Photochromic Sensors for Paper Marking

Abstract

1. Introduction

2. Materials and Methods

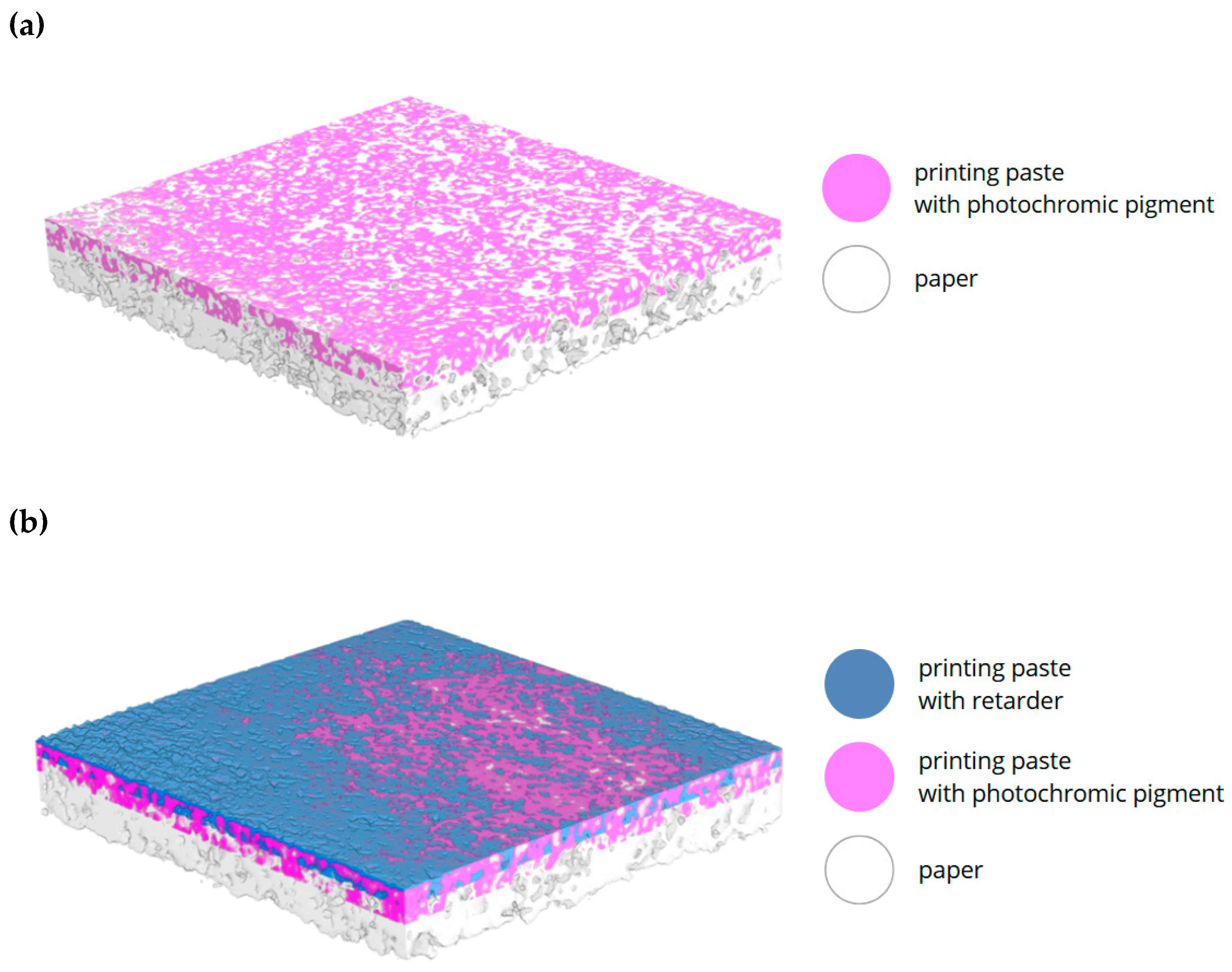

2.1. Preparation of Photochromic Sensors

2.2. Irradiation of Samples

2.3. Light Reflectance Measurements

2.4. Micro-Computed Tomography Scanning

2.5. Raman Spectroscopy Measurements

2.6. Scanning Electron Microscopy Imaging

