Unlocking the Potential of Caribbean Coarse Aggregates for High-Strength Concrete Development

Abstract

1. Introduction

1.1. Purpose of the Work and Significance

1.2. Background

1.2.1. High-Strength Concrete Mixes

1.2.2. Mechanical Properties of High-Strength Concretes (HSCs)

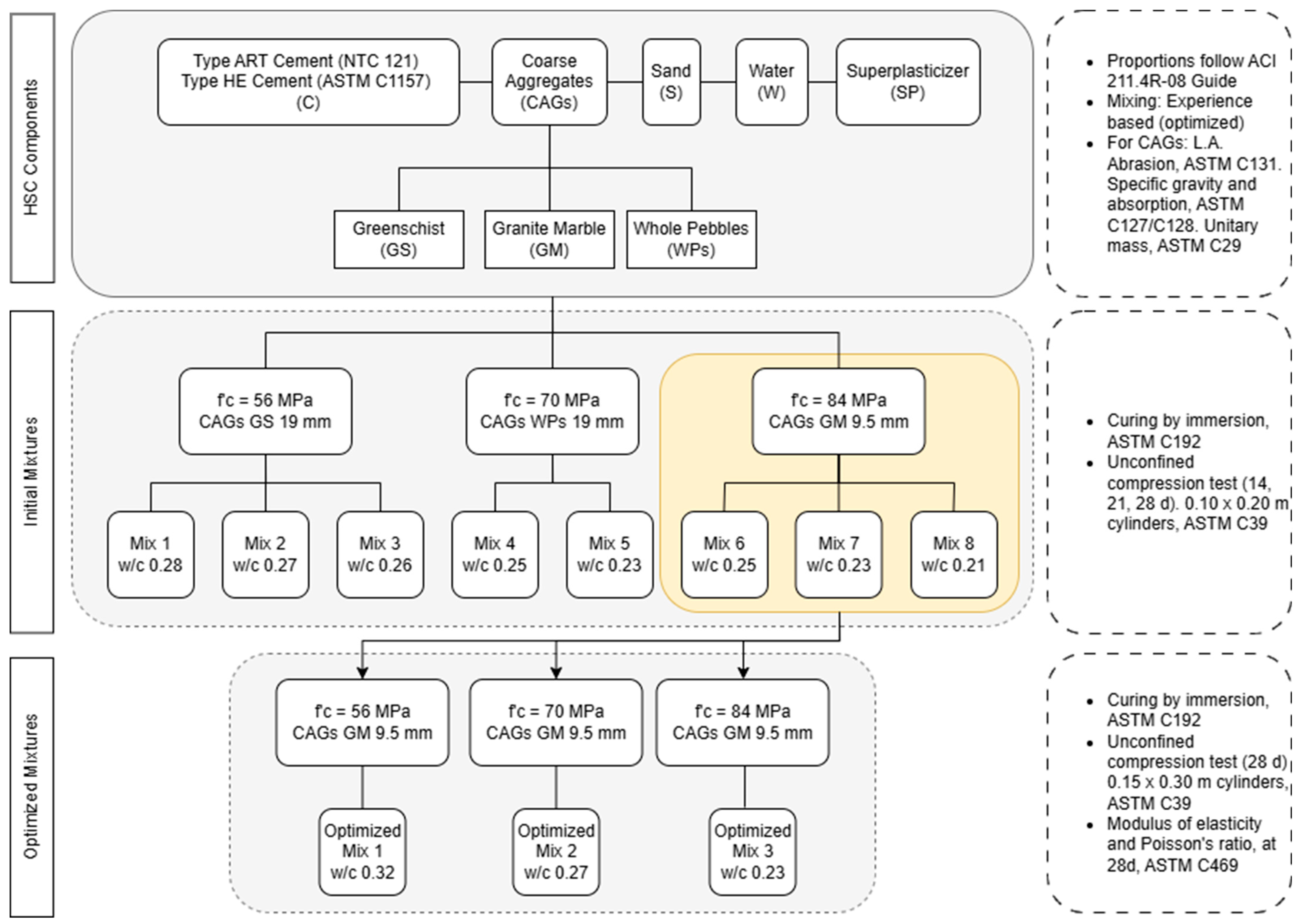

2. Materials and Methods

2.1. Material Selection

2.1.1. Cement (C)

2.1.2. Coarse Aggregates (CAGs)

2.1.3. Fine Aggregate—Sand (S)

2.1.4. Additives

2.2. Mix Design and Production

Mixing Procedure

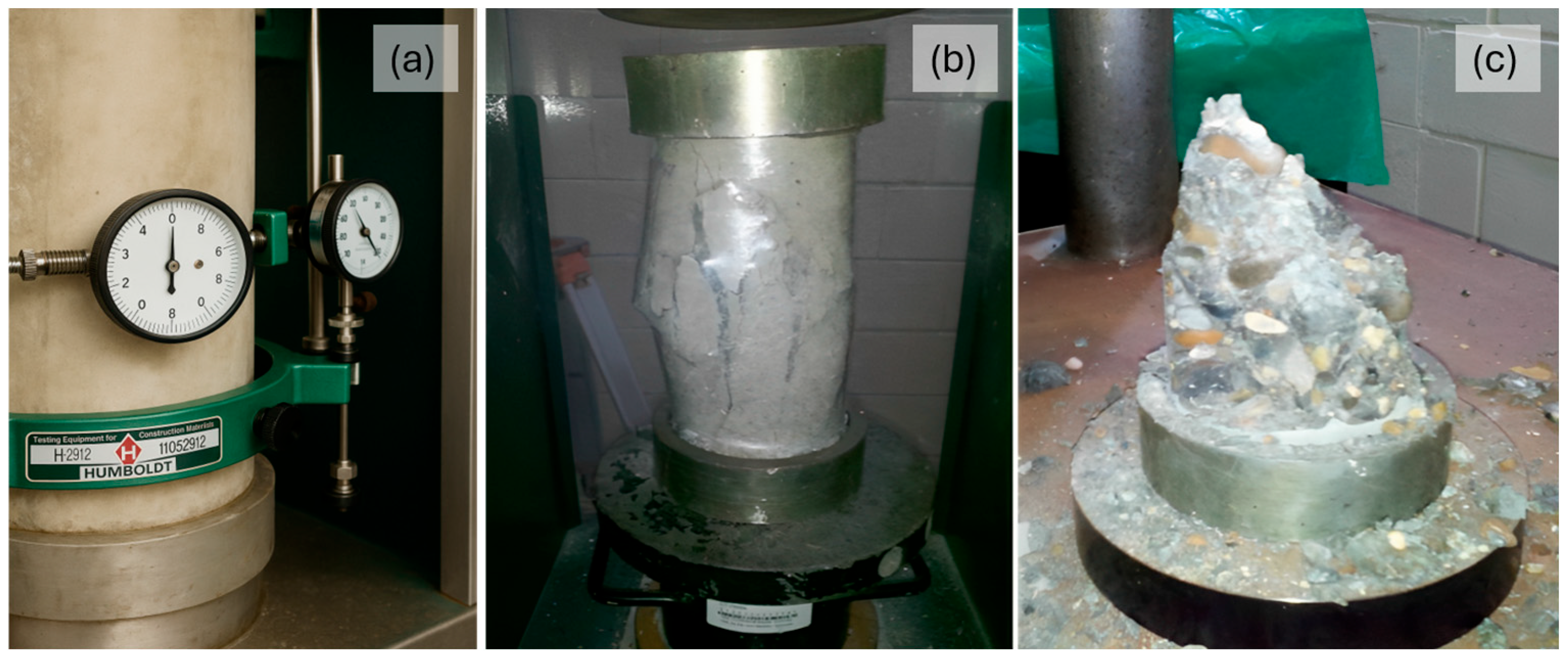

2.3. Production and Testing of Sample Cylinders

2.4. Modulus of Elasticity and Poisson’s Ratio Testing

3. Results and Discussion

3.1. Workability Observations

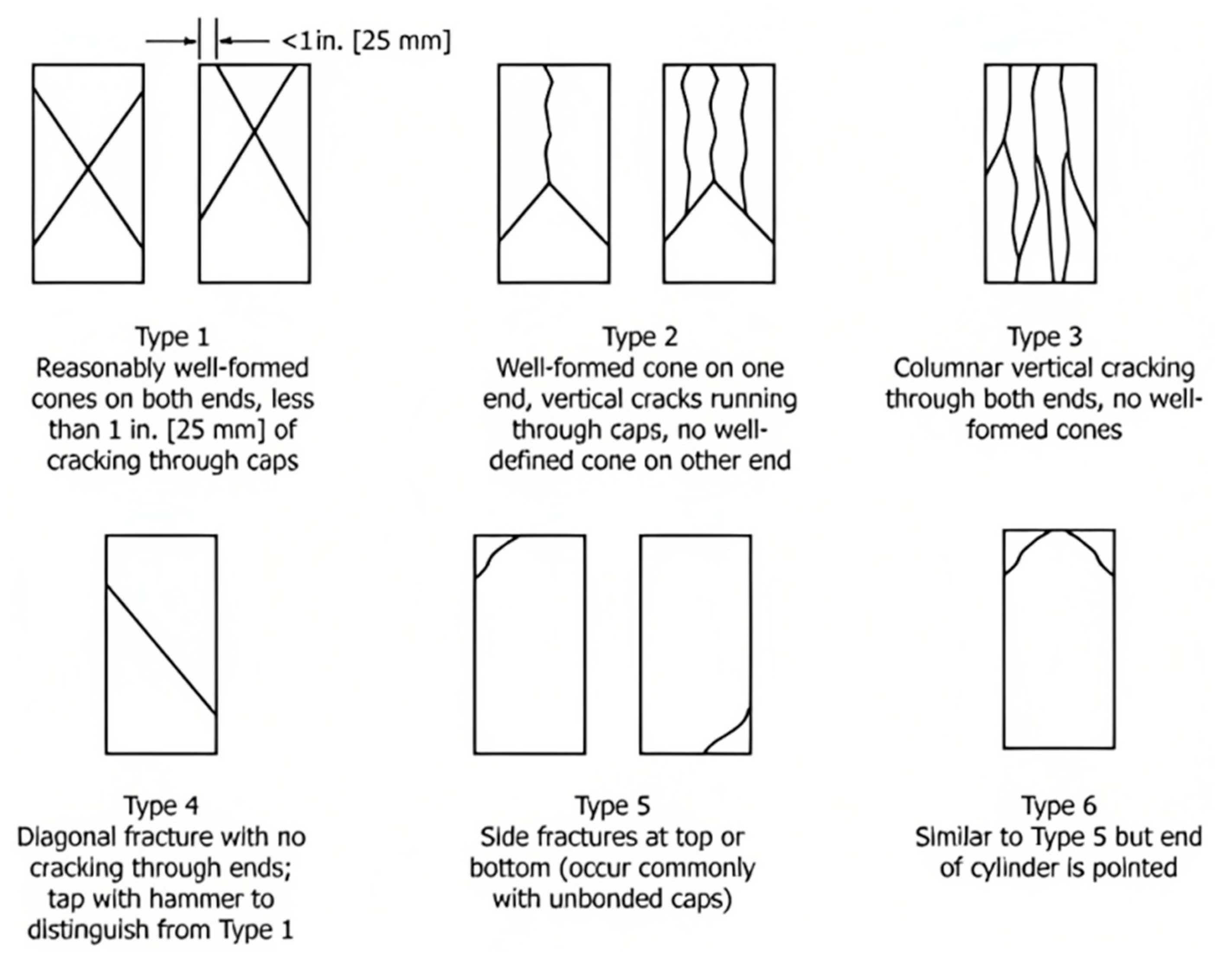

3.2. Failure Type

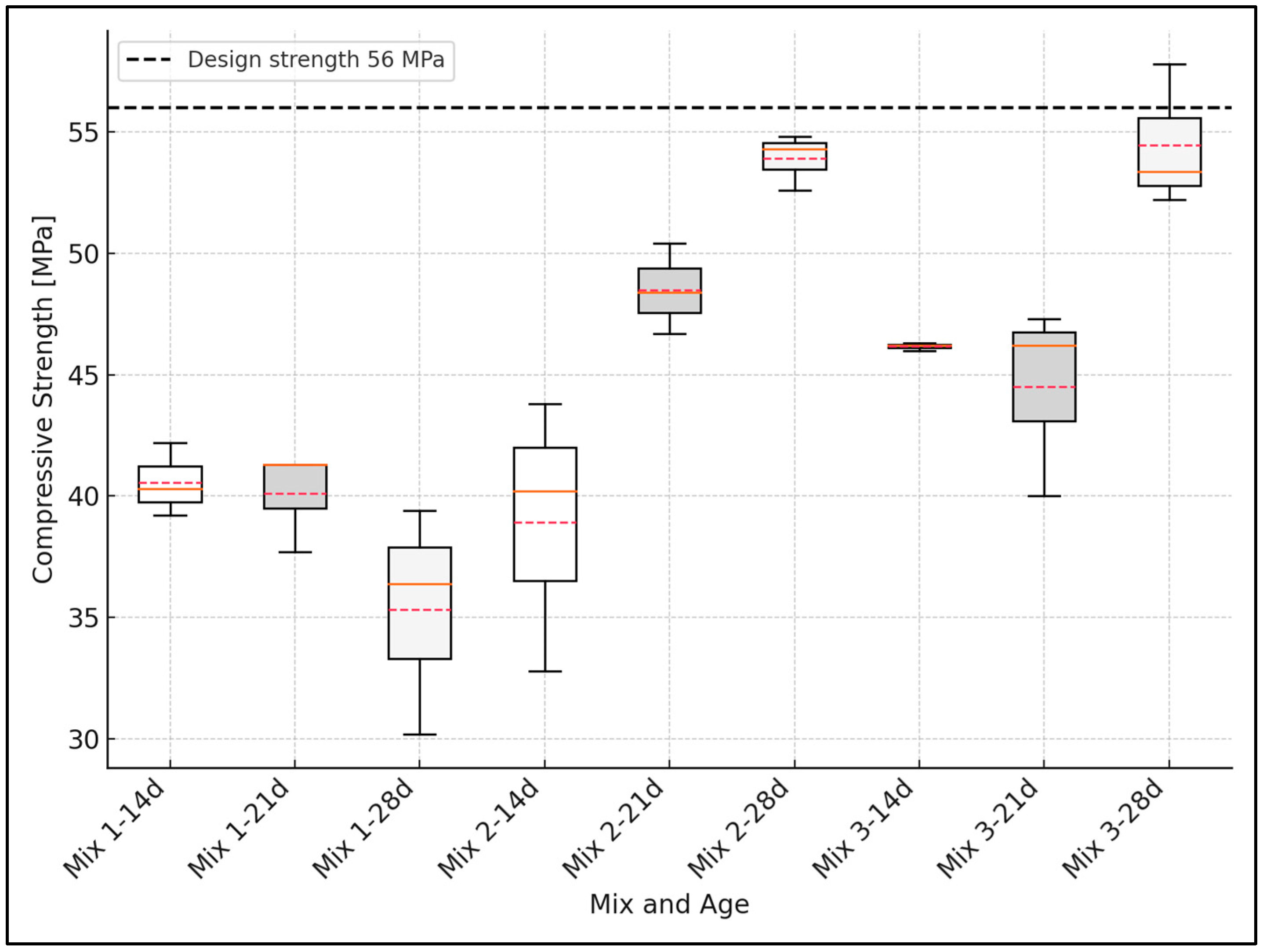

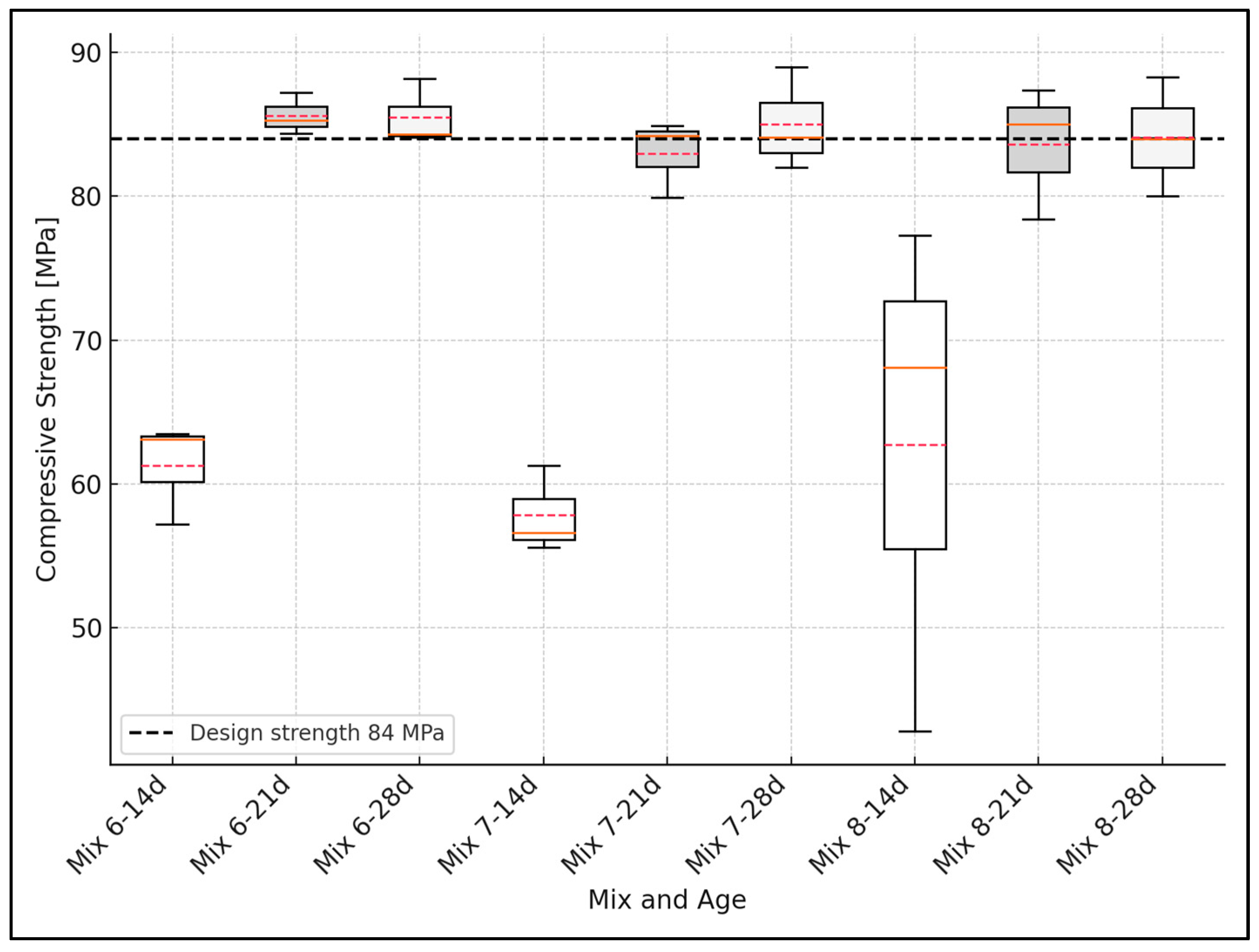

3.3. Design vs. Experimental Comparison of Compressive Strength

