Alkali-Activated Slag Repair Mortar for Old Reinforced Concrete Structures Based on Ordinary Portland Cement

Abstract

1. Introduction

2. Methods and Materials

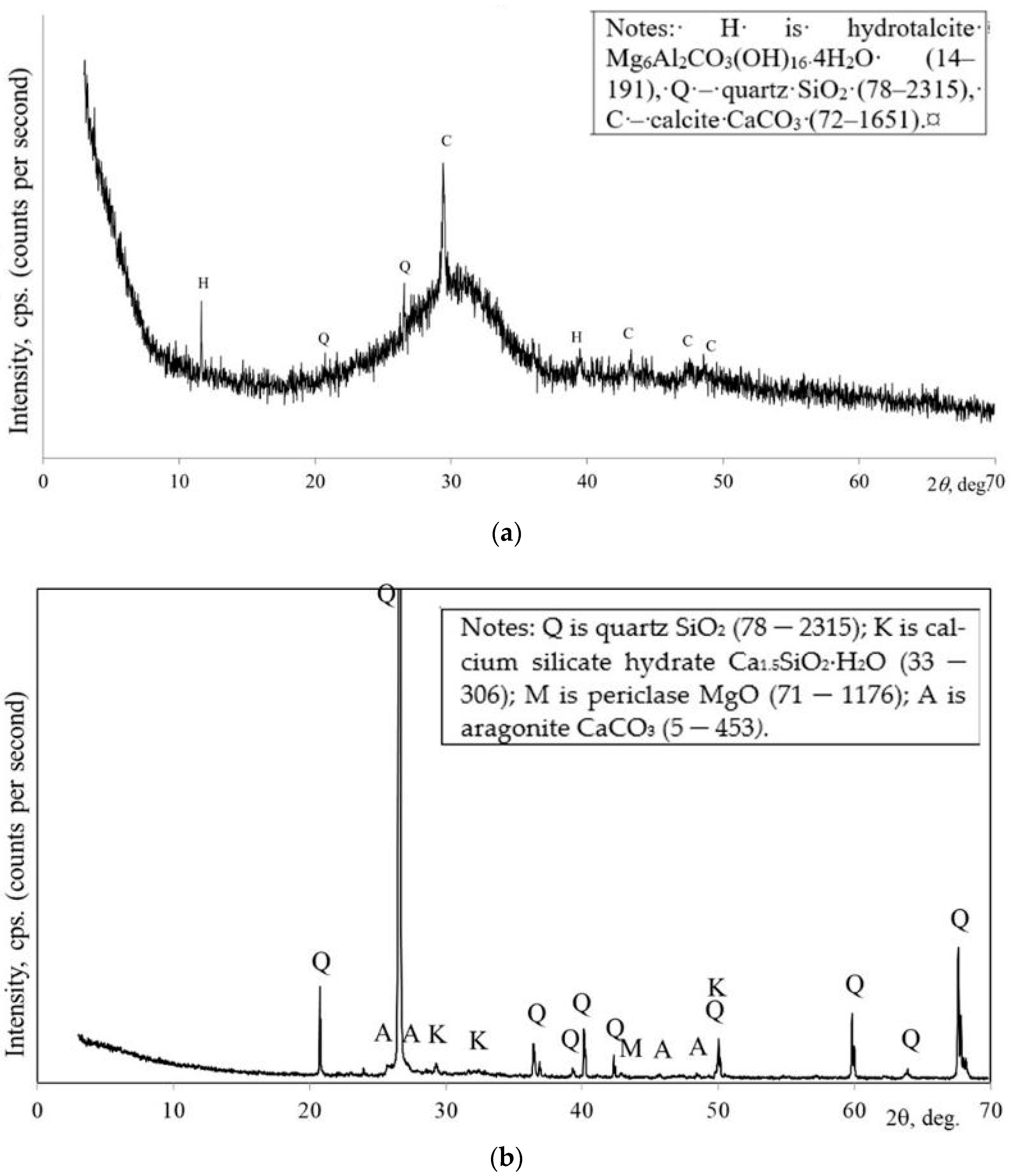

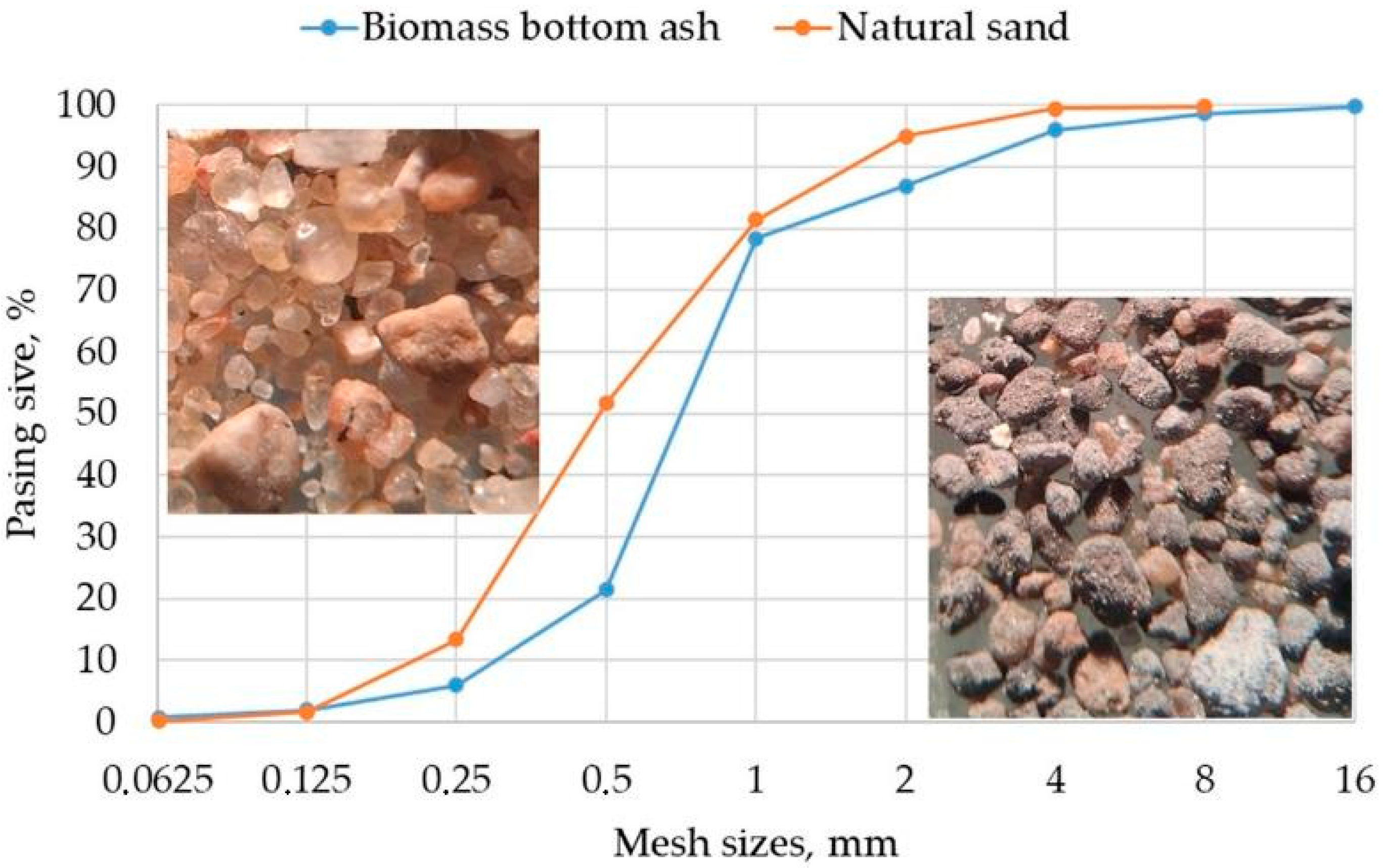

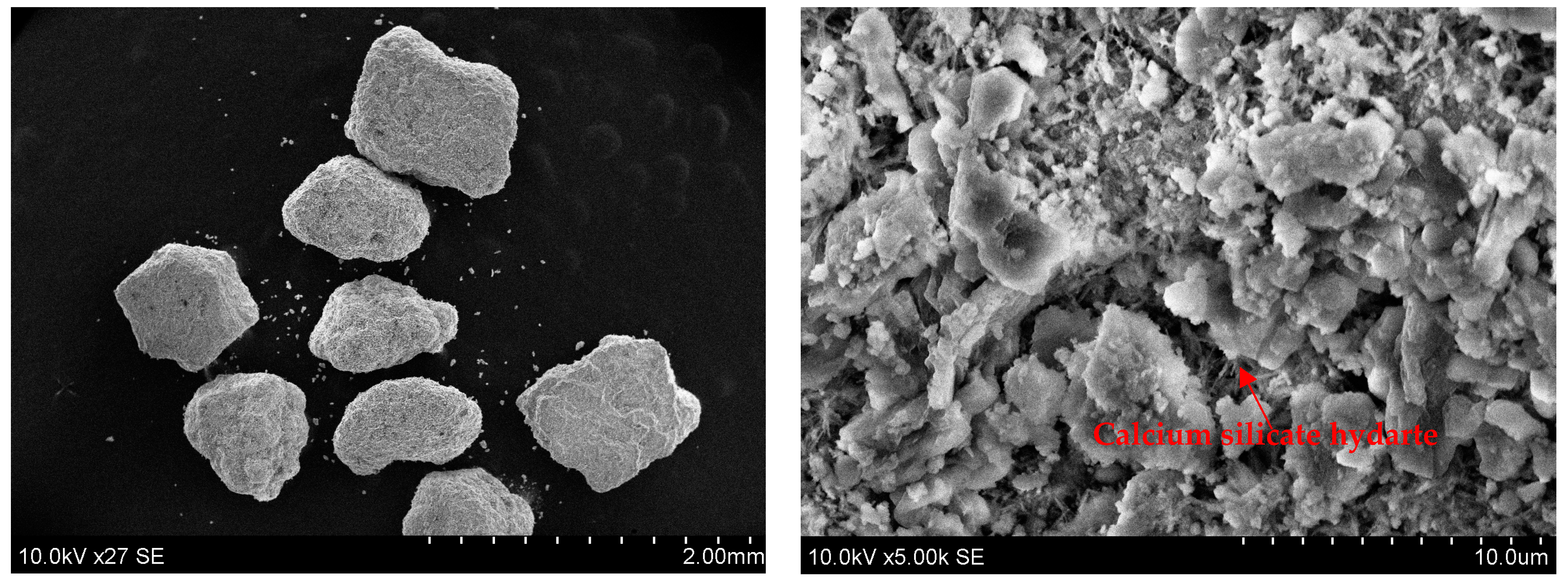

2.1. Initial Materials

2.2. Preparation of the Repairing Mortar Mixtures

2.3. Experimental Techniques

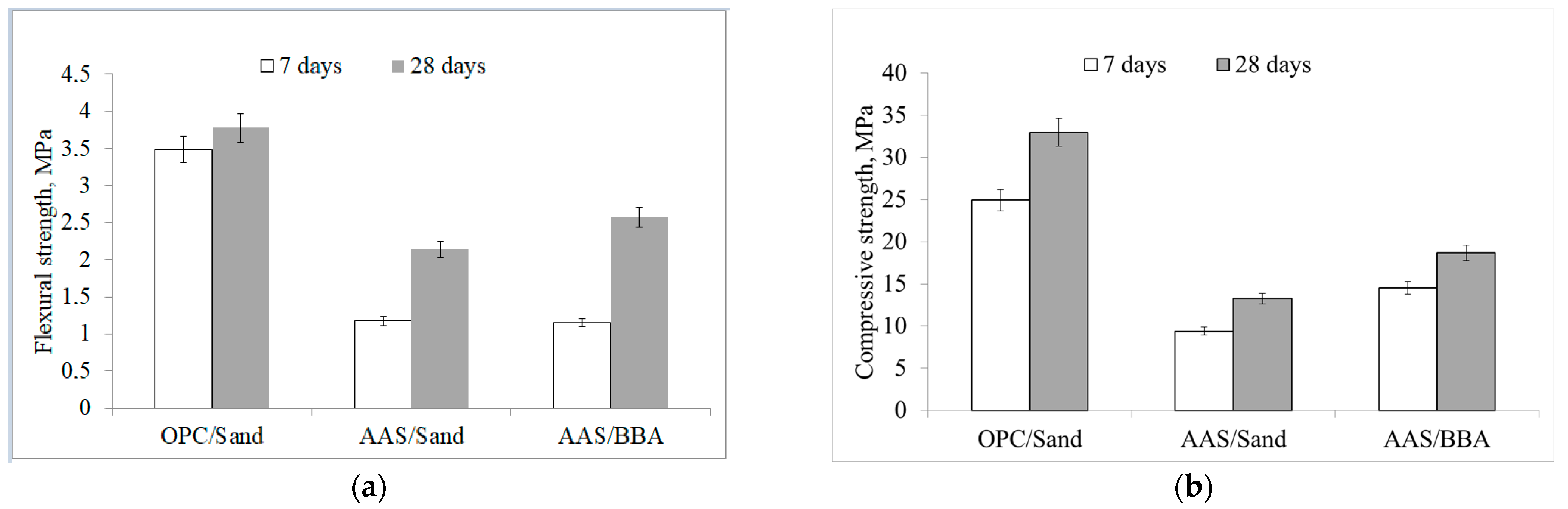

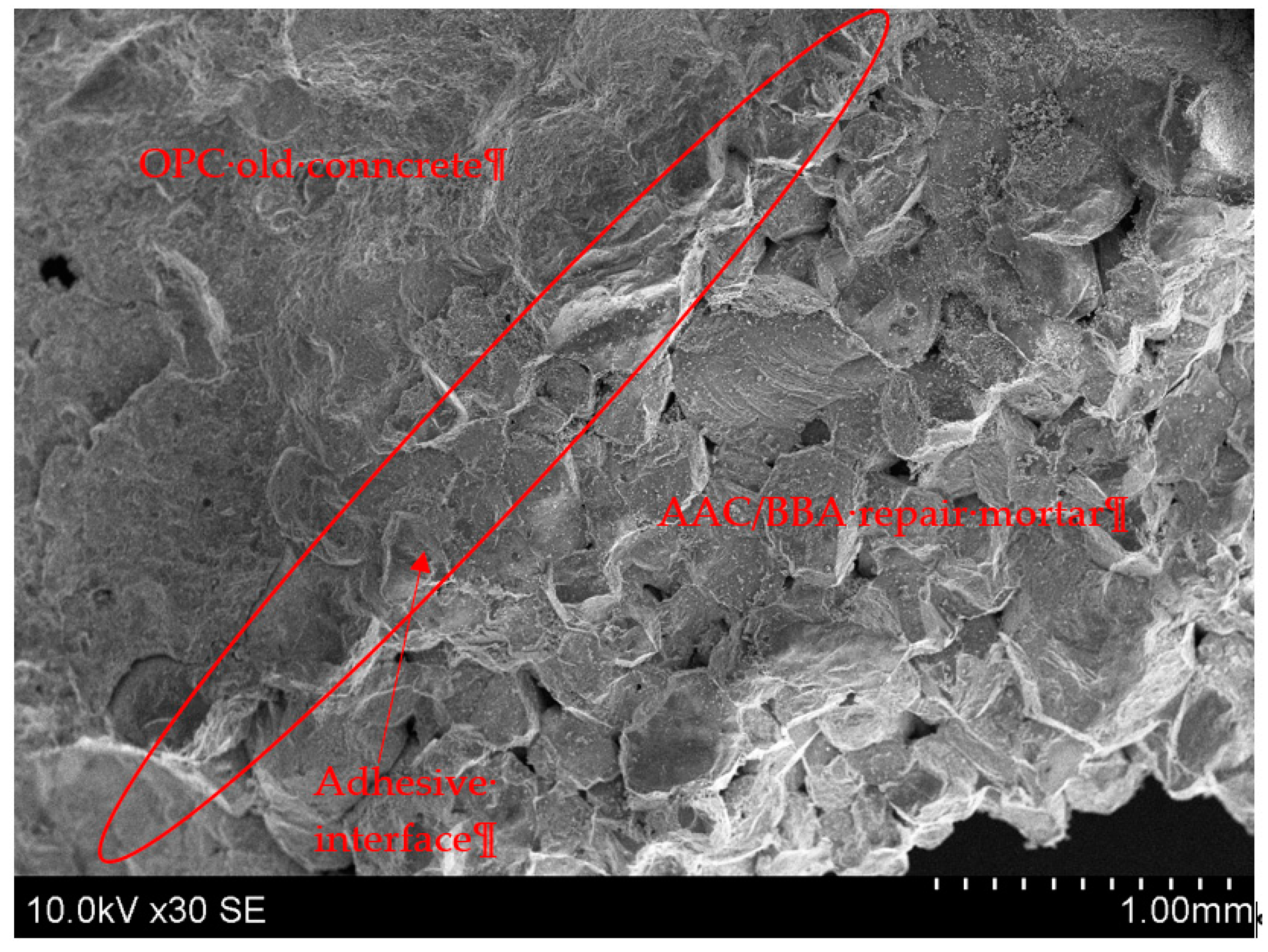

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hou, L.; Xu, R.; Zang, Y.; Ouyang, F.; Chen, D.; Zhong, L. Bond