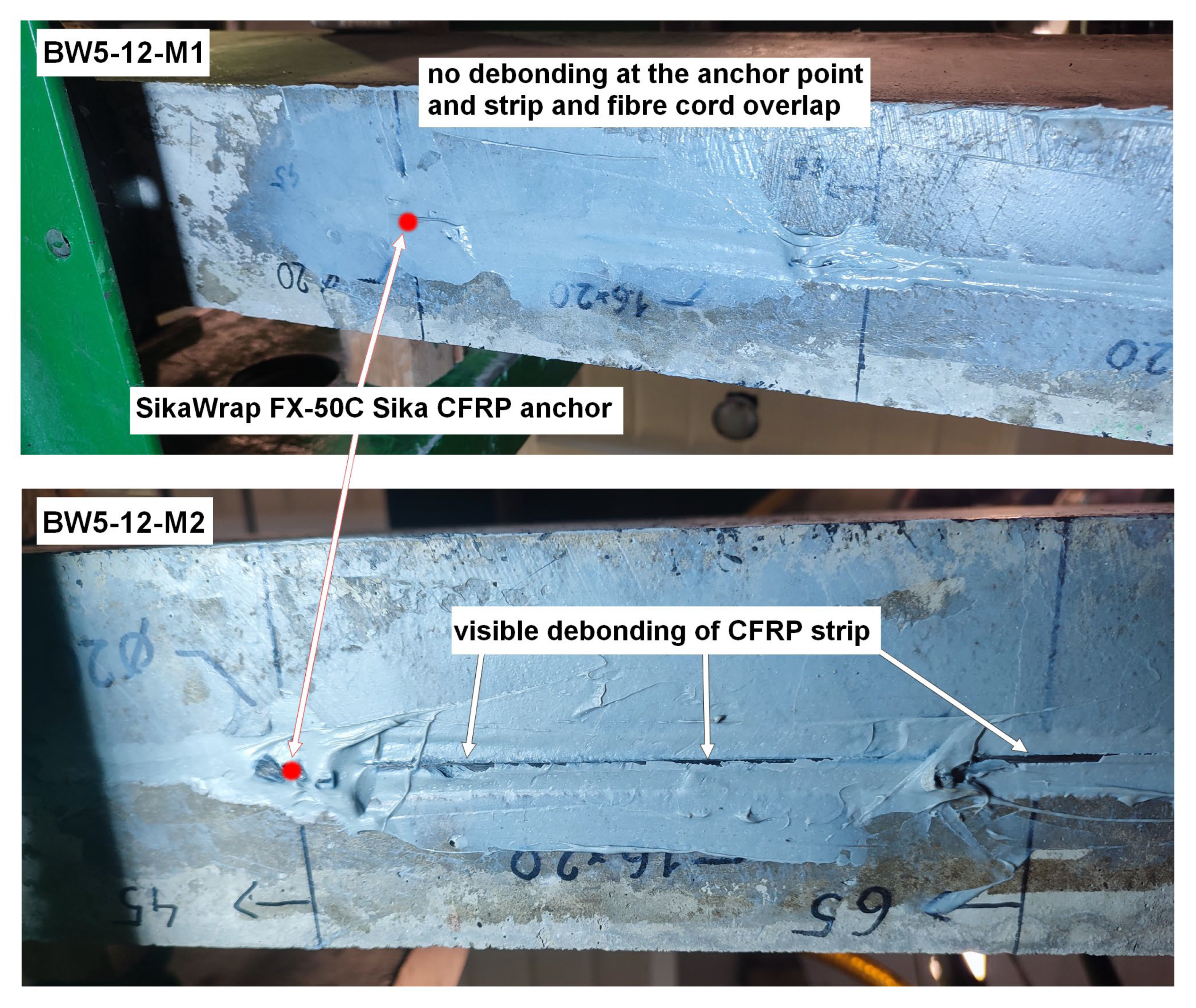

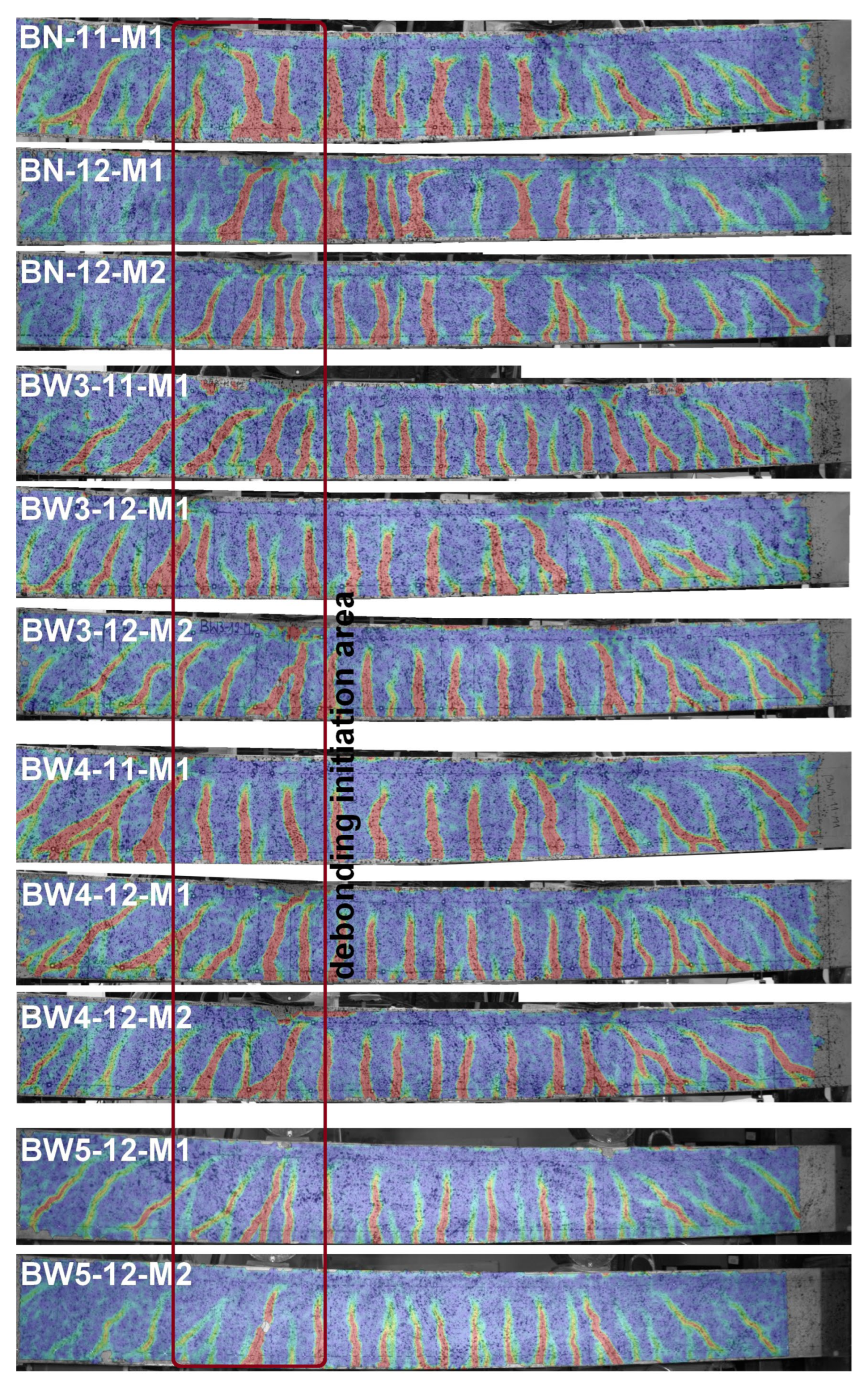

3.1. Failure Modes

- BW4

- BW3

- BW5

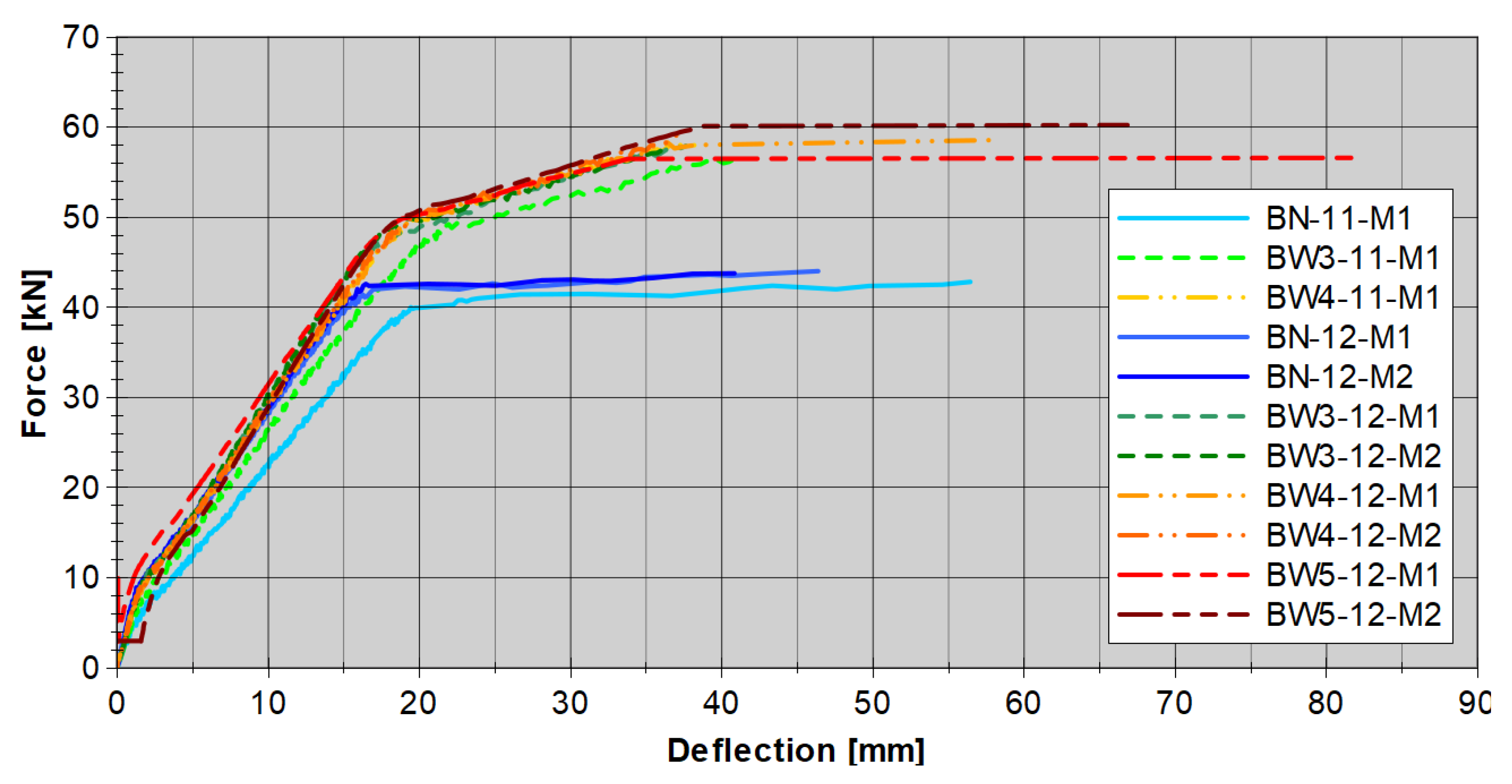

3.2. Load–Deflection Responses

3.3. Analysis of Vertical Displacements

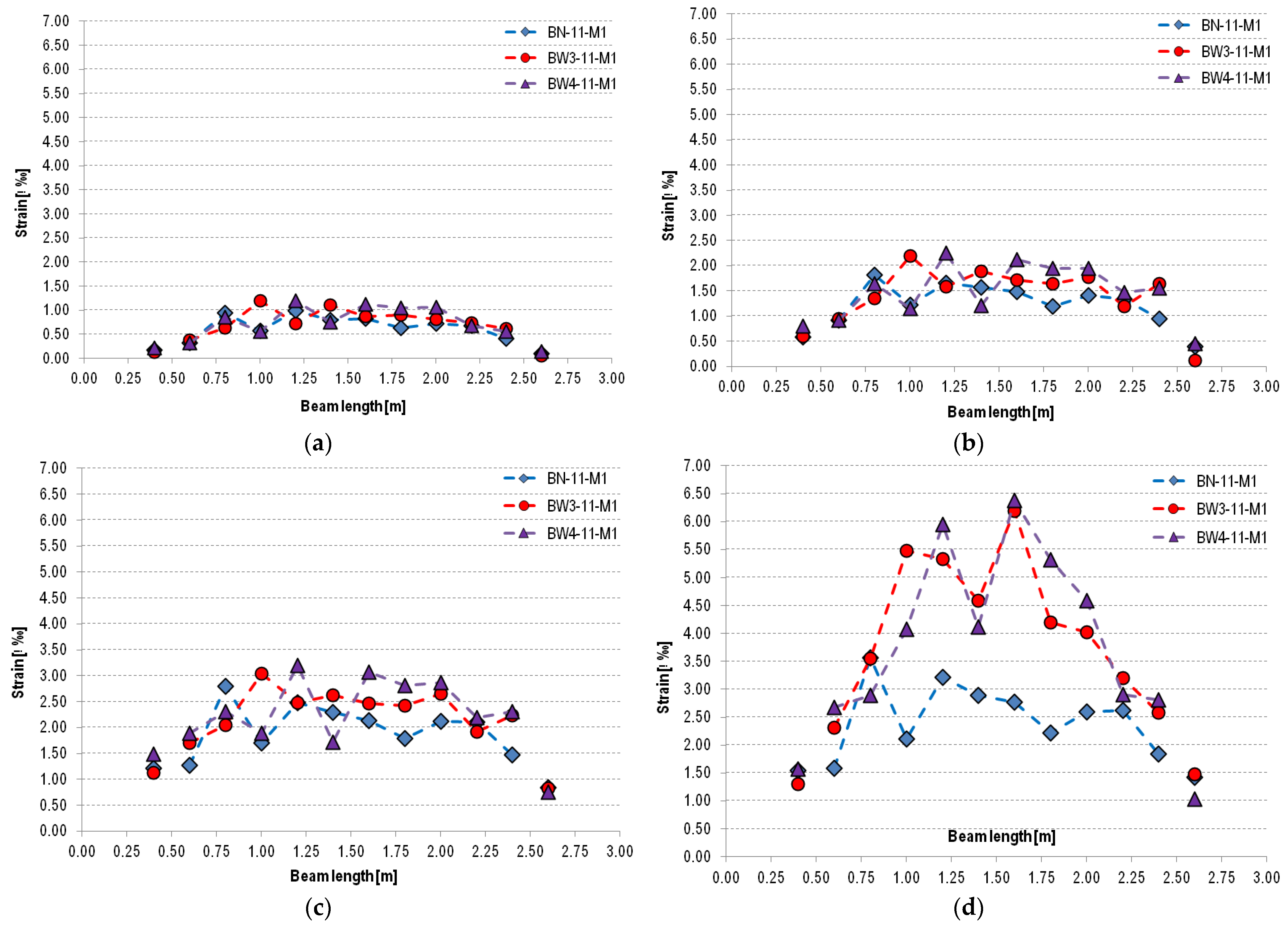

3.4. Strain Distributions

3.5. Crack Analysis

4. Discussion

5. Conclusions

- As expected, all reinforced RC beams failed as a result of the debonding CFRP strip (practically along its entire length) at the CFRP strip interface—the top layer of CFRP strip fibers remained attached to the resin filling the groove after the beam failure. This destruction was initiated by strip peeling-off at a shear crack in the area under the load application point, due to vertical crack opening displacement (mainly on the sliding support side).

- Due to the debonding of the CFRP strip, the applied anchoring systems were unable to improve the load-bearing capacity of the beams compared to beams without additional anchoring.

- The lack of debonding in the strip at the connection section, the overlap with the CFRP anchor in the BW5-12-M1 beams, and the slightly higher stiffness of both BW5 RC beams can be considered a partial success.