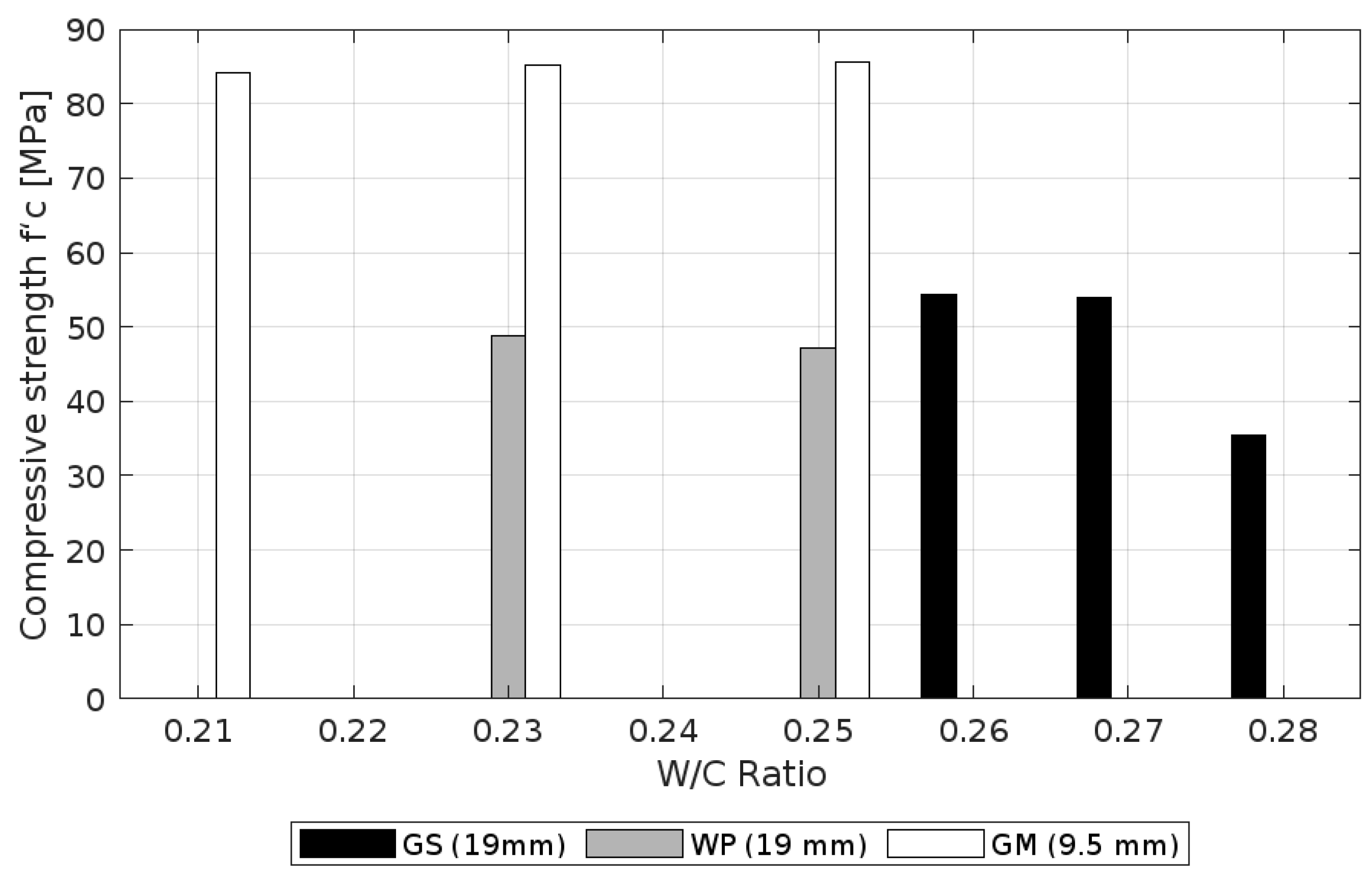

3.4. Relationship Between the Compressive Strength and the Water–Cement Ratio

3.5. Aggregate Size vs. Compressive Strength

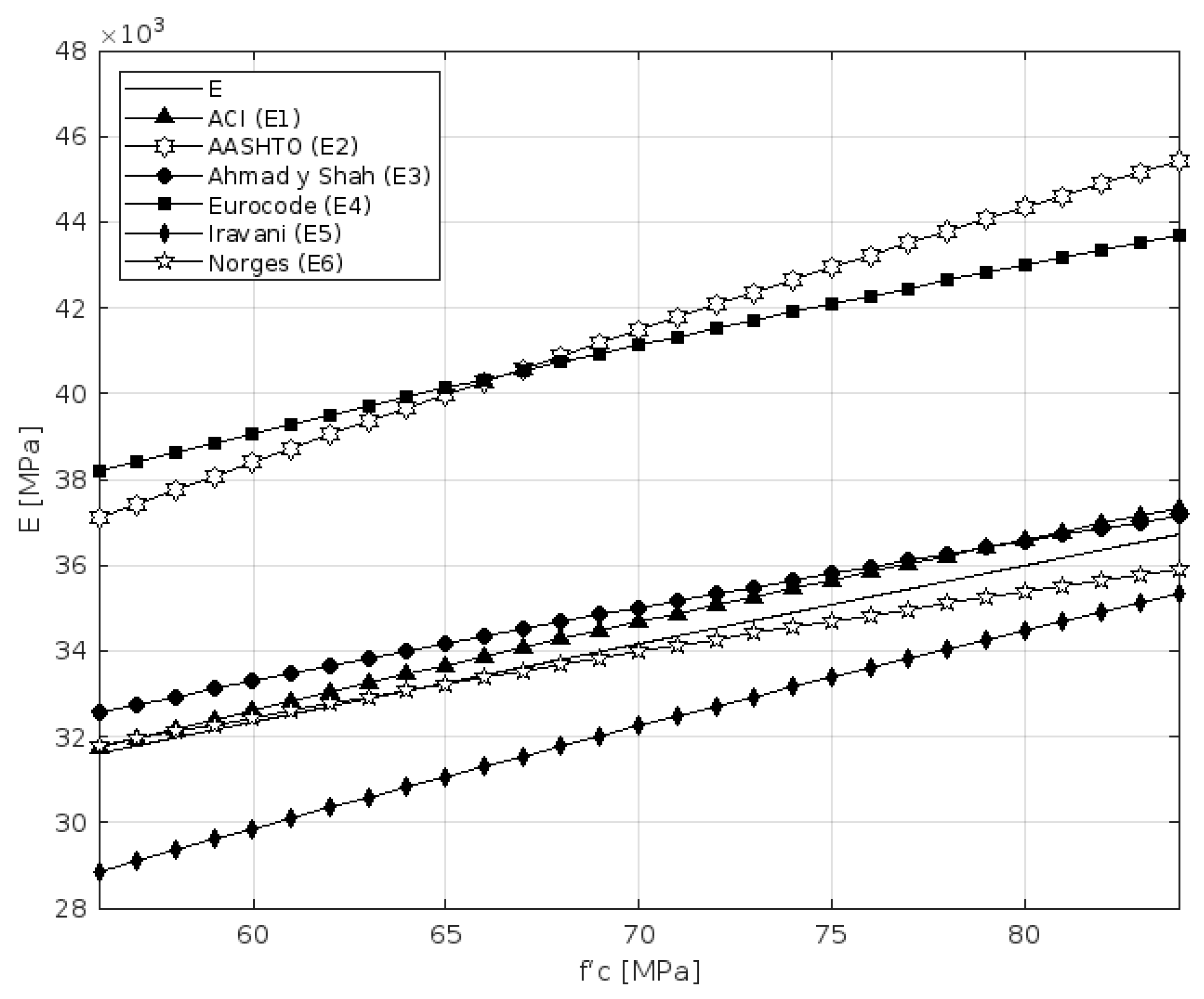

3.6. Modulus of Elasticity and Poisson’s Ratio

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CAGs | Coarse aggregates |

| Dw | Water density |

| E | (Tangent) Modulus of elasticity |

| FTs | Failure types |

| GM | Granite marble |

| GS | Greenschist |

| HE | High-early strength (cement type HE) |

| HSCs | High-strength concretes |

| HRWRs | High-range water-reducing admixtures |

| IQR | Interquartile range |

| S | Sand |

| S1 | Stress corresponding to strain ε1 |

| S2 | Stress corresponding to 40% of the ultimate load for concrete |

| SGx | Specific gravity |

| SP | Superplasticizer |

| V | Void percentage in sand |

| Vair | Air volume |

| Vcag | Coarse aggregate volume |

| Vcm | Cement volume |

