Study on the Properties of Solidified Silt Based on Microbially Stimulated Recycled Hardened Cement Powder

Abstract

1. Introduction

2. Materials and Methods

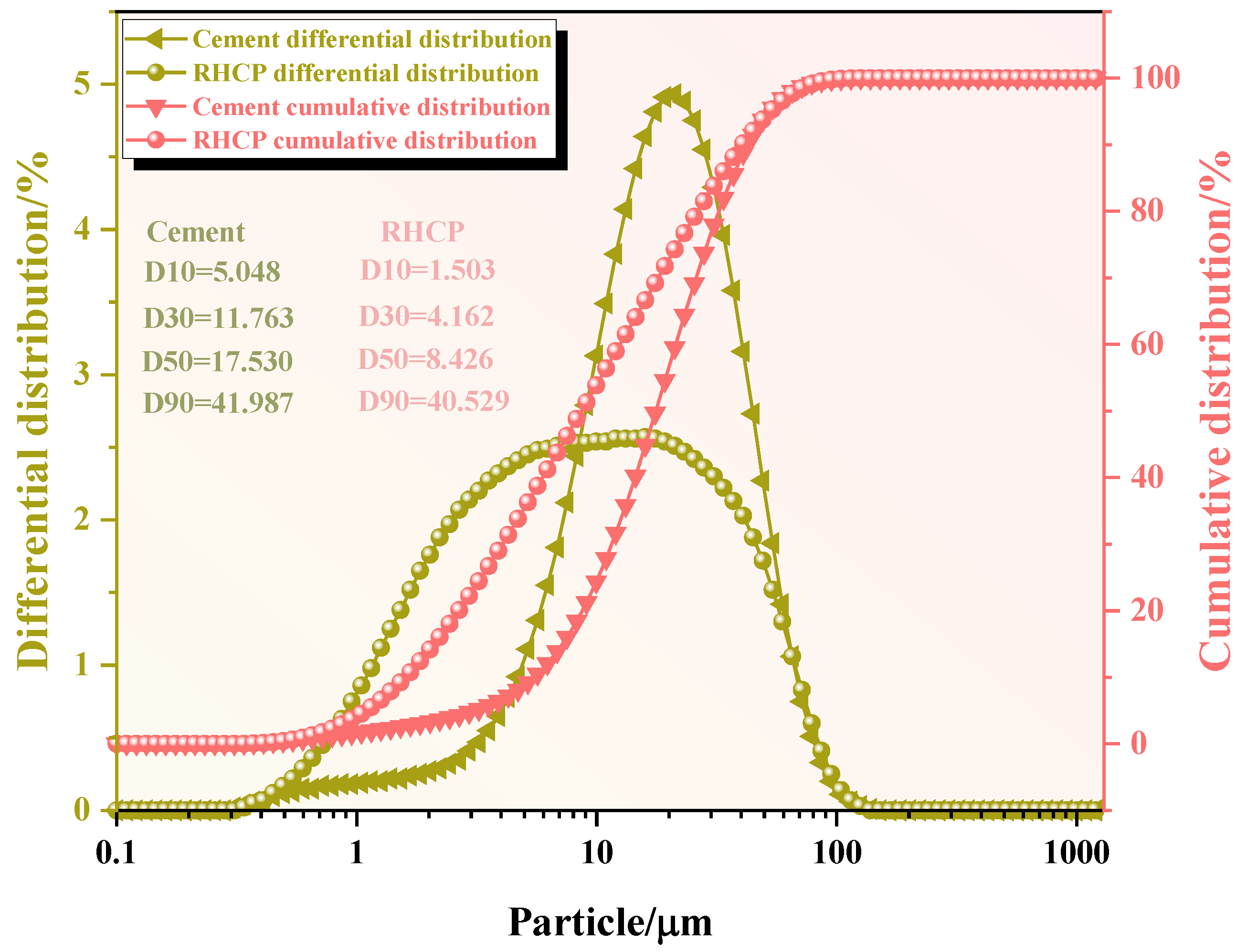

2.1. Materials

2.2. Experimental Procedure

2.3. Test Methods

2.3.1. Mineral Phase Composition

2.3.2. Microscopic Morphology and Elemental Composition

2.3.3. Quantitative Characterization of Carbon Sequestration

2.3.4. Mechanical and Long-Term Performance Testing

Unconfined Compressive Strength (UCS)

