Reassessment of Porosimetry Determinations Using Water Vapor Sorption Measurements for Pastes and Concretes Containing Basaltic Aggregates Compared to the Mercury Intrusion Method

Abstract

1. Introduction

- -

- -

- -

- -

2. Materials and Methods

2.1. Materials

2.2. Mercury Intrusion Technique (MIP)

2.3. Porosity Accessible by Water

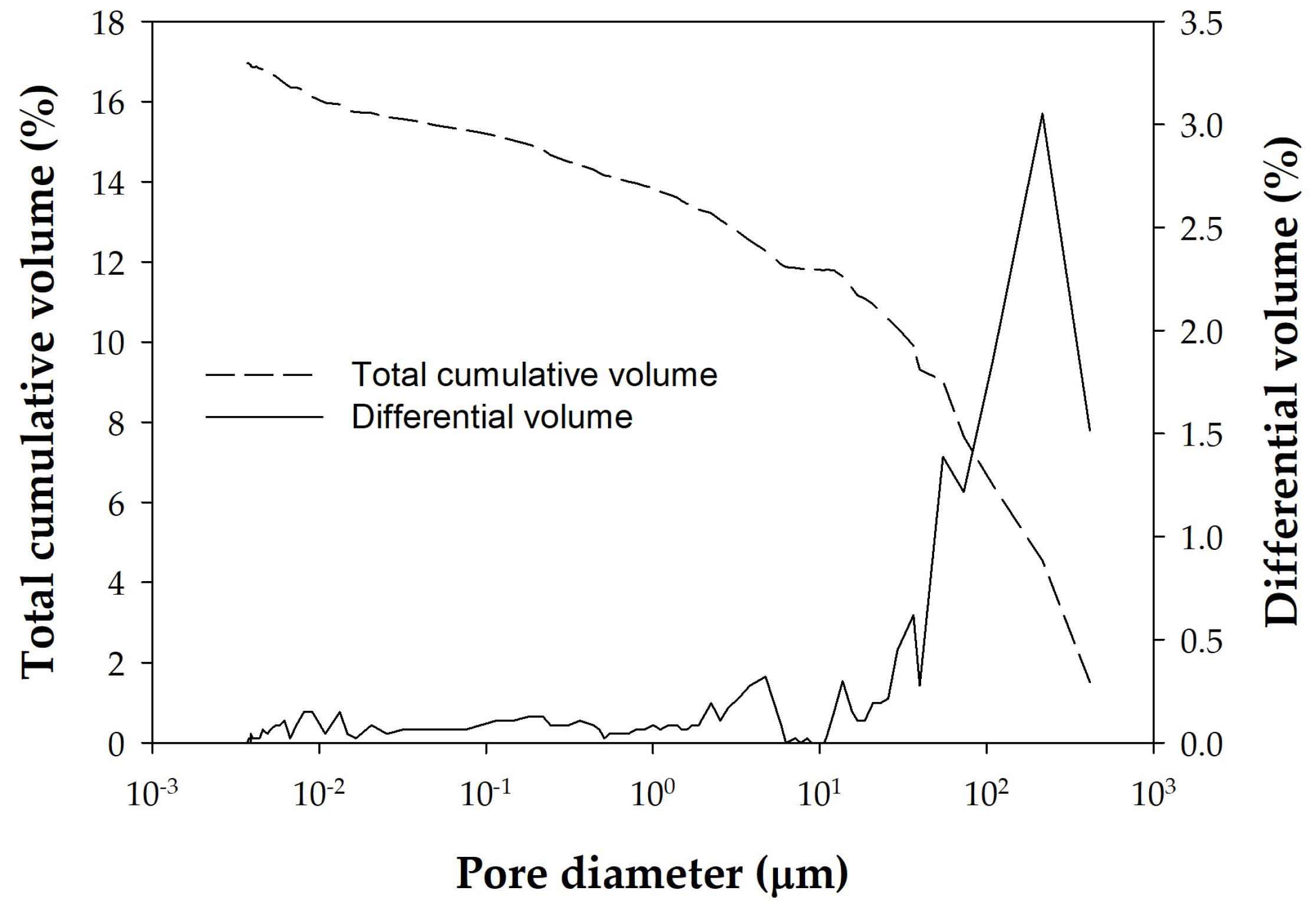

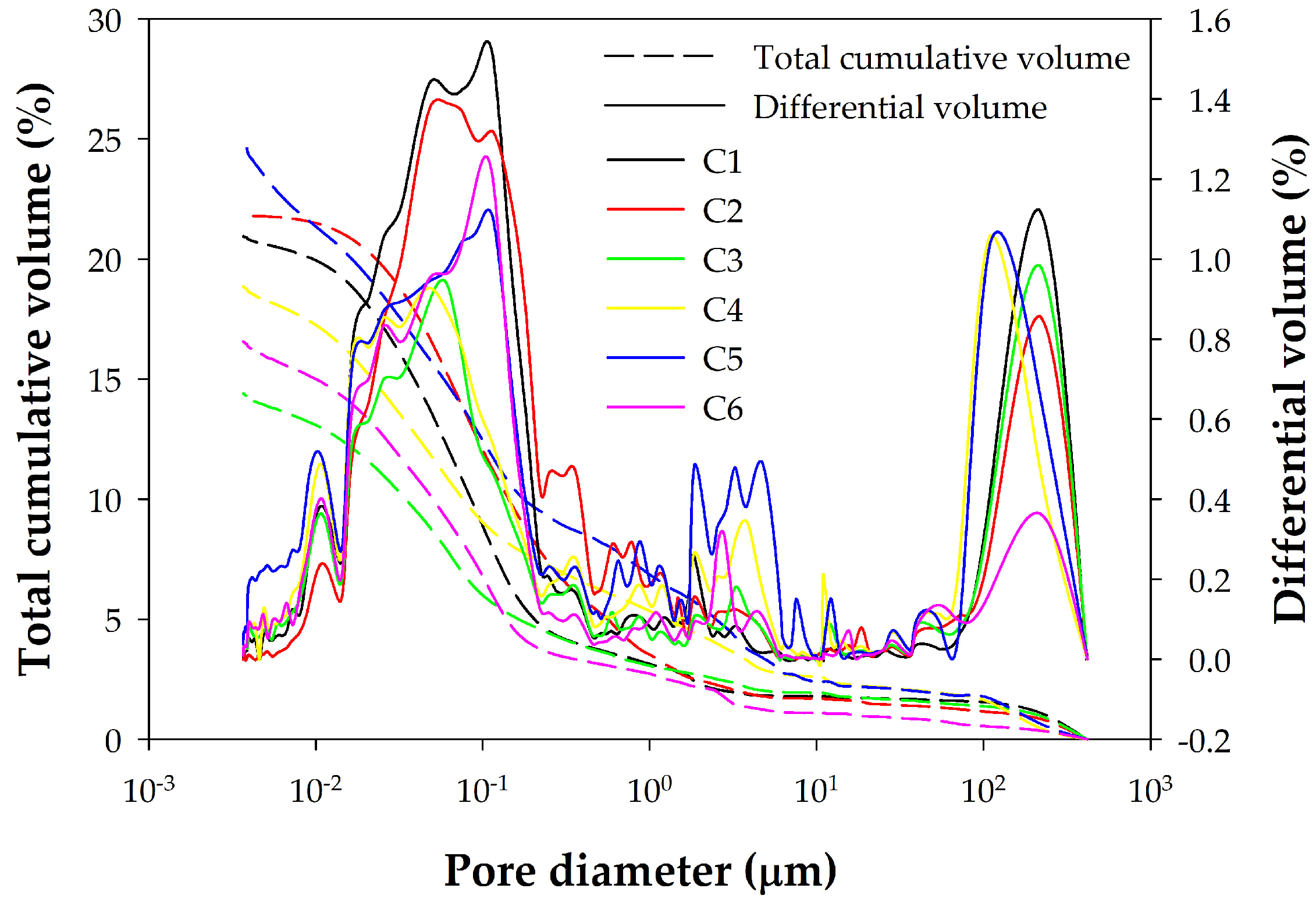

