The Effect of Austempering Temperature on the Matrix Morphology and Thermal Shock Resistance of Compacted Graphite Cast Iron

Abstract

1. Introduction

2. Materials and Methods

- –

- Heating of the wedge-shaped end using an induction coil until the target temperature was reached;

- –

- Rotating the specimen by 180°;

- –

- Cooling in water during the heating of the opposite end.

3. Results and Discussion

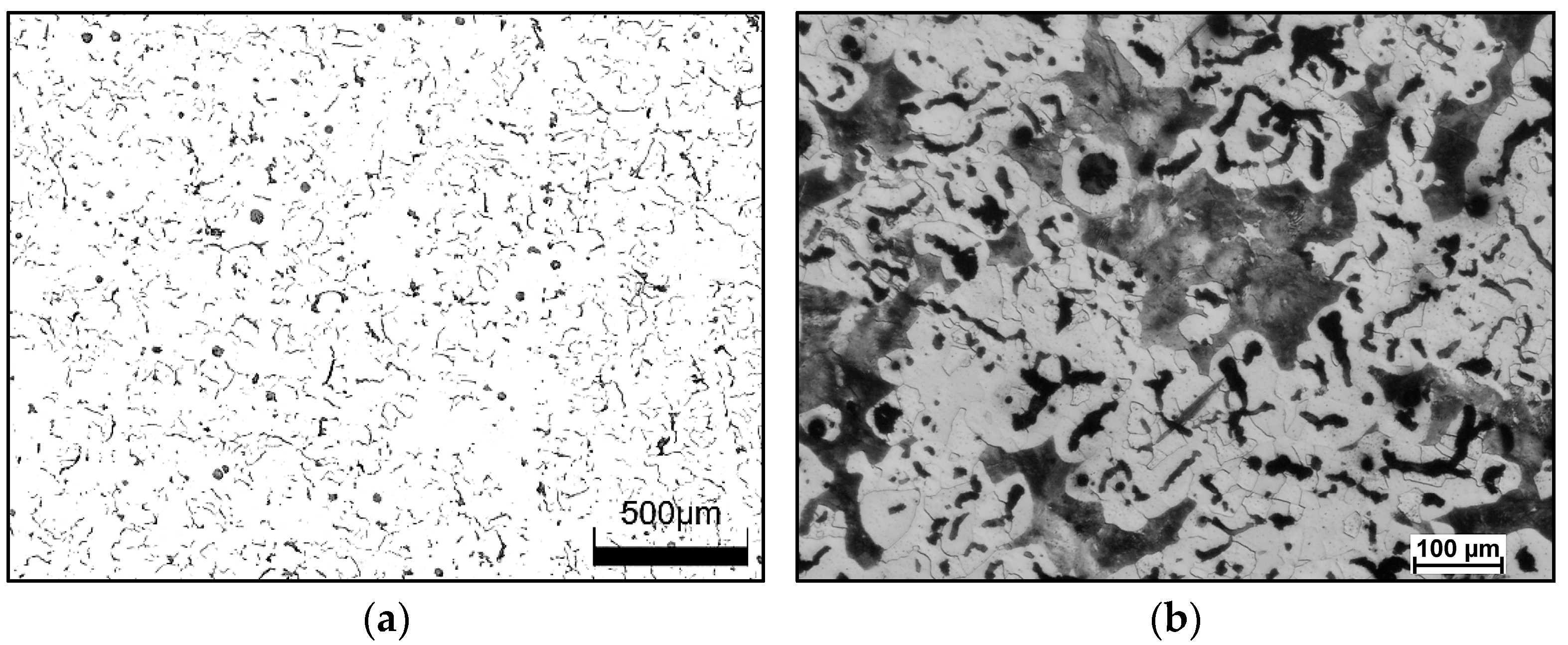

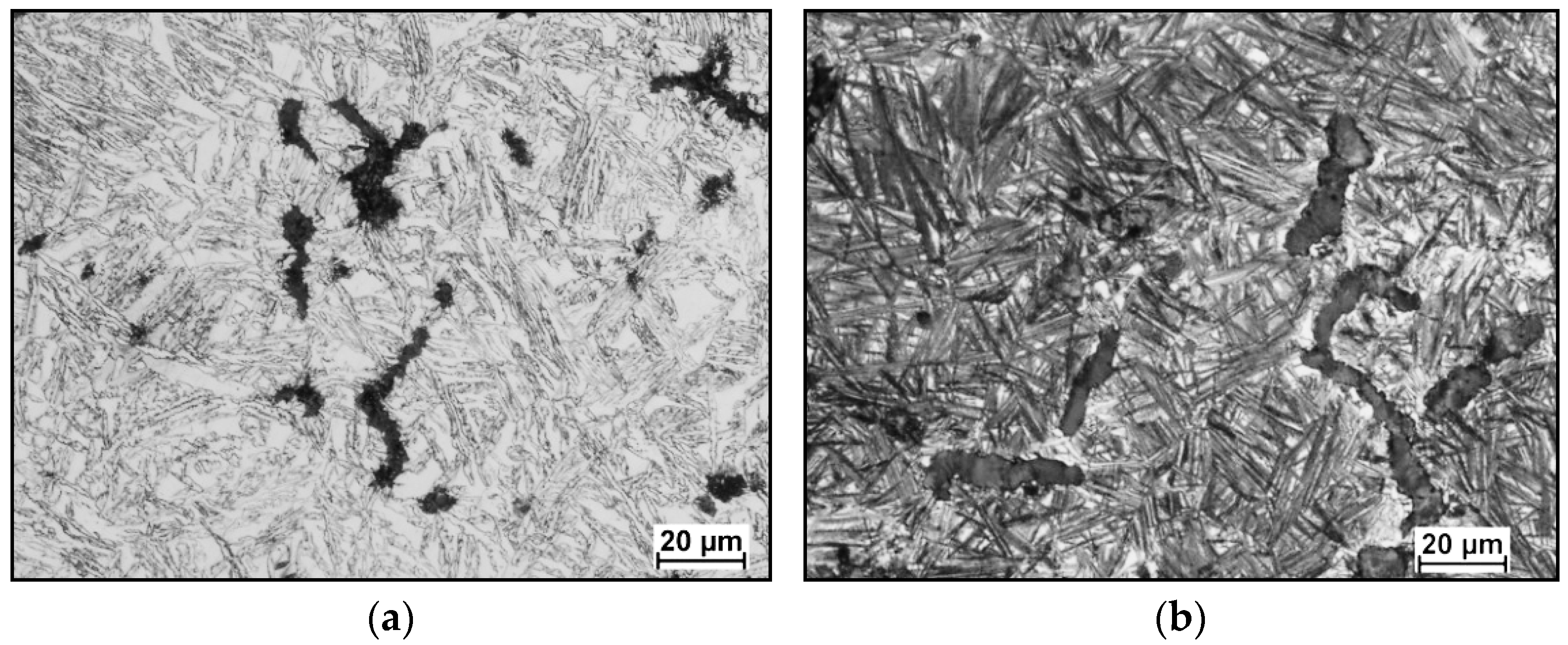

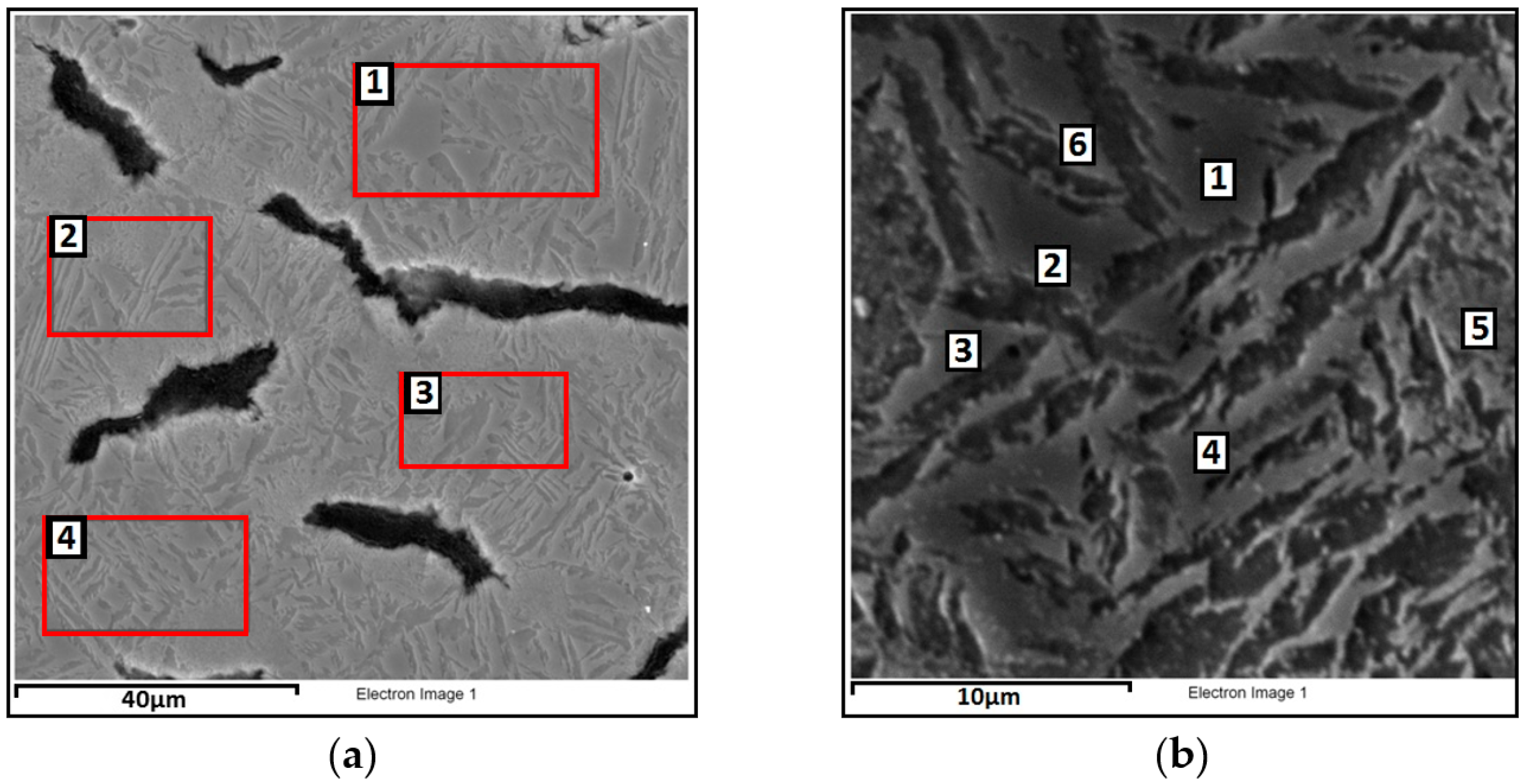

