1. Introduction

In recent years, additive manufacturing has experienced a remarkable growth, establishing itself as a key technology in several industries [

1,

2,

3,

4]. Among the many techniques available, Fused Deposition Modeling (FDM) stands out for its accessibility and versatility. This method is based on the extrusion of thermoplastic filaments layer by layer for the fabrication of three-dimensional objects, making it an ideal choice for rapid prototyping and customized production.

One of the sectors where FDM printing is becoming increasingly relevant is the construction industry [

5,

6]. In particular, 3D-printed formwork manufacturing has emerged as an innovative alternative to traditional methods. To date, formwork has mainly been made of wood or metal panels made of steel or aluminum. While the former are economical but have limited durability, the latter offer greater strength and flexibility in terms of design. However, both have a common limitation: the difficulty in generating complex shapes, such as curved geometries, organic designs, or elements with recesses. In this context, FDM printing offers a promising solution by enabling the fast and cost-effective production of formwork with a significant reduction in waste and greater freedom in the design of complex shapes.

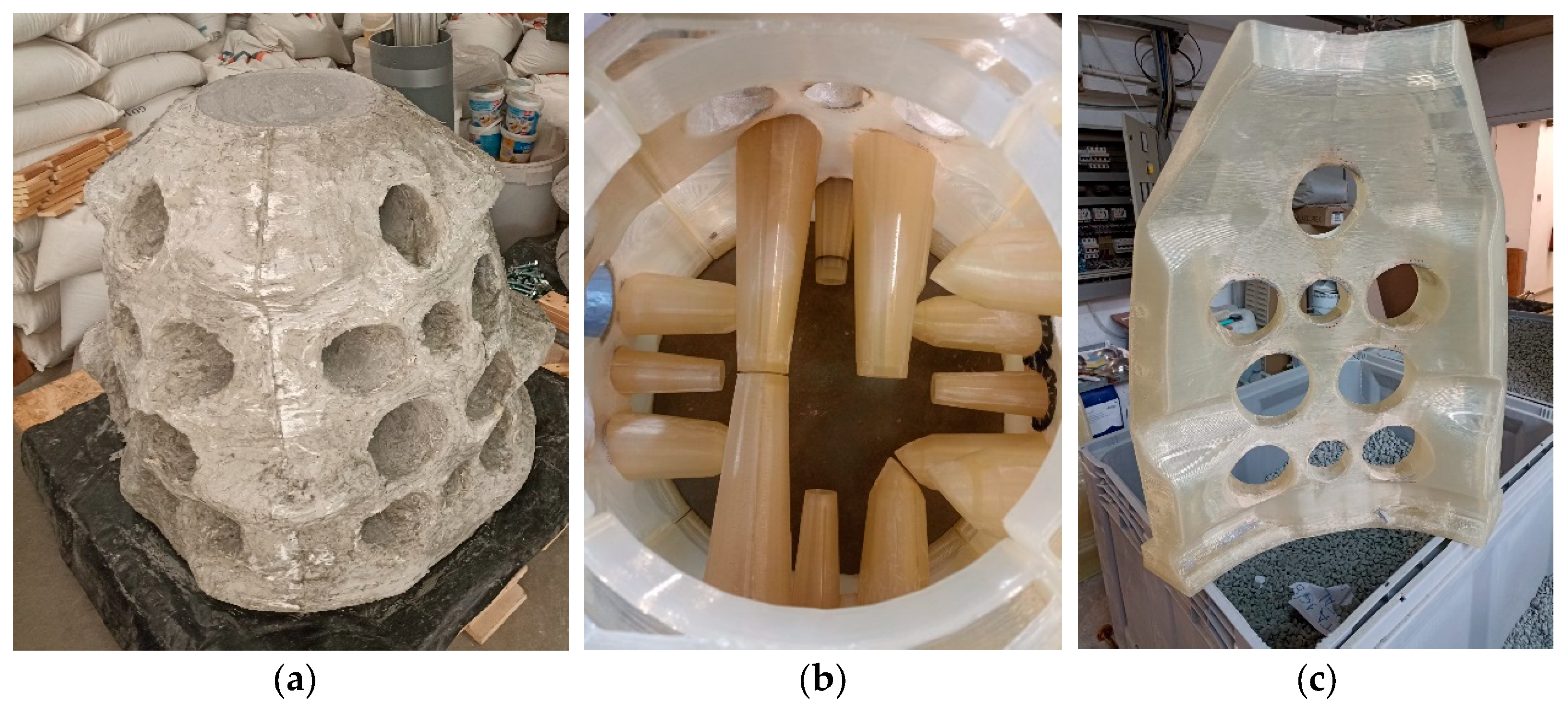

Since 2016, several studies have explored the application of this technology in the manufacture of structural and decorative elements, such as stairs [

5], domes and columns [

6], ornamental components [

6,

7], and even artificial reefs (

Figure 1). In the latter, various 3D printing-related manufacturing approaches [

8] and materials [

9] have been reported, although this work will be focused on their production using 3D printing formworks used to cast the final mortar-based geometry. After curing, they are submerged in the sea. For all applications involving formworks—whether structural, decorative, or for artificial reef construction—reusable molds have been employed in some cases. In others, particularly when producing unique geometries, skin-type formworks, for only one use, are preferred in order to minimize material consumption [

10].

While the results have been promising, the implementation of 3D-printed formwork using FDM poses certain challenges, especially with regard to its integrity and durability. In particular, reusable formworks must withstand not only direct contact with concrete but also the adverse environmental conditions to which they may be exposed during use and storage. As thermoplastics have a variable sensitivity to these factors, it is essential to assess their performance in real construction environments.

One of the most critical exposure conditions for polymeric formworks occurs during the casting and early curing stages of concrete. In these circumstances, the fresh mortar remains in prolonged contact with the formwork under highly alkaline conditions, typically with a pH around 13. Despite the relevance of this environment for the intended application, the available literature is limited and often not directly applicable. Some existing studies have explored the effects of alkaline pH on PLA-based materials [

11], but often under conditions that do not accurately replicate the continuous and immersive exposure typical of concrete casting processes. In this case, accelerated degradation with a drop of concentrated sodium hydroxide is applied to the sample, and the degradation is assessed almost immediately, with exposure times of just 1 min for bending tests and 10 min for creep tests.

Another example is [

12], which investigates PLA degradation in alkaline media, but in the context of replacing traditional steel reinforcement with 3D-printed PLA lattice structures. In such studies, the mechanical performance is derived from concrete specimens with embedded PLA rather than from the polymer material itself after exposure. This makes it difficult to isolate and understand the degradation behavior of the PLA component alone, and even more so to extrapolate the results to its application as a reusable formwork.

Furthermore, the limited number of studies that do examine PLA degradation tend to focus primarily on chemical characterization [

13], with minimal attention paid to the evolution of mechanical properties, dimensional stability, or mass loss over time—factors that are critical for the integrity and reusability of formwork structures. Among those that do consider printed specimens [

14], most neglect the combined mechanical and geometrical effects that occur under alkaline exposure.

In the specific context of reusable formworks, these properties are paramount. The polymeric elements must maintain their strength to withstand mechanical fastening (via straps or screws), resist hydrostatic pressure exerted by the fresh concrete, and endure demolding forces once the concrete has cured. Any significant degradation of mechanical strength or volumetric shrinkage not only compromises the reusability of the formwork but also affects the dimensional accuracy and surface quality of the resulting concrete component.

For these reasons, it is essential to conduct targeted degradation tests under controlled alkaline conditions, representative of actual casting environments, in order to evaluate the feasibility of PLA-based materials for this application

The second environmental condition considered in this study corresponds to the exposure of the material to atmospheric agents, primarily sunlight and rain, which are inherently accompanied by variations in temperature and humidity. In this context, the existing literature on the environmental degradation of PLA parts is limited and highly heterogeneous in terms of both methodology and findings. There is no consensus on maximum exposure thresholds or degradation kinetics for PLA under real outdoor conditions.

Previous studies have explored various degradation setups, ranging from controlled temperature and humidity chambers without solar radiation [

15] to artificial UV radiation exposure using 1000 W halogen lamps [

16] and even unmonitored open-air aging [

17]. The diversity in test conditions—including exposure times, radiation intensities, and the presence or absence of moisture—leads to widely varying outcomes. Reported effects range from slight increases in mechanical strength under dry UV exposure [

16] to significant strength reductions of up to 30% after prolonged outdoor weathering. However, these results are difficult to interpret or extrapolate, as critical environmental parameters such as UV intensity, precipitation frequency, and temperature fluctuations are often unknown or poorly controlled.

Furthermore, it must be considered that climatic conditions vary significantly depending on geographic location, which further limits the generalizability of existing data. Therefore, to reliably assess the suitability of PLA-based materials for reusable formwork in construction applications, it becomes essential to simulate UV radiation and rain exposure under controlled laboratory conditions. This allows for reproducible and quantifiable evaluation of the material’s degradation behavior, providing insights into its long-term performance in outdoor environments.

An essential aspect in the fabrication of polymeric formworks for mortar casting is the appropriate selection of the polymeric material. In this context, the most commonly employed materials in Fused Deposition Modeling (FDM) for construction-related applications are PLA, PETg, and TPU [

18,

19]. Among them, PLA has gained particular attention due to its low cost and excellent printability. Furthermore, PLA is a highly valued material as it is derived from renewable resources such as corn starch, sugarcane, or sugar beet. Since its production does not rely on fossil-based feedstocks, it contributes to a lower carbon footprint and is considered a more sustainable alternative in terms of greenhouse gas emissions and energy consumption throughout its life cycle.

In recent years, there has been a growing availability of PLA-based filaments incorporating various additives, such as metals, wood, or textile fibers [

20,

21,

22,

23,

24,

25], which can enhance certain material properties compared to neat PLA. These improvements may include increased mechanical strength [

26], thermal conductivity [

27], or other functional characteristics. However, to date, no PLA-based composite filament has been specifically investigated for its suitability in formwork fabrication. Therefore, building on the advantages of PLA as a base material, this study explores the incorporation of an industrial by-product as an additive. This approach aims not only to reduce the amount of plastic required but also to valorize a secondary material from another production process. Furthermore, the method by which the polymer matrix (PLA) and additives are combined plays a critical role in determining the mechanical strength and dimensional stability of the resulting filament material [

28,

29]. It is, therefore, necessary to evaluate whether the direct blending of PLA pellets with the powdered additive yields a homogeneous filament upon extrusion or if an alternative mixing strategy must be identified to enhance the uniformity and overall quality of the composite.