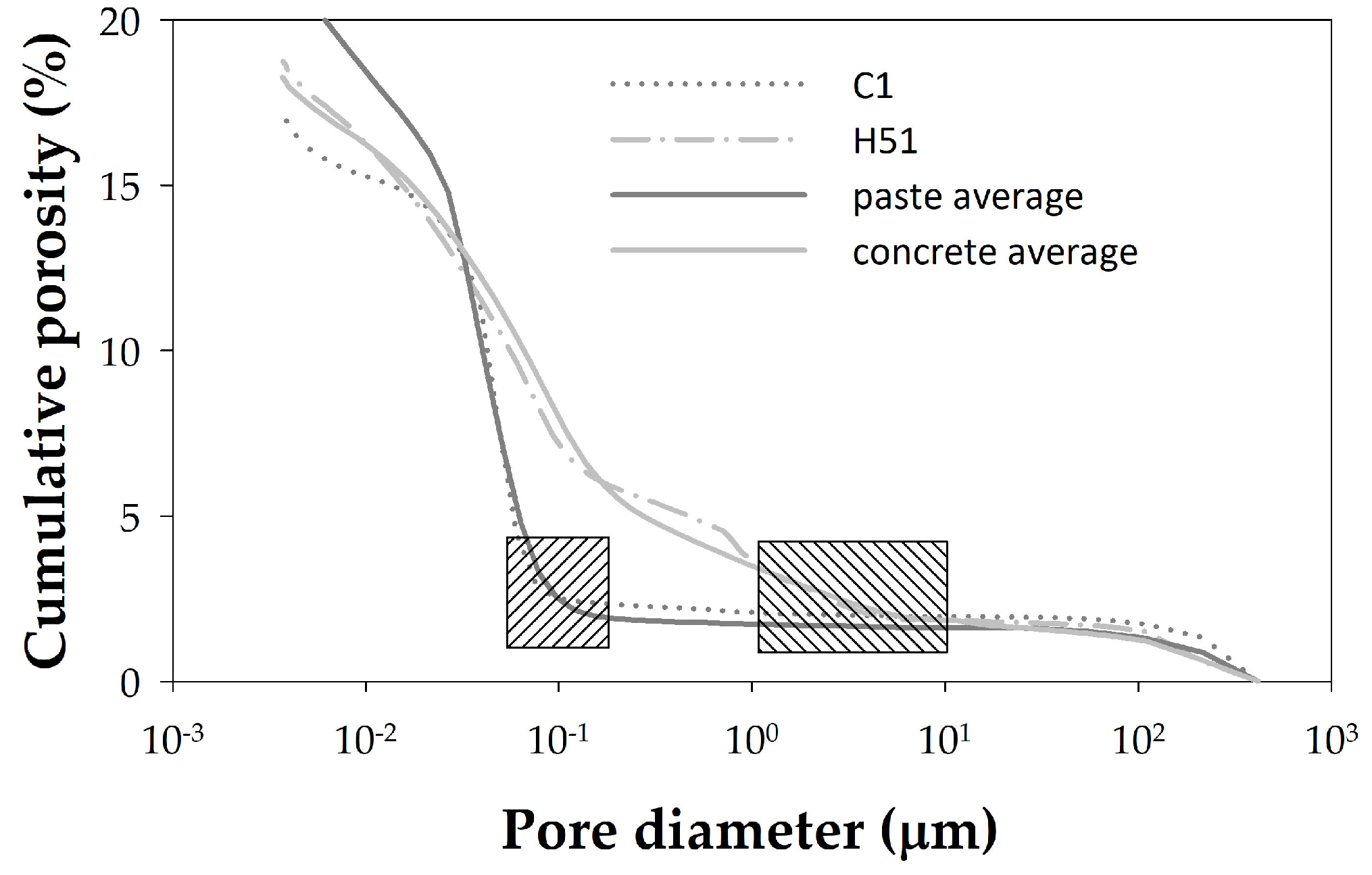

3. Results

4. Discussion

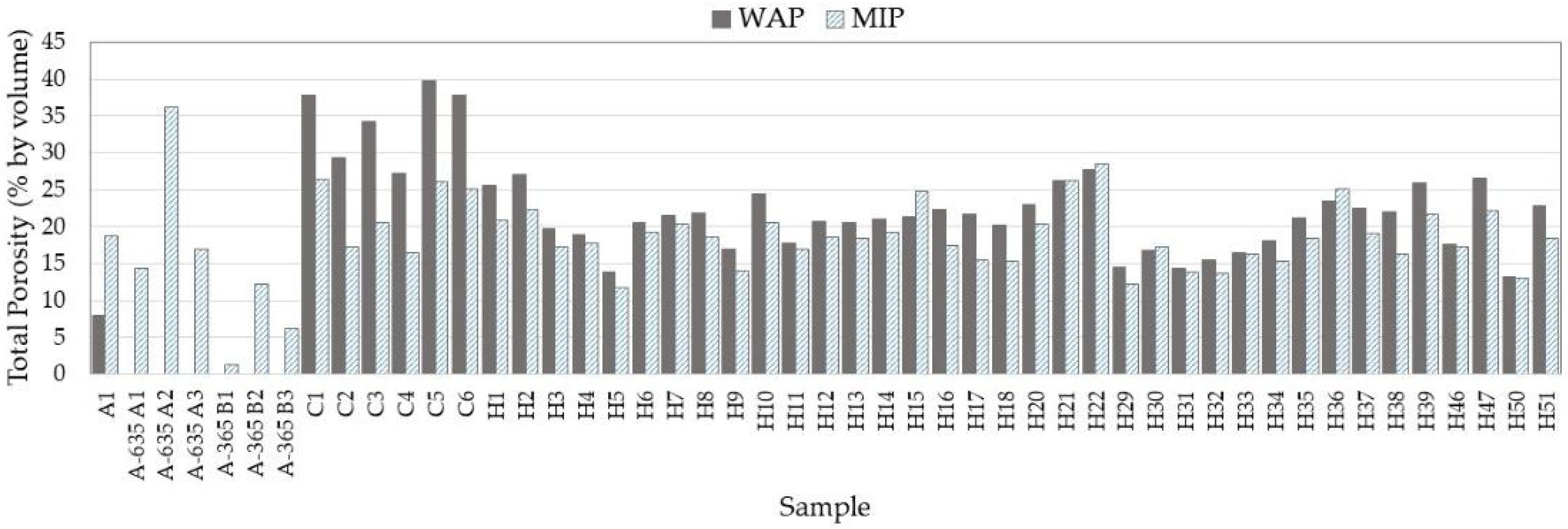

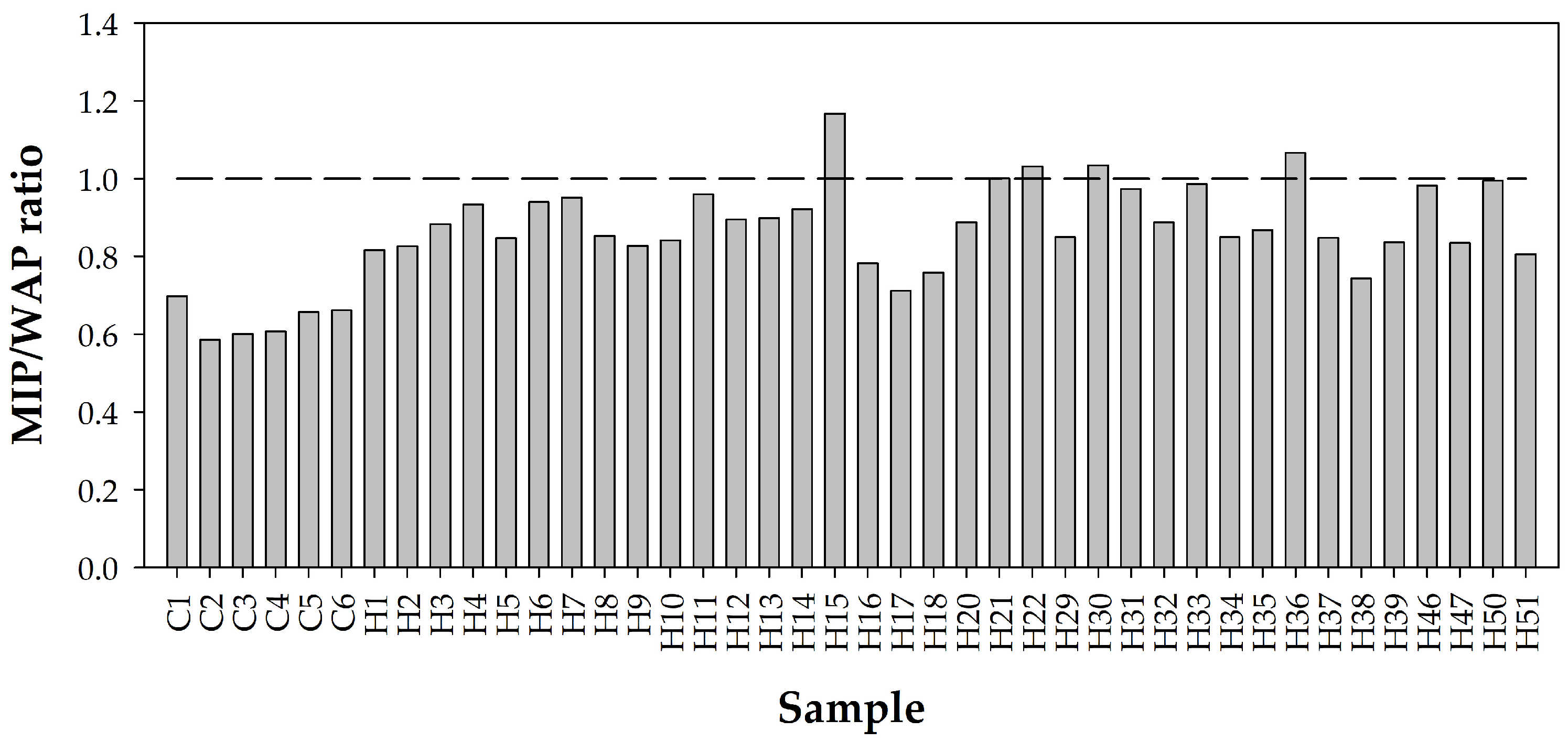

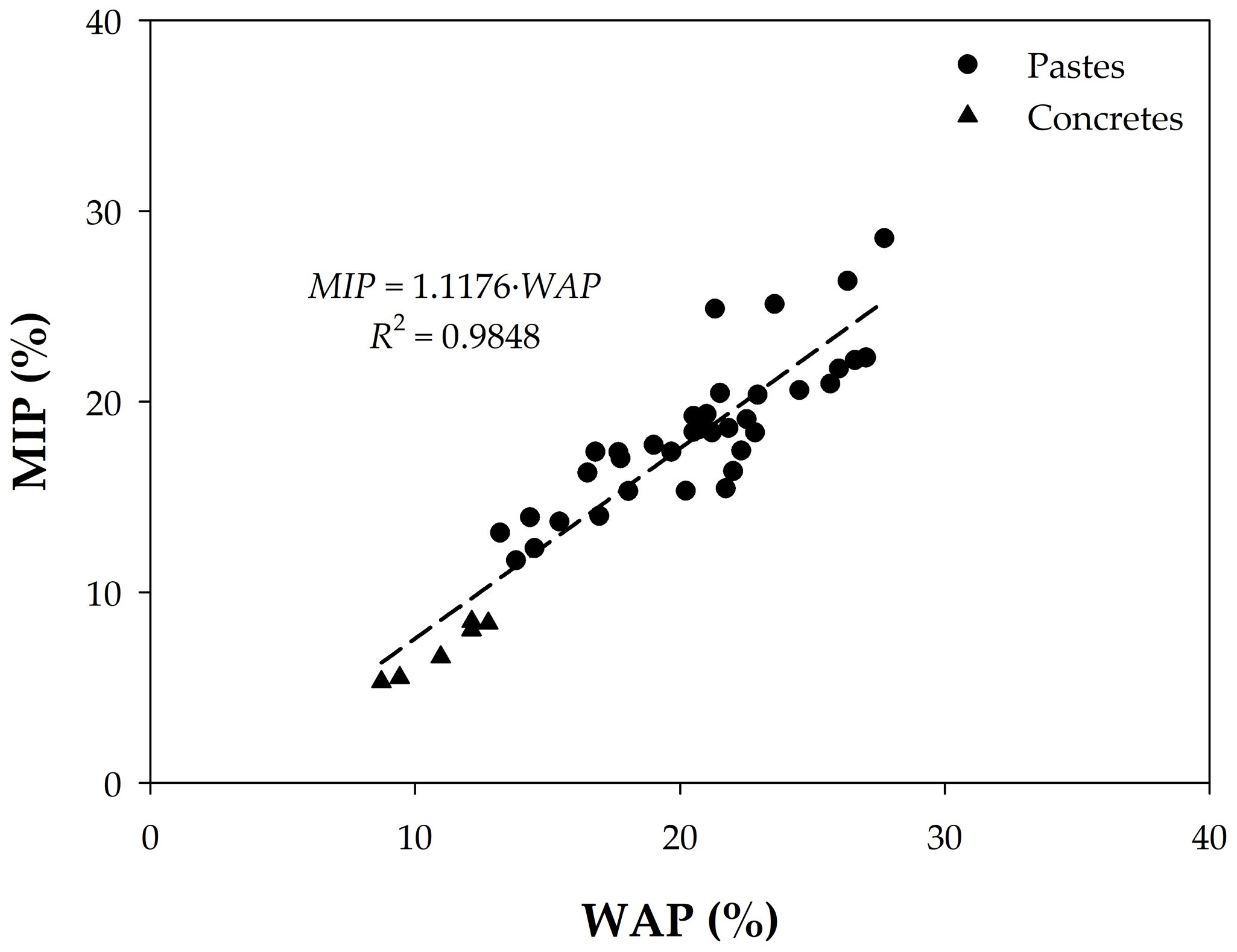

4.1. Comparative Analysis of MIP and WAP Data

4.1.1. Equivalence Between WAP and MIP Data

4.1.2. Corrections to WAP Values to Get Closer to MIP Data

4.2. Additional Calculations from MIP and WAP Data