Water Stability

Dry–Wet Cycles

Freeze–Thaw Cycling

3. Results and Discussion

3.1. The Mineral Phase Composition of C-RHCP

3.2. Quantitative Analysis of Carbon Fixation

3.3. The Microscopic Morphology of C-RHCP

3.4. The Interactions Between Bacillus, RHCP, and CO2

3.5. Mechanical Performance Analysis of SS

3.5.1. Dosage

3.5.2. Curing Age

3.5.3. Moisture Content

3.6. Long-Term Performance Analysis of SS

3.6.1. Water Stability

3.6.2. Dry and Wet Cycle

3.6.3. Freeze–Thaw Cycle

4. Conclusions

- Nonlinear regulation mechanism of pressure on the carbonization process: In the pressurized carbonization system, the solubility of CO2 was positively correlated with pressure, but the microbial activity showed an inhibitory effect. The synergistic effect of the two led to a non-monotony response characteristic of carbonization efficiency that first increased and then decreased. The experiment verified that 0.5 MPa was the critical pressure threshold. At this time, the carbonization efficiency reached the peak (59.82 g CO2/kg), reflecting the optimal regulation value of pressure parameters in the carbon storage process.

- The co-evolution law of microstructure and mechanical properties: The microscopic morphology characterization by SEM-EDS confirmed that a dense accumulation layer of nano-micron-scale calcium carbonate crystals was formed on the surface of C-RHCP. Through the pore filling effect and interface strengthening mechanism, the pore structure of the material was significantly optimized, thereby improving its macroscopic mechanical properties. The increase rate of compressive strength compared with uncarbonated RHCP reached 18.7%.

- The mechanism of bio-chemical synergistic mineralization enhancement: The proliferation effect of interfacial nucleation sites induced by microbial metabolic activity not only accelerated the kinetic process of CO2 mineralization into calcium carbonate but also optimized the crystallization orientation and spatial distribution of subsequent hydration products (such as C-S-H gel) by providing heterogeneous nucleation substrates.

- Long-term performance enhancement via carbonation-activated pozzolanic reaction: Carbonation modification significantly enhanced the reactivity of silicate/aluminate phases in RHCP. These phases interacted with Ca(OH)2 to generate amorphous silica gel and secondary C-S-H gel, forming a multi-scale cementitious network that reinforces durability and mechanical strength over extended periods.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Monteiro, P.J.M.; Miller, S.A.; Horvath, A. Towards sustainable concrete. Nat. Mater. 2017, 16, 698–699. [Google Scholar] [CrossRef]

- Yi, C.L.; Yi, M.L.; Liu, Y. Application technology of recycled concrete of construction waste. J. Green. Build. 2021, 11, 7–8. [Google Scholar]

- Xu, J.; Kang, A.H.; Wu, Z.G.; Gong, Y.F.; Xiao, P. The effect of mechanical-thermal synergistic activation on the mechanical properties and microstructure of recycled powder geopolymer. J. Clean. Prod. 2021, 327, 129477. [Google Scholar] [CrossRef]

- Sergio, M.; Sergio, L.; Fernando, P.T.; Adelino, L. Advantages and shortcomings of the utilization of recycled wastes as aggregates in structural concretes. Constr. Build. Mater. 2021, 298, 123729. [Google Scholar]

- Villagrán-Zaccardi, Y.; Sosa, E.; Carrizo, L.; Zega, C. 3-Use of Recycled Fines from Waste Concrete as an Admixture in New Concrete; Woodhead Publishing Series in Civil and Structural Engineering; Woodhead Publishing: Sawston, UK, 2022; pp. 39–65. [Google Scholar]