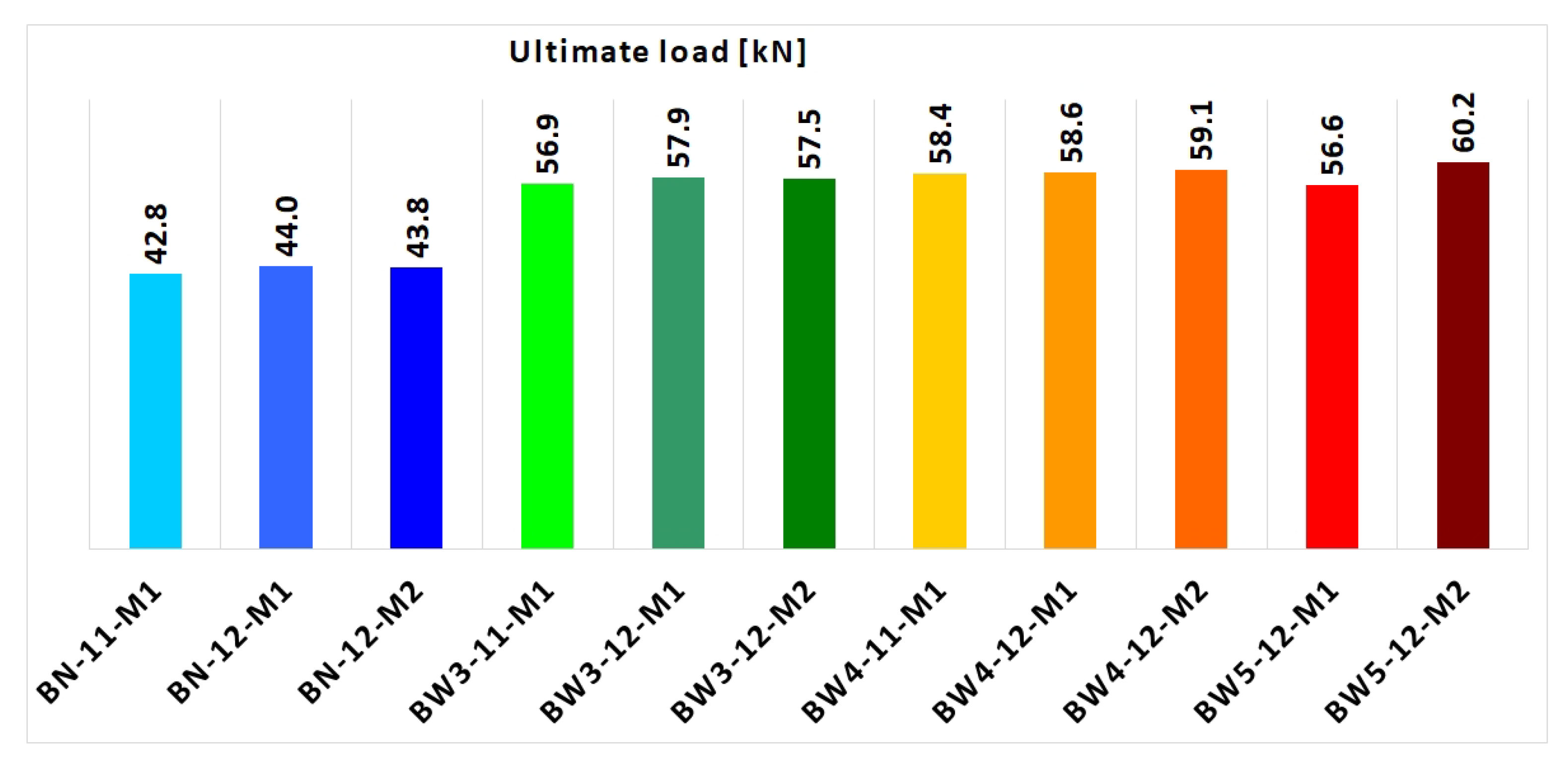

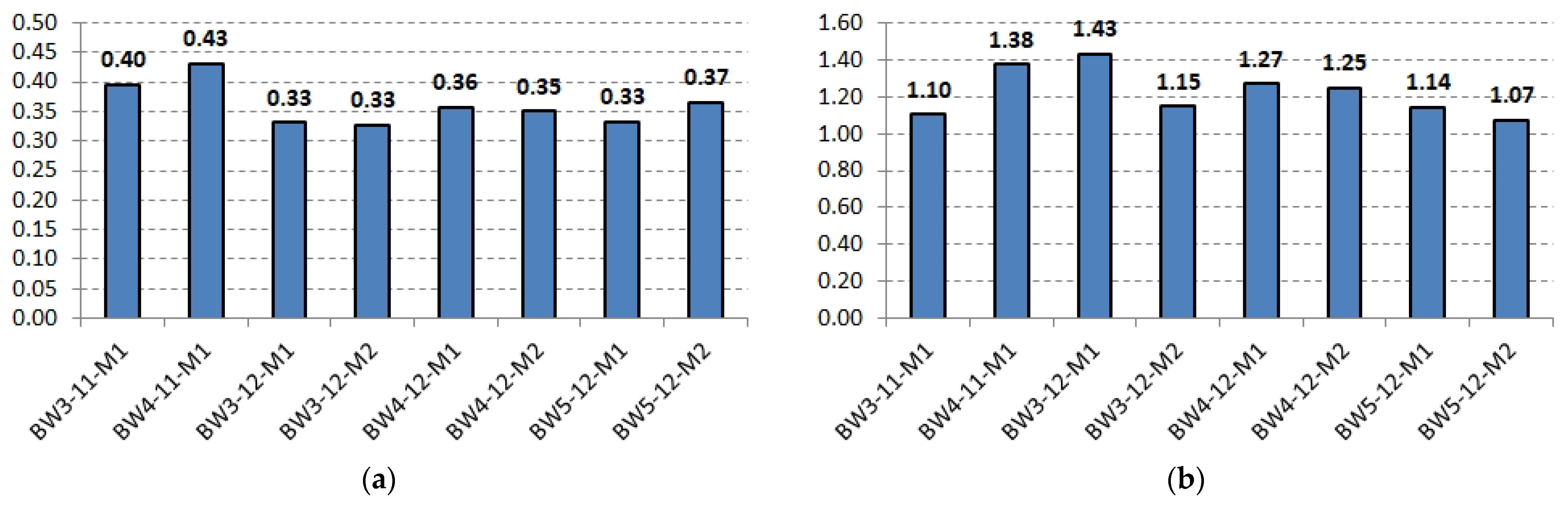

- The value of strengthening efficiency was as follows: for the BW3 type beams strengthened with an NSM CFRP strip anchored at the ends (anchor fibers fan-folded on the beam surface at the strip end), it was 31–33%, while for the BW4 type beams strengthened only with an NSM CFRP strip without additional anchorage, it was 33–36%. In the case of BW5 beams, very divergent results were obtained, i.e., for the BW5-12-M2 beam the highest value of strengthening efficiency was obtained among all beams, equal to 37%, while for the BW5-12-M1 beam, the lowest was 29%.

- The relationship between force and mid-span deflection was practically the same for each of the strengthened RC beams.

