Enhanced Mechanical Properties of Lightweight Ti65(AlCrNbV)35 Medium-Entropy Alloys via Microstructure Modification Through Minor B Doping

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Processing

2.3. Microstructure Characterization

2.4. Mechanical Properties Test

3. Results and Discussion

3.1. Properties of Homogenized (Ti65(AlCrNbV)35)100−xBx MEAs

3.2. Performance of B-Doped MEAs After TMT Processing

4. Conclusions

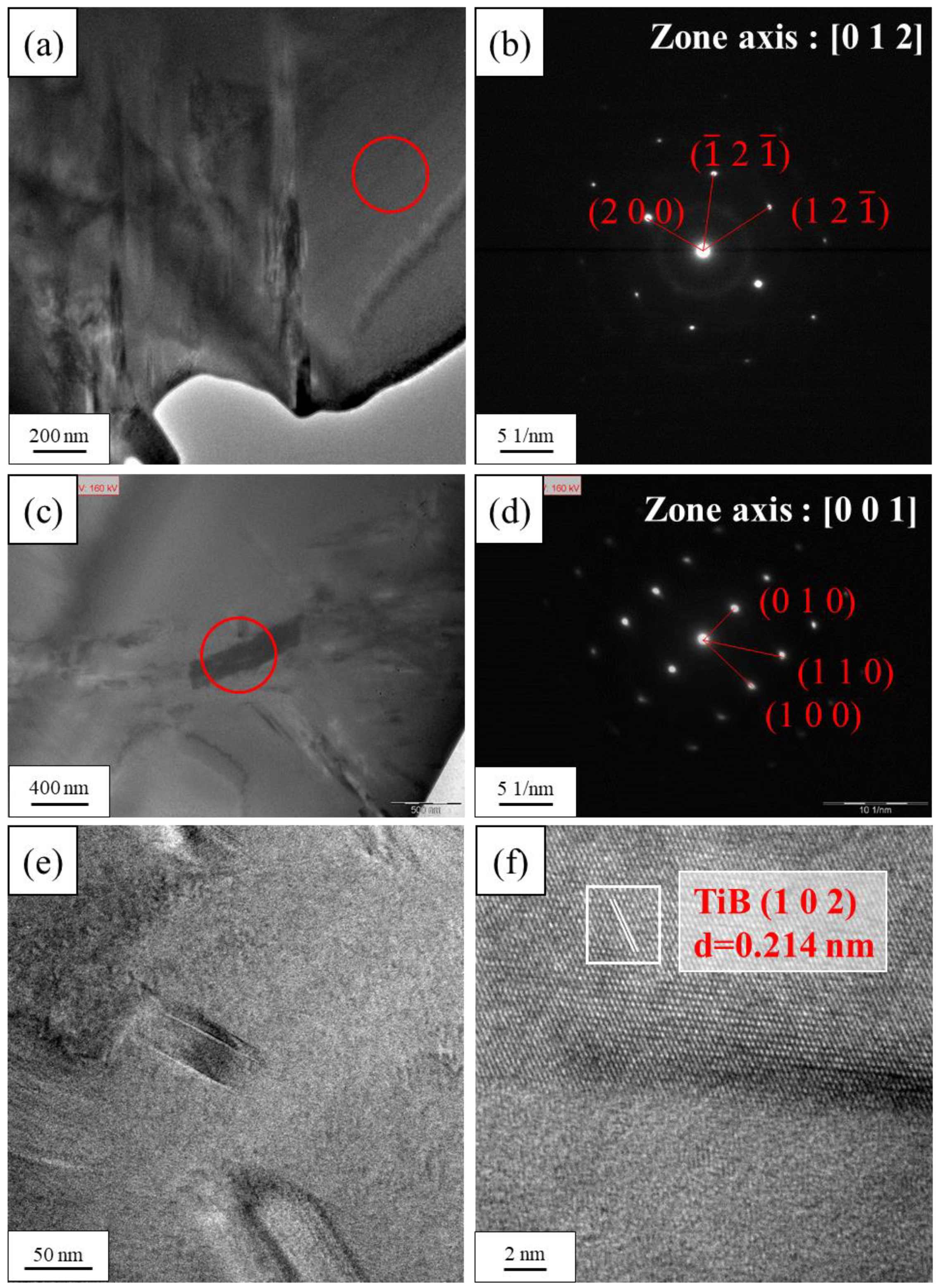

- X-ray diffraction analysis indicated that the homogenized (Ti65(AlCrNbV)35)100−xBx alloys retained their body-centered cubic structure. However, when the B doping amount was 0.4%, weak diffraction peaks corresponding to TiB coexisted in the diffraction pattern.