- Moro, C.; Francioso, V.; Velay-Lizancos, M. Modification of CO2 capture and pore structure of hardened cement paste made with nano-TiO2 addition: Influence of w/c ratio and CO2 exposure age. Constr. Build. Mater. 2021, 275, 122131. [Google Scholar] [CrossRef]

- Ma, Z.; Li, W.; Wu, H.; Cao, C. Chloride permeability of concrete mixed with activity recycled powder obtained from C&D waste. Constr. Build. Mater. 2019, 199, 652–663. [Google Scholar]

- Wang, H.; Wang, L.; Shen, W.; Cao, K.E.; Sun, L.; Wang, P.; Cui, L. Compressive strength, hydration and pore structure of alkali-activated slag mortars integrating with recycled concrete powder as binders. KSCE J. Civ. Eng. 2022, 26, 795–805. [Google Scholar] [CrossRef]

- Chen, X.; Li, Y.; Bai, H.; Ma, L. Utilization of recycled concrete powder in cement composite: Strength, microstructure and hydration characteristics. J. Renewable Mater. 2021, 9, 2189–2208. [Google Scholar] [CrossRef]

- Kim, Y. Quality properties of self-consolidating concrete mixed with waste concrete powder. Constr. Build. Mater. 2017, 135, 177–185. [Google Scholar] [CrossRef]

- Ye, T.; Xiao, J.; Duan, Z.; Li, S.J.C.; Materials, B. Geopolymers made of recycled brick and concrete powder–a critical review. Constr. Build. Mater. 2022, 330, 127232. [Google Scholar] [CrossRef]

- Zhao, Y.; Gao, J.; Liu, C. The particle-size effect of waste clay brick powder on its pozzolanic activity and properties of blended cement. J. Clean. Prod. 2020, 242, 118521. [Google Scholar] [CrossRef]

- Tang, Q.; Ma, Z.; Wu, H.; Wang, W. The utilization of eco-friendly recycled powder from concrete and brick waste in new concrete: A critical review. Cem. Concr. Compos. 2020, 114, 103807. [Google Scholar] [CrossRef]

- Li, L.K.; Liu, Q.; Huang, T.Y.; Peng, W.Z. Mineralization and utilization of CO2 in construction and demolition wastes recycling for building materials: A systematic review of recycled concrete aggregate and recycled hardened cement powder. Sep. Purif. 2022, 298, 121512. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Butera, A.; Le, K.N. Carbon-conditioned recycled aggregate in concrete production. J. Clean. Prod. 2016, 133, 672–680. [Google Scholar] [CrossRef]

- Zadeh, A.H.; Mamirov, M.; Kim, S. CO2-treatment of recycled concrete aggregates to improve mechanical and environmental properties for unbound applications. Constr. Build. Mater. 2021, 275, 122–180. [Google Scholar]

- Zhang, Y.; Wang, R.; Liu, Z. A novel carbonate binder from waste hydrated cement paste for utilization of CO2. J. CO2 Util. 2019, 32, 276–280. [Google Scholar] [CrossRef]

- Shen, P.L.; Zhang, Y.Y.; Jiang, Y.; Zhan, B.J.; Lu, J.X.; Zhang, S.P.; Xuan, D.X.; Poon, C.S. Phase assemblance evolution during wet carbonation of recycled concrete fines. Cem. Concr. Res. 2022, 154, 106733. [Google Scholar] [CrossRef]

- Photong, C.; Pragot, W. Effect of Adding Monohydrocalcite on the Microstructural Change in Cement Hydration. ACS Omega 2022, 7, 36318–36329. [Google Scholar] [CrossRef]

- Mehdizadeh, H.; Ling, T.; Cheng, X.; Mo, K.H. Effect of particle size and CO2 treatment of waste cement powder on properties of cement paste. Can. J. Civ. Eng. 2021, 48, 522–531. [Google Scholar] [CrossRef]

- Liu, X.; Feng, P.; Cai, Y.X. Carbonation behavior of calcium silicate hydrate (C-S-H): Its potential for CO2 capture. Chem. Eng. J. 2021, 431, 134243. [Google Scholar] [CrossRef]

- ASTM D2487-17; ASTM Committee D-18 on Soil and Rock. Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System) 1. ASTM International: West Conshohocken, PA, USA, 2017.

