Mechanical Performance Evaluation of Negative-Poisson’s-Ratio Honeycomb Helmets in Craniocerebral Injury Protection

Abstract

1. Introduction

2. Models and Methods

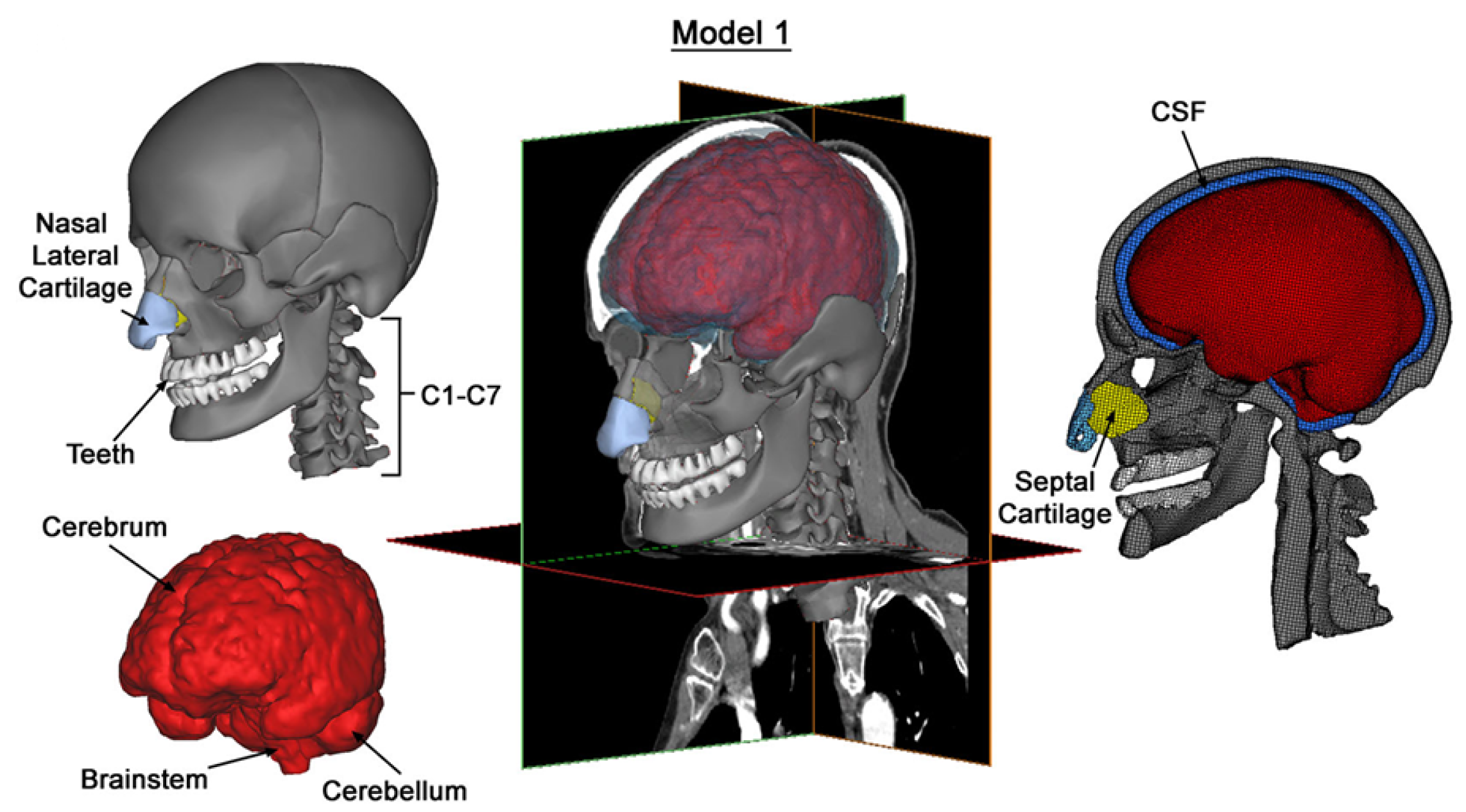

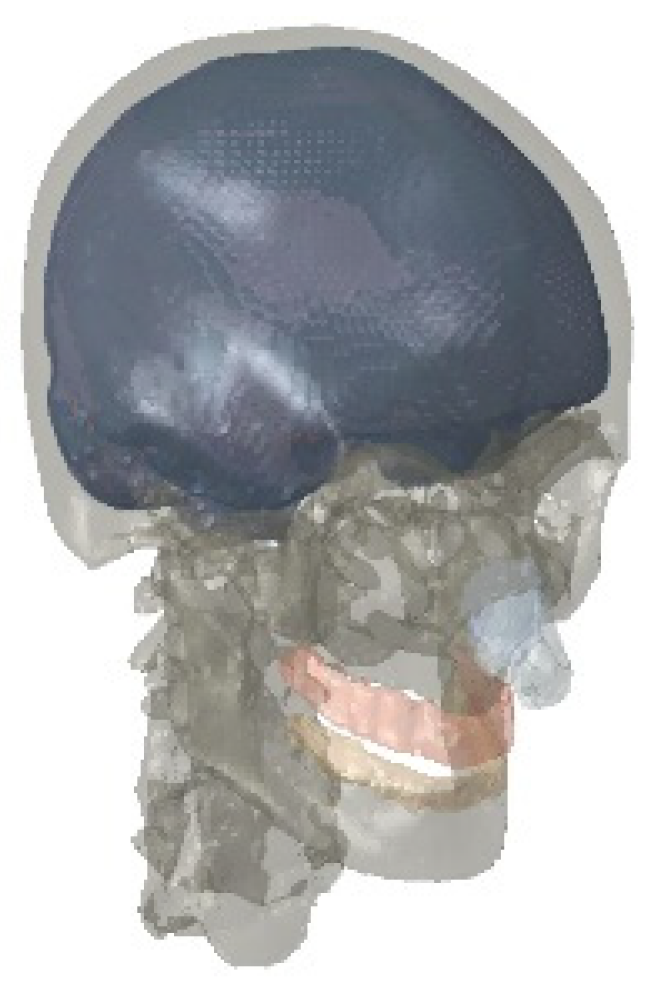

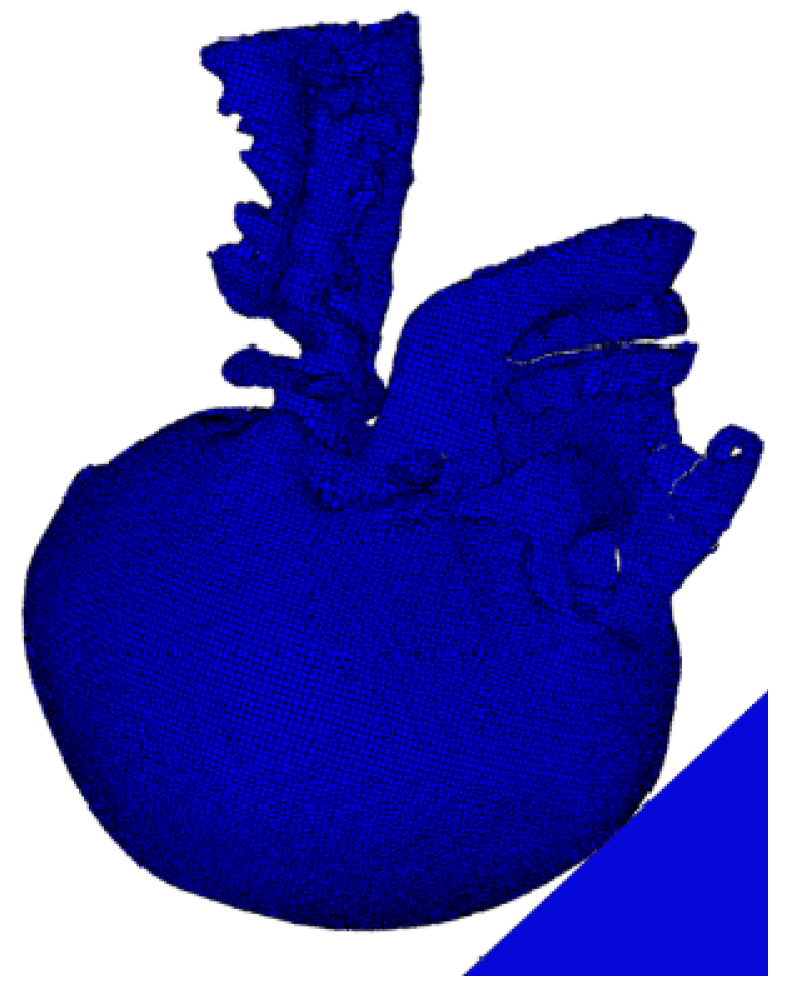

2.1. Finite Element Model of the Head

2.1.1. Model Construction

| Material Type | Element Type | Young’s Modulus E (MPa) G(t) = G∞ + (G0 − G∞) e−βt | Poisson’s Ratio | Density (kg m−3) | References | |

|---|---|---|---|---|---|---|

| Brainstem | Linear viscoelastic | Tetrahedral | G0 = 0.528, G∞ = 0.168, β = 35 s−1 | 0.48 | 1140 | [17,18,19,20,21,22,23,24] |

| Cerebral peduncle | Linear viscoelastic | Tetrahedral | G0 = 0.0225, G∞ = 0.0045, β = 80 s−1 | 0.4996 | 1060 | [25] |

| Cerebellum | Linear viscoelastic | Tetrahedral | G0 = 0.528, G∞ = 0.168, β = 35 s−1 | 0.48 | 1140 | [17,18,19,20,21,22,23,24] |

| CSF | Linear elastic | Tetrahedral | E = 1.314 | 0.4999 | 1040 | [23] |

| Gray matter | Linear viscoelastic | Tetrahedral | G0 = 0.528, G∞ = 0.168, β = 35 s−1 | 0.4996 | 1040 | [24,25] |

| Lateral cartilage | Linear elastic | Tetrahedral | E = 30 | 0.45 | 1500 | [26] |

| Septum cartilage | Linear elastic | Tetrahedral | E = 9 | 0.32 | 1500 | [27] |

| Bone | Linear elastic | Tetrahedral | E = 8000 | 0.22 | 4740 | [24] |

| Soft tissues | Linear elastic | Tetrahedral | E = 16.67 | 0.46 | 1040 | [24,28] |

| Tooth | Linear elastic | Tetrahedral | E = 2070 | 0.3 | 2250 | [29,30] |

| Ventricles | Linear elastic | Tetrahedral | E = 1.314 | 0.4999 | 1040 | [23] |

| White matter | Linear viscoelastic | Tetrahedral | G0 = 0.041, G∞ = 0.0078, β = 700 s−1 | 0.4996 | 1040 | [25] |

