Investigation of the Microstructural and Mechanical Properties of Fiber-Reinforced Roller-Compacted Concrete Under High-Temperature Exposure

Abstract

1. Introduction

2. Materials and Methods

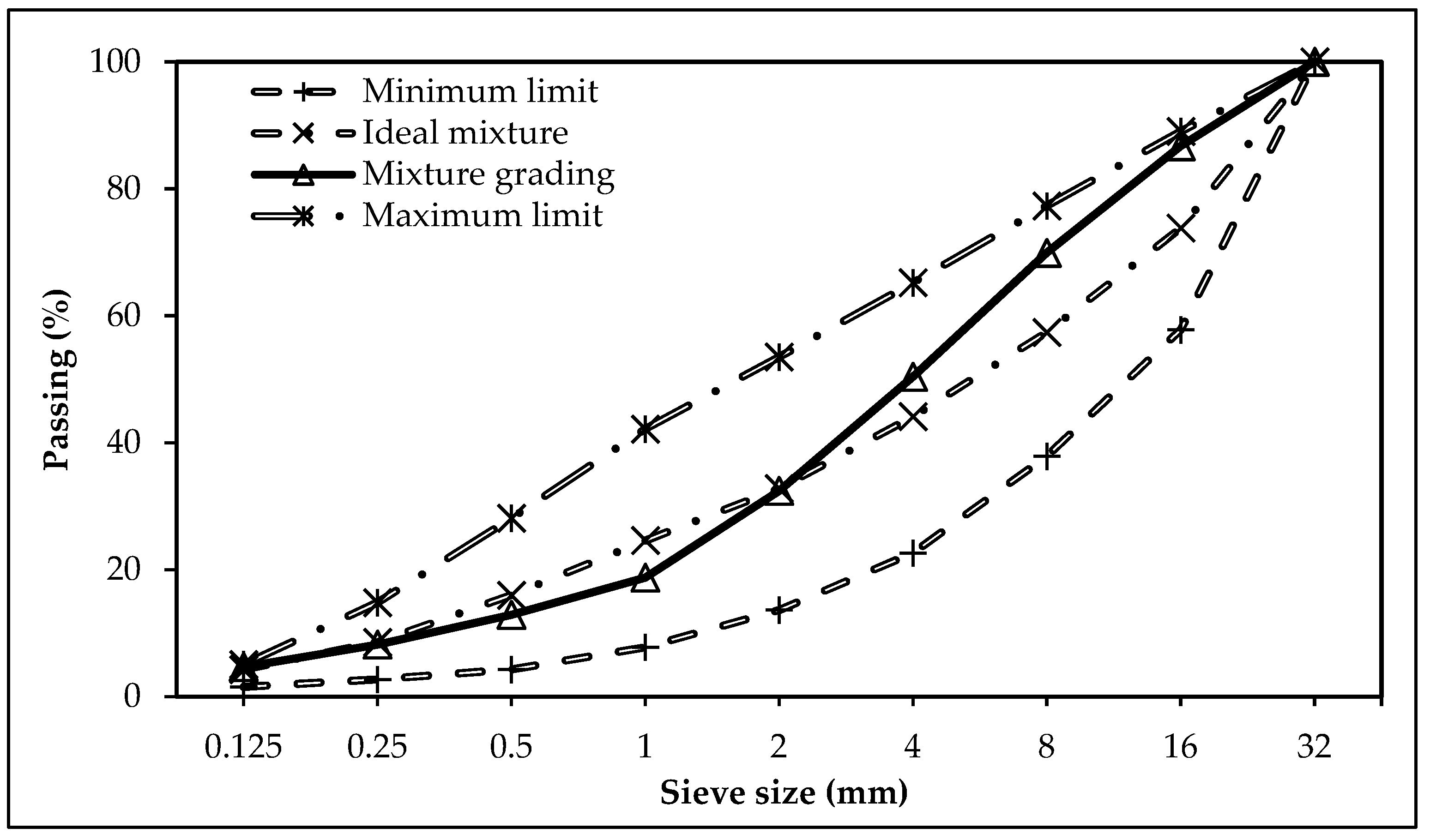

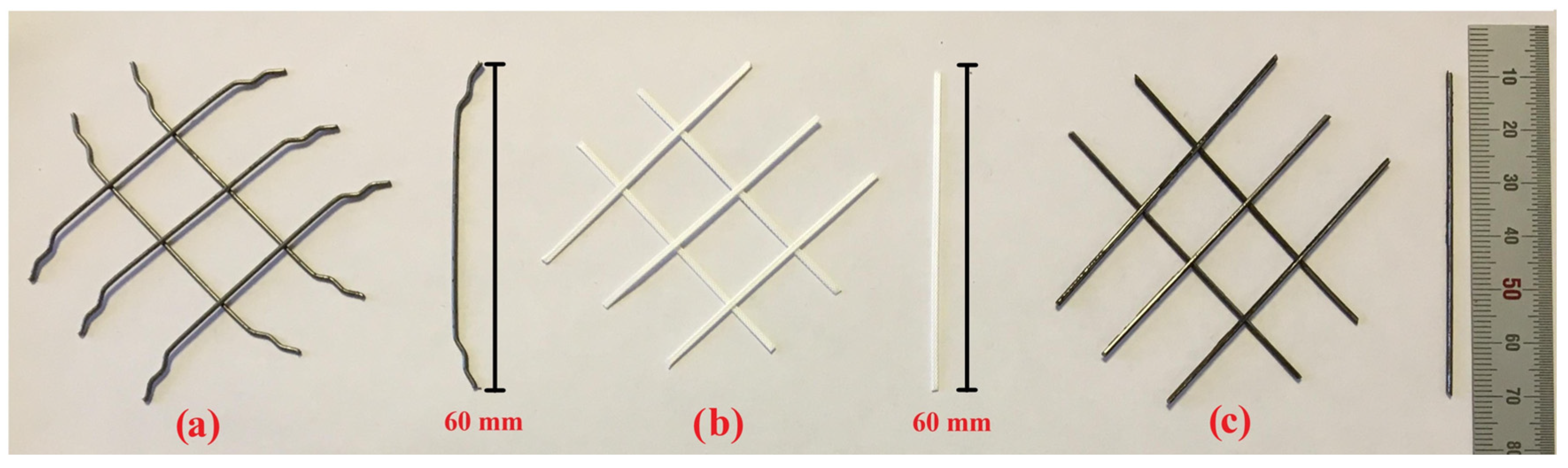

2.1. Materials

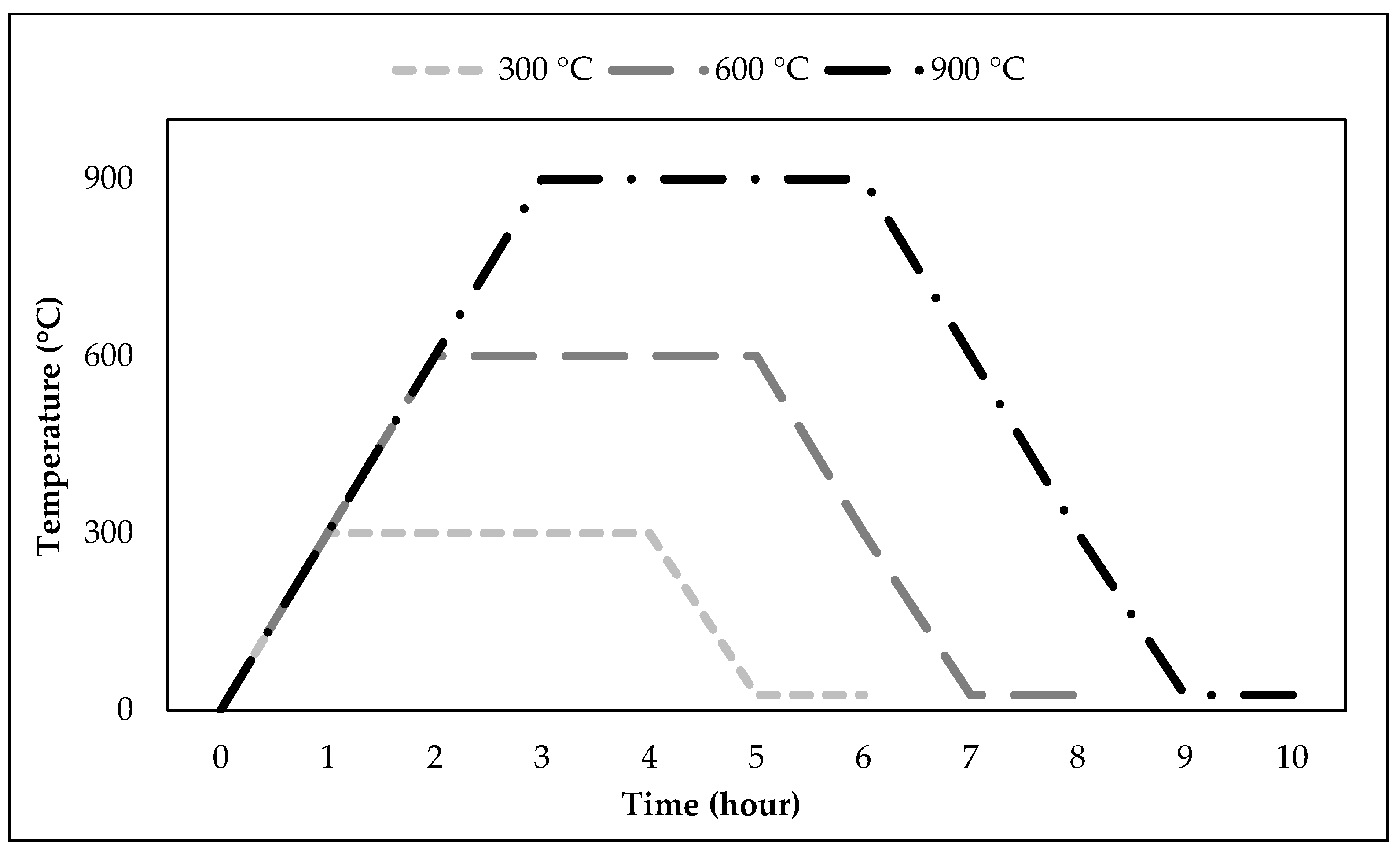

2.2. Methods

2.2.1. Preparation of Concrete

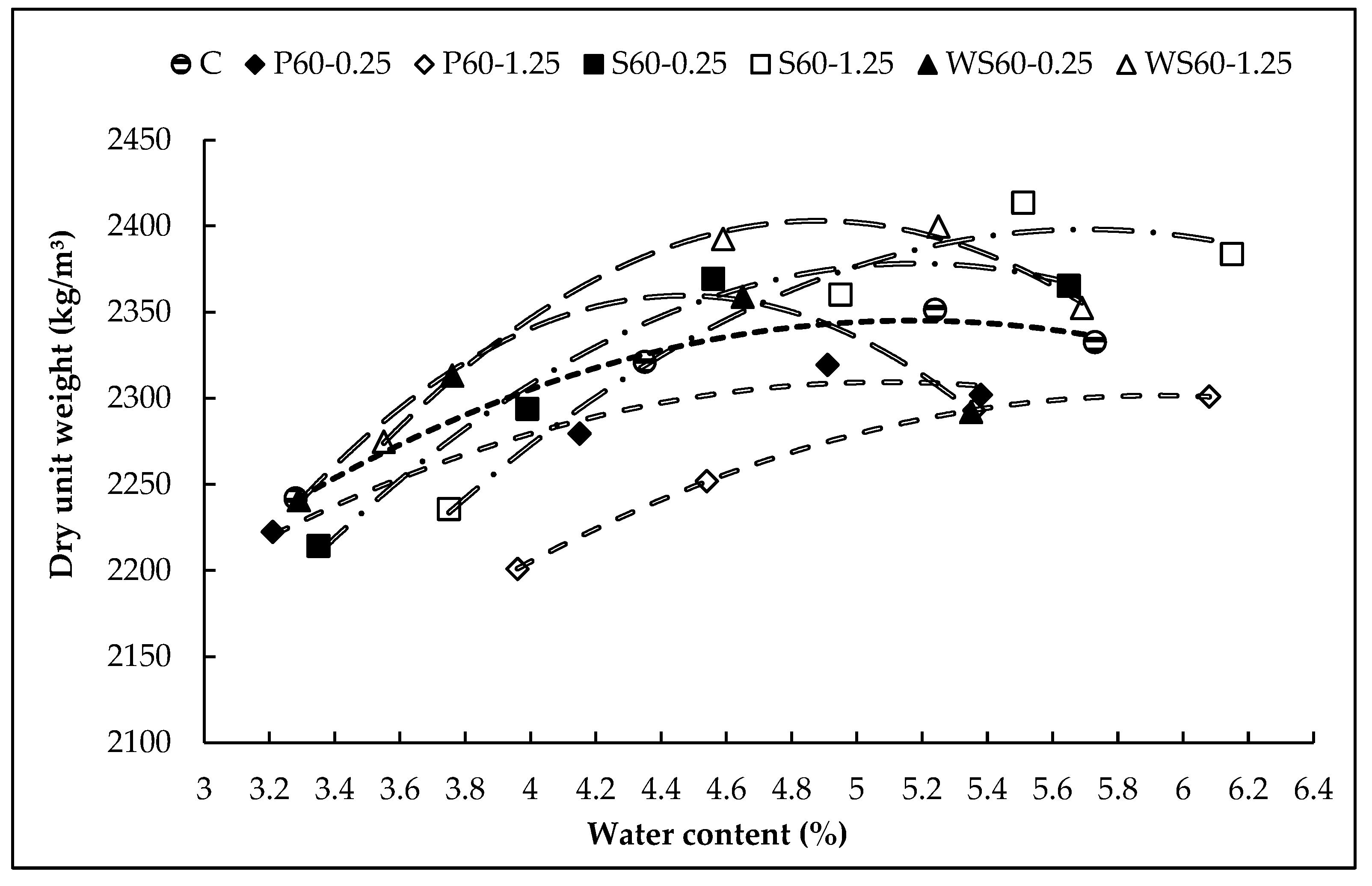

2.2.2. Optimum Water Content and Mixture Proportion

2.2.3. Experimental Study

Consistency

Properties of Hardened Concretes

2.2.4. Statistical Analysis

3. Results and Discussion

3.1. Properties of Concrete Mixtures

Consistency

3.2. Properties of Hardened Concrete

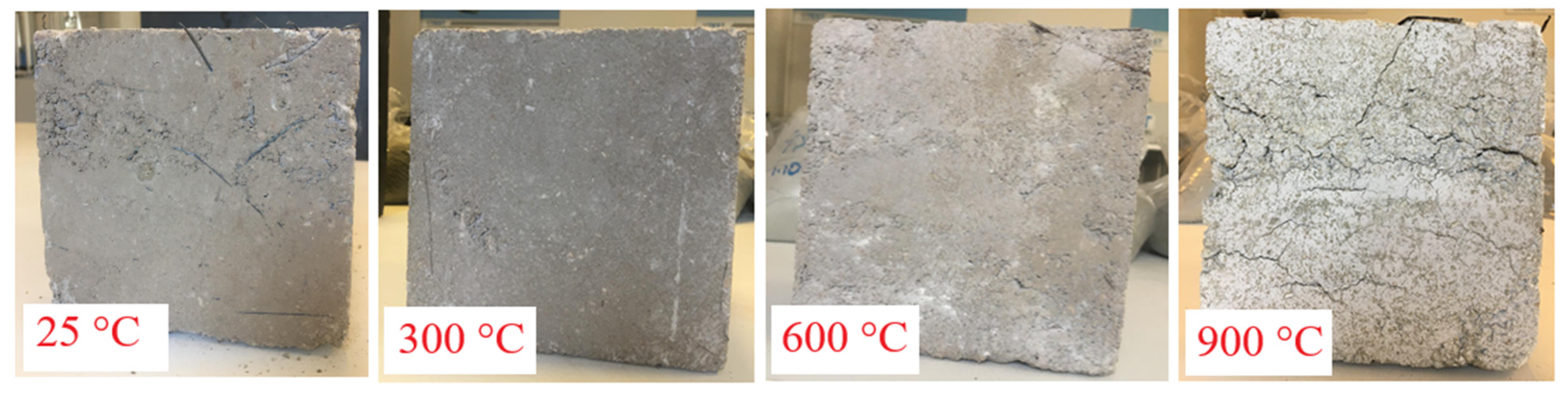

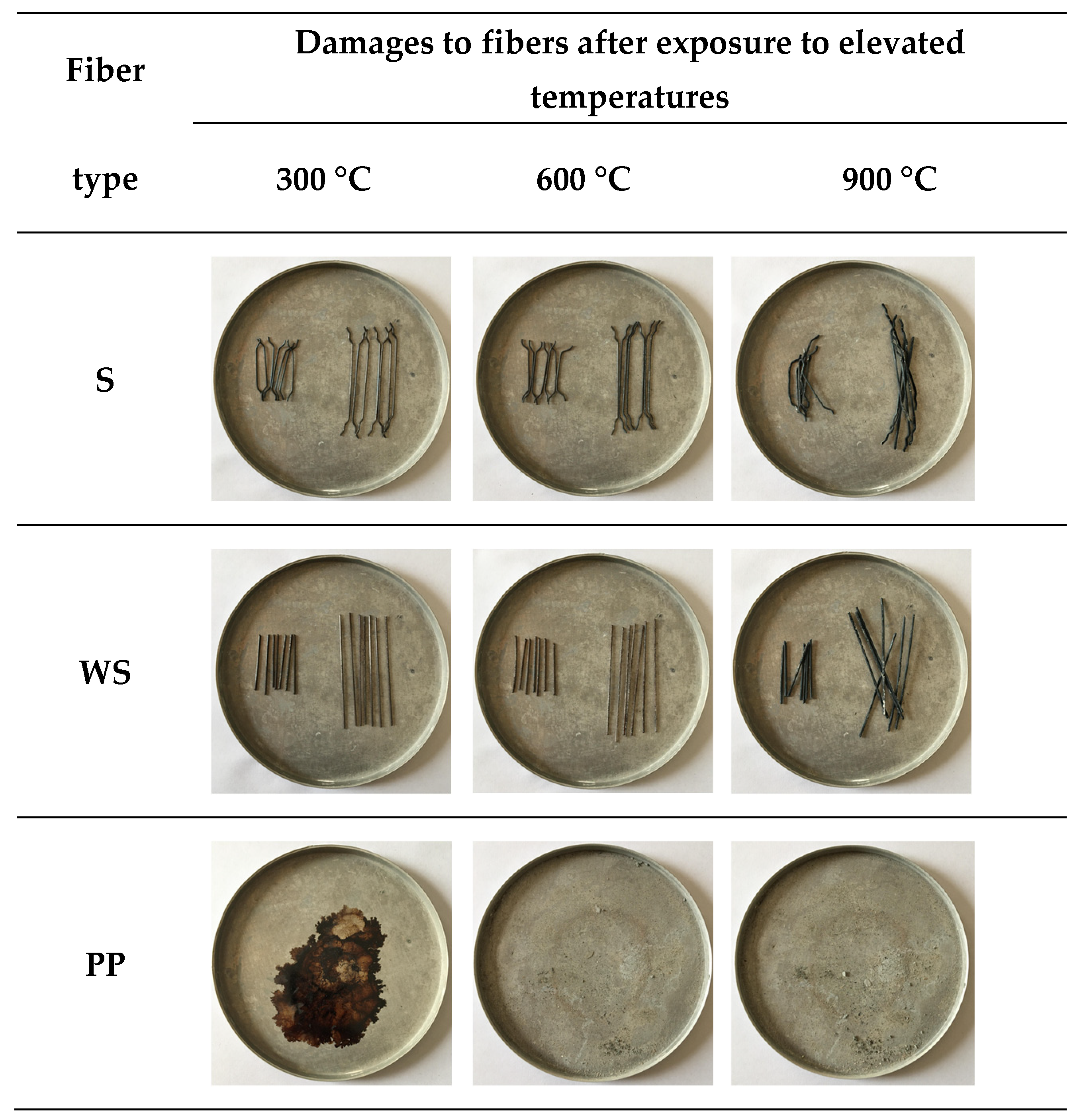

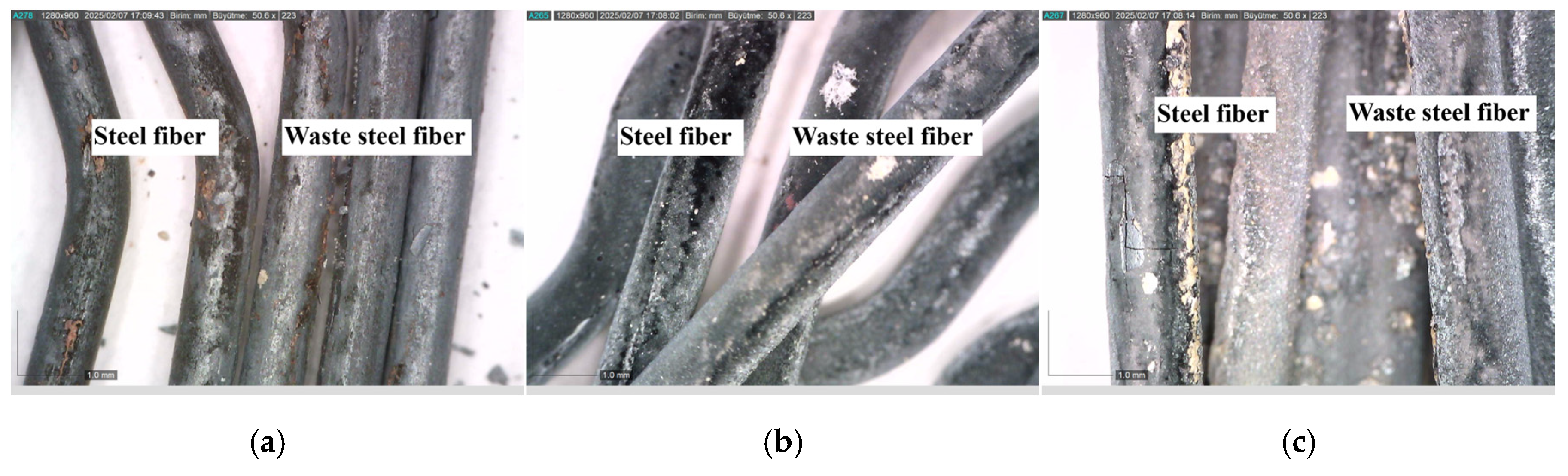

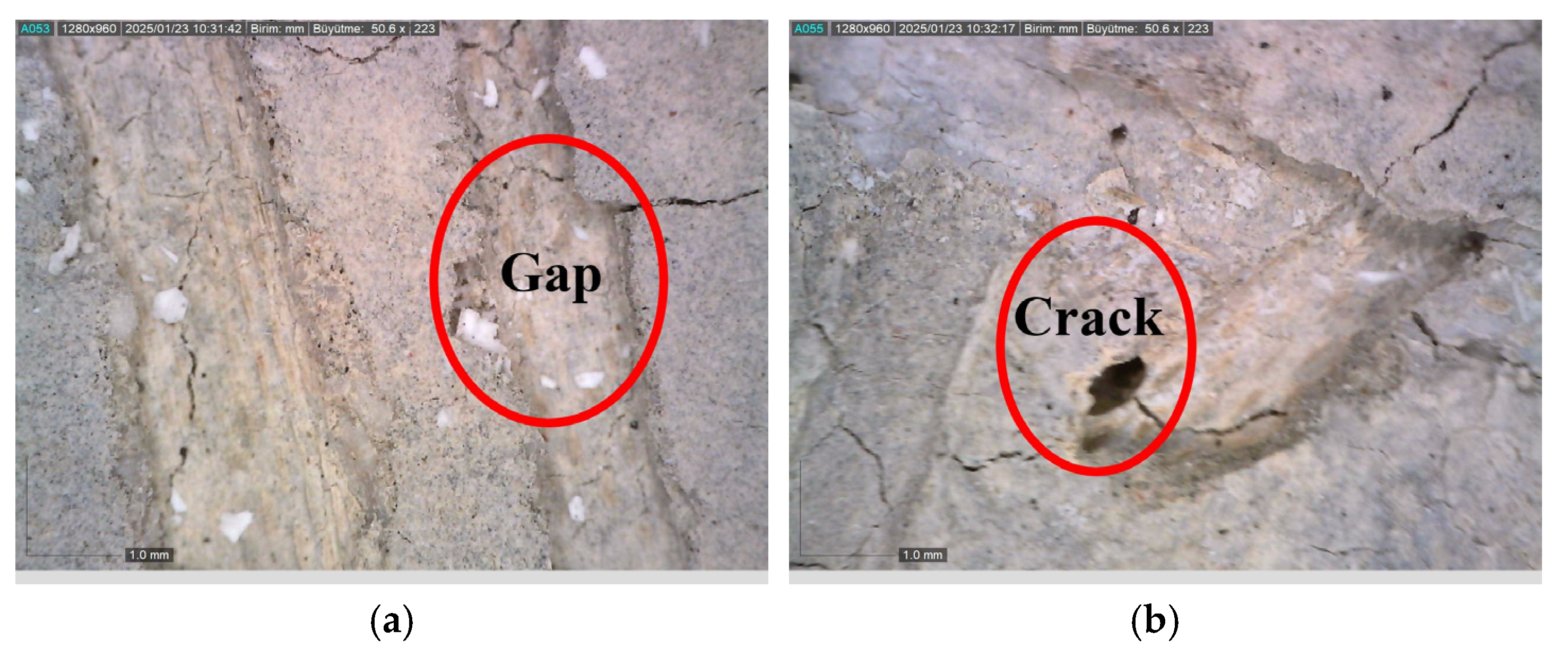

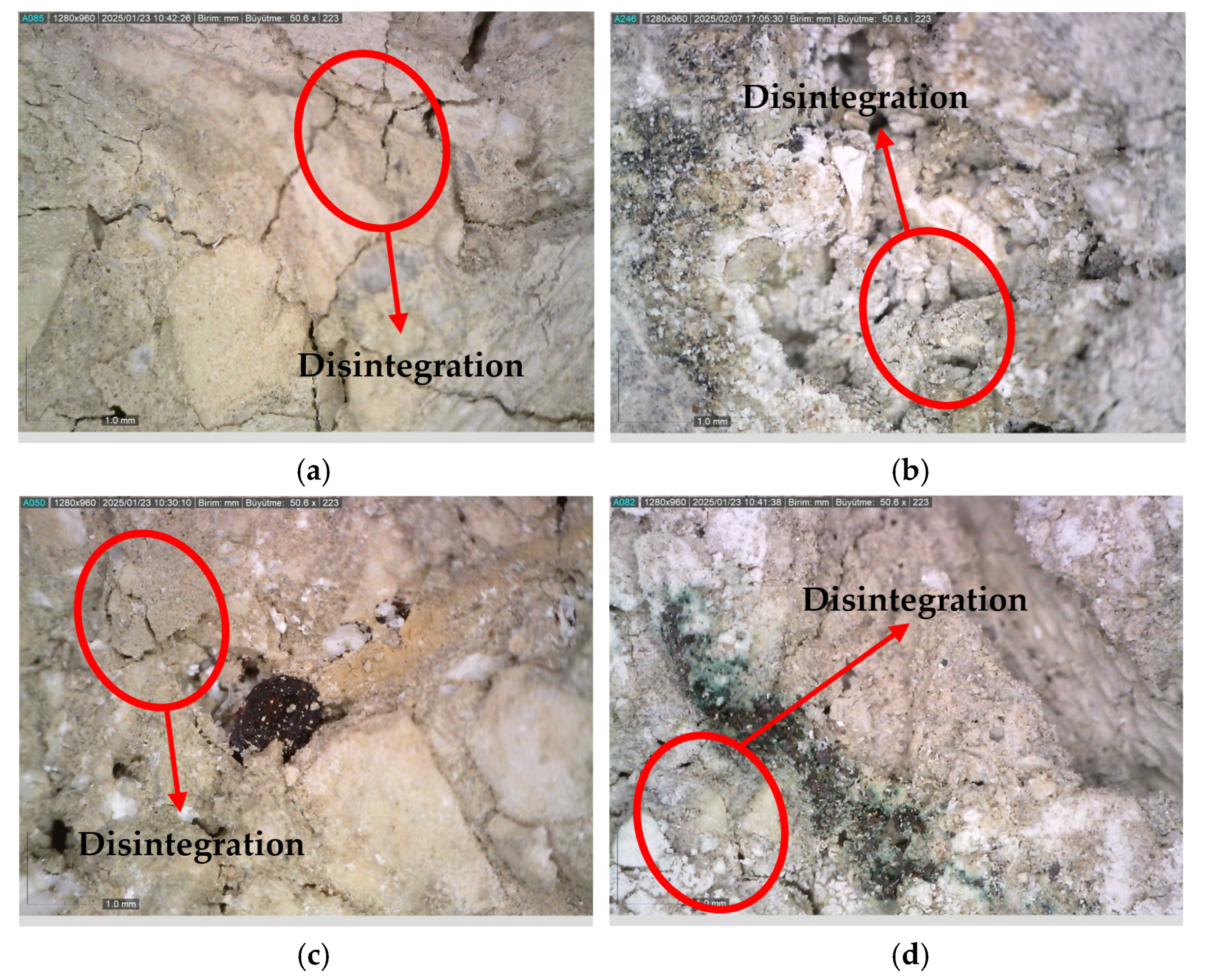

3.2.1. Surface Damage After High-Temperature Exposure

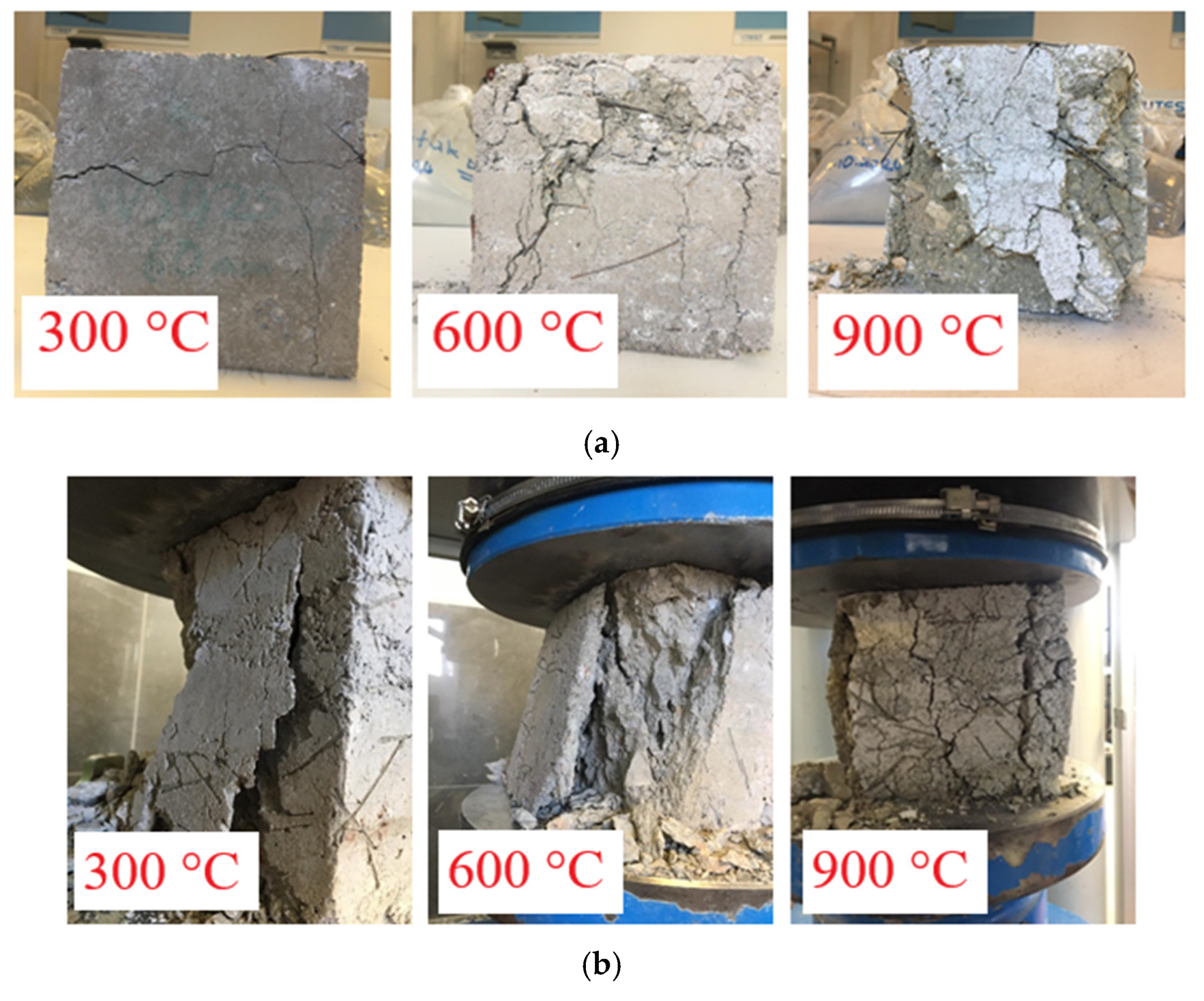

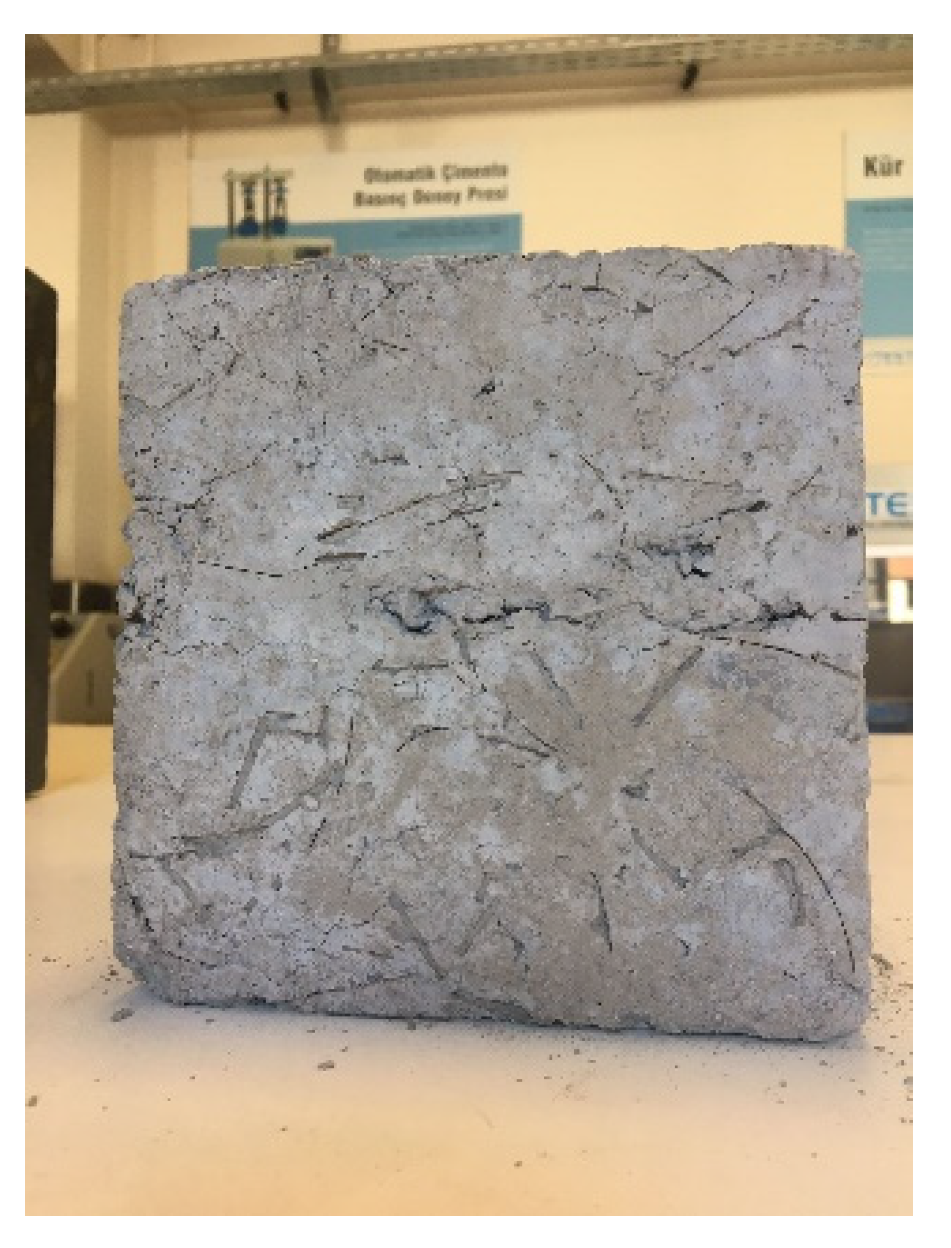

3.2.2. Failure Behavior of RCC Under Compression After Thermal Exposure

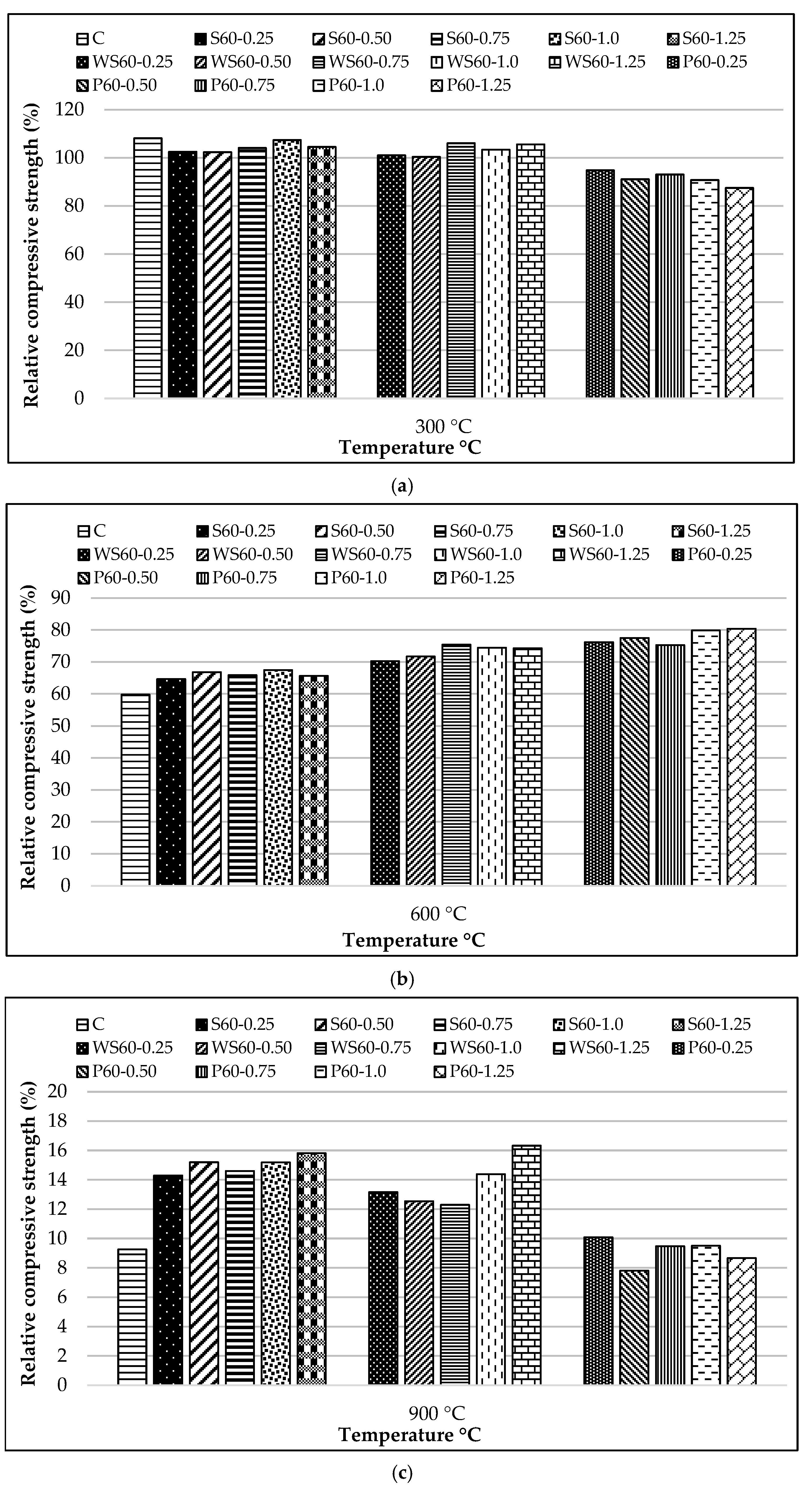

3.2.3. The Change in Compressive Strength of RCC After Exposure to High Temperatures

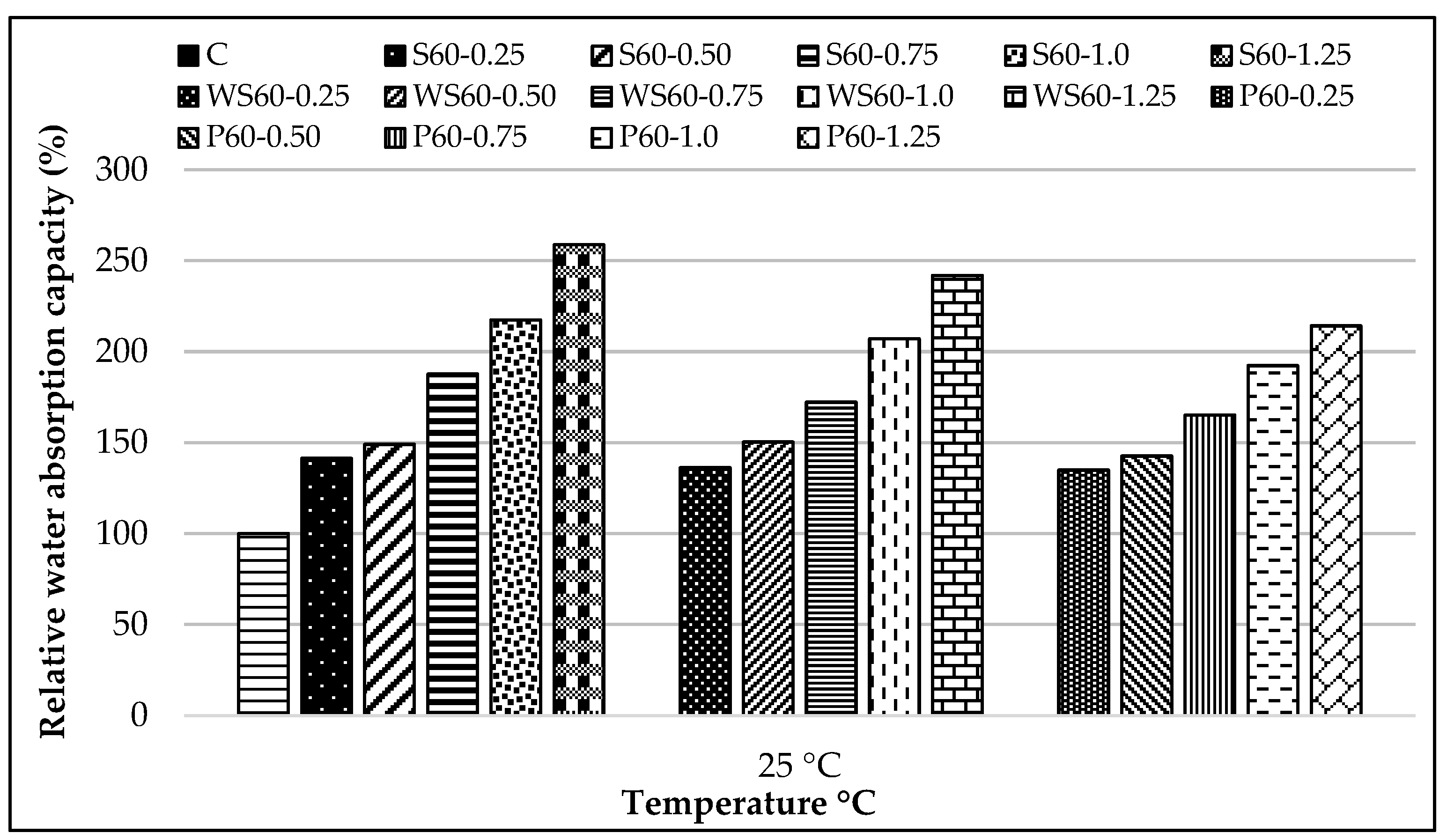

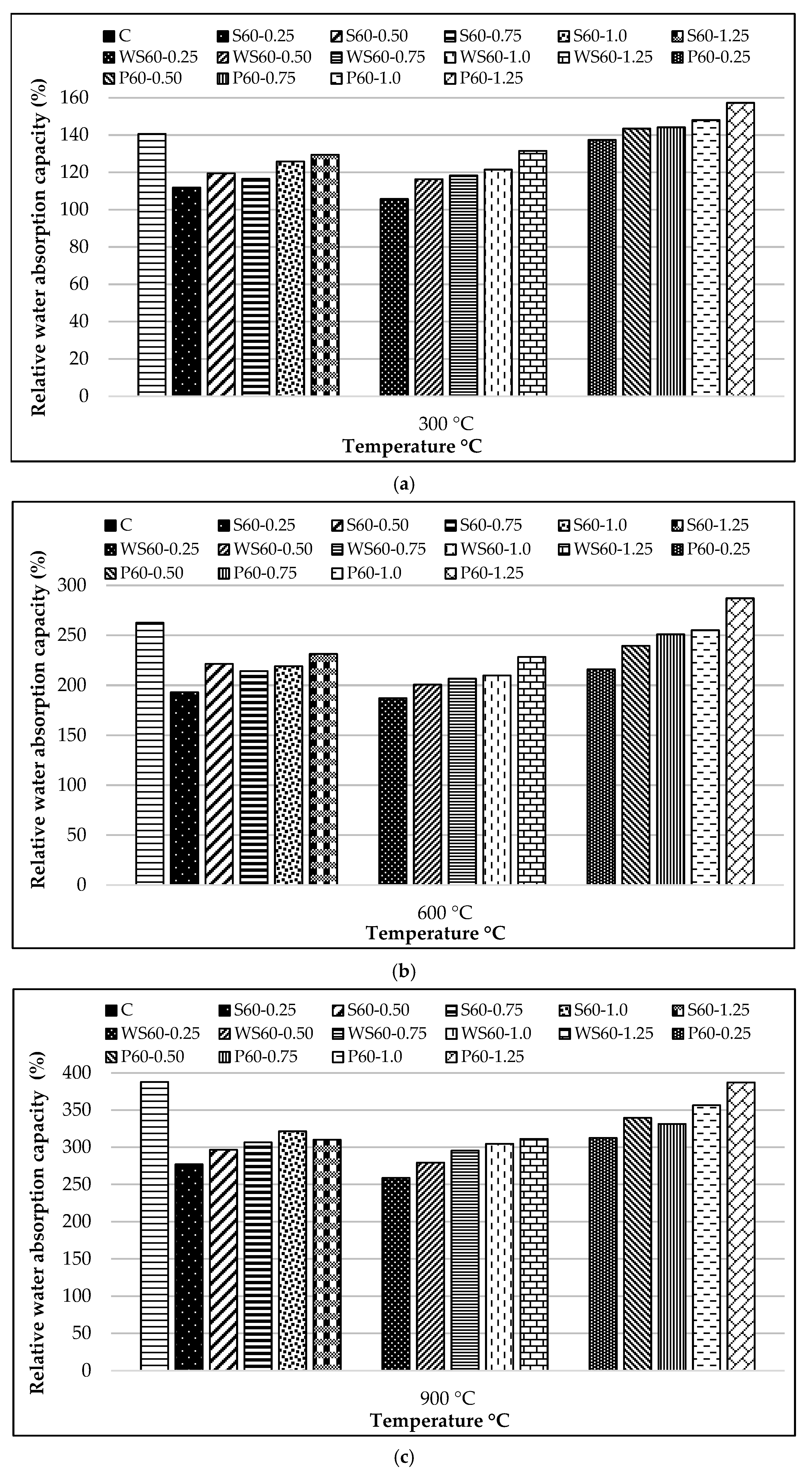

3.2.4. Change in Water Absorption Capacity of RCC After Exposure to High Temperatures

3.3. Statistical Evaluation

3.3.1. Taguchi Method

3.3.2. ANOVA Method

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Agra, R.R.; Serafini, R.; de Figueiredo, A.D. Effect of High Temperature on the Mechanical Properties of Concrete Reinforced with Different Fiber Contents. Constr. Build. Mater. 2021, 301, 124242. [Google Scholar] [CrossRef]

