Seawater-Activated Mineral Synergy in Sulfoaluminate Cement: Corrosion Resistance Optimization via Orthogonal Design

Abstract

1. Introduction

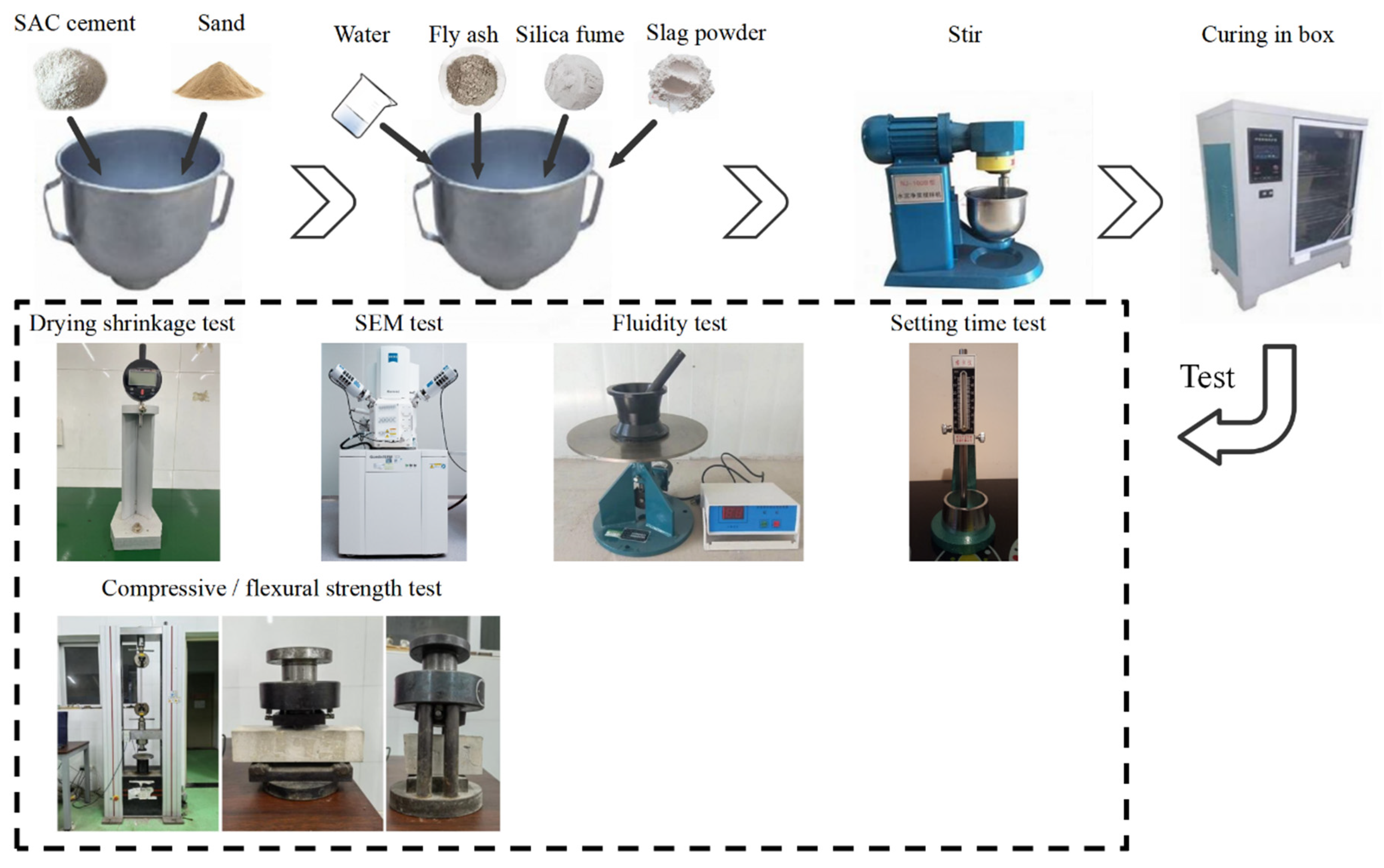

2. Materials and Methods

2.1. Raw Materials

2.2. Specimen Preparation and Curing

2.3. Testing Methods

2.3.1. Setting Time

2.3.2. Flowability

2.3.3. Drying Shrinkage

2.3.4. Compressive/Flexural Strength

2.3.5. Scanning Electron Microscope (SEM) Images

3. Results

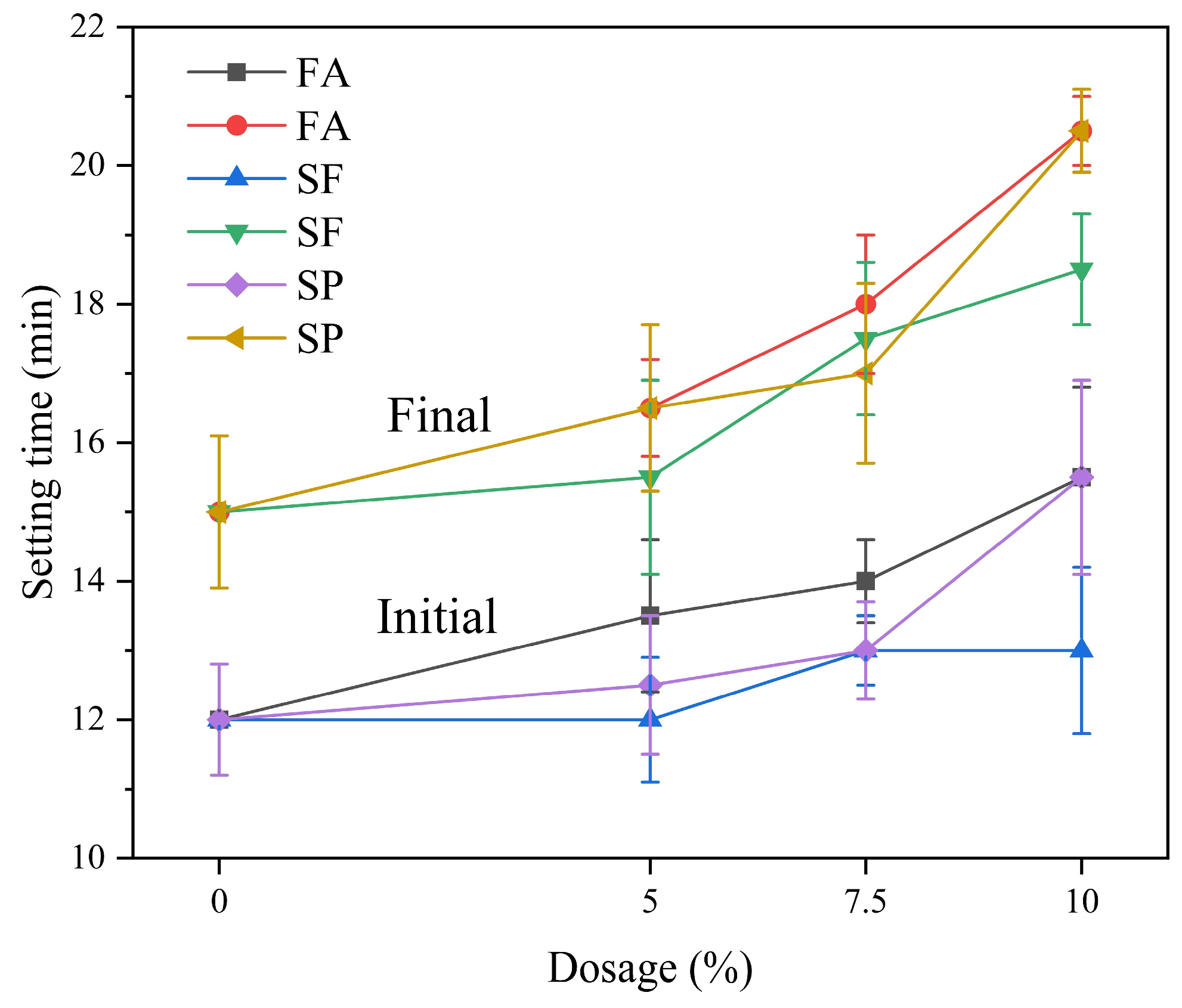

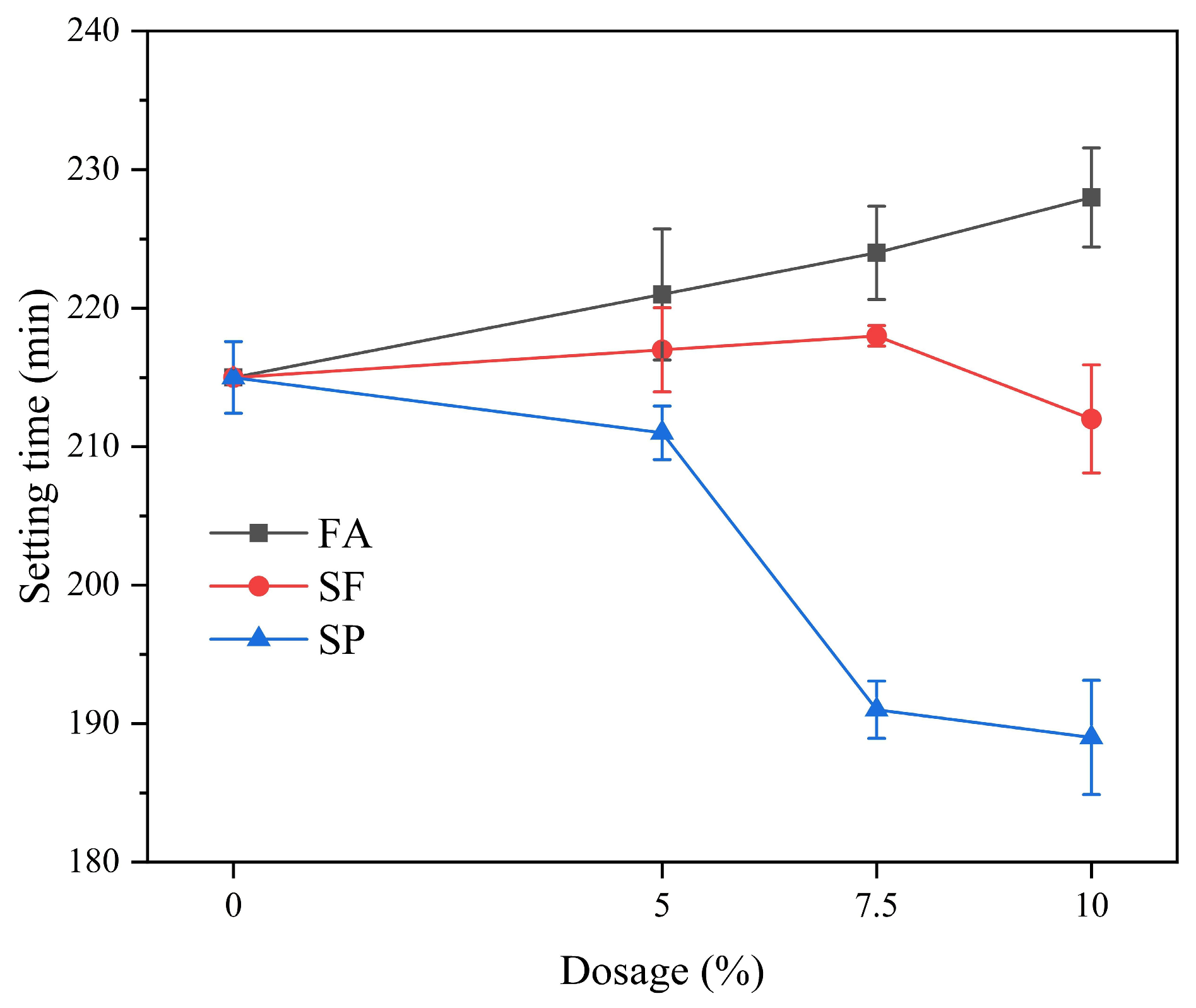

3.1. Setting Time

3.2. Fluidity

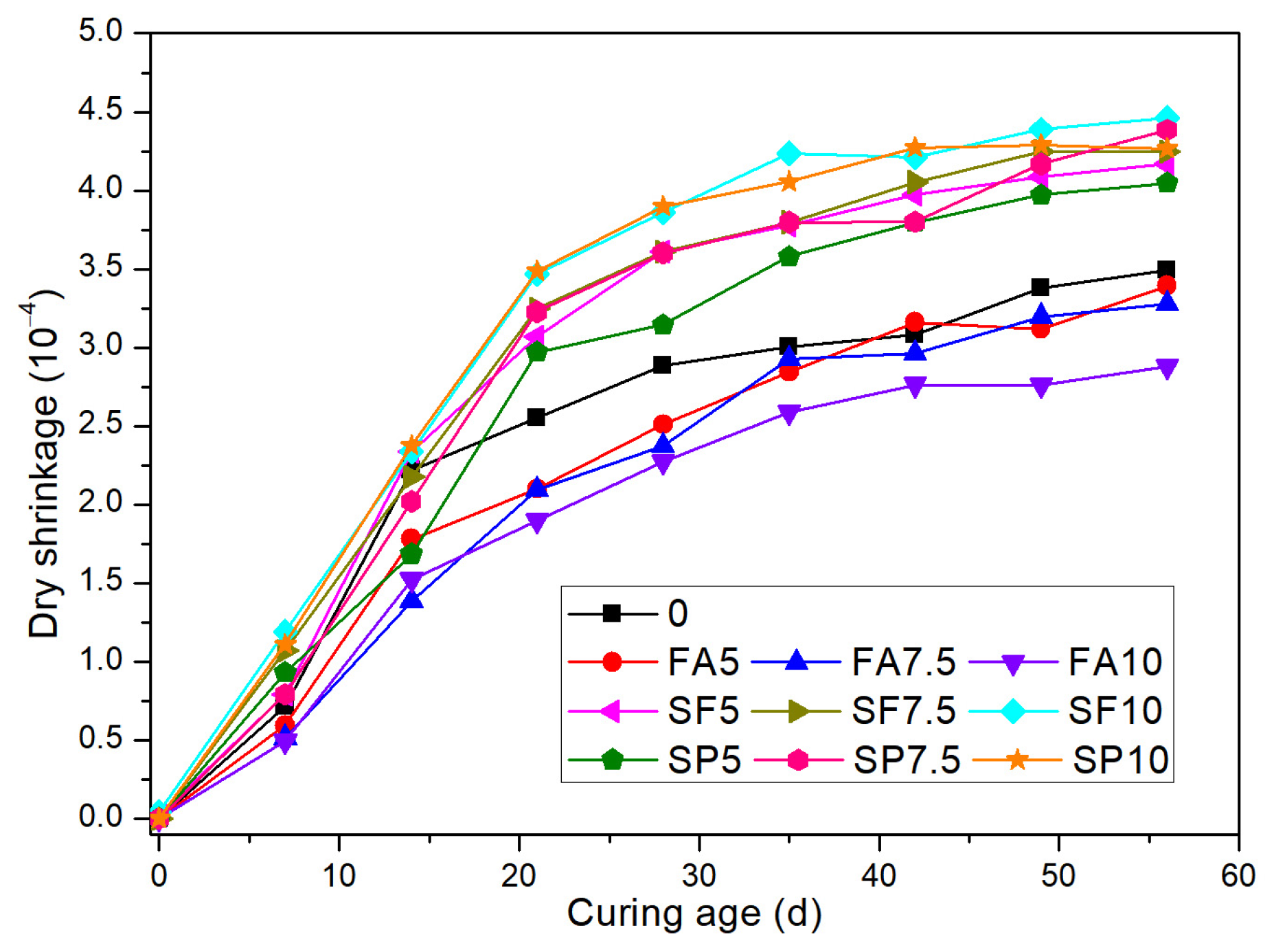

3.3. Drying Shrinkage Performance

3.4. Mechanics Performance