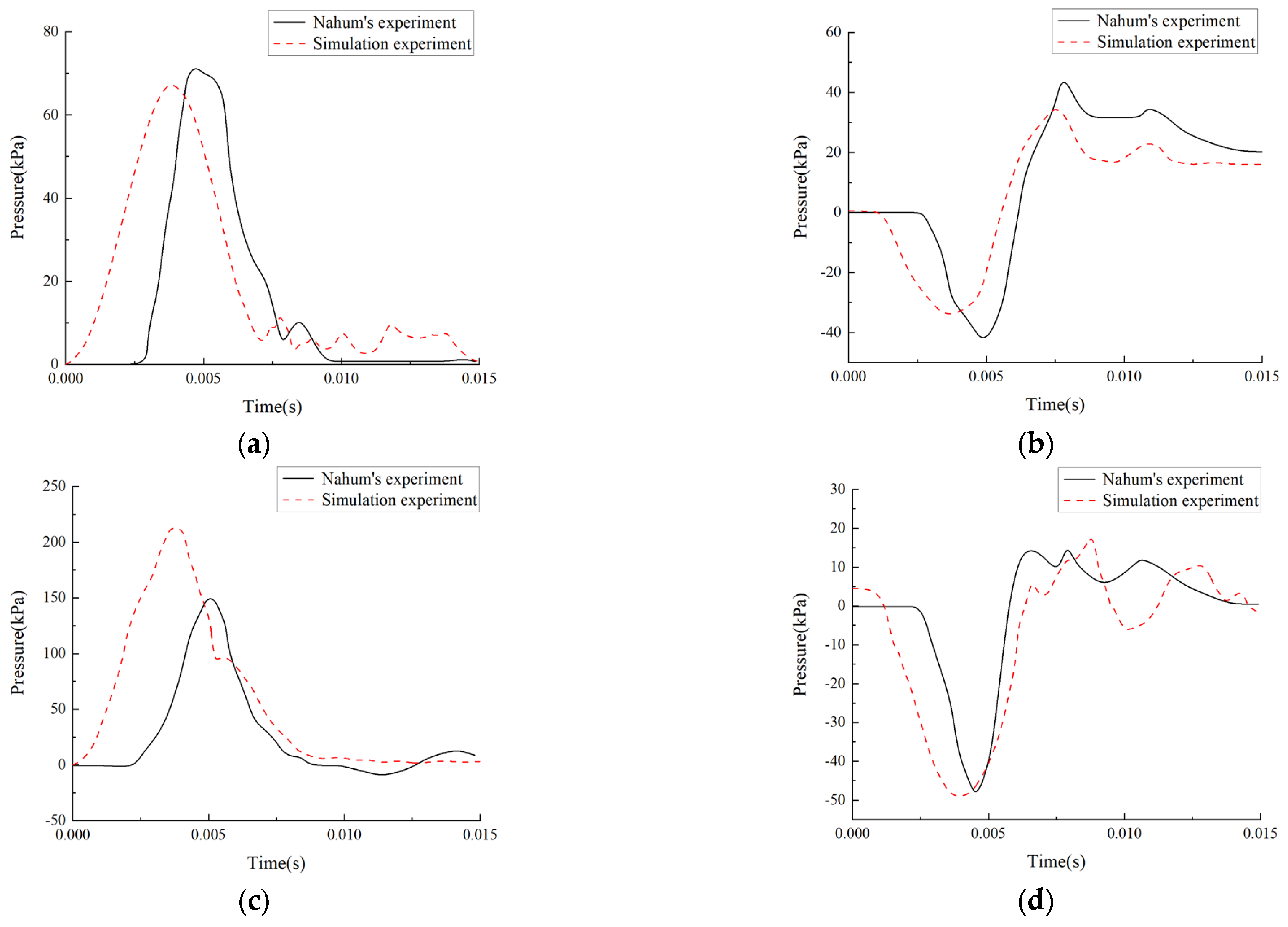

2.1.2. Experimental Validation of Nahum’s Intracranial Pressure

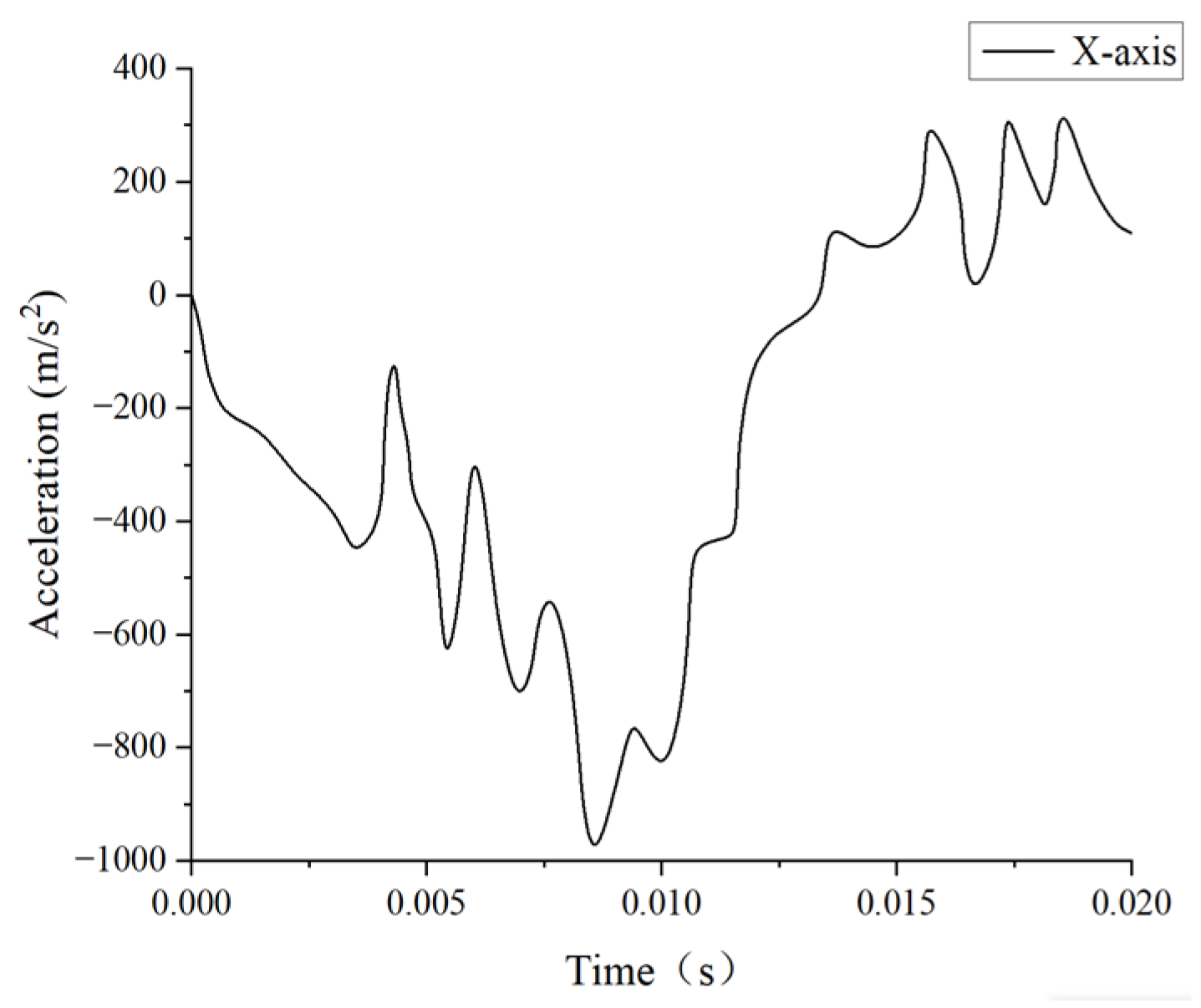

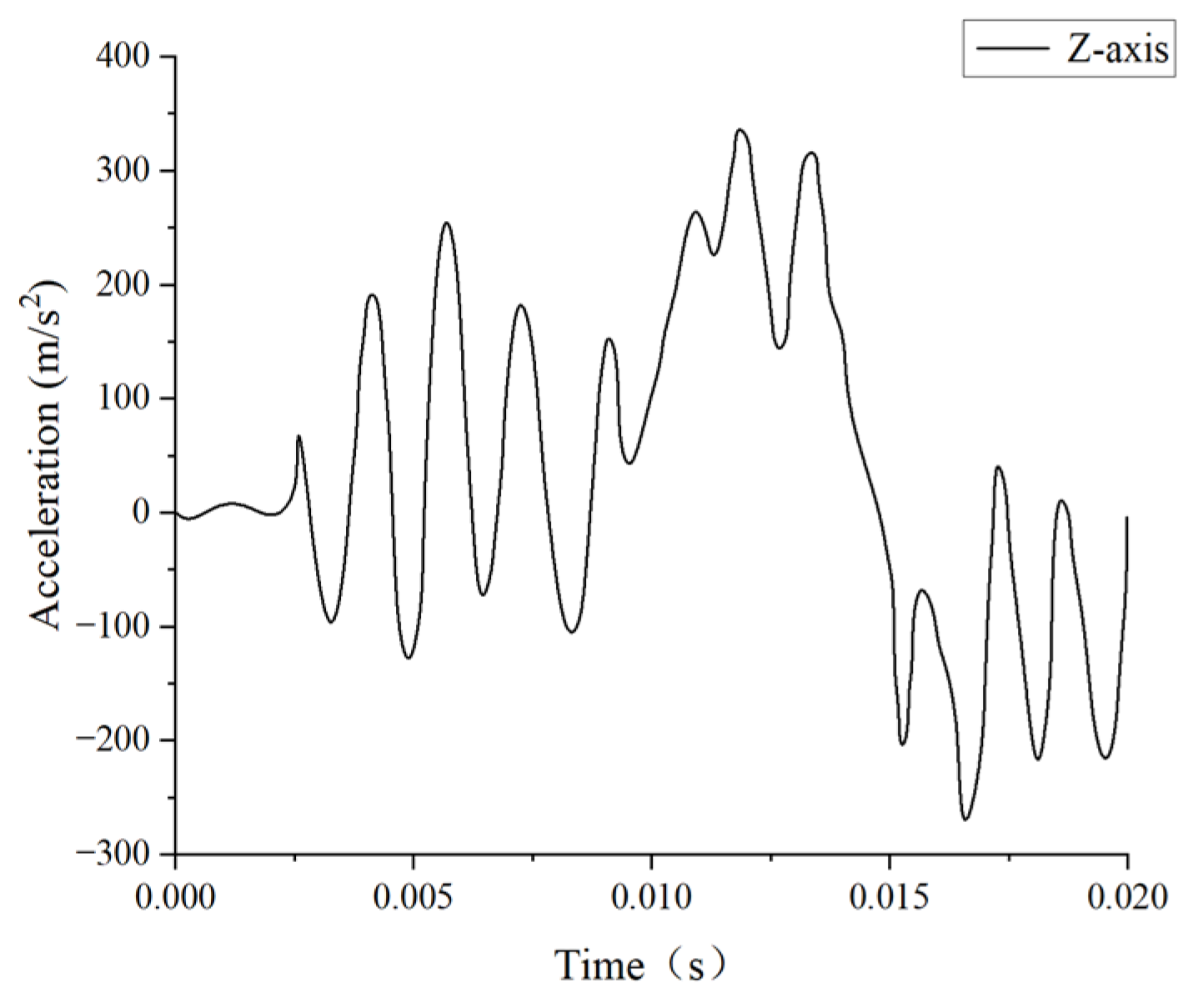

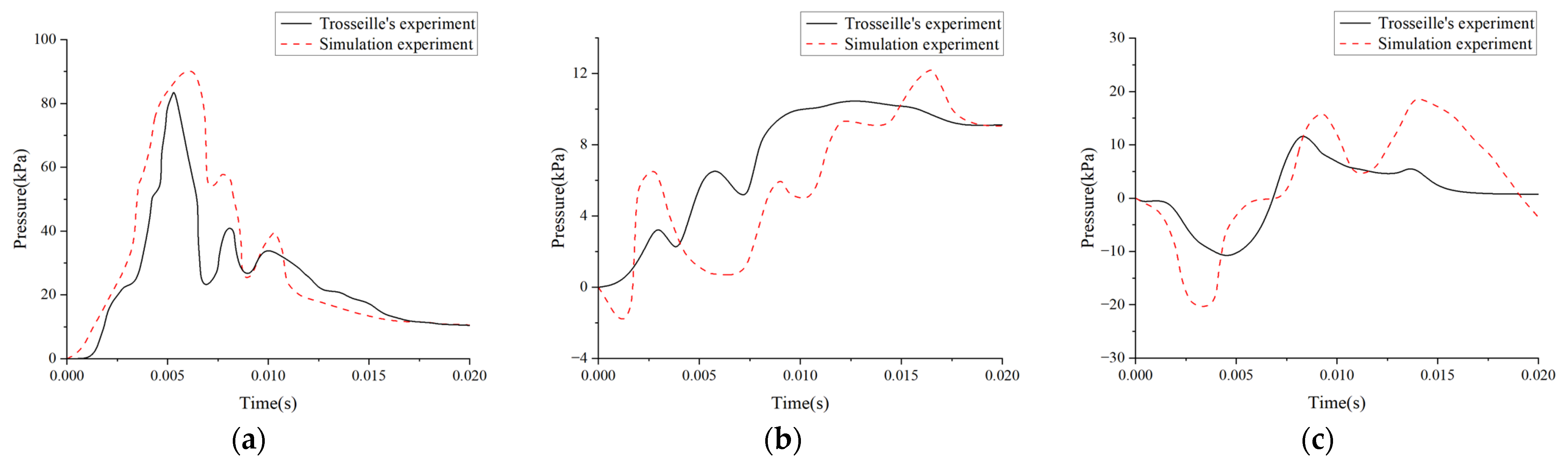

2.1.3. Experimental Validation of Trosseille’s Intracranial Kinetic Response

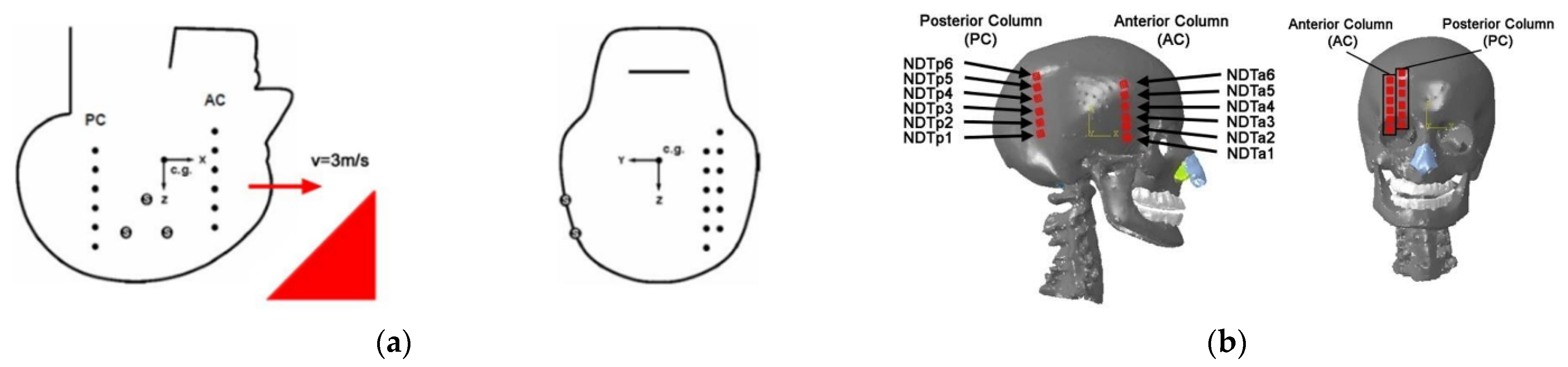

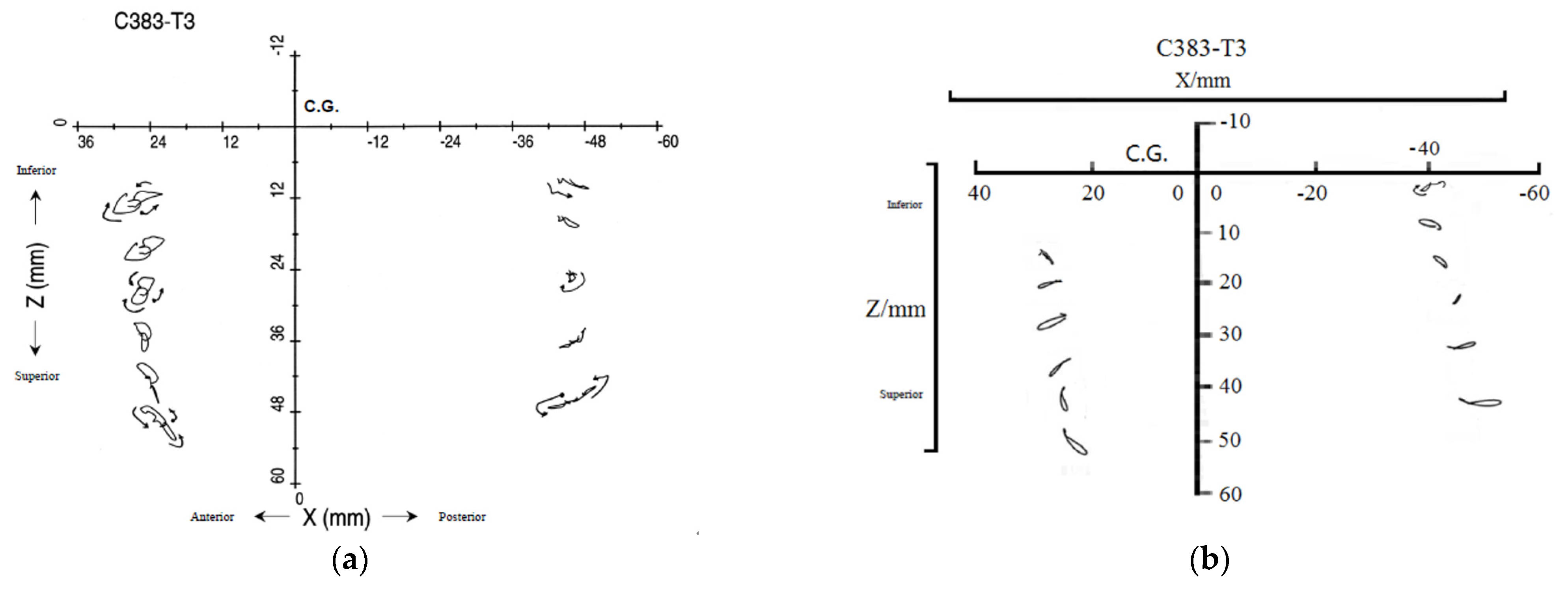

2.1.4. Experimental Validation of Hardy’s Craniocerebral Relative Displacement

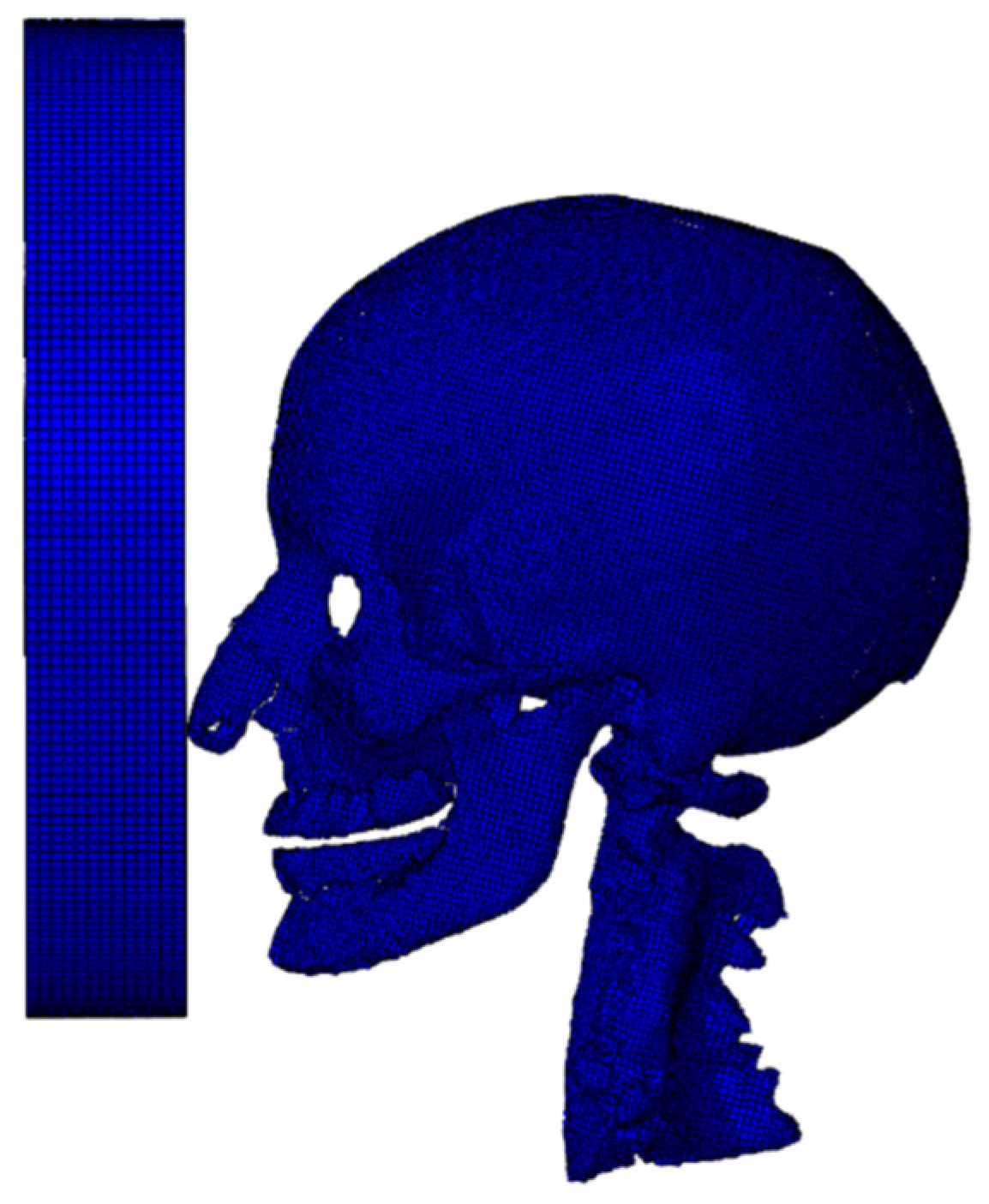

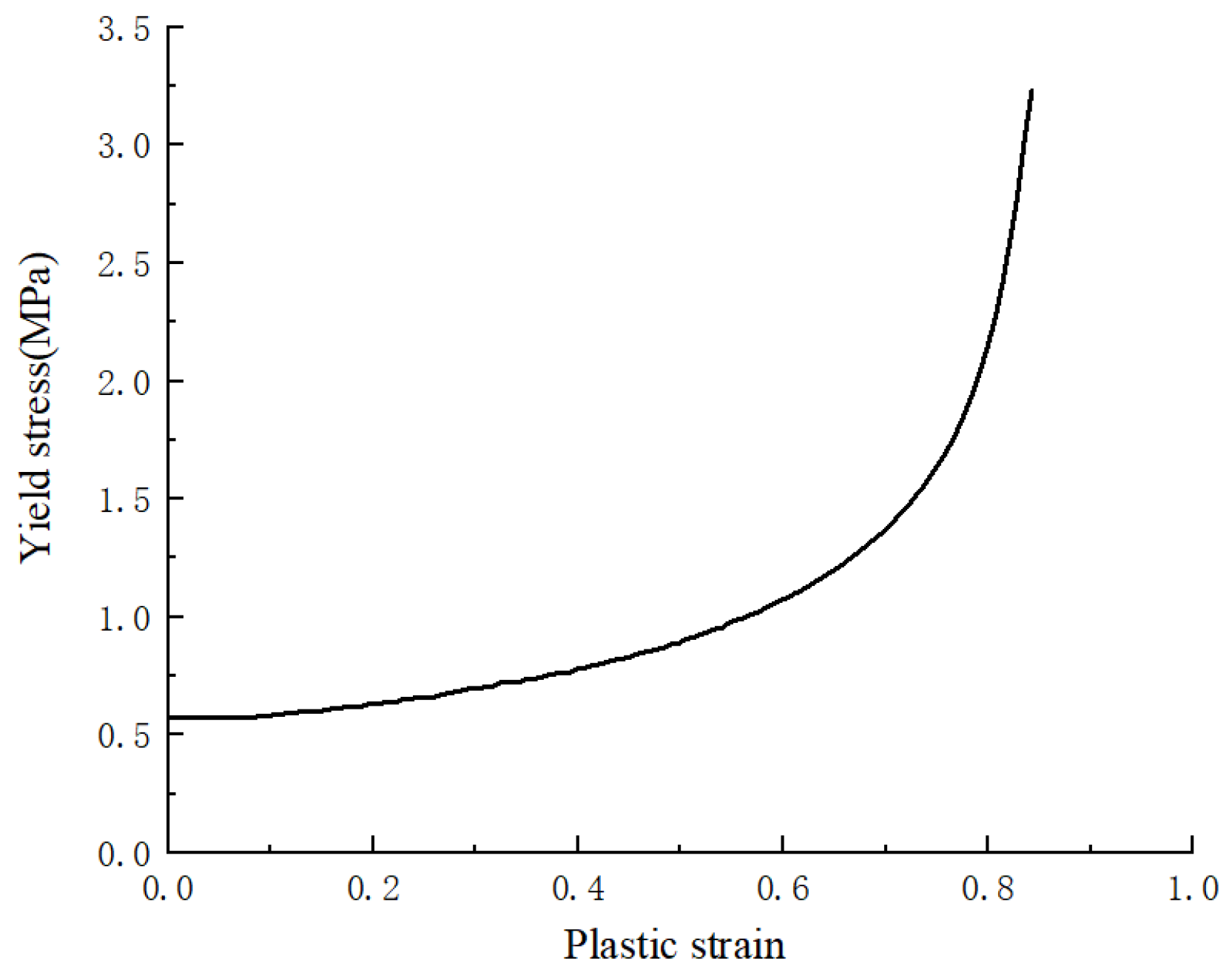

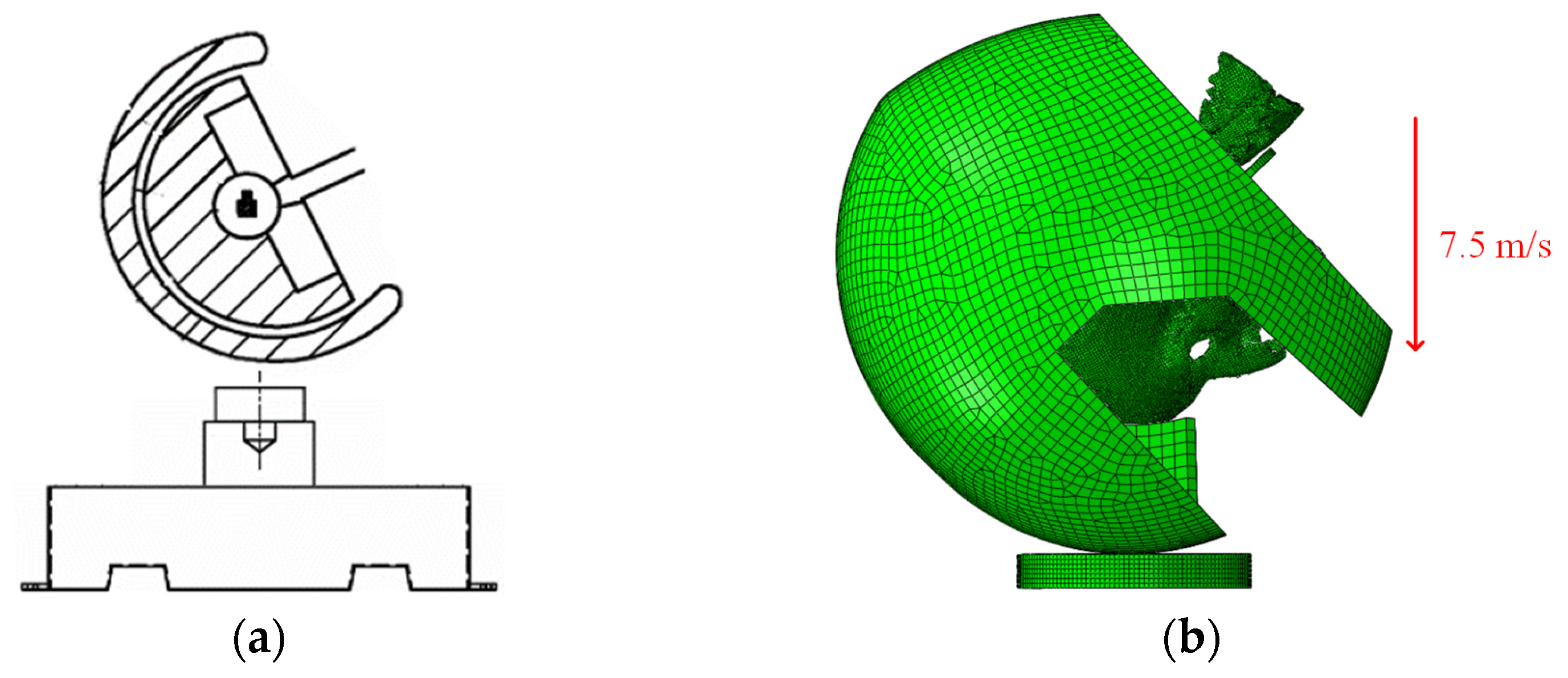

2.2. Finite Element Model of the Helmet

2.2.1. Model Construction

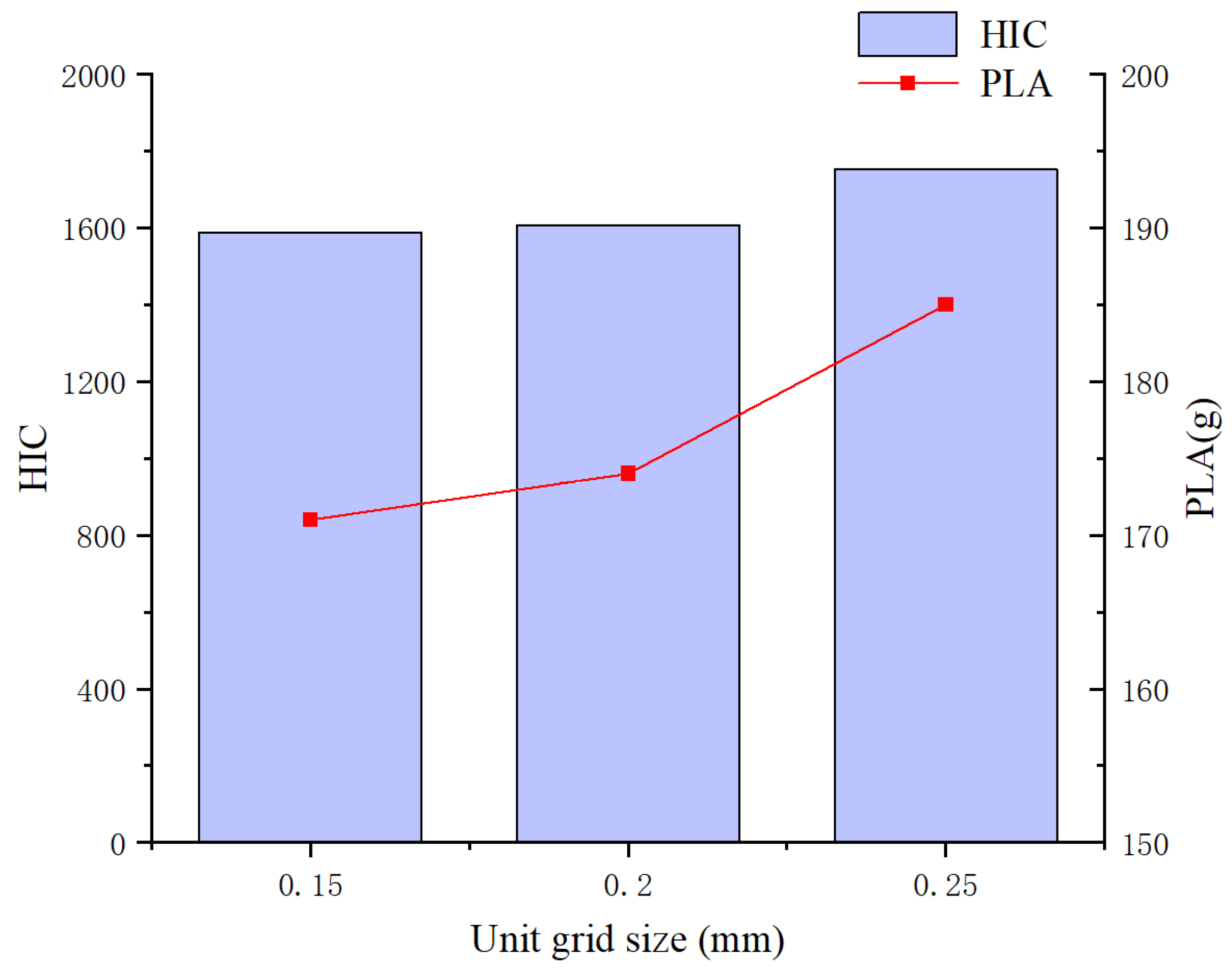

2.2.2. Grid Convergence

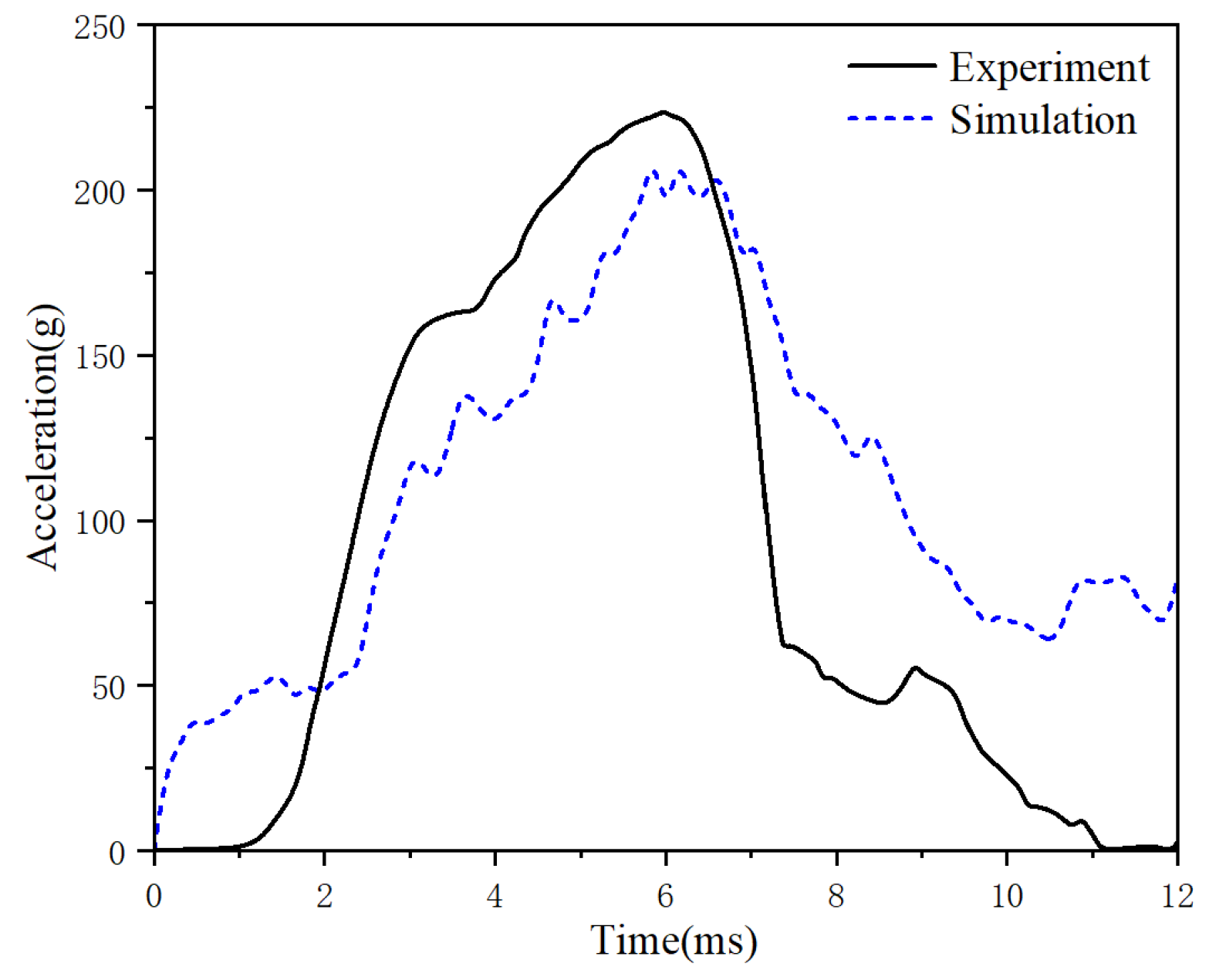

2.2.3. Validation of the Helmet–Head Coupling Model

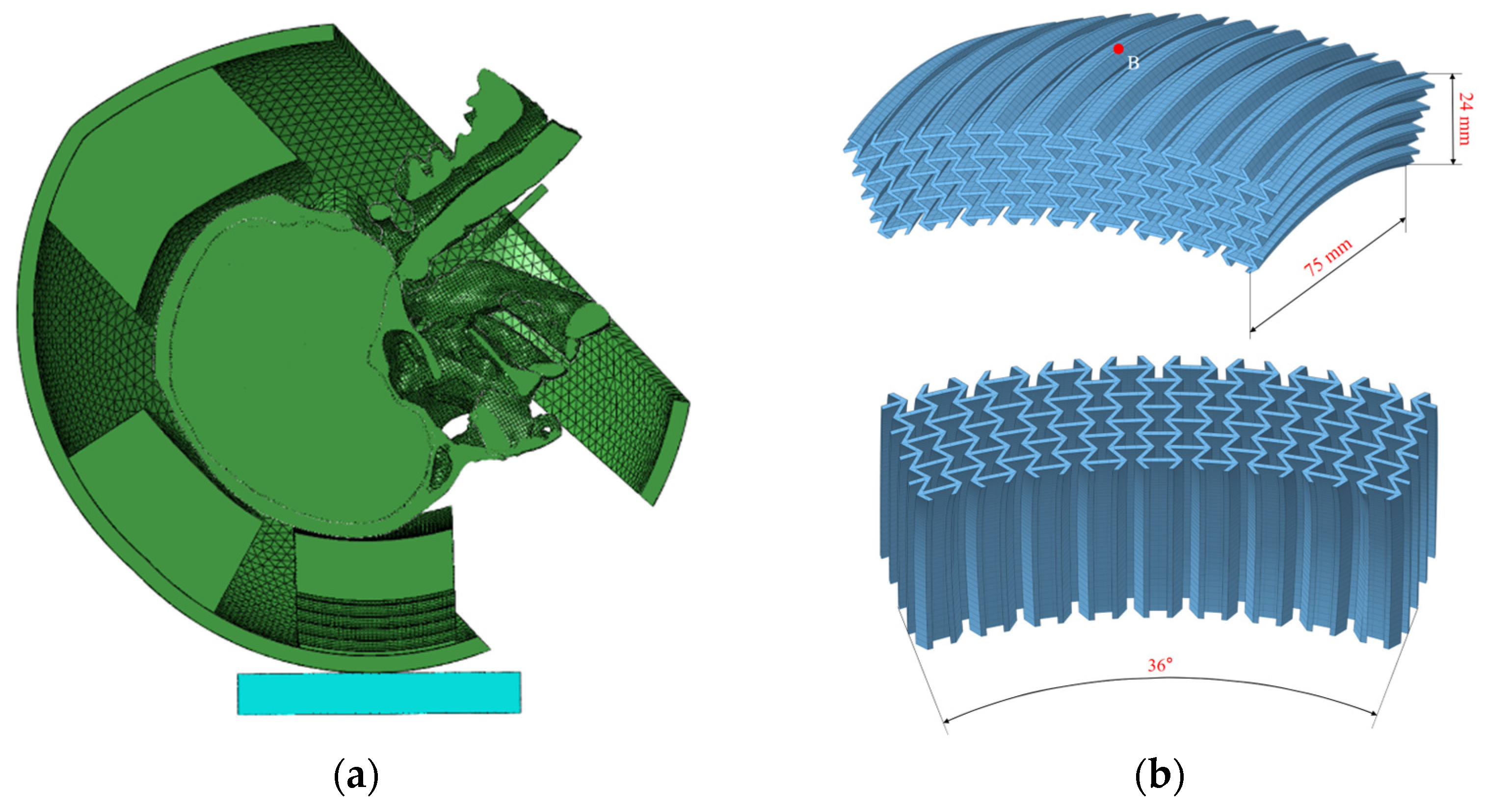

2.3. Negative-Poisson’s-Ratio Structural Helmet Liner Design

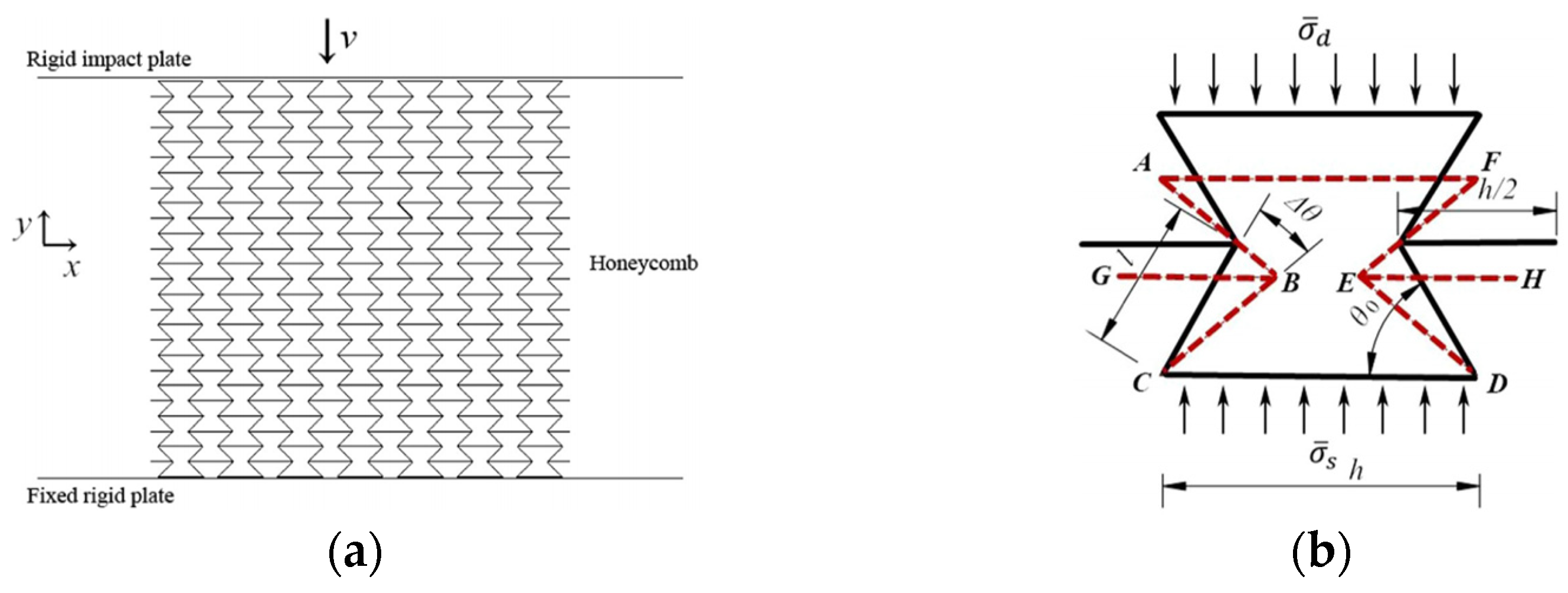

2.3.1. Theoretical Modeling of Re-Entrant Hexagonal Honeycomb Structures

2.3.2. Poisson’s Ratio

2.3.3. Plateau Stress Under Low-Velocity Crushing

2.4. Modelling of Helmet–Head Coupling Under Flat Anvil Impact Conditions

3. Results

