Research on the Interlayer Bonding and Temperature Control Optimization of Asphalt Concrete Core Wall

Abstract

1. Introduction

2. Test Raw Materials and Mix Proportions

3. Test Program

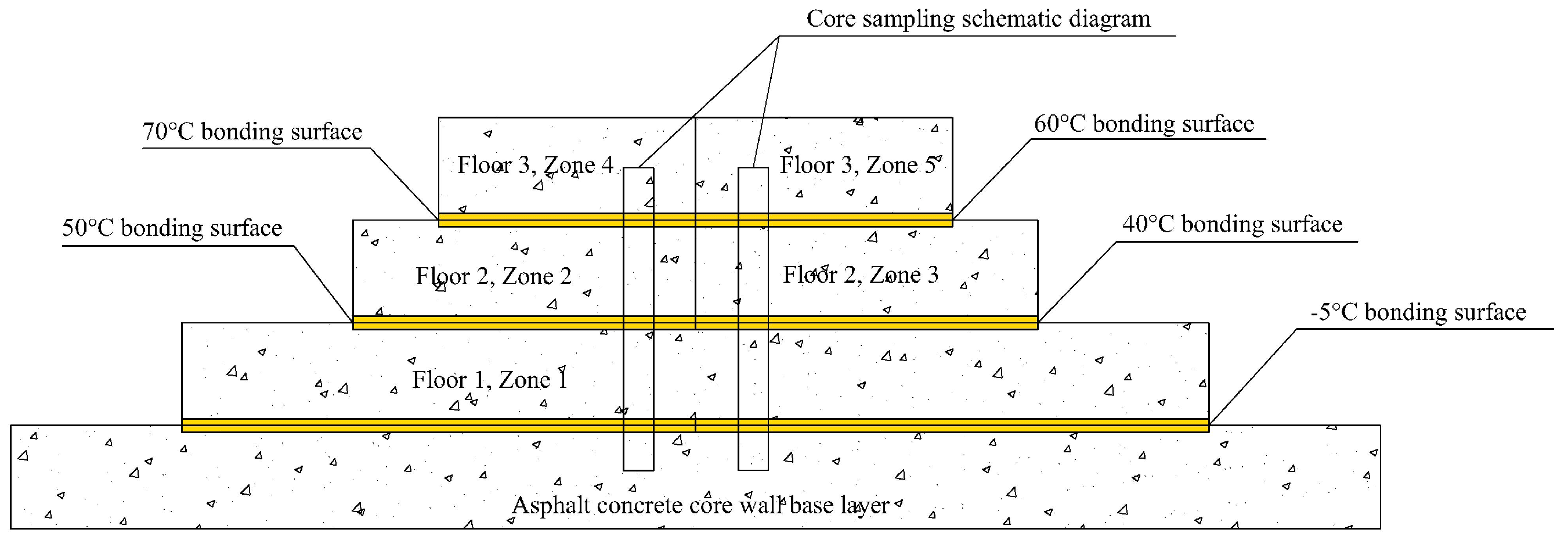

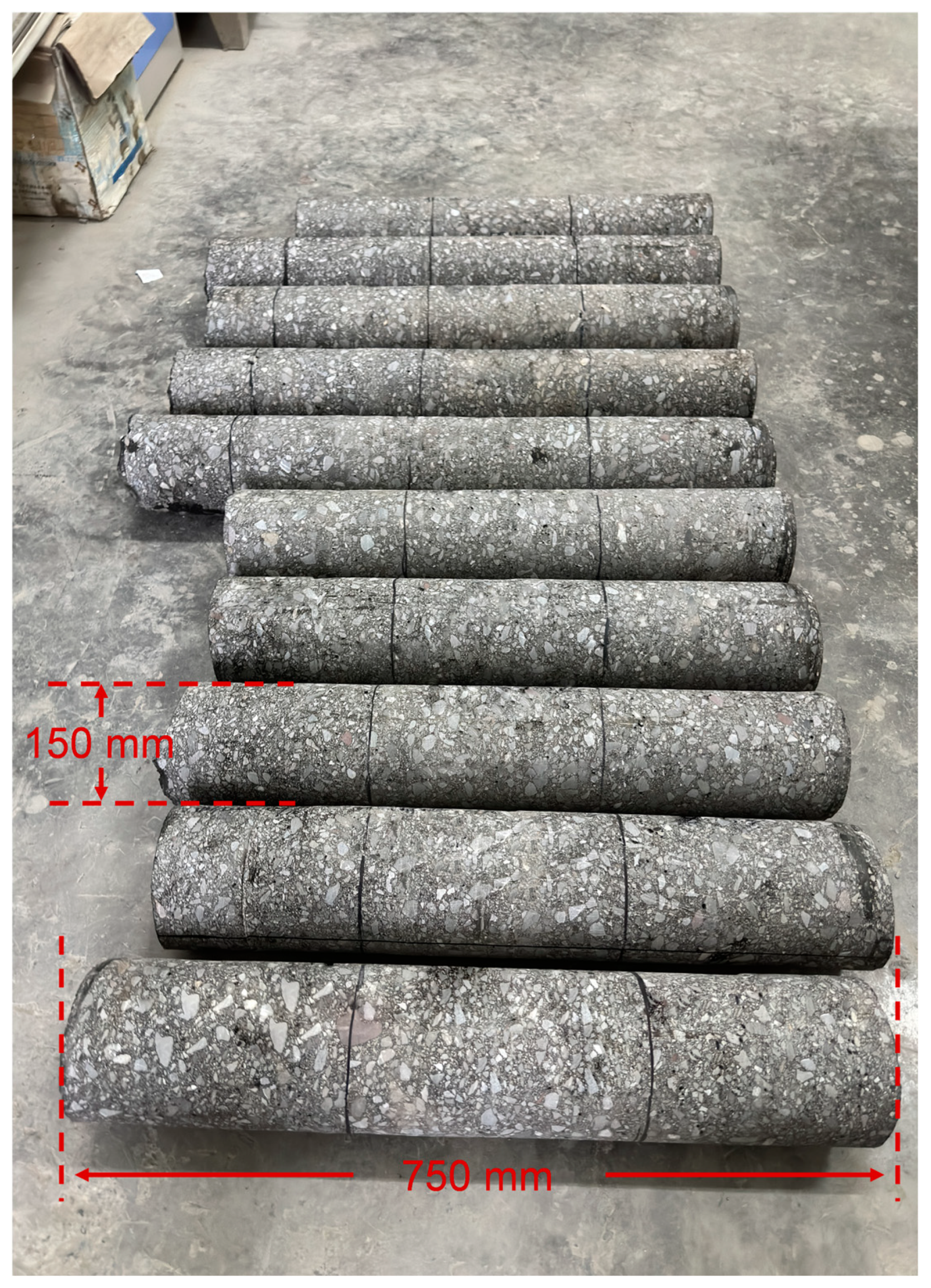

3.1. Interface Temperature Monitoring Test

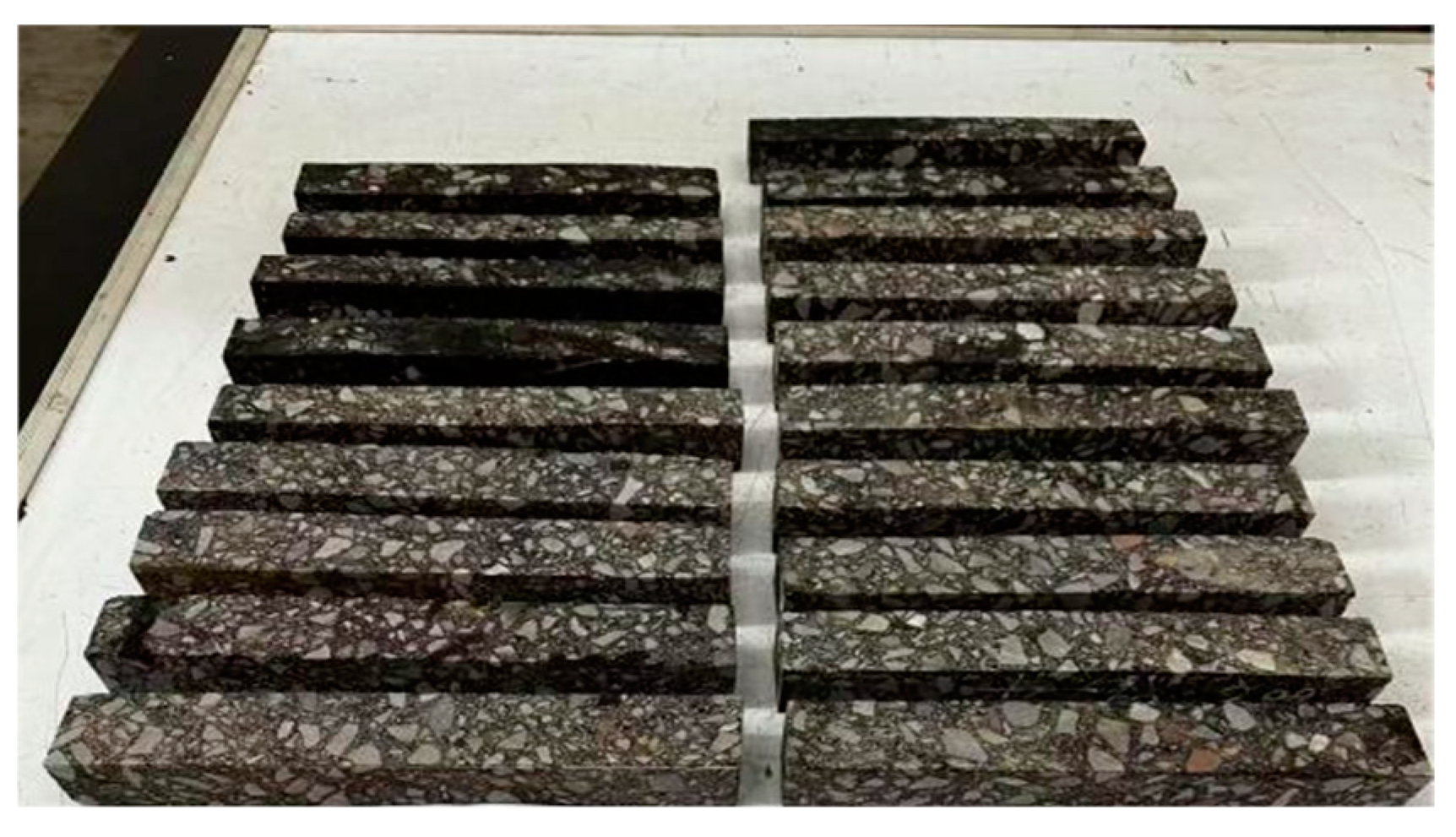

3.2. Physical and Mechanical Property Test

4. Test Results and Analysis

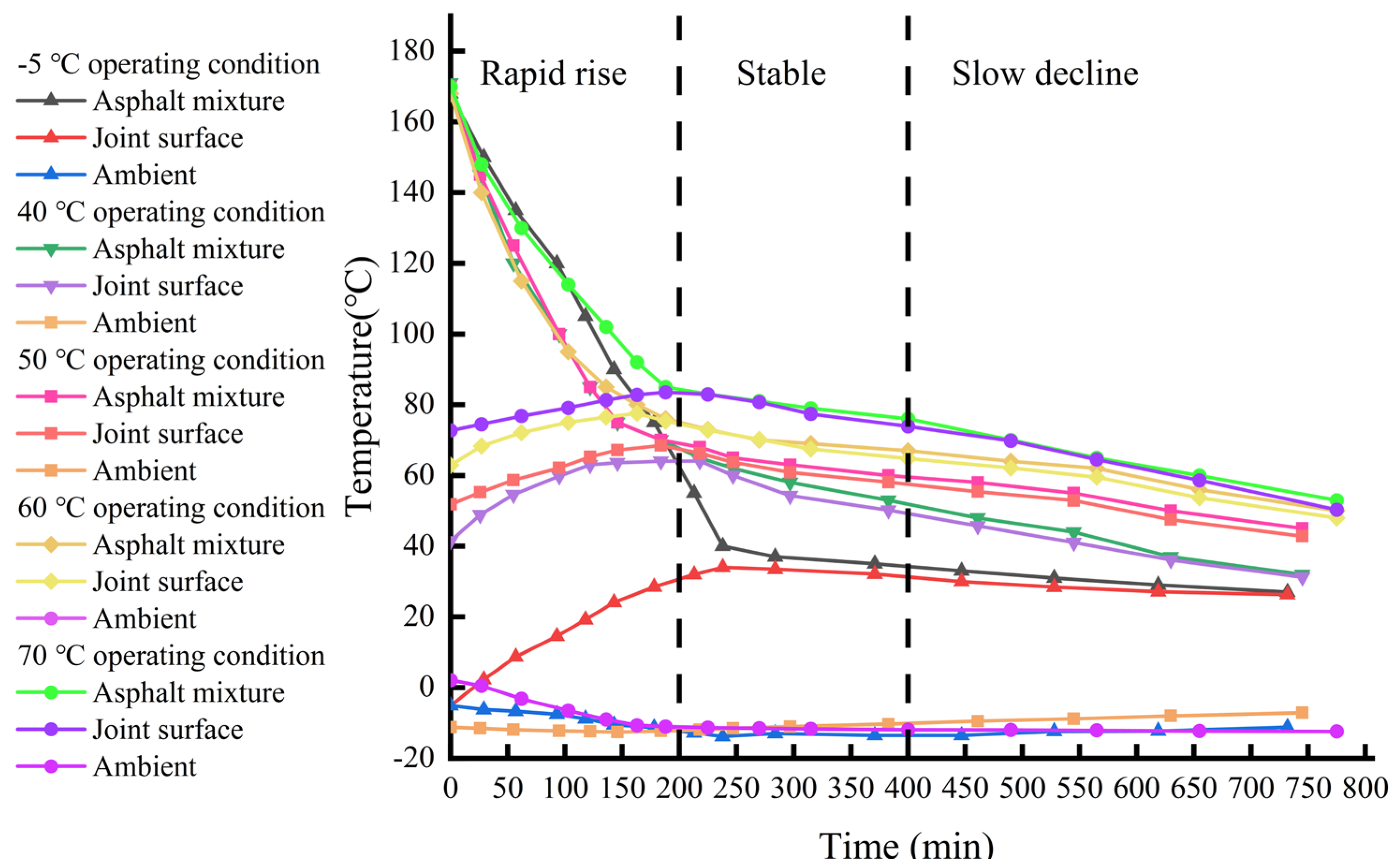

4.1. Temperature Monitoring Results and Analysis

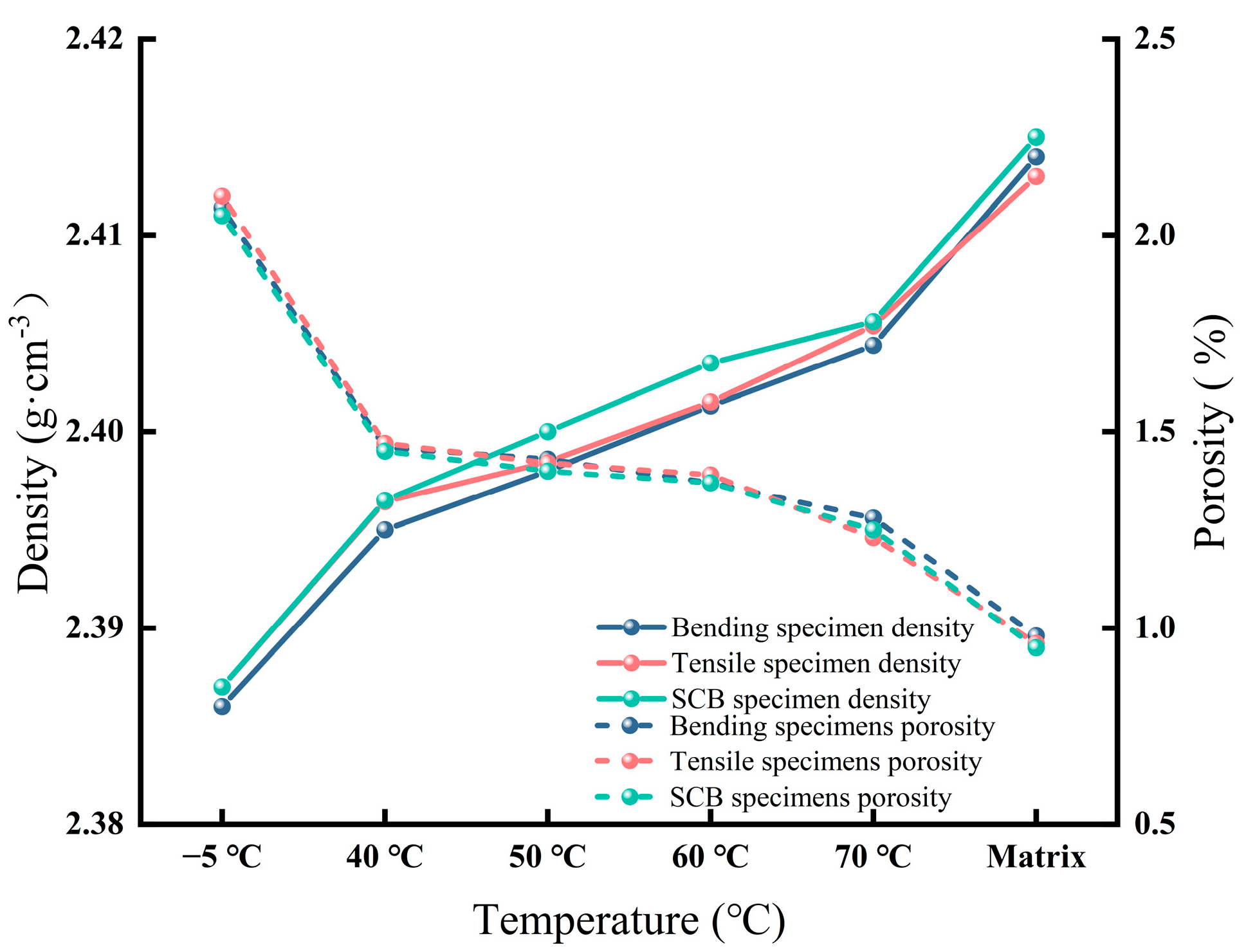

