Low-Refractive-Index SiO2 Nanocolumnar Thin Films Fabricated by Oblique Angle Deposition

Abstract

1. Introduction

2. Experimental Details

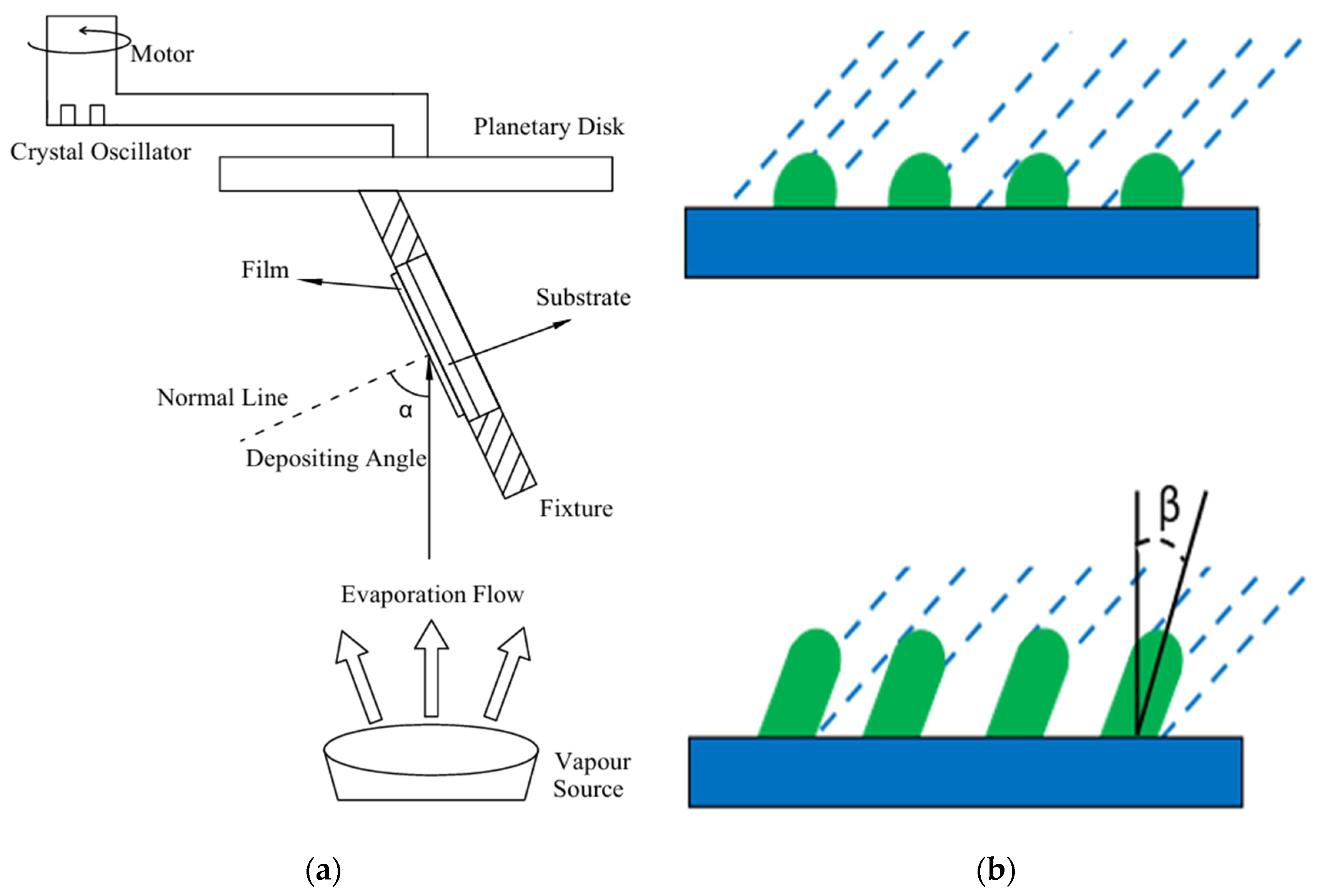

2.1. Sample Preparation

2.2. Measurement

3. Results and Discussion

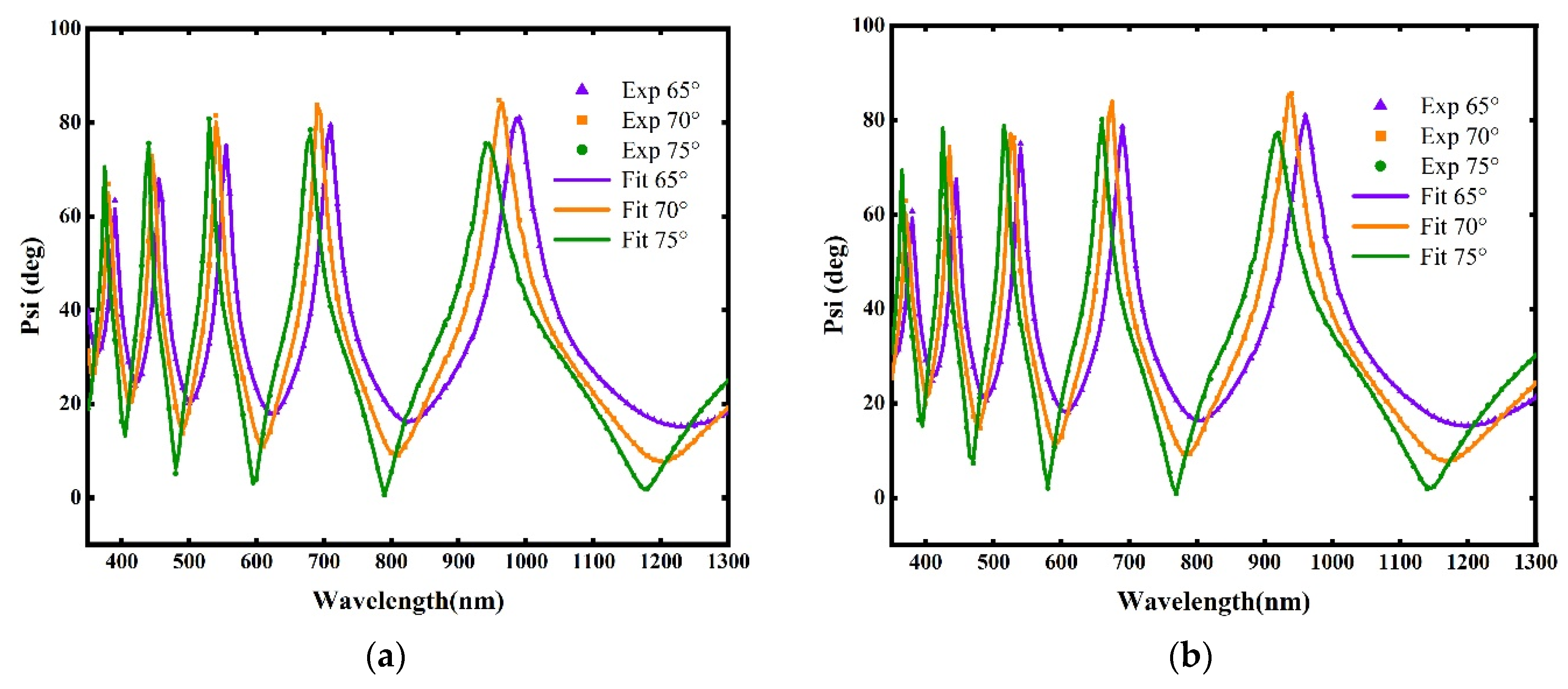

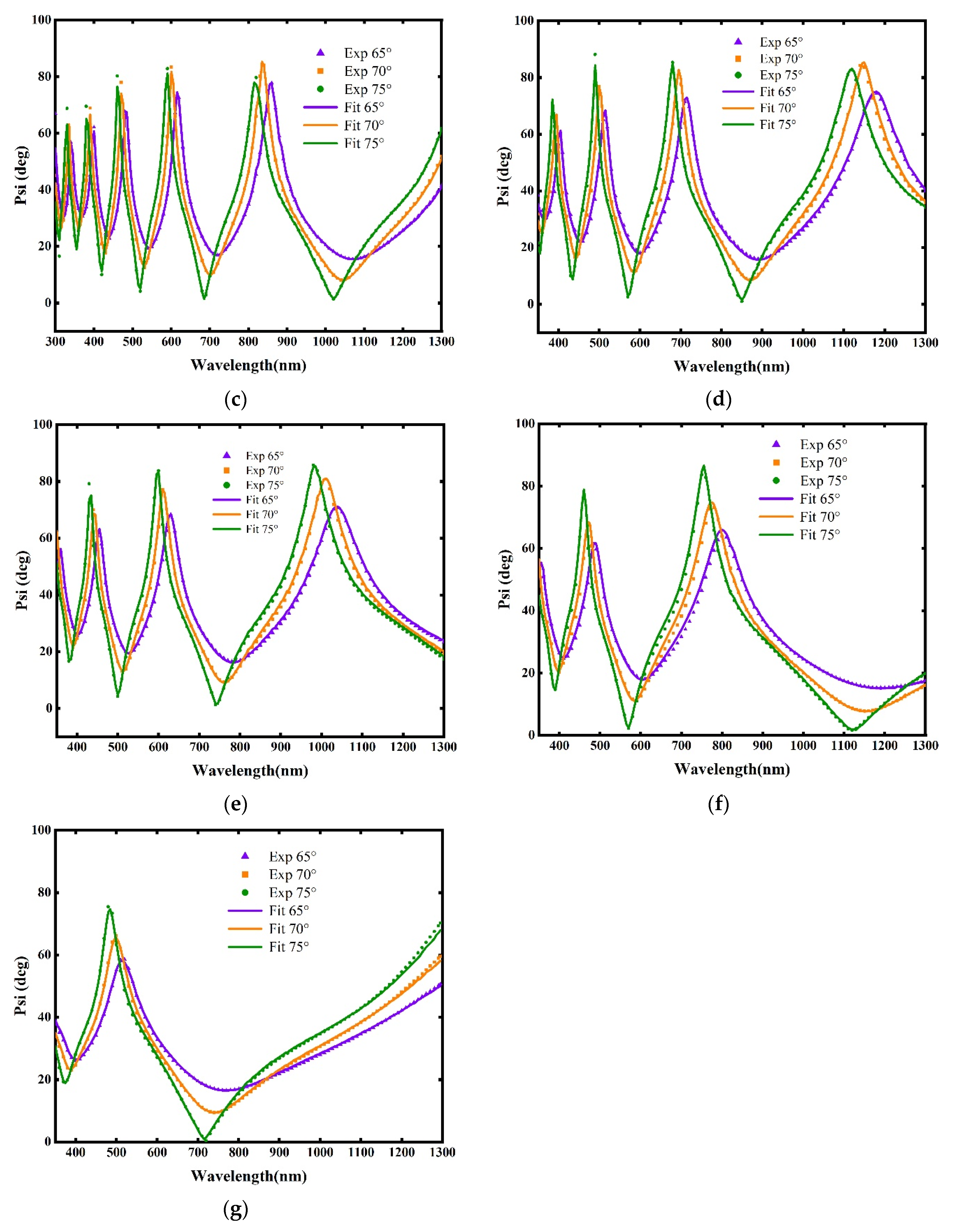