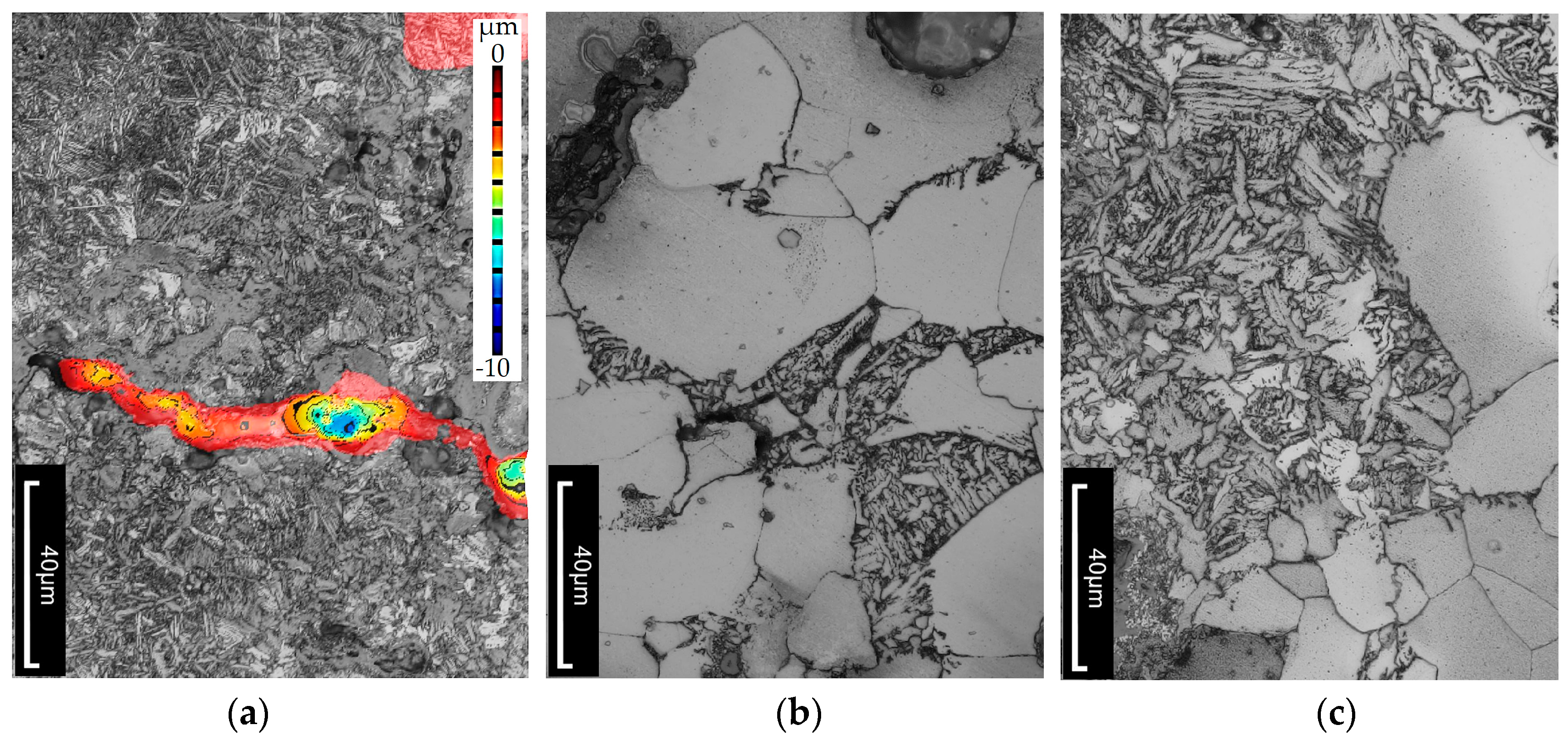

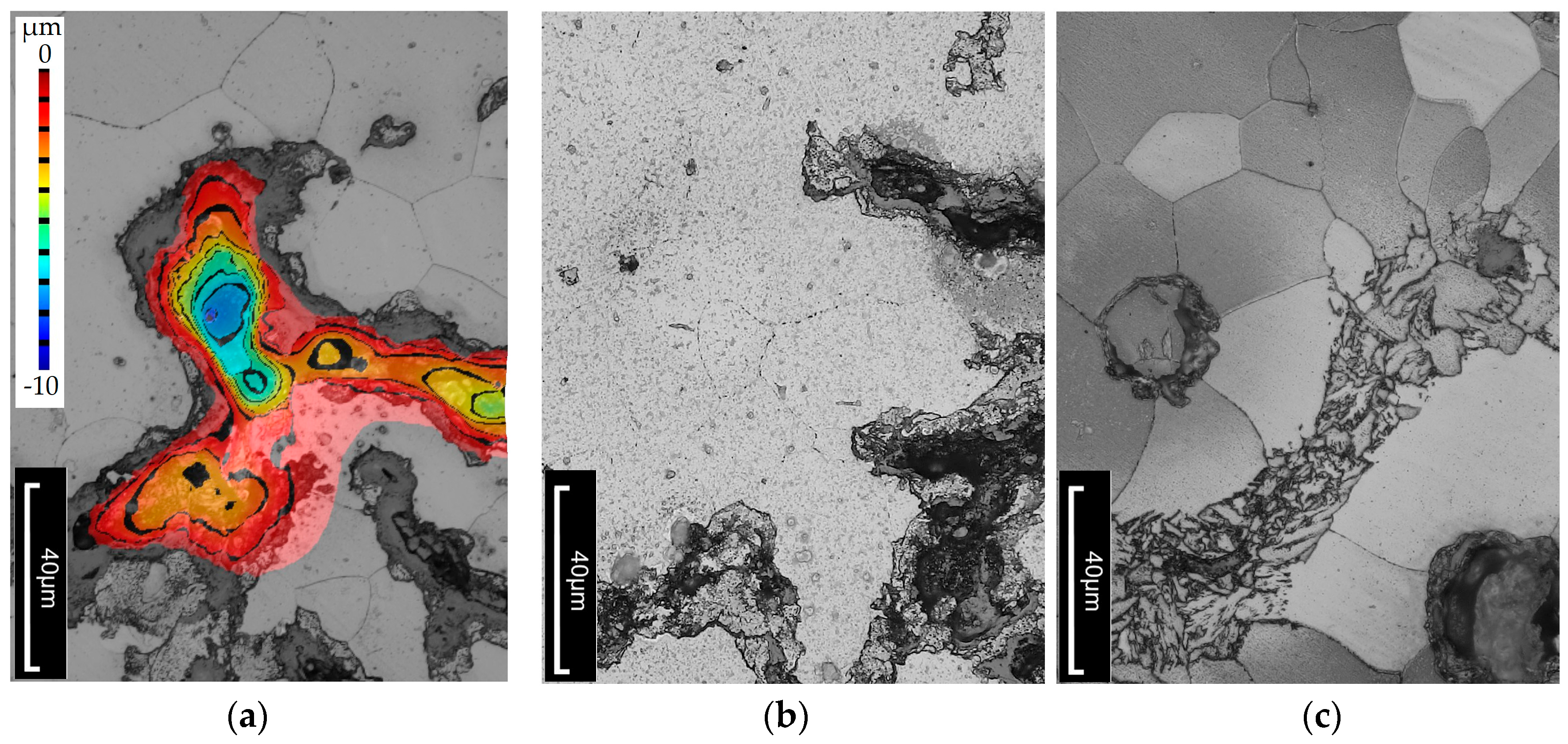

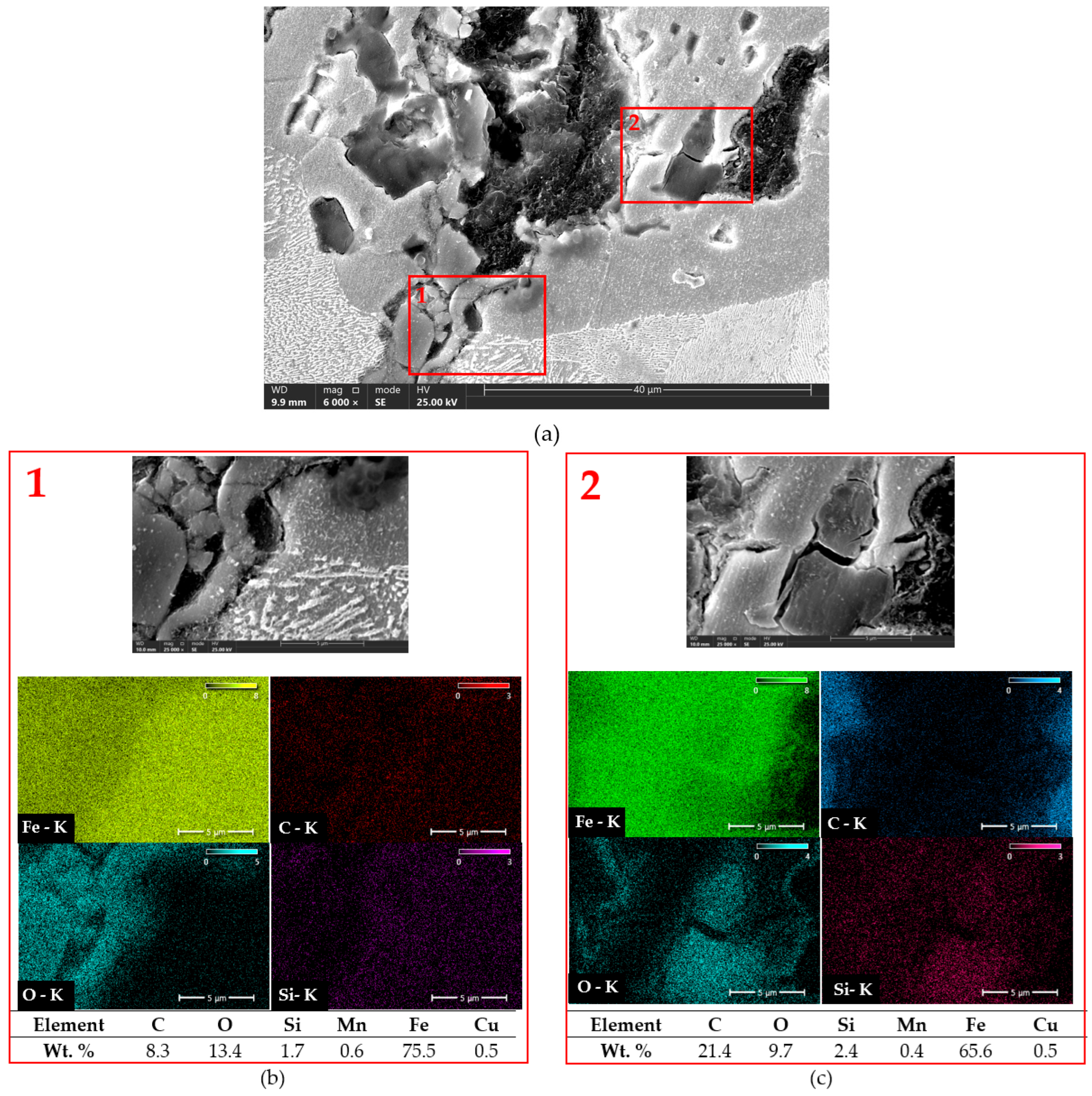

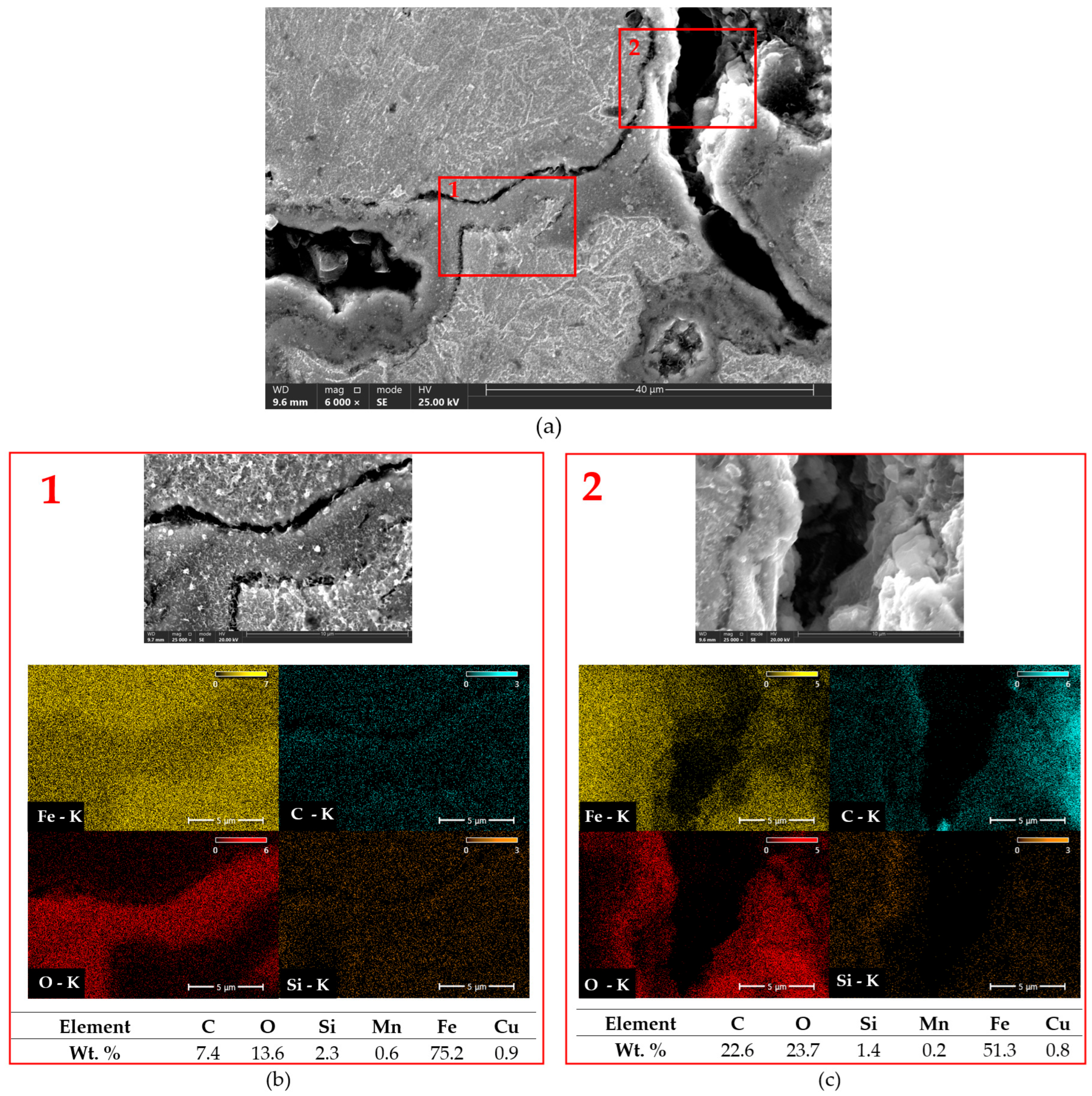

3.1. Microstructure Analysis

3.2. Mechanical Properties

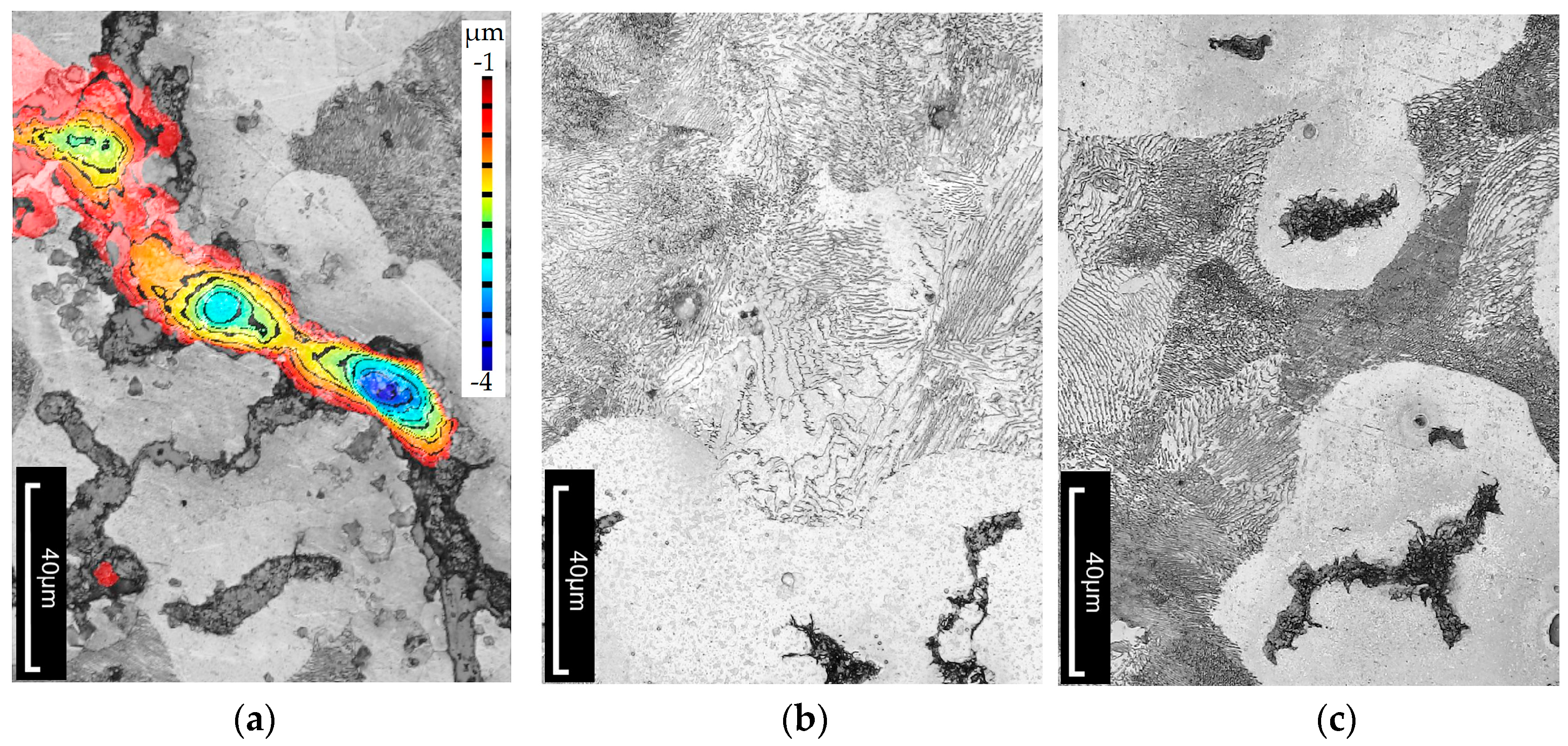

3.3. Thermal Shock Resistance

- In the as-cast condition—25,676 µm;

- After heat treatment at Tpi = 390 °C (Variant 1)—21,740 µm;

- After heat treatment at Tpi = 290 °C (Variant 2)—15,628 µm.

4. Conclusions