behavior between reinforcement and ultra-high toughness cementitious composite in flexural members. Eng. Struct. 2020, 210, 110357. [Google Scholar] [CrossRef]

- Kryvenko, P.; Rudenko, I.; Sikora, P.; Sanytsky, M.; Konstantynovskyi, O.; Kropyvnytska, T. Alkali-activated cements as sustainable materials for repairing building construction: A review. J. Build. Eng. 2024, 90, 109399. [Google Scholar] [CrossRef]

- Geraldo, R.H.; Teixeira, O.G.; Matos, S.R.; Silva, F.G.; Gonçalves, J.P.; Camarini, G. Study of alkali-activated mortar used as conventional repair in reinforced concrete. Constr. Build. Mater. 2018, 165, 914–919. [Google Scholar] [CrossRef]

- Fan, L.F.; Chen, D.K.; Zhong, W.L. Effects of slag and alkaline solution contents on bonding strength of geopolymer-concrete composites. Constr. Build. Mater. 2023, 406, 133391. [Google Scholar] [CrossRef]

- Fan, J.; Zhu, H.; Shi, J.; Li, Z.; Yang, S. Influence of slag content on the bond strength, chloride penetration resistance, and interface phase evolution of concrete repaired with alkali activated slag/fly ash. Constr. Build. Mater. 2020, 263, 120639. [Google Scholar] [CrossRef]