- Analysis of the vertical displacements for the sections along the beam at the height of the center of gravity of the tension reinforcement indicates that each of the strengthened beams experiences a vertical crack opening displacement in shear crack forming under the point of force application near the sliding support.

- In the same area, before the failure of the beams, a concentration of both perpendicular and diagonal cracks was visible. This is the location where cracks with the maximum width among those recorded on the surface of the tested beams by the DIC system occurred.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, J.; Lin, G.; Vaidya, U.; Wang, H. Past, present and future prospective of global carbon fibre composite developments and applications. Compos. Part B Eng. 2023, 250, 110463. [Google Scholar] [CrossRef]

- Du, H.; Xian, G.; Tian, J.; Ma, Z.; Li, C.; Xin, M.; Zhang, Y. Effect of fiber surface treatment with silane coupling agents and carbon nanotubes on mechanical properties of carbon fiber reinforced polyamide 6 composites. Polym. Compos. 2025, 46, 1267–1283. [Google Scholar] [CrossRef]

- Zeng, J.-J.; Feng, S.-Z.; Zhao, B.; Wu, F.-Y.; Zhuge, Y.; Wang, H. Recyclable thermoplastic FRP bars for reinforced concrete structures: Current status and future opportunities. Compos. Struct. 2024, 348, 118438. [Google Scholar] [CrossRef]

- Klym, A.; Blikharskyy, Y.; Gunka, V.; Poliak, O.; Selejdak, J.; Blikharskyy, Z. An Overview of the Main Types of Damage and the Retrofitting of Reinforced Concrete Bridges. Sustainability 2025, 17, 2506. [Google Scholar] [CrossRef]

- Raczkiewicz, W.; Bacharz, M.; Bacharz, K. Experimental verification of the concrete shrinkage strains course according to En 1992-2 standard. Adv. Mater. Sci. 2015, 15, 22–29. [Google Scholar] [CrossRef]

- Hassan, T.; Rizkalla, S. Investigation of bond in concrete structures strengthened with near surface mounted carbon fiber reinforced polymer strips. J. Compos. Constr. 2003, 7, 248–257. [Google Scholar] [CrossRef]

- Peng, H.; Zhang, J.; Cai, C.S.; Liu, Y. An experimental study on reinforced concrete beams strengthened with prestressed near surface mounted CFRP strips. Eng. Struct. 2014, 79, 222–233. [Google Scholar] [CrossRef]

- Sharaky, I.A.; Torres LComas, J.; Barris, C. Flexural response of reinforced concrete (RC) beams strengthened with near surface mounted (NSM) fibre reinforced polymer (FRP) bars. Compos. Struct. 2014, 109, 8–22. [Google Scholar] [CrossRef]

- Barros, J.A.O.; Fortes, A.S. Flexural strengthening of concrete beams with CFRP laminates bonded into slits. Cem. Concr. Compos. 2015, 27, 471–480. [Google Scholar] [CrossRef]

- Teng, J.G.; De Lorenzis, L.; Wang, B.; Li, R.; Wong, T.N.; Lam, L. Debonding failures of RC beams strengthened with near surface mounted CFRP strips. J. Compos. Constr. 2006, 10, 92–105. [Google Scholar] [CrossRef]

- Seracino, R.; Jones, N.M.; Ali, M.S.; Page, M.W.; Oehlers, D.J. Bond strength of near-surface mounted FRP strip-to-concrete joints. J. Compos. Constr. 2007, 11, 401–409. [Google Scholar] [CrossRef]

- Dias, S.J.E.; Barros, J.A.O.; Janwaen, W. Behavior of RC beams flexurally strengthened with NSM CFRP laminates. Compos. Struct. 2018, 201, 363–376. [Google Scholar] [CrossRef]

- Zhang, X.; Hao, J.; Hou, W.; Yao, J.; Wang, Y.; Su, X.; Li, X. Debonding Analysis of FRP-Strengthened Concrete Beam in High-Temperature Environment: An Enhanced Understanding on Sustainable Structure. Buildings 2024, 14, 4079. [Google Scholar] [CrossRef]

- Michałowska-Maziejuk, D.; Goszczyńska, B. Szacowanie nośności belek żelbetowych wzmocnionych kompozytami CFRP. Inżynieria I Bud. 2023, 79, 636–643. [Google Scholar] [CrossRef]

- Tworzewski, P.; Alexy, J.K.; Barnes, R.W. Intermediate Crack Debonding of Externally Bonded FRP Reinforcement—Comparison of Methods. Materials 2022, 15, 7390. [Google Scholar] [CrossRef] [PubMed]

- Said, H.; Wu, Z. Evaluating and Proposing Models of Predicting IC Debonding Failure. J. Compos. Constr. 2008, 12, 284–299. [Google Scholar] [CrossRef]

- Elsanadedy, H.M.; Abbas, H.; Al-Salloum, Y.A.; Almusallam, T.H. Prediction of Intermediate Crack Debonding Strain of Externally Bonded FRP Laminates in RC Beams and One-Way Slabs. J. Compos. Constr. 2014, 18, 284–299. [Google Scholar] [CrossRef]

- Baena, M.; Jahani, Y.; Torres, L.; Barris, C.; Perera, R. Flexural Performance and End Debonding Prediction of NSM Carbon FRP Strengthened Reinforced Concrete Beams under Different Service Temperatures. Polymers 2023, 15, 851. [Google Scholar] [CrossRef]

- Min, X.; Zhang, J.; Wang, C.; Song, S.; Yang, D. Experimental Investigation of Fatigue Debonding Growth in FRP–Concrete Interface. Materials 2020, 13, 1459. [Google Scholar] [CrossRef]

- Al Shboul, K.W.; Salahat, F.H.; Rasheed, H.A. Effects of U-wrap anchored doubly FRP strengthened reinforced concrete beams on ductility and serviceability improvements. Eng. Struct. 2024, 1314, 118349. [Google Scholar] [CrossRef]