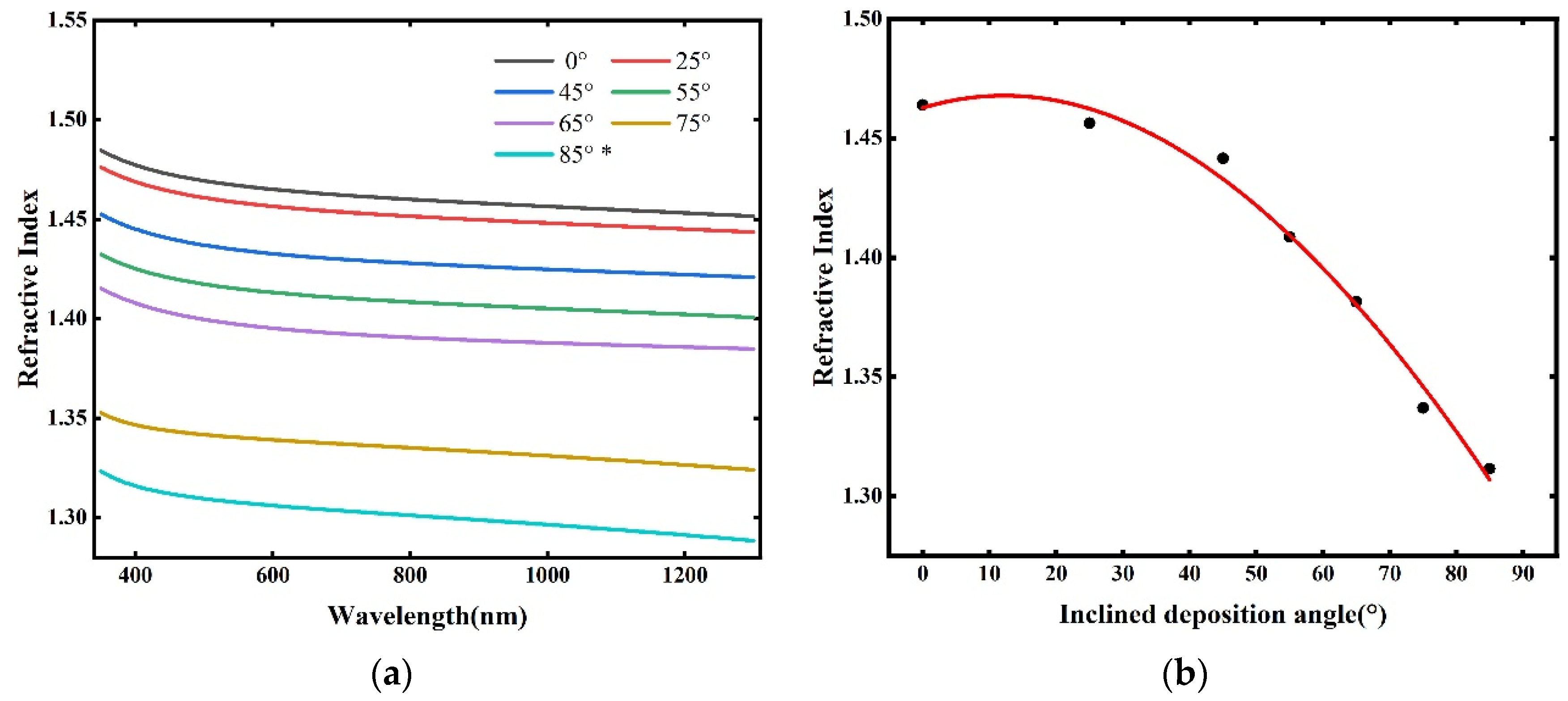

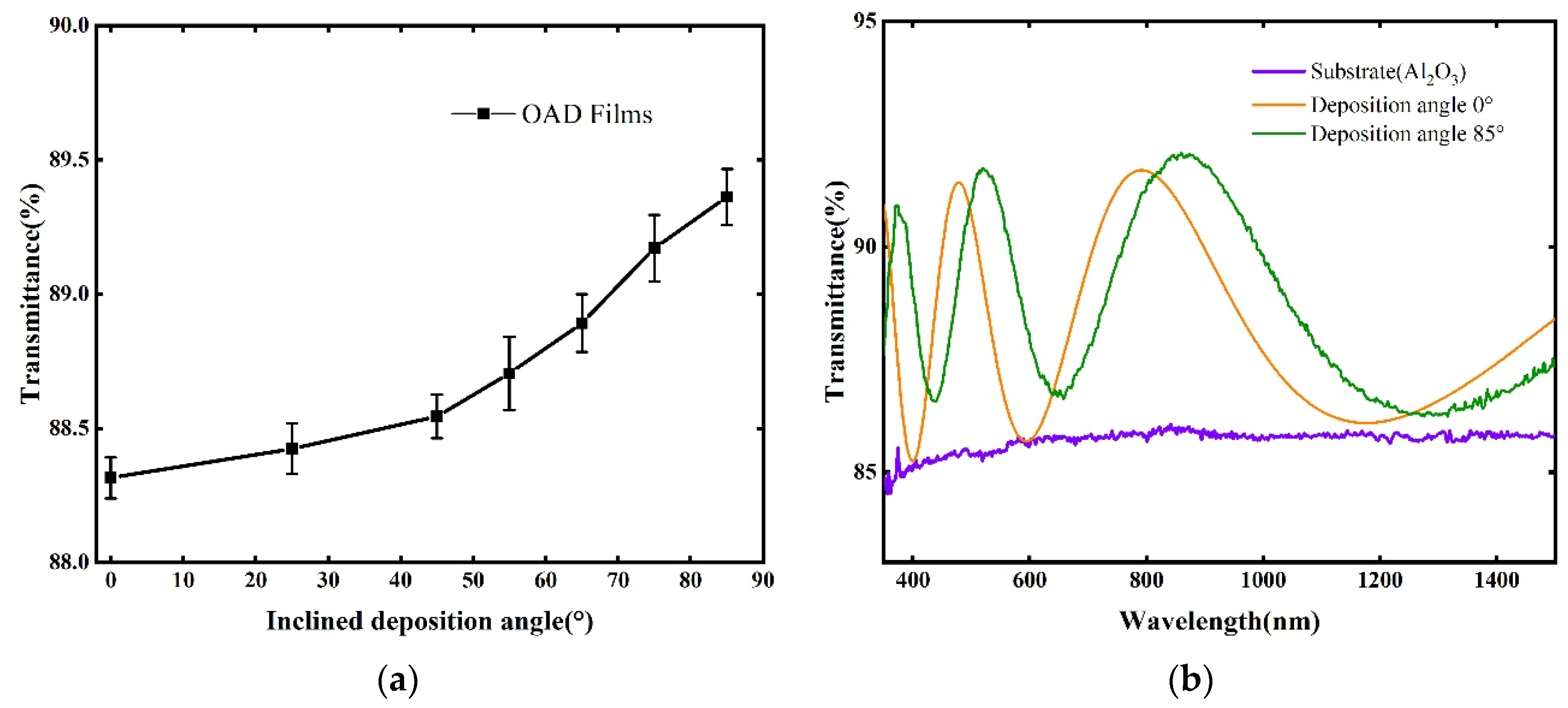

3.1. Optical Performance

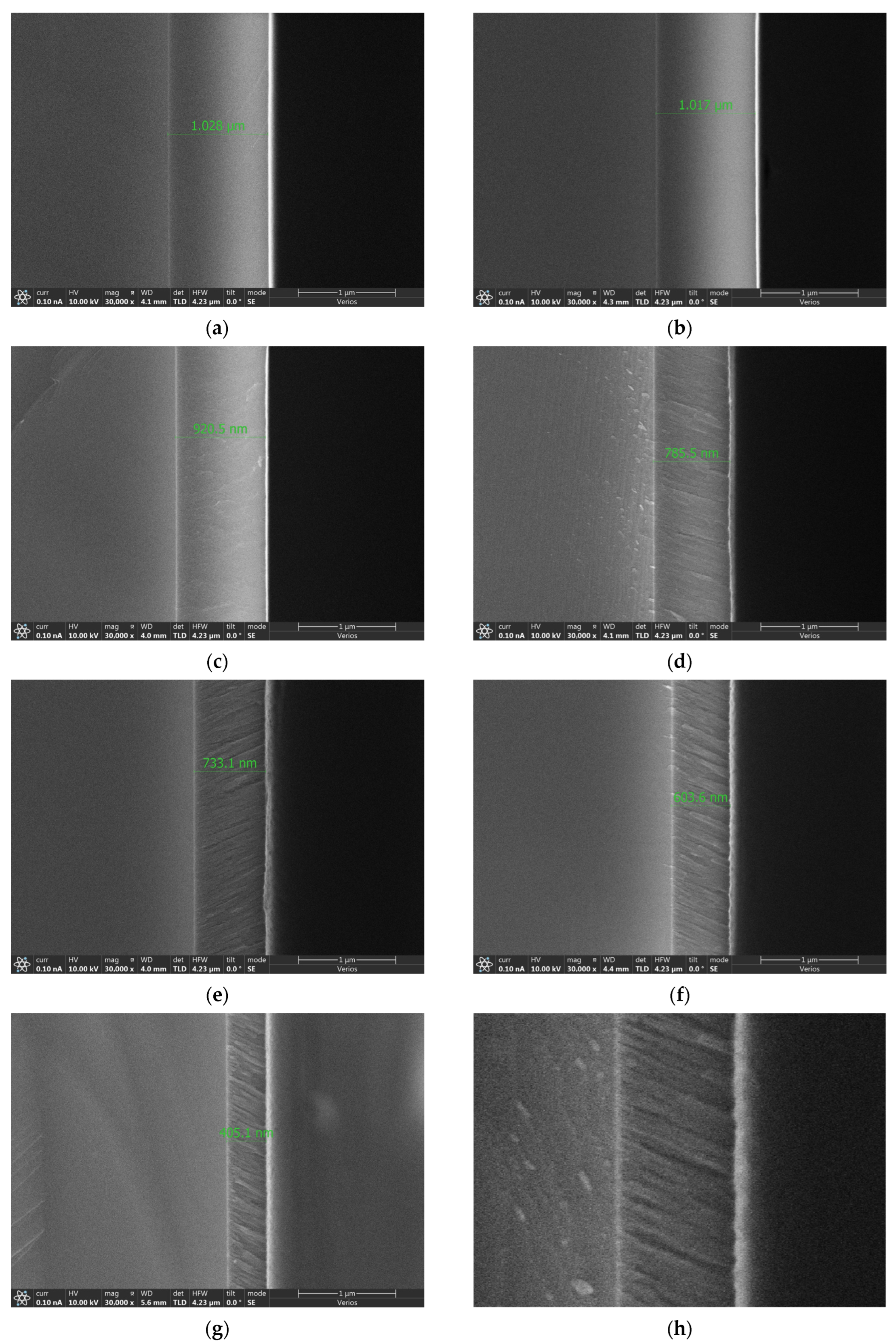

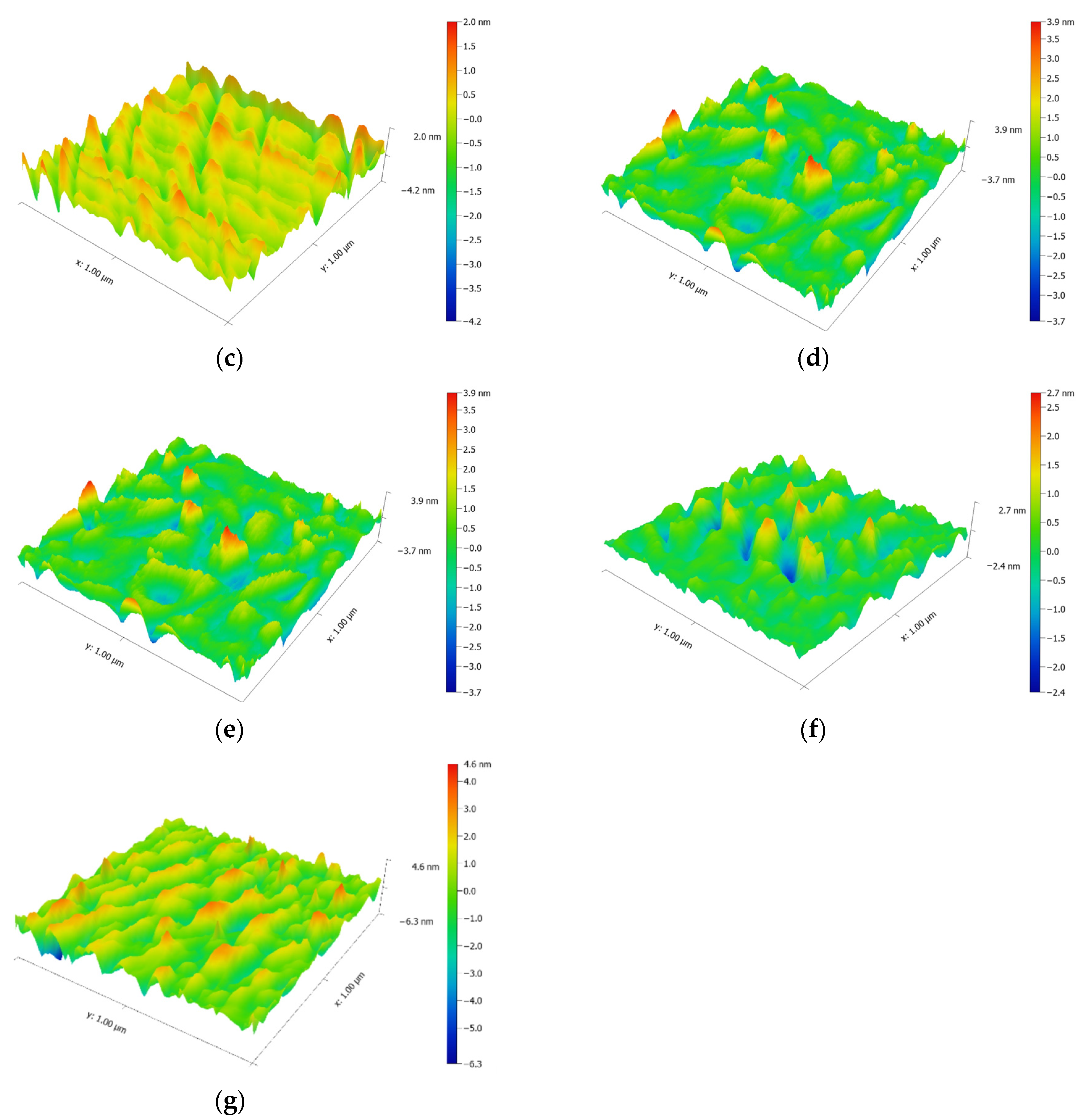

3.2. Surface and Internal Structure

4. Analysis and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Raut, H.K.; Ganesh, V.A.; Nair, A.S.; Ramakrishna, S. Anti-reflective