4.2. Changes in Density and Porosity

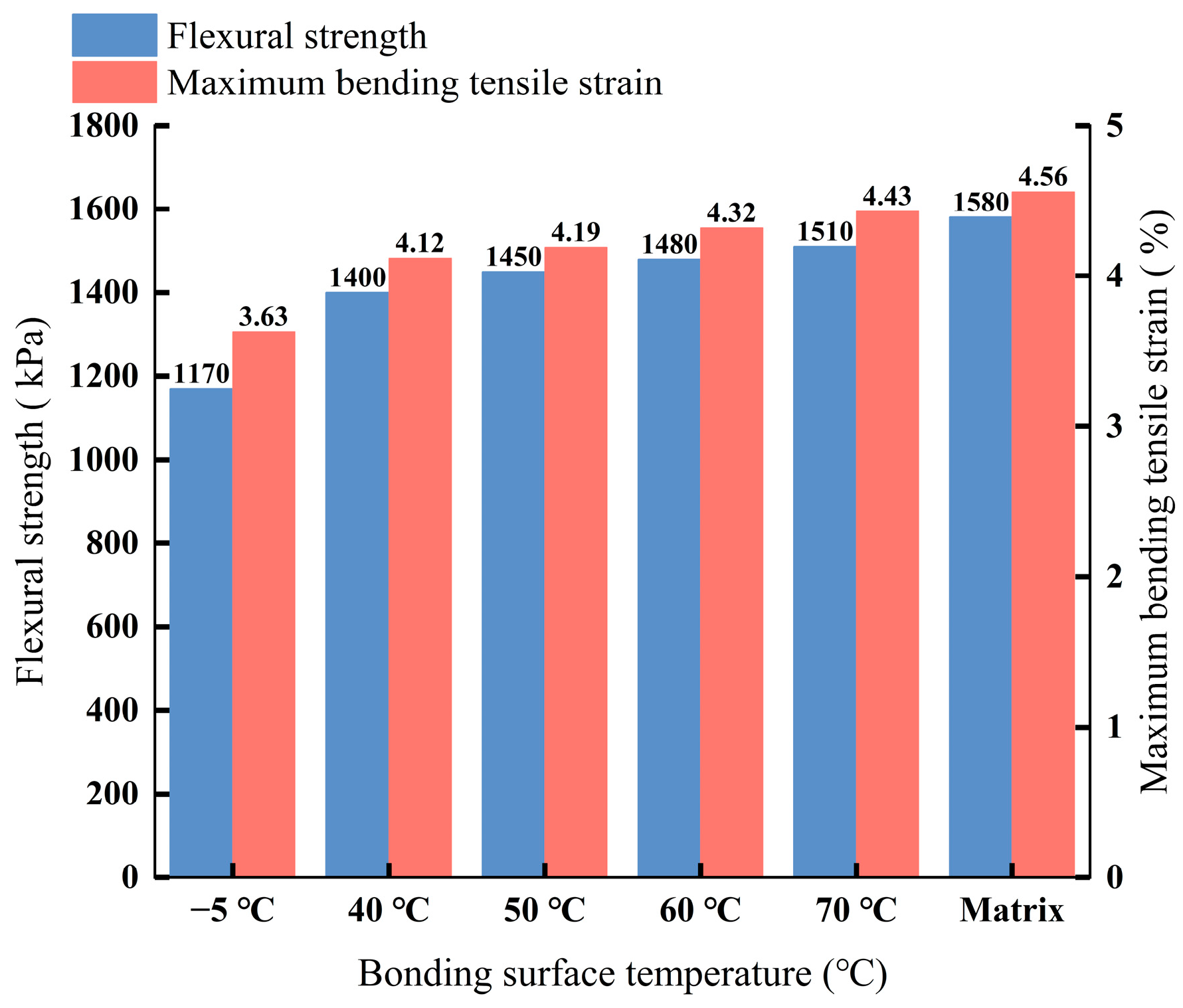

4.3. Beam Bending Test Results and Analysis

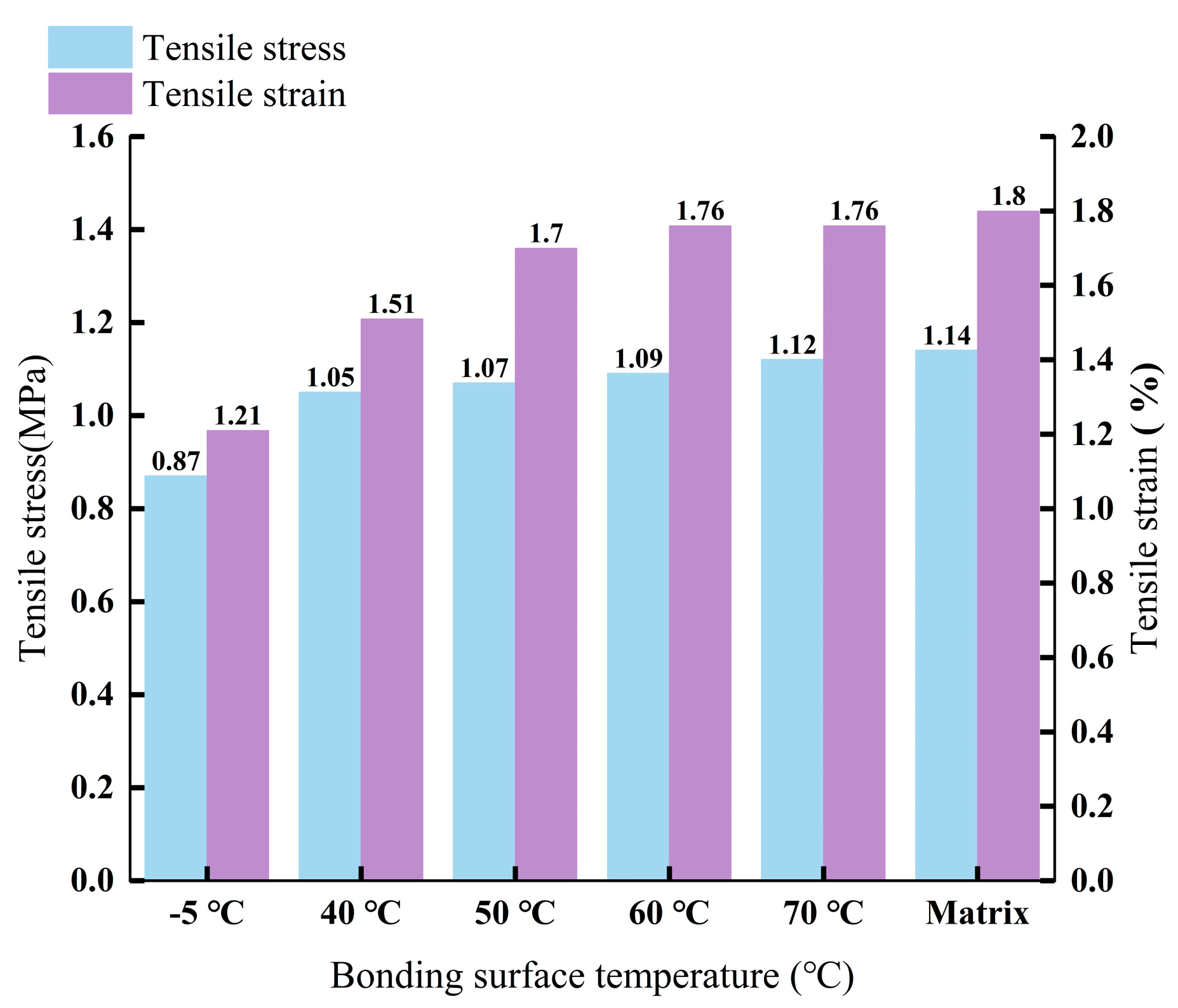

4.4. Tensile Test Results and Analysis

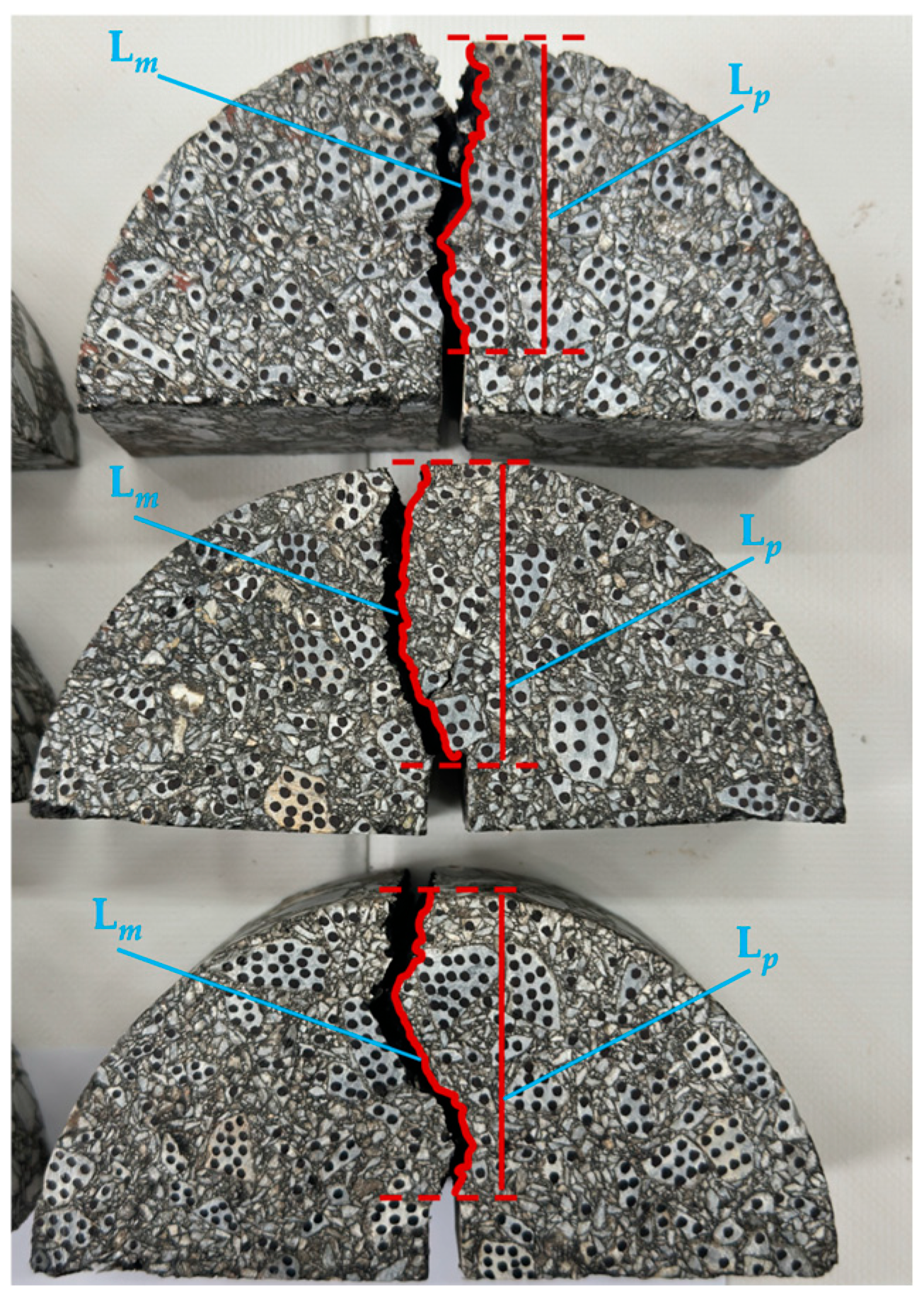

4.5. SCB Test Results and Analysis

5. Conclusions

- (1)

- Through precise temperature field monitoring of asphalt concrete core layers, a three-stage evolution pattern was observed in the interlayer temperature transfer, demonstrating dynamic characteristics of rapid rise–stability–slow