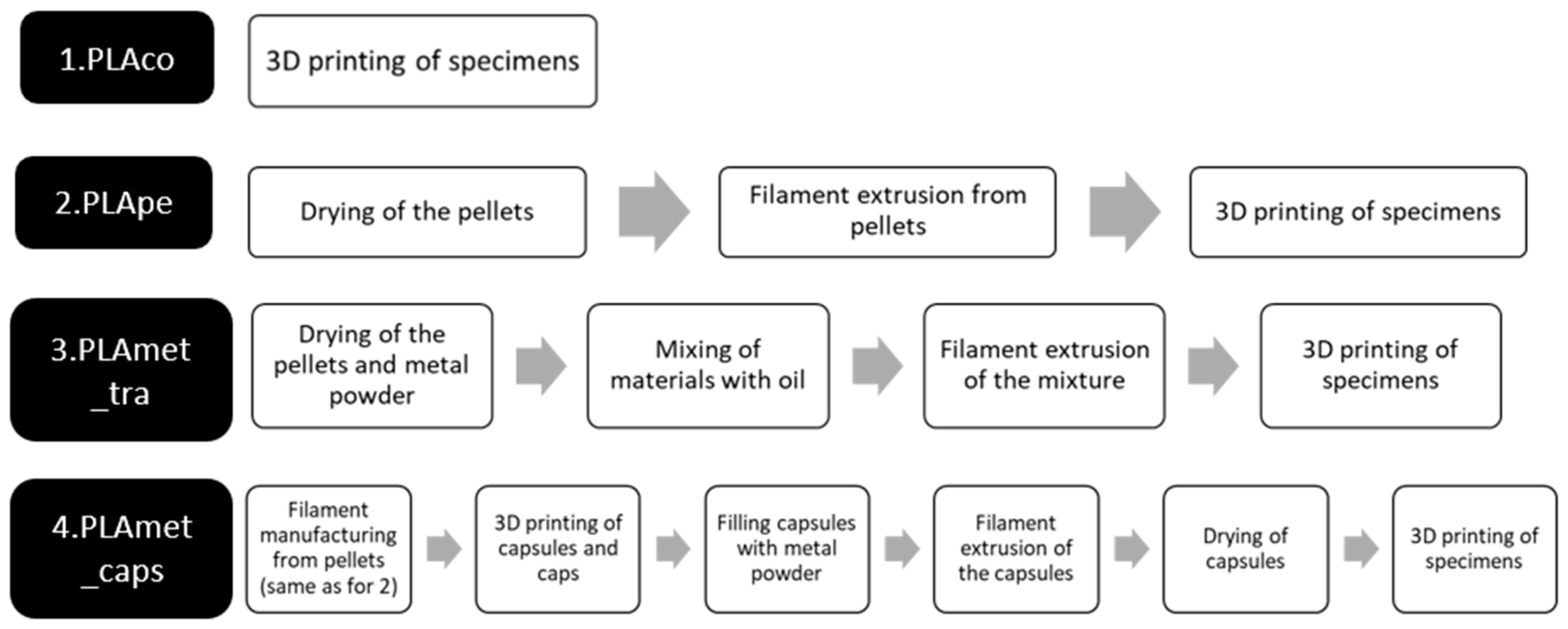

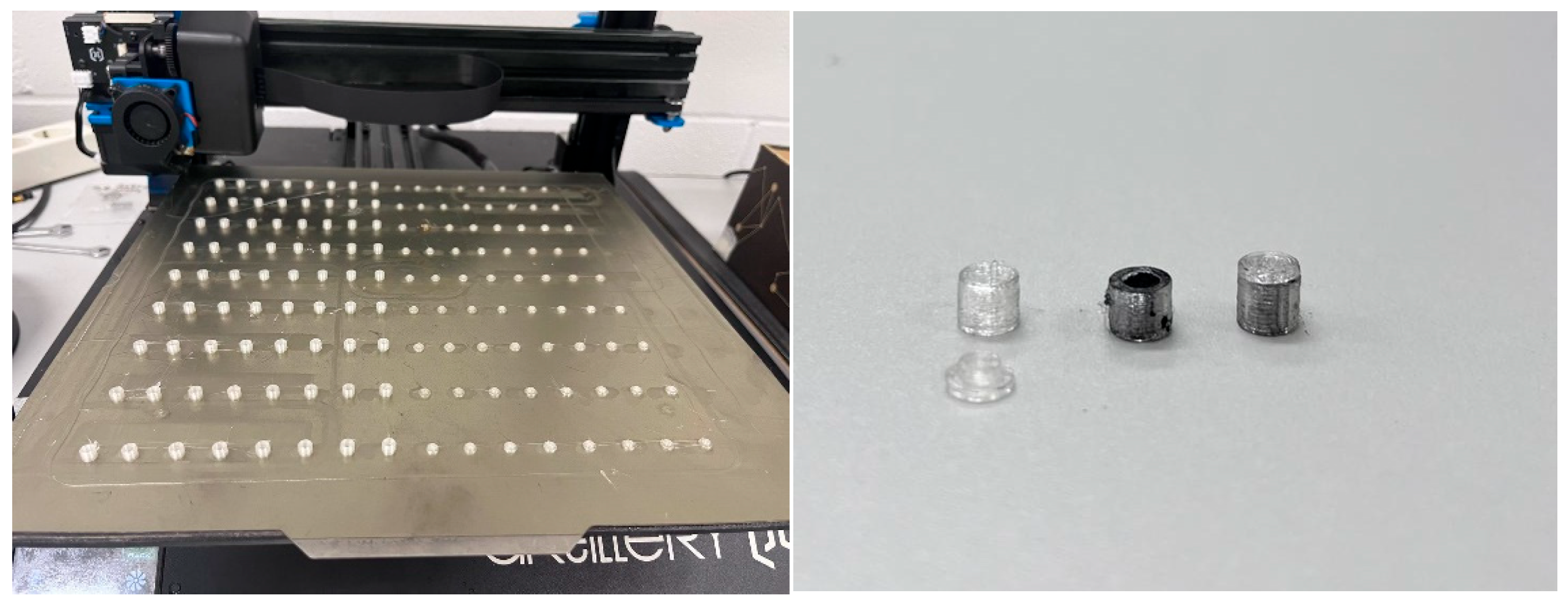

The performance of the additive-enhanced materials must be benchmarked against that of virgin PLA. In this context, two material formats are considered: commercially available PLA filament and PLA in pellet form. Although both are expected to exhibit comparable intrinsic properties, information obtained through consultations with manufacturers indicates that the production of PLA filaments—particularly those with color additives—often involves the incorporation of plasticizers. These additives are introduced to enhance certain mechanical characteristics, such as reducing stiffness and brittleness. As a result, it becomes necessary to systematically assess potential differences in the mechanical response of both material formats, particularly under pre- and post-degradation conditions. This comparison will focus on PLA filaments containing colorants versus untreated PLA pellets. Furthermore, given the increasing adoption of large-format 3D printing systems that frequently utilize pellet-fed extruders, it is critical to evaluate whether the feedstock form and extrusion method significantly affect the overall material behavior and structural performance.

The novelty of the present research lies in its comprehensive and application-driven approach to evaluating the suitability of PLA-based materials—including novel PLA composites reinforced with industrial by-products—for use as reusable 3D-printed formwork in mortar casting. Unlike previous studies, which typically focus on isolated degradation mechanisms or neglect the influence of printing and processing variables, this work systematically investigates the impact of realistic alkaline and outdoor exposure conditions on the mechanical integrity and dimensional stability of printed PLA specimens. Moreover, this study compares different material formulations and delivery formats (filament vs. pellet-based extrusion), providing new insights into their performance and feasibility in large-format FDM printing for the construction sector. This integrated methodology aims to establish robust criteria for material selection and processing strategies, ultimately supporting the development of more sustainable and durable polymeric formworks for complex concrete geometries.

4. Results and Discussion

4.1. Undegraded Material

To begin, the mechanical properties of the materials have been evaluated without degradation, i.e., after an exposure of 0 days (

Figure 7). On the left side in

Figure 8,

Figure 9 and

Figure 10, the results of maximum flexural strength, bending modulus of elasticity, and strain at break are presented. In this initial state, the elastic modulus of the commercial PLA and pellet PLA specimens is almost identical. The main difference between the two materials lies in the maximum flexural strength and strain at break, with these values being slightly lower for PLA from pellets (reductions of approximately 2 MPa and 0.2%).

When PLA is combined with metal powder, more variability in the results is observed, depending on the manufacturing method used. In particular, direct mixing of PLA pellets with metal powder results in a more elastic and deformable material, while the composite obtained by the encapsulation technique shows a significantly higher stiffness (increase of about 24%) and a 41% reduction in its deformation capacity. As for the flexural strength, the values obtained in both cases with metal are comparable to each other but show a 39.8% decrease compared to the commercial PLA supplied in filament form. This behavior is clearly seen in

Figure 7, where one representative curve of each type is represented. Although mechanical testing was performed on five non-degraded specimens for each material, only one representative stress–strain curve is shown in order to enhance the clarity of the comparison between different materials. This curve was selected as it reflects the typical behavior observed across all tested samples.

The differences observed in the elastic modulus and strain at break can be attributed to the manufacturing method used. In the case of direct mixing of PLA and metal powder (PLA_met_trad), there is a slight loss of powder during the process due to its adhesion to the walls of the mixing vessel or the feed hopper. As a consequence, the fraction of metal incorporated into the filament is slightly lower. On the other hand, the use of capsules allows us to retain all the metal powder during the manufacturing process, avoiding losses and generating a material with a higher charge content, which contributes to an increase in its stiffness and brittleness. In addition, a minimal proportion of oil is incorporated in the direct mixing, which could favor the deformability of the material by acting as a lubricant between the powder particles and the PLA matrix.