- Liu, J.K.; Xiao, J.H.; Chen, L.H.; Zhu, R.L. Mechanics properties of compacted silt on Beijing-Kowloon Railway. J. Beijing Jiaotong Univ. 2007, 31, 56–60. [Google Scholar]

- Pu, S.; Zhu, Z.; Wang, H.; Song, W.; Wei, R. Mechanical characteristics and water stability of silt solidified by incorporating lime, lime and cement mixture, and SEU-2 binder. Constr. Build. Mater. 2019, 214, 111–120. [Google Scholar] [CrossRef]

- Pu, S.Y.; Zhu, Z.D.; Song, W.L.; Wan, Y.; Wang, H.R.; Song, S.G.; Zhang, J. Mechanical and Microscopic Properties of Cement Stabilized Silt. KSCE J. Civ. Eng. 2020, 24, 2333–2344. [Google Scholar] [CrossRef]

- Lemaire, K.; Deneele, D.; Bonnet, S.; Legret, M. Effects of LC mixtures treatmenton the physicochemical, microstructural and mechanical characteristics of aplastic silt. Eng. Geol. 2013, 166, 255–261. [Google Scholar] [CrossRef]

- Jauberthie, R.; Rendell, F.; Rangeard, D.; Molez, L. Stabilisation of estuarine silt with lime and/or cement. Appl. Clay Sci. 2010, 50, 395–400. [Google Scholar] [CrossRef]

- Yuan, X.Z.; Li, S.D.; Cui, W. Silt subgrade modification and stabilization with ground granulated blast furnace slag and carbide lime in areas with a recurring high groundwater. In Proceedings of the 2010 International Conference on Mechanic Automation and Control Engineering, Wuhan, China, 26–28 June 2010; pp. 2063–2067. [Google Scholar]

- Lin, Y.K.; He, T.S.; Da, Y.Q.; Yang, R.H.; Zheng, D.L. Effects of recycled micro-powders mixing methods on the properties of recycled concrete. J. Build. Eng. 2023, 80, 107994. [Google Scholar] [CrossRef]

- Ouhadi, V.R.; Yong, R.N.; Amiri, M.; Ouhadi, M.H. Pozzolanic consolidation ofstabilized soft clays. Appl. Clay Sci. 2014, 95, 111–118. [Google Scholar] [CrossRef]

- Lv, C.; Tang, C.-S.; Zhu, C.; Li, W.-Q.; Chen, T.-Y.; Zhao, L.; Pan, X.-H. Environmental dependence of microbially induced calcium carbonate crystal precipitations: Experimental evidence and insights. J. Geotech. Geoenviron. Eng. 2022, 148, 04022050. [Google Scholar] [CrossRef]

- Zhang, X.; Qian, C.X.; Ma, Z.Y.; Li, F. Study on preparation of supplementary cementitious material using microbial CO2 fixation of steel slag powder. Constr. Build. Mater. 2022, 326, 126864. [Google Scholar] [CrossRef]

- Wang, D.X.; Zhu, J.Y.; He, F.J. CO2 carbonation-induced improvement in strength and microstructure of reactive MgO-CaO-fly ash-solidified soils. Constr. Build. Mater. 2019, 229, 116914. [Google Scholar] [CrossRef]