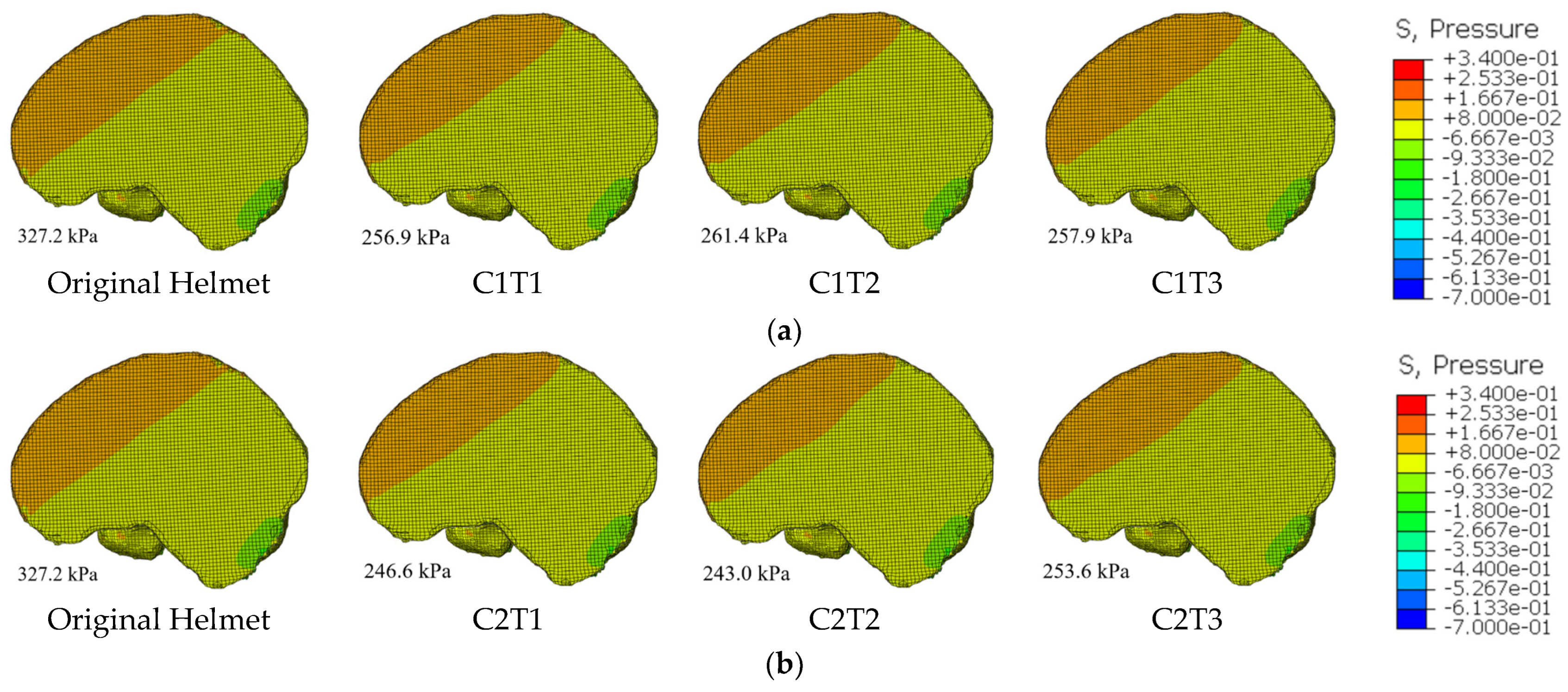

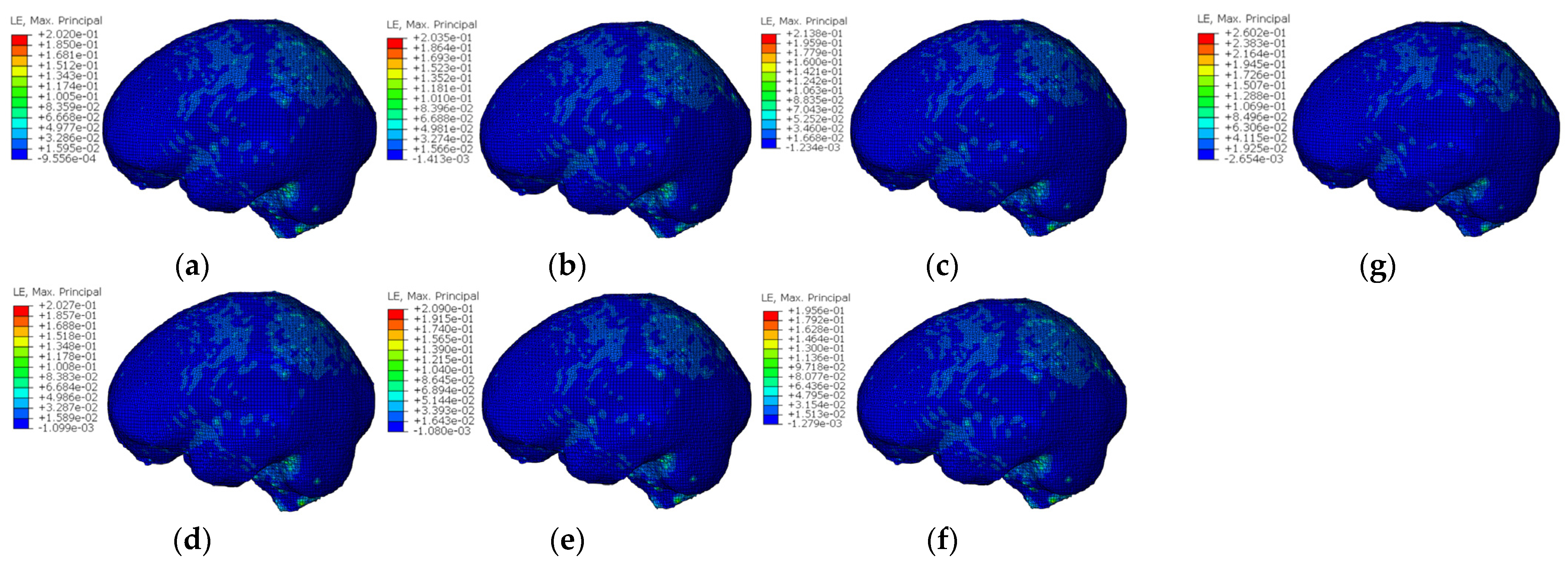

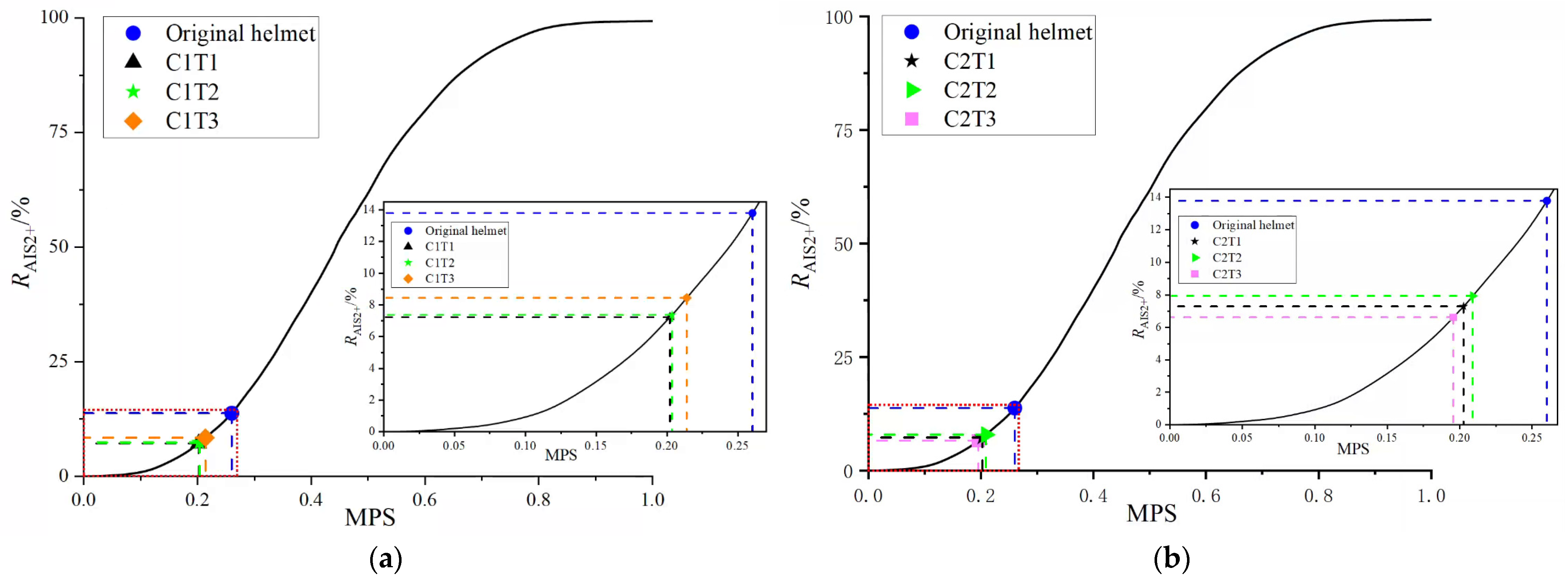

3.1. Analysis of Head Protection Performance

3.2. Head Dynamics Response

3.3. Head Dynamics Response

4. Discussion

5. Conclusions

- (1)

- In all the new helmet configurations, except C1T1, the peak point of head acceleration is significantly delayed compared with that of the EPS helmet. This implies that when the total impact momentum is constant, the average impact force can be reduced by prolonging the impact time, thereby decreasing the instantaneous compressive force exerted on the skull and enhancing the head protective performance.

- (2)

- When the wall angle of the liner is increased to θ = 60° and the wall thickness is decreased to t ≤ 1.2 mm, the energy absorption efficiency of the helmet exhibits an exponential increase. The test data indicate that this configuration can reduce the HIC value from 2004 to 1549 in the baseline group.

- (3)

- Particularly, the C2T3 helmet (wall angle 75°/wall thickness 1.2 mm) demonstrates superior head protection. It not only achieves a substantial 27.7% reduction in MPS, but also decreases the probability of AIS2+ brain injury by 7.2% through the re-configuration of the pressure wave conduction path.