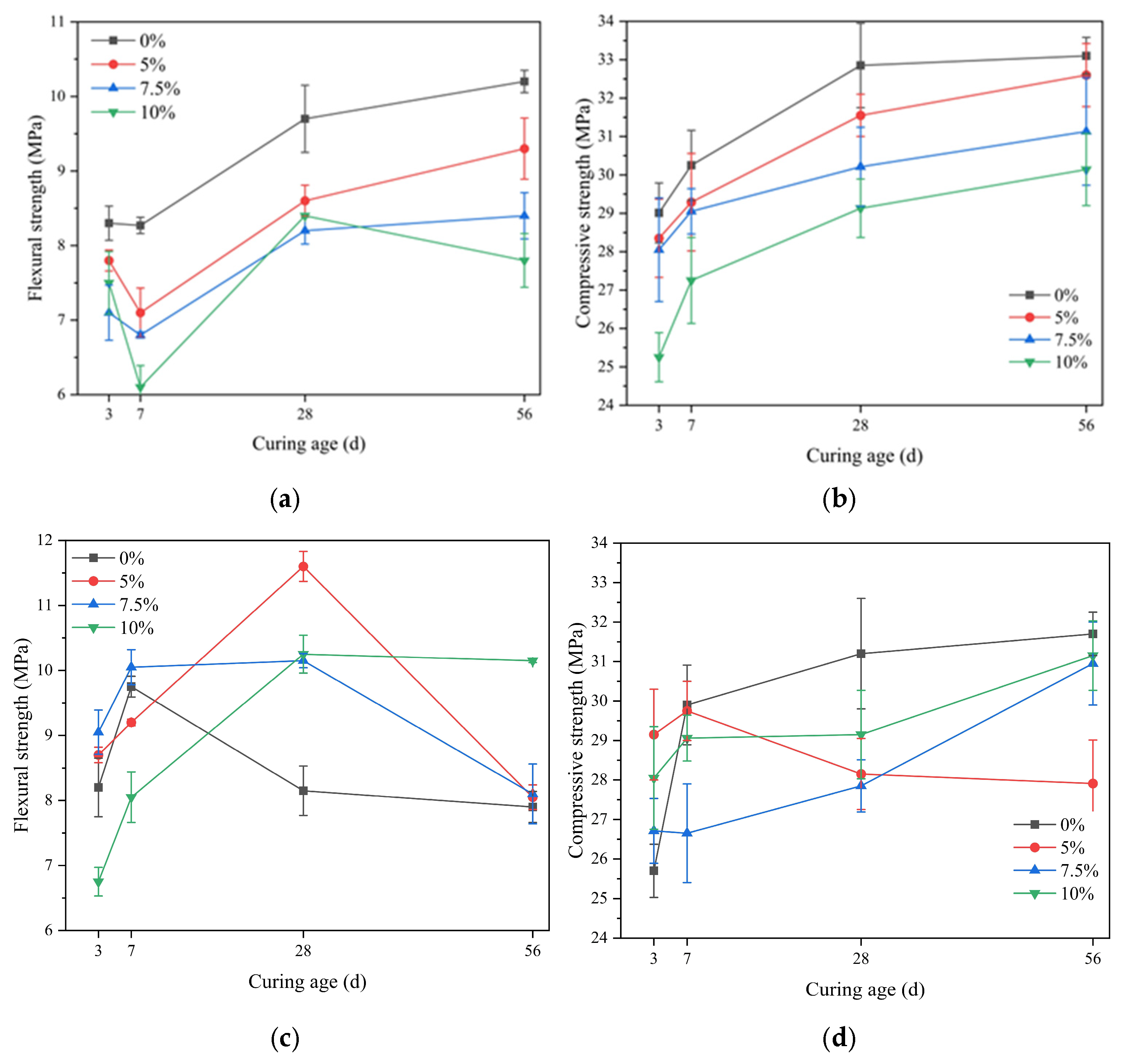

3.4.1. The Influence of Fly Ash

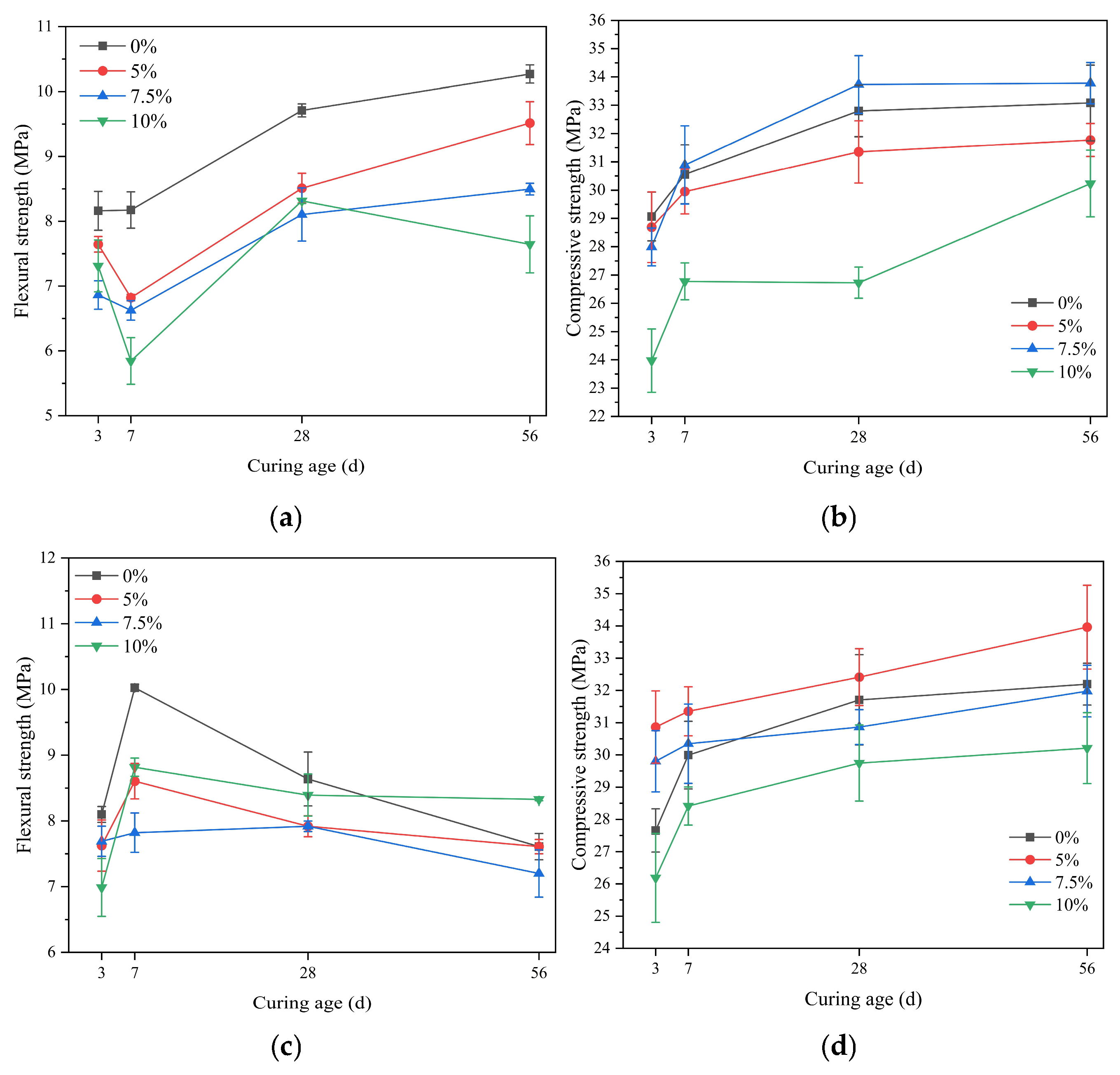

3.4.2. The Influence of Silica Fume

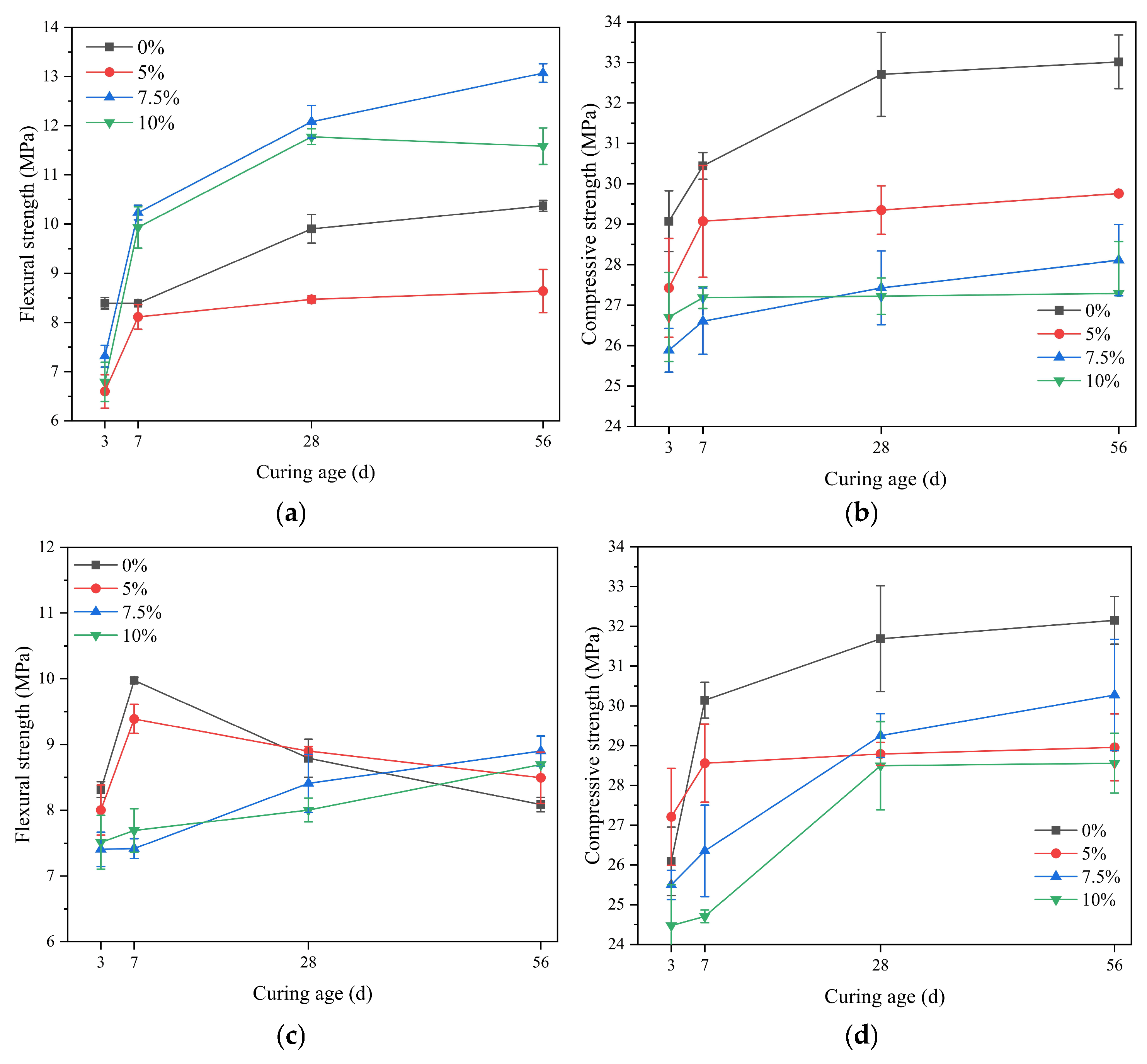

3.4.3. The Influence of Slag Powder

3.4.4. The Influence of Curing Conditions

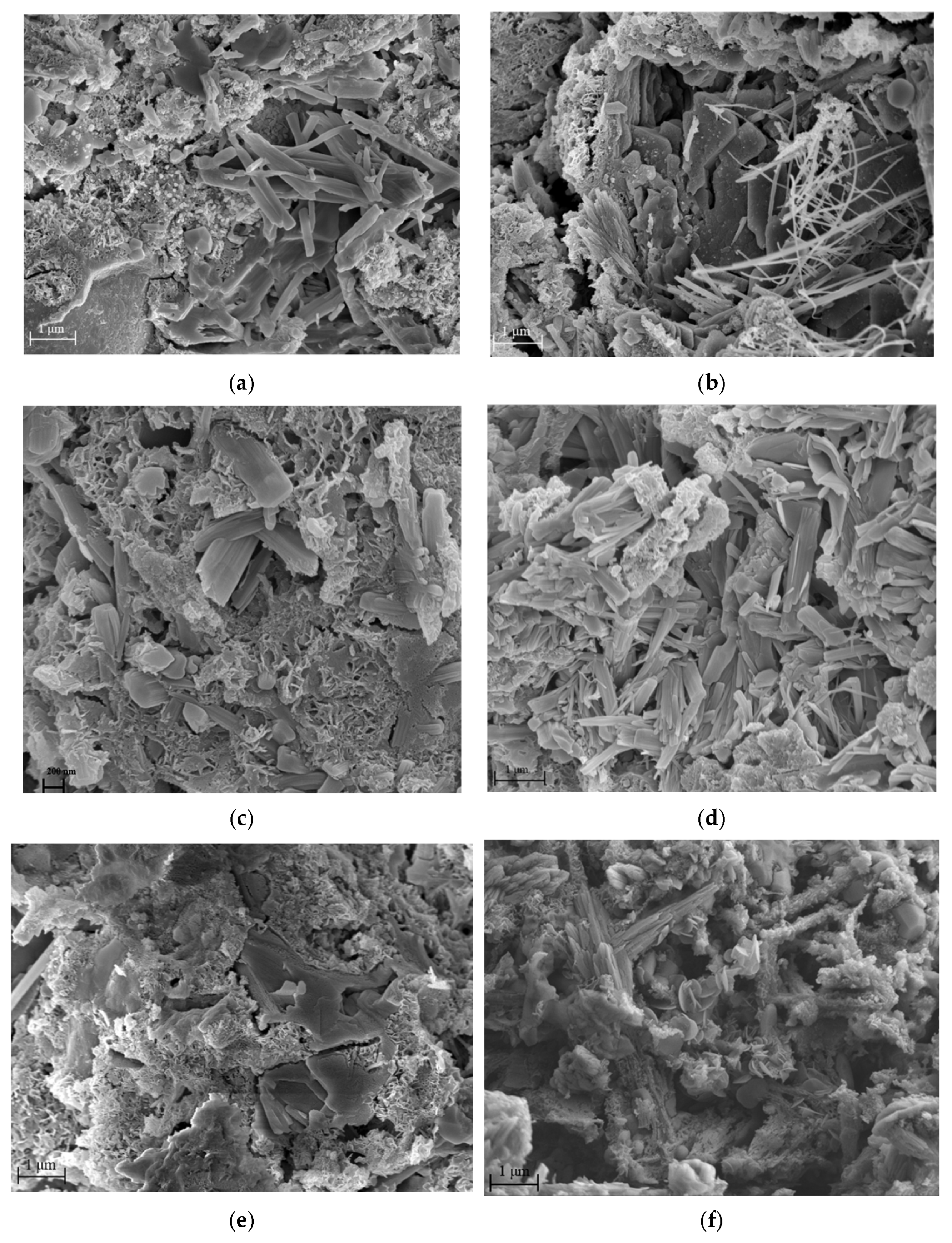

3.5. SEM Analysis

4. Influence of Composite Addition of Mineral Admixture

4.1. Experimental Design

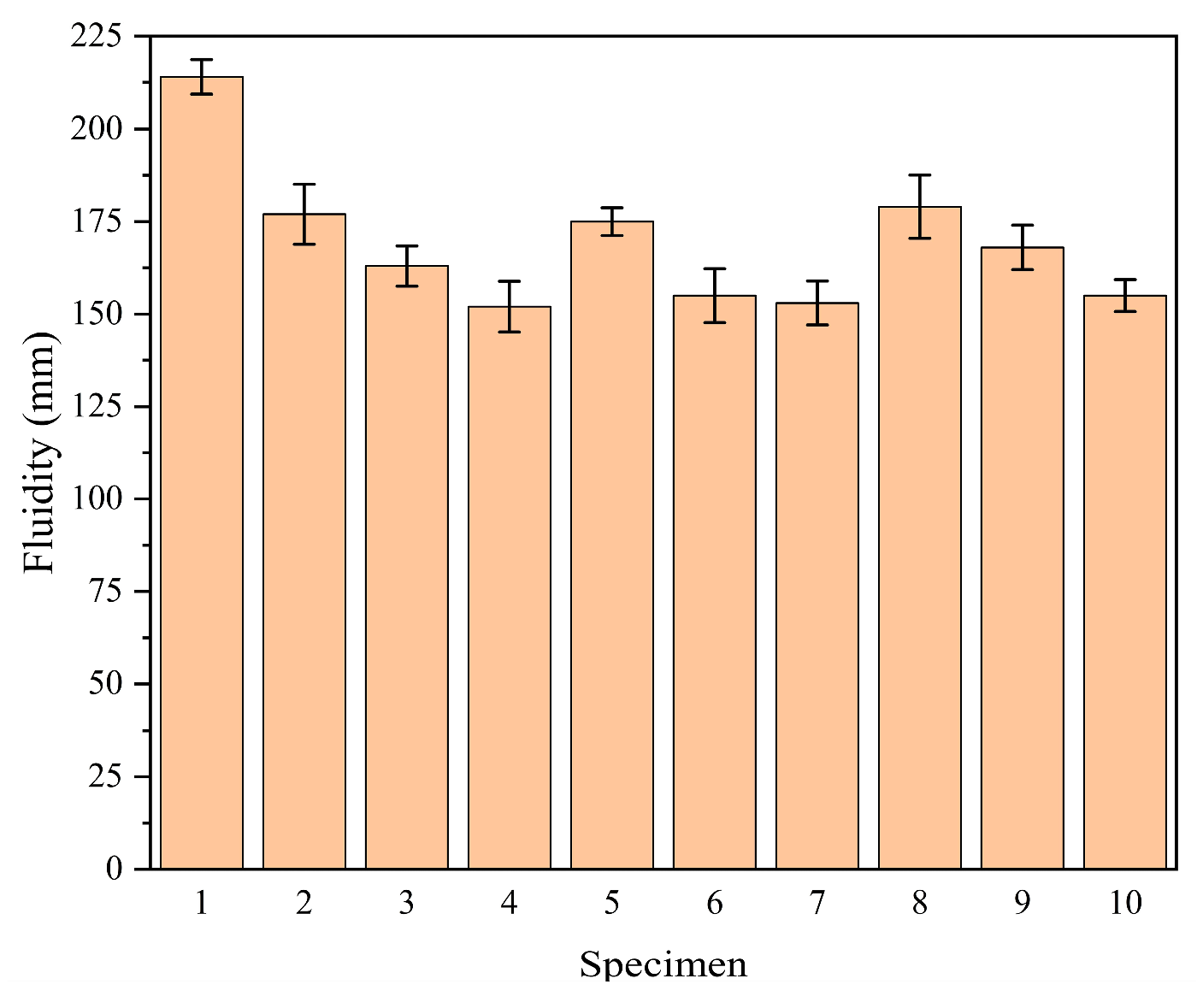

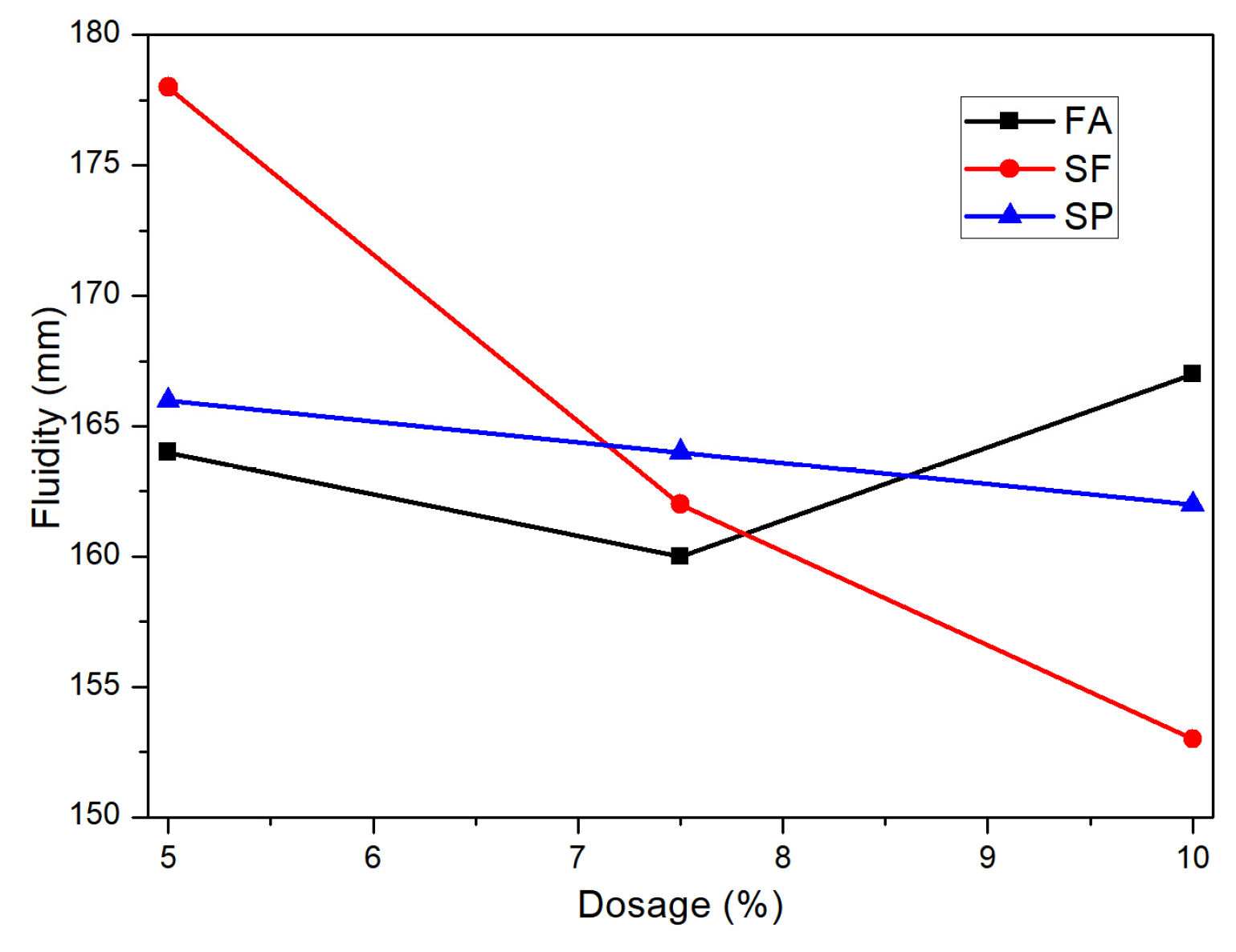

4.2. Analysis of Fluidity

4.3. Analysis of Flexural Strength

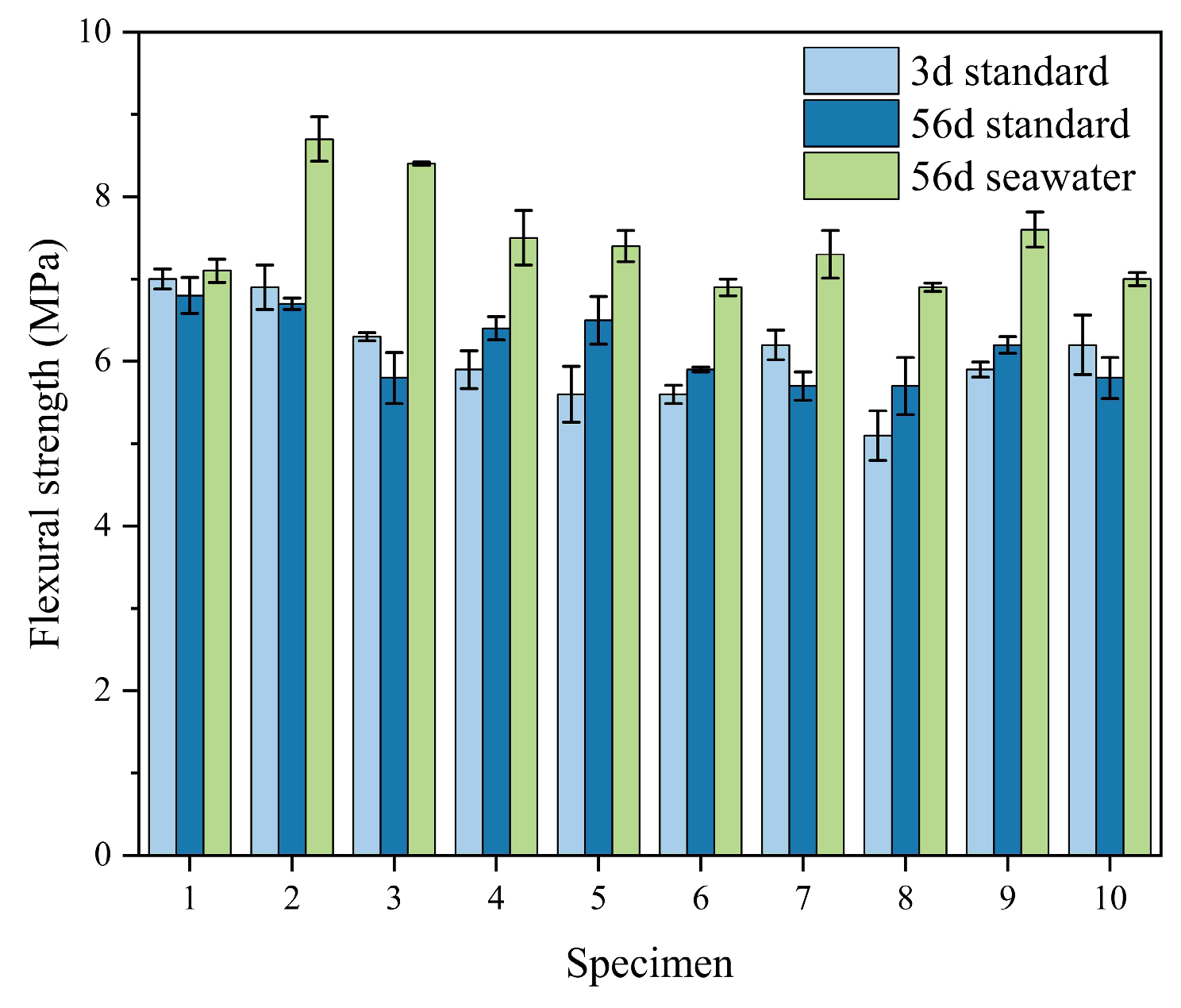

4.3.1. Basic Data Analysis

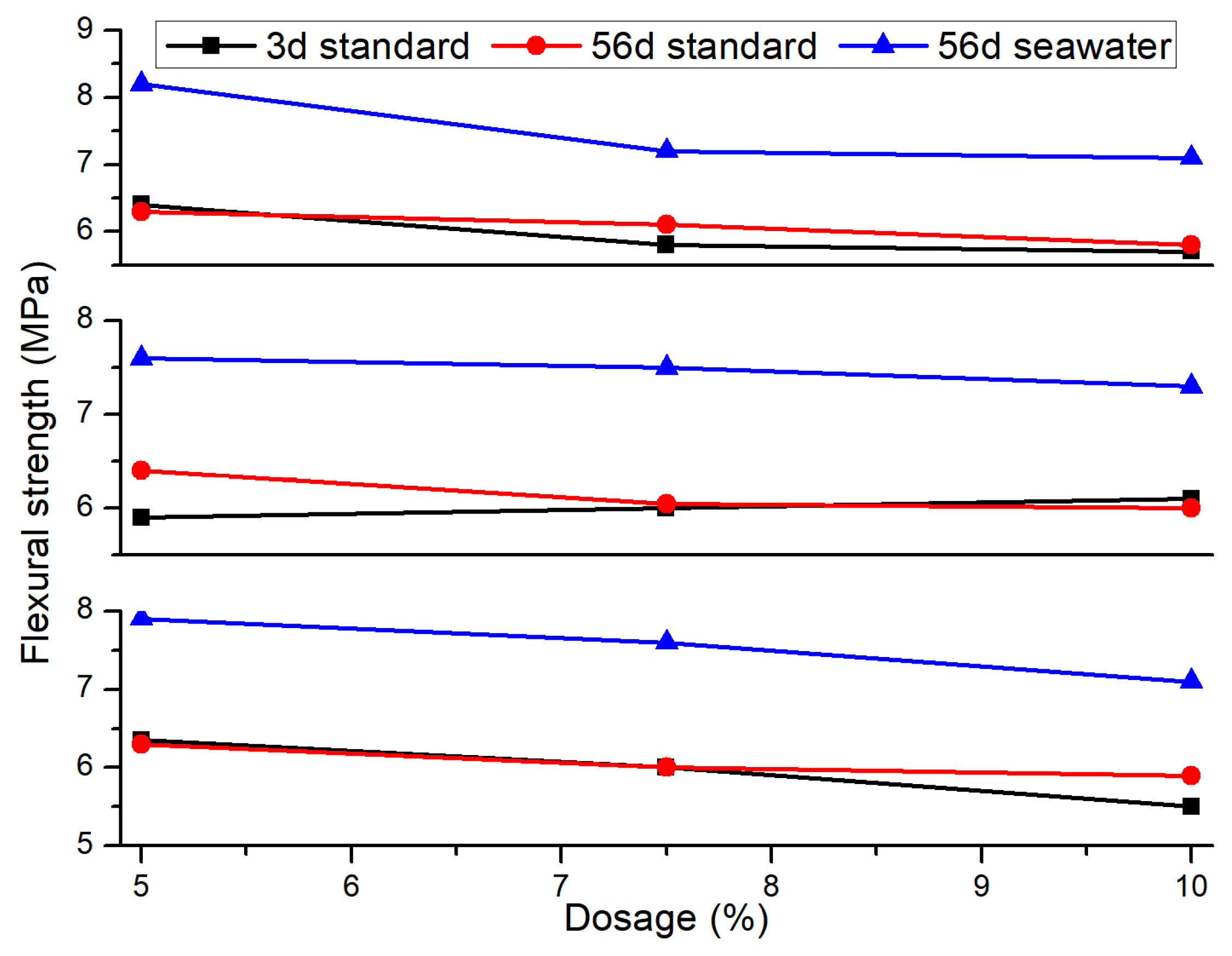

4.3.2. Range Analysis