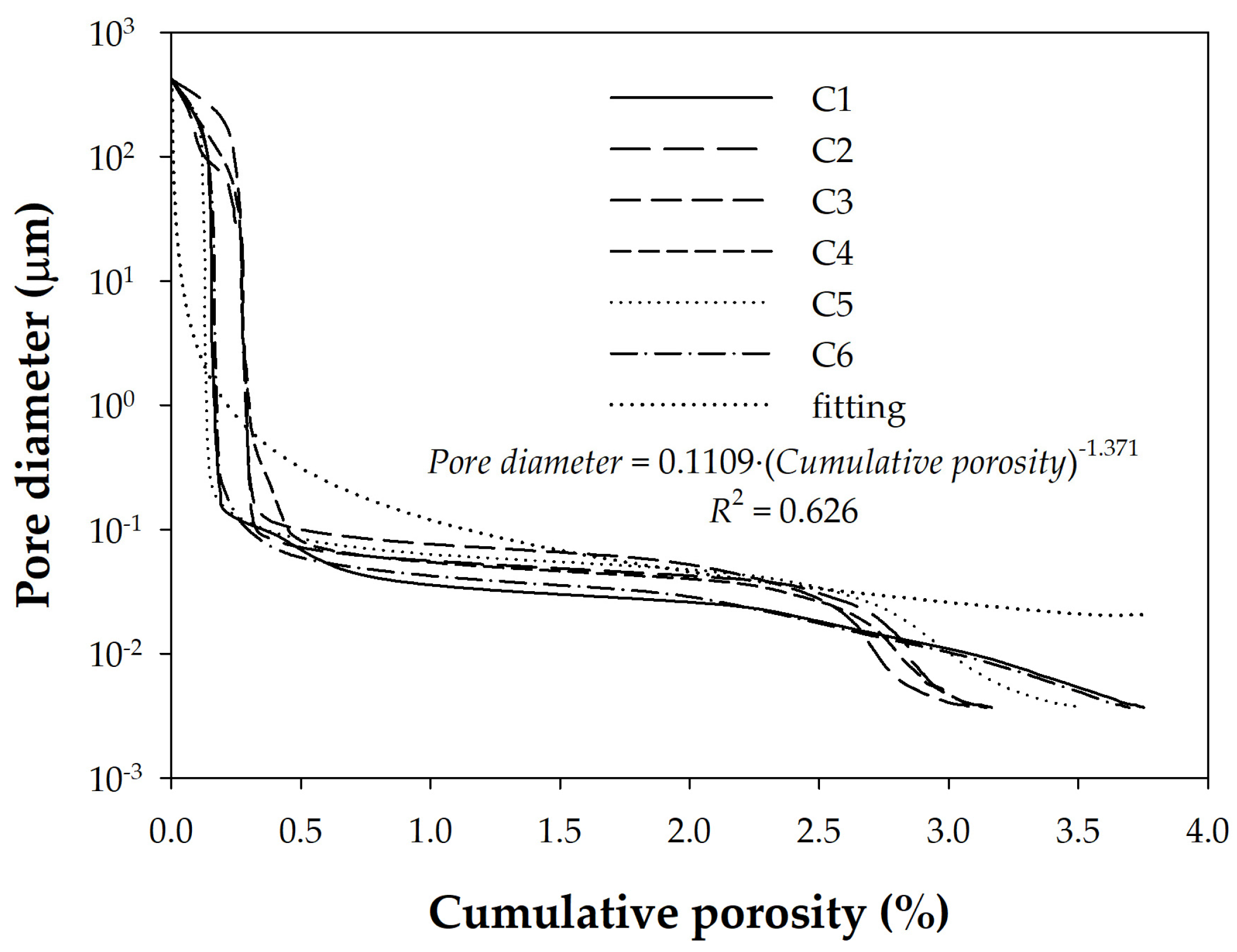

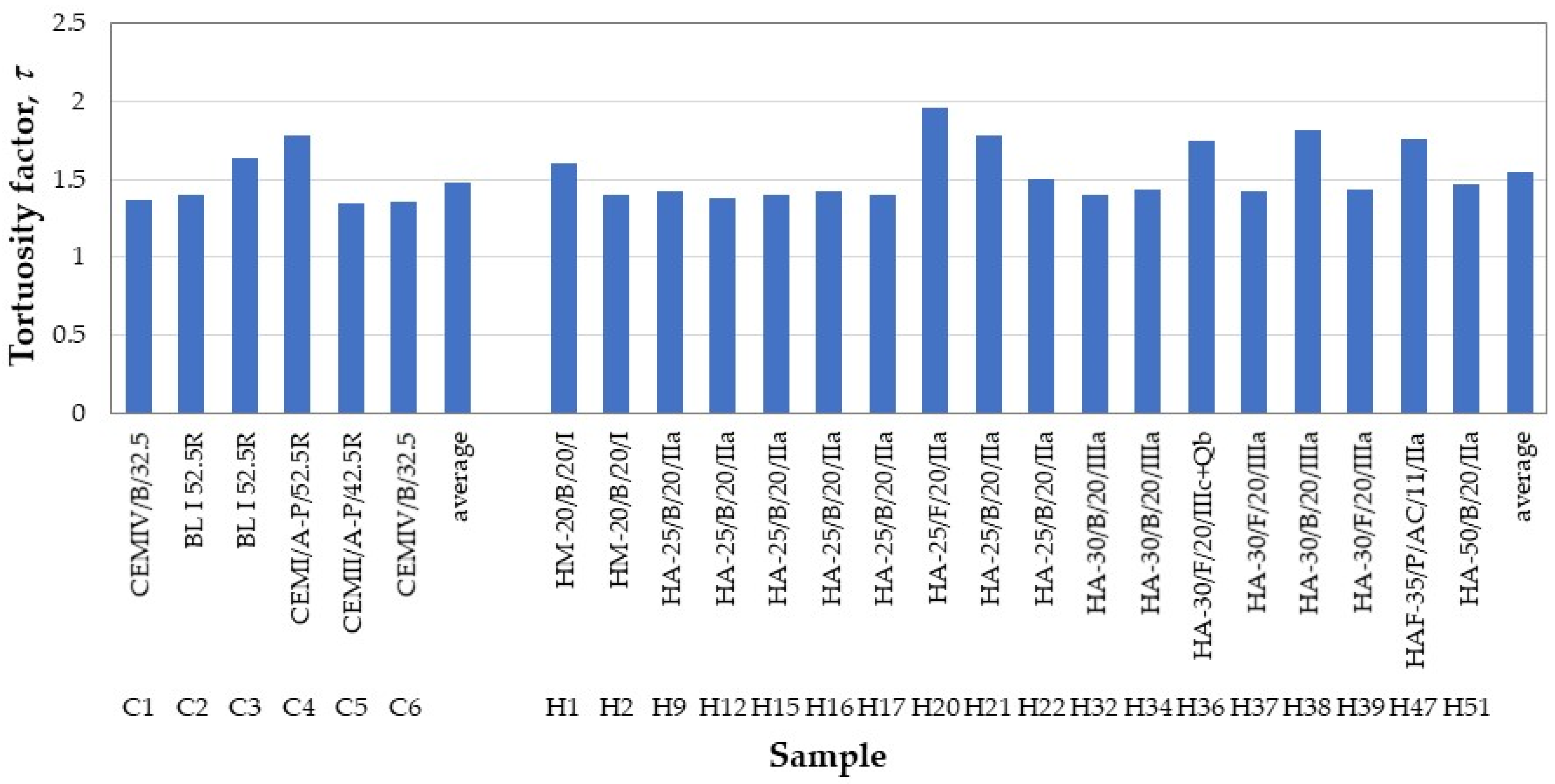

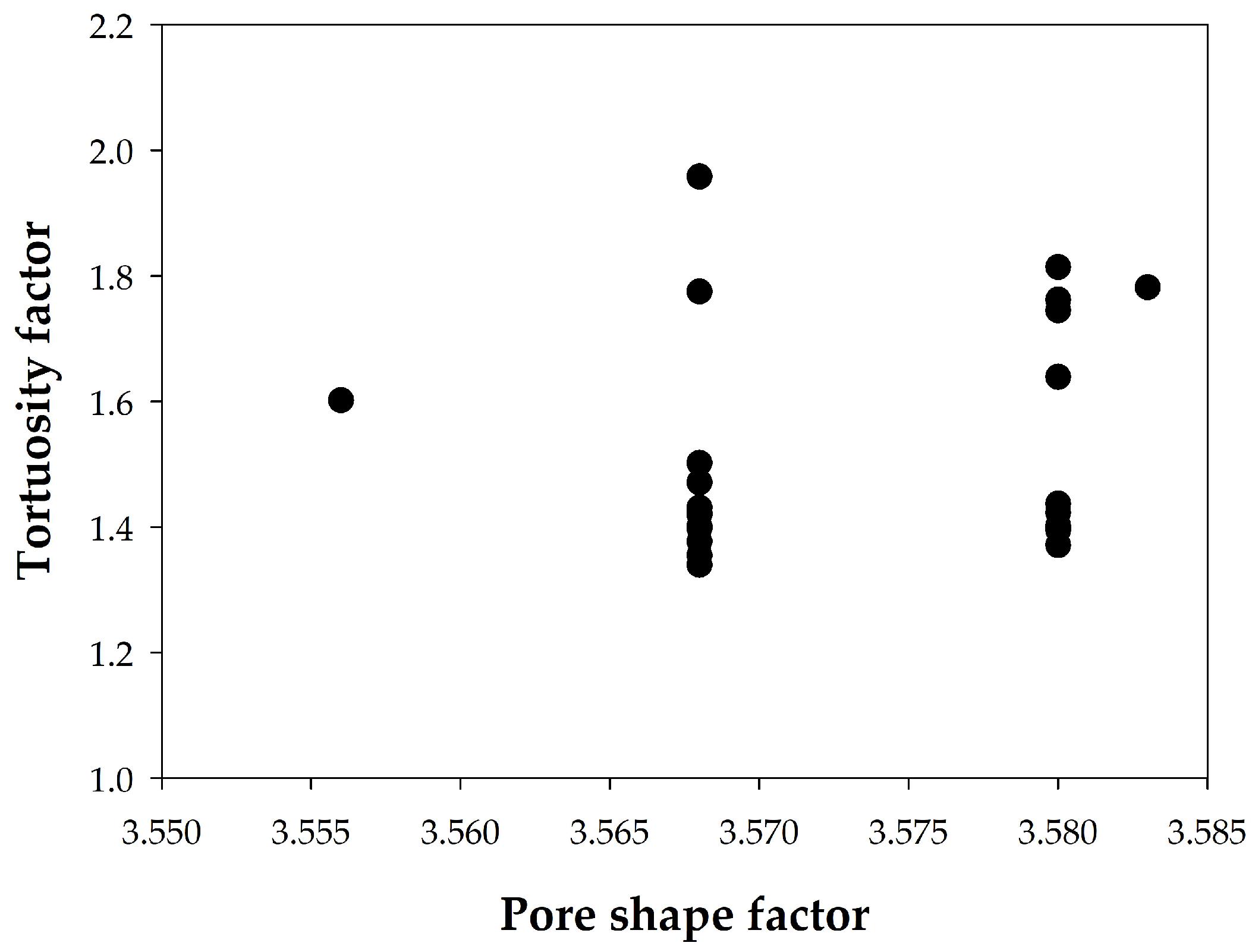

4.2.1. Tortuosity Factor

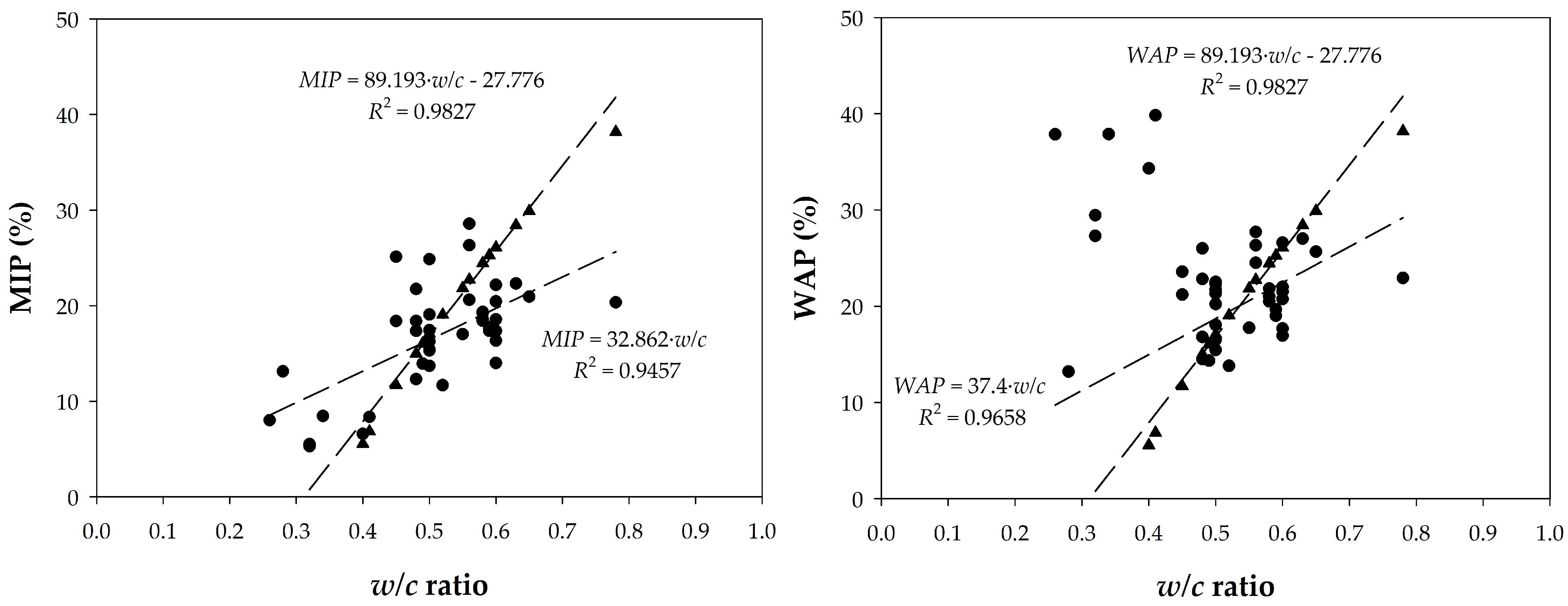

4.2.2. Relationship Between Porosity and Water/Cement Ratio

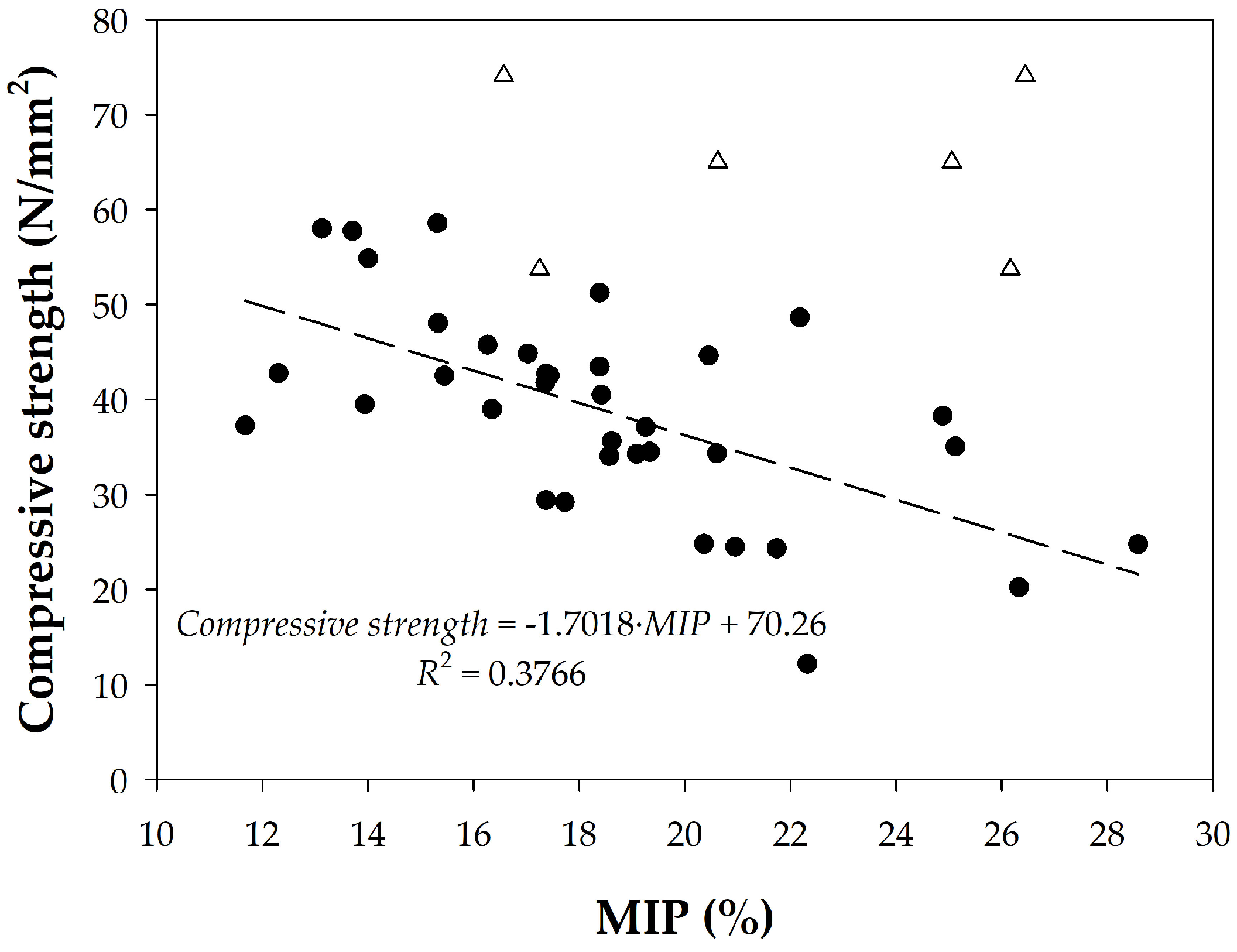

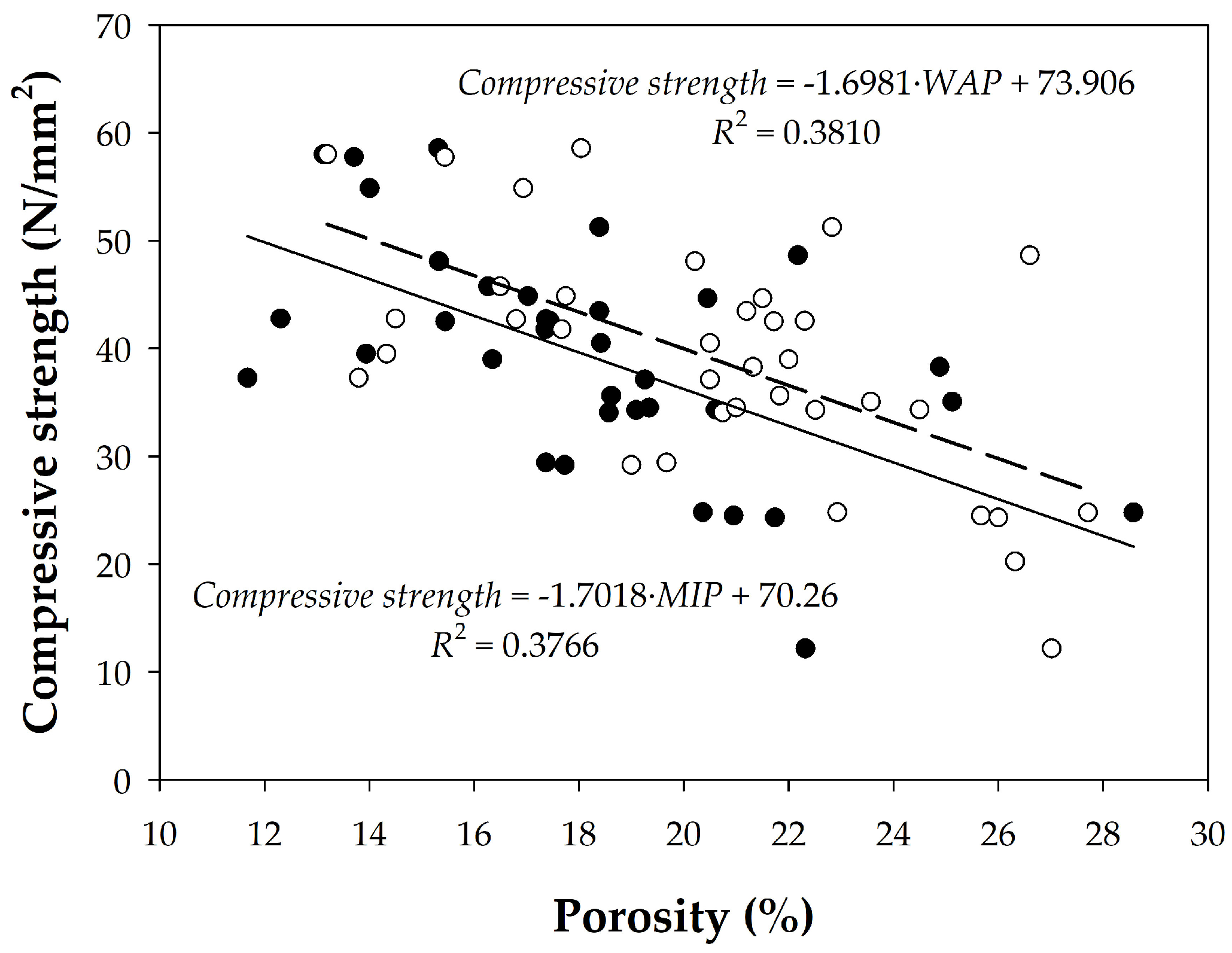

4.2.3. Relationship Between Porosity and Compressive Strength

4.2.4. Porosity and Frost Resistance

5. Conclusions

- The porosity of the pastes was generally, but not entirely, greater than that of the concretes.

- Similarly, the MIP results were generally smaller than the WAP results, but not in all cases.

- The following linear relationships with high R2 were found:MIP = 1.18 × WAP (with R2 = 0.9848) for all concretes, as well as pastes after application of a relevant adjustment procedure (i.e., fitted);MIP = 0.8923 × WAP for concretes alone (with R2 = 0.7093);Which makes WAP a suitable alternative to MIP for quality control.

- Regarding the additional information that can be extracted from the porosity measurements, in this work, the following was found:

- Tortuosity factors calculated by fitting the MIP pore size distribution with a power law were less than a value of 2, typical of Portland cement, in both pastes and concretes.