- Lu, J.; Liu, J.; Yang, H.; Gao, J.; Wan, X.; Zhang, J. Influence of Curing Temperatures on the Performances of Fiber-Reinforced Concrete. Constr. Build. Mater. 2022, 339, 127640. [Google Scholar] [CrossRef]

- Zheng, R.; Gao, G.; Yu, Z.; Wang, B.; Zhou, A.; Song, Q.; Bao, J. Dynamic Mechanical Properties of Fiber-Reinforced Lightweight Aggregate Concrete Exposed to High Temperature. J. Build. Eng. 2025, 103, 112161. [Google Scholar] [CrossRef]

- Shen, X.; Li, X.; Liu, L.; Chen, X.; Du, J. Research on Mechanical Properties of Steel-Polypropylene Fiber-Reinforced Concrete after High Temperature Treatments. Appl. Sci. 2024, 14, 3861. [Google Scholar] [CrossRef]

- Ashkezari, G.D.; Razmara, M. Thermal and Mechanical Evaluation of Ultra-High Performance Fiber-Reinforced Concrete and Conventional Concrete Subjected to High Temperatures. J. Build. Eng. 2020, 32, 101621. [Google Scholar] [CrossRef]

- Mardani-Aghabaglou, A. Durability of Fly Ash Incorporating Roller Compacted Concrete. Master’s Thesis, Thesis Center of Turkey, Ege, Turkey, 2011. [Google Scholar]

- Mardani-Aghabaglou, A.; Ramyar, K. Mechanical Properties of High-Volume Fly Ash Roller Compacted Concrete Designed by Maximum Density Method. Constr. Build. Mater. 2013, 38, 356–364. [Google Scholar] [CrossRef]

- Maafi, N.; Benouadah, A.; Benammar, A.; Kessal, O.; Belkadi, A.A.; Beddar, M. The Effects of Polypropylene Fibers on the Mechanical and Durability Performance of a Roller Compacted Concrete for Pavement. Int. J. Pavement Res. Technol. 2023, 1–11. [Google Scholar] [CrossRef]

- Berry, J.R.; Tayabji, S.D. Report on Roller-Compacted Concrete Pavements; ACI Committee Report: Farmington Hills, MI, USA, 2001. [Google Scholar]

- Naik, T.R.; Chun, Y.M.; Kraus, R.N.; Singh, S.S.; Pennock, L.L.C.; Ramme, B.W. Strength and Durability of Roller-Compacted HVFA Concrete Pavements. Pract. Period. Struct. Des. Constr. 2001, 6, 154–165. [Google Scholar] [CrossRef]