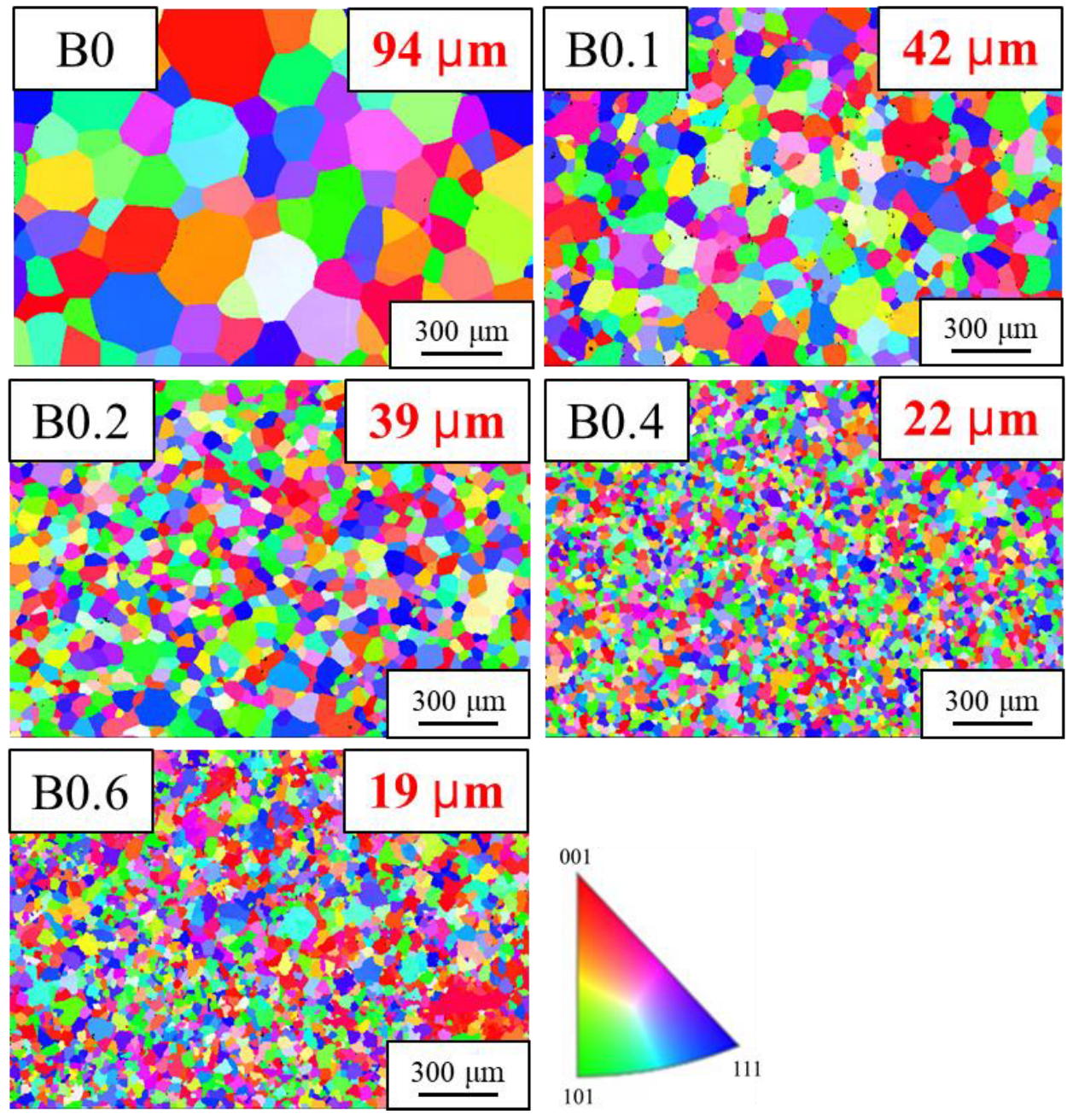

- Metallography revealed that B doping indeed reduced the grain size of the alloys. The post-homogenization grain size was 94 μm for B0, 42 μm for B0.1, 39 μm for B0.2, 22 μm for B0.4, and 19 μm for B0.6. Conversely, too much B resulted in the formation of TiB particles along the grain boundaries, considerably decreasing the ductility of the alloy.

- The B0.2 homogenized MEA had a tensile yield strength of 1054 MPa and exhibited 21% elongation, which represents 17% higher strength than that of the base alloy. Conversely, the mechanical properties of B0.4 and B0.6 were poorer due to the formation of TiB precipitates at grain boundaries.