2.7. The 2D/3D UVA Dose Distribution Measurements

3. Results and Discussion

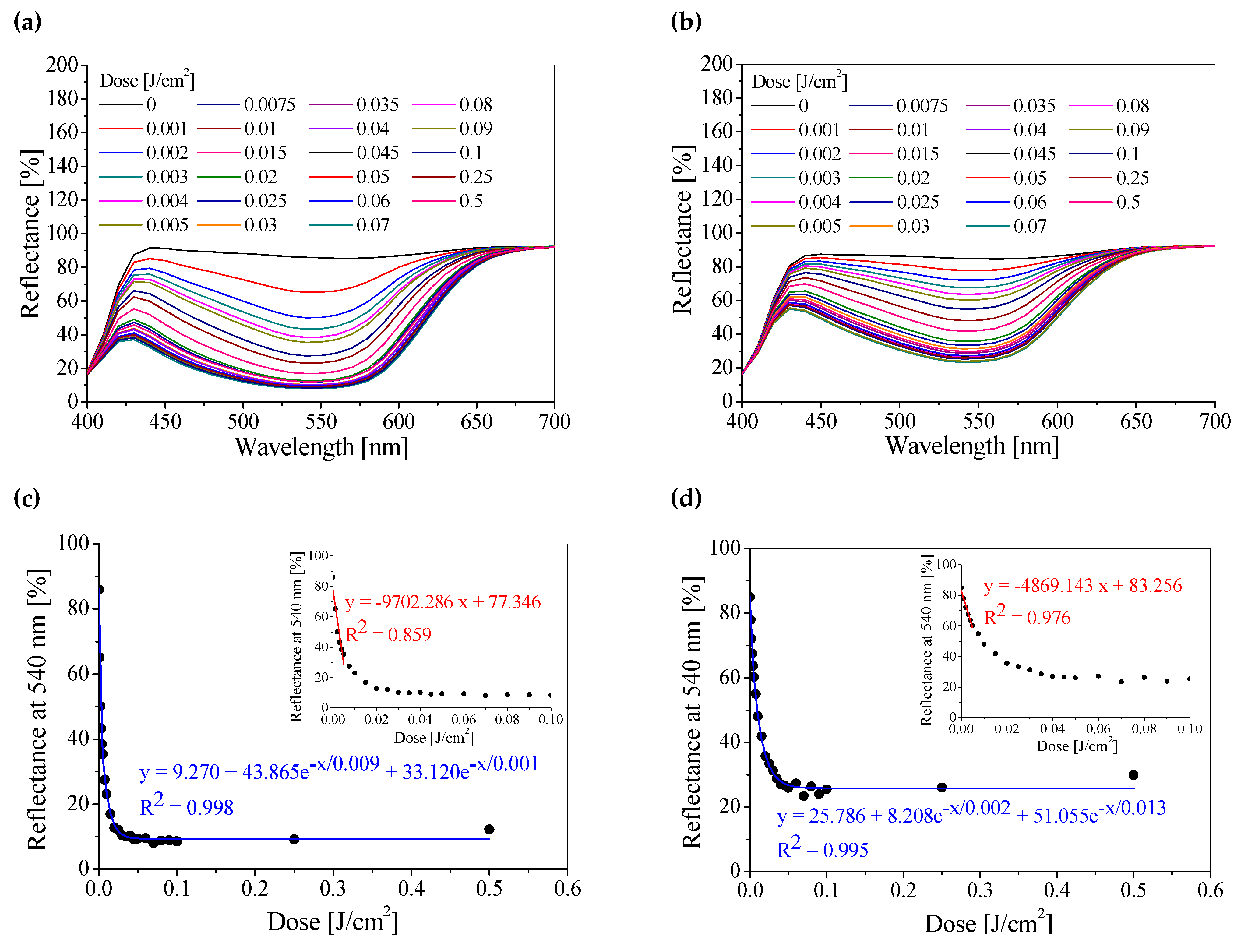

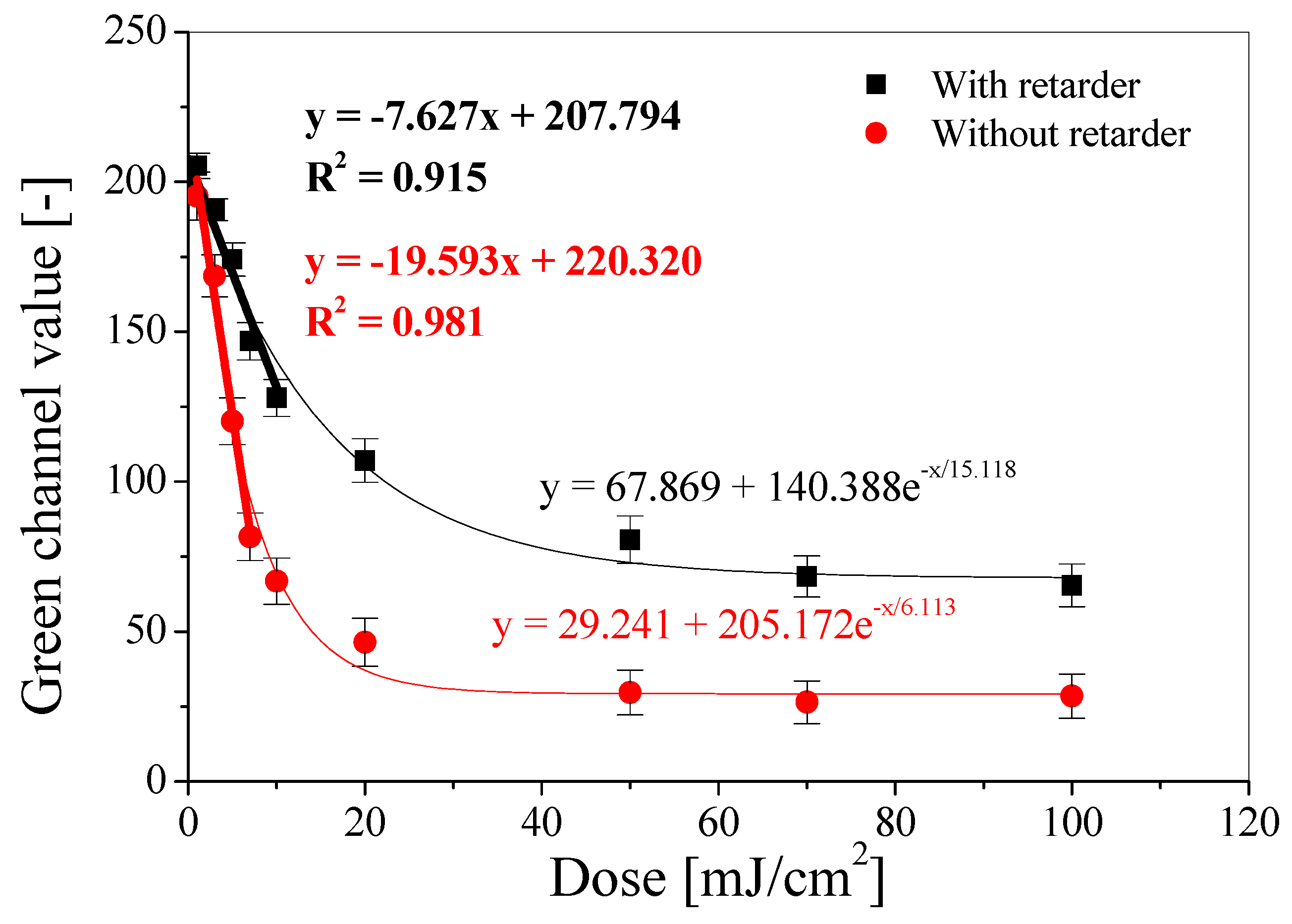

3.1. UV Dose Response of Samples

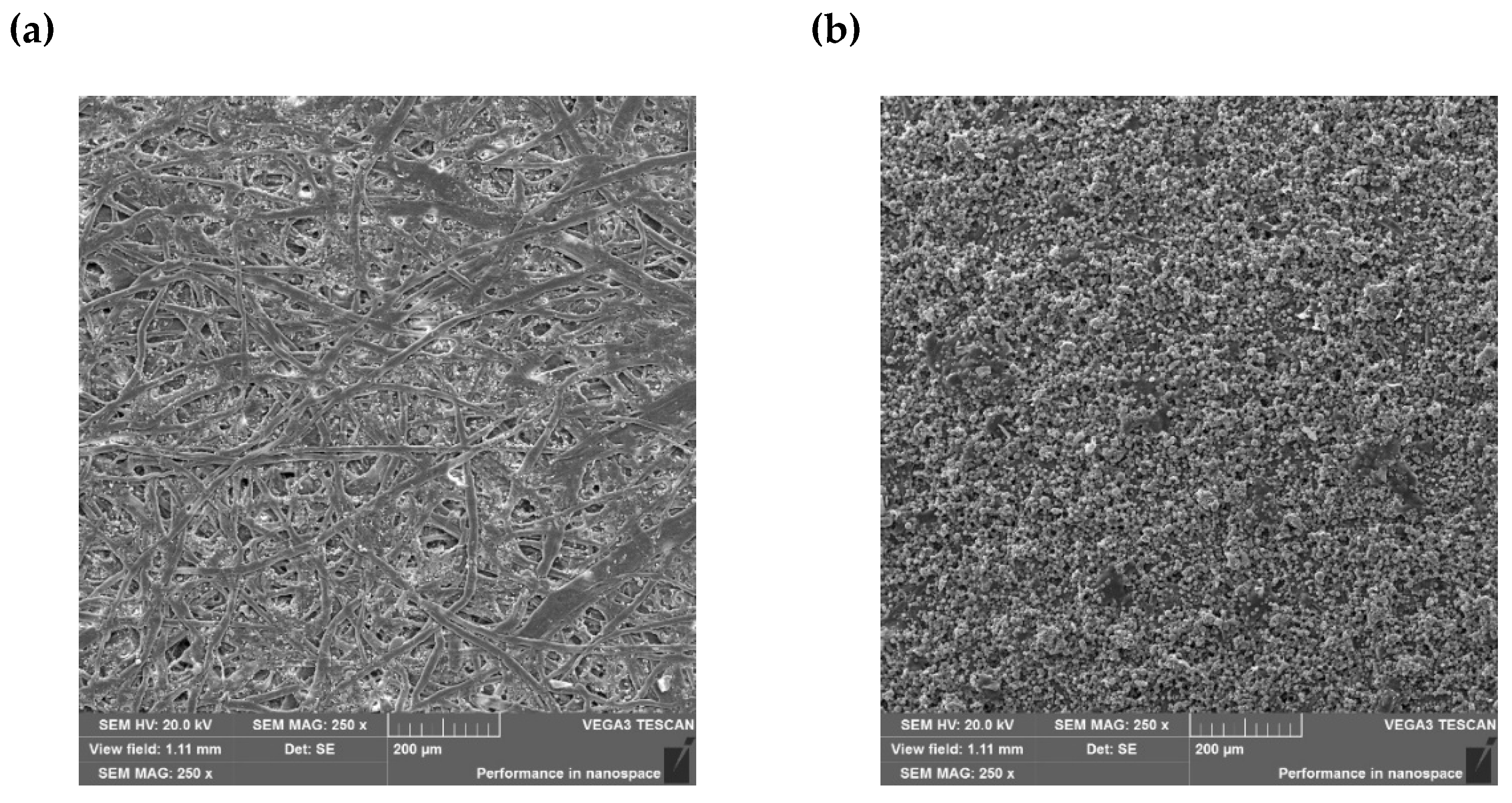

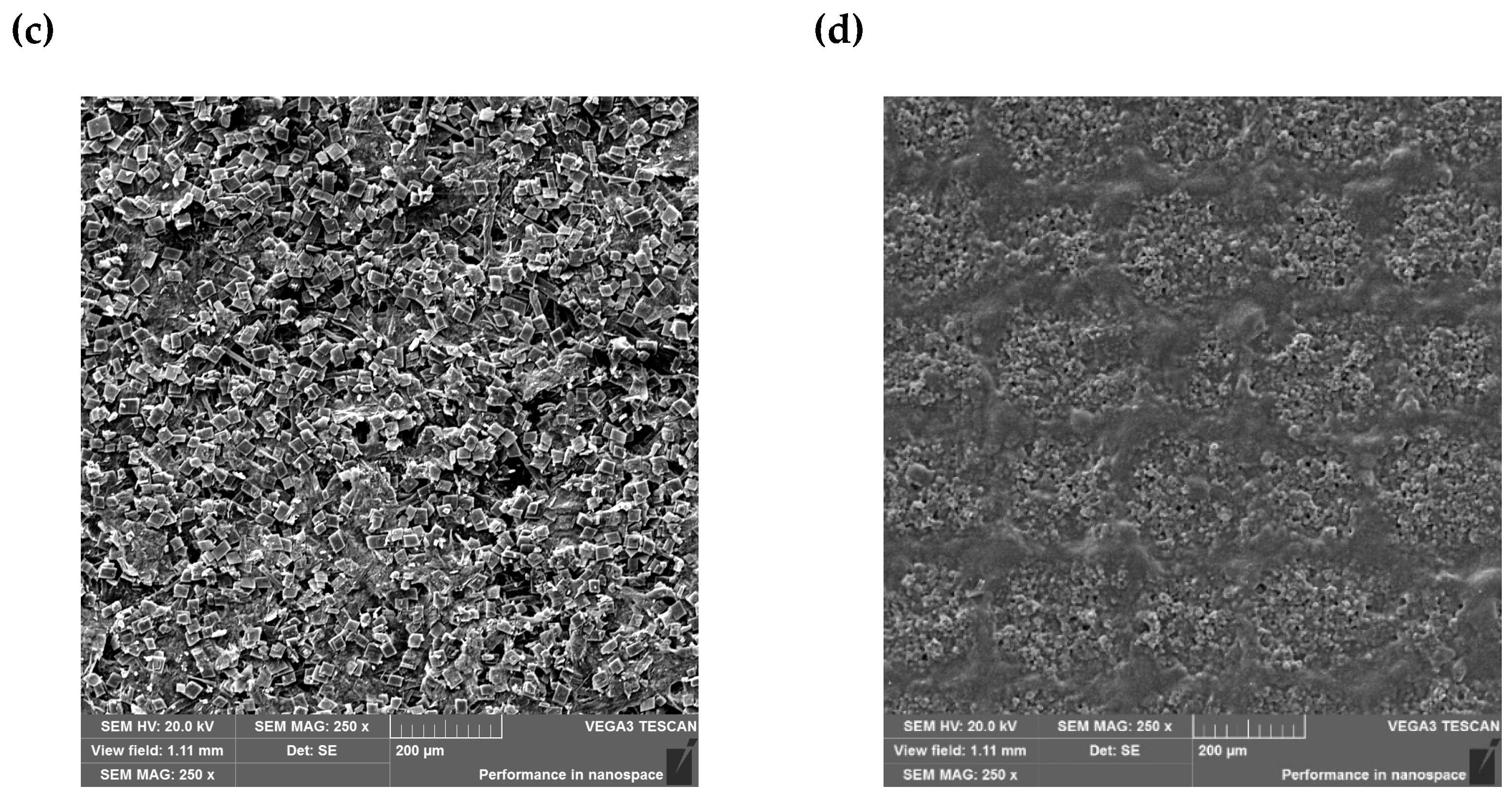

3.2. Morphology of Sensors

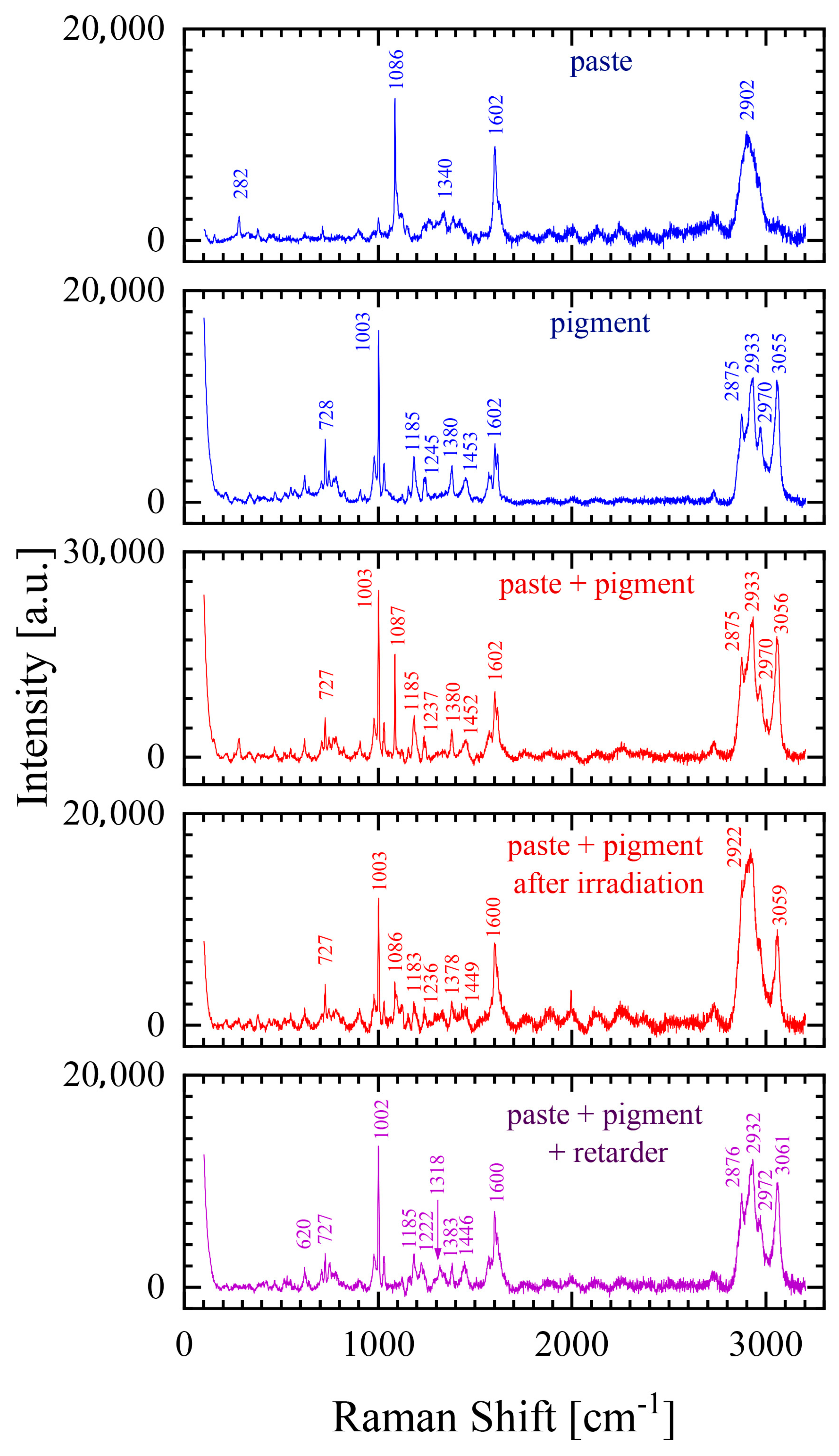