- Zaki, M.A.; Rasheed, H.A.; Alkhrdaji, T. Performance of CFRP-strengthened concrete beams fastened with distributed CFRP dowel and fiber anchors. Compos. Part B Eng. 2019, 176, 107117. [Google Scholar] [CrossRef]

- Rasheed, H.A.; Decker, B.R.; Esmaeily, A.; Peterman, R.J.; Melhem, H.G. The Influence of CFRP anchorage on achieving sectional flexural capacity of strengthened concrete beams. Fibers 2015, 3, 539–559. [Google Scholar] [CrossRef]

- Duo, Y.; Qi, L.; Huang, S.; Yue, Q.; Liu, X. Planar clamping anchorage for CFRP plate: Experimental research, friction-adhesion synergistic mechanism and theoretical model. Constr. Build. Mater. 2024, 441, 137540. [Google Scholar] [CrossRef]

- Ke, Y.; Zhang, S.S.; Smith, S.T.; Yu, T. Novel Embedded FRP Anchor for RC Beams Strengthened in Flexure with NSM FRP Bars: Concept and Behavior. J. Compos. Constr. 2023, 27, 04022093. [Google Scholar] [CrossRef]

- Ke, Y.; Shi, F.L.; Zhang, S.S.; Nie, X.F.; Li, W.G. Strength Model for Debonding Failure in RC Beams Flexurally Strengthened with NSM FRP and Anchored with FRP U-Jackets. J. Compos. Constr. 2023, 27, 107572. [Google Scholar] [CrossRef]

- Rasheed, H.A.; Zaki, M.A.; Raheem, M.M. Effectiveness of Fiber Anchors in CFRP Flexural Strengthening of RC Girders. J. Compos. Constr. 2024, 28, e04368. [Google Scholar] [CrossRef]

- Smith, S.T.; Hu, S.; Kim, S.J.; Seracino, R. FRP-strengthened RC slabs anchored with FRP anchors. Eng. Struct. 2011, 33, 1075–1087. [Google Scholar] [CrossRef]

- Fu, B.; Tang, X.T.; Li, L.J.; Liu, F.; Lin, G. Inclined FRP U-jackets for enhancing structural performance of FRP-plated RC beams suffering from IC debonding. Compos. Struct. 2018, 200, 36–46. [Google Scholar] [CrossRef]

- Alshamrani, S.; Rasheed, H.A.; Salahat, F.H.; Borwankar, A.; Divilbiss, N. Seismic flexural behavior of CFRP strengthened reinforced concrete beams secured with fiber anchors. Eng. Struct. 2024, 305, 117728. [Google Scholar] [CrossRef]

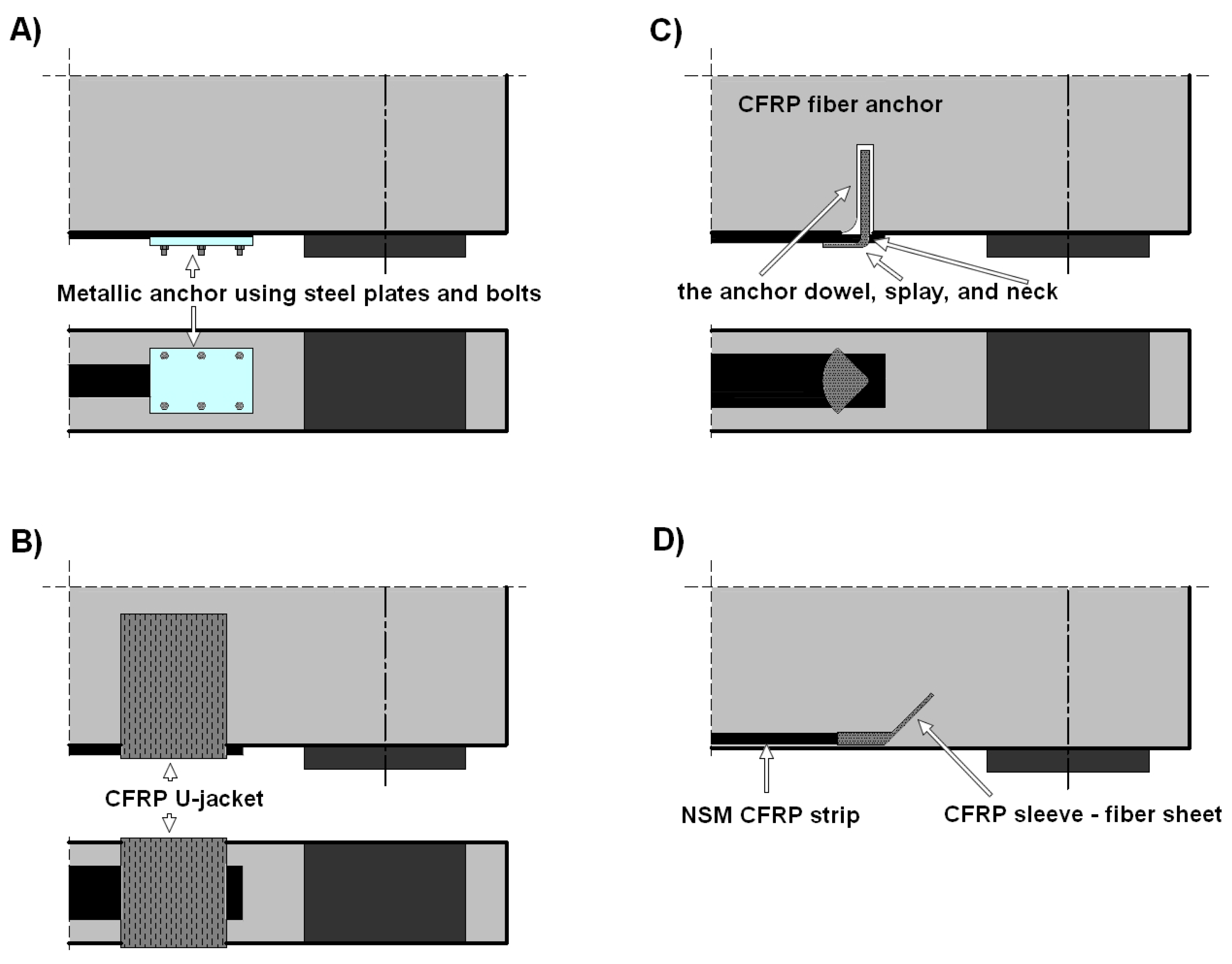

- Tworzewski, P.; Bacharz, K.; Michałowska-Maziejuk, D. Anchorage Systems in FRP-Strengthened Reinforced Concrete. J. Civ. Eng. Environ. Archit. 2018, 65, 101–110. [Google Scholar] [CrossRef]