- Chhorn, C.; Kim, Y.K.; Hong, S.J.; Lee, S.W. Evaluation on Compactibility and Workability of Roller-Compacted Concrete for Pavement. Int. J. Pavement Eng. 2019, 20, 905–910. [Google Scholar] [CrossRef]

- Shafabakhsh, G.; Najafi, M.; Hassani, A.; Sarkar, A. Laboratory Investigation of the Impact of Water-Cement Ratio on the Mechanical Properties and Durability of Roller-Compacted Concrete Mixtures Containing Polypropylene Fibers. Innov. Infrastruct. Solut. 2024, 9, 416. [Google Scholar] [CrossRef]

- Latifi, M.R.; Biricik, Ö.; Mardani-Aghabaglou, A. Effect of the Addition of Polypropylene Fiber on Concrete Properties. J. Adhes. Sci. Technol. 2022, 36, 345–369. [Google Scholar] [CrossRef]

- Islam, G.S.; Gupta, S.D. Evaluating Plastic Shrinkage and Permeability of Polypropylene Fiber Reinforced Concrete. Int. J. Sustain. Built Environ. 2016, 5, 345–354. [Google Scholar] [CrossRef]

- Mardani-Aghabaglou, A.; Yüksel, C.; Hosseinnezhad, H.; Ramyar, K. Performance of Steel Micro Fiber Reinforced Mortar Mixtures Containing Plain, Binary and Ternary Cementitious Systems. J. Green Build. 2016, 11, 109–130. [Google Scholar] [CrossRef]

- Banthia, N.; Gupta, R. Hybrid Fiber Reinforced Concrete (HyFRC: Fiber Synergy in High Strength Matrices. Mater. Struct. 2004, 37, 707–716. [Google Scholar] [CrossRef]

- Yoo, D.; Yoon, Y.; Banthia, N. Flexural Response of Steel-Fiber-Reinforced Concrete Beams: Effects of Strength, Fiber Content, and Strain-Rate. Cem. Concr. Compos. 2015, 64, 84–92. [Google Scholar] [CrossRef]

- Shafigh, P.; Hashemi, M.; Nam, B.H.; Koting, S. Optimum Moisture Content in Roller-Compacted Concrete Pavement. Int. J. Pavement Eng. 2020, 21, 1769–1779. [Google Scholar] [CrossRef]

