Fatigue Life Anisotropy of API 5L X42 Pipeline Steel in Axial Force-Controlled Tests

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

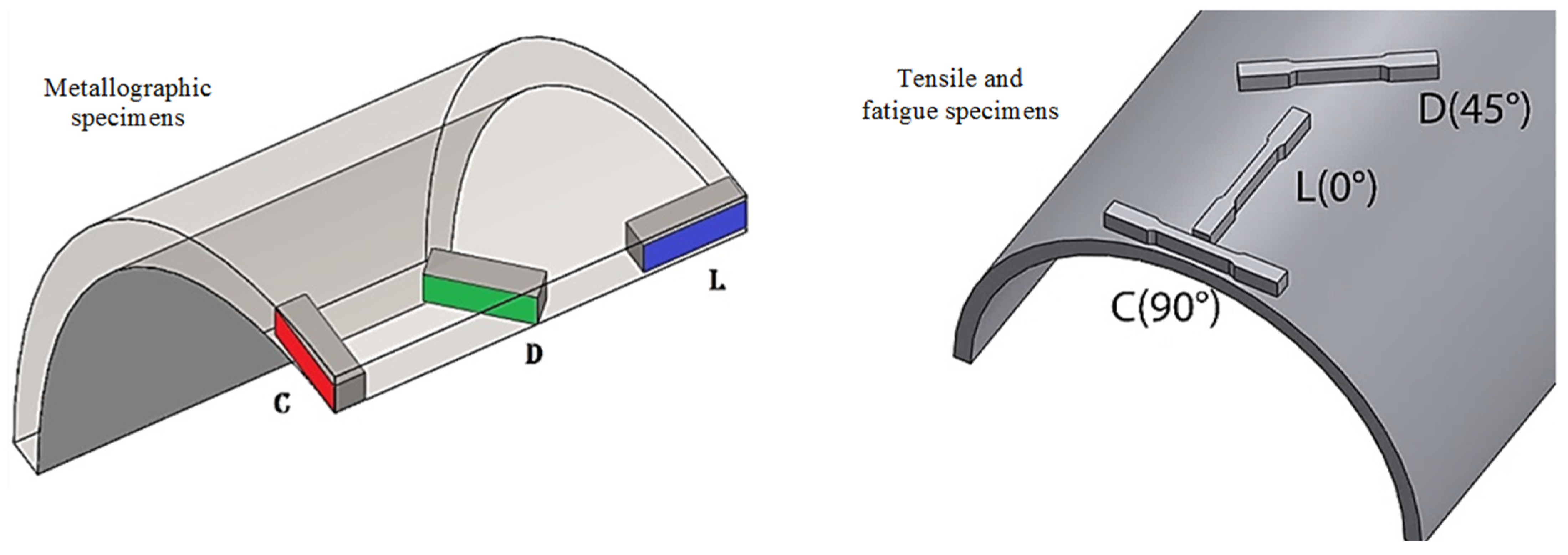

2.2. Microstructural Examination

2.3. Mechanical Tests

2.4. Force-Controlled Fatigue Tests

3. Results and Discussion

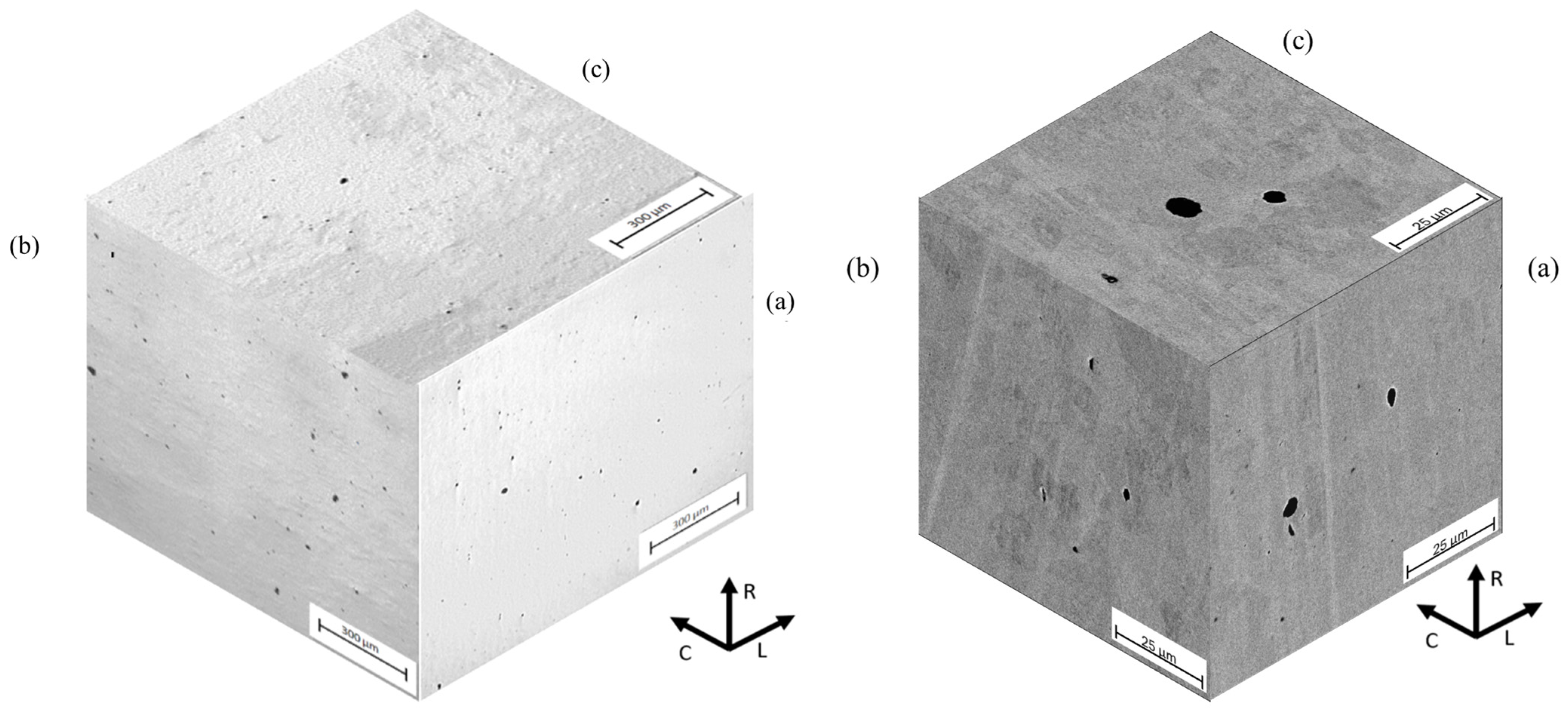

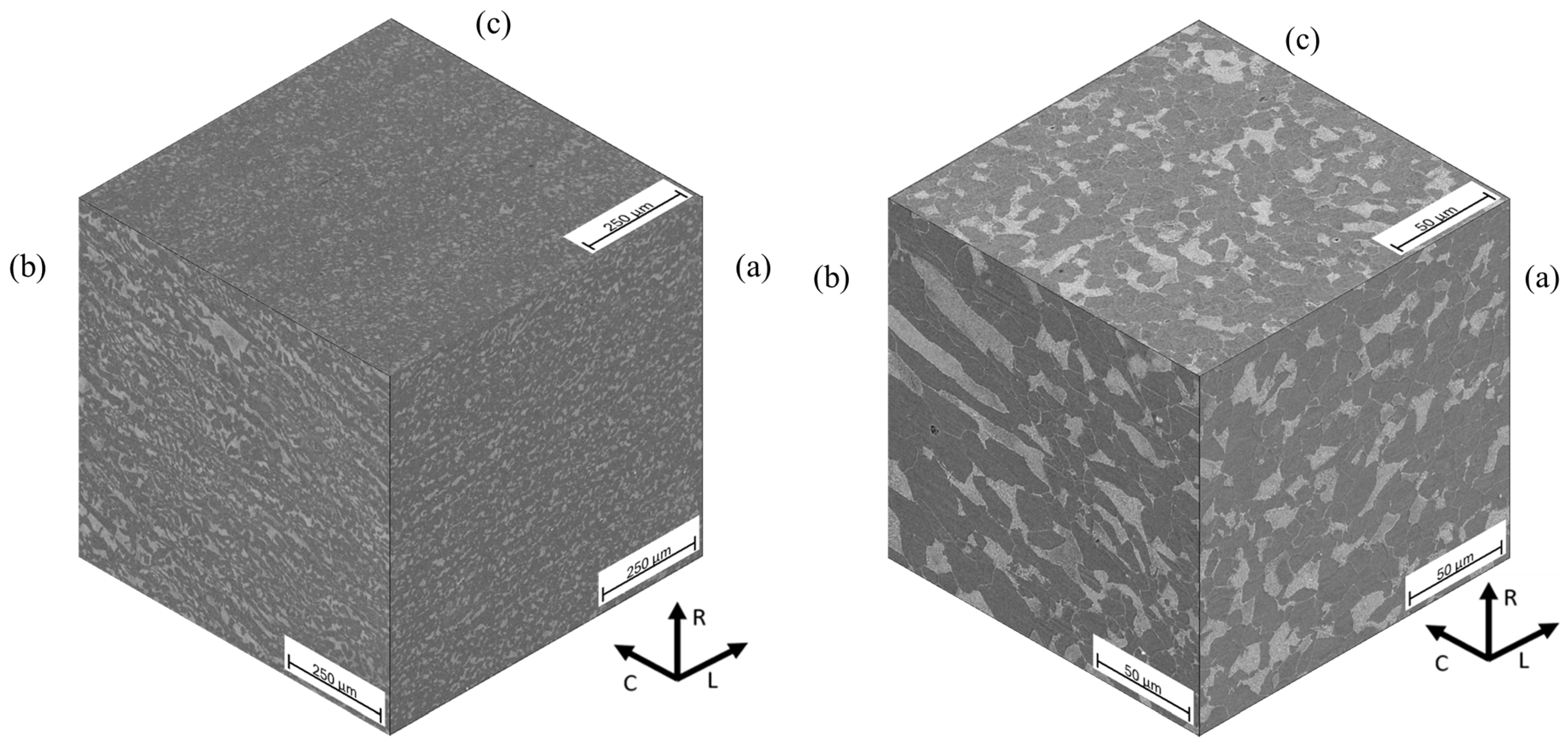

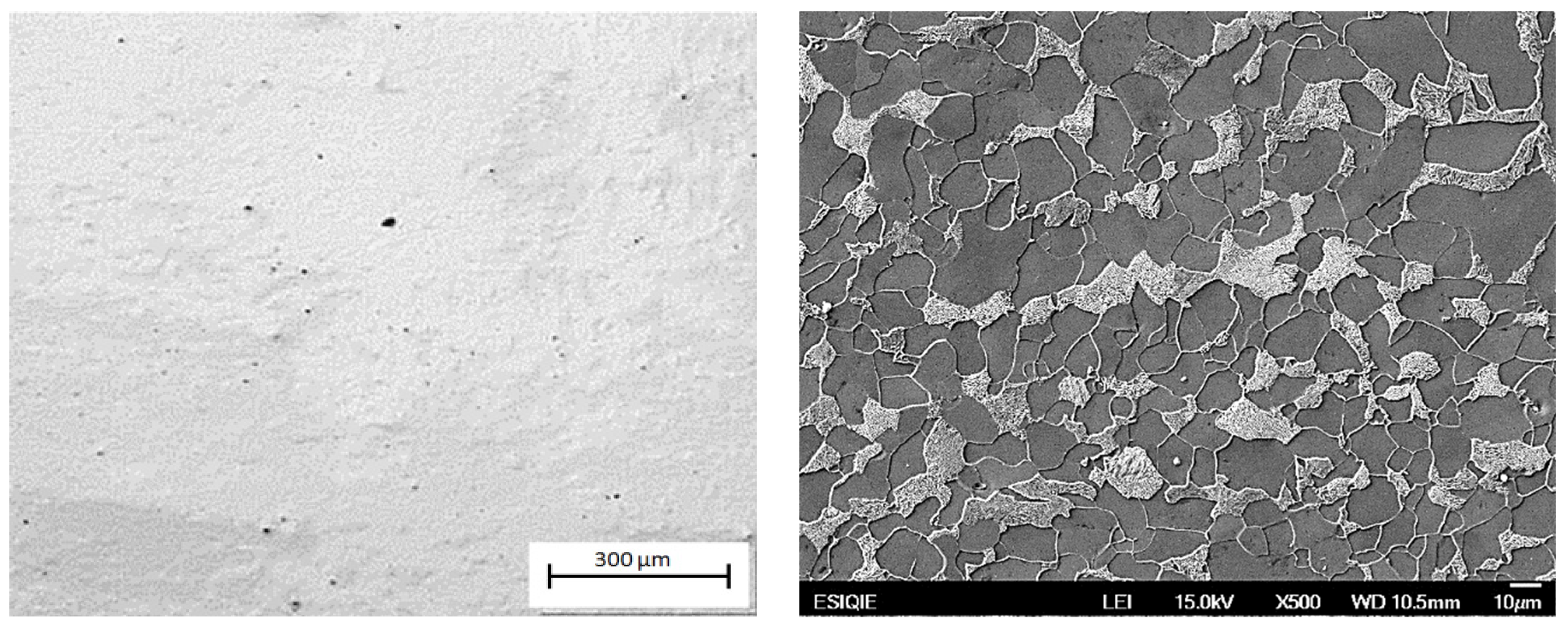

3.1. Metallographic Examination

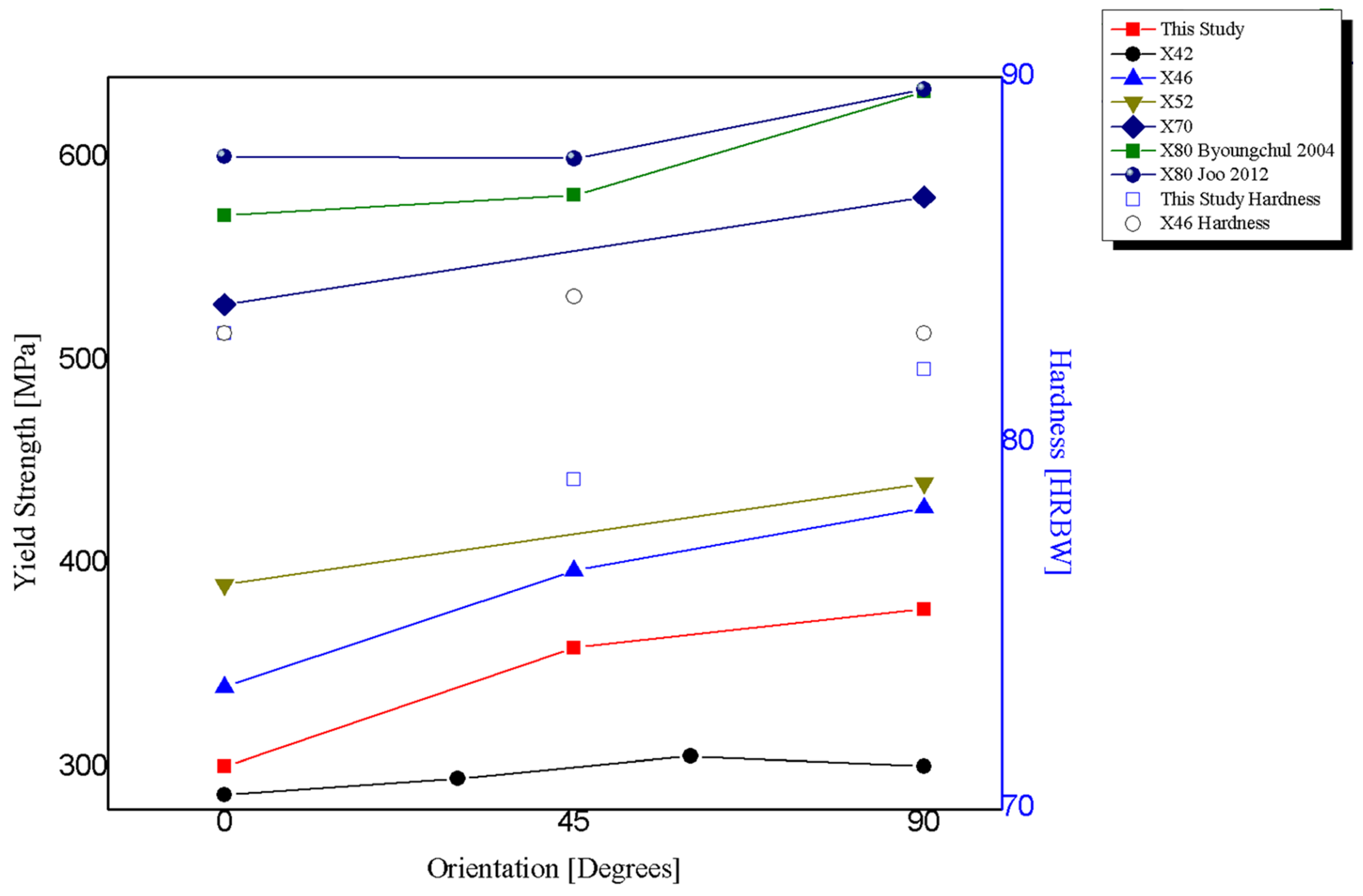

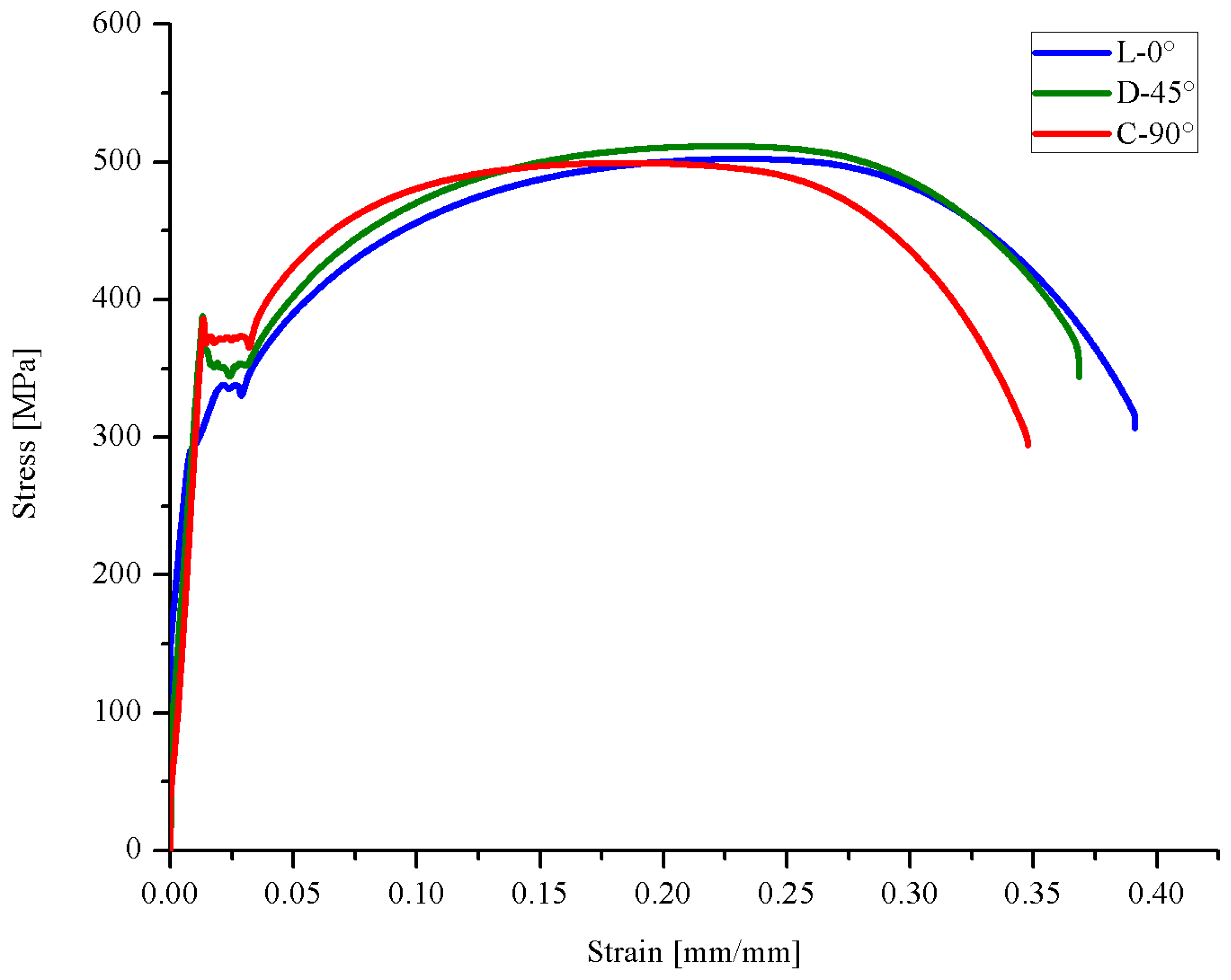

3.2. Mechanical Properties