3.3. Raman Spectroscopy Analysis

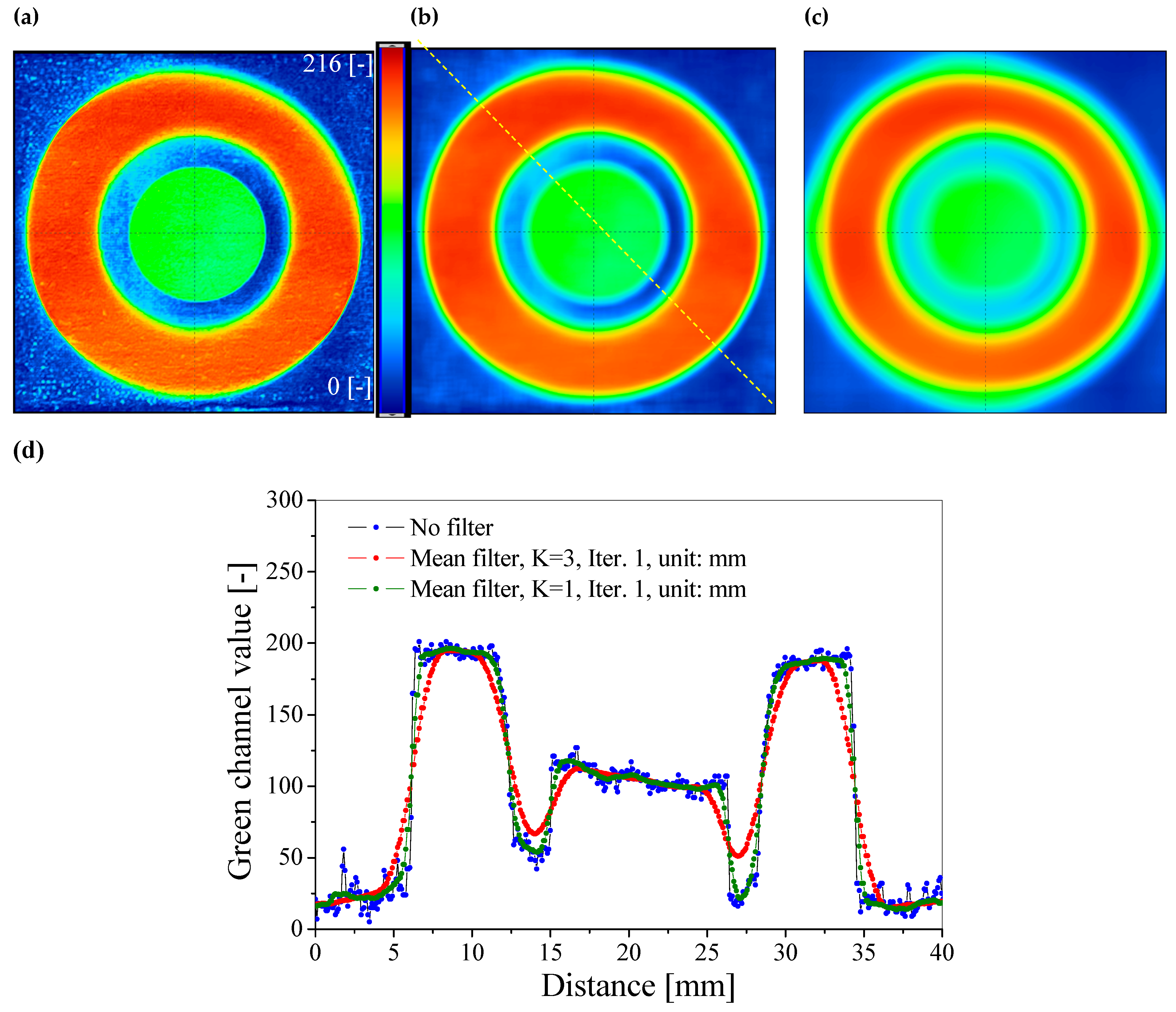

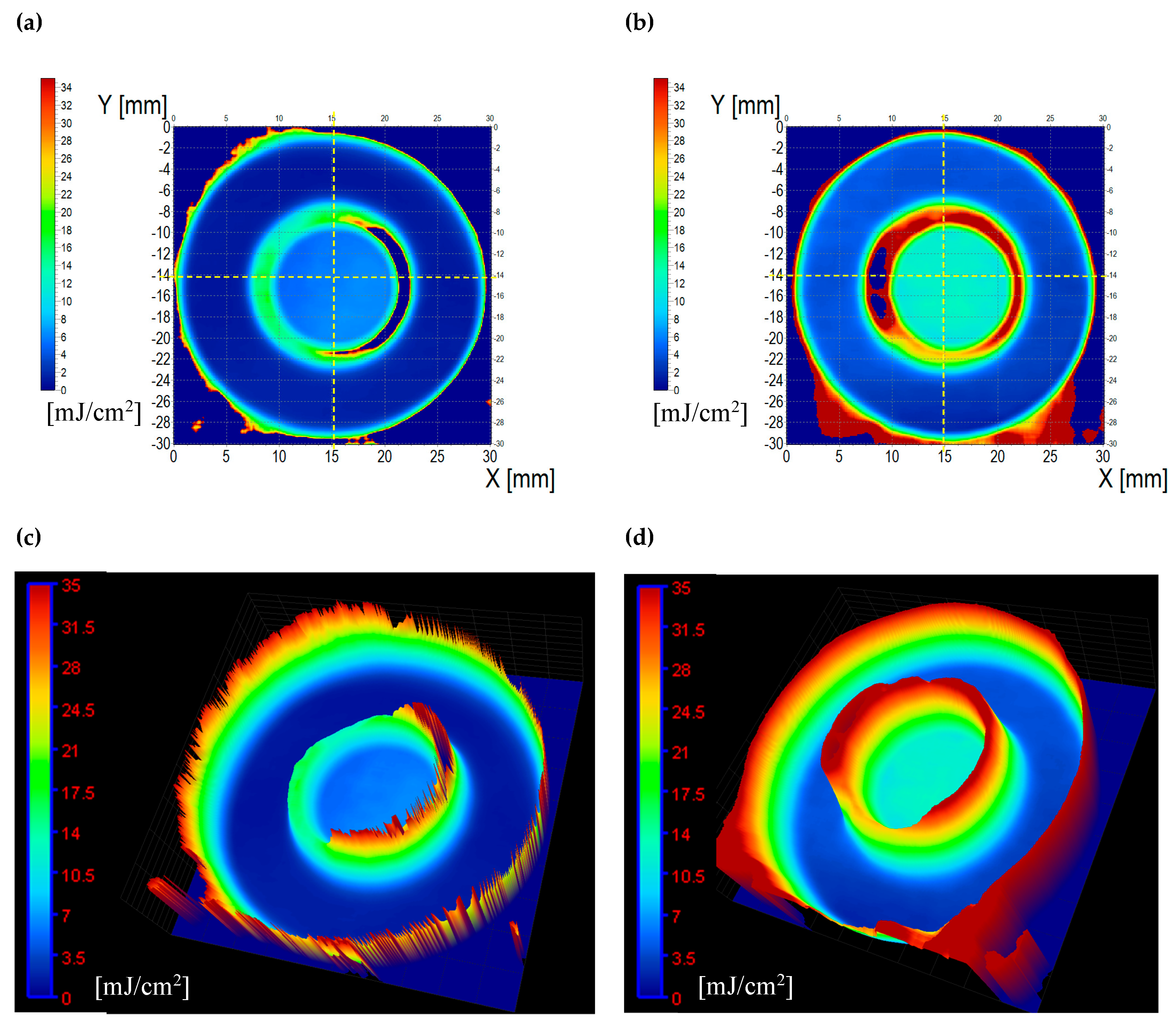

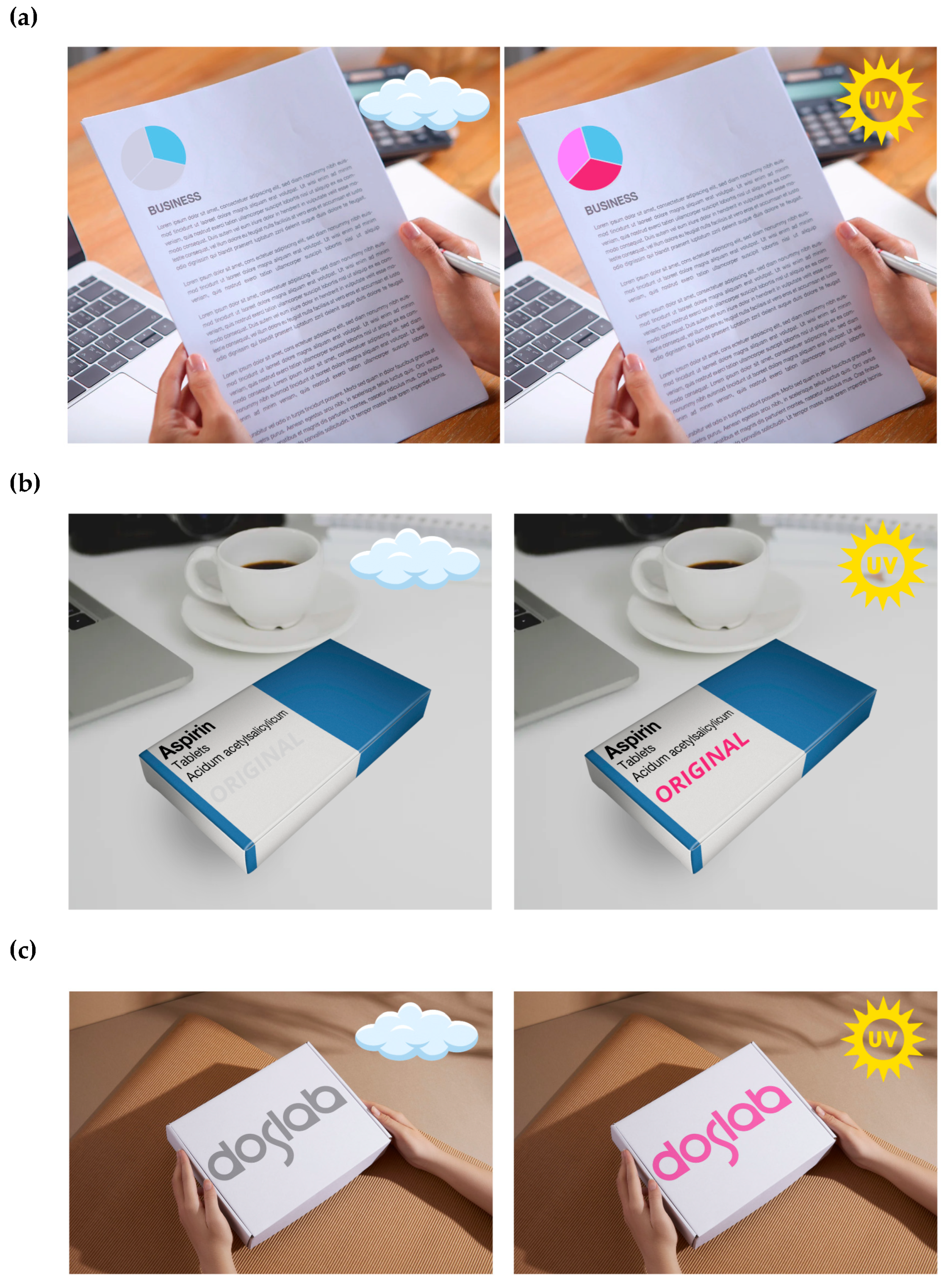

3.4. Proposition of Applications

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sayed, M.M.K.E. Security printing methods from a digital printing perspective. Int. Des. J. 2021, 11, 497–512. [Google Scholar]