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- China Road Traffic Accident Statistics Annual Report. Available online: https://data.stats.gov.cn/easyquery.htm?cn=C01&zb=A0S0D01&sj=2023 (accessed on 10 April 2025).

- Li, X.; Li, Z.; Guo, Z.; Mo, Z.; Li, J. A novel star-shaped honeycomb with enhanced energy absorption. Compos. Struct. 2023, 309, 116716. [Google Scholar] [CrossRef]

- Lin, H.B.; Liu, H.T.; An, M.R. In-plane dynamic impact behaviors of a self-similar concentric star honeycomb with negative Poisson’s ratio. Mater. Today Commun. 2022, 33, 104474. [Google Scholar] [CrossRef]

- Song, Y.; Jiang, S.; Zhang, B.; Liu, H.; Liu, F. In-Plane Impact Performance of a Gradient Sinusoidal Negative Poisson-Ratio Honeycomb Structure. J. Vib. Eng. Technol. 2025, 13, 202. [Google Scholar] [CrossRef]

- Qin, S.; Deng, X.; Yang, F.; Lu, Q. Energy absorption characteristics and negative Poisson’s ratio effect of axisymmetric tetrachiral honeycombs under in-plane impact. Compos. Struct. 2023, 323, 117493. [Google Scholar] [CrossRef]

- Zhu, D.; Wei, Y.; Shen, X.; Yan, K.; Yuan, M.; Qi, S. A novel elliptical annular re-entrant auxetic honeycomb with enhanced stiffness. In. J. Mech. Sci. 2024, 262, 108732. [Google Scholar] [CrossRef]