- Wang, D.X.; Xiao, J.; He, F.J.; Zhou, Y.D. Durability evolution and associated micro-mechanisms of carbonated reactive MgO-fly ash solidified sludge from East Lake, China. Constr. Build. Mater. 2019, 208, 1–12. [Google Scholar] [CrossRef]

- Wang, D.X.; Zhu, J.Y.; He, F.J. Quantification and micro-mechanisms of CO2 sequestration in magnesialime-fly ash/slag solidified soils. Int. J. Greenh. Gas Control 2019, 91, 102827. [Google Scholar] [CrossRef]

- Liu, L.; Zhou, A.; Deng, Y.F.; Cui, Y.J.; Yu, Z.; Yu, C. Strength performance of cement/slag-based stabilized soft clays. Constr. Build. Mater. 2019, 211, 909–918. [Google Scholar] [CrossRef]

- Zhou, A.X.; Qian, R.S.; Miao, G.X.; Zhang, Y.S.; Xue, C.Z.; Zhang, Y.; Qiao, H.X.; Shi, J.H. Gas permeability characteristics of granite-manufactured sand concrete and its numerical simulation using NMR-MIP modified method. Constr. Build. Mater. 2024, 431, 136520. [Google Scholar] [CrossRef]

- Dong, W.Y.; Zhan, Q.W.; Zhang, X.; Su, Y.L.; Zhou, J.L. Study on accelerating activation of recycled hardened concrete powder based on microbial induced calcium precipitation. Constr. Build. Mater. 2024, 411, 134710. [Google Scholar] [CrossRef]

- Jang, J.G.; Kim, G.M.; Kim, H.J.; Lee, H.K. Review recent advances in CO2 utilization and sequestration technologies in cement-based materials. Construct. Build. Mater. 2016, 127, 762–773. [Google Scholar] [CrossRef]

- Liu, G.; Schollbach, K.; van der Laan, S.; Tang, P.; Florea, M.V.A.; Brouwers, H.J.H. Recycling and utilization of high volume converter steel slag into CO2 activated mortars—The role of slag particle size. Resour. Conserv. Recycl. 2020, 160, 104883. [Google Scholar] [CrossRef]

- Mo, L.; Zhang, F.; Deng, M. Mechanical performance and microstructure of the calcium carbonate binders produced by carbonating steel slag paste under CO2 curing. Cem. Concr. Res. 2016, 88, 217–226. [Google Scholar] [CrossRef]

- Ma, X.N.; Liu, Y.H.; Hao, Z.X.; Yin, W.H. Study on mechanical properties and durability of composite improved loess using CG-2 curing agent and cement. Constr. Build. Mater. 2024, 451, 138801. [Google Scholar] [CrossRef]

- Wang, A.H.; Dong, W.Y.; Zhan, Q.W.; Zhou, J.L. Study on Long Term Property of Soft Soil Solidified with Industrial Waste Residue and Regenerated Fine Aggregate. Materials 2023, 16, 2447. [Google Scholar] [CrossRef]

- Sodeifian, G.; Nasri, L.; Razmimanesh, F.; Abadian, M. CO2 utilization for determining solubility of teriflunomide (immunomodulatory agent) in supercritical carbon dioxide: Experimental investigation and thermodynamic modeling. J. CO2 Util. 2022, 58, 101931. [Google Scholar] [CrossRef]

- Gohil, R.B.; Raval, V.H.; Panchal, R.R.; Rajput, K.N. Plant Growth-Promoting Activity of Bacillus sp. PG-8 Isolated From Fermented Panchagavya and Its Effect on the Growth of Arachis hypogea. Front. Agron. 2022, 4, 805454. [Google Scholar] [CrossRef]

- Villar-Cociña, E.; Rodier, L.; Savastano, H., Jr.; Lefrán, M.; Rojas, M.F. A Comparative Study on the Pozzolanic Activity Between Bamboo Leaves Ash and Silica Fume: Kinetic Parameters. Waste Biomass Valorization 2020, 11, 1627–1634. [Google Scholar] [CrossRef]