- Ouedraogo, H.A.; Özen, S.; Kobya, V.; Sağıroğlu, S.; Mardani-Aghabaglou, A. Comparison of Fresh and Hardened Properties of Self-Compacting Concrete Mixture from Different Aspect Ratio of Steel Fiber Viewpoint. J. Green Build. 2021, 16, 115–138. [Google Scholar] [CrossRef]

- Mardani-Aghabaglou, A.; Özen, S.; Altun, M.G. Durability Performance and Dimensional Stability of Polypropylene Fiber Reinforced Concrete. J. Green Build. 2018, 13, 20–41. [Google Scholar] [CrossRef]

- Huang, Z.; Pan, Z.; Zeng, B. Crack Width and Crack Spacing of Glass-FRP Reinforced Concrete Beams under Flexure: Simulation and Analysis. J. Reinf. Plast. Compos. 2025, 07316844251315868. [Google Scholar] [CrossRef]

- Khalel, H.H.Z.; Khan, M.; Starr, A.; Sadawi, N.; Mohamed, O.A.; Khalil, A.; Esaker, M. Parametric Study for Optimizing Fiber-reinforced Concrete Properties. Struct. Concr. 2025, 26, 88–110. [Google Scholar] [CrossRef]

- Moussa, A.M.; Said, H.O.; Khodary, F.; Hassanean, Y.A. Shear Behavior of High-Strength Concrete Beams Reinforced with Carbon Fiber-Reinforced Polymer Bars. Eng. Struct. 2025, 325, 119411. [Google Scholar] [CrossRef]

- Nia, A.A.; Hedayatian, M.; Nili, M.; Sabet, V.A. An Experimental and Numerical Study on How Steel and Polypropylene Fibers Affect the Impact Resistance in Fiber-Reinforced Concrete. Int. J. Impact Eng. 2012, 46, 62–73. [Google Scholar] [CrossRef]

- Shah, I.; Li, J.; Yang, S.; Zhang, Y.; Anwar, A. Experimental Investigation on the Mechanical Properties of Natural Fiber Reinforced Concrete. J. Renew. Mater. 2022, 10, 1307. [Google Scholar] [CrossRef]

- Deng, Q.; Zhang, R.; Liu, C.; Duan, Z.; Xiao, J. Influence of Fiber Properties on Abrasion Resistance of Recycled Aggregate Concrete: Length, Volume Fraction, and Types of Fibers. Constr. Build. Mater. 2023, 362, 129750. [Google Scholar] [CrossRef]