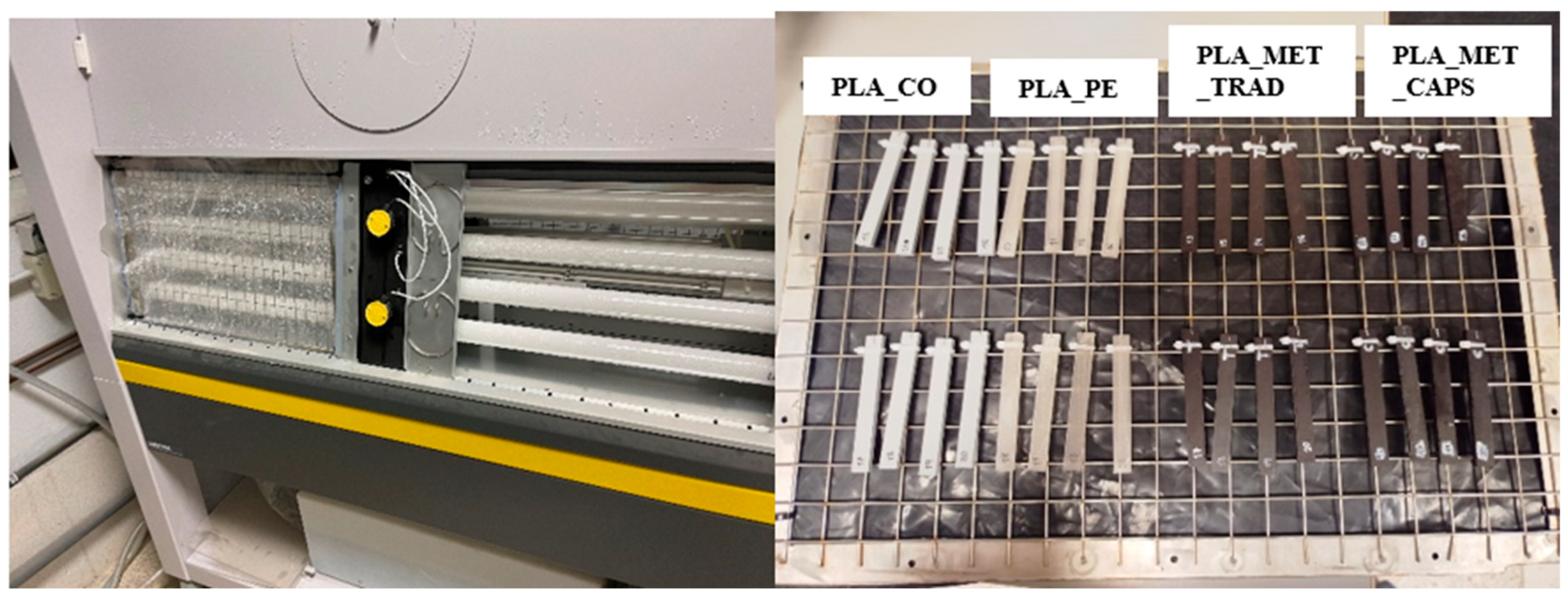

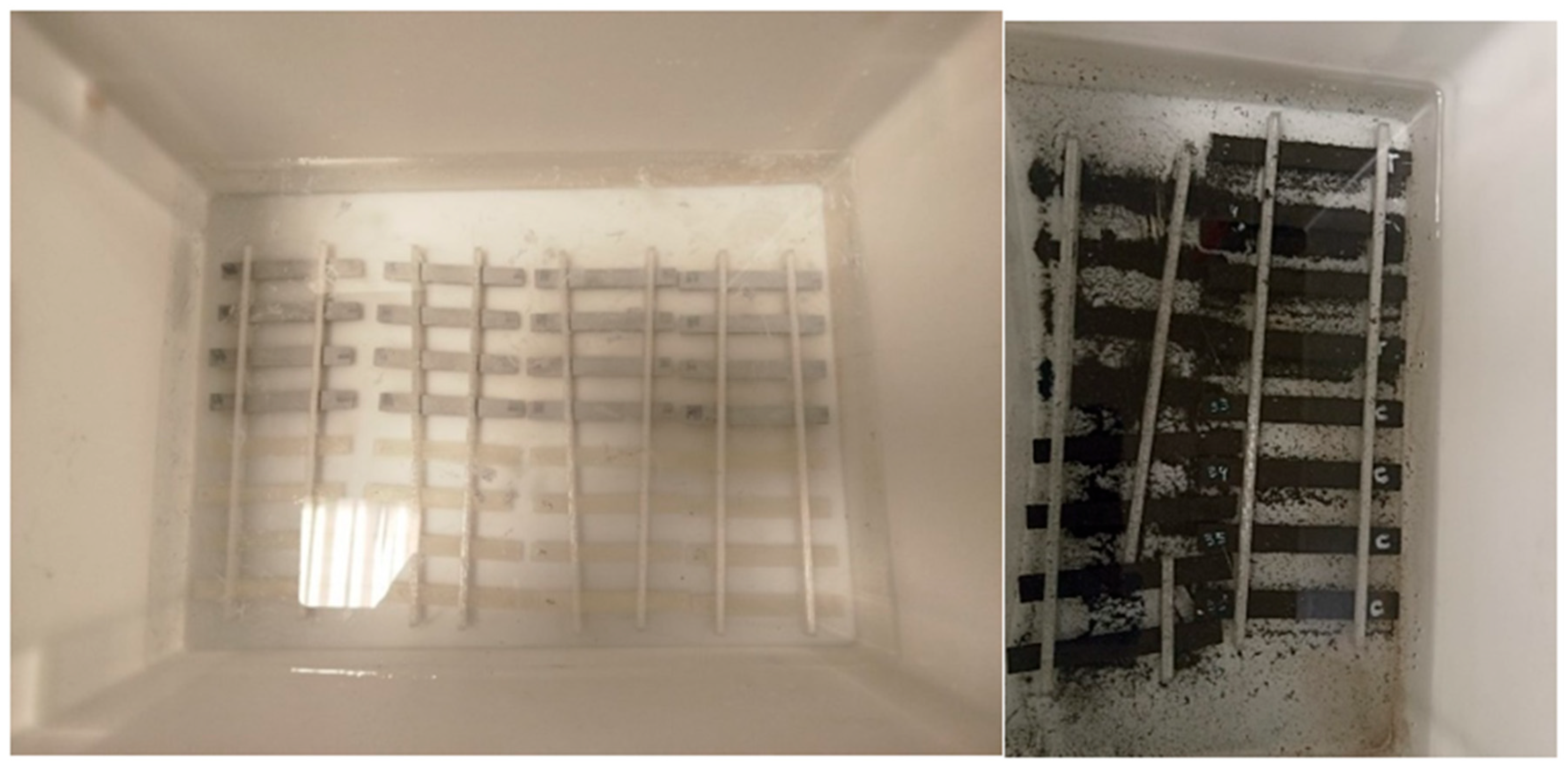

4.2. UVA Exposure and Water Spraying

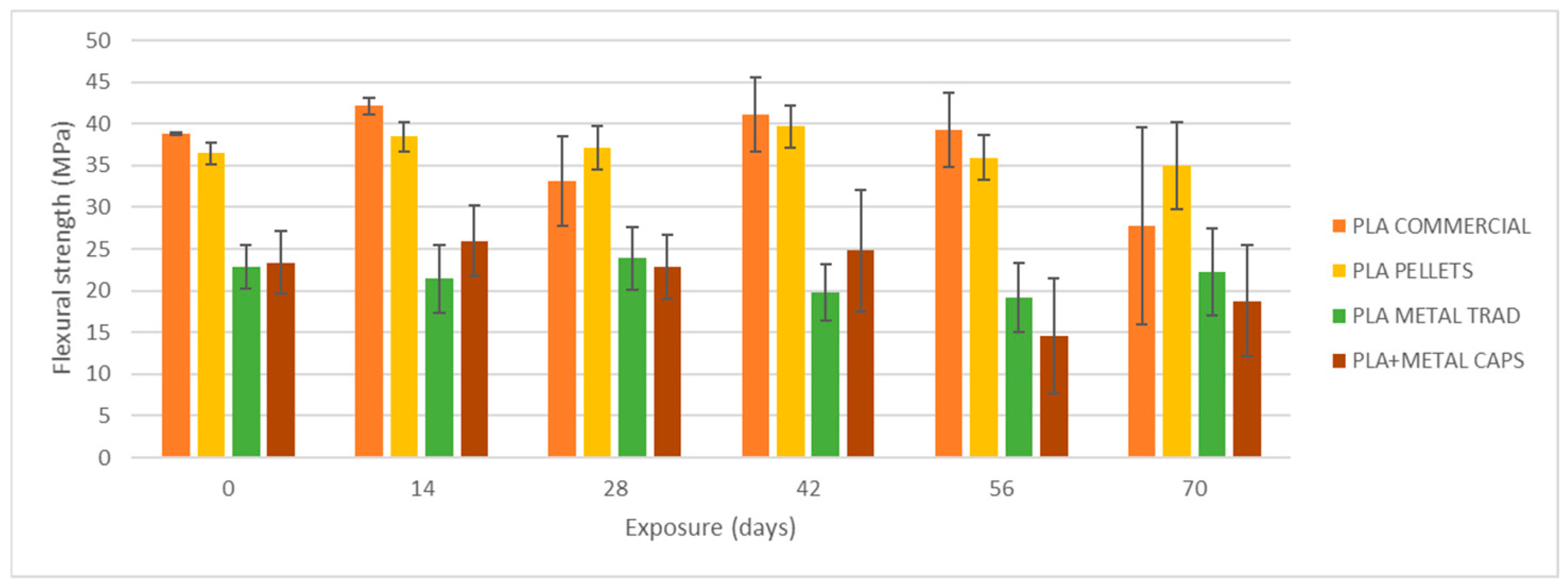

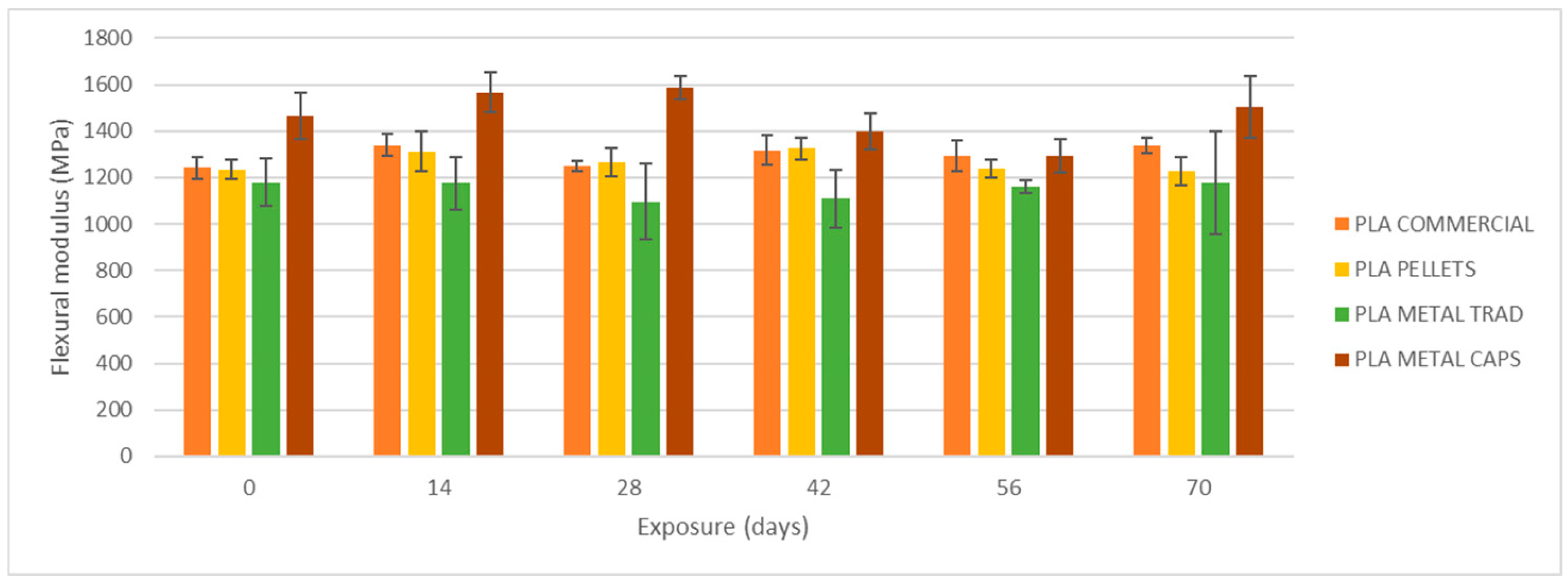

Figure 8,

Figure 9 and

Figure 10 show the evolution of the flexural strength, the elastic flexural modulus, and the flexural strain at the break of the specimens subjected to environmental conditions of combined exposure to ultraviolet radiation and water spray (UVA + spray).

The results indicate that neither the flexural strength nor the elastic modulus shows significant variations in the commercial PLA specimens or those made from pellets after exposure. However, a reduction in the strain at break is observed, especially after 70 days of exposure. In addition, the longer the exposure time, the greater the increase in the dispersion of the results for all four types of specimens, as reflected by the deviation bars in the three graphs. This suggests that UV and spray-induced degradation leads to less predictable mechanical behavior, resulting in a higher variability in the flexural strength values at failure.