- No relationship was found between these tortuosity factors and the pore shape factors obtained by varying the pore geometry factor and the surface tension in MIP measurements.

- Calculation of porosity by Powers formula for capillary porosity presented a different trend with the water/binder ratio than the values found by MIP or WAP, although the values for typical w/c ratios of concrete were quite close.

- The relationship between porosity and strength suggested by Powers was found, but with low R2 values, although improved when the concretes were grouped into several “families”.

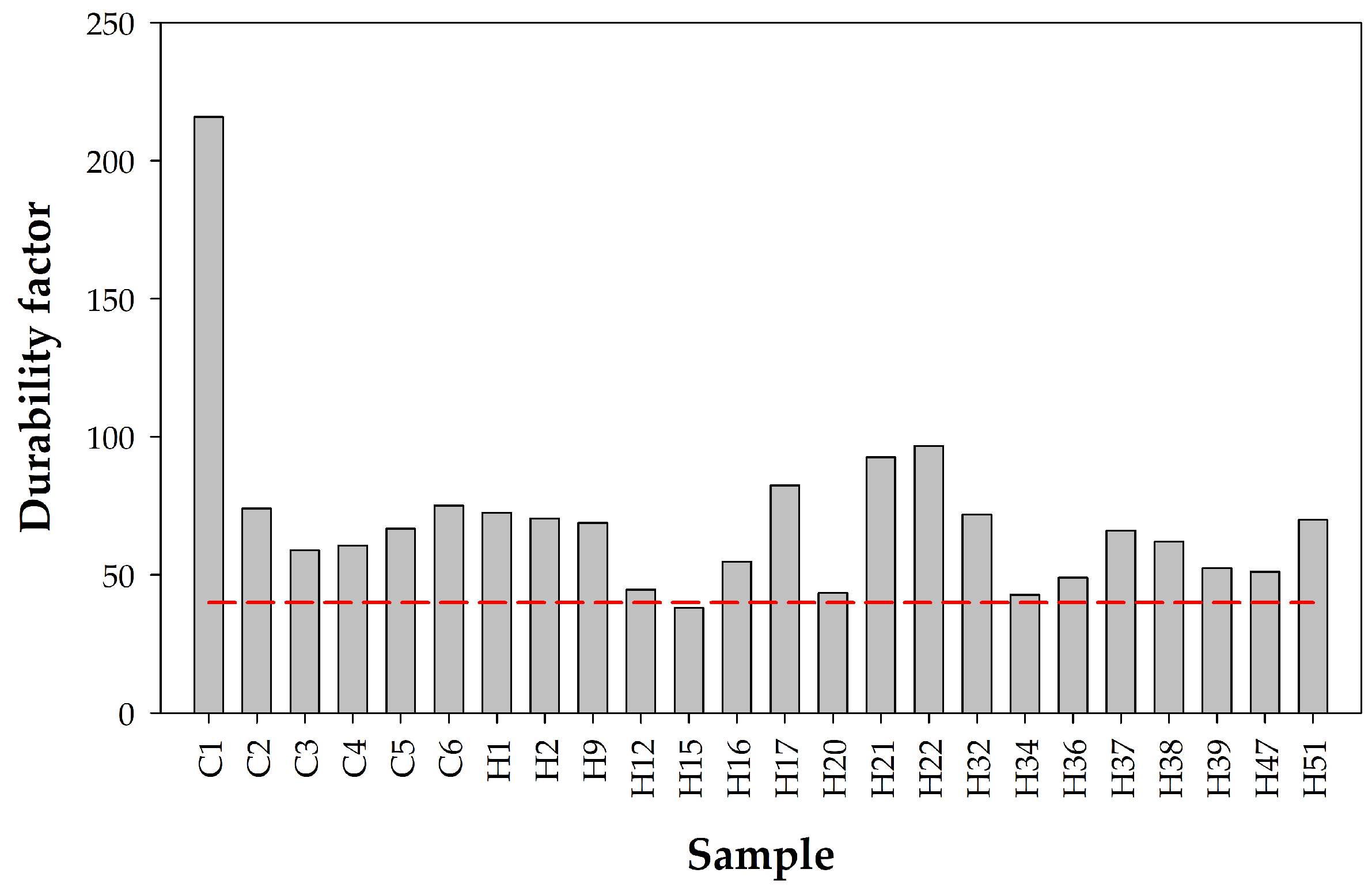

- The frost durability factor calculated following the literature had a coherent trend with the tortuosity factors calculated in the present work.

- Porosity is the characteristic of concrete that is often related to its durability, but its determination faces several difficulties. The first of these is the selection of the measurement technique, followed by the establishment of significant relationships between the porosity and relevant characteristics of concrete. Much remains to be performed to achieve a more in-depth understanding than is currently the case.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abell, A.B.; Willis, K.L.; Lange, D.A. Mercury intrusion porosimetry and image analysis of cement-based materials. J. Colloid Interface Sci. 1999, 211, 39–44. [Google Scholar] [CrossRef] [PubMed]

- Cnudde, V.; Cwirzen, A.; Masschaele, B.; Jacobs, P.J.S. Porosity and microstructure characterization of building stones and concretes. Eng. Geol. 2009, 103, 76–83. [Google Scholar] [CrossRef]

- Feldman, R.F.; Beaudoin, J.J. Microstructure and strength of hydrated cement. Cem. Concr. Res. 1976, 6, 389–400. [Google Scholar] [CrossRef]

- Powers, T.C. The physical structure and engineering properties of concrete. Portl. Cem. Assoc. RD Bull. 1958, 90, 1–28. [Google Scholar]

- Powers, T.C. Structure and physical properties of hardened Portland cement paste. J. Am. Ceram. Soc. 1958, 41, 1–6. [Google Scholar] [CrossRef]

- Nyame, B.K. Permeability of normal and lightweight mortars. Mag. Concr. Res. 1985, 37, 44–48. [Google Scholar] [CrossRef]

- Okpala, D.C. Pore structure of hardened cement paste and mortar. Int. J. Cem. Compos. Light. Concr. 1989, 11, 245–254. [Google Scholar] [CrossRef]

- Thomas, J.J.; Jennings, H.M.; Allen, A.J. The surface area of hardened cement paste as measured by various techniques. Concr. Sci. Eng. 1999, 1, 45–64. [Google Scholar]

- Bochen, J.; Gil, S.; Szwabowski, J. Influence of ageing process on porosity changes of the external plasters. Cem. Concr. Compos. 2005, 27, 769–775. [Google Scholar] [CrossRef]

- Rostásy, F.S.; Weiβ, R.; Wiedemann, G. Changes of pore structure of cement mortars due to temperature. Cem. Concr. Res. 1980, 10, 157–164. [Google Scholar] [CrossRef]

- Alford, N.M.; Rahman, A.A. An assessment of porosity and pore sizes in hardened cement pastes. J. Mater. Sci. 1981, 16, 3105–3114. [Google Scholar] [CrossRef]

- Midgley, H.G.; Illston, J.M. Some comments on the microstructure of hardened cement pastes. Cem. Concr. Res. 1983, 13, 197–206. [Google Scholar] [CrossRef]

- Marchand, J.; Hornain, H.; Diamond, S.; Pigeon, M.; Guiraud, H. The microstructure of dry concrete products. Cem. Concr. Res. 1996, 26, 427–438. [Google Scholar] [CrossRef]

- Holly, J.; Hampton, D.; Thomas, M.D.A. Modelling relationships between permeability and cement paste pore microstructures. Cem. Concr. Res. 1993, 23, 1317–1330. [Google Scholar] [CrossRef]

- El-Dieb, A.S.; Hooton, R.D. Evaluation of the Katz-Thompson model for estimating the water permeability of cement-based materials from mercury intrusion porosimetry data. Cem. Concr. Res. 1994, 24, 443–455. [Google Scholar] [CrossRef]

- Windslow, D.; Diamond, S. A Mercury Porosimetry Study of the Evolution of Porosity in Portland Cement; Technical Publication: Lafayette, IN, USA, 1969. [Google Scholar]

- Adolphs, J.; Setzer, M.J.; Heine, P. Changes in pore structure and mercury contact angle of hardened cement paste depending on relative humidity. Mater. Struct. 2002, 35, 477–486. [Google Scholar] [CrossRef]

- Gallé, C. Effect of drying on cement-based materials pore structure as identified by mercury intrusion porosimetry. Cem. Concr. Res. 2001, 31, 1467–1477. [Google Scholar] [CrossRef]

- Snoeck, D.; Velasco, L.F.; Mignon, A.; Van Vlierberghe, S.; Dubruel, P.; Lodewyckx, P.; De Belie, N. The influence of different drying techniques on the water sorption properties of cement-based materials. Cem. Concr. Res. 2014, 64, 54–62. [Google Scholar] [CrossRef]

- Beaudoin, J.J. Porosity measurement of some hydrated cementitious systems by high pressure mercury intrusion-microstructural limitations. Cem. Concr. Res. 1979, 9, 771–781. [Google Scholar] [CrossRef]