- Yu, S.; Liu, Z.; Cao, X.; Liu, J.; Huang, W.; Wang, Y. The compressive responses and failure behaviors of composite graded auxetic re-entrant honeycomb structure. Thin Wall Struct. 2023, 187, 110721. [Google Scholar] [CrossRef]

- Yang, K.; Teng, F.; Wang, Y.B.; Hu, Y.H. Study on impact energy absorption performance and optimization of negative Poisson’s ratio structure. J. Braz. Soc. Mech. Sci. 2023, 45, 16. [Google Scholar]

- Hai, H.; Chen, C.; Wang, W.; Xu, W. Impact resistance of a double re-entrant negative poisson’s ratio honeycomb structure. Phys. Scr. 2024, 99, 025919. [Google Scholar] [CrossRef]

- Wang, J.; Wu, Z.; Xiao, R.; Tang, C.; Yang Xu, Y. A 3D re-entrant structural metamaterial with negative Poisson’s ratio reinforced by adding arrow structures. Smart Mater. Struct. 2023, 32, 035001. [Google Scholar] [CrossRef]

- Feng, J.; Liang, Q.; Dou, Y.; He, J.; Wu, Y.; Chen, T. Higher stiffness hierarchical embedded strengthening honeycomb metastructure with small negative Poisson’s ratio reduction. Thin-Walled Struct. 2020, 179, 109561. [Google Scholar] [CrossRef]