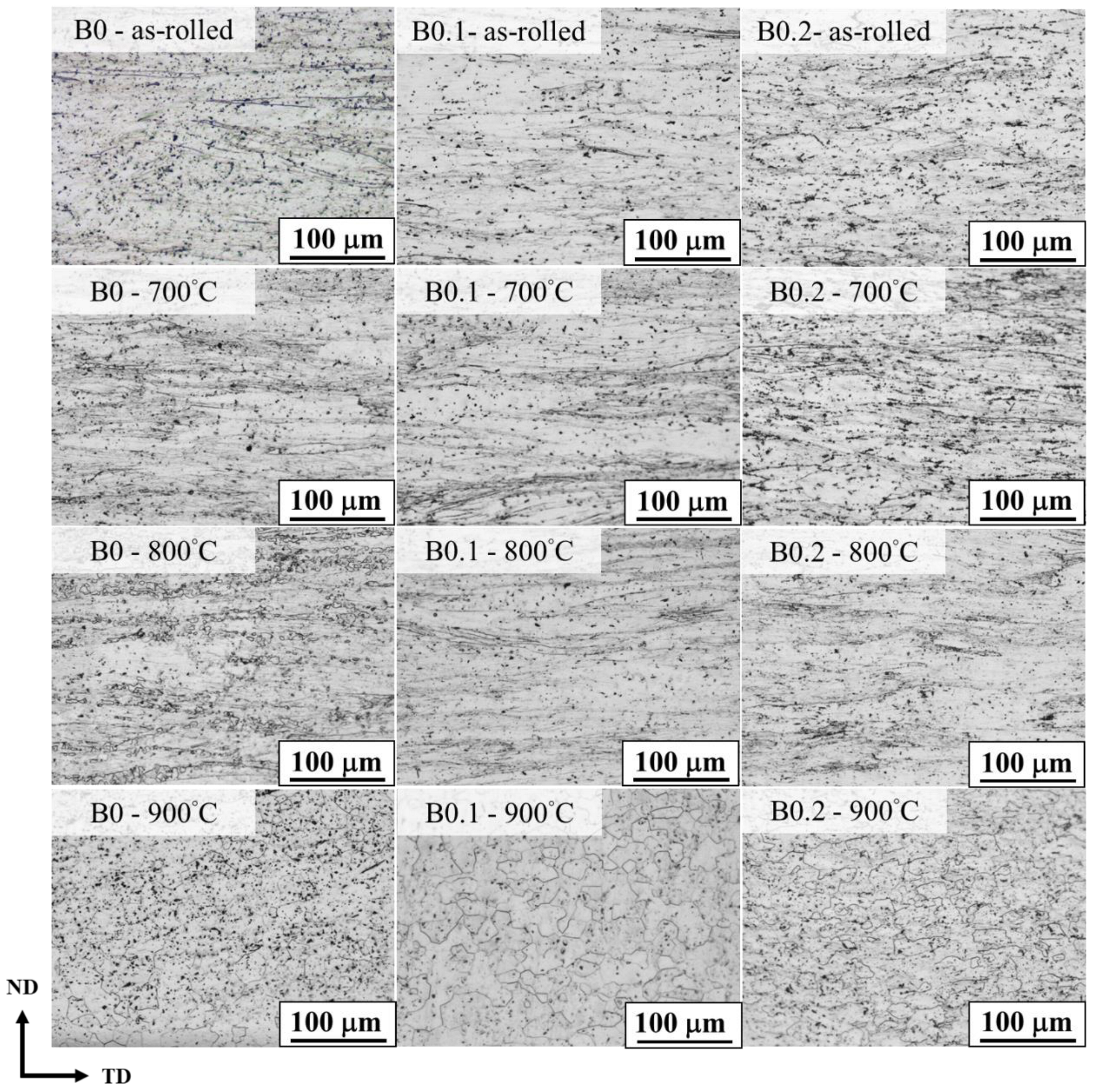

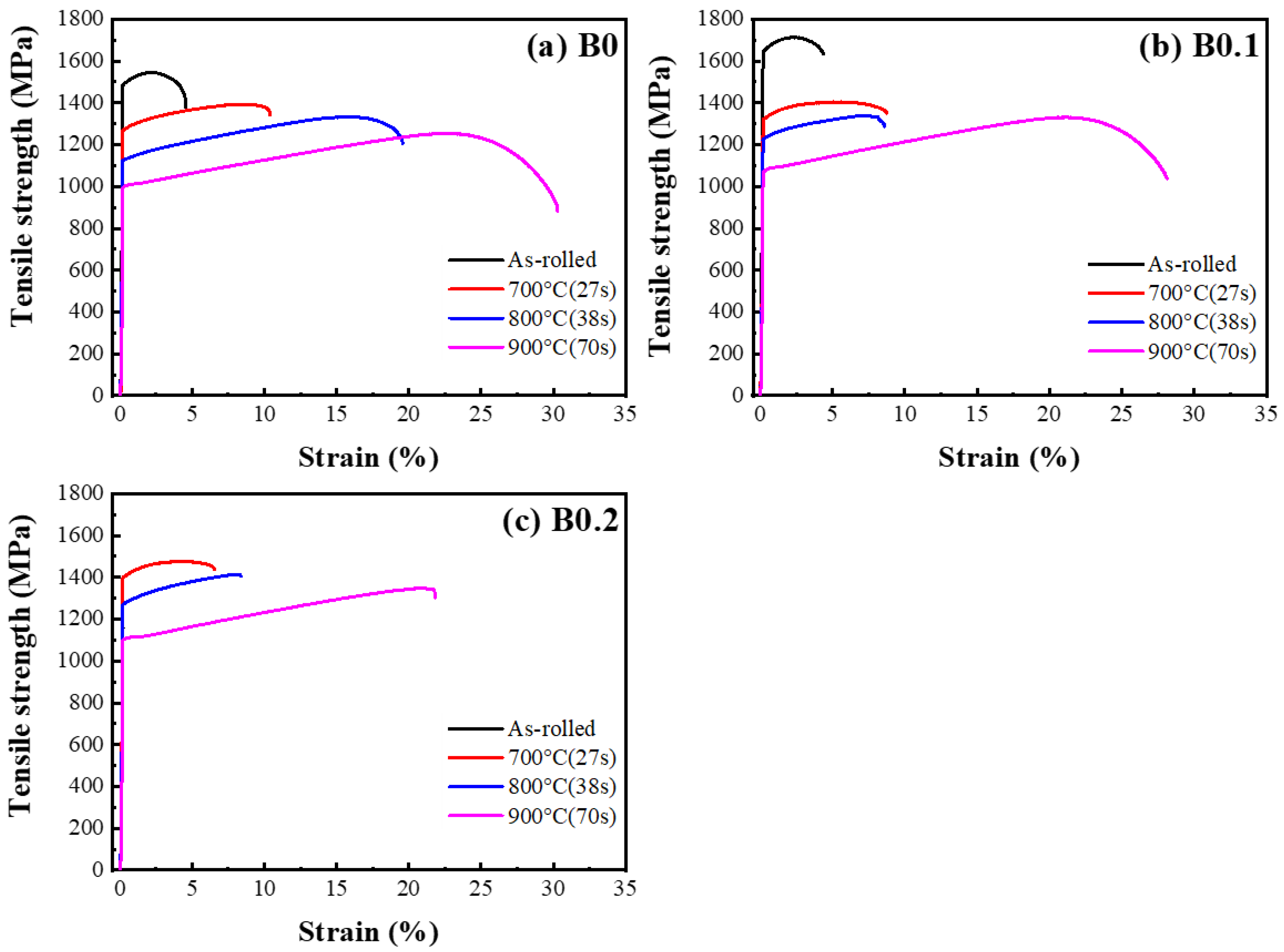

- After TMT, the recrystallization behavior of the B-doped alloys tended to be delayed to a higher B addition, resulting in smaller grains on average at a given annealing temperature (e.g., 900 °C). The yield strength and hardness of the B-doped alloys increased with increasing B content.