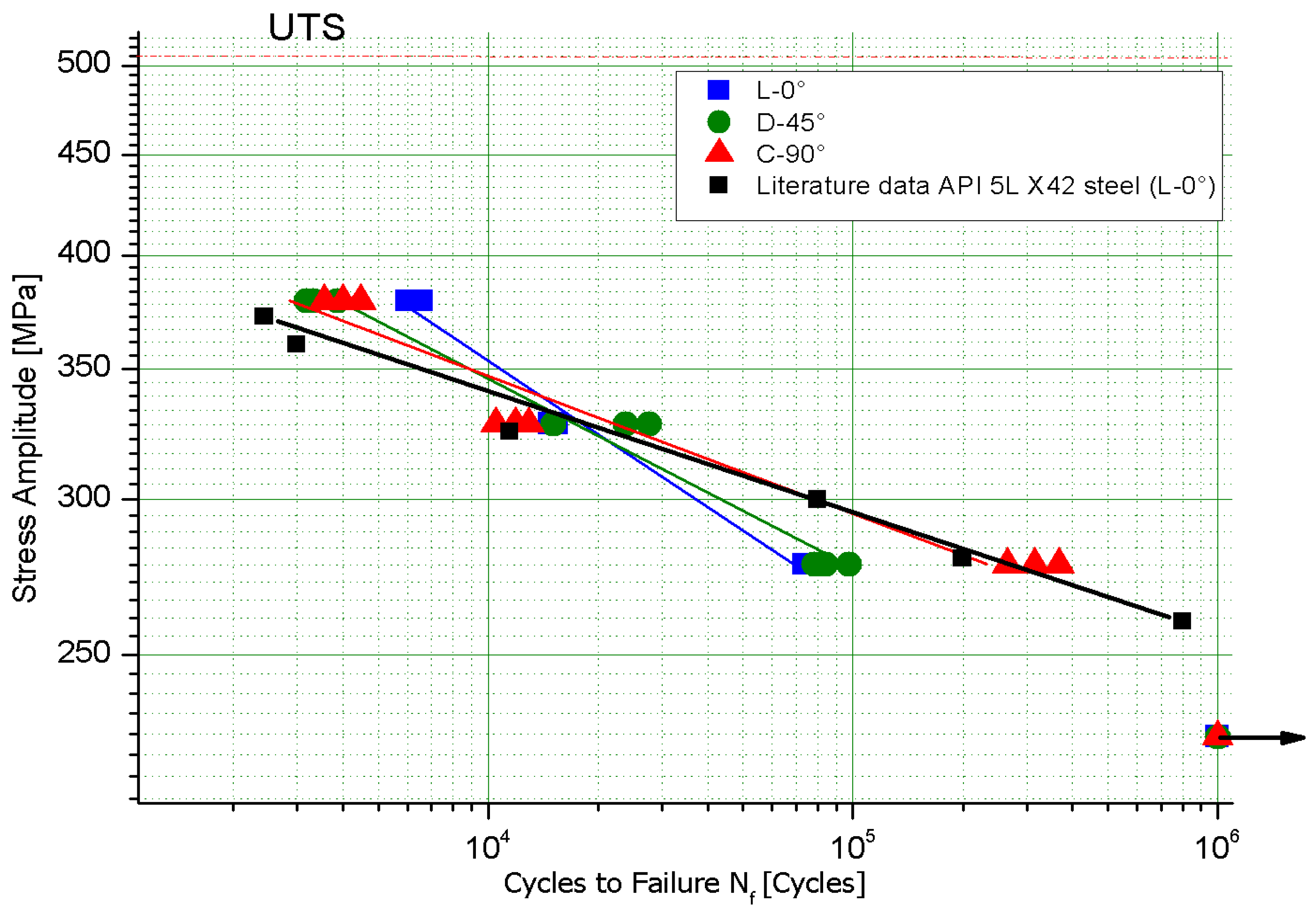

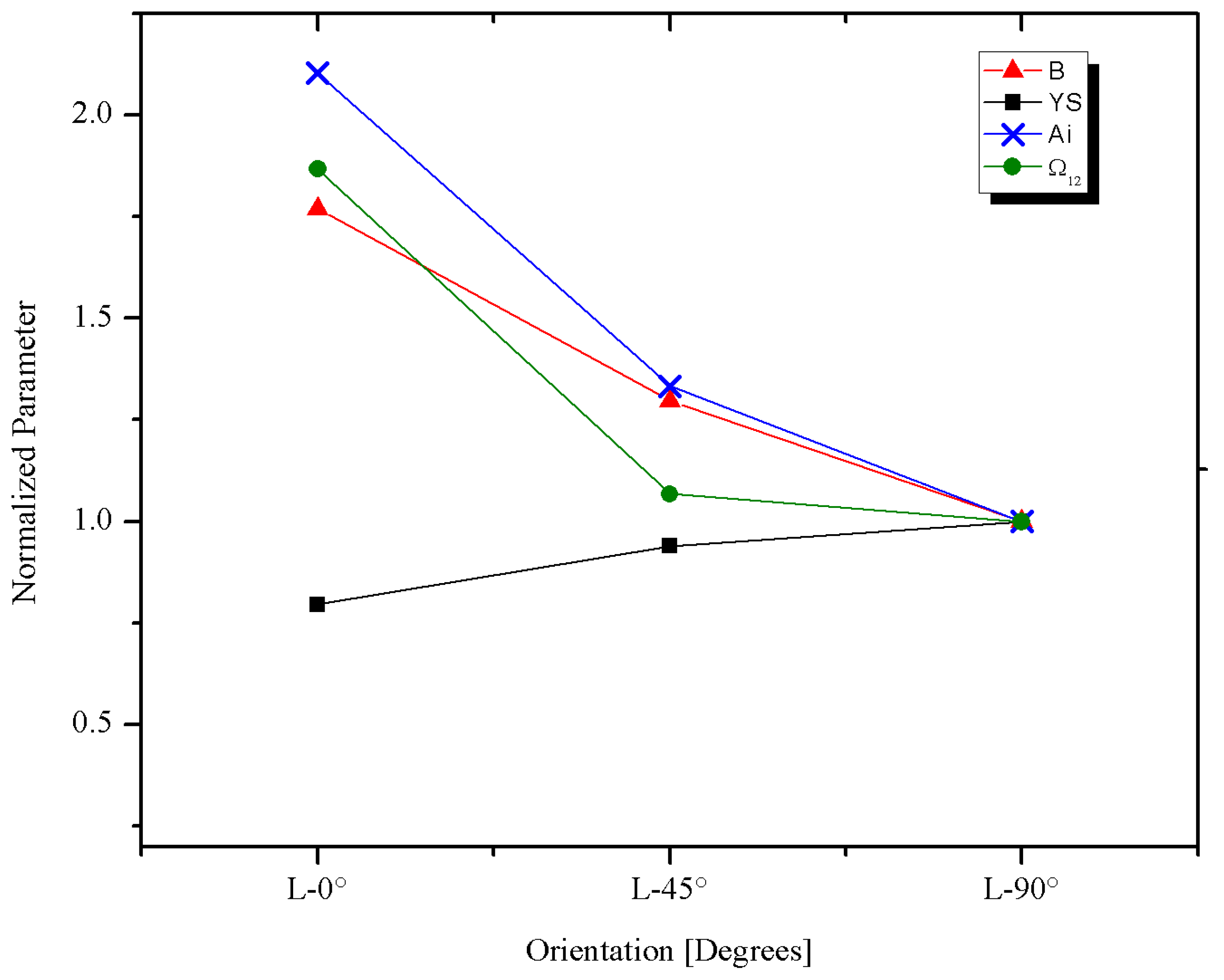

3.3. Fatigue Tests Results and Analysis

4. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations, Symbols, and Definitions

| A | Strength fatigue coefficient |

| Ai | Banding degree |

| API | American Petroleum Institute |

| ASTM | American Society for Testing and Materials |

| B | Fatigue strength exponent |

| FSW | Friction Stir Welding |

| HRBW | Hardness Rockwell B |

| ID | Identification |

| K | Ramberg-Osgood Strength Coefficient |

| n | Ramberg-Osgood Strain Hardening Constant |