- Kapeluszna, E.; Kotwica, L.; Rozycka, A.; Golek, L. Incorporation of Al in C-A-S-H gels with various Ca/Si and Al/Si ratio: Microstructural and structural characteristics with DTA/TG, XRD, FTIR and TEM analysis. Constr. Build. Mater. 2017, 155, 643–653. [Google Scholar] [CrossRef]

- Liu, H.S.; Kaya, H.; Lin, Y.-T.; Ogrinc, A.; Kim, S.H. Vibrational spectroscopy analysis of silica and silicate glass networks. J. Am. Ceram. 2022, 105, 2355–2384. [Google Scholar] [CrossRef]

- Ashraf, W.; Olek, J. Carbonation behavior of hydraulic and nonhydraulic calcium silicates: Potential of utilizing low-lime calcium silicates in cement-based materials. Mater. Sci. 2016, 51, 6173–6191. [Google Scholar] [CrossRef]

- Jin, P.; Wang, R.X.; Su, Y.; Dong, H.; Wang, Q.X. Study on carbonation process of beta-C2S under microbial enzymatic action. Constr. Build. Mater. 2019, 228, 117110. [Google Scholar] [CrossRef]

- Zhao, J.; Li, Y.Q.; Yang, J.J.; Cao, X.Q.; Wang, J.X.; Wang, G.; Sun, L.L.; Huang, Q.M.; Cheng, W.M.; Lyu, Z.W. Preparation of slag-based foam concrete and its carbon dioxide sequestration performance. Int. J. Greenh. Gas Control 2024, 135, 104156. [Google Scholar] [CrossRef]

- de Oliveira Maciel, A.; Christakopoulos, P.; Rova, U.; Antonopoulou, I. Carbonic anhydrase to boost CO2 sequestration: Improving carbon capture utilization and storage (CCUS). Chemosphere 2022, 299, 134419. [Google Scholar] [CrossRef]

- Talekar, S.; Jo, B.H.; Dordick, J.S.; Kim, J. Carbonic anhydrase for CO2 capture, conversion and utilization. Curr. Opin. Biotechnol. 2022, 74, 230–240. [Google Scholar] [CrossRef]

- Mao, L.; Chen, Y.X.; Zhang, R.F.; Yang, C.; Zhou, Y.H.; Zhang, G.Y. Cost-Effective Preparation of Carbonic Anhydrase with Superior Performance for Assisting Amine and Amino Acid Ionic Liquid Blends in CO2 Absorption and Desorption. ACS Sustain. Chem. Eng. 2024, 12, 4444–4455. [Google Scholar] [CrossRef]

- Liu, M.; Cai, L.X.; Luo, H.B. Effect of nano-silica on microbiologically induced calcium carbonate precipitation. Constr. Build. Mater. 2022, 314, 125661. [Google Scholar] [CrossRef]

- Fu, Q.; Zhang, Z.R.; Zhao, X.; Xu, W.R.; Niu, D.T. Effect of nano calcium carbonate on hydration characteristics and microstructure of cement-based materials: A review. J. Build. 2022, 50, 104220. [Google Scholar] [CrossRef]

- Chen, Y.Q.; Wang, S.Q.; Tong, X.Y.; Kang, X. Crystal transformation and self-assembly theory of microbially induced calcium carbonate precipitation. Appl. Microbiol. Biotechnol. 2022, 106, 3555–3569. [Google Scholar] [CrossRef] [PubMed]

- Chang, Z.Y.; Long, G.C.; Zhou, J.L.; Ma, C. Valorization of sewage sludge in the fabrication of construction and building materials: A review. Resour. Conserv. Recycl. 2020, 154, 104606. [Google Scholar] [CrossRef]

- Huang, S.B.; He, Y.B.; Liu, G.F.; Lu, Z.X.; Xin, Z.K. Effect of water content on the mechanical properties and deformation characteristics of the clay-bearing red sandstone. Bull. Eng. Geol. Environ. 2021, 80, 1767–1790. [Google Scholar] [CrossRef]