- Samples subjected to austempering at 390 °C exhibited a higher content of retained austenite (approximately 38%) compared to samples austempered at 290 °C (approximately 24%).

- Samples austempered at 290 °C are characterized by a higher carbon content in the ausferrite compared to the samples from variant no. 1 (austempered at 390 °C), which may be the reason for higher thermal stability and mechanical strength of this microstructure.

- The applied heat treatment of vermicular cast iron resulted in an increase in tensile strength, yield strength, and hardness, accompanied by a decrease in elongation. Samples austempered at 290 °C exhibited the most significant changes in mechanical properties compared to the as-cast condition. It should be emphasized that these samples also demonstrated the highest resistance to thermal shocks.

- After conducting the experiment and analyzing the effect of thermal shocks on microstructural changes, it can be stated that in vermicular cast iron in the as-cast state, no significant structural changes were observed. In the case of CGI, a transformation of the matrix from ausferritic to a ferritic matrix with carbides was noted. In the sample austempered at 390 °C, ferrite occupies approximately 20% of the matrix, while the remaining part is composed of the untransformed ausferritic matrix. In the sample austempered at 290 °C, the matrix is composed of approximately 90% ferrite and 10% untransformed microstructure.

- It can be concluded that a high austenite content reduces the material’s resistance to rapid and variable temperature fluctuations.