4.4. Analysis of Compressive Strength

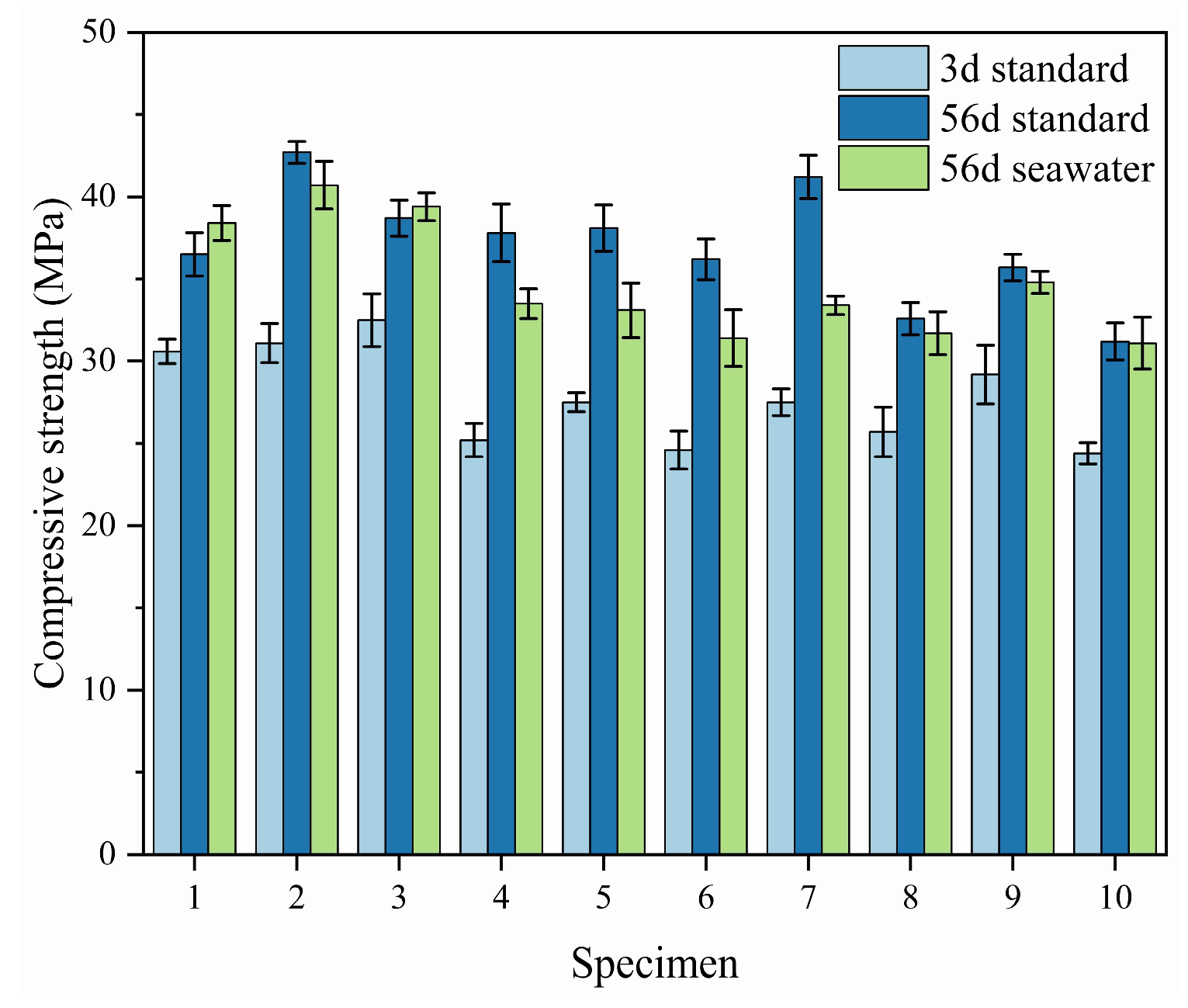

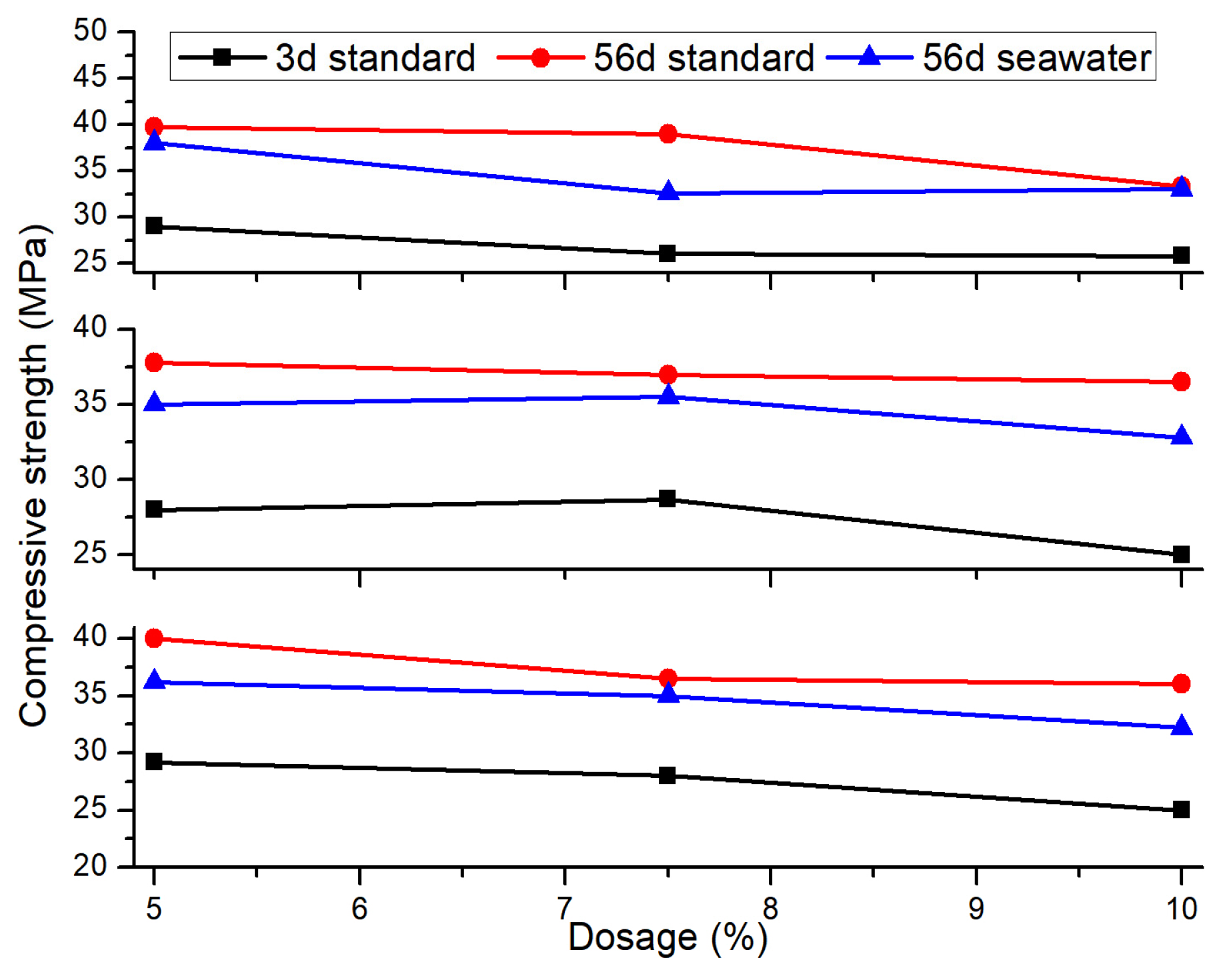

4.4.1. Basic Data Analysis

4.4.2. Range Analysis

5. Conclusions

- (1)

- The addition of mineral admixtures exhibits a dilution effect, with the addition of fly ash, silica fume, and slag powder all prolonging the setting time of SAC.

- (2)

- A higher dosage of fly ash is more beneficial for the fluidity of SAC mortar and has a more significant inhibitory effect on the drying shrinkage of the mortar. Under standard curing conditions, the strength of SAC mortar decreases with the increase in fly ash dosage. At low dosages, the microstructure of the