- Chen, H.; Li, F. Design, simulation and experimental verification of novel 3D metamaterial structures with negative Poisson’s ratio. Mech. Adv. Mater. Struct. 2023, 30, 17–28. [Google Scholar] [CrossRef]

- ECE R22 05; Uniform Provision Concerning the Approval of Protective Helmets and Their Visors for Driver and Passengers of Motor Cycles and Mopeds. United Engineering Construction (UNEC): Geneva, Switzerland, 2002.

- Zhou, Z.; Li, X.; Kleiven, S. Fluid–structure interaction simulation of the brain–skull interface for acute subdural haematoma prediction. Biomech. Model. Mechanobiol. 2019, 18, 155–173. [Google Scholar] [CrossRef]

- Willinger, R.; Baumgartner, D. Human head tolerance limits to specific injury mechanisms. Int. J. Crashworthiness 2003, 8, 605–617. [Google Scholar] [CrossRef]

- Gao, F.; Yang, B.; Wu, J.; Li, X.; Tse, K.M. Parameter optimization design of the helmet liner structure for mitigating traumatic brain injury under impact loading. Smart Mater. Struct. 2024, 33, 11–115050. [Google Scholar] [CrossRef]

- Willinger, R.; Kang, H.S.; Diaw, B. Three-dimensional human head finite-element model validation against two experimental impacts. Ann. Biomed. Eng. 1999, 27, 403–410. [Google Scholar] [CrossRef]