- Behnood, A.; Ghandehari, M. Comparison of Compressive and Splitting Tensile Strength of High-Strength Concrete with and without Polypropylene Fibers Heated to High Temperatures. Fire Saf. J. 2009, 44, 1015–1022. [Google Scholar] [CrossRef]

- Arshad, S.; Ahmad, R.; Ali, M. Optimizing RCC Slabs Using Compressive Strenght of Fiber Reinforced Composites. Tech. J. 2024, 3, 1010–1015. [Google Scholar]

- Jahanbakhsh, P.; Saberi K, F.; Soltaninejad, M.; Hashemi, S.H. Laboratory Investigation of Modified Roller Compacted Concrete Pavement (RCCP) Containing Macro Synthetic Fibers. Int. J. Pavement Res. Technol. 2023, 16, 745–759. [Google Scholar] [CrossRef]

- Jafarifar, N.; Pilakoutas, K.; Angelakopoulos, H.; Bennett, T. Post-Cracking Tensile Behaviour of Steel-Fibre-Reinforced Roller-Compacted-Concrete for FE Modelling and Design Purposes. Mater. Constr. 2017, 67, e122. [Google Scholar] [CrossRef]

- Kılıç, I.; Gök, S. Strength and Durability of Roller Compacted Concrete with Different Types and Addition Rates of Polypropylene Fibers. Rev. Constr. 2021, 20, 205–214. [Google Scholar] [CrossRef]

- Hejazi, S.M.; Abtahi, S.M.; Safaie, F. Investigation of Thermal Stress Distribution in Fiber-Reinforced Roller Compacted Concrete Pavements. J. Ind. Text. 2016, 45, 896–914. [Google Scholar] [CrossRef]

- Ali, M.; Chen, L.; Feng, B.; Rusho, M.A.; Durán, M.E.R.; Samandari, N. Unveiling the Combined Thermal and High Strain Rate Effects on Compressive Behavior of Steel Fiber-Reinforced Concrete: A Novel Predictive Approach. Case Stud. Constr. Mater. 2025, e04384. [Google Scholar] [CrossRef]

- Zheng, W.; Li, H.; Wang, Y. Compressive Behaviour of Hybrid Fiber-Reinforced Reactive Powder Concrete after High Temperature. Mater. Des. 2012, 41, 403–409. [Google Scholar] [CrossRef]