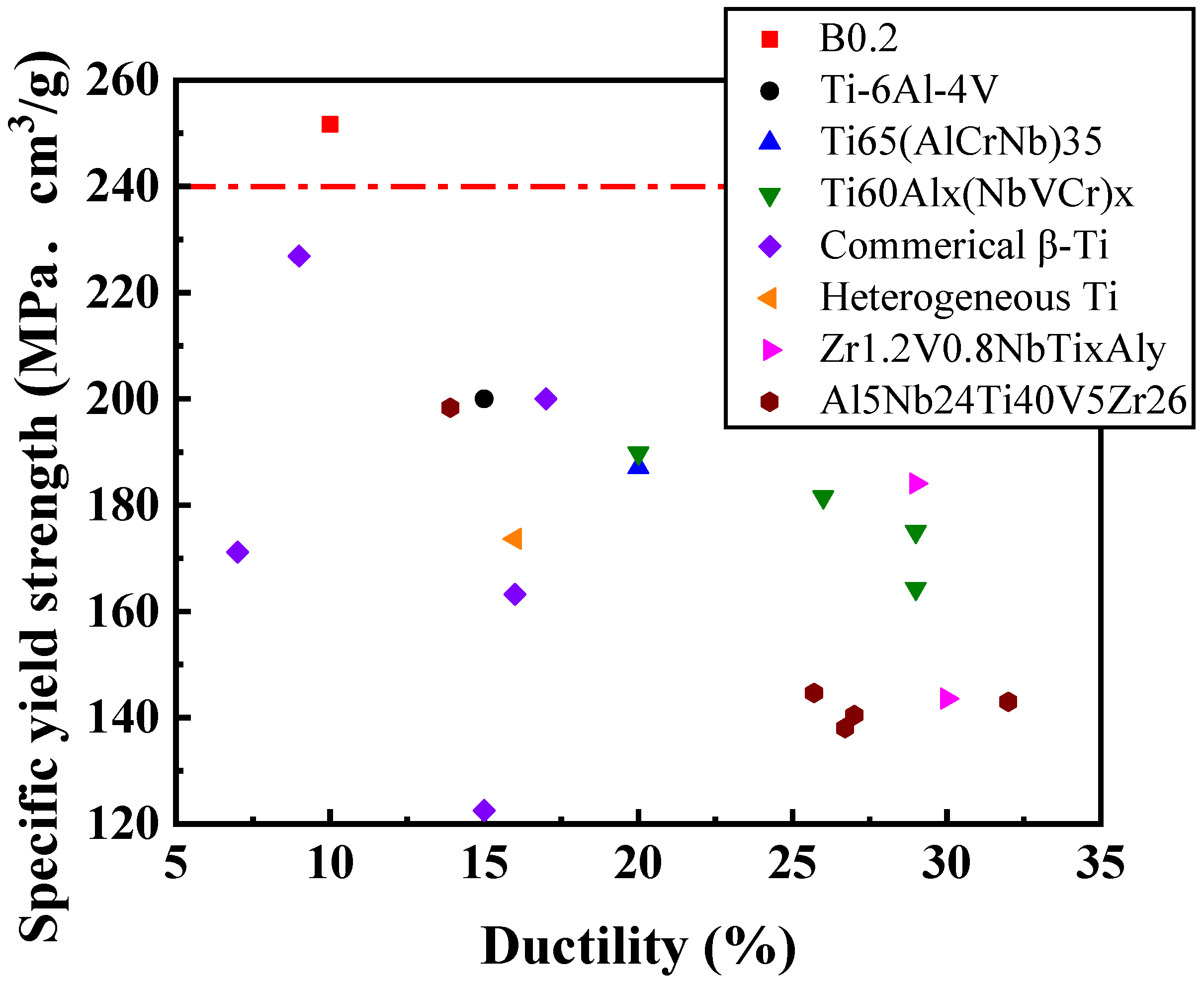

- Of all the MEA samples subjected to TMT in this study, B0.1 and B0.2 exhibited excellent combinations of yield strength (>1200 MPa) and ductility (>10%). Notably, the B0.2 MEA, after suitable TMT, exhibited a specific yield strength of 250 MPa·cm3/g and a ductility of 10%. These values are superior to those of commercial Ti alloys and some other lightweight alloys.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chu, L.L.; Li, Q.; Gu, F.; Du, X.T.; He, Y.Q.; Deng, Y.C. Design, modeling, and control of morphing aircraft: A review. Chin. J. Aeronaut. 2022, 35, 220–246. [Google Scholar] [CrossRef]

- Parveez, B.; Kittur, M.I.; Badruddin, I.A.; Kamangar, S.; Hussien, M.; Umarfarooq, M.A. Scientific Advancements in Composite Materials for Aircraft Applications: A Review. Polymers 2022, 14, 5007. [Google Scholar] [CrossRef]

- Springer, H.; Baron, C.; Szczepaniak, A.; Uhlenwinkel, V.; Raabe, D. Stiff, light, strong and ductile: Nano-structured High Modulus Steel. Sci. Rep. 2017, 7, 2757. [Google Scholar] [CrossRef]

- Gludovatz, B.; Hohenwarter, A.; Thurston, K.; Bei, H.; Wu, Z.; George, E.; Ritchie, R. Exceptional damage-tolerance of a medium-entropy alloy CrCoNi at cryogenic temperatures. Nat. Commun. 2016, 7, 10602. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhou, D.; Jin, X.; Zhang, L.; Du, X.; Li, B. Design of non-equiatomic medium-entropy alloys. Sci. Rep. 2018, 8, 1236. [Google Scholar] [CrossRef] [PubMed]

- Shaysultanov, D.; Nepapushev, A.; Zherebtsov, S.; Moskovskikh, D.; Stepanov, N. Structure and mechanical properties of a low-density AlCrFeTi medium entropyalloy produced by spark plasma sintering. Mater. Sci. Eng. A 2020, 795, 140018. [Google Scholar] [CrossRef]