- Yusslee, E.; Beskhyroun, S. The potential of one-part alkali-activated materials (AAMs) as a concrete patch mortar. Sci. Rep. 2022, 12, 15902. [Google Scholar] [CrossRef]

- Gomaa, E.; Gheni, A.; ElGawady, M.A. Repair of ordinary Portland cement concrete using ambient-cured alkali-activated concrete: Interfacial behavior. Cem. Concr. Res. 2020, 129, 105968. [Google Scholar] [CrossRef]

- Zhang, B. Repair of ordinary concrete using alkali activated slag/fly ash: High temperature resistance and micro structure evolution of adhesive interface. Constr. Build. Mater. 2023, 386, 131559. [Google Scholar] [CrossRef]

- Coppola, L.; Coffetti, D.; Crotti, E. Pre-packed alkali activated cement-free mortars for repair of existing masonry buildings and concrete structures. Constr. Build. Mater. 2018, 173, 111–117. [Google Scholar] [CrossRef]

- Ali, H.A.; Keke, S.; Alrefaei, Y.; Poon, C.S. A study on the use of waste glass in preparing alkali-activated repairing material. Constr. Build. Mater. 2024, 435, 136803. [Google Scholar] [CrossRef]

- LST EN 12620:2003+A1:2008; Aggregates for Concrete. Lithuanian Standard Board: Vilnius, Lithuania, 2009; 49p.