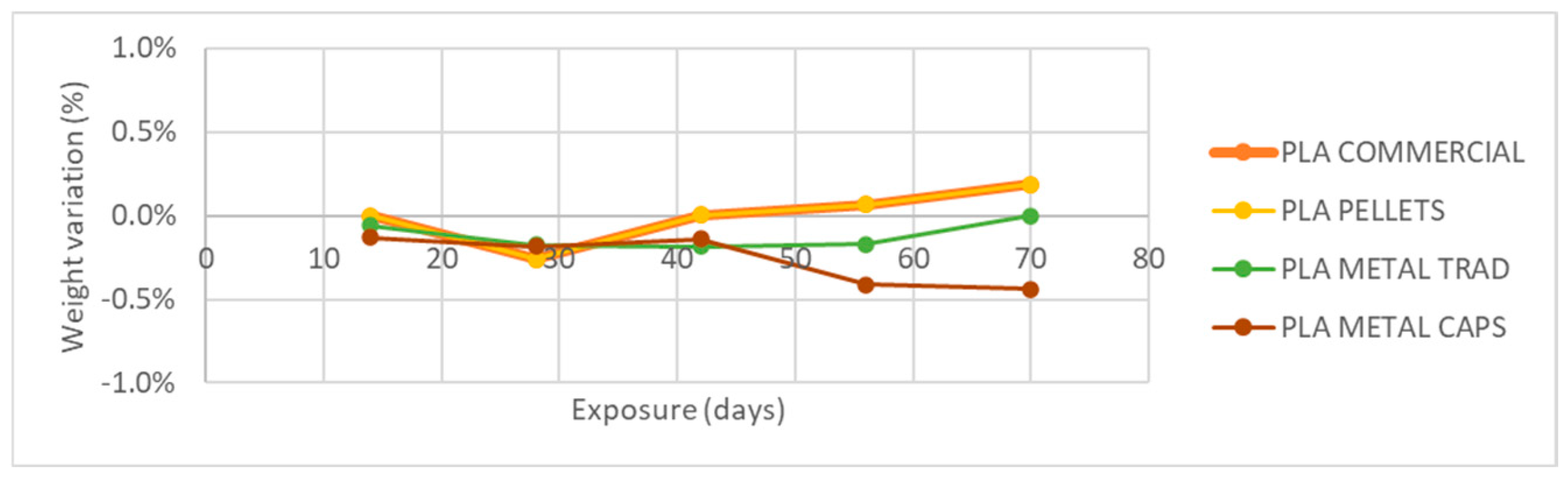

The analysis of the weight variation (

Figure 11) reveals that none of the four case studies shows significant changes after exposure to atmospheric agents. The recorded variations do not exceed 0.5% in any case and can, therefore, be considered negligible.

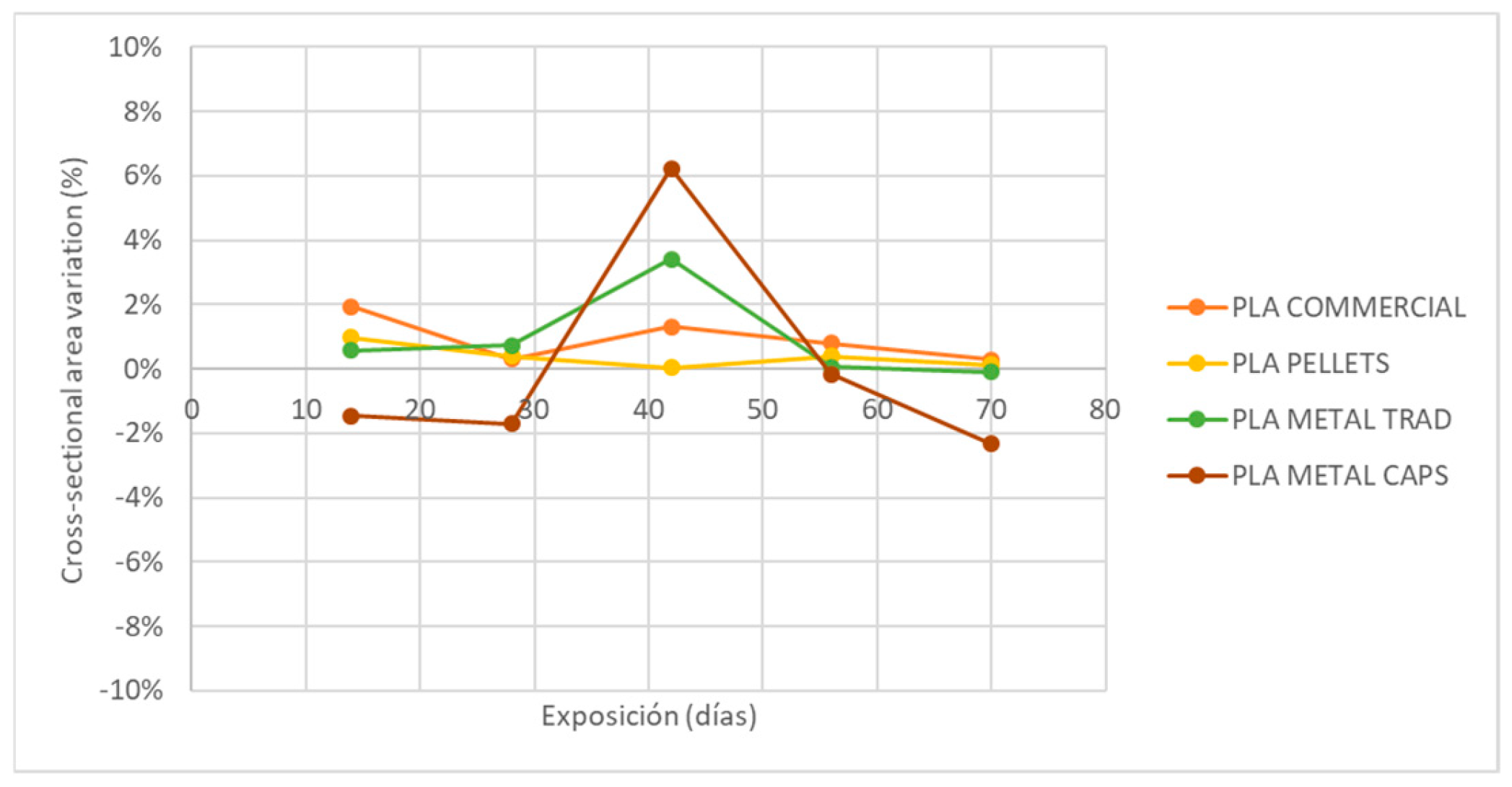

Finally,

Figure 12 shows the variation in the cross-sectional area of the specimens after exposure. In all cases, except for the metal PLA specimens made by encapsulation, the variation in area remains between 0 and 3.4%, suggesting some degree of swelling during exposure.

However, in the specific case of metal PLA obtained by encapsulation, a reduction in the cross-section is observed after all exposures, with the exception of the third extraction (45 days), where an increase in area is recorded. Despite this erratic behavior, it is not considered to be relevant because its variation does not exceed 6% in any case. In order to better understand the causes of this phenomenon, a microscopic analysis of the samples by scanning electron microscopy (SEM) is proposed as a future work.

As shown in

Figure 8,

Figure 9,

Figure 10,

Figure 11 and

Figure 12, the differences observed in the four evaluated parameters (flexural strength, flexural modulus, ultimate strain, cross-sectional change, and mass change) are relatively small. To support the interpretation of these results and to assess whether the variations caused by UV exposure and spraying are statistically significant, an ANOVA (Analysis of Variance) was performed using a significance level of α = 0.05. If the

p-value is less than or equal to the significance level, the null hypothesis is rejected, indicating that not all population means are equal.

Table 5 summarizes all evaluated parameters along with their corresponding

p-values.

No statistically significant differences were identified in flexural strength or flexural modulus across the four tested materials. Although this trend was already apparent from the graphical analysis (

Figure 8 and

Figure 9), it is now quantitatively confirmed through inferential statistics. Conversely, ultimate strain exhibited a statistically significant response to the applied degradation conditions. As for the weight and cross-sectional changes, statistical significance was not uniform and appeared to be material dependent; in the case of non-additivated materials (commercial PLA and PLA pellets), UV and spraying exposure did not induce statistically significant variations in mass.

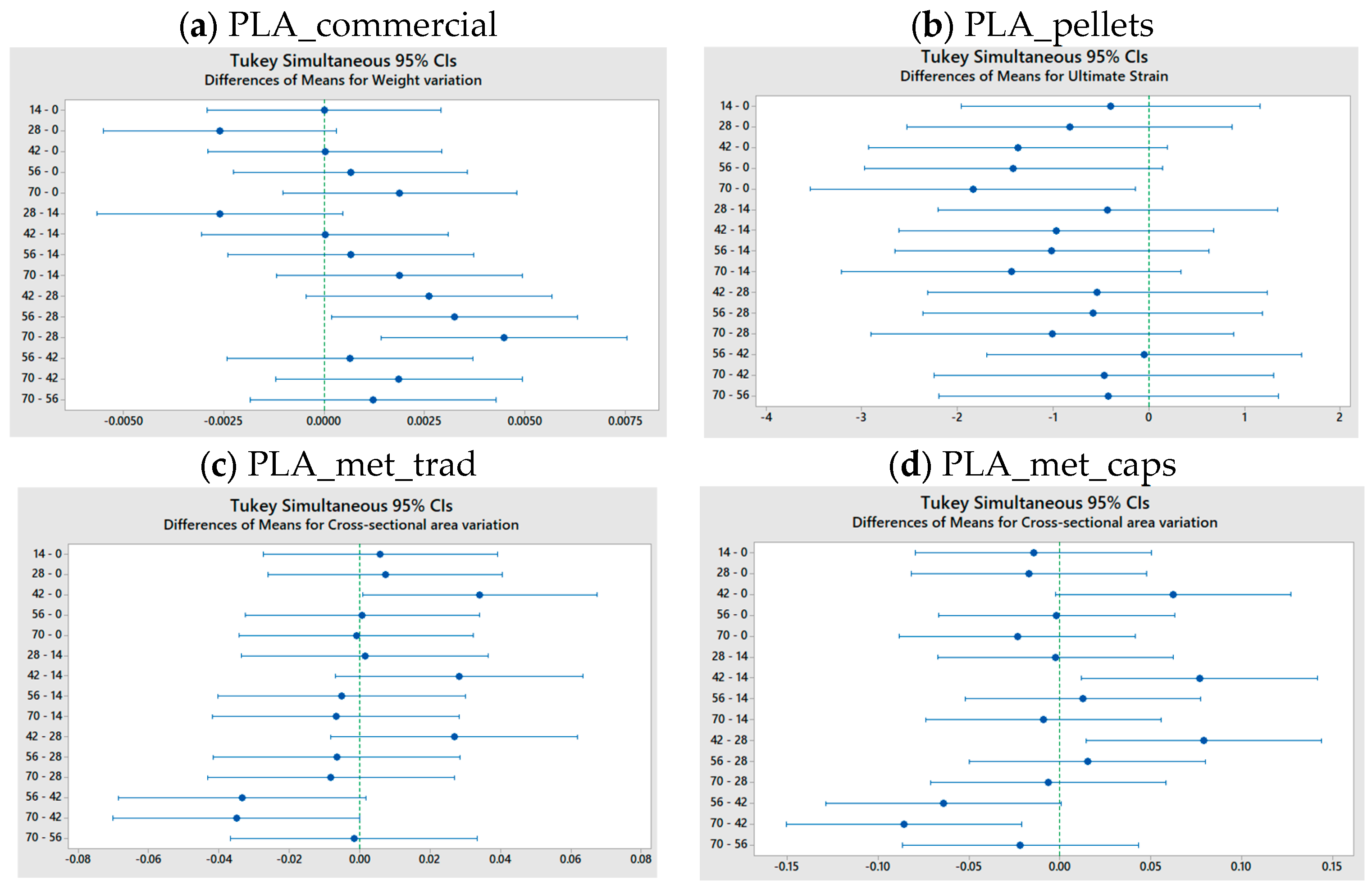

For those response variables where the ANOVA indicated a significant overall effect, a Tukey’s Honest Significant Difference (HSD) post hoc test was performed. The most relevant pairwise comparisons are depicted in the plots in

Figure 13. These allow for the identification of specific exposure durations whose group means differ significantly. In this analysis, the groups correspond to the exposure times (0, 14, 28, 42, 56, and 60 days). Confidence intervals that do not intersect the zero line indicate statistically significant differences between the corresponding group means.