- Novák, J.; Kohoutková, A. Fibre Reinforced Concrete Exposed to Elevated Temperature. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Busan, Republic of Korea, 25–27 August 2017; Volume 246, p. 012045. [Google Scholar]

- Beytekin, H.E.; Kaya, Y.; Mardani, A.; Sezer, F.Ş. Improving Fire Resistance of Lightweight Concrete Facade Elements by Using Fibers. Arch. Civ. Mech. Eng. 2025, 25, 70. [Google Scholar] [CrossRef]

- Gong, F.; Jiang, X.; Gamil, Y.; Iftikhar, B.; Thomas, B.S. An Overview on Spalling Behavior, Mechanism, Residual Strength and Microstructure of Fiber Reinforced Concrete under High Temperatures. Front. Mater. 2023, 10, 1258195. [Google Scholar] [CrossRef]

- Wu, H.; Lin, X.; Zhou, A. A Review of Mechanical Properties of Fibre Reinforced Concrete at Elevated Temperatures. Cem. Concr. Res. 2020, 135, 106117. [Google Scholar] [CrossRef]

- Mahmoud, M.S.; Shanour, A.S.; Abdelaziz, G.E.; Hammad, M.S. Influence of Elevated Temperature on Performance of Ultra High Strength Fibre Reinforced Self Compacting Concrete (UHSFRSCC) Produced from Local Materials. Eng. Res. J. 2023, 52, 1–11. [Google Scholar] [CrossRef]

- Ning, X.; Li, J.; Li, Y. An Explorative Study into the Influence of Different Fibers on the Spalling Resistance and Mechanical Properties of Self-Compacting Concrete after Exposure to Elevated Temperatures. Appl. Sci. 2022, 12, 12779. [Google Scholar] [CrossRef]

- Novak, J.; Kohoutkova, A. Mechanical Properties of Concrete Composites Subject to Elevated Temperature. Fire Saf. J. 2018, 95, 66–76. [Google Scholar] [CrossRef]

- EN 197-1; Cement-Part 1: Composition, Specifications and Conformity Criteria for Common Cements. European Committee for Standardization: London, UK, 2011.

- EN 1097-6; Tests for Mechanical and Physical Properties of Aggregates—Part 6: Determination of Particle Density and Water Absorption. European Committee for Standardization: London, UK, 2013.

- EN 933-1; Testing for Geometric Properties of Aggregates—Part 1: Determination of Particle Size Distribution-Sieve Method. European Committee for Standardization: London, UK, 2012.

- TS 802; Design of Concrete Mixes. Turkish Standard Institution: Ankara, Turkey, 2016.

- ASTM C1435/C1435M-20; Standard Practice for Molding Roller-Compacted Concrete in Cylinder Molds Using a Vibrating Hammer. ASTM International: West Conshohocken, PA, USA, 2020.

- Bayqra, S.H.; Mardani-Aghabaglou, A.; Ramyar, K. Physical and Mechanical Properties of High Volume Fly Ash Roller Compacted Concrete Pavement (A Laboratory and Case Study). Constr. Build. Mater. 2022, 314, 125664. [Google Scholar] [CrossRef]

- ACI 207.5R-99; Roller-Compacted Mass Concrete. ACI Committee Report: Farmington Hills, MI, USA, 1999.

- ASTM C1170/C1170M-20; Determining Consistency and Density of Roller-Compacted Concrete Using a Vibrating Table. ASTM International: West Conshohocken, PA, USA, 2020.

- EN 12390-3; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. European Committee for Standardization: London, UK, 2019.

- ASTM C642-21; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2021.

- Beytekin, H.E.; Şahin, H.G.; Mardani, A. Effect of Recycled Concrete Aggregate Utilization Ratio on Thermal Properties of Self-Cleaning Lightweight Concrete Facades. Sustainability 2024, 16, 6056. [Google Scholar] [CrossRef]

- Kaya, Y.; Kobya, V.; Mardani, A.; Mardani, N.; Beytekin, H.E. Effect of Grinding Conditions on Clinker Grinding Efficiency: Ball Size, Mill Rotation Speed, and Feed Rate. Buildings 2024, 14, 2356. [Google Scholar] [CrossRef]

- Mandal, N.; Doloi, B.; Mondal, B.; Das, R. Optimization of Flank Wear Using Zirconia Toughened Alumina (ZTA) Cutting Tool: Taguchi Method and Regression Analysis. Measurement 2011, 44, 2149–2155. [Google Scholar] [CrossRef]

- Ghahari, S.; Mohammadi, A.; Ramezanianpour, A. Performance Assessment of Natural Pozzolan Roller Compacted Concrete Pavements. Case Stud. Constr. Mater. 2017, 7, 82–90. [Google Scholar] [CrossRef]

- Haghnejad, M.; Modarres, A. Effect of Freeze-Thaw Cycles on the Response of Roller Compacted Concrete Pavement Reinforced by Recycled Polypropylene Fibre under Monotonic and Cyclic Loadings. Road Mater. Pavement Des. 2020, 22, 2704–2720. [Google Scholar] [CrossRef]

- Dvorkin, L.; Dvorkin, O.; Zhitkovsky, V.; Ribakov, Y. A Method for Optimum Design of Steel Fiber Reinforced Concrete Composition. Mater. Des. 2011, 32, 3254–3262. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Chaisakulkiet, U.; Jamsawang, P.; Horpibulsuk, S.; Jaturapitakkul, C.; Chindaprasirt, P. Case Investigation on Application of Steel Fibers in Roller Compacted Concrete Pavement in Thailand. Case Stud. Constr. Mater. 2019, 11, e00271. [Google Scholar] [CrossRef]

- Sharbatdar, M.K.; Rahmati, F. Experimental Evaluation of Multi-Functional Effects of Fibers on Mechanical and Performance Properties of Roller-Compacted Concrete Pavements (RCCP). Constr. Build. Mater. 2022, 316, 125890. [Google Scholar] [CrossRef]

- Abu-Bakr, M.; Mahmood, H.F.; Mohammed, A.A. Investigation of Metakaolin and Steel Fiber Addition on Some Mechanical and Durability Properties of Roller Compacted Concrete. Case Stud. Constr. Mater. 2022, 16, e01136. [Google Scholar] [CrossRef]

- Siamardi, K.; Shabani, S. Evaluation the Effect of Micro-Synthetic Fiber on Mechanical and Freeze-Thaw Behavior of Non-Air-Entrained Roller Compacted Concrete Pavement Using Response Surface Methodology. Constr. Build. Mater. 2021, 295, 123628. [Google Scholar] [CrossRef]

- Yildizel, S.A.; Tayeh, B.A.; Uzun, M. The Evaluation of Calcium Carbonate Added and Basalt Fiber Reinforced Roller Compacted High Performance Concrete for Pavement. Case Stud. Constr. Mater. 2022, 17, e01293. [Google Scholar] [CrossRef]

- Benyarar, F.D.; Yildizel, S.A.; Misir, G.; Calis, G. The RSM-Based Optimization of Recycled Polypropylene Fiber Reinforced and Ground Calcium Carbonate Incorporated Roller Compacted Concrete for Pavement. Int. J. Pavement Res. Technol. 2023, 1–13. [Google Scholar] [CrossRef]

- Bao, J.; Zheng, R.; Zhang, P.; Cui, Y.; Xue, S.; Song, Q.; Ma, Y. Thermal Resistance, Water Absorption and Microstructure of High-Strength Self-Compacting Lightweight Aggregate Concrete (HSSC-LWAC) after Exposure to Elevated Temperatures. Constr. Build. Mater. 2023, 365, 130071. [Google Scholar] [CrossRef]

- Naveen, A.P.; Priyadarsini, R.S.; Krishna, D.A. Effect of High Temperature on the Compressive and Flexural Performance of Fibrous Concrete-an Experimental Investigation. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Guo, Z.; Zhuang, C.; Li, Z.; Chen, Y. Mechanical Properties of Carbon Fiber Reinforced Concrete (CFRC) after Exposure to High Temperatures. Compos. Struct. 2021, 256, 113072. [Google Scholar] [CrossRef]

- Kaya, Y.; Biricik, Ö.; Bayqra, S.H.; Mardani, A. Effect of Fibre Type and Utilisation Rate on Dimensional Stability and Frost Resistance of Pavement Mortar Mixture. Int. J. Pavement Eng. 2023, 24, 2154351. [Google Scholar] [CrossRef]

- Tong, L.Y.; Cai, Y.; Liu, Q.F. Carbonation Modelling of Hardened Cementitious Materials Considering Pore Structure Characteristics: A Review. J. Build. Eng. 2024, 96, 110547. [Google Scholar] [CrossRef]

- Irshidat, M.R.; Al-Nuaimi, N.; Rabie, M. Hybrid Effect of Carbon Nanotubes and Polypropylene Microfibers on Fire Resistance, Thermal Characteristics and Microstructure of Cementitious Composites. Constr. Build. Mater. 2021, 266, 121154. [Google Scholar] [CrossRef]

- Durgun, M.Y.; Özen, S.; Karakuzu, K.; Kobya, V.; Bayqra, S.H.; Mardani-Aghabaglou, A. Effect of High Temperature on Polypropylene Fiber-Reinforced Mortars Containing Colemanite Wastes. Constr. Build. Mater. 2022, 316, 125827. [Google Scholar] [CrossRef]

- Haddad, R.H.; Al-Saleh, R.J.; Al-Akhras, N.M. Effect of Elevated Temperature on Bond between Steel Reinforcement and Fiber Reinforced Concrete. Fire Saf. J. 2008, 43, 334–343. [Google Scholar] [CrossRef]

- Gao, W.; Yu, H.; Ma, H.; Guo, J.; Zhang, J.; Liu, T.; Tao, Q. Mesoscopic Mechanical Study on Quasi-Static Compression of Coral Aggregate Seawater Concrete after High Temperature Exposure. J. Build. Eng. 2024, 88, 109160. [Google Scholar] [CrossRef]

- Düğenci, O.; Haktanir, T.; Altun, F. Experimental Research for the Effect of High Temperature on the Mechanical Properties of Steel Fiber-Reinforced Concrete. Constr. Build. Mater. 2015, 75, 82–88. [Google Scholar] [CrossRef]

- Bangi, M.R.; Horiguchi, T. Effect of Fibre Type and Geometry on Maximum Pore Pressures in Fibre-Reinforced High Strength Concrete at Elevated Temperatures. Cem. Concr. Res. 2012, 42, 459–466. [Google Scholar] [CrossRef]

- Liang, J.; Liu, K.; Wang, C.; Wang, X.; Liu, J. Mechanical Properties of Steel Fiber-Reinforced Rubber Concrete after Elevated Temperature. Sci. Rep. 2025, 15, 6965. [Google Scholar] [CrossRef] [PubMed]

- Madhkhan, M.; Azizkhani, R.; Harchegani, M.T. Effects of Pozzolans Together with Steel and Polypropylene Fibers on Mechanical Properties of RCC Pavements. Constr. Build. Mater. 2012, 26, 102–112. [Google Scholar] [CrossRef]

- Saidani, M.; Saraireh, D.; Gerges, M. Behaviour of Different Types of Fiber Reinforced Concrete without Admixture. Eng. Struct. 2016, 113, 328–334. [Google Scholar] [CrossRef]

- Fallah, S.; Nematzadeh, M. Mechanical Properties and Durability of High-Strength Concrete Containing Macro-Polymeric and Polypropylene Fibers with Nano-Silica and Silica Fume. Constr. Build. Mater. 2017, 132, 170–187. [Google Scholar] [CrossRef]

- Paul, S.C.; van Zijl, G.P.; Šavija, B. Effect of Fibers on Durability of Concrete: A Practical Review. Materials 2020, 13, 4562. [Google Scholar] [CrossRef]