| Nf | Number of cycles to failure |

| R | Stress ratio |

| RD | Rolling direction |

| S | Maximum value of constant amplitude cyclic stress |

| UOE | U-ing, O-ing, and Expanding process |

| UTS | Ultimate Tensile Strength |

| YS | Yield Strength |

| Ω12 | Microstructural orientation parameter |

References

- González-Velázquez, J.L. Capítulo 2- Diseño y construcción de ductos marinos de conducción de hidrocarburos. In Ingeniería de Ductos de Transporte de Hidrocarburos; González-Velázquez, J.L., Ed.; Baker & Jules: Tacoma, WA, USA, 2020; pp. 95–180. [Google Scholar]

- ASME B31.8; Gas Transmission and Distribution Piping Systems. The American Society of Mechanical Engineers: New York, NY, USA, 2021. Available online: https://www.asme.org/codes-standards/find-codes-standards/b31-8-gas-transmission-distribution-piping-systems (accessed on 12 November 2024).

- ASME B31.4; Pipeline Transportation Systems for Liquids and Slurries. The American Society of Mechanical Engineers: New York, NY, USA, 2019. Available online: https://www.asme.org/codes-standards/find-codes-standards/b31-4-pipeline-transportation-systems-liquids-slurries (accessed on 12 November 2024).

- DNV-OS-F101; Offshore Standard, SUBMARINE PIPELINE SYSTEMS. Det Norske Veritas: Byrum, Norway, 2005. Available online: https://rules.dnv.com/docs/pdf/dnvpm/codes/docs/2017-10/DNV-OS-F101.pdf (accessed on 12 November 2024).

- DNVGL-OS-C101; Offshore Standard, Design of Offshore Steel Structures, General-LRFD Method. Det Norske Veritas: Byrum, Norway, 2015. Available online: https://www.dnv.com/news/dnv-rules-and-standards-for-offshore-units-july-2023-edition-245184 (accessed on 12 November 2024).