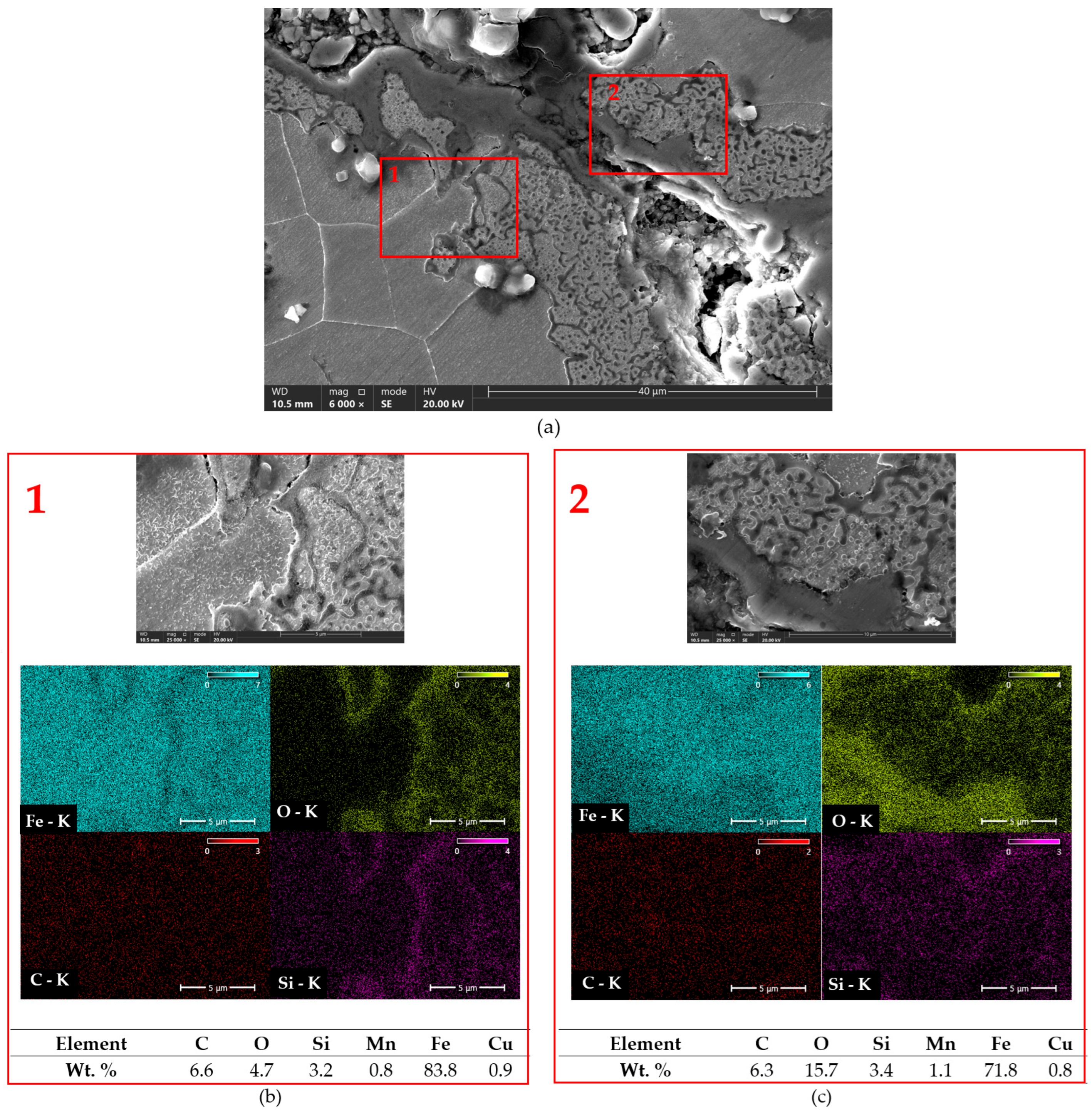

- Thermal shock exposure resulted in surface oxidation of the material, particularly along cracks and graphite regions. This led to increased high-temperature corrosion of the compacted graphite iron after austempering, compared to the as-cast condition.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mróz, M.; Orłowicz, A.W.; Tupaj, M.; Jacek-Burek, M.; Radoń, M.; Kawiński, M. The Effect of Structure on Thermal Power of Cast-Iron Heat Exchangers. Arch. Foundry Eng. 2020, 20, 27–30. [Google Scholar] [CrossRef]

- Zhu, J.; Liu, Q.; Jiang, A.; Lian, X.; Fang, D.; Dong, H. The Effect of Cu on the Morphology and Growth Mode of Graphite in Compacted Graphite Iron. Trans. Indian Inst. Met. 2021, 74, 1529–1536. [Google Scholar] [CrossRef]

- Jakubus, A.; Kostrzewa, J.; Ociepa, E. The Influence of Heat Treatment Parameters on the Microstructure and Mechanical Properties of ADI and AVGI Irons. In Proceedings of the 30th Anniversary International Conference on Metallurgy and Materials, Brno, Czech Republic, 26–28 May 2021. [Google Scholar]

- Klimek, L.; Gumienny, G.; Januszewicz, B.; Atraszkiewicz, R.; Buczkowska, K. Structural and Phase Analysis of the Ausferritic Ductile Cast Iron Matrix Obtained by Heat Treatment and in the Raw State. C 2024, 10, 45. [Google Scholar] [CrossRef]

- Soiński, M.S.; Jakubus, A.; Borowiecki, B.; Mierzwa, P. Initial Assessment of Graphite Precipitates in Vermicular Cast Iron in the As-Cast State and after Thermal Treatments. Arch. Foundry Eng. 2021, 20, 131–136. [Google Scholar] [CrossRef]

- Darmawan, A.S.; Anggono, A.D.; Yulianto, A.; Febriantoko, B.W.; Hamid, A. Effect of Austempering Holding Time Variations of 30, 60, and 90 Minutes at 300 °C on the Microstructure and Toughness of Nodular Cast Iron. J. Phys. Conf. Ser. 2024, 2739, 012029. [Google Scholar] [CrossRef]

- Mrzygłód, B.; Kowalski, A.; Olejarczyk-Wożenska, I.; Giętka, T.; Głowacki, M. Characteristics of ADI Ductile Cast Iron with a Single Addition of 1.56% Ni. Arch. Metall. Mater. 2017, 4, 2273–2280. [Google Scholar] [CrossRef]

- Jaśkowiec, K.; Opaliński, A.; Kustra, P.; Jach, D.; Wilk-Kołodziejczyk, D. Prediction of Selected Mechanical Properties in Austempered Ductile Iron with Different Wall Thickness by Decision Support Systems. Arch. Foundry Eng. 2023, 23, 137–144. [Google Scholar] [CrossRef]

- Rodríguez-Rosales, N.A.; Montes-González, F.A.; Gómez-Casas, O.; Gómez-Casas, J.; Galindo-Valdés, J.S.; Ortiz-Cuellar, J.C.; Martínez-Villafañe, J.F.; García-Navarro, D.; Muñiz-Valdez, C.R. Statistical Data-Driven Model for Hardness Prediction in Austempered Ductile Irons. Metals 2022, 12, 676. [Google Scholar] [CrossRef]

- Jakubus, A.; Soiński, M.S.; Mierzwa, P.; Stradomski, G. Regression Analysis and Optimum Values of Austempering Affecting Mechanical Properties of Compacted Graphite Iron. Materials 2024, 17, 5024. [Google Scholar] [CrossRef]

- Akinribide, O.J.; Olusunle, S.O.O.; Akinwamide, S.O.; Babalola, B.J.; Olubambi, P.A. Impact of Heat Treatment on Mechanical and Tribological Behaviour of Unalloyed and Alloyed Ductile Iron. J. Mater. Res. Technol. 2021, 14, 1809–1819. [Google Scholar] [CrossRef]