- Yuan, Z.; Jia, Y. Mechanical Properties and Microstructure of Glass Fiber and Polypropylene Fiber Reinforced Concrete: An Experimental Study. Constr. Build. Mater. 2021, 266, 121048. [Google Scholar] [CrossRef]

- Rooholamini, H.; Hassani, A.; Aliha, M.R.M. Evaluating the Effect of Macro-Synthetic Fiber on the Mechanical Properties of Roller-Compacted Concrete Pavement Using Response Surface Methodology. Constr. Build. Mater. 2018, 159, 517–529. [Google Scholar] [CrossRef]

- Huang, T.; Yuan, Q.; Zuo, S.; Yao, H.; Zhang, K.; Wang, Y.; Shi, C. Physio-Chemical Effects on the Temperature-Dependent Elasticity of Cement Paste during Setting. Cem. Concr. Compos. 2022, 134, 104769. [Google Scholar] [CrossRef]

- Ji, X.; Pan, T.; Fu, C.; Han, F.; Zhao, W.; Sha, J.; Liu, J. Hydration, Microstructure and Mechanical Properties of Cement-Based Materials with Heat-Modified Autoclaved Aerated Concrete Waste. Constr. Build. Mater. 2024, 419, 135482. [Google Scholar] [CrossRef]

- Shaikh, F.U.A.; Taweel, M. Compressive Strength and Failure Behaviour of Fibre Reinforced Concrete at Elevated Temperatures. Adv. Concr. Constr. 2015, 3, 283–293. [Google Scholar] [CrossRef]

- Liao, Q.; Zhao, X.D.; Wu, W.W.; Lu, J.X.; Yu, K.Q.; Poon, C.S. A Review on the Mechanical Performance and Durability of Fiber Reinforced Lightweight Cement Composites: The Roles of Fiber and Lightweight Aggregate. J. Build. Eng. 2024, 88, 109121. [Google Scholar] [CrossRef]

- Sellevold, E.J.; Bjøntegaard, Ø. Coefficient of Thermal Expansion of Cement Paste and Concrete: Mechanisms of Moisture Interaction. Mater. Struct. 2006, 39, 809–815. [Google Scholar] [CrossRef]

- Thomas, J.; Ramaswamy, A. Mechanical Properties of Steel Fiber-Reinforced Concrete. J. Mater. Civ. Eng. 2007, 19, 385–392. [Google Scholar] [CrossRef]

- Gautam, S.; Charak, R. Calcium Oxide. In Calcium-Based Materials: Processing, Characterization, and Applications; CRC Press: Boca Raton, FL, USA, 2024; Volume 88. [Google Scholar]

- Kara, I.B. Effects of Cooling Regimes on Limestone Rock and Concrete with Limestone Aggregates at Elevated Temperatures. Int. J. Rock Mech. Min. Sci. 2021, 138, 104618. [Google Scholar] [CrossRef]

- Li, Q.; Wang, M.; Sun, H.; Yu, G. Effect of Heating Rate on the Free Expansion Deformation of Concrete during the Heating Process. J. Build. Eng. 2021, 34, 101896. [Google Scholar] [CrossRef]

- Cui, K.; Liang, K.; Chang, J.; Lau, D. Investigation of the Macro Performance, Mechanism, and Durability of Multiscale Steel Fiber Reinforced Low-Carbon Ecological UHPC. Constr. Build. Mater. 2022, 327, 126921. [Google Scholar] [CrossRef]

- Yang, M.; Xiong, Y.; Shang, X.; Wang, Z.; Zhao, J.; Liu, Y.; Yuan, Y. Effect of Steel Fibers on the Stress-Strain Behavior of Aligned Steel Fiber Ultra-High Performance Concrete under Uniaxial Compression. J. Build. Eng. 2024, 98, 111092. [Google Scholar] [CrossRef]

- Yassin, A.M.; Mohie Eldin, M.; Hafez, M.A.; Elnaggar, M.A. The Flexural Behavior and Mechanical Properties of Super High-Performance Concrete (SHPC) Reinforced Using the Hybridization of Micro Polypropylene and Macro Steel Fibers. Buildings 2024, 14, 1887. [Google Scholar] [CrossRef]

- Li, Z.; Yang, Y.; Wang, Y.; Wang, W.; Zhang, B. Effect of Macro Fibers on Chloride Permeability and Damage of Concrete Under Uniaxial Compression. Materials 2025, 18, 784. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Wu, H.; Liu, Y.; Yang, J.; Fang, Z.; Lin, B. Preparation and Optimization of Ultra-Light and Thermal Insulative Aerogel Foam Concrete. Constr. Build. Mater. 2019, 205, 529–542. [Google Scholar] [CrossRef]

- Li, X.; Lu, C.; Cui, Y.; Zhou, L. Study on the Bond Properties between Steel Bar and Fiber Reinforced Concrete after High Temperatures. Structures 2023, 49, 889–902. [Google Scholar] [CrossRef]

- Tanyildizi, H.; Şengür, A.; Akbulut, Y.; Şahin, M. Deep Learning Model for Estimating the Mechanical Properties of Concrete Containing Silica Fume Exposed to High Temperatures. Front. Struct. Civ. Eng. 2020, 14, 1316–1330. [Google Scholar] [CrossRef]

- Ba, G.; Miao, J.; Zhang, W.; Liu, C. Influence of Cracking on Heat Propagation in Reinforced Concrete Structures. J. Struct. Eng. 2016, 142, 04016035. [Google Scholar] [CrossRef]

- González, D.C.; Rahman, M.; Mínguez, J.; Vicente, M.A.; Hindi, R. Influence of Fibers and Curing Conditions on the Pore Morphology in Plain and Fiber-Reinforced High-Performance Concrete through the Use of Computed Tomography Scan Technology. Appl. Sci. 2020, 10, 4286. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, S.; Niu, D.; Fu, Q. Quantitative Evaluation of the Characteristics of Air Voids and Their Relationship with the Permeability and Salt Freeze-Thaw Resistance of Hybrid Steel-Polypropylene Fiber-Reinforced Concrete Composites. Cem. Concr. Compos. 2022, 125, 104292. [Google Scholar] [CrossRef]

- Khosh, B.; Atapour, H. Assessment of Mechanical Behavior of Sprayed Concrete Reinforced with Waste Tire Textile Fibers. Sci. Rep. 2024, 14, 8873. [Google Scholar] [CrossRef]

- Doğruyol, M.; Ayhan, E.; Karaşin, A. Effect of Waste Steel Fiber Use on Concrete Behavior at High Temperature. Case Stud. Constr. Mater. 2024, 20, e03051. [Google Scholar] [CrossRef]

- Yi, F.; Kazmi, S.M.S.; Hu, B.; Wu, Y.F. Mitigating the Brittle Behavior of Compression Cast Concrete Using Polypropylene Fibers. Constr. Build. Mater. 2024, 440, 137435. [Google Scholar] [CrossRef]

- Benouadah, A.; Beddar, M.; Meddah, A. Physical and Mechanical Behaviour of a Roller Compacted Concrete Reinforced with Polypropylene Fiber. J. Fundam. Appl. Sci. 2017, 9, 623–635. [Google Scholar] [CrossRef][Green Version]

- Algin, Z.; Gerginci, S. Freeze-Thaw Resistance and Water Permeability Properties of Roller Compacted Concrete Produced with Macro Synthetic Fibre. Constr. Build. Mater. 2020, 234, 117382. [Google Scholar] [CrossRef]

- Lugaresi, F.; Kotsovinos, P.; Lenk, P.; Rein, G. Review of the Mechanical Failure of Non-Combustible Facade Systems in Fire. Constr. Build. Mater. 2022, 361, 129506. [Google Scholar] [CrossRef]

- Biolzi, L.; Cattaneo, S.; Rosati, G. Evaluating Residual Properties of Thermally Damaged Concrete. Cem. Concr. Compos. 2008, 30, 907–916. [Google Scholar] [CrossRef]

- Wu, B.; Yu, Y.; Zhao, X.Y. Residual Mechanical Properties of Compound Concrete Containing Demolished Concrete Lumps after Exposure to High Temperatures. Fire Saf. J. 2019, 105, 62–78. [Google Scholar] [CrossRef]

- Grzesiak, S.; Pahn, M.; Schultz-Cornelius, M.; Harenberg, S.; Hahn, C. Influence of Fiber Addition on the Properties of High-Performance Concrete. Materials 2021, 14, 3736. [Google Scholar] [CrossRef]

| Cement Characteristic | Wt (%) | Physical Property | ||

|---|---|---|---|---|

| SiO2 | 18.81 | Specific gravity | 3.15 | |

| Al2O3 | 5.71 | Blaine specific surface (cm2/g) | 3530 | |

| Fe2O3 | 3.09 | 0.045 mm elekte kalan (%) | 7.6 | |

| CaO | 62.70 | |||

| MgO | 1.16 | Mechanical property | ||

| SO3 | 2.39 | Compressive strength (MPa) | 1-day | 14.7 |

| Na2O + 0.658 K2O | 0.92 | 2-day | 26.80 | |

| Cl− | 0.01 | 7-day | 49.80 | |

| Loss on ignition | 3.20 | 28-day | 58.5 | |

| Free CaO | 1.26 | |||

| Crushed Lime Stone | Size (mm) | SSD Bulk Specific Gravity | Loose Bulk Density (kg/m3) | Water Absorption Capacity (%) |

| 0–5 | 2.68 | 1655 | 1.64 | |

| 5–12 | 2.68 | 1441 | 0.51 | |

| 12–22 | 2.69 | 1405 | 0.40 |

| Property | Length (l) (mm) | Diameter (d) (mm) | Slenderness (l/d) | Specific Gravity | Tensile Strength (MPa) | Melting Point (°C) |

|---|---|---|---|---|---|---|

| S fiber | 60 | 1 | 60 | 7.8 | 1000–1400 | >1500 |

| PP fiber | 60 | 0.9 | 67 | 0.91 | 450–700 | 162 |

| WS fiber | 60 | 1 | 60 | 7.85 | 800–1200 | >1400 |

| Series Designation | Optimum Water Content (%) | Maximum Dry Unit Weight | SSD Aggregate | S Fiber | WS Fiber | PP Fiber | Cement | w/c Ratio | ||

|---|---|---|---|---|---|---|---|---|---|---|

| 0–5 (mm) | 5–12 (mm) | 12–22 (mm) | ||||||||

| C | 4.97 | 2345 | 1236 | 412 | 414 | 0 | 0 | 0 | 300 | 0.42 |

| S60-0.25 | 5.07 | 2372 | 1227 | 409 | 411 | 19.50 | 0 | 0 | 300 | 0.43 |

| S60-0.50 | 5.23 | 2356 | 1223 | 408 | 409 | 39.00 | 0 | 0 | 300 | 0.43 |

| S60-0.75 | 5.42 | 2399 | 1210 | 403 | 405 | 58.50 | 0 | 0 | 300 | 0.45 |

| S60-1.0 | 5.47 | 2387 | 1196 | 399 | 400 | 78.00 | 0 | 0 | 300 | 0.47 |

| S60-1.25 | 5.51 | 2394 | 1192 | 397 | 399 | 97.50 | 0 | 0 | 300 | 0.47 |

| WS60-0.25 | 4.53 | 2359 | 1227 | 409 | 411 | 0 | 19.63 | 0 | 300 | 0.43 |

| WS60-0.50 | 4.65 | 2367 | 1223 | 408 | 409 | 0 | 39.25 | 0 | 300 | 0.43 |

| WS60-0.75 | 5.03 | 2365 | 1210 | 403 | 405 | 0 | 58.88 | 0 | 300 | 0.45 |

| WS60-1.0 | 5.36 | 2406 | 1196 | 399 | 400 | 0 | 78.50 | 0 | 300 | 0.47 |

| WS60-1.25 | 4.96 | 2403 | 1192 | 397 | 399 | 0 | 98.13 | 0 | 300 | 0.47 |

| P60-0.25 | 4.87 | 2311 | 1227 | 409 | 411 | 0 | 0 | 2.28 | 300 | 0.43 |

| P60-0.50 | 5.35 | 2325 | 1218 | 406 | 408 | 0 | 0 | 4.55 | 300 | 0.43 |

| P60-0.75 | 5.46 | 2330 | 1204 | 402 | 403 | 0 | 0 | 6.83 | 300 | 0.46 |

| P60-1.0 | 5.47 | 2331 | 1186 | 395 | 397 | 0 | 0 | 9.10 | 300 | 0.49 |

| P60-1.25 | 5.66 | 2301 | 1182 | 394 | 396 | 0 | 0 | 11.38 | 300 | 0.49 |

| Series Designation | SSD Aggregate | S Fiber | WS Fiber | PP Fiber | Cement | w/c Ratio | ||