| Vfa | Fine aggregate volume |

| Vw | Water volume |

| Vx | Mix volume for each constituent material |

| W | Water |

| wc | Concrete specific weight |

| w/c | Water–cement ratio |

| Wcm | Cement weight |

| Wfa | Fine aggregate weight |

| WPs | Whole pebbles |

| Ws | Sand weight |

| Wsp | Superplasticizer weight |

| Ww | Water weight |

| Wx | Mix weight for each constituent material |

| ε2 | Longitudinal strain produced in S2 |

| εt1 | Transverse strain according to the average height of the specimen, produced by stress S1 |

| εt2 | Transverse strain according to the average height of the specimen, produced by stress S2 |

| f’c | Compressive strength of concrete |

| μ | Poisson’s ratio |

References

- ACI 363R-10; Report on High-Strength Concrete. American Concrete Institute: Farmington Hills, MI, USA, 2010; ISBN 978-0-87031-254-0.

- Mehta, P.K.; Monteiro, P.J. Concrete: Microstructure, Properties, and Materials; McGraw-Hill Education: New York, NY, USA, 2014; Volume 3, ISBN 978-0-07-179787-0. [Google Scholar]

- Hattori, K. Experiences with Mighty Superplasticizer in Japan. Spec. Publ. 1979, 62, 37–66. [Google Scholar]

- Aignesberger, A.; Kern, A. Use of Melamine-Based Super-Plasticizer as a Water Reducer. Spec. Publ. 1981, 68, 61–80. [Google Scholar]

- Bindiganavile, V.; Banthia, N.; Aarup, B. Impact Response of Ultra-High-Strength Fiber-Reinforced Cement Composite. ACI Mater. J. 2002, 99, 543–548. [Google Scholar] [CrossRef]

- Bharatkumar, B.H.; Narayanan, R.; Raghuprasad, B.K.; Ramachandramurthy, D.S. Mix Proportioning of High Performance Concrete. Cem. Concr. Compos. 2001, 23, 71–80. [Google Scholar] [CrossRef]

- Hover, K.C. Concrete Mixture Proportioning with Water-Reducing Admixtures to Enhance Durability: A Quantitative Model. Cem. Concr. Compos. 1998, 20, 113–119. [Google Scholar] [CrossRef]

- Alsadey, S.; Omran, A. Effect of Superplasticizers to Enhance the Properties of Concrete. Des. Constr. Maint. 2022, 2, 84–91. [Google Scholar] [CrossRef]

- Ezeagu, A.C.; Edwin, E.E. Influence of Super Plasticizer on the Compressive Strength and Setting Time of Concrete. Am. J. Eng. Technol. Manag. 2021, 6, 82–88. [Google Scholar] [CrossRef]

- Nawy, E. Reinforced Concrete: A Fundamental Approach, 6th ed.; Pearson: Upper Saddle River, NJ, USA, 2009. [Google Scholar]

- Derrouiche, Y.; Achoura, D.; Saliba, J.; Cassagnabère, F. Natural Pozzolan as a Sustainable Cement Replacement in High-Performance Concrete: Effects on Mechanical Properties, Durability, and Microstructural Development. Sci. Afr. 2025, 27, e02574. [Google Scholar] [CrossRef]

- Hasan, M.; Alkhaly, Y.R.; Hamzani; Fikri, R.; Saidi, T. Properties of High-Strength Concrete Incorporating Calcined Diatomaceous Earth, Polypropylene, and Glass Fibers. Buildings 2025, 15, 225. [Google Scholar] [CrossRef]