coatings: A critical, in-depth review. Energy Environ. Sci. 2011, 4, 3779–3804. [Google Scholar] [CrossRef]

- Yang, Y.T.; Cai, Q.Y.; Liu, D.Q.; Gao, L.S.; Zhang, H.T.; Peng, L.; Hu, E.T.; Liu, B.J.; Luo, H.H.; Zhang, R.J.; et al. Low polarization-sensitive ultra-broadband anti-reflection coatings with improved reliability. Opt. Express 2023, 31, 25477–25489. [Google Scholar] [CrossRef]

- Pfeiffer, K.; Ghazaryan, L.; Schulz, U.; Szeghalmi, A. Wide-angle broadband antireflection coatings prepared by atomic layer deposition. ACS Appl. Mater. Interfaces 2019, 11, 21887–21894. [Google Scholar] [CrossRef]

- Xi, J.-Q.; Schubert, M.F.; Kim, J.K.; Schubert, E.F.; Chen, M.; Lin, S.-Y.; Liu, W.; Smart, J.A. Optical thin-film materials with low refractive index for broadband elimination of Fresnel reflection. Nat. Photonics 2007, 1, 176–179. [Google Scholar] [CrossRef]

- Prevo, B.G.; Hwang, Y.; Velev, O.D. Convective assembly of antireflective silica coatings with controlled thickness and refractive index. Chem. Mater. 2005, 17, 3642–3651. [Google Scholar] [CrossRef]

- Ito, M.; Tajima, N.; Murotani, H.; Matsudaira, T. Super Hydrophilic Low Refractive Index SiO2 Optical Thin Films Deposited by Using a Combination Coating Method. e-J. Surf. Sci. Nanotechnol. 2023, 22, 53–57. [Google Scholar] [CrossRef]