- Kryvenko, P.; Rudenko, I.; Kovalchuk, O.; Gelevera, O.; Konstantynovskyi, O. Influence of dosage and modulus on soluble sodium silicate for Early Strength Development of Alkali-Activated Slag Cements. Minerals 2023, 13, 1164. [Google Scholar] [CrossRef]

- Luna-Galiano, Y.; Leiva Fernández, C.; Villegas Sánchez, R.; Fernández-Pereira, C. Development of geopolymer mortars using air-cooled blast furnace slag and biomass bottom ashes as fine aggregates. Processes 2023, 11, 1597. [Google Scholar] [CrossRef]

- Tarelho, L.A.C.; Teixeira, E.R.; Silva, D.F.R.; Modolo, R.C.E.; Labrincha, J.A.; Rocha, F.J.F.T. Characteristics of distinct ash flows in a biomass thermal power plant with bubbling fluidised bed combustor. Energy 2015, 90, 387–402. [Google Scholar] [CrossRef]

- Modolo, R.E.; Silva, T.; Senff, L.; Tarelho, L.A.C.; Labrincha, J.A.; Ferreira, V.M.; Silva, L. Bottom ash from biomass combustion in BFB and its use in adhesive-mortars. Fuel Process. Technol. 2015, 129, 192–202. [Google Scholar] [CrossRef]

- EN 1015-11; Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. CEN/TC 125 Masonry.; European Committee for Standardization: Brussels, Belgium, 1999.

- EN 196-6; Methods of Testing Cement—Part 6: Determination of Fineness. European Committee for Standatization: Brussels, Belgium, 2010.

- BS EN 12390-16: 2019; Testing Hardened Concrete—Part 16: Determination of the Shrinkage of Concrete. British Standards Institution: London, UK, 2019.

- BS EN 12390-4; Testing Hardened Concrete–Part 4: Compressive Strength–Specification for Testing Machines. British Standard Specification: London, UK, 2000.

- LST EN 12390-7:2009/AC:2005; Concrete test. Part 7. Density of Concrete. Lithuanian Standard Board: Vilnius, Lithuania, 2005; 2p.

- EN 1542-1999; Products and Systems for the Protection and Repair of Concrete Structures. Test Methods. Measurement of Bond Strength by Pull-Off. European Committee for Standatization: Brussels, Belgium, 1999.

- Atiş, C.D.; Bilim, C.; Çelik, Ö.; Karahan, O. Influence of activator on the strength and drying shrinkage of alkali-activated slag mortar. Constr. Build. Mater. 2009, 23, 548–555. [Google Scholar] [CrossRef]

- Schlupp, F.; Page, J.; Djelal, C.; Libessart, L. Use of biomass bottom ash as granular substitute in mortar. J. Build. Eng. 2023, 75, 106927. [Google Scholar] [CrossRef]

- Diamond, S.; Kjellsen, K.O. Resolution of fine fibrous CSH in backscatter SEM examination. Cem. Concr. Compos. 2006, 28, 130–132. [Google Scholar] [CrossRef]

- Puligilla, S.; Chen, X.; Mondal, P. Does synthesized CSH seed promote nucleation in alkali activated fly ash-slag geopolymer binder? Mater. Struct. 2019, 52, 52–65. [Google Scholar] [CrossRef]

- Leong, H.Y.; Ong, D.E.L.; Sanjayan, J.G.; Nazari, A. The effect of different Na2O and K2O ratios of alkali activator on compressive strength of fly ash based-geopolymer. Constr. Build. Mater. 2016, 106, 500–511. [Google Scholar] [CrossRef]