decline. The first 200 min represents the critical period for the rapid temperature rise. Specifically, when the temperature of the underlying core layer exceeds 40 °C, the interface exhibits a temperature self-adaptive capacity, maintaining stable thermal transfer despite ambient fluctuations. These findings provide technical support for temperature regulation during asphalt concrete core wall construction.

- (2)

- System experiments indicate that 40 °C is the critical performance threshold temperature between layers of asphalt concrete core walls. When the temperature drops to this value, the asphalt concrete exhibits a unique performance compensation effect. Despite the decline in various mechanical indicators, the material can still maintain stable engineering performance through internal structural reorganization. This finding overturns the traditional view that when continuous paving of asphalt concrete core walls is performed, a drop in interface temperature to 40 °C will inevitably lead to a decline in core wall performance.

- (3)

- Based on multi-dimensional experimental validation (11.39% reduction in flexural strength, 9.65% reduction in maximum bending strain, 7.89% reduction in tensile strength, 16.11% reduction in critical tensile strain, and 10.06% reduction in crack curvature coefficient), an interface temperature control evaluation system was established with 40 °C as the benchmark, reducing the traditional 70 °C temperature control standard by 30 °C. This not only significantly improves construction efficiency but also provides a new technical approach for hydraulic engineering construction in cold regions, achieving an important shift from empirical to mechanistic temperature control standards.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yan, X.H.; Yao, X.H.; Wang, X.J.; Yang, H.Q. Experimental study on the ratio of asphalt concrete core wall material for earth and stone dam. J. Changjiang Acad. Sci. 2017, 34, 143–148. [Google Scholar]

- Zhang, B.Y.; Li, Q.M.; Xiong, Y.; Gao, L.S. Stress and deformation analysis of asphalt-concrete heartwall rockfill dam at Maoping Creek in Three Gorges. J. Changjiang Acad. Sci. 2004, 2, 18–21. [Google Scholar]