- Feldman, R.F. Pore structure damage in blended cements caused by mercury intrusion. J. Am. Ceram. Soc. 1984, 67, 30–33. [Google Scholar] [CrossRef]

- Olson, R.A.; Neubauer, C.M.; Jennings, H.M. Damage to the pore structure of hardened Portland cement paste by mercury intrusion. J. Am. Ceram. Soc. 1997, 80, 2454–2458. [Google Scholar] [CrossRef]

- Diamond, S. Mercury porosimetry: An inappropriate method for the measurement of pore size distributions in cement-based materials. Cem. Concr. Res. 2000, 30, 1517–1525. [Google Scholar] [CrossRef]

- Zhang, A.; Ge, Y.; Yang, W.; Wang, G. New insight of solvent-replacement-induced damage to pores of cement stone by comparison with 1H NMR relaxometry, mercury intrusion porosimetry, and nitrogen adsorption. Constr. Build. Mater. 2023, 409, 133981. [Google Scholar] [CrossRef]

- Ludwig, U.; Schwiete, H.E. Porosity measurements of cement pastes, cement mortars, and concretes. In Proceedings of the 8th Conference on the Silicate Industry, Budapest, Hungary, 8–13 June 1966; pp. 235–251. [Google Scholar]

- Verbeck, G.J.; Helmuth, R.H. Structures and physical properties of cement paste. In Proceedings of the Fifth International Symposium on the Chemistry of Cement; Cement Association of Japan: Tokyo, Japan, 1968; pp. 1–32. [Google Scholar]

- Cook, R.A. Fundamentals of Mercury Intrusion Porosimetry and Its Application to concrete Materials Science; Cornell University: New York, NY, USA, 1991. [Google Scholar]

- Laskar, M.A.I.; Kumar, R.; Bhattacharjee, B. Some aspects of evaluation of concrete through mercury intrusion porosimetry. Cem. Concr. Res. 1997, 27, 93–105. [Google Scholar] [CrossRef]

- Cook, R.A.; Hover, K.C. Mercury porosimetry of hardened cement pastes. Cem. Concr. Res. 1999, 29, 933–943. [Google Scholar] [CrossRef]

- Zeng, Q.; Li, K.; Fen-Chong, T.; Dangla, P. Analysis of pore structure, contact angle and pore entrapment of blended cement pastes from mercury porosimetry data. Cem. Concr. Compos. 2012, 34, 1053–1060. [Google Scholar] [CrossRef]

- Muller, A.C.A.; Scrivener, K.L. A reassessment of mercury intrusion porosimetry by comparison with 1H NMR relaxometry. Cem. Concr. Res. 2017, 100, 350–360. [Google Scholar] [CrossRef]

- Joseph, S.; Mutti, M.; Ohkubo, T.; Maruyama, I.; Cizer, Ö. Microstructural analysis of cement paste blended with blast furnace slag using 1H NMR relaxometry. Cem. Concr. Compos. 2024, 146, 105377. [Google Scholar] [CrossRef]

- Kumar, R.; Bhattacharjee, B. Study on some factors affecting the results in the use of MIP method in concrete research. Cem. Concr. Res. 2003, 33, 417–424. [Google Scholar] [CrossRef]

- Diamond, S.; Bonen, D. Microstructure of hardened cement paste-A new interpretation. J. Am. Ceram. Soc. 1993, 76, 2993–2999. [Google Scholar] [CrossRef]

- Winslow, D.N.; Diamond, S. A mercury porosimetry study of the evolution of porosity in cement. ASTM J. Mater. 1970, 5, 564–585. [Google Scholar]

- Garboczi, E.J. Permeability, diffusivity, and microstructural parameters: A critical review. Cem. Concr. Res. 1990, 20, 591–601. [Google Scholar] [CrossRef]

- Diamond, S. A critical comparison of mercury porosimetry and capillary condensation pore size distributions of Portland cement pastes. Cem. Concr. Res. 1971, 1, 531–545. [Google Scholar] [CrossRef]

- Cheng-yi, H.; Feldman, R.F. Influence of silica fume on the microstructural development in cement mortars. Cem. Concr. Res. 1985, 15, 285–294. [Google Scholar] [CrossRef]

- Odler, I.; Köster, H. Investigations on the structure of fully hydrated Portland cement and tricalcium silicate pastes. II. Total porosity and pore size distribution. Cem. Concr. Res. 1986, 16, 893–901. [Google Scholar] [CrossRef]

- Gu, P.; Xie, P.; Beaudoin, J.J. Microstructural characterization of the transition zone in cement systems by means of A.C. impedance spectroscopy. Cem. Concr. Res. 1993, 23, 581–591. [Google Scholar] [CrossRef]

- AENOR UNE-EN 1936; Natural Stone Test Methods—Determination of Real Density and Apparent Density, and of Total and Open Porosity. Asociación Española de Normalización y Certificación (AENOR): Madrid, Spain, 2007.

- AENOR UNE 83980:2014; Concrete Durability. Test Methods. Determination of the Water Absorption, Density and Accessible Porosity for Water in Concrete. Asociación Española de Normalización y Certificación (AENOR): Madrid, Spain, 2014.

- Hall, C. Capillary imbibition in cement-based materials with time-dependent permeability. Cem. Concr. Res. 2019, 124, 105835. [Google Scholar] [CrossRef]

- Hall, C. Anomalous diffusion in unsaturated flow: Fact or fiction? Cem. Concr. Res. 2007, 37, 378–385. [Google Scholar] [CrossRef]

- Panesar, D.K.; Francis, J. Influence of limestone and slag on the pore structure of cement paste based on mercury intrusion porosimetry and water vapour sorption measurements. Constr. Build. Mater. 2014, 52, 52–58. [Google Scholar] [CrossRef]

- Andrade, M.C.; Bolzoni, F.; Fullea, J. Analysis of the relation between water and resistivity isotherms in concrete. Mater. Corros. 2011, 62, 130–138. [Google Scholar] [CrossRef]

- Safiuddin, M.; Hearn, N. Comparison of ASTM saturation techniques for measuring the permeable porosity of concrete. Cem. Concr. Res. 2005, 35, 1008–1013. [Google Scholar] [CrossRef]

- Das, B.B.; Singh, D.N.; Pandey, S.P. A comparative study for determining pore volume of concrete. Indian Concr. J. 2010, 84, 7–12. [Google Scholar]

- Andrade, C.; Rebolledo, N.; Menéndez, E.; Pérez, R.; Baz, M. Characterization through mercury porosimetry of tortuosity factors of concretes containing mineral additions. In Proceedings of the XIII DCBM- International Conference on Durability of Building Materials and Components, Sao Paulo, Brazil, 2–5 September 2014. [Google Scholar]

- AENOR UNE-EN 12390-1; Testing Hardened Concrete—Part 1: Shape, Dimensions and Other Requirements for Specimens and Moulds. Asociación Española de Normalización y Certificación (AENOR): Madrid, Spain, 2001.

- AENOR UNE-EN 12390-2; Testing Hardened Concrete—Part 2: Making and Curing Specimens for Strength Test. Asociación Española de Normalización y Certificación (AENOR): Madrid, Spain, 2009.

- ASTM D4404—84 (Reapproved 1998); Standard Test Method for Determination of Pore Volume and Pore Volume Distribution of Soil and Rock by Mercury Intrusion Porosimetry. ASTM: West Conshohocken, PA, USA, 1998.

- Washburn, E.W. Note on a method of determining the distribution of pore sizes in a porous material. Proc. Natl. Acad. Sci. USA 1921, 7, 115–116. [Google Scholar] [CrossRef]

- Cook, R.A.; Hover, K.C. Mercury porosimetry of cement-based materials and associated correction factors. Constr. Build. Mater. 1993, 7, 231–240. [Google Scholar] [CrossRef]

- Powers, T.C.; Brownyard, T.L. Studies of the physical properties of hardened Portland cement paste. ACI J. Proc. 1946, 43, 249–336. [Google Scholar]

- Powers, T.C. Physical properties of cement paste. In Proceedings of the 4th International Symposium on the Chemistry of Cement, Washington, DC, USA, 2–7 October 1960; National Bureau of Standards, Monograph 43; National Bureau of Standards: Washington, DC, USA, 1960; Volume II, pp. 577–613. [Google Scholar]

- Powers, T.C. Some Physical aspects of the hydration of Portland cement. J. Portl. Cem. Assoc. Res. Dev. Lab. 1961, 3, 47–56. [Google Scholar]