- Ruud, C.J.; Cleri, A.; Maria, J.-P.; Giebink, N.C. Ultralow index SiO2 antireflection coatings produced via magnetron sputtering. Nano Lett. 2022, 22, 7358–7362. [Google Scholar] [CrossRef]

- Dubey, R.; Rajesh, Y.; More, M. Synthesis and characterization of SiO2 nanoparticles via sol-gel method for industrial applications. Mater. Today Proc. 2015, 2, 3575–3579. [Google Scholar] [CrossRef]

- Chen, D. Anti-reflection (AR) coatings made by sol-gel processes: A review. Sol. Energy Mater. Sol. Cells 2001, 68, 313–336. [Google Scholar] [CrossRef]

- Zhang, W.; Tu, J.; Long, W.; Lai, W.; Sheng, Y.; Guo, T. Preparation of SiO2 anti-reflection coatings by sol-gel method. Energy Procedia 2017, 130, 72–76. [Google Scholar] [CrossRef]

- Shen, B.; Xiong, H.; Zhang, X.; Chen, Z.; Pang, X.; Guo, Y.; Liang, C.; Li, H. Post-treatment of 351 nm SiO2 antireflective coatings for high power laser systems prepared by the sol-gel method. Chin. Opt. Lett. 2022, 20, 011601. [Google Scholar] [CrossRef]

- Li, D.; Huang, F.; Ding, S. Sol-gel preparation and characterization of nanoporous ZnO/SiO2 coatings with broadband antireflection properties. Appl. Surf. Sci. 2011, 257, 9752–9756. [Google Scholar] [CrossRef]

- Barranco, A.; Borras, A.; Gonzalez-Elipe, A.R.; Palmero, A. Perspectives on oblique angle deposition of thin films: From fundamentals to devices. Prog. Mater. Sci. 2016, 76, 59–153. [Google Scholar] [CrossRef]

- Robbie, K.; Brett, M.J. Sculptured thin films and glancing angle deposition: Growth mechanics and applications. J. Vac. Sci. Technol. A Vac. Surf. Film. 1997, 15, 1460–1465. [Google Scholar] [CrossRef]

- Xi, J.-Q.; Kim, J.K.; Schubert, E.F. Silica nanorod-array films with very low refractive indices. Nano Lett. 2005, 5, 1385–1387. [Google Scholar] [CrossRef]

- Xi, J.Q.; Kim, J.K.; Schubert, E.E.; Ye, D.; Juneja, J.S. Very low-refractive-index optical thin films consisting of an array of SiO2 nanorods. Opt. Lett. 2006, 31, 601–603. [Google Scholar] [CrossRef]

- Prachachet, R.; Samransuksamer, B.; Horprathum, M.; Eiamchai, P.; Limwichean, S.; Chananonnawathorn, C.; Lertvanithphol, T.; Muthitamongkol, P.; Boonruang, S.; Buranasiri, P. A comparative study on omnidirectional anti-reflection SiO2 nanostructure films coating by glancing angle deposition. In Proceedings of the Oxide-Based Materials and Devices IX; SPIE: Bellingham, WA, USA, 2018; pp. 261–267. [Google Scholar]

- Zhao, Y.; Ye, D.; Wang, G.-C.; Lu, T.-M. Designing nanostructures by glancing angle deposition. In Proceedings of the Nanotubes and Nanowires; SPIE: Bellingham, WA, USA, 2003; pp. 59–73. [Google Scholar]

- Sobahan, K.; Park, Y.J.; Kim, J.J.; Hwangbo, C.K. Nanostructured porous SiO2 films for antireflection coatings. Opt. Commun. 2011, 284, 873–876. [Google Scholar] [CrossRef]

- Chhajed, S.; Poxson, D.J.; Yan, X.; Cho, J.; Schubert, E.F.; Welser, R.E.; Sood, A.K.; Kim, J.K. Nanostructured multilayer tailored-refractive-index antireflection coating for glass with broadband and omnidirectional characteristics. Appl. Phys. Express 2011, 4, 052503. [Google Scholar] [CrossRef]

- Feng, C.; Zhang, P.; Zhang, W.; Sun, J.; Wang, J.; Zhao, Y.; Shao, J. “Interface-free” ultrabroadband antireflection film based on nanorod structure with continuous change in refractive index. Opt. Mater. 2023, 141, 113965. [Google Scholar] [CrossRef]

- Feng, C.; Zhang, W.; Wang, J.; Ma, H.; Liu, S.; Yi, K.; He, H.; Shao, J. Broadband antireflection film by glancing angle deposition. Opt. Mater. 2021, 111, 110720. [Google Scholar] [CrossRef]