paste has well-formed calcium sulfate hexahydrate (ettringite) and gel; however, in the seawater immersion environment, the fly ash is activated by the seawater components, and the strength of the mortar increases with the fly ash dosage. The microstructure at low dosages is less dense than that under standard curing. Under standard curing conditions, a fly ash dosage of 5.0% is more appropriate, while in the seawater environment, a fly ash dosage of 10.0% is more suitable.

- (3)

- Silica fume has a high specific surface area and absorbs a large amount of water, leading to reduced fluidity of the mortar and an inhibitory effect on drying shrinkage. Under standard curing conditions, a silica fume dosage of 7.5% has an enhancing effect on compressive strength. In the seawater environment, the compressive strength of SAC mortar gradually decreases with the increase in silica fume dosage, but when the dosage is 5.0%, the compressive strength is higher than that of the blank group, showing good resistance to seawater erosion. The microstructure of the paste is similar under both curing conditions, but the microstructure in the seawater environment has more pores. Under standard curing conditions, a silica fume dosage of 7.5% is more appropriate, while in the seawater environment, a silica fume dosage of 5.0% is more suitable.

- (4)

- Slag powder has little effect on the fluidity of the mortar and exacerbates the degree of drying shrinkage. Under standard curing conditions, slag powder is detrimental to the compressive strength of SAC mortar and, as the dosage of slag powder increases, the later-stage compressive strength decreases. In the seawater environment, the addition of slag powder is not beneficial for the compressive strength and early flexural strength of SAC mortar, and the overall effect of slag powder on resistance to seawater erosion is poor. From the microstructure observations, the addition of slag powder results in a slower hydration process of SAC under both curing conditions compared to fly ash and silica fume.