- Hasan, M.; Jamil, M.; Saidi, T. Mechanical Properties and Durability of Ultra-High-Performance Concrete with Calcined Diatomaceous Earth as Cement Replacement. J. Mech. Behav. Mater. 2023, 32, 20220272. [Google Scholar] [CrossRef]

- Hasan, M.; Saidi, T.; Mubarak, A.; Jamil, M. Effect of Calcined Diatomaceous Earth, Polypropylene Fiber, and Glass Fiber on the Mechanical Properties of Ultra-High-Performance Fiber-Reinforced Concrete. J. Mech. Behav. Mater. 2023, 32, 20220275. [Google Scholar] [CrossRef]

- Rashid, M.A.; Mansur, M.A.; Paramasivam, P. Correlations between Mechanical Properties of High-Strength Concrete. J. Mater. Civ. Eng. 2002, 14, 230–238. [Google Scholar] [CrossRef]

- Shah, S.P.; Ahmad, S.H. Structural Properties of High Strength Concrete and Its Implications for Precast Prestressed Concrete. PCI J. 1985, 30, 92–119. [Google Scholar] [CrossRef]

- Herrera, M.; Mercado, A. Diseño de Mezcla de Concreto de Alta Resistencia a La Compresión Inconfinada. Bacherlor’s Thesis, Universidad del Norte, Barranquilla, Colombia, 2009. [Google Scholar]

- Shen, Z.; Deifalla, A.F.; Kamiński, P.; Dyczko, A. Compressive Strength Evaluation of Ultra-High-Strength Concrete by Machine Learning. Materials 2022, 15, 3523. [Google Scholar] [CrossRef] [PubMed]

- López Yépez, L.G. Influencia del Porcentaje de Adición de la Microsilice y del Tipo de Curado, en la Penetración del ion Cloruro en el Concreto de alto Desempeño. Ph.D. Dissertation, Universidad Nacional de Colombia, Bogotá, Colombia, 2011. [Google Scholar]

- Ren, X.; Yang, W.; Zhou, Y.; Li, J. Behavior of High-Performance Concrete under Uniaxial and Biaxial Loading. ACI Mater. J. 2008, 105, 548–557. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Das, B.B. Molecular Dynamics Simulation in Concrete Research: A Systematic Review of Techniques, Models and Future Directions. J. Build. Eng. 2023, 76, 107267. [Google Scholar] [CrossRef]

- Li, L.; Wei, Y.; Feng, Q.; Liu, F.; Liu, B.; Pu, B. A Review: Progress in Molecular Dynamics Simulation of Portland Cement (Geopolymer)—Based Composites and the Interface between These Matrices and Reinforced Material. Buildings 2023, 13, 1875. [Google Scholar] [CrossRef]

- Cao, J.; Wang, C.; Gonzalez-Libreros, J.; Wang, T.; Tu, Y.; Elfgren, L.; Sas, G. Extended Applications of Molecular Dynamics Methods in Multiscale Studies of Concrete Composites: A Review. Case Stud. Constr. Mater. 2025, 22, e04153. [Google Scholar] [CrossRef]

- ICONTEC. NTC 121: Especificación de Desempeño Para Cemento Hidráulico; ICONTEC: Bogotá, Colombia, 2021. [Google Scholar]

- ASTM C1157/C1157M-23; Standard Performance Specification for Hydraulic Cement. ASTM International: West Conshohocken, PA, USA, 2023. [CrossRef]

- ASTM C131/C131M-20:; Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine. Elsevier: West Conshohocken, PA, USA, 2020; ISBN 978-0-8155-1425-1.

- ACI 211.4R-08; Guide for Selecting Proportions for High-Strength Concrete Using Portland Cement and Other Cementitious Materials. American Concrete Institute: Farmington Hills, MI, USA, 2008; ISBN 978-0-87031-314-1.

- ASTM C192/C192M-24; Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory. 2024th ed. ASTM International: West Conshohocken, PA, USA, 2024. [CrossRef]

- ASTM C39/C39M-24; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2024. [CrossRef]

- ASTM C469/C469M-22; Test Method for Static Modulus of Elasticity and Poissons Ratio of Concrete in Compression. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- ASTM C127-24; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2024. [CrossRef]

- ASTM C128-22; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- ASTM C29/C29M-23; Standard Test Method for Bulk Density (“Unit Weight”) and Voids in Aggregate. ASTM International: West Conshohocken, PA, USA, 2023. [CrossRef]

- Wang, F.; Hua, J.; Xue, X.; Wang, N.; Yan, F.; Feng, D. Effect of Superfine Cement Modification on Properties of Coral Aggregate Concrete. Materials 2023, 16, 1103. [Google Scholar] [CrossRef]

- Kiliç, A.; Atiş, C.D.; Teymen, A.; Karahan, O.; Özcan, F.; Bilim, C.; Özdemir, M. The Influence of Aggregate Type on the Strength and Abrasion Resistance of High Strength Concrete. Cem. Concr. Compos. 2008, 30, 290–296. [Google Scholar] [CrossRef]

- Weber, M.; Bustamante, C.; Garcia-Casco, A.; Saldarriaga, M.; Valencia, V.; Cardona, A. Metamorfismo de Los Esquistos Verdes y Anfibolitas Pertenecientes a Los Esquistos de Santa Marta, Sierra Nevada de Santa Marta (Colombia): ¿registro de La Colisión Entre El Arco Caribe y La Margen Suramericana? Bol. Cienc. Tierra 2008, 25, 7–25. [Google Scholar]

- González Iregui, H.; Orrego López, A.; Ballesteros Torres, I.; Forero Onofre, H.F.; Ramírez Quiroga, C.J.; Zambrano Ortiz, F.; Duque Caro, H.; Vargas Higuera, R.; Núñez Tello, A.; Álvarez Agudelo, A.J.; et al. Mapa de Terrenos Geológicos de Colombia; U.S. Geological Survey (USGS), Ed.; Instituto Nacional de Investigaciones Geológico Mineras (INGEOMINAS): Bogotá, Colombia, 1983. [Google Scholar]

- Rivera, G. Concreto Simple 2006; Universidad del Cauca: Popayán, Colombia, 2006. [Google Scholar]

- Kabir, N.; Aliyu, S.; Nasara, M.A.; Chinade, A.U.; Shehu, A. Characteristics of Different Type of Coarse Aggregate on Properties of High Performance Concrete. Sustain. Struct. Mater. 2019, 2, 88–96. [Google Scholar]

- Gonzalez-Corominas, A.; Etxeberria, M.; Poon, C. Influence of the Quality of Recycled Aggregates on the Mechanical and Durability Properties of High Performance Concrete. Waste Biomass Valorization 2017, 8, 1421–1432. [Google Scholar] [CrossRef]

- Chang, T.; Lin, S.-H.; Lin, H.-C.; Lin, P. Effects of Various Fineness Moduli of Fine Aggregate on Engineering Properties of High-performance Concrete. J. Chin. Inst. Eng. 2001, 24, 289–300. [Google Scholar] [CrossRef]

- Sika Data Sheet Sika® ViscoCrete®. Available online: https://www.sika.com/ (accessed on 12 April 2025).