Figure 13a reveals that the global statistical significance observed for weight reduction in PLA_commercial is primarily driven by significant differences between the exposure durations of 28 and 56 days, as well as between 28 and 70 days. In the case of PLA_pellets (

Figure 13b), the overall significant difference arises mainly from the contrast between the means at 0 and 70 days of exposure. However, the results lie very close to the threshold of statistical significance, as is also the case in

Figure 13c, where the confidence intervals for the significant pairwise comparisons barely deviate from the vertical zero line. Finally, for PLA_met_caps (

Figure 13d), the

p-value is considerably lower, and the corresponding plot clearly shows statistically significant differences across three exposure groups, with confidence intervals that deviate substantially from zero, indicating a more pronounced degradation effect.

4.3. Exposure to Basic pH

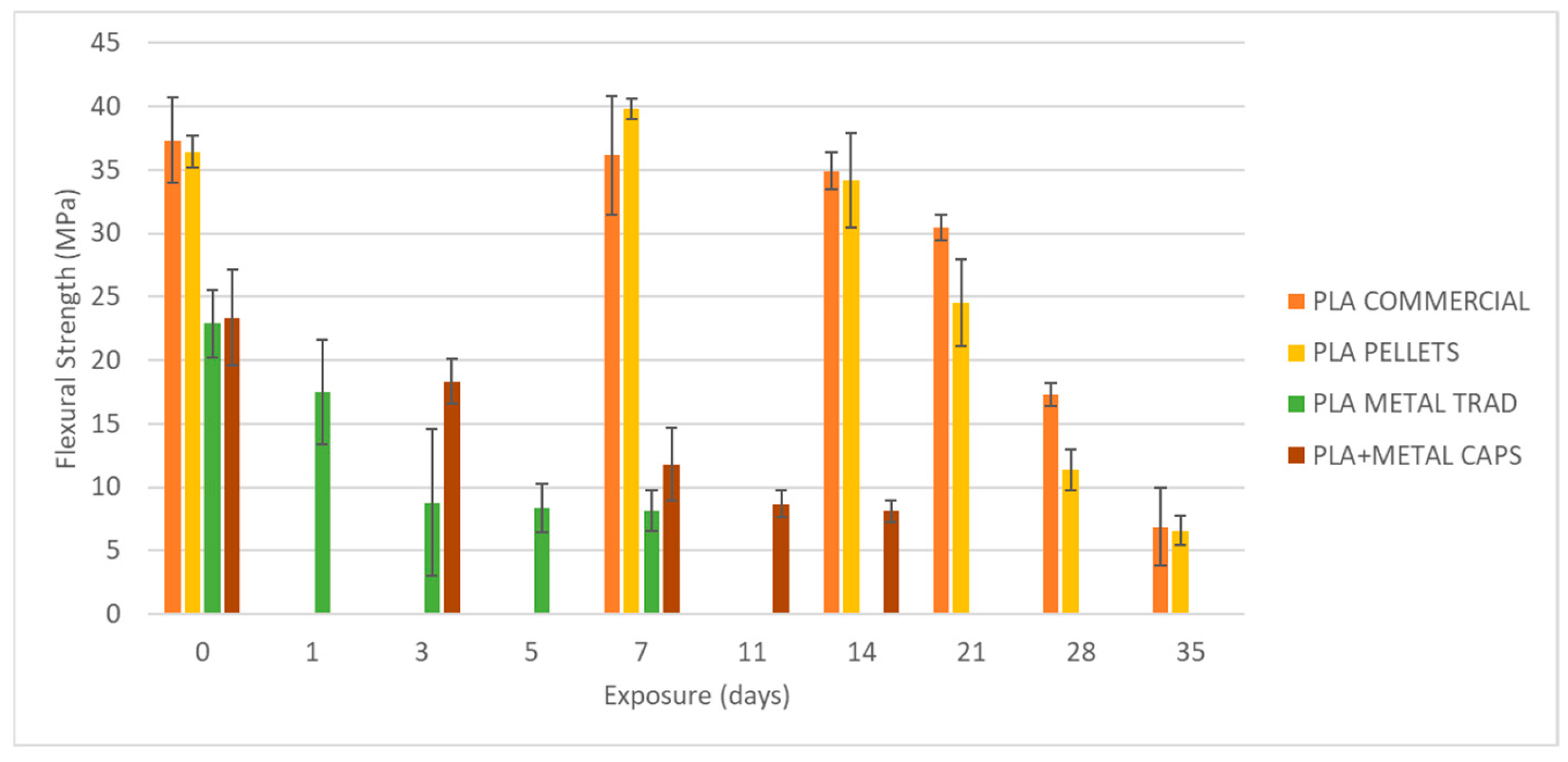

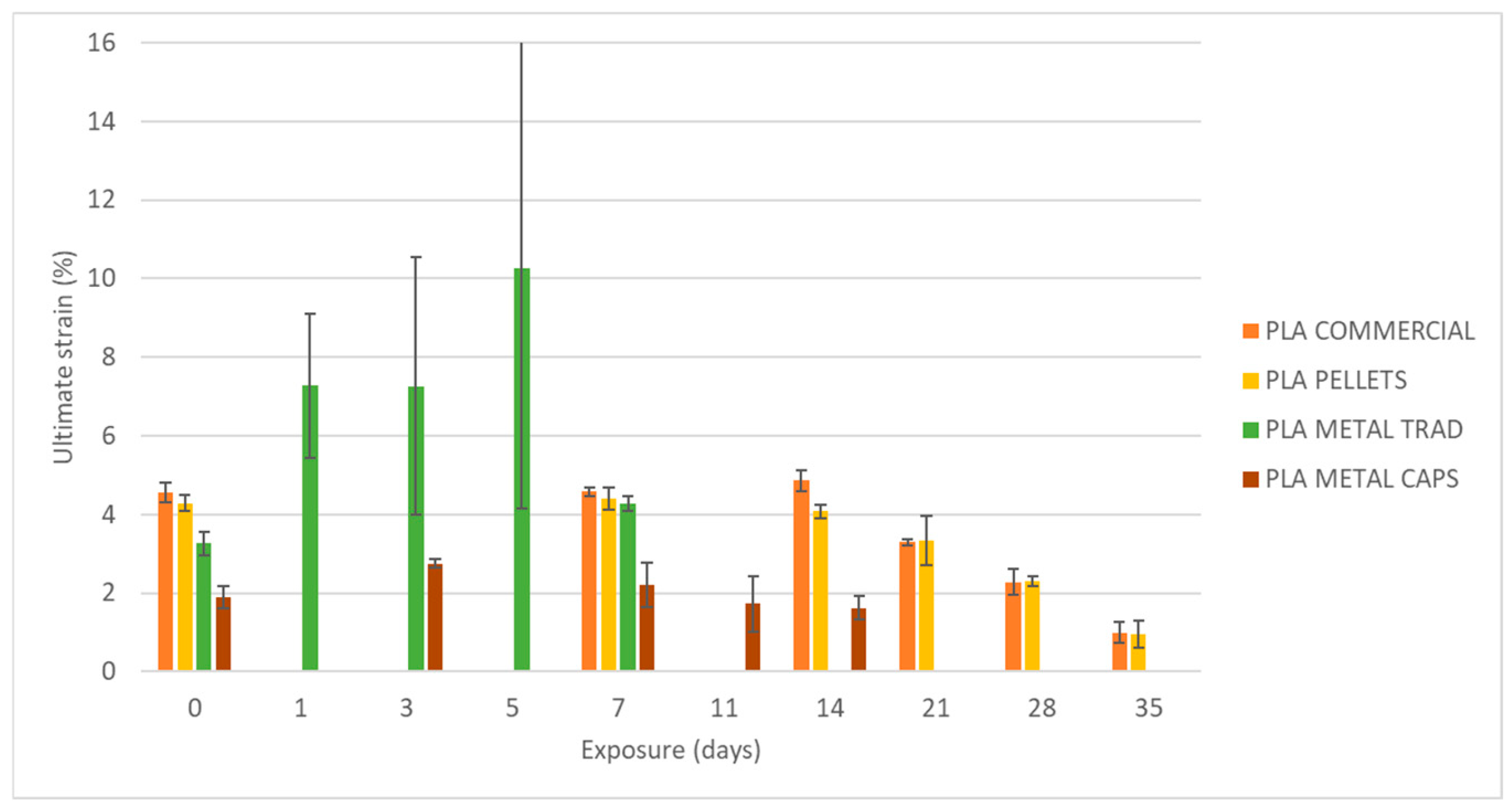

Figure 14,

Figure 15 and

Figure 16 present the evolution of the flexural strength, the elastic flexural modulus, and the flexural strain at break of specimens exposed to a basic pH similar to that of fresh concrete.

Firstly, it is observed that PLA without additives (commercial PLA and PLA made from pellets) shows a lower degradation rate compared to formulations containing metal powder. This behavior can be attributed to the higher susceptibility of the metal (iron and its alloys) to oxidation, which would accelerate its deterioration in alkaline media. As a consequence, the exposure times initially foreseen (35 days) had to be reduced for the metal-containing materials, being limited to 11 days for PLA+metal manufactured by direct mixing and 21 days for PLA+metal obtained by encapsulation. In addition, the specimens that reached these exposure periods could not be tested due to the drastic reduction in their dimensions, which prevented the testing machine from applying the minimum required load. For this reason, flexural strength, elastic flexural modulus, and the flexural strain at break values for all exposure times are not presented in the figures.