- (5)

- When fly ash, silica fume, and slag powder are added together, under both standard curing conditions and seawater immersion, the order of influence of different factor levels on the fluidity of SAC mortar is: silica fume > fly ash > slag powder. The most significant influence on the flexural strength and compressive strength of SAC mortar is fly ash. Under standard curing conditions, the optimal combination for flexural strength is a fly ash dosage of 5.0%, a silica fume dosage of 10.0%, and a slag powder dosage of 10.0%, while the optimal combination for compressive strength is a fly ash dosage of 5.0%, a silica fume dosage of 5.0%, and a slag powder dosage of 5.0%. In seawater immersion, the optimal 56-day strength combination was 5% fly ash, 5% silica fume, and 5% slag powder.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dikshit, A.K.; Gupta, S.; Chaturvedi, S.K.; Singh, L.P. Usage of lime sludge waste from paper industry for production of Portland cement Clinker: Sustainable expansion of Indian cement industry. Case Stud. Chem. Environ. Eng. 2024, 9, 100557. [Google Scholar] [CrossRef]

- Benjamin, B.; Zachariah, S.; Sudhakumar, J.; Suchithra, T. Harnessing construction biotechnology for sustainable upcycled cement composites: A meta-analytical review. J. Build. Eng. 2024, 86, 108973. [Google Scholar] [CrossRef]

- Liu, J.; Liu, J.; Cheng, L.; Zhu, J.; Xing, F.; Fan, X.; Tang, L. Determining the influence of LC2 and FA on the iodide diffusion coefficient of in seawater and sea sand concrete: A novel modified RIM test method. Cem. Concr. Compos. 2023, 143, 105257. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, X.; Yu, M.; Yao, J. An analytical approach to predict fracture parameters of coral aggregate concrete immersed in seawater. Ocean Eng. 2019, 191, 106508. [Google Scholar] [CrossRef]

- Zhu, M.; Chen, B.; Wu, M.; Han, J. Preparation and mechanical characterization of cost-effective low-carbon engineered cementitious composites with seawater and sea-sand. Cem. Concr. Compos. 2023, 136, 104883. [Google Scholar] [CrossRef]

- Brenna, A.; Beretta, S.; Berra, M.; Diamanti, M.V.; Ormellese, M.; Pastore, T.; Pedeferri, M.; Bolzoni, F. Effect of polymer modified cementitious coatings on chloride-induced corrosion of steel in concrete. Struct. Concr. 2020, 21, 1810–1822. [Google Scholar] [CrossRef]

- Guo, C.; Chen, N.; Wang, R. Study on hydroxypropyl methylcellulose modified Portland cement-sulphoaluminate cement composites: Rheology, setting time, mechanical strength, resistance to chloride ingress, early reaction kinetics and microstructure. J. Build. Eng. 2024, 98, 111070. [Google Scholar] [CrossRef]

- Jin, L.; Wu, T.; Liu, P.; Wang, Z.; Zhou, P. Macro-Meso Degradation Evolution of Fully Recycled Coarse Aggregate Concrete Under Sulfate Attack in Marine Environment, Structures; Elsevier: Amsterdam, The Netherlands, 2024; p. 107536. [Google Scholar]

- Tao, L.; Deng, F.; Xu, K.; Dong, X.; Xu, D.; Liao, Y.; Tang, S. Effect of calcium sulfoaluminate cement on the hydration process and water resistance of phosphogypsum slag cement. J. Mater. Res. Technol. 2024, 33, 5375–5383. [Google Scholar] [CrossRef]

- Jing, H.; Xu, M.; Gao, M.; Li, M.; Dai, S. Effect of compounding retarder and PCE on the early properties and hydration of high-belite sulphoaluminate cement. Appl. Sci. 2022, 12, 10731. [Google Scholar] [CrossRef]

- Wei, Y.; Cao, Z.; Hou, J.; Li, B.; Jia, G.; Chen, P.; Liu, P. Study on the chloride ion binding rate of sulfoaluminate cement mortars containing different mineral admixtures. Sci. Rep. 2024, 14, 24277. [Google Scholar] [CrossRef]

- Zhang, G.; Yang, Y.; Yang, H.; Li, H. Calcium sulphoaluminate cement used as mineral accelerator to improve the property of Portland cement at sub-zero temperature. Cem. Concr. Compos. 2020, 106, 103452. [Google Scholar] [CrossRef]

- Zhu, J.; Cui, H.; Cui, L.; Yang, S.; Zhang, C.; Liu, W.; Zheng, D. Mutual activation mechanism of cement–GGBS–steel slag ternary system excited by sodium sulfate. Buildings 2024, 14, 631. [Google Scholar] [CrossRef]

- Martin, L.H.; Winnefeld, F.; Müller, C.J.; Lothenbach, B. Contribution of limestone to the hydration of calcium sulfoaluminate cement. Cem. Concr. Compos. 2015, 62, 204–211. [Google Scholar] [CrossRef]

- Chaunsali, P.; Mondal, P. Physico-chemical interaction between mineral admixtures and OPC–calcium sulfoaluminate (CSA) cements and its influence on early-age expansion. Cem. Concr. Res. 2016, 80, 10–20. [Google Scholar] [CrossRef]

- Martin, L.H.; Winnefeld, F.; Tschopp, E.; Müller, C.J.; Lothenbach, B. Influence of fly ash on the hydration of calcium sulfoaluminate cement. Cem. Concr. Res. 2017, 95, 152–163. [Google Scholar] [CrossRef]

- Hashem, F.; Hekal, E.; Wahab, M. The influence of Triethanol amine and Ethylene glycol on the grindability, setting and hydration characteristics of Portland cement. Petrol. Chem 2019, 4, 81–88. [Google Scholar] [CrossRef]

- Liu, S.; Pan, C.; Zhang, H.; Yao, S.; Shen, P.; Guan, X.; Shi, C.; Li, H. Development of novel mineral admixtures for sulphoaluminate cement clinker: The effects of wet carbonation activated red mud. J. Build. Eng. 2023, 67, 105920. [Google Scholar] [CrossRef]

- Oleiwi, S.M. Compressive Strength of Mortar with Partial Replacement of Cement by Fly Ash and GGBFS. Diyala J. Eng. Sci. 2021, 14, 146–155. [Google Scholar] [CrossRef]

- Ioannou, S.; Chowdhury, M.; Badr, A. Conformity of the performance of calcium sulfoaluminate cement based concretes to empirical models in current international design standards. Constr. Build. Mater. 2022, 326, 126748. [Google Scholar] [CrossRef]

- Fikeni, K.G.; Pang, X.; Zhao, Y.; Guo, S.; Ren, J.; Lv, K.; Sun, J. Synergistic effects of silica fume, nanomaterials and inorganic salts on the hydration and compressive strength of low-density oil well cement slurry. Cement 2025, 19, 100125. [Google Scholar] [CrossRef]

- Makó, É.; Őze, C. The effects of silica fume and diatomaceous earth on the mechanochemical activation and pozzolanic activity of kaolin. Appl. Clay Sci. 2022, 228, 106636. [Google Scholar] [CrossRef]

- Fode, T.A.; Jande, Y.A.C.; Kivevele, T. Effects of different supplementary cementitious materials on durability and mechanical properties of cement composite–Comprehensive review. Heliyon 2023, 9, e17924. [Google Scholar] [CrossRef] [PubMed]

- Abbas, S.; Abbass, W.; Nehdi, M.L.; Ahmed, A.; Yousaf, M. Investigation of alkali-silica reactivity in sustainable ultrahigh performance concrete. Sustainability 2021, 13, 5680. [Google Scholar] [CrossRef]

- Sun, L.; Wang, G.; Zhang, C.; Liang, T. Rheological properties and the intrinsic mechanisms of fly ash/silicon-based shear thickening fluid. Rheol. Acta 2024, 63, 603–613. [Google Scholar] [CrossRef]

- Azmakan, A.; Ahmadi, J.; Shahani, A.; Badarloo, B.; Garbowski, T. Optimal Quantity Investigation of Metakaolin and Silica Fume in Production of Durable Acid Resistance Alkali Activated Slag Concrete. Buildings 2023, 14, 21. [Google Scholar] [CrossRef]

- Arshad, M.T.; Ahmad, S.; Khitab, A.; Hanif, A. Synergistic use of fly ash and silica fume to produce high-strength self-compacting cementitious composites. Crystals 2021, 11, 915. [Google Scholar] [CrossRef]

- Luo, T.; Hua, C.; Li, L.; Zhang, T.; Lu, X.; Li, L.G.; Mostafa, S.A. The effect of micro silica fume (MSF) content on pore fractal dimension (PFD) and mechanical properties of self-consolidating concrete. Case Stud. Constr. Mater. 2024, 21, e04065. [Google Scholar] [CrossRef]

- GB/T 1346-2011; Test Methods for Water Demand of Standard Consistency, Setting Time, and Stability of Cement. Standardization Administration of China: Beijing, China, 2011.

- GB/T 0507-2005; Test Method for Flowability of Cement Mortar. Standardization Administration of China: Beijing, China, 2005.

- GB/T 0511-2005; Test Method for Drying Shrinkage of Cement Mortar. Standardization Administration of China: Beijing, China, 2005.

- GB/T 17671-1999; Test Method for Strength of Cement Mortar (ISO Method). Standardization Administration of China: Beijing, China, 1999.