- Ci, R.Y.D.; Wang, L.J.; Zhaxi, D.Z.; Mao, H.Y.; Li, R.P. Experimental study on the effect of temperature on the strength and shear expansion characteristics of hydraulic asphalt concrete. J. Changjiang Acad. Sci. 2024, 41, 190–195. [Google Scholar]

- Li, H.; He, J.; Zhong, S.; Liu, L.; Yang, W. Experimental study on key techniques for the construction of high asphalt concrete core rockfill dam under unfavorable geological conditions. Buildings 2024, 14, 1968. [Google Scholar] [CrossRef]

- Remišová, E.; Decký, M.; Podolka, L.; Kováč, M.; Vondráčková, T.; Bartuška, L. Frost index from aspect of design of pavement construction in Slovakia. Procedia Earth Planet. Sci. 2015, 15, 3–10. [Google Scholar] [CrossRef]

- Li, J.; Liu, Y.; He, J.X.; Peng, Z.X.; Yang, Y.S. Key technology and application of high asphalt concrete heart wall dam construction in Xinjiang. Water Resour. Hydropower Eng. 2021, 52, 85–97. [Google Scholar] [CrossRef]

- Wang, W.; Hu, K.; Feng, S.; Li, G.; Höeg, K. Shear behavior of hydraulic asphalt concrete at different temperatures and strain rates. Constr. Build. Mater. 2020, 230, 117022. [Google Scholar] [CrossRef]

- Ning, Z.; Liu, Y.; Wang, W. Compressive behavior of hydraulic asphalt concrete under different temperatures and strain rates. J. Mater. Civ. Eng. 2021, 33, 04021013. [Google Scholar] [CrossRef]

- Tao, H.; Fischer, T.; Su, B.; Mao, W.; Jiang, T.; Fraedrich, K. Observed changes in maximum and minimum temperatures in Xinjiang autonomous region, China. Int. J. Climatol. 2017, 37, 5120–5128. [Google Scholar] [CrossRef]

- DL/T 5363-2006; Construction Specification for Hydraulic Milled Asphalt Concrete. China Gezhouba Water Conservancy and Hydroelectric Engineering Group Co.: Wuhan, China, 2006.

- Zhang, Y.Z.; Liu, W.X. Winter construction measures for milled asphalt concrete core wall of Topa Reservoir. Constr. Des. Eng. 2023, 13, 204–206. [Google Scholar] [CrossRef]

- Shao, Y.; Xu, G.A.; Zhu, R.; Luo, X.X. Seepage control treatment and seepage analysis of Daxigou asphalt core wall dam. J. Changjiang Acad. Sci. 2009, 26, 76–81. [Google Scholar]

- Kumlai, S.; Jitsangiam, P.; Pichayapan, P. The implications of increasing temperature due to climate change for asphalt concrete performance and pavement design. KSCE J. Civ. Eng. 2017, 21, 1222–1234. [Google Scholar] [CrossRef]

- Huang, B.; Li, G.; Mohammad, L.N. Analytical modeling and experimental study of tensile strength of asphalt concrete composite at low temperatures. Compos. Part B Eng. 2003, 34, 705–714. [Google Scholar] [CrossRef]

- Ahmed, M.U.; Rahman, A.S.M.A.; Islam, M.R.; Tarefder, R.A. Combined effect of asphalt concrete cross-anisotropy and temperature variation on pavement stress–strain under dynamic loading. Constr. Build. Mater. 2015, 93, 685–694. [Google Scholar] [CrossRef]

- Pirmohammad, S.; Momeni, R.; Khanghahi, S.H. Effect of SCB specimen size on mode I fracture parameters of asphalt concrete at low and intermediate temperatures. Theor. Appl. Fract. Mech. 2024, 130, 104314. [Google Scholar] [CrossRef]

- Yang, D.; Karimi, H.R.; Aliha, M.R.M. Comparison of Testing Method Effects on Cracking Resistance of Asphalt Concrete Mixtures. Appl. Sci. 2021, 11, 5094. [Google Scholar] [CrossRef]

- Son, S.; Said, I.M.; Al-Qadi, I.L. Fracture properties of asphalt concrete under various displacement conditions and temperatures. Constr. Build. Mater. 2019, 222, 332–341. [Google Scholar] [CrossRef]

- Kim, K.W.; El Hussein, M. Variation of fracture toughness of asphalt concrete under low temperatures. Constr. Build. Mater. 1997, 11, 403–411. [Google Scholar] [CrossRef]

- Saeidi, H.; Aghayan, I. Investigating the effects of aging and loading rate on low-temperature cracking resistance of core-based asphalt samples using semi-circular bending test. Constr. Build. Mater. 2016, 126, 682–690. [Google Scholar] [CrossRef]

- Wan, L.B.; Pei, C.Y.; Yang, H.G. Research on interlayer bond quality of asphalt concrete core wall under conventional temperature conditions. Water Resour. Hydropower Eng. 2011, 42, 62–68. [Google Scholar] [CrossRef]

- Hakimzadeh, S.; Kebede, N.A.; Buttlar, W.G.; Ahmed, S.; Exline, M. Development of fracture-energy based interface bond test for asphalt concrete. Road Mater. Pavement Des. 2012, 13, 76–87. [Google Scholar] [CrossRef]