|---|---|---|---|---|---|---|---|---|

| 0–5 (mm) | 5–12 (mm) | 12–22 (mm) | ||||||

| C | 1307 | 436 | 438 | 0 | 0 | 0 | 300 | 0.42 |

| S60-0.25 | 1287 | 429 | 431 | 20.46 | 0 | 0 | 300 | 0.43 |

| S60-0.50 | 1300 | 434 | 435 | 41.46 | 0 | 0 | 300 | 0.43 |

| S60-0.75 | 1265 | 421 | 423 | 61.15 | 0 | 0 | 300 | 0.45 |

| S60-1.0 | 1264 | 422 | 423 | 82.43 | 0 | 0 | 300 | 0.47 |

| S60-1.25 | 1254 | 418 | 420 | 102.58 | 0 | 0 | 300 | 0.47 |

| WS60-0.25 | 1299 | 433 | 435 | 0 | 20.77 | 0 | 300 | 0.43 |

| WS60-0.50 | 1297 | 433 | 434 | 0 | 41.62 | 0 | 300 | 0.43 |

| WS60-0.75 | 1280 | 426 | 429 | 0 | 62.30 | 0 | 300 | 0.45 |

| WS60-1.0 | 1253 | 418 | 419 | 0 | 82.23 | 0 | 300 | 0.47 |

| WS60-1.25 | 1250 | 416 | 418 | 0 | 102.89 | 0 | 300 | 0.47 |

| P60-0.25 | 1317 | 439 | 441 | 0 | 0 | 2.44 | 300 | 0.43 |

| P60-0.50 | 1289 | 430 | 432 | 0 | 0 | 4.81 | 300 | 0.43 |

| P60-0.75 | 1268 | 423 | 424 | 0 | 0 | 7.19 | 300 | 0.46 |

| P60-1.0 | 1234 | 411 | 413 | 0 | 0 | 9.47 | 300 | 0.49 |

| P60-1.25 | 1234 | 411 | 414 | 0 | 0 | 11.88 | 300 | 0.49 |

| Parameter | Symbol | Level 1 | Level 2 | Level 3 | Level 4 | Level 5 | Level 6 |

|---|---|---|---|---|---|---|---|

| Fiber dosage | A | 0 | 0.25 | 0.5 | 0.75 | 1 | 1.25 |

| Temperature (°C) | B | 25 | 300 | 600 | - | - | - |

| Fiber type | C | PP | S | WS | - | - | - |

| Fiber Type | Fiber Dosage (%) | |||||

|---|---|---|---|---|---|---|

| 0 | 0.25 | 0.5 | 0.75 | 1 | 1.25 | |

| C | 33 | - | - | - | - | - |

| S60 | - | 41 | 69 | 83 | 92 | 109 |

| WS60 | - | 39 | 67 | 75 | 89 | 103 |

| P60 | - | 37 | 53 | 71 | 81 | 94 |

| Temperature | 25 °C | 300 °C | 600 °C | 900 °C | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Series Designation | CS * (MPa) | WAC ** (%) | CS (MPa) | WAC (%) | WL *** (%) | CS (MPa) | WAC (%) | WL (%) | CS (MPa) | WAC (%) | WL (%) |

| C | 59.70 | 1.55 | 64.53 | 2.18 | 1.73 | 35.67 | 4.07 | 5.19 | 5.53 | 6.01 | 10.86 |

| S60-0.25 | 63.61 | 2.19 | 65.18 | 2.45 | 1.89 | 41.09 | 4.23 | 5.40 | 9.09 | 6.07 | 11.52 |

| S60-0.50 | 62.27 | 2.31 | 63.71 | 2.76 | 2.19 | 41.58 | 5.11 | 5.62 | 9.46 | 6.85 | 11.11 |

| S60-0.75 | 65.02 | 2.91 | 67.66 | 3.39 | 2.50 | 42.81 | 6.23 | 6.32 | 9.49 | 8.92 | 11.13 |

| S60-1.0 | 66.64 | 3.37 | 71.55 | 4.24 | 3.11 | 44.95 | 7.38 | 7.07 | 10.12 | 10.83 | 10.86 |

| S60-1.25 | 56.48 | 4.01 | 59.03 | 5.19 | 3.36 | 37.04 | 9.27 | 7.89 | 8.93 | 12.43 | 12.21 |

| WS60-0.25 | 62.23 | 2.11 | 62.87 | 2.23 | 1.97 | 43.71 | 3.95 | 4.88 | 8.19 | 5.46 | 11.30 |

| WS60-0.50 | 63.98 | 2.33 | 64.22 | 2.71 | 2.33 | 45.87 | 4.67 | 5.53 | 8.02 | 6.51 | 11.57 |

| WS60-0.75 | 61.44 | 2.67 | 65.15 | 3.16 | 2.66 | 46.31 | 5.51 | 6.40 | 7.55 | 7.89 | 11.57 |

| WS60-1.0 | 65.81 | 3.21 | 68.01 | 3.90 | 3.07 | 48.99 | 6.73 | 6.25 | 9.46 | 9.78 | 9.53 |

| WS60-1.25 | 58.25 | 3.75 | 61.47 | 4.93 | 2.88 | 43.26 | 8.56 | 6.96 | 9.51 | 11.67 | 12.52 |

| P60-0.25 | 61.12 | 2.09 | 57.94 | 2.87 | 2.49 | 46.55 | 4.51 | 6.00 | 6.16 | 6.53 | 14.16 |

| P60-0.50 | 61.73 | 2.21 | 56.21 | 3.17 | 2.77 | 47.84 | 5.29 | 6.96 | 4.82 | 7.50 | 12.26 |

| P60-0.75 | 62.16 | 2.56 | 57.83 | 3.69 | 2.89 | 46.78 | 6.42 | 6.57 | 5.89 | 8.48 | 13.73 |

| P60-1.0 | 60.77 | 2.98 | 55.14 | 4.41 | 3.06 | 48.51 | 7.60 | 7.13 | 5.78 | 10.62 | 14.17 |

| P60-1.25 | 54.10 | 3.32 | 47.32 | 5.22 | 3.74 | 43.47 | 9.53 | 7.84 | 4.69 | 12.85 | 14.79 |

| Experiment Number | Control Factors | Compressive Strength (MPa) | S/N Ratio for Compressive Strength | Means for Compressive Strength | ||

|---|---|---|---|---|---|---|

| Fiber Dosage | Temperature | Fiber Type | ||||

| 1 | 0 | 25 | PP | 59.70 | 35.5195 | 59.70 |

| 2 | 0 | 300 | S | 64.53 | 36.1952 | 64.53 |

| 3 | 0 | 600 | WS | 35.67 | 31.0461 | 35.67 |

| 4 | 0.25 | 25 | PP | 61.12 | 35.7237 | 61.12 |

| 5 | 0.25 | 300 | S | 65.18 | 36.2823 | 65.18 |

| 6 | 0.25 | 600 | WS | 43.71 | 32.8116 | 43.71 |

| 7 | 0.5 | 25 | S | 62.27 | 35.8856 | 62.27 |

| 8 | 0.5 | 300 | WS | 64.22 | 36.1534 | 64.22 |

| 9 | 0.5 | 600 | PP | 47.84 | 335958 | 47.84 |

| 10 | 0.75 | 25 | WS | 61.44 | 35.7690 | 61.44 |

| 11 | 0.75 | 300 | PP | 57.83 | 35.2431 | 57.83 |

| 12 | 0.75 | 600 | S | 42.81 | 32.6309 | 42.81 |

| 13 | 1 | 25 | S | 66.64 | 36.4747 | 66.64 |

| 14 | 1 | 300 | WS | 68.01 | 36.6515 | 68.01 |

| 15 | 1 | 600 | PP | 48.51 | 33.7166 | 48.51 |

| 16 | 1.25 | 25 | WS | 58.25 | 35.3059 | 58.25 |

| 17 | 1.25 | 300 | PP | 4732 | 33.5009 | 47.32 |

| 18 | 1.25 | 600 | S | 37.04 | 31.3734 | 37.04 |

| Response for Signal-to-Noise Ratios | Response for Means | ||||||

|---|---|---|---|---|---|---|---|

| Level | Fiber Dosage | Temperature | Fiber Type | Level | Fiber Dosage | Temperature | Fiber Type |

| 1 | 34.25 | 35.78 | 34.55 | 1 | 53.30 | 61.57 | 53.72 |

| 2 | 34.94 | 35.67 | 34.81 | 2 | 56.67 | 61.18 | 56.41 |

| 3 | 35.21 | 32.53 | 34.62 | 3 | 58.11 | 42.60 | 55.22 |

| 4 | 34.55 | 4 | 54.03 | ||||

| 5 | 35.61 | 5 | 61.05 | ||||

| 6 | 33.39 | 6 | 47.54 | ||||

| Delta | 2.22 | 3.25 | 0.26 | Delta | 13.52 | 18.97 | 2.69 |

| Rank | 2 | 1 | 3 | Rank | 2 | 1 | 3 |

| Source | Degree of Freedom (DoF) | Sum of Squares (SS) | Mean Square (MS) | F-Value | p-Value | Effect Rates (%) |

|---|---|---|---|---|---|---|

| Fiber dosage | 5 | 325.69 | 65.14 | 4.26 | 0.035 | 17.31% |

| Temperature | 2 | 1411.08 | 705.54 | 46.09 | 0 | 75.02% |

| Fiber type | 2 | 21.83 | 10.91 | 0.71 | 0.519 | 1.16% |

| Error | 8 | 122.46 | 15.31 | 6.51% | ||

| Total | 17 | 1881.05 | 100.00% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ünverdi, M.; Kaya, Y.; Mardani, N.; Mardani, A. Investigation of the Microstructural and Mechanical Properties of Fiber-Reinforced Roller-Compacted Concrete Under High-Temperature Exposure. Materials 2025, 18, 2430. https://doi.org/10.3390/ma18112430

Ünverdi M, Kaya Y, Mardani N, Mardani A. Investigation of the Microstructural and Mechanical Properties of Fiber-Reinforced Roller-Compacted Concrete Under High-Temperature Exposure. Materials. 2025; 18(11):2430. https://doi.org/10.3390/ma18112430

Chicago/Turabian StyleÜnverdi, Murteda, Yahya Kaya, Naz Mardani, and Ali Mardani. 2025. "Investigation of the Microstructural and Mechanical Properties of Fiber-Reinforced Roller-Compacted Concrete Under High-Temperature Exposure" Materials 18, no. 11: 2430. https://doi.org/10.3390/ma18112430

APA StyleÜnverdi, M., Kaya, Y., Mardani, N., & Mardani, A. (2025). Investigation of the Microstructural and Mechanical Properties of Fiber-Reinforced Roller-Compacted Concrete Under High-Temperature Exposure. Materials, 18(11), 2430. https://doi.org/10.3390/ma18112430