- Vaičiukynienė, D.; Nizevičienė, D.; Kantautas, A.; Bocullo, V.; Kielė, A. Alkali activated paste and concrete based on of biomass bottom ash with phosphogypsum. Appl. Sci. 2020, 10, 5190. [Google Scholar] [CrossRef]

- Peng, M.; Zhao, Q.; Zhang, Y.; Ma, H.; Song, F. Synthesizing Less Alkali-Activated Binders from Na2o (K2o)-Cao-Al2o3-Sio2 Vitreous Precursors Comparing with Ground Granulated Blast Furnace Slag. 2024. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Castro-Gomes, J.P.; Jalali, S. Adhesion characterization of tungsten mine waste geopolymeric binder. Influence of OPC concrete substrate surface treatment. Constr. Build. Mater. 2008, 22, 154–161. [Google Scholar] [CrossRef]

- EN 1504-3:2005; Products and Systems for the Protection and Repair of Concrete Structures. European Committee for Standatization: Brussels, Belgium, 2005.

| Oxides | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | CaO | SO3 | Al2O3 | Fe2O3 | MgO | K2O | Na2O | TiO2 | P2O5 | Other | |

| OPC | 19.51 | 61.32 | 4.3 | 5.25 | 3.28 | 3.84 | 1.01 | 0.94 | 0.13 | 4.26 | |

| Slag | 37.1 | 45.2 | 1.85 | 6.44 | 0.793 | 5.76 | 0.517 | 1.02 | 0.285 | 0.683 | 0.33 |

| Sand | 97.89 | 0.72 | 0.06 | 0.6 | 0.46 | 0.27 | |||||

| BBA | 43.66 | 24.08 | 3.21 | 7.28 | 10.34 | 2.44 | 1.76 | 2.1 | 1.34 | 1.39 | 2.3 |

| Samples | OPC | Slag | Sand | BBA | Water | NaOH |

|---|---|---|---|---|---|---|

| OPC/Sand | 0.450 | - | 1.350 | - | 0.235 | - |

| AAS/Sand | - | 0.450 | 1.350 | - | 0.245 | 0.0097 |

| AAS/BBA | - | 0.450 | - | 1.350 | 0.237 | 0.0097 |

| Mortars | Density, kg/m3 | Shrinkage, mm/m | ||

|---|---|---|---|---|

| After 7 Days | After 28 Days | After 7 Days | After 28 Days | |

| OPC/Sand | 2072 | 2098 | 3.162 | 3.210 |

| OPC/Sand | 1859 | 1894 | 2.020 | 1.903 |

| AAC/BBA | 1892 | 1936 | 3.660 | 3.121 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vaičiukynienė, D.; Liudvinavičiūtė, A.; Bistrickaitė, R.; Boiko, O.; Vaičiukynas, V. Alkali-Activated Slag Repair Mortar for Old Reinforced Concrete Structures Based on Ordinary Portland Cement. Materials 2025, 18, 2272. https://doi.org/10.3390/ma18102272

Vaičiukynienė D, Liudvinavičiūtė A, Bistrickaitė R, Boiko O, Vaičiukynas V. Alkali-Activated Slag Repair Mortar for Old Reinforced Concrete Structures Based on Ordinary Portland Cement. Materials. 2025; 18(10):2272. https://doi.org/10.3390/ma18102272

Chicago/Turabian StyleVaičiukynienė, Danutė, Agnė Liudvinavičiūtė, Reda Bistrickaitė, Olha Boiko, and Vilimantas Vaičiukynas. 2025. "Alkali-Activated Slag Repair Mortar for Old Reinforced Concrete Structures Based on Ordinary Portland Cement" Materials 18, no. 10: 2272. https://doi.org/10.3390/ma18102272

APA StyleVaičiukynienė, D., Liudvinavičiūtė, A., Bistrickaitė, R., Boiko, O., & Vaičiukynas, V. (2025). Alkali-Activated Slag Repair Mortar for Old Reinforced Concrete Structures Based on Ordinary Portland Cement. Materials, 18(10), 2272. https://doi.org/10.3390/ma18102272