- Guo, N.; Zhao, Y.; Long, S.; Song, B.; Hu, J.; Gan, B.; Chai, L.; Guo, S. Microstructure and mechanical properties of (CrCoNi)97Al1.5Ti1.5 medium entropy alloy twisted by free-end-torsion at room and cryogenic temperatures. Mater. Sci. Eng. A 2020, 797, 140101. [Google Scholar] [CrossRef]

- Laplanche, G.; Kostka, A.; Reinhart, C.; Hunfeld, J.; Eggeler, G.; George, E. Reasons for the superior mechanical properties of medium-entropy CrCoNi compared to high-entropy CrMnFeCoNi. Acta Mater. 2017, 128, 292–303. [Google Scholar] [CrossRef]

- Callister, W.D.; Rethwisch, D.G. Materials Science and Engineering; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2011; Volume 8. [Google Scholar]

- Hou, L.; Hui, J.; Yao, Y.; Chen, J.; Liu, J. Effects of Boron Content on microstructure and mechanical properties of AlFeCoNiBx High Entropy Alloy Prepared by vacuum arc melting. Vacuum 2019, 164, 212–218. [Google Scholar] [CrossRef]

- Xin, B.; Zhang, A.; Han, J.; Zhang, J.; Meng, J. Enhancing mechanical properties of the boron doped Al0.2Co1.5CrFeNi1.5Ti0.5 high entropy alloy via tuning composition and microstructure. J. Alloys Compd. 2022, 896, 162852. [Google Scholar] [CrossRef]

- Calcagnotto, M.; Ponge, D.; Adachi, Y.; Raabe, D. Effect of Grain Refinement on Strength and Ductility in Dual-Phase Steels. In Proceedings of the 2nd International Symposium on Steel Science, Kyoto, Japan, 21–24 October 2009; pp. 195–198. [Google Scholar]

- Helth, A.; Siegel, U.; Kühn, U.; Gemming, T.; Gruner, W.; Oswald, S.; Marr, T.; Freudenberger, J.; Scharnweber, J.; Oertel, C.; et al. Influence of boron and oxygen on the microstructure and mechanical properties of high-strength Ti66Nb13Cu8Ni6.8Al6.2 alloys. Acta Mater. 2013, 61, 3324–3334. [Google Scholar] [CrossRef]

- Fan, Z.; Wang, Y.; Zhang, Y.; Qin, T.; Zhou, X.R.; Thompson, G.E.; Pennycookc, T.; Hashimotob, T. Grain refining mechanism in the Al/Al–Ti–B system. Acta Mater. 2015, 84, 292–304. [Google Scholar] [CrossRef]

- Pang, J.; Zhang, H.; Zhang, L.; Zhu, Z.; Fu, H.; Li, H.; Wang, A.; Li, Z.; Zhang, H. Simultaneous enhancement of strength and ductility of body-centered cubic TiZrNb multi-principal element alloys via boron-doping. J. Mater. Sci. Technol. 2021, 78, 74–80. [Google Scholar] [CrossRef]

- Yao, M.; Pradeep, K.; Tasan, C.; Raabe, D. A novel, single phase, non-equiatomic FeMnNiCoCr high entropy alloy with exceptional phase stability and tensile ductility. Scr. Mater. 2014, 72–73, 5–8. [Google Scholar] [CrossRef]

- Luan, X.; Zhao, W.; Liang, Z.; Xiao, S.; Liang, G.; Chen, Y.; Zou, S.; Wang, X. Experimental study on surface integrity of ultra-high-strength steel by ultrasonic hot rolling surface strengthening. Surf. Coat. Technol. 2020, 392, 125745. [Google Scholar] [CrossRef]

- Eleti, R.R.; Raju, V.; Veerasham, M.; Reddy, S.R.; Bhattacharjee, P.P. Influence of strain on the formation of cold-rolling and grain growth textures of an equiatomic HfZrTiTaNb refractory high entropy alloy. Mater. Charact. 2018, 136, 286–292. [Google Scholar] [CrossRef]

- Liao, Y.C.; Chen, P.S.; Tsai, P.H.; Jang, J.S.C.; Hsieh, K.C.; Chang, H.W.; Chen, C.Y.; Huang, J.C.; Wu, H.J.; Lo, Y.C.; et al. Effect of thermomechanical treatment on the microstructure evolution and mechanical properties of lightweight Ti65(AlCrNb)35 medium-entropy alloy. Intermetallics 2022, 143, 107470. [Google Scholar] [CrossRef]

- Zherebtsov, S.; Yurchenko, N.; Panina, E.; Tikhonovsky, M.; Stepanov, N. Gum-like mechanical behavior of a partially ordered Al5Nb24Ti40V5Zr26 high entropy alloy. Intermetallics 2020, 116, 106652. [Google Scholar] [CrossRef]