- Zhu, X.C.; He, J.X.; Yang, H.H. Influence of temperature of core wall bond surface on strength of milled asphalt concrete. China Rural Water Hydropower 2014, 8, 138–141. [Google Scholar]

- Cai, Q. Research on the effect of improved construction measures on the interlayer bonding quality of asphalt concrete core wall. Water Resour. Hydropower Eng. 2017, 48, 89–99. [Google Scholar] [CrossRef]

- Han, Q.; Dong, H.; Zhang, Y.; Gao, T.; Song, G.; Wang, S. Effect of interlayer bonding temperature on the bending properties of asphalt concrete core wall. Materials 2023, 16, 4133. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.Y.; Wan, L.B.; Yang, G.Q.; He, C.Q. Experimental study on shear performance of milled asphalt concrete bond. J. Water Resour. Water Eng. 2014, 25, 57–60. [Google Scholar]

- He, J.X.; Lun, J.B.; Yang, W. Research on combining process of winterization level of milled asphalt concrete core wall. Water Resour. Hydropower Eng. 2016, 47, 48–51. [Google Scholar] [CrossRef]

- SL 501-2010; Design Specification for Asphalt Concrete Panels and Core Walls for Earth and Rock Dams. China Institute of Water Resources and Hydropower: Beijing, China, 2010.

- DL/T5362-2018; Test Code for Hydraulic Asphalt Concrete. China Three Gorges Project Corporation: Wuhan, China, 2018.

- Hassan, N.A.; Airey, G.D.; Hainin, M.R. Characterisation of micro-structural damage in asphalt mixtures using image analysis. Constr. Build. Mater. 2014, 54, 27–38. [Google Scholar] [CrossRef]

| Project | Normative Indicators | Actual Testing | ||

|---|---|---|---|---|

| coarse aggregate | Apparent density (g/cm3) | ≥2.6 | 2.7 | |

| Water absorption rate (%) | ≤2 | 0.2 | ||

| Mud content (%) | ≤0.5 | 0.2 | ||

| Durability (%) | ≤12 | 2.2 | ||

| Crushing rate (%) | ≤30 | 17.6 | ||

| Adhesion | ≥4 | Level 5 | ||

| fine aggregate | Apparent density (g/cm3) | ≥2.55 | 2.67 | |

| Water absorption rate (%) | ≤2 | 0.8 | ||

| Mud content (%) | ≤2 | 0.3 | ||

| Durability (%) | ≤15 | 1.7 | ||

| Water stability grade | ≥6 | Level 10 | ||

| mineral powder | Apparent density (g/cm3) | ≥2.5 | 2.6 | |

| Hydrophilic coefficient | ≤1 | 0.8 | ||

| Water content (%) | ≤0.5 | 0.1 | ||

| asphalt | Needle penetration 25 °C (0.1 mm) | 80~100 | 92 | |

| Softening point (°C) | 44~52 | 48.2 | ||

| Elongation 15 °C (cm) | ≥100 | >100 | ||

| Density 15 °C (g/cm3) | Actual testing | 0.997 | ||

| Wax content (%) | <2.2 | 1.8 | ||

| Solubility (%) | >99.5 | 99.9 | ||

| Flash point (°C) | ≥245 | 303 | ||

| After heating the film | Mass change (%) | ≤±0.8 | −0.05 | |

| Residual penetration (%) | ≥57 | 75 | ||

| Residual elongation (cm) | ≥75 | >100 | ||

| Temperature | Specimen 1 | Specimen 2 | Specimen 3 | Median | Range | CV | MRD |

|---|---|---|---|---|---|---|---|

| Matrix | 1.6343 | 1.5934 | 1.5368 | 1.593 | 0.098 | 3.1% | 6.1% |

| 70 °C | 1.5681 | 1.5018 | 1.4603 | 1.502 | 0.108 | 3.5% | 7.3% |

| 60 °C | 1.4956 | 1.4632 | 1.4548 | 1.464 | 0.041 | 1.5% | 2.8% |

| 50 °C | 1.5012 | 1.4524 | 1.4223 | 1.452 | 0.079 | 2.9% | 5.4% |

| 40 °C | 1.4488 | 1.4369 | 1.4012 | 1.437 | 0.048 | 1.7% | 3.3% |

| −5 °C | 1.3754 | 1.3725 | 1.1690 | 1.375 | 0.206 | 8.2% | 15.0% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, Z.; Yang, W.; Han, D.; Pan, D.; Yu, L.; Guo, T. Research on the Interlayer Bonding and Temperature Control Optimization of Asphalt Concrete Core Wall. Materials 2025, 18, 2199. https://doi.org/10.3390/ma18102199

Luo Z, Yang W, Han D, Pan D, Yu L, Guo T. Research on the Interlayer Bonding and Temperature Control Optimization of Asphalt Concrete Core Wall. Materials. 2025; 18(10):2199. https://doi.org/10.3390/ma18102199

Chicago/Turabian StyleLuo, Ziyang, Wu Yang, Deqiang Han, Deyou Pan, Lei Yu, and Tingpeng Guo. 2025. "Research on the Interlayer Bonding and Temperature Control Optimization of Asphalt Concrete Core Wall" Materials 18, no. 10: 2199. https://doi.org/10.3390/ma18102199

APA StyleLuo, Z., Yang, W., Han, D., Pan, D., Yu, L., & Guo, T. (2025). Research on the Interlayer Bonding and Temperature Control Optimization of Asphalt Concrete Core Wall. Materials, 18(10), 2199. https://doi.org/10.3390/ma18102199