- Mao, Y.; Jiao, D.; Hu, X.; Jiang, Z.; Shi, C. Effect of dispersion behavior of silica fume on the rheological properties and early hydration characteristics of ultra-high strength mortar. Cem. Concr. Compos. 2024, 152, 105654. [Google Scholar] [CrossRef]

- Han, Y.; Lapeyre, J.; Levy, N.V.D.; Ucak-Astarlioglu, M.G.; Burroughs, J.F.; Bullard, J.W. Dissolution kinetics of densified and undensified silica fume in a KOH solution at pH 13 and 23 °C. Cem. Concr. Res. 2024, 183, 107586. [Google Scholar] [CrossRef]

- Yang, H.-Q.; Liu, X.-Y.; Chen, X.-D. Study on the Influence of fly ash, mineral powder and silicon powder on the performance of high-performance concrete. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2021; p. 03018. [Google Scholar]

- Zhu, H.; He, Y.; Ji, D.; Tang, J.; Li, C. Experimental research on the mechanical properties and autogenous shrinkage of precast members joint concrete. Buildings 2022, 12, 373. [Google Scholar] [CrossRef]

- Samad, S.; Shah, A. Comparative analysis of flexural strength and modulus elasticity of sustainable concrete using supplementary cementitious material (scm). Preprints 2020, 1–10. [Google Scholar] [CrossRef]

- Wang, J.; Yu, Y. Influence of Natural Volcanic Ash on Shrinkage and Cracking of Concrete. In Proceedings of the 2018 3rd International Conference on Materials Science, Machinery and Energy Engineering (MSMEE 2018), Taiyuan, China, 29–30 June 2018. [Google Scholar]

- Londono-Zuluaga, D.; Tobón, J.I.; Aranda, M.; Santacruz, I.; De la Torre, A. Influence of fly ash blending on hydration and physical behavior of belite–alite–ye’elimite cements. Mater. Struct. 2018, 51, 128. [Google Scholar] [CrossRef]

- Kryvenko, P.; Sikora, P.; Rudenko, I.; Konstantynovskyi, O. Advances in using seawater in slag-containing cement systems. J. Build. Eng. 2024, 96, 110386. [Google Scholar] [CrossRef]

- Boakye, K.; Khorami, M. Hydration, reactivity and durability performance of low-grade calcined clay-silica fume hybrid mortar. Appl. Sci. 2023, 13, 11906. [Google Scholar] [CrossRef]

- Shanmugapriya, T.; Uma, R. Experimental investigation on silica fume as partial replacement of cement in high performance concrete. Int. J. Eng. Sci. 2013, 2, 40–45. [Google Scholar]

- Biricik, H.; Sarier, N. Comparative study of the characteristics of nano silica-, silica fume-and fly ash-incorporated cement mortars. Mater. Res. 2014, 17, 570–582. [Google Scholar] [CrossRef]

- Liu, J.; Wu, L.; Zhu, J.; Jia, H.; Liu, L.; Zhang, S.; Yang, C.; Chen, Z.; Shi, C. Effect of silica fume on corrosion resistance of cement-based materials under carbonic acid water environment. Cem. Concr. Compos. 2025, 157, 105949. [Google Scholar] [CrossRef]

- Long, Z.; Long, G.; Tang, Z.; Shangguan, M.; Zhang, Y.; Wang, L.; Peng, L.; Yi, M. Hydration, strength, and microstructure evolution of Portland cement-calcium sulphoaluminate cement-CSH seeds ultra-early strength cementitious system. Constr. Build. Mater. 2024, 430, 136492. [Google Scholar] [CrossRef]

- She, A.; Li, G.; Tan, L.; Wei, Y.; Zuo, J.; Yao, W. Comprehensive analysis of early-stage hydration and microstructure evolution in Sufflaminate cement: Insights from low-field NMR and isothermal calorimetry. J. Build. Eng. 2023, 80, 108076. [Google Scholar] [CrossRef]

- Yuan, Y.; Ding, C.; Wu, Z.; Zhou, J.; Zhao, Y.; Shao, W. Compressive failure analysis of seawater-mixed aluminate cement concrete based on digital image correlation technique. J. Build. Eng. 2024, 85, 108594. [Google Scholar] [CrossRef]

- Padilla-Encinas, P.; Palomo, A.; Fernández-Jiménez, A. Effect of Na versus Ca Sulfate Salts on the Hydration of Calcium Sulfoaluminate Clinker. Molecules 2023, 28, 7651. [Google Scholar] [CrossRef] [PubMed]

- Rathnarajan, S.; Cendrowski, K.; Sibera, D.; Sikora, P. Comprehensive evaluation of early-age hydration and compressive strength development in seawater-mixed binary and ternary cementitious systems. Arch. Civ. Mech. Eng. 2024, 24, 121. [Google Scholar] [CrossRef]

- Moa, J.P.S.; Gaw, B.A.C.; Co, J.L.O.; Coo, K.A.C.; Elevado, K.J.T.; Roxas, C.L.C. Performance of seawater-derived Mg(OH)2 as a sustainable coating solution for hydrogen sulfide-induced corrosion mitigation in concrete pipes. Clean. Eng. Technol. 2025, 24, 100872. [Google Scholar] [CrossRef]

| Ingredient | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | K2O | Na2O |

|---|---|---|---|---|---|---|---|

| Fly ash | 46.44 | 38.01 | 3.12 | 7.50 | 0.23 | 0.88 | 0.33 |

| Silica fume | 92.18 | 0.23 | 0.09 | 0.99 | 1.83 | 0.31 | 0.05 |

| Slag powder | 34.50 | 17.70 | 1.03 | 34.00 | 6.01 | - | - |

| Group | Blank | FA5 | FA7.5 | FA10 | SF5 | SF7.5 | SF10 | SP5 | SP7.5 | SP10 |

|---|---|---|---|---|---|---|---|---|---|---|

| 3 d | 0.88 | 1.03 | 0.95 | 1.10 | 1.07 | 1.06 | 1.09 | 0.98 | 0.97 | 0.90 |

| 7 d | 0.98 | 1.01 | 0.91 | 1.07 | 1.05 | 0.99 | 1.06 | 0.98 | 0.97 | 0.88 |

| 28 d | 0.96 | 0.90 | 0.92 | 0.97 | 1.03 | 0.90 | 1.12 | 0.89 | 1.06 | 1.04 |

| 56 d | 0.97 | 0.86 | 0.98 | 1.02 | 1.07 | 0.94 | 1.00 | 0.96 | 1.07 | 1.04 |

| Level | Factor | ||

|---|---|---|---|

| A: Fly Ash Content | B: Silica Fume Content | C: Slag Powder Content | |

| 1 | 5.0% | 5.0% | 5.0% |

| 2 | 7.5% | 7.5% | 7.5% |

| 3 | 10.0% | 10.0% | 10.0% |

| Group | Orthogonal Combination | Fly Ash | Silica Fume | Slag Powder | Cement | River Sand | Water |

|---|---|---|---|---|---|---|---|

| 1 | — | 0 | 0 | 0 | 1.000 | 1.5 | 0.45 |

| 2 | A1B1C1 | 0.050 | 0.050 | 0.050 | 0.850 | 1.5 | 0.45 |

| 3 | A1B2C2 | 0.050 | 0.075 | 0.075 | 0.800 | 1.5 | 0.45 |

| 4 | A1B3C3 | 0.050 | 0.100 | 0.100 | 0.750 | 1.5 | 0.45 |

| 5 | A2B1C2 | 0.075 | 0.050 | 0.075 | 0.800 | 1.5 | 0.45 |

| 6 | A2B2C3 | 0.075 | 0.075 | 0.100 | 0.750 | 1.5 | 0.45 |

| 7 | A2B3C1 | 0.075 | 0.100 | 0.050 | 0.775 | 1.5 | 0.45 |

| 8 | A3B1C3 | 0.100 | 0.050 | 0.100 | 0.750 | 1.5 | 0.45 |

| 9 | A3B2C1 | 0.100 | 0.075 | 0.050 | 0.775 | 1.5 | 0.45 |

| 10 | A3B3C2 | 0.100 | 0.100 | 0.075 | 0.725 | 1.5 | 0.45 |

| Factor | Fly Ash (A) | Silica Fume (B) | Slag Powder (C) |

|---|---|---|---|

| K1 | 164 | 177 | 166 |

| K2 | 161 | 162 | 164 |

| K3 | 167 | 152 | 162 |

| R | 6 | 25 | 4 |

| Influence degree | B > A > C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Zhou, S.; Ou, Q.; Liu, J.; Wu, M. Seawater-Activated Mineral Synergy in Sulfoaluminate Cement: Corrosion Resistance Optimization via Orthogonal Design. Materials 2025, 18, 2428. https://doi.org/10.3390/ma18112428

Wang C, Zhou S, Ou Q, Liu J, Wu M. Seawater-Activated Mineral Synergy in Sulfoaluminate Cement: Corrosion Resistance Optimization via Orthogonal Design. Materials. 2025; 18(11):2428. https://doi.org/10.3390/ma18112428

Chicago/Turabian StyleWang, Chuanlin, Shupeng Zhou, Qingyou Ou, Junkai Liu, and Ming Wu. 2025. "Seawater-Activated Mineral Synergy in Sulfoaluminate Cement: Corrosion Resistance Optimization via Orthogonal Design" Materials 18, no. 11: 2428. https://doi.org/10.3390/ma18112428

APA StyleWang, C., Zhou, S., Ou, Q., Liu, J., & Wu, M. (2025). Seawater-Activated Mineral Synergy in Sulfoaluminate Cement: Corrosion Resistance Optimization via Orthogonal Design. Materials, 18(11), 2428. https://doi.org/10.3390/ma18112428