- Bozhkova, T.; Spiridonov, I.; Shterev, K. Overview of security printing types and trends in its future development. Bulg. Chem. Commun. 2017, 49, 195–201. [Google Scholar]

- Jakucewicz, S.; Khadzhynova, S. Methods of Securing Documents; Wydawnictwo Politechniki Łódzkiej: Lodz, Poland, 2020. (In Polish) [Google Scholar]

- Becidyan, N. Luminescent pigments in security applications. Color Res. Appl. 1995, 20, 124–130. [Google Scholar] [CrossRef]

- Singh, A.K.; Singh, S.; Gupta, B. Highly-efficient, Chemically-stable, UV/blue Light Excitable Biluminescent Security Ink to Combat Counterfeiting. ACS Appl. Mater. Interfaces 2018, 10, 44570–44575. [Google Scholar] [CrossRef] [PubMed]

- Jangra, V. Security Printing: Innovative Technologies with Comprehensive Approach as an Anti-Counterfeiting Tool. Int. J. Sci. Res. Dev. 2016, 4, 690–693. [Google Scholar]

- Van der Horst, F.; Snell, J.; Theeuwes, J. Finding counterfeited banknotes: The roles of vision and touch. Cogn. Res. Princ. Implic. 2020, 5, 2–14. [Google Scholar] [CrossRef] [PubMed]

- Ramos-de-Campos, J.A.; Gamob, J.; Sorianoa, C.; Varelab, P.; Péreza, E. Laser engraving of paper and polymeric materials for tactile detection. In Proceedings of the XVII International Symposium on Gas Flow, Chemical Lasers, and High-Power Lasers (Proc. SPIE 7131), Lisboa, Portugal, 21 April 2009. [Google Scholar]