- Turquier, F.; Kang, H.S.; Trosseille, X.; Willinger, R.; Lavaste, F.; Tarriere, C.; Dömont, A. Validation Study of a 3D Finite Element Head Model Against Experimental Data; SAE Technical Paper No. 962431; SAE International: Warrendale, PA, USA, 1996; Volume 105, pp. 1912–1923. [Google Scholar]

- Stalnaker, R.L. Mechanical Properties of the Head. Ph.D. Thesis, West Virginia University, Morgantown, WV, USA, 1969. [Google Scholar]

- Shuck, L.Z.; Advani, S.H. Rheological response of human brain tissue in shear. ASME J. Basic Eng. 1972, 94, 905–911. [Google Scholar] [CrossRef]

- Yoganandan, N.; Li, J.; Zhang, J.; Pintar, F.A. Role of falx on brain stress-strain responses. In Mechanosensitivity of the Nervous System: Forewords by Nektarios Tavernarakis and Pontus Persson; Springer: Berlin/Heidelberg, Germany, 2009; pp. 281–297. [Google Scholar]

- Horgan, T.J.; Gilchrist, M.D. Influence of FE model variability in predicting brain motion and intracranial pressure changes in head impact simulations. Int. J. Crashworthiness 2004, 9, 401–418. [Google Scholar] [CrossRef]

- Tse, K.M. Development of a Realistic Finite Element Model of Human Head and Its Applications to Head Injuries. Ph.D. Thesis, National University of Singapore, Kent Ridge, Singapore, 2013. [Google Scholar]