- Mikael, W. Braestrup, Chapter 6 Design. In Design and Installation of Marine Pipelines; Blackwell Science Ltd.: Oxford, UK, 2005; Available online: https://www.wiley.com/en-us/Design+and+Installation+of+Marine+Pipelines-p-9781405148740 (accessed on 12 November 2024).

- Kim, K.; Bae, J.-H. Metallurgical and process parameters for commercial production of high toughness API–X80 grade hot rolled strips. In Proceedings of the Biennial International Pipeline Conference, IPC, Calgary, AB, Canada, 29 September–3 October 2008; Volume 3, pp. 167–173. [Google Scholar] [CrossRef]

- Seo, D.H.; Song, W.H.; Ahn, S.S.; Kim, C.M.; Yoo, J.Y. Microstructure and Mechanical Properties of API–X80/X100 Grade Plates and Pipes. In Proceedings of the Seventeenth International Offshore and Polar Engineering Conference, Lisboa, Portugal, 1–6 July 2007; Volume 12, pp. 20–27. [Google Scholar]

- Nafisi, S.; Arafin, M.; Collins, L.; Szpunar, J. Texture and mechanical properties of API X100 steel manufactured under various thermomechanical cycles. Mater. Sci. Eng. A 2012, 531, 2–11. [Google Scholar] [CrossRef]

- Kichkina, A.A.; Matrosov, M.Y.; Efron, L.I.; Klyukvin, M.B.; Golovanov, A.V. Effect of structural anisotropy of ferrite-bainite pipe steel on mechanical properties in tensile and impact bending tests. Metallurgist 2011, 54, 808–816. [Google Scholar] [CrossRef]

- Inagaki, H.; Kurihara, K.; Kozasu, I. Influence of crystallographic texture on the strength and toughness of the controlled rolled high tensile strength steel. Iron Steel Inst. Jpn. 1975, 61, 991–1011. [Google Scholar] [CrossRef][Green Version]

- Ghosh, A.; Modak, P.; Dutta, R.; Chakrabarti, D. Effect of MnS inclusion and crystallographic texture on anisotropy in Charpy impact toughness of low carbon ferritic steel. Mater. Sci. Eng. A 2016, 654, 298–308. [Google Scholar] [CrossRef]

- Joo, M.S.; Suh, D.-W.; Bae, J.H.; JBhadeshia, H. Role of delamination and crystallography on anisotropy of Charpy toughness in API X80 steel. Mater. Sci. Eng. A 2012, 546, 314–322. [Google Scholar] [CrossRef]

- Joo, M.S.; Suh, D.-W.; Bae, J.H.; Mouriño, S.N. Experiments to separate the effect of texture on anisotropy of pipeline steel. Mater. Sci. Eng. A 2012, 556, 601–606. [Google Scholar] [CrossRef]

- Zong, C.; Zhu, G.; Mao, W. Effect of crystallographic texture on the anisotropy of Charpy impact behaviour in pipeline steel. Mater. Sci. Eng. A 2013, 563, 1–7. [Google Scholar] [CrossRef]

- Brozzo, P.; Buzzichelli, G. Effect of plastic anisotropy on the occurrence of separations on fracture surfaces of hot rolled steel specimens. Scr. Metall. 1976, 10, 235–240. [Google Scholar] [CrossRef]

- Chae, D.; Koss, D.; Wilson, A.; Howell, P. The effect of microstructural banding on failure initiation of HY-100 steel. Met. Mater. Trans. A 2000, 31, 995–1005. [Google Scholar] [CrossRef]

- Joo, M.S.; Suh, D.; Bae, J. Toughness anisotropy in X70 and X80 line-pipe steels. Mater. Sci. Technol. 2014, 30, 439–446. [Google Scholar] [CrossRef]

- Fegredo, D.; Faucher, B.; Shehata, M. Strength of Metals and Alloys. In Influence of Inclusion Content, Texture and Microstructure on the Toughness Anisotropy of Low Carbon Steels; Pergamon Press: Oxford, UK, 1985; Volume 2, pp. 1127–1132. [Google Scholar]

- Baczynski, G.J.; Jonas, J.J.; Collins, L.E. The influence of rolling practice on notch toughness and texture development in high-strength line-pipe. Met. Mater. Trans. A 1999, 30, 3045–3054. [Google Scholar] [CrossRef]

- Sang, Y.; Hwang, B.; Lee, S.; Kim, N.J. Correlation of microstructure and Charpy impact properties in API X70 and X80 line-pipe steels. Mater. Sci. Eng. A 2007, 458, 281–289. [Google Scholar] [CrossRef]

- Garwood, S.J. The effect of temperature, orientation and constraint on the toughness of A 533 B Class I steel. In Application of Fracture Mechanics to Materials and Structures; Martinus Nijhoff Publishers: Leiden, The Netherlands, 1984; Volume 1, pp. 939–950. [Google Scholar] [CrossRef]

- Byoungchul, H.; Yang, G.K.; Sunghak, L.; Young, M.K.; Nack, J.K.; Jang, Y.J. Effective grain size and Charpy impact properties of high toughness X70 pipeline steels. Met. Mater. Trans. A 2004, 36A, 2107–2114. [Google Scholar] [CrossRef]

- Yang, X.-L.; Xu, Y.-B.; Tan, X.-D.; Wu, D. Relationships among crystallographic texture, fracture behaviour and Charpy impact toughness in API X100 pipe-line steel. Mater. Sci. Eng. A 2015, 641, 96–106. [Google Scholar] [CrossRef]

- Beltran-Zuñiga, M.A.; González-Velázquez, J.L.; Rivas-López, D.I.; Dorantes-Rosales, H.J.; Hernández-Santiago, F. Effect of microstructure and crystallographic texture on the toughness anisotropy of API 5L X46 steel. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 749–761. [Google Scholar] [CrossRef]

- Ju, J.-B.; Lee, J.-S.; Jang, J.-I. Fracture toughness anisotropy in API steel line-pipe. Mater. Lett. 2007, 61, 5178–5180. [Google Scholar] [CrossRef]

- Sang, Y.S.; Byoungchul, H.; Sangho, K.; Sunghak, L. Fracture toughness analysis in transition temperature region of API X70 pipeline steels. Mater. Sci. Eng. A 2006, 429, 196–204. [Google Scholar] [CrossRef]