Analysis of the results reveals a reduction of up to 82% in the flexural strength of the commercial PLA after 35 days of exposure from 37 MPa to 6.87 MPa. An identical decrease (82%) is recorded for PLA made from pellets, although in this case, the material experiences a slight increase of about 4 MPa in its flexural strength after one week of exposure, before starting its progressive degradation. In addition, some stability in flexural strength, strain at break, and elastic modulus is observed during the first two weeks of exposure, followed by an acceleration of mechanical deterioration.

In the case of PLA with metal additives, the degradation of mechanical properties is more pronounced in the specimens manufactured by direct mixing with metal powder (PLA_met_trad). In addition, this method shows a higher dispersion of results, especially in terms of deformation, indicating a lower reproducibility and an accelerated degradation of the material. These findings suggest that fabrication by direct mixing is not the most suitable method, as it leads to a significant loss of uniformity and reliability in the mechanical properties of the material.

On the other hand, the specimens obtained by encapsulation were able to remain submerged for 10 days longer than those manufactured by direct mixing. However, they also suffered severe deterioration, with a 65% reduction in flexural strength after 14 days of exposure and complete degradation (100%) at 21 days.

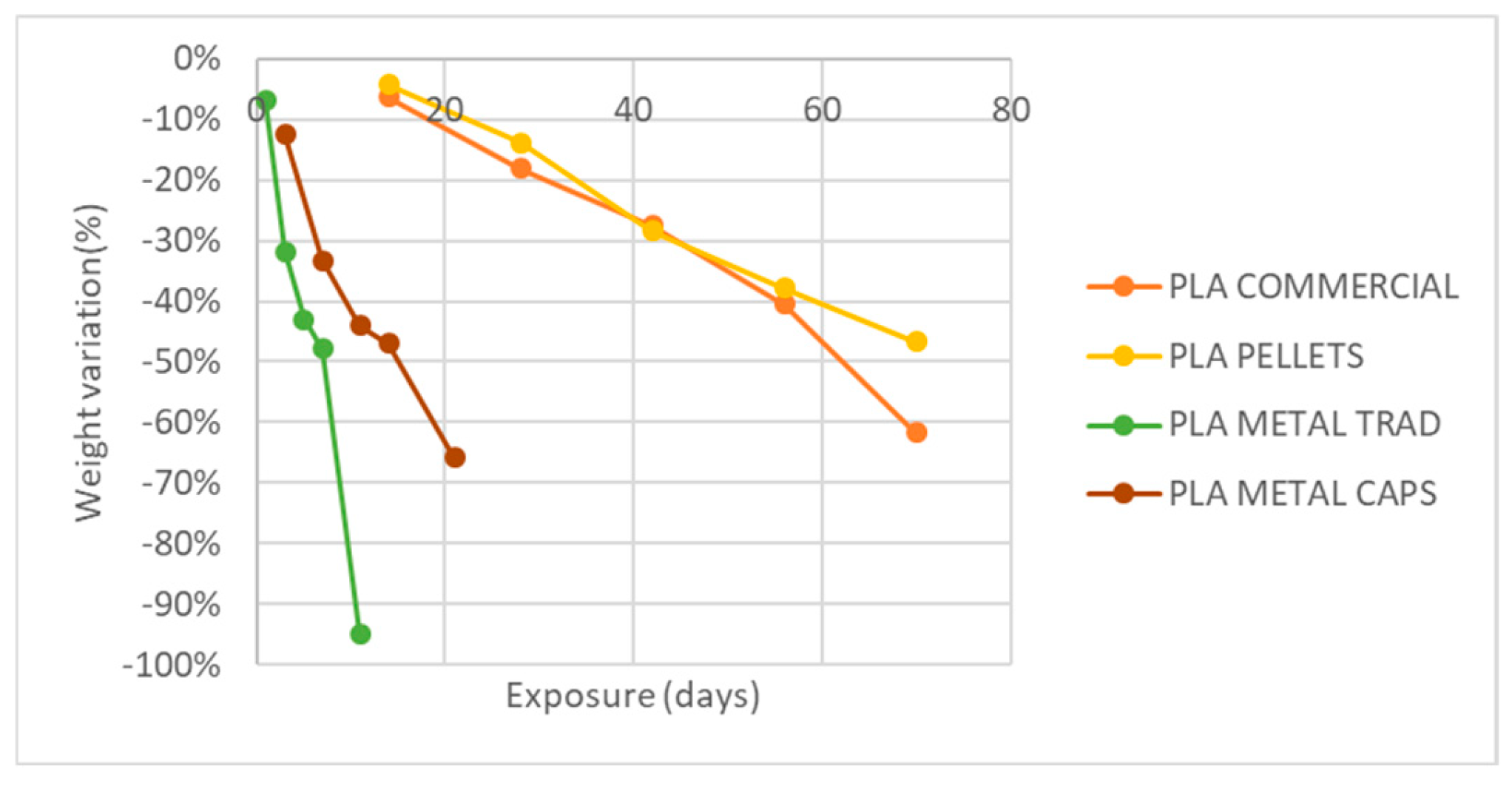

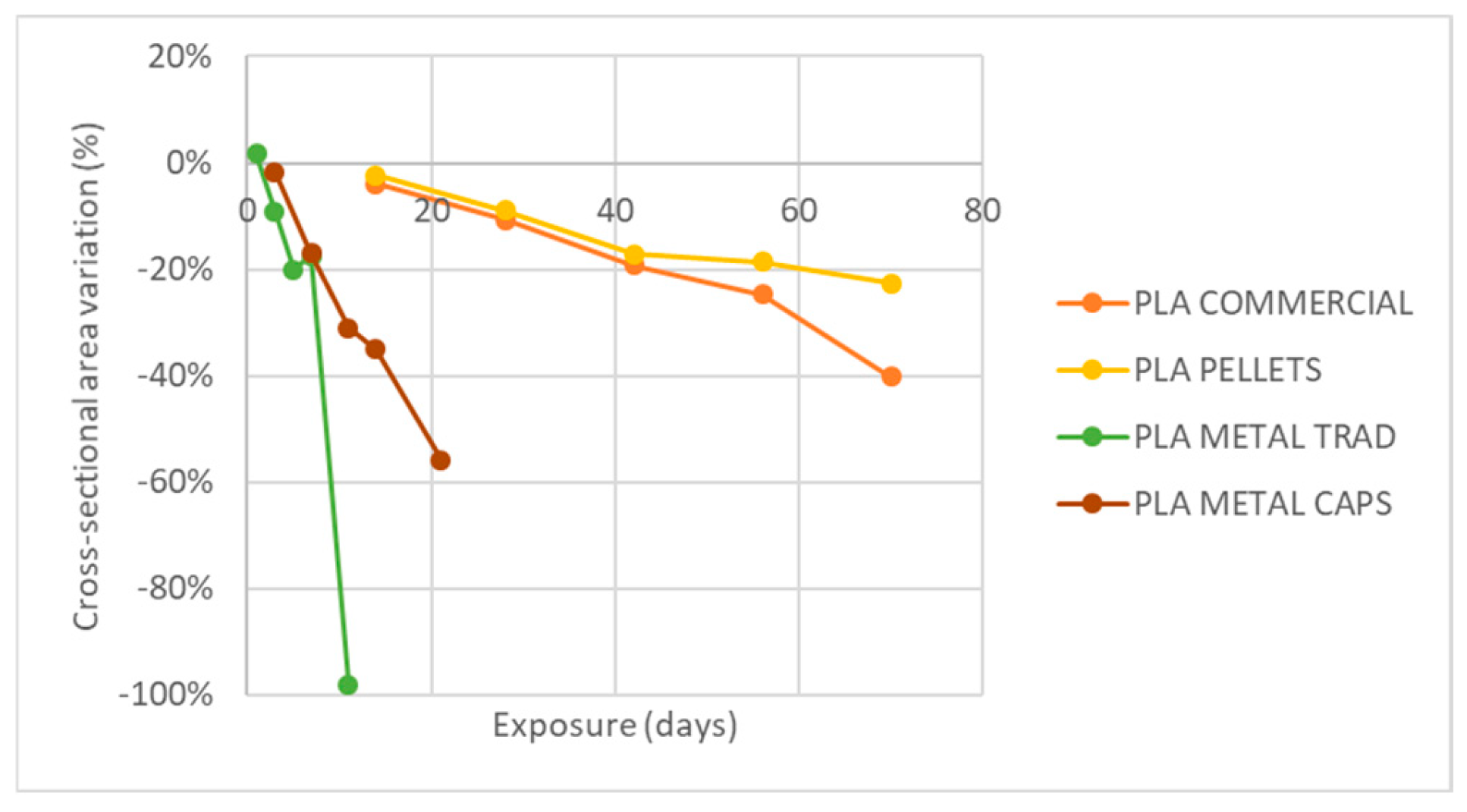

The analysis of weight reduction and the cross-section (

Figure 17 and

Figure 18) reveals that pure PLA, both in its commercial version and in the one obtained from pellets, shows an approximately linear decrease in both parameters. In the case of commercial PLA, the weight reduction reaches up to 62%, while the cross-section decreases by 40% after 70 days of exposure. However, a more pronounced degradation is observed in the commercial PLA during the last two extractions compared to the PLA made from pellets during the same periods.

On the other hand, PLA specimens with metal addition exhibit a considerably faster weight loss than in the previous cases. In specimens made by encapsulation, the weight reduction amounts to 65% in only 21 days, while in those obtained by direct mixing of pellets with metal powder in the hopper (trad method), the weight loss reaches almost 95% in only 11 days.

Finally, as expected, the ANOVA results confirmed that all evaluated parameters exhibit statistically significant variation under alkaline pH exposure, with p-values equal to 0 in all cases. This extremely low p-value is attributable to the clear and consistent differences observed between the mean values of the groups corresponding to each exposure time.