- Kaneuji, M.; Winslow, D.N.; Dolch, W.L. The relationship between an aggregate’s pore size distribution and its freeze thaw durability in concrete. Cem. Concr. Res. 1980, 10, 433–441. [Google Scholar] [CrossRef]

| Sample Code | Type | w/c Ratio | Cement Content (kg/m3) | Compressive Strength at 28 Days (N/mm2) |

|---|---|---|---|---|

| Cement pastes | ||||

| C1 | CEMIV/B/32.5 | 0.34 | 74.10 | |

| C2 | BL I 52.5R | 0.32 | 53.70 | |

| C3 | BL I 52.5R | 0.40 | 65.00 | |

| C4 | CEMI/A-P/52.5R | 0.32 | 74.10 | |

| C5 | CEMII/A-P/42.5R | 0.41 | 53.70 | |

| C6 | CEMIV/B/32.5 | 0.26 | 65.00 | |

| Concretes | ||||

| H1 | HM-20/B/20/I | 0.65 | 275 | 24.49 |

| H2 | HM-20/B/20/I | 0.63 | 250 | 12.18 |

| H3 | HA-25/B/20/IIa | 0.59 | 344 | 29.40 |

| H4 | HA-25/B/20/IIa | 0.59 | 344 | 29.20 |

| H5 | HA-25/B/20/IIa | 0.52 | 350 | 37.27 |

| H6 | HA-25/B/20/IIa | 0.58 | 340 | 37.12 |

| H7 | HA-25/B/20/IIa | 0.60 | 340 | 44.64 |

| H8 | HA-25/B/20/IIa | 0.58 | 340 | 35.61 |

| H9 | HA-25/B/20/IIa | 0.60 | 350 | 54.86 |

| H10 | HA-25/F/12/IIa | 0.56 | 324 | 34.33 |

| H11 | HA-25/B/20/IIa | 0.55 | 355 | 44.84 |

| H12 | HA-25/B/20/IIa | 0.60 | 390 | 34.05 |

| H13 | HA-25/F/12/IIa | 0.58 | 330 | 40.50 |

| H14 | HA-25/F/12/IIa | 0.58 | 330 | 34.50 |

| H15 | HA-25/B/20/IIa | 0.50 | 325 | 38.28 |

| H16 | HA-25/B/20/IIa | 0.50 | 300 | 42.54 |

| H17 | HA-25/B/20/IIa | 0.5 | 300 | 42.50 |

| H18 | HA-25/F/20/IIIa | 0.5 | 370 | 48.07 |

| H20 | HA-25/F/20/IIa | 0.78 | 300 | 24.81 |

| H21 | HA-25/B/20/IIa | 0.56 | 300 | 20.25 |

| H22 | HA-25/B/20/IIa | 0.56 | 240 | 24.79 |

| H29 | HA-30/B/20/IIIa | 0.48 | 390 | 42.77 |

| H30 | HA-30/B/20/IIIa | 0.48 | 395 | 42.70 |

| H31 | HA-30/B/20/IIIa | 0.49 | 385 | 39.50 |

| H32 | HA-30/B/20/IIIa | 0.50 | 370 | 57.75 |

| H33 | HA-30/B/20/IIIa | 0.50 | 360 | 45.75 |

| H34 | HA-30/B/20/IIIa | 0.50 | 350 | 58.55 |

| H35 | HA-30/F/20/IIIc + Qb | 0.45 | 370 | 43.46 |

| H36 | HA-30/F/20/IIIc + Qb | 0.45 | 360 | 35.06 |

| H37 | HA-30/F/20/IIIa | 0.50 | 360 | 34.28 |

| H38 | HA-30/B/20/IIIa | 0.60 | 365 | 38.99 |

| H39 | HA-30/F/20/IIIa | 0.48 | 300 | 24.32 |

| H46 | HAF-35/P/AC/11/IIa | 0.60 | 380 | 41.77 |

| H47 | HAF-35/P/AC/11/IIa | 0.60 | 380 | 48.63 |

| H50 | HA-50/F/12/IIa | 0.28 | 500 | 57.99 |

| H51 | HA-50/B/20/IIa | 0.48 | 380 | 51.24 |

| Cement | Basaltic Gravel | Basaltic Sand | African Sand | Water | Total Mass | |

|---|---|---|---|---|---|---|

| Min., % | 10.94 | 36.23 | 20.71 | 9.26 | 6.58 | 2135 |

| Max., % | 15.47 | 44.31 | 31.71 | 19.88 | 7.43 | 2263 |

| Med., % | 13.15 | 41.42 | 24.57 | 13.45 | 6.90 | 2193.2 |

| Sample Code | Dry Density at 70 °C (g/cm2) | Water-Accessible Porosity (%) | Mercury Intrusion Porosity (%) | Tortuosity Factor |τ| |

|---|---|---|---|---|

| Aggregates | ||||

| A1 | 2.66 | 8.00 | 18.80 | |

| A-635 A1 | 2.80 | 14.4 | ||

| A-635 A2 | 2.24 | 36.2 | ||

| A-635 A3 | 2.57 | 16.9 | ||

| A-365 B1 | 2.35 | 1.3 | ||

| A-365 B2 | 2.72 | 12.2 | ||

| A-365 B3 | 2.85 | 6.27 | ||

| Cement pastes | ||||

| C1 | 1.57 | 37.89 | 26.44 | 1.371 |

| C2 | 1.75 | 29.45 | 17.25 | 1.395 |

| C3 | 1.59 | 34.31 | 20.62 | 1.639 |

| C4 | 1.71 | 27.30 | 16.57 | 1.782 |

| C5 | 1.46 | 39.83 | 26.16 | 1.34 |

| C6 | 1.58 | 37.86 | 25.05 | 1.355 |

| Concretes | ||||

| H1 | 2.14 | 25.67 | 20.95 | 1.602 |

| H2 | 1.96 | 27.02 | 22.32 | 1.399 |

| H3 | 2.19 | 19.67 | 17.37 | |

| H4 | 2.14 | 19.00 | 17.73 | |

| H5 | 2.20 | 13.80 | 11.68 | |

| H6 | 2.20 | 20.50 | 19.26 | |

| H7 | 2.18 | 21.50 | 20.45 | |

| H8 | 2.20 | 21.83 | 18.62 | |

| H9 | 2.25 | 16.94 | 14.01 | 1.422 |

| H10 | 2.07 | 24.50 | 20.61 | |

| H11 | 2.22 | 17.75 | 17.03 | |

| H12 | 2.18 | 20.74 | 18.57 | 1.377 |

| H13 | 2.15 | 20.50 | 18.42 | |

| H14 | 2.24 | 21.00 | 19.34 | |

| H15 | 2.23 | 21.32 | 24.88 | 1.402 |

| H16 | 2.17 | 22.31 | 17.44 | 1.42 |

| H17 | 2.23 | 21.72 | 15.45 | 1.398 |

| H18 | 2.24 | 20.21 | 15.33 | |

| H20 | 2.15 | 22.93 | 20.36 | 1.958 |

| H21 | 2.05 | 26.32 | 26.33 | 1.775 |

| H22 | 1.98 | 27.71 | 28.58 | 1.502 |

| H29 | 2.28 | 14.50 | 12.31 | |

| H30 | 2.17 | 16.80 | 17.37 | |

| H31 | 2.19 | 14.33 | 13.94 | |

| H32 | 2.32 | 15.44 | 13.71 | 1.401 |

| H33 | 2.27 | 16.50 | 16.27 | |

| H34 | 2.27 | 18.04 | 15.32 | 1.431 |

| H35 | 2.19 | 21.20 | 18.39 | |

| H36 | 2.14 | 23.57 | 25.12 | 1.745 |

| H37 | 2.14 | 22.51 | 19.09 | 1.423 |

| H38 | 2.22 | 22.00 | 16.35 | 1.814 |

| H39 | 1.97 | 26.00 | 21.74 | 1.437 |

| H46 | 2.19 | 17.67 | 17.36 | |

| H47 | 1.87 | 26.60 | 22.18 | 1.762 |

| H50 | 2.31 | 13.20 | 13.13 | |

| H51 | 2.10 | 22.83 | 18.39 | 1.471 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodríguez-Brito, N.; Blanco-Peñalver, C.; Souto, R.M.; Andrade, C.; Santana, J.J. Reassessment of Porosimetry Determinations Using Water Vapor Sorption Measurements for Pastes and Concretes Containing Basaltic Aggregates Compared to the Mercury Intrusion Method. Materials 2025, 18, 2257. https://doi.org/10.3390/ma18102257

Rodríguez-Brito N, Blanco-Peñalver C, Souto RM, Andrade C, Santana JJ. Reassessment of Porosimetry Determinations Using Water Vapor Sorption Measurements for Pastes and Concretes Containing Basaltic Aggregates Compared to the Mercury Intrusion Method. Materials. 2025; 18(10):2257. https://doi.org/10.3390/ma18102257

Chicago/Turabian StyleRodríguez-Brito, Natalia, Concepción Blanco-Peñalver, Ricardo M. Souto, Carmen Andrade, and Juan J. Santana. 2025. "Reassessment of Porosimetry Determinations Using Water Vapor Sorption Measurements for Pastes and Concretes Containing Basaltic Aggregates Compared to the Mercury Intrusion Method" Materials 18, no. 10: 2257. https://doi.org/10.3390/ma18102257

APA StyleRodríguez-Brito, N., Blanco-Peñalver, C., Souto, R. M., Andrade, C., & Santana, J. J. (2025). Reassessment of Porosimetry Determinations Using Water Vapor Sorption Measurements for Pastes and Concretes Containing Basaltic Aggregates Compared to the Mercury Intrusion Method. Materials, 18(10), 2257. https://doi.org/10.3390/ma18102257