- Beltrán-Zúñiga, M.A.; González-Velázquez, J.L.; Rivas-López, D.I.; Hernández-Santiago, F.; Dorantes-Rosales, H.J.; López-Hirata, V.M. Determination of fracture toughness in the short transverse direction of low carbon steel pipes by compact-tension specimens completed by welded attachments. Eng. Fract. Mech. 2019, 222, 106711. [Google Scholar] [CrossRef]

- Lai, M.O.; Ferguson, W.G. Relationship between fracture topography and fracture toughness of high strength steel. J. Mater. Sci. 1985, 20, 1985–1992. [Google Scholar] [CrossRef]

- Heiser, F.; Hertzberg, R. Anisotropy of fatigue crack propagation. J. Basic Eng. 1971, 93, 211–217. [Google Scholar] [CrossRef]

- Ohji, K.; Ogura, K.; Harada, S.; Taji, T. Fatigue crack growth behavior of anisotropic rolled steel plate with special reference to laminated structure and inclusions. Bull. JSME 1978, 21, 939–947. [Google Scholar] [CrossRef]

- Slot, H.; Nicoreac, M.; Maljaars, J. Influence of material anisotropy on fatigue crack growth in C–Mn steels of existing structures. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 2527–2541. [Google Scholar] [CrossRef]

- Cavaliere, P.; De Santis, A.; Panella, F.; Squillace, A. Effect of anisotropy on fatigue properties of 2198 Al–Li plates joined by friction stir welding. Eng. Fail. Anal. 2009, 16, 1856–1865. [Google Scholar] [CrossRef]

- Pessard, E.; Morel, F.; Morel, A. The anisotropic fatigue behavior of forged steel. Adv. Eng. Mater. 2009, 11, 732–735. [Google Scholar] [CrossRef]

- ASTM E3-11(2017); Standard Guide for Preparation of Metallographic Specimens. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM E407-07(2015); Standard Practice for Microetching Metals and Alloys. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM E1268-01(2016); Standard Practice for Assessing the Degree of Banding or Orientation of Microstructures. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM E112-13(2021); Standard Test Methods for Determining Average Grain Size. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM E45-18a; Standard Test Methods for Determining the Inclusion Content of Steel. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM E-8; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2024.

- ASTM E18; Standard Test Methods for Rockwell Hardness of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2024.

- ASTM E466-21; Standard Practice for Conducting Force Controlled Constant Amplitude Axial Fatigue Tests of Metallic Materials. American Society of Testing Materials Book of Standards. ASTM International: Philadelphia, PA, USA, 2021; pp. 1–7. [CrossRef]

- ASTM E739-10(2015); Standard Practice for Statistical Analysis of Linear or Linearized Stress-Life (S-N) and Strain-Life (ε-N) Fatigue Data, American Society of Testing Materials Book of Standards. ASTM International: Philadelphia, PA, USA, 2015; pp. 1–7. [CrossRef]

- Venegas, V.; Caleyo, F.; Baudin, T.; Espina-Hernández, J.H.; Hallen, J.M. On the role of crystallographic texture in mitigating hydrogen-induced cracking in pipeline steels. Corros. Sci. 2011, 53, 4204–4212. [Google Scholar] [CrossRef]

- Hong, S.W.; Koo, J.M.; Seok, C.S.; Kim, J.W.; Kim, J.H.; Hong, S.K. Fatigue life prediction for an API 5L X42 natural gas pipeline. Eng. Fail. Anal. 2015, 56, 396–402. [Google Scholar] [CrossRef]

- González-Velázquez, J. Fatigue. In Mechanical Behavior and Fracture of Engineering Materials; Structural Integrity; Springer: Cham, Switzerland, 2020; Volume 12. [Google Scholar] [CrossRef]

| Properties/Operation Condition | API 5L X42 Steel |

|---|---|

| Product Specification Level | PSL1 |

| Transported product | Light crude oil |

| Nominal Diameter | 24 in (609.6 mm) |

| Nominal Thickness | 0.500 in (12.7 mm) |

| Design Pressure | 80 kg/cm2 (1138 psi) |

| Working Pressure | 65.3 kg/cm2 (929 psi) |

| Design Temperature | 45.0 °C (113 °F) |

| Working Temperature | 22.1 °C (71.78 °F) |

| Run time | 8 years |

| ID | C | S | Mn | Cu | P | Cr | Si | Mo | Ti |

|---|---|---|---|---|---|---|---|---|---|

| Tested Steel API 5L X42 | 0.220 | 0.040 | 1.240 | 0.023 | 0.003 | 0.085 | 0.260 | 0.260 | 0.002 |

| API 5L Spec | 0.260 [max.] | 0.030 [max.] | 1.300 [max.] | 0.035 [max.] | 0.030 [max.] | - | - | - | 0.040 [max.] |

| Direction | Non-Metallic Inclusions [%] | Ferrite [%] | Pearlite [%] | Ai | Ω12 | Grain Size | |

|---|---|---|---|---|---|---|---|

| [μm] | ASTM | ||||||

| L-0° | 0.552 ± 0.058 | 71.54 ± 2.76 | 28.46 ± 2.76 | 1.64 | 0.28 | 24.4 ± 1.98 | 8.0 |

| D-45° | 0.506 ± 0.036 | 70.65 ± 2.25 | 29.35 ± 2.25 | 1.04 | 0.16 | 24.2 ± 2.20 | 8.0 |

| C-90° | 0.533 ± 0.035 | 70.14 ± 2.07 | 29.86 ± 2.07 | 0.78 | 0.15 | 29.76 ± 2.50 | 7.0 |

| R | 0.497 ± 0.062 | 74.15 ± 2.01 | 25.85 ± 2.01 | - | - | 10.87 ± 3.61 | 10.0 |

| ID | Direction | Diameter | Area | YS Load | YS | Ultimate Load | UTS | Elongation | Ramberg-Osgood Constants | |

|---|---|---|---|---|---|---|---|---|---|---|

| [mm] | [mm2] | [kN] | [MPa] | [kN] | [MPa] | [%] | Strength Coefficient K [MPa] | Strain Hardening Constant n | ||

| This study | L-0° | 12.57 | 124.10 | 38.38 | 309.24 | 61.06 | 492.07 | 40.16 | - | - |