- Maudet, F.; Lacroix, B.; Santos, A.J.; Paumier, F.; Paraillous, M.; Hurand, S.; Corvisier, A.; Marsal, C.; Giroire, B.; Dupeyrat, C. Optical and nanostructural insights of oblique angle deposited layers applied for photonic coatings. Appl. Surf. Sci. 2020, 520, 146312. [Google Scholar] [CrossRef]

- Zhang, J.-C.; Xiong, L.-M.; Fang, M.; He, H.-B. Wide-angle and broadband graded-refractive-index antireflection coatings. Chin. Phys. B 2013, 22, 044201. [Google Scholar] [CrossRef]

- Dirks, A.G.; Leamy, H.J. Columnar microstructure in vapor-deposited thin films. Thin Solid Film. 1977, 47, 219–233. [Google Scholar] [CrossRef]

- Tait, R.N.; Smy, T.; Brett, M.J. Modelling and characterization of columnar growth in evaporated films. Thin Solid Film. 1993, 226, 196–201. [Google Scholar] [CrossRef]

- Zhou, Q.; Li, Z.; Ni, J.; Zhang, Z. A Simple Model to Describe the Rule of Glancing Angle Deposition. Mater. Trans. 2011, 52, 469–473. [Google Scholar] [CrossRef]

- Lalova, A.; Todorov, R. Optical properties of porous chalcogenide films for sensor application. In Proceedings of the Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2012; p. 012023. [Google Scholar]

- Eastman, J.M. Surface Scattering in Optical Interference Coatings. Ph.D. Thesis, University of Rochester, Rochester, NY, USA, 1974. [Google Scholar]

| Substrate | Si | Si | Si | Si | Si | Si | Si |

|---|---|---|---|---|---|---|---|

| Deposition angle | 0° | 25° | 45° | 55° | 65° | 75° | 85° |

| Film thickness (nm) | 1028 | 1017 | 915 | 785 | 733 | 603 | 408 |

| Substrate | Si | Si | Si | Si | Si | Si | Si |

|---|---|---|---|---|---|---|---|

| Deposition angle | 0° | 25° | 45° | 55° | 65° | 75° | 85° |

| Extinction Coefficient | 3 × 10−7 | 5 × 10−7 | 7 × 10−7 | 4 × 10−6 | 6 × 10−6 | 8 × 10−6 | 3 × 10−5 |

| Substrate | Si | Si | Si | Si | Si | Si | Si |

|---|---|---|---|---|---|---|---|

| Deposition angle | 0° | 25° | 45° | 55° | 65° | 75° | 85° |

| Porosity | 0% | 4.2% | 6.4% | 10.6% | 19.0% | 27.4% | 33.7% |

| Substrate | Si | Si | Si | Si | Si | Si | Si |

|---|---|---|---|---|---|---|---|

| Deposition angle | 0° | 25° | 45° | 55° | 65° | 75° | 85° |

| Inclination angle β of the nanocolumn | No obvious nanocolumn | 17° | 24° | 26° | 29° | ||

| Substrate | Si | Si | Si | Si | Si | Si | Si |

|---|---|---|---|---|---|---|---|

| Deposition angle | 0° | 25° | 45° | 55° | 65° | 75° | 85° |

| RMS (nm) | 0.447 | 0.496 | 0.588 | 0.790 | 0.842 | 0.992 | 1.128 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, B.; Chen, G.; Zhou, S.; Ma, X.; Zhang, Q.; Geng, Y.; Xu, T.; Liu, D. Low-Refractive-Index SiO2 Nanocolumnar Thin Films Fabricated by Oblique Angle Deposition. Materials 2025, 18, 2225. https://doi.org/10.3390/ma18102225

Jia B, Chen G, Zhou S, Ma X, Zhang Q, Geng Y, Xu T, Liu D. Low-Refractive-Index SiO2 Nanocolumnar Thin Films Fabricated by Oblique Angle Deposition. Materials. 2025; 18(10):2225. https://doi.org/10.3390/ma18102225

Chicago/Turabian StyleJia, Bojie, Gang Chen, Sheng Zhou, Xiaofeng Ma, Qiuyu Zhang, Yujia Geng, Teng Xu, and Dingquan Liu. 2025. "Low-Refractive-Index SiO2 Nanocolumnar Thin Films Fabricated by Oblique Angle Deposition" Materials 18, no. 10: 2225. https://doi.org/10.3390/ma18102225

APA StyleJia, B., Chen, G., Zhou, S., Ma, X., Zhang, Q., Geng, Y., Xu, T., & Liu, D. (2025). Low-Refractive-Index SiO2 Nanocolumnar Thin Films Fabricated by Oblique Angle Deposition. Materials, 18(10), 2225. https://doi.org/10.3390/ma18102225