- ASTM C143/C143M-20; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- Montgomery, D.C.; Runger, G.C. Applied Statistics and Probability for Engineers, 7th ed.; EMEA Edition; Wiley: Hoboken, NJ, USA, 2018; ISBN 978-1-119-40036-3. [Google Scholar]

- ACI 363.2R-11; Guide to Quality Control and Assurance of High-Strength Concrete. American Concrete Institute: Farmington Hills, MI, USA, 2011.

- Baduge, S.K.; Mendis, P.; San Nicolas, R.; Rupasinghe, M.; Portella, J. Aggregate-Dependent Approach to Formulate and Predict Properties of High-Strength and Very-High-Strength Concrete. J. Mater. Civ. Eng. 2020, 32, 04020053. [Google Scholar] [CrossRef]

- Sohail, M.G.; Wang, B.; Jain, A.; Kahraman, R.; Ozerkan, N.G.; Gencturk, B.; Dawood, M.; Belarbi, A. Advancements in Concrete Mix Designs: High-Performance and Ultrahigh-Performance Concretes from 1970 to 2016. J. Mater. Civ. Eng. 2018, 30, 04017310. [Google Scholar] [CrossRef]

- Popovics, S.; Ujhelyi, J. Contribution to the Concrete Strength versus Water-Cement Ratio Relationship. J. Mater. Civ. Eng. 2008, 20, 459–463. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete, 5th ed.; Prentice Hall: Harlow, UK; New York, NY, USA, 2012; ISBN 978-0-273-75580-7. [Google Scholar]

- Vakhshouri, B.; Nejadi, S. Empirical Models and Design Codes in Prediction of Modulus of Elasticity of Concrete. Front. Struct. Civ. Eng. 2019, 13, 38–48. [Google Scholar] [CrossRef]

- Alfonso, D.; Dugarte, M.; Carrillo, J.; Arteta, C.A. Effect of Aggregate Type on the Elastic Modulus and Compressive Behavior of Concrete: A Case Study in Colombia. Constr. Build. Mater. 2024, 411, 134131. [Google Scholar] [CrossRef]

| Type of CAGs | Abrasion Test (%) L.A. (ASTM C131) | Specific Gravity | Absorption (%) | Unitary Mass [g/cm3] | Aggregate Size [mm] |

|---|---|---|---|---|---|

| Greenschist (GS) | 25.73 | 2.90 | 1.83 | 1.60 | 19.0 |

| Granite marble (GM) | 22.78 | 2.68 | 2.59 | 1.51 | 9.5 |

| Whole pebbles (WPs) | 23.04 | 2.63 | 2.04 | 1.77 | 19.0 |

| Mix Design | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

|---|---|---|---|---|---|---|---|---|

| f’cr (28 days) [MPa] | 56 | 70 | 84 | |||||

| CAG diameter [mm] | GS, 19 | WP, 19 | GM, 9.5 | |||||

| Fineness modulus | 3 | 3 | 3 | |||||

| Volume unity CAGs 1 | 0.72 | 0.72 | 0.65 | |||||

| CAG weight [kg] | 1152 | 1274 | 983.45 | |||||

| W content [L] 2 | 175.0 | 175.0 | 189.8 | |||||

| Slump [mm] [43] | 50–75 | 50–75 | 50–75 | |||||

| w/c ratio 3 | 0.28 | 0.27 | 0.26 | 0.25 | 0.23 | 0.25 | 0.23 | 0.21 |

| Wcm [kg] | 616.27 | 639.10 | 663.68 | 690.22 | 750.24 | 749.50 | 814.68 | 892.27 |

| Ws [kg] | 559.10 | 540.19 | 519.82 | 269.92 | 220.19 | 488.99 | 434.99 | 370.70 |

| SP [%] | 0.8 | 0.8 | 0.8 | |||||

| Wsp [kg] | 4.93 | 5.11 | 5.31 | 1.77 | 19.0 | 6.00 | 6.52 | 7.14 |

| Mix Design | 1 | 2 | 3 |

|---|---|---|---|

| f’cr (28 days) [MPa] | 56 | 70 | 84 |

| CAG diameter [mm] | GM, 9.5 | ||

| Volume Unity CAG 1 | 0.65 | ||

| CAG weight [kg] | 983.45 | ||

| W content [L] 2 | 189.7 | ||

| w/c ratio 3 | 0.32 | 0.27 | 0.23 |

| Wcm [kg] | 585.11 | 693.47 | 814.07 |

| Ws [kg] | 625.56 | 535.78 | 435.86 |

| SP [%] | 1.60 | ||

| Wsp [kg] | 9.36 | 11.10 | 13.03 |

| Mix Design | f’c 14 d [MPa] | Avg. f’c 14 d [MPa] | FT 1 | f’c 21 d [MPa] | Avg. f’c 21 d [MPa] | FT | f’c 28 d [MPa] | Avg. f’c 28 d [MPa] | FT | Exp. f’c 2 28 d [MPa] | % | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 39.2 | 40.3 | 42.2 | 40.6 | 5 | 41.3 | 37.7 | 41.3 | 40.1 | 5 | 39.4 | 30.2 | 36.4 | 35.3 | 5 | 55.2 | 64.1 |

| 2 | 32.8 | 43.8 | 40.2 | 38.9 | 5 | 46.7 | 50.4 | 48.4 | 48.5 | 4 | 52.6 | 54.8 | 54.3 | 53.9 | 3 | 55.2 | 97.7 |

| 3 | 46.3 | 46.2 | 46.0 | 46.2 | 5 | 47.3 | 46.2 | 40.0 | 44.5 | 5 | 53.4 | 52.2 | 57.8 | 54.4 | 3 | 55.2 | 98.7 |