- Mahovic Poljacek, S.; Strižic Jakovljevic, M.; Tomašegovic, T. Photochromic Responses and Stability of Functional Inks Applied on Sustainable Packaging Materials. Micro 2024, 4, 33–48. [Google Scholar] [CrossRef]

- Khattab, T.A.; El-Naggar, M.E.; Abdelrahman, M.S.; Aldalbahi, A.; Hatshan, M.R. Facile development of photochromic cellulose acetate transparent nanocomposite film immobilized with lanthanide doped pigment: Ultraviolet blocking, superhydrophobic, and antimicrobial activity. Luminescence 2021, 36, 543–555. [Google Scholar] [CrossRef] [PubMed]

- Abdelhameed, M.M.; Attia, Y.A.; Abdelrahman, M.S.; Khattab, T.A. Photochromic and fluorescent ink using photoluminescent strontium aluminate pigment and screen printing towards anticounterfeiting documents. Luminescence 2021, 36, 865–874. [Google Scholar] [CrossRef] [PubMed]

- King, L.; Xiang, F.; Swaminathan, A.; Lucas, R.M. Measuring sun exposure in epidemiological studies: Matching the method to the research question. J. Photochem. Photobiol. B Biol. 2015, 153, 373–379. [Google Scholar] [CrossRef] [PubMed]

- ISO/CIE 11664-4; Colorimetry—Part 4: CIE 1976 L*a*b* Colour Space. CIE Central Bureau: Vienna, Austria, 2019.

- Jaszczak-Kuligowska, M.; Sąsiadek-Andrzejczak, E.; Kozicki, M. Elastic TTC–PVA gel dosimeters for personal UV exposure measurements. Measurement 2024, 228, 114332. [Google Scholar] [CrossRef]

- Kozicki, M.; Maras, P.; Karwowski, A.C. Software for 3D radiotherapy dosimetry. Validation. Phys. Med. Biol. 2014, 59, 4111–4136. [Google Scholar] [CrossRef] [PubMed]

- Wiley, J.H.; Atalla, R.H. Band assignments in the Raman spectra of celluloses. Carbohydr. Res. 1987, 160, 113–129. [Google Scholar] [CrossRef]

- Dudek, M.; Sąsiadek-Andrzejczak, E.; Jaszczak-Kuligowska, M.; Rokita, B.; Kozicki, M. The Surface Modification of Papers Using Laser Processing towards Applications. Materials 2023, 16, 6691. [Google Scholar]

- Lambert, J.B.; Shurvell, H.F.; Lightner, D.A.; Cooks, R.G. Introduction to Organic Spectroscopy; MacMillan Publishing Company: New York, NY, USA, 1987. [Google Scholar]

- Aubard, J.; Maurel, F.; Buntinx, G.; Guglielmetti, R.; Levi, G. Picosecond Time-Resolved Resonance Raman Spectroscopy and Vibrational Analysis in Spirooxazine Photochromism. Mol. Cryst. Liq. Cryst. Sci. Technology. Sect. A 2000, 345, 203–208. [Google Scholar] [CrossRef]

- Wang, J.-L.; Zhao, R.; Dai, J.-L.; Jia, P.-K.; Yin, B.-W.; Wang, H.-G.; Xie, B.-B. A different photochromic mechanism of spirooxadiazine: Electronic structure calculations and nonadiabatic dynamics simulations. Dye. Pigment. 2024, 230, 112332. [Google Scholar] [CrossRef]

| Dose [J/cm2] | Photograph | CIELab Analysis | ||

|---|---|---|---|---|

| L* | a* | b* | ||

| Photochromic paper sensor | ||||

| 0 |  | 94.69 | 0.02 | 0.17 |

| 0.001 |  | 88.06 | 9.74 | −5.34 |

| 0.01 |  | 66.71 | 37.20 | −16.73 |

| 0.1 |  | 49.70 | 49.46 | −16.21 |

| Photochromic paper sensor with retarder | ||||

| 0 |  | 94.22 | −0.44 | 2.50 |

| 0.001 |  | 92.11 | 2.75 | 0.59 |

| 0.01 |  | 80.87 | 18.35 | −7.38 |

| 0.1 |  | 67.48 | 33.36 | −12.52 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sąsiadek-Andrzejczak, E.; Jaszczak-Kuligowska, M.; Dudek, M.; Puszkarz, A.K.; Kozicki, M. Photochromic Sensors for Paper Marking. Materials 2025, 18, 2501. https://doi.org/10.3390/ma18112501

Sąsiadek-Andrzejczak E, Jaszczak-Kuligowska M, Dudek M, Puszkarz AK, Kozicki M. Photochromic Sensors for Paper Marking. Materials. 2025; 18(11):2501. https://doi.org/10.3390/ma18112501

Chicago/Turabian StyleSąsiadek-Andrzejczak, Elżbieta, Malwina Jaszczak-Kuligowska, Mariusz Dudek, Adam K. Puszkarz, and Marek Kozicki. 2025. "Photochromic Sensors for Paper Marking" Materials 18, no. 11: 2501. https://doi.org/10.3390/ma18112501

APA StyleSąsiadek-Andrzejczak, E., Jaszczak-Kuligowska, M., Dudek, M., Puszkarz, A. K., & Kozicki, M. (2025). Photochromic Sensors for Paper Marking. Materials, 18(11), 2501. https://doi.org/10.3390/ma18112501