- Liao, Y.C.; Li, T.H.; Tsai, P.H.; Jang, J.S.C.; Hsieh, K.C.; Chen, C.Y.; Huang, J.C.; Wu, H.J.; Lo, Y.C.; Huang, C.W.; et al. Designing novel lightweight, high-strength and high-plasticity Tix(AlCrNb)100-x medium-entropy alloys. Intermetallics 2020, 117, 106673. [Google Scholar] [CrossRef]

- Liao, Y.; Ye, W.; Chen, P.; Tsai, P.; Jang, J.; Hsieh, K.; Chen, C.; Huang, J.; Wu, H.; Lo, Y.; et al. Effect of Al concentration on the microstructural and mechanical properties of lightweight Ti60Alx(VCrNb)40-x medium-entropy alloys. Intermetallics 2021, 135, 107213. [Google Scholar] [CrossRef]

- Chen, P.S.; Shiu, S.J.; Tsai, P.H.; Liao, Y.C.; Jang, J.S.C.; Wu, H.J.; Chang, S.Y.; Chen, C.Y.; Tsao, I.Y. Remarkable Enhanced Mechanical Properties of TiAlCrNbV Medium-Entropy Alloy with Zr Additions. Materials 2022, 15, 6324. [Google Scholar] [CrossRef] [PubMed]

- Chen, P.S.; Sung, T.W.; Tsai, P.H.; Liao, Y.C.; Jang, J.S.C.; Wu, H.J.; Chang, S.Y.; Chen, C.Y.; Tsao, I.Y. Enhancing Mechanical Properties of a Lightweight TiAlCrNbVZr Medium-Entropy Alloy: Fine-Tuning Alloy Composition and Thermomechanical Treatment. J. Mater. Sci. Technol. Res. 2024, 11, 1–9. [Google Scholar] [CrossRef]

- Chen, P.S.; Liu, J.R.; Tsai, P.H.; Liao, Y.C.; Jang, J.S.C.; Wu, H.J.; Chang, S.Y.; Chen, C.Y.; Tsao, I.Y. Enhancing the Strength and Ductility Synergy of Lightweight Ti-Rich Medium-Entropy Alloys through Ni Microalloying. Materials 2024, 17, 2900. [Google Scholar] [CrossRef]

- Liao, Y.C.; Chen, P.S.; Tsai, P.H.; Jang, J.S.C.; Hsieh, K.C.; Chen, C.Y.; Huang, J.C.; Wu, H.J.; Tsao, I.Y. Tailored rapid annealing to obtain heterostructured ultra-high-strength lightweight Ti-rich medium-entropy alloys. Results Mater. 2022, 16, 100342. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, S.; Cao, Y.; Xu, S.; Zhang, X.; Wang, J.; Si, C. Nanostructure evolution of reticular nano-TiB whiskers reinforced titanium matrix composite subjected to ultrasonic shot peening. J. Alloys Compd. 2023, 948, 169704. [Google Scholar] [CrossRef]

- de Boer, F.R.; Mattens, W.C.M.; Boom, R.; Miedema, A.R. Cohesion in Metals–Transition Metal Alloys; North-Holland: Amsterdam, The Netherlands, 1988; p. 130. ISBN 0-444-87098-9. [Google Scholar]

- Seol, J.B.; Bae, J.W.; Li, Z.M.; Han, J.C.; Kim, J.G.; Raabe, D.; Kim, H.S. Boron doped ultrastrong and ductile high-entropy alloys. Acta Mater. 2018, 151, 366–376. [Google Scholar] [CrossRef]

- Nes, E. The effect of a fine particle dispersion on heterogeneous recrystallization. Acta Metall. 1976, 24, 391–398. [Google Scholar] [CrossRef]

- Online Materials Information Resource—MatWeb. 2023. Available online: http://www.matweb.com/index.aspx (accessed on 30 April 2023).

- Shin, S.; Zhu, C.; Zhang, C.; Vecchio, K. Extraordinary strength-ductility synergy in a heterogeneous-structured β-Ti alloy through microstructural optimization. Mater. Res. Lett. 2019, 7, 467–473. [Google Scholar] [CrossRef]