4.4. Geometric Changes After Degradation

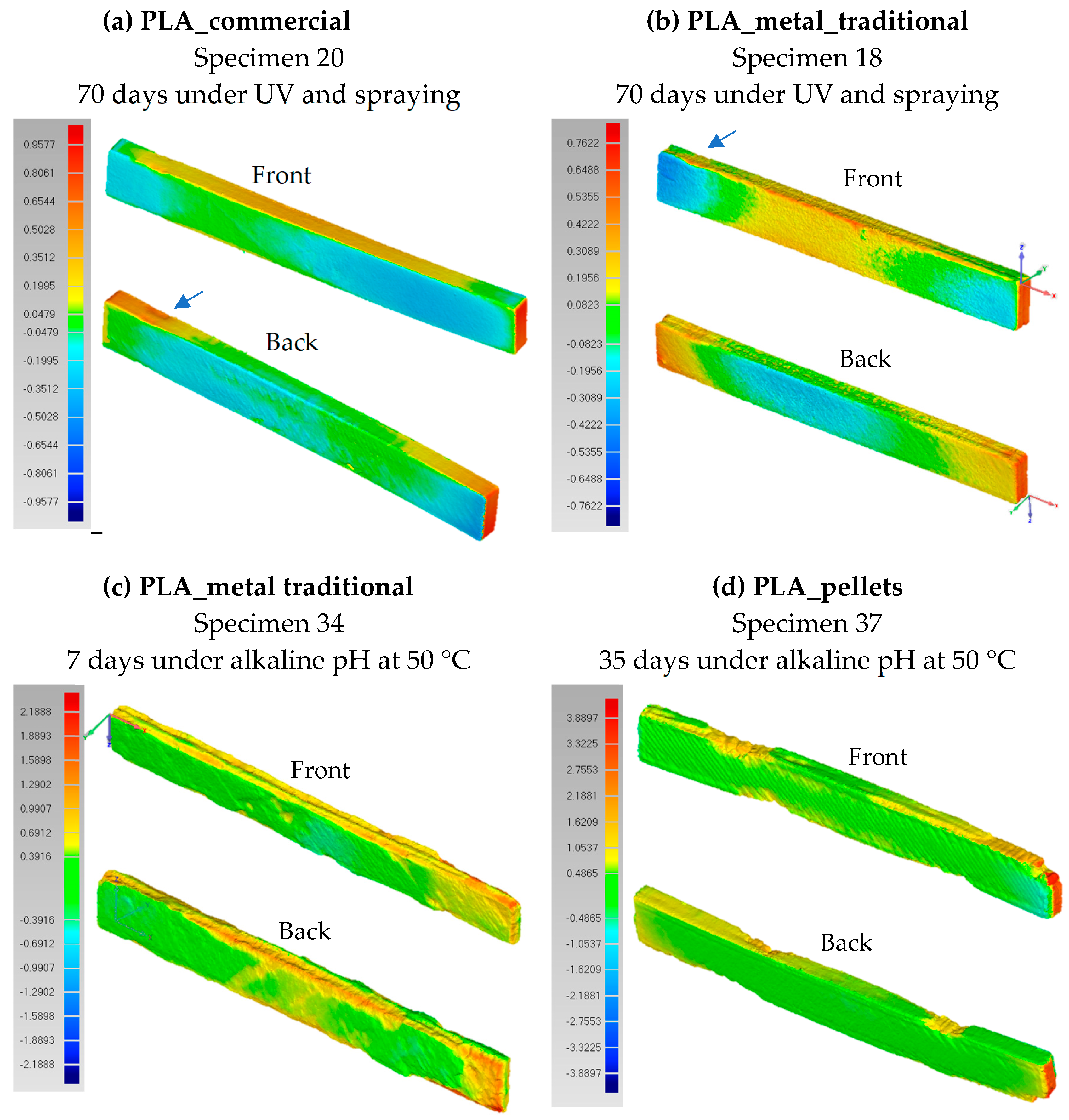

A 3D scanner was used to compare the dimensions of the sample before and after exposure (

Figure 19). In scans a and b, the behavior of commercial PLA and PLA with traditional metal fillers after 70 days of UV exposure and spraying is analyzed. In both cases, a constriction mark is visible on the left side of the specimen, caused by the clamp used to secure the samples to the UV chamber grid. Although this might suggest a slight increase in the cross-sectional area,

Figure 12 confirms that this increase is less than 0.2% or even negligible in the case of PLA with traditional metal fillers. Therefore, this mark is attributed to the compression of the four corners due to the softening of the material under UV radiation exposure. Additionally, both specimens (

Figure 19a and b) exhibit warping, likely resulting from the combined effects of temperature and humidity. This deformation is more pronounced in the case of PLA with traditional metal fillers. The greatest dimensional deviations compared to the pre-exposure specimen are observed at the edges; however, they do not exceed 0.96 mm for commercial PLA and 0.77 mm for PLA with traditional metal fillers.

Scans c and d (

Figure 19) illustrate the behavior of PLA with traditional metal fillers and PLA with pellet-based fabrication after exposure to an alkaline pH environment at 50 °C. A significant difference in geometric degradation is observed, with the traditionally manufactured PLA–metal specimens exhibiting greater deterioration compared to those produced from pellets, even considering the difference in exposure time (7 days for PLA_metal_trad versus 35 days for PLA_pellets). Focusing first on the PLA_pellets specimen, three distinct erosion zones can be identified: two on one side and two more on the opposite side, one of which is located at a corner. These defects may be attributed to printing errors that were not detected prior to exposure, leading to an increased number of voids that facilitated solution penetration and accelerated degradation. However, these are localized defects that could be mitigated by improving print quality. The greatest deviation from the original, non-degraded geometry occurs along the specimen’s length, with the maximum displacement observed at the corner, reaching a magnitude of 3.9 mm.

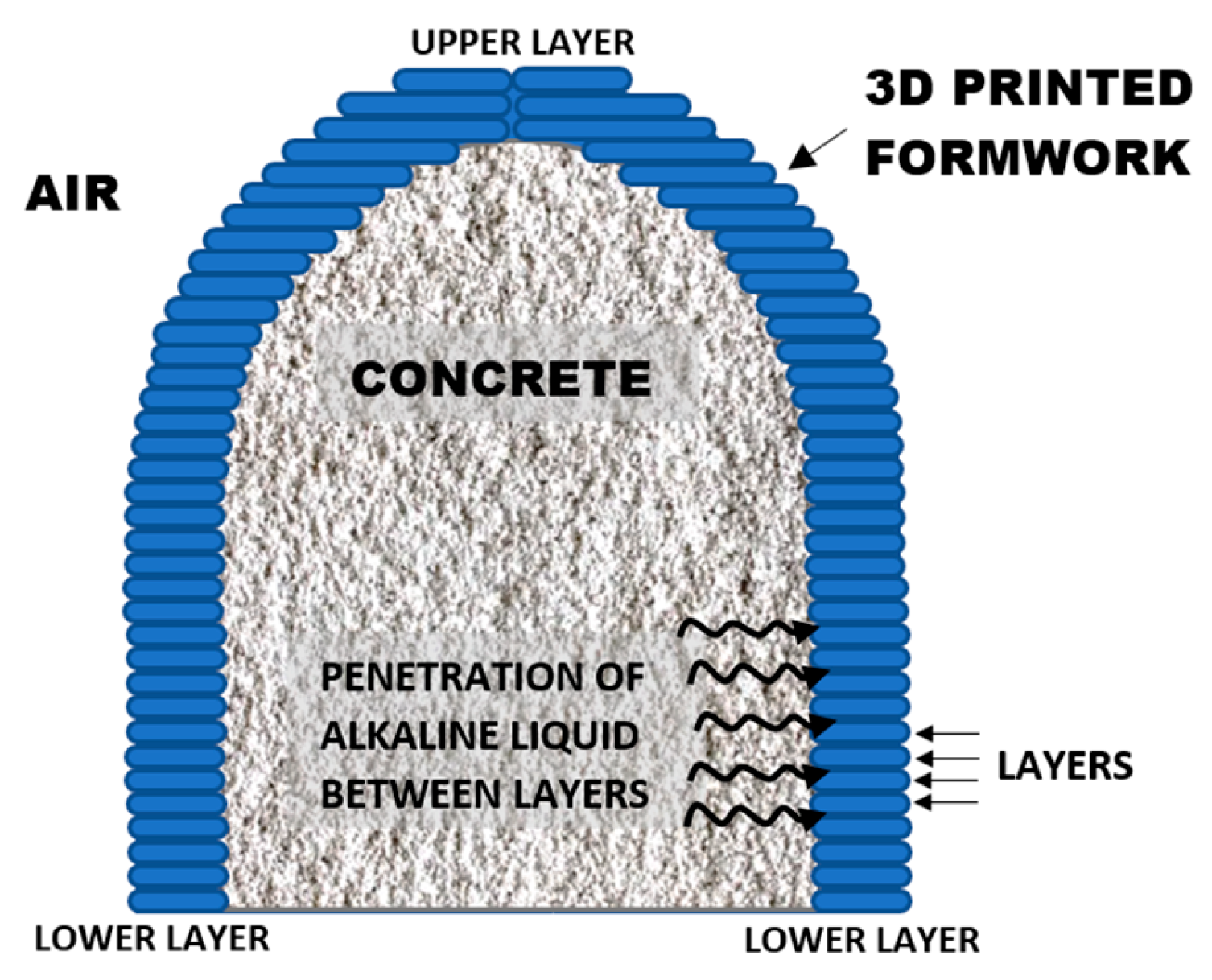

Conversely, in the traditionally manufactured PLA–metal specimens (c), a different degradation mechanism occurs. The results indicate the presence of areas of material loss in the contours of some of the intermediate layers of the specimen, suggesting that the basic pH solution may have penetrated into the interior of the structure, causing weight loss and delamination.

Figure 19c shows these voids in the interlayers from two different orientations. Extrapolating this behavior to the manufacturing process of real concrete parts, such as artificial reefs, like those in

Figure 1, and of other concrete types, like columns or sculptures [

5,

6,

7], the PLA formwork would be subjected to direct exposure to a basic pH on its outer wall, specifically at the layer boundaries (

Figure 20), rather than on the flat surfaces of the top and bottom layers. As demonstrated in the scan, this zone exposed to an alkaline pH is highly susceptible to formwork failure. The presence of voids—whether due to porosity, material deficiencies, or poor interlayer adhesion—can allow the alkaline liquid mortar to infiltrate, progressively degrading the specimen from within. This deterioration reduces the load-bearing capacity of the formwork and, in the worst case, can lead to interlayer delamination and structural failure, causing the formwork to break into multiple parts.

The results of PLA_metal_trad under alkaline pH at 50 °C also show an uneven degradation, with areas of high material disappearance, especially in the right and central part, while the left part shows less loss. This heterogeneity in degradation makes it very difficult to accurately determine the actual cross-section at fracture during the flexural test.

4.5. Equivalence to Real-Time Exposure

To establish an equivalence between the experimental exposure time and real-world exposure, the following considerations were considered:

- ♦

The weathering exposure equipment does not accelerate the UV effect of sunlight but rather simulates it. The accelerated aging effect is due to continuous operation, including night-time exposure, rather than harsher conditions.

- ♦

Two locations in Spain with distinct climatic conditions were selected: Cantabria, characterized by higher rainfall and fewer hours of solar exposure, and Seville, which has a drier climate with significantly greater solar exposure. According to the solar panel company Solfy [

33], the annual direct solar exposure in Cantabria is 1639 h, whereas in Seville, it reaches 3526 h. Regarding precipitation, Cantabria records an annual average of 1095.6 mm, whereas Seville experiences considerably lower levels, at 336 mm [

34]. Therefore, the lifespan of the plastic when exposed to atmospheric agents varies depending on the geographic location.

Based on these data and considering that the equipment’s solar and rain cycles consist of 5 h of solar exposure followed by 1 h of rainfall, the total equivalent real-world exposure time (in months) for these two geographic regions was estimated. This analysis allowed for the evaluation of variations in the mechanical properties of maximum tensile strength and strain at break compared to the non-degraded material (

Table 6).

Regarding the equivalence with spraying, no relevant references have been found to establish a direct comparison with real-world conditions. A possible quantitative analysis could be conducted as follows: each panel, equipped with three nozzles, sprays 1.75 L/min over an area of 280 mm × 485 mm. Consequently, each specimen, with a surface area of 10 mm × 80 mm, receives 0.618 L/h. In Cantabria, the average annual precipitation is 1095 L/m2, which corresponds to 0.876 L per specimen per year. This implies that one hour of testing in the chamber would subject the specimens to an amount of water equivalent to 70% of the total annual precipitation in Cantabria. In Seville, where annual precipitation amounts to 336 L/m2, one hour of testing in the chamber would expose each specimen to 2.3 times the amount of rainfall received in an entire year under natural conditions.