| 4 | 32.0 | 37.5 | 36.2 | 35.2 | 5 | 41.2 | 37.0 | 40.5 | 39.6 | 5 | 43.2 | 52.3 | 46.2 | 47.2 | 5 | 68.9 | 68.5 |

| 5 | 27.3 | 39.1 | 34.0 | 33.5 | 5 | 39.8 | 25.3 | 54.6 | 39.9 | 5 | 50.9 | 44.9 | 50.3 | 48.7 | 5 | 68.9 | 70.6 |

| 6 | 63.5 | 57.2 | 63.1 | 61.3 | 5 | 84.4 | 85.3 | 87.2 | 85.6 | 3 | 88.2 | 84.3 | 84.1 | 85.6 | 4 | 82.7 | 103.4 |

| 7 | 55.6 | 56.6 | 61.3 | 57.8 | 5 | 84.2 | 79.9 | 84.9 | 83.0 | 4 | 89.0 | 84.1 | 82.0 | 85.1 | 4 | 82.7 | 102.8 |

| 8 | 42.8 | 77.3 | 68.1 | 62.7 | 5 | 85.0 | 87.4 | 78.4 | 83.6 | 3 | 84.0 | 80.0 | 88.3 | 84.1 | 4 | 82.7 | 101.6 |

| Standard/Researcher (Ref. for Table 6) | Ec Equation [MPa] | Compressive Strength Range |

|---|---|---|

| ACI (1992) [1] | 3320 × (f’c)0.5 + 6900 | 21 MPa < f’c < 83 MPa |

| AASHTO-LRFD [2] | 0.043 × (wc)1.5 × (f’c)0.5 | Not specified |

| Ahmad and Shah (1985) [3] | 8800 × (f’c)0.325 | f’c < 84 MPa |

| CEB-FIP (1993) (EuroCode2) [4] | 21,500 × αE × (f’c/10)1/3 | f’c < 80 MPa |

| Iravani (1996) [5] | 4700Cca × (f’c)0.5 | 55 MPa < f’c < 125 MPa |

| Norges (1992) [6] | 9500 × (f’c)0.3 | 25 MPa < f’c < 85 MPa |

| Sample | wc | ν | E | E(1) | %E(1) | E(2) | %E(2) | E(3) | %E(3) | E(4) | %E(4) | E(5) | %E(5) | E(6) | %E(6) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (84 MPa) | 1 | 2398 | 0.27 | 36,212 | 37,328 | 3.0% | 46,285 | 21.8% | 37,143 | 2.5% | 43,705 | 17.1% | 35,322 | 2.5% | 35,893 | 0.9% |

| 2 | 2378 | 0.28 | 37,479 | 37,328 | 0.4% | 45,715 | 18.0% | 37,143 | 0.9% | 43,705 | 14.2% | 35,322 | 6.1% | 35,893 | 4.4% | |

| 3 | 2438 | 0.26 | 36,131 | 37,328 | 3.2% | 47,448 | 23.9% | 37,143 | 2.7% | 43,705 | 17.3% | 35,322 | 2.3% | 35,893 | 0.7% | |

| 4 | 2359 | 0.28 | 38,022 | 37,328 | 1.9% | 45,141 | 15.8% | 37,143 | 2.4% | 43,705 | 13.0% | 35,322 | 7.6% | 35,893 | 5.9% | |

| (70 MPa) | 5 | 2376 | 0.28 | 33,763 | 34,677 | 2.6% | 45,647 | 26.0% | 35,006 | 3.5% | 41,128 | 17.9% | 32,245 | 4.7% | 33,982 | 0.6% |

| 6 | 2399 | 0.28 | 32,677 | 34,677 | 5.8% | 42,272 | 22.7% | 35,006 | 6.7% | 41,128 | 20.5% | 32,245 | 1.3% | 33,982 | 3.8% | |

| 7 | 2337 | 0.27 | 33,465 | 34,677 | 3.5% | 40,653 | 17.7% | 35,006 | 4.4% | 41,128 | 18.6% | 32,245 | 3.8% | 33,982 | 1.5% | |

| 8 | 2351 | 0.27 | 34,777 | 34,677 | 0.3% | 41,015 | 15.2% | 35,006 | 0.7% | 41,128 | 15.4% | 32,245 | 7.9% | 33,982 | 2.3% | |

| (56 MPa) | 9 | 2307 | 0.27 | 29,103 | 31,745 | 8.3% | 35,653 | 18.4% | 32,557 | 10.6% | 38,180 | 23.8% | 28,841 | 0.9% | 31,782 | 8.4% |

| 10 | 2385 | 0.22 | 34,279 | 31,745 | 8.0% | 37,473 | 8.5% | 32,557 | 5.3% | 38,180 | 10.2% | 28,841 | 18.9% | 31,782 | 7.9% | |

| 11 | 2335 | 0.23 | 32,854 | 31,745 | 3.5% | 36,309 | 9.5% | 32,557 | 0.9% | 38,180 | 13.9% | 28,841 | 13.9% | 31,782 | 3.4% | |

| 12 | 2360 | 0.24 | 31,183 | 31,745 | 1.8% | 36,881 | 15.5% | 32,557 | 4.2% | 38,180 | 18.3% | 28,841 | 8.1% | 31,782 | 1.9% | |

| avg. wc | 2369 | |||||||||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mattos-Rodríguez, A.; Guzmán, A.; Abudinen, D. Unlocking the Potential of Caribbean Coarse Aggregates for High-Strength Concrete Development. Materials 2025, 18, 2503. https://doi.org/10.3390/ma18112503

Mattos-Rodríguez A, Guzmán A, Abudinen D. Unlocking the Potential of Caribbean Coarse Aggregates for High-Strength Concrete Development. Materials. 2025; 18(11):2503. https://doi.org/10.3390/ma18112503

Chicago/Turabian StyleMattos-Rodríguez, Adriana, Andrés Guzmán, and Daniel Abudinen. 2025. "Unlocking the Potential of Caribbean Coarse Aggregates for High-Strength Concrete Development" Materials 18, no. 11: 2503. https://doi.org/10.3390/ma18112503

APA StyleMattos-Rodríguez, A., Guzmán, A., & Abudinen, D. (2025). Unlocking the Potential of Caribbean Coarse Aggregates for High-Strength Concrete Development. Materials, 18(11), 2503. https://doi.org/10.3390/ma18112503