- Wang, L.; Chen, S.; Li, B.; Cao, T.; Wang, B.; Wang, L.; Ren, Y.; Liang, J.; Xue, Y. Lightweight Zr1.2V0.8NbTixAly high-entropy alloys with high tensile strength and ductility. Mater. Trans. 2015, 56, 1800–1806. [Google Scholar]

| Composition | ΔS (kJ·mol−1) | Δr (%) |

|---|---|---|

| B0 | 9.42 | 4.78 |

| B0.1 | 9.47 | 5.63 |

| B0.2 | 9.52 | 6.36 |

| B0.4 | 9.59 | 7.63 |

| B0.6 | 9.66 | 8.71 |

| Composition | Theoretical Density (g/cm3) | Measured Density (g/cm3) | Error (%) |

|---|---|---|---|

| B0 | 5.101 | 5.091 | 0.19 |

| B0.1 | 5.098 | 5.137 | 0.76 |

| B0.2 | 5.095 | 5.066 | 0.56 |

| B0.4 | 5.088 | 5.133 | 0.88 |

| B0.6 | 5.082 | 5.043 | 0.76 |

| Composition | Hardness (HV) | Yield Strength (MPa) | Ultimate Strength (MPa) | Ductility (%) |

|---|---|---|---|---|

| B0 | 321 ± 3 | 903 ± 9 | 1112 ± 34 | 27 ± 3 |

| B0.1 | 356 ± 2 | 1011 ± 5 | 1232 ± 28 | 24 ± 1 |

| B0.2 | 363 ± 3 | 1054 ± 17 | 1286 ± 31 | 21 ± 1 |

| B0.4 | 367 ± 2 | 1066 | 1227 | 14 |

| B0.6 | 378 ± 1 | Rupture | ||

| Ti-6Al-4V | 318 | 885 | 985 | 15 |

| Composition | B0 | B0.1 | B0.2 |

|---|---|---|---|

| As-rolled | 419 ± 5 | 435 ± 3 | 456 ± 2 |

| 700 °C | 388 ± 2 | 402 ± 3 | 431 ± 6 |

| 800 °C | 347 ± 5 | 374 ± 3 | 399 ± 4 |

| 900 °C | 322 ± 3 | 336 ± 4 | 353 ± 3 |

| Processing | B0 | B0.1 | B0.2 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Mechanical Properties | Yield Strength | Ultimate Strength | Ductility | Yield Strength | Ultimate Strength | Ductility | Yield Strength | Ultimate Strength | Ductility |

| (MPa) | (MPa) | (%) | (MPa) | (MPa) | (%) | (MPa) | (MPa) | (%) | |

| As-rolled | 1484 | 1547 | 4.5 | 1650 | 1713 | 4.4 | N/A | N/A | N/A |

| 700 °C | 1249 ± 21 | 1367 ± 26 | 9.8 ± 0.7 | 1328 ± 11 | 1424 ± 23 | 9.1 ± 0.4 | 1351 ± 34 | 1446 ± 29 | 8.3 ± 1.2 |

| 800 °C | 1098 ± 24 | 1321 ± 20 | 19.6 ± 1.2 | 1200 ± 24 | 1324 ± 14 | 10.5 ± 1.0 | 1275 ± 13 | 1415 ± 6 | 10.0 ± 1.2 |

| 900 °C | 999 ± 3 | 1262 ± 8 | 30.2 ± 0.1 | 1050 ± 18 | 1295 ± 35 | 28.2 ± 1.3 | 1085 ± 14 | 1329 ± 19 | 24.6 ± 1.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, P.-S.; Kuo, B.-T.; Tsai, P.-H.; Jang, J.S.-C.; Chen, C.-Y.; Tsao, I.-Y. Enhanced Mechanical Properties of Lightweight Ti65(AlCrNbV)35 Medium-Entropy Alloys via Microstructure Modification Through Minor B Doping. Materials 2025, 18, 2219. https://doi.org/10.3390/ma18102219

Chen P-S, Kuo B-T, Tsai P-H, Jang JS-C, Chen C-Y, Tsao I-Y. Enhanced Mechanical Properties of Lightweight Ti65(AlCrNbV)35 Medium-Entropy Alloys via Microstructure Modification Through Minor B Doping. Materials. 2025; 18(10):2219. https://doi.org/10.3390/ma18102219

Chicago/Turabian StyleChen, Po-Sung, Bao-Teng Kuo, Pei-Hua Tsai, Jason Shian-Ching Jang, Chih-Yen Chen, and I-Yu Tsao. 2025. "Enhanced Mechanical Properties of Lightweight Ti65(AlCrNbV)35 Medium-Entropy Alloys via Microstructure Modification Through Minor B Doping" Materials 18, no. 10: 2219. https://doi.org/10.3390/ma18102219

APA StyleChen, P.-S., Kuo, B.-T., Tsai, P.-H., Jang, J. S.-C., Chen, C.-Y., & Tsao, I.-Y. (2025). Enhanced Mechanical Properties of Lightweight Ti65(AlCrNbV)35 Medium-Entropy Alloys via Microstructure Modification Through Minor B Doping. Materials, 18(10), 2219. https://doi.org/10.3390/ma18102219