- Tse, K.M.; Tan, L.B.; Lee, S.J.; Lim, S.P.; Lee, H.P. Development and validation of two subject-specific finite element models of human head against three cadaveric experiments. Int. J. Numer. Methods Biomed. 2014, 30, 397–415. [Google Scholar] [CrossRef]

- Al-Bsharat, A.S. Computational Analysis of Brain Injury. Ph.D. Thesis, Detroit Wayne State University, Detroit, MI, USA, 2000. [Google Scholar]

- Westreich, R.W.; Courtland, H.W.; Nasser, P.; Jepsen, K.; Lawson, W. Defining nasal cartilage elasticity: Biomechanical testing of the tripod theory based on a cantilevered model. Arch. Facial Plast. Surg. 2007, 9, 264–270. [Google Scholar] [CrossRef]

- Grellmann, W.; Berghaus, A.; Haberland, E.J.; Jamali, Y.; Holweg, K.; Reincke, K.; Bierögel, C. Determination of strength and deformation behavior of human cartilage for the definition of significant parameters. J. Biomed. Mater. Res. A 2006, 78, 168–174. [Google Scholar] [CrossRef] [PubMed]

- Kleiven, S. Evaluation of head injury criteria using a finite element model validated against experiments on localized brain motion, intracerebral acceleration, and intracranial pressure. Int. J. Crashworthiness 2006, 11, 65–79. [Google Scholar] [CrossRef]

- Tanne, K.; Hiraga, J.; Kakiuchi, K.; Yamagata, Y.; Sakuda, M. Biomechanical effect of anteriorly directed extraoral forces on the craniofacial complex: A study using the finite element method. Am. J. Orthod. Dentofac. 1989, 95, 200–207. [Google Scholar] [CrossRef]

- Payan, Y.; Bettega, G.; Raphaël, B. A biomechanical model of the human tongue and its clinical implications. In Medical Image Computing and Computer-Assisted Intervention; Springer: Berlin/Heidelberg, Germany, 1998; pp. 688–695. [Google Scholar]

- Nahum, A.M.; Smith, R.; Ward, C.C. Intracranial Pressure Dynamics During Head Impact; SAE Technical Paper No. 770922; SAE International: Warrendale, PA, USA, 1977; p. 28. Available online: https://www.sae.org/publications/technical-papers/content/770922/ (accessed on 12 April 2025).

- Trosseille, X.; Tarriere, C.; Lavaste, F.; Guillon, F.; Domont, A. Development of a FEM of the Human Head According to a Specific Test Protocol; SAE Technical Paper No. 922527; SAE International: Warrendale, PA, USA, 1992; p. 19. Available online: https://www.sae.org/publications/technical-papers/content/922527/ (accessed on 12 April 2025).

- Bierbrauer, J. Construction of orthogonal arrays. J. Stat. Plan. Infer. 1996, 56, 39–47. [Google Scholar] [CrossRef]

- DeCock, D.; Stufken, J. On finding mixed orthogonal arrays of strength 2 with many 2-level factors. Stat. Probab. Lett. 2000, 50, 383–388. [Google Scholar] [CrossRef]

- Hardy, W.N.; Foster, C.D.; Mason, M.J.; Yang, K.H.; King, A.I.; Tashman, S. Investigation of Head Injury Mechanisms Using Neutral Density Technology and High-Speed Biplanar X-Ray; SAE Technical Paper No. 2001-22-0016; SAE International: Warrendale, PA, USA, 2001. [Google Scholar]

- Sandberg, M.; Tse, K.M.; Tan, L.B.; Lee, H.P. A computational study of the EN 1078 impact test for bicycle helmets using a realistic subject-specific finite element head model. Comput. Method Biomech. 2018, 21, 684–692. [Google Scholar] [CrossRef]

- Cui, L.; Rueda, M.A.F.; Gilchrist, M.D. Optimisation of energy absorbing liner for equestrian helmets. Part II: Functionally graded foam liner. Mater. Design. 2009, 30, 3414–3419. [Google Scholar] [CrossRef]

- Fahlstedt, M.; Halldin, P.; Kleiven, S. The protective effect of a helmet in three bicycle accidents—A finite element study. Accid. Anal. Prev. 2016, 91, 135–143. [Google Scholar] [CrossRef]

- Zheng, G.; Zhang, X.; Li, S.; Pang, T.; Li, Q.; Sun, G. Correlation between kinematics and biomechanics of helmeted head under different impact conditions. Compos. Struct. 2022, 291, 115514. [Google Scholar] [CrossRef]

- Hu, L.L.; Yu, T.X. Dynamic crushing strength of hexagonal honeycombs. Int. J. Impact Eng. 2009, 5, 467–474. [Google Scholar] [CrossRef]

- Hu, L.L.; Yu, T.X. Mechanical behavior of hexagonal honeycombs under low-velocity impact–theory and simulations. Int. J. Solids Struct. 2013, 50, 3152–3165. [Google Scholar] [CrossRef]

- Hu, L.L.; Zhou, M.Z.; Deng, H. Dynamic crushing response of auxetic honeycombs under large deformation: Theoretical analysis and numerical simulation. Thin-Wall Struct. 2018, 131, 373–384. [Google Scholar] [CrossRef]

- Zhang, X. Damage Response and Prediction of Helmet Wearing Head Under Different Impact Conditions. Master’s Thesis, Hunan University, Changsha, China, 2022. [Google Scholar]

- Tse, K.M.; Lim, S.P.; Tan, V.B.C.; Lee, H.P. A review of head injury and finite element head models. Am. J. Eng. Technol. Soc. 2014, 1, 28–52. [Google Scholar]

- Galbraith, J.A.; Thibault, L.E.; Matteson, D.R. Mechanical and electrical responses of the squid giant axon to simple elongation. J. Biomech. Eng. 1993, 115, 13–22. [Google Scholar] [CrossRef]

- Shreiber, D.I.; Bain, A.C.; Meaney, D.F. In Vivo Thresholds for Mechanical Injury to the Blood-Brain Barrier; SAE Technical Paper No. 973335; SAE International: Warrendale, PA, USA, 1997. [Google Scholar]

- Wang, J.; Wang, R.; Gao, W.; Chen, S.; Wang, C. Numerical investigation of impact injury of a human head during contact interaction with a windshield glazing considering mechanical failure. Int. J. Impact Eng. 2020, 141, 103577. [Google Scholar] [CrossRef]

- Meng, H.S.; Mao, Z.Y.; Ma, H.X.; Wang, F.; Xiao, Z.; Li, G.B. Head injury risk analysis of two wheeled cyclists under the protection of airbag helmet. J. Med. Biomech. 2022, 37, 460–466. (In Chinese) [Google Scholar]

| Test | Crash Site | Impactor (23.4 kg) | Impact Velocity (m s−1) |

|---|---|---|---|

| MS408-1 | Chests | Flat Panel | 5 |

| MS408-2 | Forehead | Polystyrene Foam | 5 |

| MS408-3 | Face | Rigid Circles N1 | 5 |

| MS428-1 | Forehead | Polystyrene Foam | 6 |

| MS428-2 | Face | Rigid Circles N2 | 7 |

| MS428-1 | Face | Rigid Circles N2 | 7 |

| Element Type | Material Type | Density (kg m−3) | Elasticity (MPa) | Poisson’s Ratio | Yielding Strength (MPa) | |

|---|---|---|---|---|---|---|

| Shell | Hexahedral | Linear Elastic | 1150 | E = 2000 | 0.37 | 34.3 |

| Energy-absorbing liner | Hexahedral | Crushable Foam | 80 | E = 20; = 0.6; k = 1.933; k_t = 0.1 | 0.01 | — |

| Straps | Tetrahedral | Linear Elastic | 1100 | E = 3000 | 0.42 | — |

| Anvil | Hexahedral | Linear Elastic | 7800 | E = 210,000 | 0.3 | — |

| Number | Honeycomb Wall Angle () | Honeycomb Wall Thickness (t) |

|---|---|---|

| C1T1 | 45° | 0.8 mm |

| C1T2 | 45° | 1.0 mm |

| C1T3 | 45° | 1.2 mm |

| C2T1 | 60° | 0.8 mm |

| C2T2 | 60° | 1.0 mm |

| C2T3 | 60° | 1.2 mm |

| PLA (g) | HIC | Time Point of PLA (ms) | |

|---|---|---|---|

| Original Helmet | 206 | 1756 | 6.60 |

| C1T1 | 207 | 1579 | 6.60 |

| C1T2 | 182 | 2058 | 8.85 |

| C1T3 | 171 | 1733 | 8.70 |

| C2T1 | 193 | 1549 | 8.85 |

| C2T2 | 174 | 1606 | 7.68 |

| C2T3 | 214 | 2004 | 7.35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, B.; Zhang, X.; Zheng, Y.; Zhang, P.; Li, X.; Wu, J.; Gao, F.; Zou, J.; Ma, X.; Feng, H.; et al. Mechanical Performance Evaluation of Negative-Poisson’s-Ratio Honeycomb Helmets in Craniocerebral Injury Protection. Materials 2025, 18, 2188. https://doi.org/10.3390/ma18102188

Yang B, Zhang X, Zheng Y, Zhang P, Li X, Wu J, Gao F, Zou J, Ma X, Feng H, et al. Mechanical Performance Evaluation of Negative-Poisson’s-Ratio Honeycomb Helmets in Craniocerebral Injury Protection. Materials. 2025; 18(10):2188. https://doi.org/10.3390/ma18102188

Chicago/Turabian StyleYang, Bin, Xingyu Zhang, Yang Zheng, Peng Zhang, Xin Li, Jinguo Wu, Feng Gao, Jiajia Zou, Xuan Ma, Hao Feng, and et al. 2025. "Mechanical Performance Evaluation of Negative-Poisson’s-Ratio Honeycomb Helmets in Craniocerebral Injury Protection" Materials 18, no. 10: 2188. https://doi.org/10.3390/ma18102188

APA StyleYang, B., Zhang, X., Zheng, Y., Zhang, P., Li, X., Wu, J., Gao, F., Zou, J., Ma, X., Feng, H., Li, L., & Wei, X. (2025). Mechanical Performance Evaluation of Negative-Poisson’s-Ratio Honeycomb Helmets in Craniocerebral Injury Protection. Materials, 18(10), 2188. https://doi.org/10.3390/ma18102188