- Tworzewski, P.; Bacharz, K. Flexural strengthening of reinforced concrete beams using CFRP rope with additional anchorage to limit debonding. Adv. Sci. Technol. Res. J. 2025, 19, 72–87. [Google Scholar] [CrossRef] [PubMed]

- Hoque, N.; Jumaat, M.Z.; Sulong, N.H.R. Global Energy Balance–Based Debonding Modeling of NSM FRP-Strengthened Concrete Beam. J. Compos. Constr. 2020, 24, 04019053. [Google Scholar] [CrossRef]

- El-Hacha, R.; Rizkalla, S.H. Near-surface-mounted fiberreinforced polymer reinforcements for flexural strengthening of concrete structures. ACI Struct. J. 2004, 101, 717–726. [Google Scholar] [CrossRef]

- Hassan, T.K.; Rizkalla, S.H. Bond mechanism of near-surfacemounted fiber-reinforced polymer bars for flexural strengthening ofconcrete structures. ACI Struct. J. 2011, 101, 830–839. [Google Scholar] [CrossRef]

- Duo, Y.; Ma, M.; Xu, G.; Liu, X. Effect of adhesive on the anchorage performance of variable curvature waveform clamping anchor for CFRP plate: Experimental investigation and carrying capacity calculation. Case Stud. Constr. Mater. 2025, 22, e04322. [Google Scholar] [CrossRef]

- Li, C.; Xian, G. Novel wedge-shaped bond anchorage system for pultruded CFRP plates. Mater. Struct. 2018, 51, 162. [Google Scholar] [CrossRef]

- Assad, M.; Hawileh, R.A.; Abdalla, J.A. Flexural strengthening of reinforced concrete beams with CFRP laminates and spike anchors. Compos. Part C Open Access 2024, 13, 100443. [Google Scholar] [CrossRef]

- Tasdemir, E.; Seracino, R.; Kowalsky, M.J.; Nau, J. Behavior of large diameter carbon fiber anchors. Constr. Build. Mater. 2023, 394, 132174. [Google Scholar] [CrossRef]

- Gowrishankar, P.; Hawileh, R.; Sahoo, S.; Abdalla, J.A. Optimizing anchor fan geometry for enhanced bond characteristics in CFRP-strengthened concrete members. Structures 2025, 76, 108998. [Google Scholar] [CrossRef]

- Sun, W. Development of a testing methodology for the design and quality control of carbon fiber reinforced polymer (CFRP) anchors. Constr. Build. Mater. 2018, 164, 150–163. [Google Scholar] [CrossRef]

- Alotaibi, N.K. Evaluating the impact of different anchor configurations and patch arrangements on the performance of fiber-reinforced polymer (FRP) anchors. Constr. Build. Mater. 2024, 415, 135110. [Google Scholar] [CrossRef]

- Zhang, S.S.; Jedrzejko, M.J.; Ke, Y.; Yu, T.; Nie, X.F. Shear strengthening of RC beams with NSM FRP strips: Concept and behaviour of novel FRP anchors. Compos. Struct. 2023, 312, 116790. [Google Scholar] [CrossRef]

- Sika® CarboDur® S NSM, Karta Informacyjna Produktu, (Product Data Sheet), Sika Poland Sp. z o.o., Warszawa, Poland Version 05.01, 2020. Available online: https://pol.sika.com/content/dam/dms/plcon/f/sika_carbodur_s_nsm.pdf (accessed on 4 May 2025).

- SikaWarp® FX-50 C, Karta Informacyjna Produktu, (Product Data Sheet), Sika Poland Sp. z o.o., Warszawa, Poland, Version 05.02, 2025. Available online: https://pol.sika.com/content/dam/dms/plcon/8/sikawrap_fx-50_c.pdf (accessed on 4 May 2025).

- ITB. Krajowa Ocena Techniczna ITB-KOT-2019/0415 Wydanie 2, Zestaw Wyrobów Sika® CarboDur® z Kompozytowym Sznurem SikaWarp® FX-50 C do Wzmacniania Konstrukcji Betonowych; ITB: Warszawa, Poland, 2019; Available online: https://pol.sika.com/dam/dms/plcon/z/pl-itb-kot-2019-0415wydanie2zestawwyrobowsikacarbodurzkompozytow.pdf (accessed on 4 May 2025).