However, a strictly quantitative evaluation is not considered appropriate, as the alternation between one hour of water spraying and four hours of UV exposure induces a temperature fluctuation from 50 °C (under UV radiation) to 25 °C during water spraying and relevant variations in surface humidity on the specimens, which are complex to quantify and equate to real environmental conditions.

By analyzing

Table 6, the most significant variations in maximum flexural strength and strain at break occur after 56 days of experimentation in PLA–metal specimens, with a more pronounced effect on maximum strain. This corresponds to 8.3 months of solar exposure in Cantabria or 3.9 months in Seville. However, for PLA specimens without metal, a critical level of deterioration may be expected after 70 days of testing, which equates to 10.4 months in Cantabria or 4.8 months in Seville.

Regarding the equivalence between the pH exposure test and real-world conditions, formworks for structures, such as the artificial reefs shown in

Figure 1, with an approximate volume of 300 dm

3, are considered. These structures were demolded one day after the mortar was poured, representing the period during which the high-pH environment actively contributed to the degradation of the formwork. Therefore, the fabrication of a single reef corresponds to approximately 24 h of exposure to alkaline conditions. Under this hypothesis, establishing a correlation between the experimental exposure time and real-world conditions is straightforward, as one day of exposure in the experiment is considered equivalent to one day in actual conditions (

Table 7). Although the concrete gradually hardens over this period, leading to a reduction in moisture content, accurately determining the precise moment at which its alkaline pH no longer affects the polymer remains highly complex. Consequently, it is assumed that the material undergoes continuous exposure to alkaline degradation throughout the entire contact period. This approach ensures a conservative and safety-oriented assessment.

Based on this hypothesis, it can be concluded that after the fabrication of 28 components, corresponding to 28 days of exposure, the formworks manufactured from commercial PLA and PLA derived from pellets exhibit a reduction of 54% and 69%, respectively, in their load-bearing capacity, along with a 50% decrease in strain at break.

Notably, the PLA_met_trad formulation demonstrates a distinct mechanical response. After just three days of use, it undergoes a 62% reduction in flexural strength, while from the first day, its maximum strain increases by up to 123%. This pronounced increase in deformability is attributed to the weaker interlayer adhesion between printed layers, which promotes interlayer slippage, enabling greater bending under reduced loads.

In contrast, the behavior of PLA_met_caps falls between the previously analyzed materials, although its durability remains significantly lower than that of unmodified PLA. Specifically, when incorporating metal encapsulation, the formwork fabricated from this material experiences a 50% reduction in flexural strength after seven reuse cycles.

In particular, for the initially intended application—namely, the fabrication of artificial reefs or any other ornamental structure—the significance of the mechanical degradation tests can be interpreted as follows. If the formwork design is carried out using finite element analysis software, such as Ansys or Abaqus, it is standard engineering practice to apply a safety factor to the design loads. Assuming a safety factor of 1.2 applied to the loads, a 20% reduction in flexural strength due to material degradation would mark the threshold at which the structural integrity of the formwork is compromised. Therefore, setting a usability limit at a 20% decrease in flexural strength, it can be estimated that PLA_commercial formworks could be used for up to approximately 21 days, while PLA_pellet formworks would be suitable for around 18 days. The incorporation of metallic fillers does not appear to provide any benefit in terms of durability under these conditions; instead, it accelerates degradation, with the 20% reduction being reached in as little as 1 to 3 days, depending on whether PLA_metal_trad or PLA_metal_caps is used, respectively. These estimations are based on the most aggressive exposure condition tested, namely, immersion in an alkaline environment.

4.6. Applicability to Artificial Reef (AR) Manufacturing

This research contributes to the expanding field of sustainable marine restoration through the development of innovative manufacturing strategies for artificial reefs. Among these, 3D printing has emerged as a particularly promising technique. The review by Yoris-Nobile et al. [

35] systematizes current practices in the design, material selection, and fabrication of artificial reefs via additive manufacturing. Most existing approaches rely on the direct 3D printing of reef structures using the extrusion of cementitious or geopolymer mortars, which introduces challenges related to rheological control and the mechanical stability of the printed elements. In particular, Yoris-Nobile et al. [

36] emphasize the need for a carefully balanced mortar formulation—neither overly fluid nor excessively stiff—to ensure both geometric fidelity during printing and sufficient mechanical resistance to withstand marine forces, such as waves and currents.

The comprehensive review by Matus et al. [

37] further explores additive manufacturing methods applied to marine restoration, including binder jetting, polymer extrusion (FFF), and the use of cementitious or geopolymer materials. While polymer-based approaches are noted for their environmental limitations and low durability in seawater, cement-based systems are recognized for their structural robustness. However, all reviewed cases rely on the direct 3D printing of the final reef geometry. None consider the use of polymeric molds created via 3D printing and subsequently filled with a mortar or geopolymer, highlighting the originality of the method proposed in this study.

Additionally, the work by Silva Lima et al. [

38] provides a broad overview of artificial reef research, covering ecological, engineering, socio-economic, and environmental aspects. Although not focused specifically on additive manufacturing, this review underscores the importance of integrating ecological functionality with fabrication efficiency—an objective that aligns with the methodology presented here, which enables controlled production of complex reef geometries while maintaining structural integrity.

The method developed in this study, based on 3D-printed polymer molds filled with conventional cementitious mixtures, offers notable advantages over direct extrusion printing. These include lower sensitivity to environmental conditions during manufacturing, the use of standard mortar formulations without rheological modification, and the potential for mold reuse, improving both sustainability and economic viability. To date, five artificial reefs have been fabricated using this technique with PLA pellet-based formworks, with the aim of deploying them in the Bay of Santander (Spain). These units will serve to compare biodiversity outcomes with those from reefs produced via direct mortar printing, following a defined immersion period of 1 year. Although biodiversity data are not yet available, this field deployment seeks to validate the capacity of the proposed solution to foster ecological enhancement in marine environments. From a manufacturing standpoint, the molds performed reliably; no degradation-related damage was observed, and the system effectively withstood all applied loads and boundary conditions. Therefore, this study has already confirmed the technical feasibility of using PLA for the production of reusable molds, offering a robust, low-cost, and adaptable solution for fabricating complex cementitious structures for marine applications.

While the scope of this research extends beyond AR manufacturing, the proposed approach is particularly well suited to such applications. It enables the replication of biologically inspired, complex geometries essential for promoting marine biodiversity in a controlled and potentially scalable manner. Compared to existing methods, this hybrid technique—combining 3D-printed molds with traditional casting—constitutes a versatile and innovative contribution to ecological restoration in coastal and marine environments.

5. Conclusions

In this study, the behavior of four types of 3D-printed specimens, manufactured using different combinations of materials and production methods, was analyzed in order to evaluate the effect of exposure to environmental conditions of sun and rain, as well as alkaline solutions, on their degradation. For this purpose, three-point bending tests were carried out, and the dimensions and weights of the specimens before and after exposure were analyzed.

From the results obtained, the following conclusions can be drawn:

- ♦

Exposure to an alkaline medium at 50 °C is significantly more aggressive than exposure to UVA radiation and spray. This aspect is crucial in the manufacture of formwork with PLA or PLA with metal additives, as these materials have a limited lifetime before degradation, leading to a loss of both strength and dimensions.

- ♦

The dispersion of flexural strength, elastic modulus, and strain at break values increases with exposure time. Also, the addition of metal powder increases the variability of the results in both formulations evaluated. This suggests that the printing process plays a fundamental role in the degradation of the material since the presence of pores or micro-defects in the specimens facilitates the penetration of liquids (distilled water from the spray or alkaline solutions), which modifies both the mechanism and the rate of degradation.

- ♦

The incorporation of 50% by weight of metal powder into PLA not only fails to improve its flexural mechanical properties but actually results in their significant deterioration under alkaline pH conditions. Specifically, a reduction in flexural strength of approximately 65% is observed after 7 days of exposure when the PLA pellets are directly mixed with metal powder, and after 14 days when the filament is produced using pre-filled capsules. Therefore, PLA with metallic additives is not suitable for formwork applications. In contrast, virgin PLA—whether in filament or pellet form—remains stable for up to 14 days of exposure, after which a progressive decline in flexural strength occurs, reaching a reduction of approximately 82% after 35 days. Consequently, while the addition of metal powder is not recommended, virgin PLA emerges as a more reliable alternative, allowing for the reuse of the same formwork for at least 14 days (or 14 casting cycles) with only a 6% decrease in flexural strength.

- ♦

The most suitable material for use as concrete formwork is unmodified PLA. There are no conclusive results regarding whether commercial PLA or PLA with pellet additives performs better. No significant differences were found in the maximum flexural strength and elastic modulus between the specimens made from commercial PLA in coil and those obtained from pellets in the laboratory. In terms of ultimate strain, commercial PLA specimens show slightly higher values (between 4% and 30%), although these differences disappear after 70 days of exposure to UVA radiation and spraying, as well as after 35 days of exposure to the alkaline solution. Therefore, it can be determined that both exhibit nearly identical behavior. This confirms that the addition of colorant pellets during the manufacturing of commercial PLA does not introduce any plasticizers that enhance its properties. If any plasticizing effect is present, its proportion is either negligible or insufficient.

- ♦

While the degradation of commercial PLA and pellet-based PLA in an alkaline pH environment leads to localized material loss in highly concentrated areas, the dissolution attack on PLA–metal specimens (in both manufacturing processes studied) induces delamination, i.e., interlayer separation, occurring unevenly along the entire length of the specimen.

- ♦

The exposure of 3D-printed PLA beyond 8.3 months in humid climates with lower solar exposure (e.g., Northern Spain) or 3.9 months in dry, high-sunlight environments (e.g., Southern Spain) is not recommended, especially if PLA with metal powder additions is employed. The determination of the exposure limit to alkaline pH mortar, beyond which the use of formworks should be discontinued, depends on the specific application and, in particular, on the safety factor considered in their design to withstand hydrostatic pressure, mold tightening, and demolding forces.

Table 6 provides an estimate of the variation in mechanical resistance, offering a quantitative basis for decision making according to the selected safety factor.

The degradation results obtained under atmospheric conditions of UVA radiation and spraying are not only applicable to the use of formworks in outdoor environments but also to any other 3D-printed components with the same composition that are exposed to sunlight and rainfall. Examples include protective casings for outdoor electronic devices, structural elements in temporary architectural installations, and customized components for urban furniture.

Although the present work focuses on the evaluation of mechanical performance and dimensional stability of PLA-based materials under alkaline and outdoor exposure, further research is required to understand the underlying molecular degradation mechanisms. Future studies should include advanced analytical techniques, such as Gel Permeation Chromatography (GPC), to determine changes in molecular weight and estimate degradation rates. Additionally, Differential Scanning Calorimetry (DSC) and Fourier-Transform Infrared (FTIR) spectroscopy can provide insights into thermal transitions and structural modifications of the polymer chains, respectively. Incorporating these techniques would complement the findings of this study and contribute to a more comprehensive understanding of the degradation behavior of these materials under realistic service conditions.