- Liu, L.; Zhao, K.; Zhang, H.; Tang, C.; Han, Q.; Chen, J.; Tao, D.; Yang, Z. Surface Evolution of Vermicular Cast Iron in High Frequent Cyclic Plasma and Different Facial Cooling Airflows. Metals 2023, 13, 577. [Google Scholar] [CrossRef]

- Zhang, M.X.; Pang, J.C.; Meng, L.J.; Li, S.X.; Liu, Q.Y.; Jiang, A.L.; Zhang, Z.F. Study on Thermal Fatigue Behaviors of Two Kinds of Vermicular Graphite Cast Irons. Mater. Sci. Eng. A 2021, 814, 141212. [Google Scholar] [CrossRef]

- Stradomski, G.; Gzik, S.; Jakubus, A.; Nadolski, M. Assessment of Resistance to Thermal Fatigue and Thermal Shock of Cast Iron Used for Glass Moulds. Arch. Foundry Eng. 2018, 18, 173–178. [Google Scholar] [CrossRef]

- Zycha, J.; Żyrek, A. Vermicular Cast Iron Production Using Inmold Technology and Evaluation of Thermal Fatigue Resistance. Arch. Foundry Eng. 2011, 11, 255–260. [Google Scholar]

- Żyrek, A. Production of Vermicular Cast Iron by the Inmold Method Using Magnesium Alloys and Evaluation of Its Thermal Fatigue Resistance. Ph.D. Thesis, AGH University of Science and Technology, Kraków, Poland, 2014. [Google Scholar]

- Jakubus, A.; Soiński, M.S. Thermal Shock Resistance of Cast Iron with Various Graphite Precipitate Shapes. Arch. Foundry Eng. 2018, 18, 121–124. [Google Scholar] [CrossRef]

- Soiński, M.S.; Jakubus, A. Initial Assessment of Abrasive Wear Resistance of Austempered Cast Iron with Vermicular Graphite. Arch. Metall. Mater. 2014, 59, 1073–1076. [Google Scholar] [CrossRef]

- Kaczorowski, M. Structure and Mechanical Properties of ADI Cast Iron. Arch. Foundry Eng. 2001, 1, 149–158. [Google Scholar]

- Myszka, D.; Kaczorowski, M.; Tybulczuk, J.; Kowalski, A. ADI Cast Iron Production Parameters and Their Influence on Mechanical Properties. Arch. Foundry Eng. 2004, 4, 355–364. [Google Scholar]

- Binczyk, F.; Gradoń, P. Influence of Heat Treatment Parameters on the Microstructure Formation in ADI Iron. IMŻ Works 2010, 4, 5–14. [Google Scholar]

- Pietrowski, S. Spheroidal Cast Iron with Ferritic-Bainitic Matrix Containing Austenite or Bainite. Arch. Mater. Sci. 1997, 18, 253–273. [Google Scholar]

- Borowski, A.W. Synthetic Spheroidal Cast Iron Subjected to Isothermal Heat Treatment (ADI). In Proceedings of the 23rd Scientific-Technical Symposium of the Foundry Department ITMat, Warsaw University of Technology, Warszawa, Poland, 1998; p. 29. [Google Scholar]

- Mierzwa, P. Influence of Heat Treatment on Selected Properties of Compacted Graphite Iron. Ph.D. Thesis, Czestochowa University of Technology, Częstochowa, Poland, 2010. [Google Scholar]

- PN-EN 16079:2012; Foundry—Cast Iron with Compacted (Vermicular) Graphite. European Committee for Standardization: Brussels, Belgium, 2012.

- PN-EN ISO 945-1:2009; Microstructure of Cast Irons—Part 1: Graphite Classification by Visual Analysis. Correction: PN-EN ISO 945-1:2009/AC; Polish Committee for Standardization: Warsaw, Poland, 2010.

- PN-75/H-04661; Grey, Ductile, and Malleable Cast Irons—Metallographic Examination—Microstructure Determination. Polish Committee for Standardization: Warsaw, Poland, 2013.

- Jakubus, A.; Soiński, M.S. The Influence of the Shape of Graphite Precipitates on the Cast Iron Abrasion Resistance. Arch. Foundry Eng. 2019, 19, 87–90. [Google Scholar] [CrossRef]

- Stradomski, G.; Krupop, M.; Jakubus, A.; Nadolski, M. Thermal Shock Resistance of 21CrMoV5-7 Steel. In Proceedings of the 27th International Conference on Metallurgy and Materials, Brno, Czech Republic, 23–25 May 2018; pp. 873–878. [Google Scholar]

- Ramos, P.A.; Melo, I.N.R.; Medeiros, V.H.M.; Brito, P.P. Influence of Heat Treatment Time on Microstructure Evolution of Austempered Nodular Cast Iron Evaluated by Image Segmentation. J. Alloys Metall. Syst. 2024, 8, 100135. [Google Scholar] [CrossRef]

- Krawiec, H.; Lelito, J.; Mróz, M.; Radoń, M. Influence of Heat Treatment Parameters of Austempered Ductile Iron on Microstructure, Corrosion and Tribological Properties. Materials 2023, 16, 4107. [Google Scholar] [CrossRef] [PubMed]

- PN-EN 16079:2024-06; Foundry Technology—Compacted (Vermicular) Graphite Cast Irons. Polish Committee for Standardization: Warsaw, Poland, 2024.

- PN-EN ISO 6506-1:2014-12; Metallic Materials—Brinell Hardness Test—Part 1: Test Method. Polish Committee for Standardization: Warsaw, Poland, 2014.

- Wang, X.; Zhang, W. Oxidation and Thermal Cracking Behavior of Compacted Graphite Iron under High Temperature and Thermal Shock. Oxid. Met. 2017, 87, 179–188. [Google Scholar] [CrossRef]

- Zou, C.L.; Pang, J.C.; Zhang, M.X.; Qiu, Y.; Li, S.X.; Chen, L.J.; Li, J.P.; Yang, Z.; Zhang, Z.F. The High Cycle Fatigue, Deformation and Fracture of Compacted Graphite Iron: Influence of Temperature. Mater. Sci. Eng. A 2018, 724, 606–615. [Google Scholar] [CrossRef]

- Shi, G.Q.; Yang, Z.; Guo, M.; Tao, D.; Sun, S.; Li, J.P.; Yan, F.H. Investigation on Thermal Fatigue and Microstructure Evolution Mechanism of Graphite Iron at Elevated Temperature. J. Mater. Eng. Perform. 2022, 31, 2593–2605. [Google Scholar] [CrossRef]