| 12.62 | 125.09 | 36.60 | 292.617 | 62.85 | 502.42 | 38.2 | - | - | ||

| 12.68 | 126.28 | 38.15 | 302.15 | 62.74 | 496.87 | 39.6 | - | - | ||

| Average | 12.62 ± 0.06 | 125.15 ± 1.09 | 37.71 ± 0.96 | 301 ± 6.81 | 62.22 ± 1.01 | 497 ± 4.26 | 39.3 ± 0.8 | 515 | 0.095 | |

| D-45° | 12.68 | 126.28 | 45.47 | 360.1 | 64.53 | 510.98 | 35.92 | - | - | |

| 12.66 | 125.88 | 46.03 | 365.69 | 64.41 | 511.68 | 37.65 | - | - | ||

| 12.59 | 124.49 | 43.88 | 352.44 | 63.86 | 512.93 | 38.18 | - | - | ||

| Average | 12.64 ± 0.04 | 123.3 ± 0.94 | 45.13 ± 1.12 | 359 ± 6.35 | 65.26 ± 0.33 | 512 ± 0.81 | 37.2 ± 0.96 | 524 | 0.079 | |

| C-90° | 12.56 | 123.90 | 46.22 | 373.08 | 61.88 | 499.42 | 33.99 | - | - | |

| 12.49 | 122.52 | 46.82 | 382.14 | 62.53 | 510.39 | 34.5 | - | - | ||

| 12.54 | 123.51 | 46.84 | 379.26 | 62.32 | 504.56 | 35.53 | - | - | ||

| Average | 12.53 ± 0.04 | 123.31 ± 0.71 | 46.62 ± 0.35 | 378 ± 3.77 | 62.24 ± 0.33 | 505 ± 4.48 | 34.7 ± 0.6 | 516 | 0.066 | |

| Spec. | API 5L X42 | - | - | Min. 290 | - | Min. 414 | Min. 22 | - | - | |

| ID | Direction | YS [MPa] | UTS [MPa] | Elongation [%] | Hardness [HRBW] |

|---|---|---|---|---|---|

| This study | L-0° | 301 ± 8.13 | 497 ± 5.17 | 39.2 ± 0.8 | 83 ± 2 |

| D-45° | 359 ± 6.35 | 512 ± 0.63 | 37.2 ± 0.8 | 79 ± 1 | |

| C-90° | 378 ± 4.53 | 505 ± 5.49 | 34.7 ± 0.6 | 82 ± 1 | |

| X42 [12] | L-0° | 287 | - | 35.9 | - |

| D-30° | 295 | - | 35.1 | - | |

| D-60° | 306 | - | 29.5 | - | |

| C-90° | 301 | - | 15.5 | - | |

| X46 [25] | L-0° | 340 ± 5 | 505 ± 9 | 35.4 ± 0.8 | 83 |

| D-45° | 397 ± 4 | 517 ± 8 | 34.9 ± 0.5 | 84 | |

| C-90° | 428 ± 10 | 532 ± 12 | 31.7 ± 0.7 | 83 | |

| X52 [44] | L-0° | 390 | 473 | 31 | - |

| C-90° | 440 | 536 | 34 | - | |

| X70 [23] | L-0° | 528 ± 17 | 631 ± 5 | - | - |

| C-90° | 581 ± 2 | 657 ± 5 | - | - | |

| X80 [23] | L-0° | 572 ± 9 | 691 ± 3 | 17.1 ± 1.2 | - |

| D-45° | 582 ± 13 | 667 ± 6 | 19.7 ± 0.5 | - | |

| C-90° | 633 ± 8 | 722 ± 4 | 15.8 ± 1.5 | - | |

| X80 [13] | L-0° | 601 ± 35 | 676 ± 4 | 13 ± 2 | - |

| D-45° | 600 ± 35 | 663 ± 10 | 16 ± 2 | - | |

| C-90° | 634 ± 29 | 707 ± 16 | 15 ± 1 | - | |

| Spec. | API 5L X42 | Min. 290 | Min. 414 | Min. 22 | - |

| Direction | B | A [MPa] |

|---|---|---|

| C-90° | −0.0714 | 704 |

| D-45° | −0.0926 | 868 |

| L-0° | −0.1240 | 1195 |

| Hong et al. [45] | −0.0606 | 593 |

| Linear Fatigue Life Parameters at 95% Confidence | Specimen Direction | ||

|---|---|---|---|

| L-0° | D-45° | C-90° | |

| B(θ)/B(C-90°) | 1.736 | 1.297 | 1.0 |

| YS(θ)/YS(C-90°) | 0.796 | 0.940 | 1.0 |

| Ai(θ)/Ai(C-90°) | 2.103 | 1.333 | 1.0 |

| Ω12(θ)/Ω12(C-90) | 1.867 | 1.067 | 1.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Beltrán-Zúñiga, M.A.; González-Velázquez, J.L.; Rivas-López, D.I.; Dorantes-Rosales, H.J.; Ferreira-Palma, C.; Hernández-Santiago, F.; Larios-Flores, F. Fatigue Life Anisotropy of API 5L X42 Pipeline Steel in Axial Force-Controlled Tests. Materials 2025, 18, 2484. https://doi.org/10.3390/ma18112484

Beltrán-Zúñiga MA, González-Velázquez JL, Rivas-López DI, Dorantes-Rosales HJ, Ferreira-Palma C, Hernández-Santiago F, Larios-Flores F. Fatigue Life Anisotropy of API 5L X42 Pipeline Steel in Axial Force-Controlled Tests. Materials. 2025; 18(11):2484. https://doi.org/10.3390/ma18112484

Chicago/Turabian StyleBeltrán-Zúñiga, Manuel A., Jorge L. González-Velázquez, Diego I. Rivas-López, Héctor J. Dorantes-Rosales, Carlos Ferreira-Palma, Felipe Hernández-Santiago, and Fernando Larios-Flores. 2025. "Fatigue Life Anisotropy of API 5L X42 Pipeline Steel in Axial Force-Controlled Tests" Materials 18, no. 11: 2484. https://doi.org/10.3390/ma18112484

APA StyleBeltrán-Zúñiga, M. A., González-Velázquez, J. L., Rivas-López, D. I., Dorantes-Rosales, H. J., Ferreira-Palma, C., Hernández-Santiago, F., & Larios-Flores, F. (2025). Fatigue Life Anisotropy of API 5L X42 Pipeline Steel in Axial Force-Controlled Tests. Materials, 18(11), 2484. https://doi.org/10.3390/ma18112484