- Yang, X.; Hu, Z.Q.; Wang, Y.; Wang, X.L. Aeolian sand stabilized by using fiber- and silt-reinforced cement: Mechanical properties, microstructure evolution, and reinforcement mechanism. Constr. Build. Mater. 2024, 411, 134750. [Google Scholar] [CrossRef]

- Zajac, M.; Irbe, L.; Bullerjahn, F.; Hilbig, H.; Haha, M.B. Mechanisms of carbonation hydration hardening in Portland cements. Cem. Concr. Res. 2022, 152, 106687. [Google Scholar] [CrossRef]

- de Jesús Arrieta Baldovino, J.; dos Santos Izzo, R.L.; Rose, J.L. Effects of Freeze–thaw Cycles and Porosity/cement index on Durability, Strength and Capillary Rise of a Stabilized Silty Soil Under Optimal Compaction Conditions. Geotech. Geol. Eng. 2021, 39, 481–498. [Google Scholar] [CrossRef]

- Xia, C.; Liu, Z.; Zhou, C. Strength Deterioration Model of Soft Rock Considering Mesoscopic Bonding–Expansion Coupling Mechanism under Freeze–Thaw Cycles. Sustainability 2022, 14, 11766. [Google Scholar] [CrossRef]

| Material | SiO2 | CaO | Al2O3 | Fe2O3 | K2O | MgO | SO3 |

|---|---|---|---|---|---|---|---|

| Cement | 61.501 | 17.014 | 10.388 | 3.747 | 2.510 | 1.293 | 1.217 |

| RHCP | 21.556 | 63.460 | 7.396 | 3.267 | 0.881 | 1.782 | 0.907 |

| Pressure/MPa | W1/% | W2/% | (W1 − W2)/% | Increased Carbon Sequestration/g·kg−1 |

|---|---|---|---|---|

| 0.1 | 91.20 | 83.86 | 7.34 | 46.41 |

| 0.3 | 89.98 | 81.78 | 8.20 | 59.16 |

| 0.5 | 90.30 | 82.03 | 8.28 | 59.82 |

| 0.7 | 91.41 | 83.74 | 7.67 | 50.48 |

| 0.9 | 91.91 | 85.38 | 6.53 | 35.37 |

| Curing Age/Days | 7 | 14 | 21 | 28 | |

|---|---|---|---|---|---|

| Group | |||||

| Single cement | 1.07 | 0.92 | 0.96 | 0.89 | |

| 30% RHCP | 0.96 | 0.94 | 0.87 | 0.82 | |

| 30% C-RHCP | 1.16 | 1.13 | 1.10 | 0.88 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, X.; Tian, C.; Hong, J.; Zhan, Q.; Wang, X.; Dong, W. Study on the Properties of Solidified Silt Based on Microbially Stimulated Recycled Hardened Cement Powder. Materials 2025, 18, 2575. https://doi.org/10.3390/ma18112575

Yin X, Tian C, Hong J, Zhan Q, Wang X, Dong W. Study on the Properties of Solidified Silt Based on Microbially Stimulated Recycled Hardened Cement Powder. Materials. 2025; 18(11):2575. https://doi.org/10.3390/ma18112575

Chicago/Turabian StyleYin, Xihui, Chuanjiang Tian, Jintao Hong, Qiwei Zhan, Xinyu Wang, and Wanying Dong. 2025. "Study on the Properties of Solidified Silt Based on Microbially Stimulated Recycled Hardened Cement Powder" Materials 18, no. 11: 2575. https://doi.org/10.3390/ma18112575

APA StyleYin, X., Tian, C., Hong, J., Zhan, Q., Wang, X., & Dong, W. (2025). Study on the Properties of Solidified Silt Based on Microbially Stimulated Recycled Hardened Cement Powder. Materials, 18(11), 2575. https://doi.org/10.3390/ma18112575