- Górny, M.; Krawczyk, J.; Zieliński, A. Stability and Transformations of Retained Austenite in Ductile and Vermicular Austempered Cast Irons. Arch. Metall. Mater. 2015, 60, 3067–3072. [Google Scholar] [CrossRef][Green Version]

- Esteban, H.R.W.; Torralba, J.M. An Analysis of Retained Austenite in Austempered Ductile Iron. Metall. Mater. Trans. A 2003, 34, 1687–1696. [Google Scholar] [CrossRef]

- Saal, D.; Górny, M.; Krawczyk, J. Phase Transition Kinetics in Austempered Ductile Iron (ADI) with Regard to Mo Content. Materials 2020, 13, 5266. [Google Scholar] [CrossRef]

- Górny, M.; Krawczyk, J.; Zieliński, A. Effect of Austenitizing Temperature and Austempering Time on the Microstructure and Mechanical Properties of Austempered Ductile Iron. Arch. Foundry Eng. 2016, 16, 79–84. [Google Scholar] [CrossRef][Green Version]

- Yilmaz, R.; Bayata, F.; Solak, N. High Temperature Oxidation Behavior of High Al-Si Alloyed Vermicular Graphite Cast Iron for Internal Combustion Engine’s Hot-End Exhaust Components. Metals 2024, 14, 574. [Google Scholar] [CrossRef]

- Guo, Q.; Yang, Z.; Guo, D.; Tao, D.; Guo, Y.; Li, J.; Bai, Y. Research on the Oxidation Mechanism of Vermicular Graphite Cast Iron. Materials 2019, 12, 3130. [Google Scholar] [CrossRef] [PubMed]

- Kowalski, M. Effect of Mo Addition on the Chemical Corrosion Process of SiMo Cast Iron. Materials 2020, 13, 1745. [Google Scholar] [CrossRef] [PubMed]

| C | Si | Mn | Cu | P | S | Mg |

|---|---|---|---|---|---|---|

| 3.22 | 2.38 | 0.192 | 1.02 | 0.054 | 0.022 | 0.0271 |

| Designation of Heat Treatment Variants | Austenitization Temperature Tγ [°C] | Austenitization Time τγ [min] | Austempering Temperature Tpi [°C] | Austempering Time τpi [min] |

|---|---|---|---|---|

| Variant 1 | 960 | 90 | 390 | 90 |

| Variant 2 | 960 | 290 |

| Heat Treatment Variant of Cast Iron and Analyzed Structural Constituents | Fraction (%) | |||||

|---|---|---|---|---|---|---|

| C, % | Si, % | Fe, % | Cu, % | |||

| Variant 1 | Content in ausferrite—Figure 7a | 1 | 2.98 | 2.85 | 93.32 | 0.85 |

| 2 | 3.75 | 2.58 | 92.85 | 0.82 | ||

| 3 | 2.78 | 2.61 | 93.84 | 0.77 | ||

| 4 | 2.61 | 2.65 | 93.90 | 0.84 | ||

| Average: | 3.03 | 2.67 | 93.48 | 0.82 | ||

| Content in austenite—Figure 7b | 1 | 3.87 | 2.92 | 92.22 | 0.99 | |

| 2 | 3.65 | 2.81 | 92.46 | 1.08 | ||

| 3 | 3.56 | 2.88 | 92.33 | 1.22 | ||

| 4 | 3.63 | 2.94 | 92.27 | 1.16 | ||

| 5 | 4.64 | 2.84 | 91.58 | 0.94 | ||

| 6 | 3.29 | 2.89 | 92.85 | 0.97 | ||

| Average: | 3.77 | 2.88 | 92.29 | 1.06 | ||

| Variant 2 | Content in ausferrite—Figure 8a | 1 | 6.07 | 2.75 | 90.11 | 1.07 |

| 2 | 6.08 | 2.61 | 90.25 | 1.06 | ||

| 3 | 4.85 | 2.82 | 91.25 | 1.07 | ||

| 4 | 4.96 | 2.73 | 91.28 | 1.03 | ||

| 5 | 6.07 | 2.62 | 90.34 | 0.97 | ||

| Average: | 5.61 | 2.71 | 90.65 | 1.04 | ||

| Content in austenite—Figure 8b | 1 | 4.49 | 2.46 | 92.32 | 0.73 | |

| 2 | 4.15 | 2.73 | 92.17 | 0.96 | ||

| 3 | 4.54 | 2.52 | 91.89 | 0.79 | ||

| 4 | 5.04 | 2.55 | 91.39 | 0.78 | ||

| 5 | 4.61 | 2.66 | 92.07 | 0.66 | ||

| 6 | 3.69 | 2.46 | 93.10 | 0.56 | ||

| 7 | 3.80 | 2.23 | 93.20 | 0.51 | ||

| Average: | 4.33 | 2.52 | 92.31 | 0.71 | ||

| Tensile Strength Rm [MPa] | Yield Strength Rp [MPa] | Elongation A5 [%] | Hardness HB [MPa] |

|---|---|---|---|

| Compacted graphite cast iron (as-cast) | |||

| 371 | 331 | 2.1 | 183 |

| Austempered compacted graphite cast iron at 390 °C | |||

| 623 | 485 | 1.6 | 260 |

| Austempered compacted graphite cast iron at 290 °C | |||

| 824 | 584 | 0.7 | 334 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jakubus, A.; Soiński, M.S.; Stradomski, G.; Nadolski, M.; Mróz, M. The Effect of Austempering Temperature on the Matrix Morphology and Thermal Shock Resistance of Compacted Graphite Cast Iron. Materials 2025, 18, 2200. https://doi.org/10.3390/ma18102200

Jakubus A, Soiński MS, Stradomski G, Nadolski M, Mróz M. The Effect of Austempering Temperature on the Matrix Morphology and Thermal Shock Resistance of Compacted Graphite Cast Iron. Materials. 2025; 18(10):2200. https://doi.org/10.3390/ma18102200

Chicago/Turabian StyleJakubus, Aneta, Marek Sławomir Soiński, Grzegorz Stradomski, Maciej Nadolski, and Marek Mróz. 2025. "The Effect of Austempering Temperature on the Matrix Morphology and Thermal Shock Resistance of Compacted Graphite Cast Iron" Materials 18, no. 10: 2200. https://doi.org/10.3390/ma18102200

APA StyleJakubus, A., Soiński, M. S., Stradomski, G., Nadolski, M., & Mróz, M. (2025). The Effect of Austempering Temperature on the Matrix Morphology and Thermal Shock Resistance of Compacted Graphite Cast Iron. Materials, 18(10), 2200. https://doi.org/10.3390/ma18102200