- Mohammadi Firouz, R.; Matos, L.M.P.; Pereira, E.B.; Barros, J.A.O. Analysis of the Interfacial Debonding Behaviour of NSM CFRP Laminates with Cement-Based Adhesive Using Digital Image Correlation Technique. In Proceedings of the 3rd RILEM Spring Convention and Conference (RSCC2020), Guimarães, Portugal, 9–14 March 2020; RILEM Bookseries. Pereira, E.B., Barros, J.A.O., Figueiredo, F.P., Eds.; Springer: Cham, Switzerland, 2021; Volume 32. [Google Scholar] [CrossRef]

- Adamczak-Bugno, A.; Lipiec, S.; Adamczak, J.; Vičan, J.; Bahleda, F. Identification of Destruction Processes and Assessment of Deformations in Compressed Concrete Modified with Polypropylene Fibers Exposed to Fire Temperatures Using Acoustic Emission Signal Analysis, Numerical Analysis, and Digital Image Correlation. Materials 2023, 16, 6786. [Google Scholar] [CrossRef] [PubMed]

- Michałowska-Maziejuk, D.; Goszczyńska, B. Effectiveness of Strengthening RC Beams Using Composite Materials—An Accelerated Strengthening Method. Materials 2023, 16, 4847. [Google Scholar] [CrossRef]

- Goszczyńska, B.; Trąmpczyński, W.; Tworzewska, J. Analysis of Crack Width Development in Reinforced Concrete Beams. Materials 2021, 14, 3043. [Google Scholar] [CrossRef]

- Bakalarz, M.M.; Kossakowski, P.G. Strengthening of Laminated Veneer Lumber Slabs with Fiber-Reinforced Polymer Sheets—Preliminary Study. Fibers 2024, 12, 22. [Google Scholar] [CrossRef]

| Specimen | Concrete | Steel Bars | CFRP Strip | CFRP Anchor | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| fc 1 [MPa] | Ec 2 [GPa] | As1 3 [cm2] | fy 4 [MPa] | Es 5 [GPa] | Typ 6 | Af 7 [mm2] | ff 8 [MPa] | Ef 9 [GPa] | Af,A 10 [mm2] | ff,A 11 [MPa] | Ef,A 12 [GPa] | |

| BN-11-M1 | 50.1 | 35.7 | 3.08 | 505.8 | 219.8 | - | - | - | - | - | - | - |

| BN-12-M1 | 57.1 | 37.1 | 3.08 | 505.8 | 219.8 | - | - | - | - | - | - | - |

| BN-12-M2 | 57.1 | 37.1 | 3.08 | 505.8 | 219.8 | - | - | - | - | - | - | - |

| BW3-11-M1 | 50.1 | 35.7 | 3.08 | 505.8 | 219.8 | II | 37.5 | 3100 | 170 | 28 | 2000 | 230 |

| BW3-12-M1 | 57.1 | 37.1 | 3.08 | 505.8 | 219.8 | II | 37.5 | 3100 | 170 | 28 | 2000 | 230 |

| BW3-12-M2 | 57.1 | 37.1 | 3.08 | 505.8 | 219.8 | II | 37.5 | 3100 | 170 | 28 | 2000 | 230 |

| BW4-11-M1 | 50.1 | 35.7 | 3.08 | 505.8 | 219.8 | I | 37.5 | 3100 | 170 | - | - | - |

| BW4-12-M1 | 57.1 | 37.1 | 3.08 | 505.8 | 219.8 | I | 37.5 | 3100 | 170 | - | - | - |

| BW4-12-M2 | 57.1 | 37.1 | 3.08 | 505.8 | 219.8 | I | 37.5 | 3100 | 170 | - | - | - |

| BW5-12-M1 | 53.5 | 36.4 | 3.08 | 505.8 | 219.8 | III | 37.5 | 3100 | 170 | 28 | 2000 | 230 |

| BW5-12-M2 | 53.5 | 36.4 | 3.08 | 505.8 | 219.8 | III | 37.5 | 3100 | 170 | 28 | 2000 | 230 |

| Specimen | Expected Ultimate Load [kN] | Ultimate Load [kN] | ηf * [%] | Failure Mode |

|---|---|---|---|---|

| BN-11-M1 | - | 42.8 | - | - |

| BN-12-M1 | - | 44.0 | - | - |

| BN-12-M2 | - | 43.8 | - | - |

| BW3-11-M1 | 59.2 | 56.9 | 33 | Debonding of the CFRP strip at the left end and middle of the FRP material followed by compressive concrete crushing on the top surface of the beam. |

| BW3-12-M1 | 59.7 | 57.9 | 32 | Debonding of the CFRP strip along its entire length followed by concrete compressive crushing on the top surface of the beam. |

| BW3-12-M2 | 57.5 | 31 | ||

| BW4-11-M1 | 59.2 | 58.4 | 36 | Debonding of the CFRP strip along its entire length followed by concrete compressive crushing on the top surface of the beam. |

| BW4-12-M1 | 59.7 | 58.6 | 33 | |

| BW4-12-M2 | 59.1 | 35 | ||

| BW5-12-M1 | 59.5 | 56.6 | 29 | Debonding of the CFRP strip followed by compressive concrete crushing on the top surface of the beam. No debonding at the anchor point and the strip and fiber anchor overlap. |

| BW5-12-M2 | 59.5 | 60.2 | 37 | Debonding of the CFRP strip along its entire length followed by concrete compressive crushing on the top surface of the beam. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tworzewski, P.; Bacharz, K. Flexural Strengthening of Reinforced Concrete Beams Using Near-Surface Mounted (NSM) Carbon Fiber-Reinforced Polymer (CFRP) Strips with Additional Anchorage. Materials 2025, 18, 2579. https://doi.org/10.3390/ma18112579

Tworzewski P, Bacharz K. Flexural Strengthening of Reinforced Concrete Beams Using Near-Surface Mounted (NSM) Carbon Fiber-Reinforced Polymer (CFRP) Strips with Additional Anchorage. Materials. 2025; 18(11):2579. https://doi.org/10.3390/ma18112579

Chicago/Turabian StyleTworzewski, Paweł, and Kamil Bacharz. 2025. "Flexural Strengthening of Reinforced Concrete Beams Using Near-Surface Mounted (NSM) Carbon Fiber-Reinforced Polymer (CFRP) Strips with Additional Anchorage" Materials 18, no. 11: 2579. https://doi.org/10.3390/ma18112579

APA StyleTworzewski, P., & Bacharz, K. (2025). Flexural Strengthening of Reinforced Concrete Beams Using Near-Surface Mounted (NSM) Carbon Fiber-Reinforced Polymer (CFRP) Strips with Additional Anchorage. Materials, 18(11), 2579. https://doi.org/10.3390/ma18112579