Influence of Cu Content on Precipitation Behavior and Mechanical Properties Under Aging Treatment of Al-Cu-Li Alloys

Abstract

1. Introduction

2. Materials and Methods

3. Results

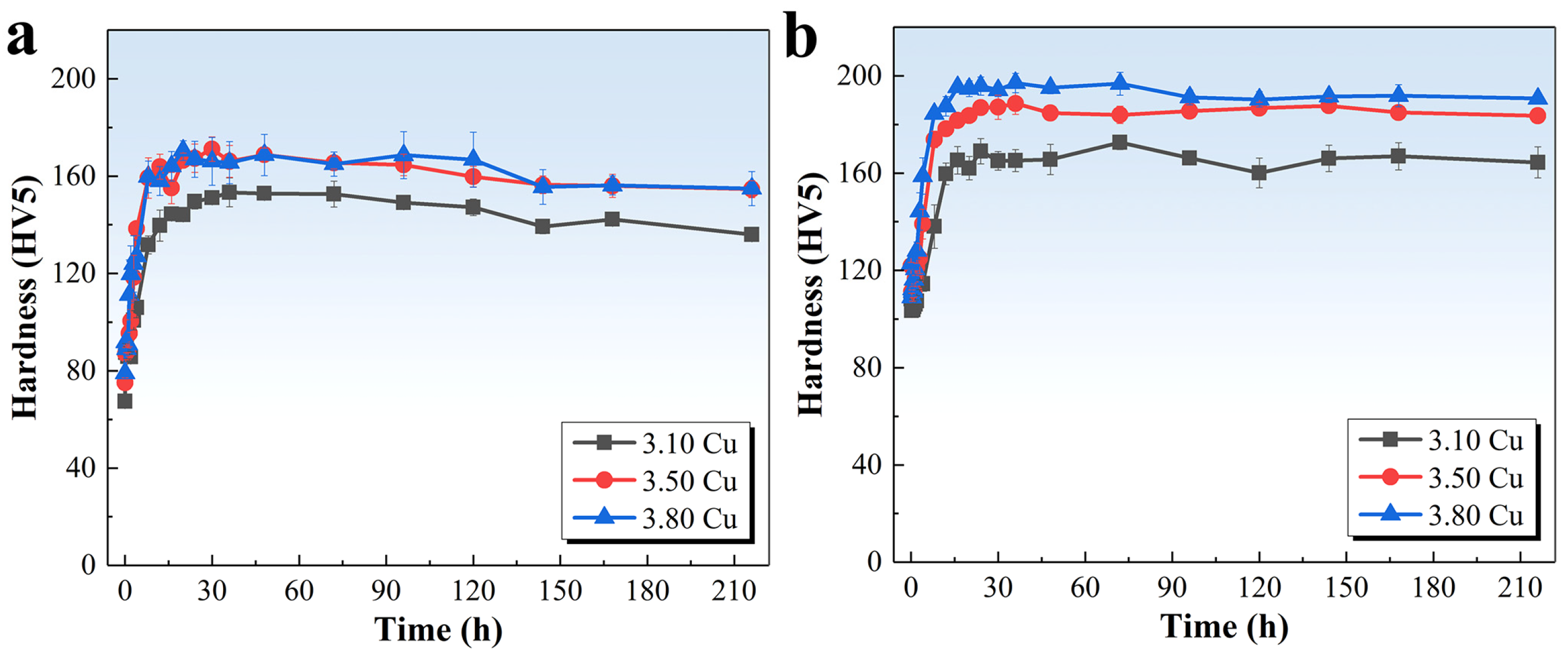

3.1. Artificial Age-Hardening Behavior

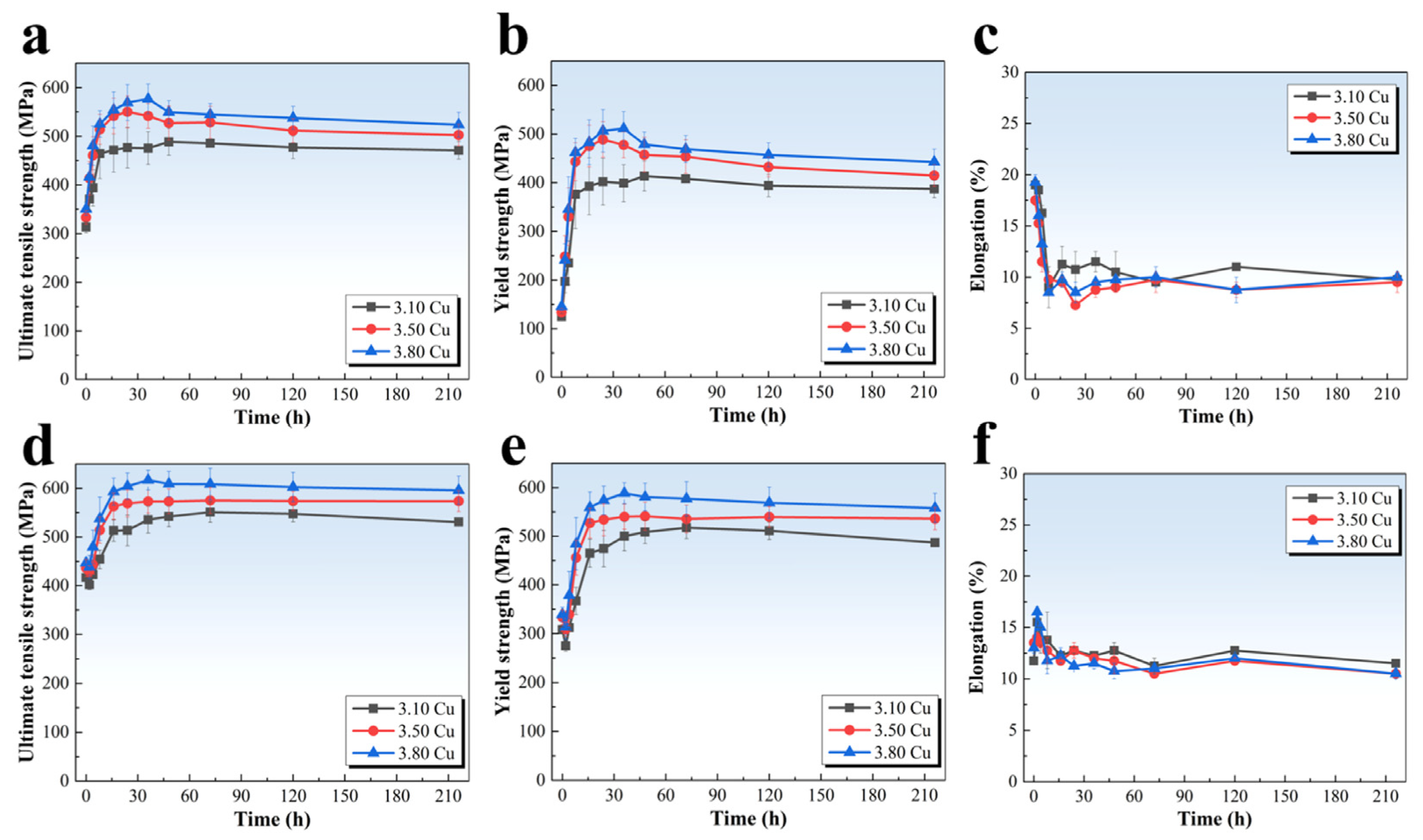

3.2. Mechanical Properties

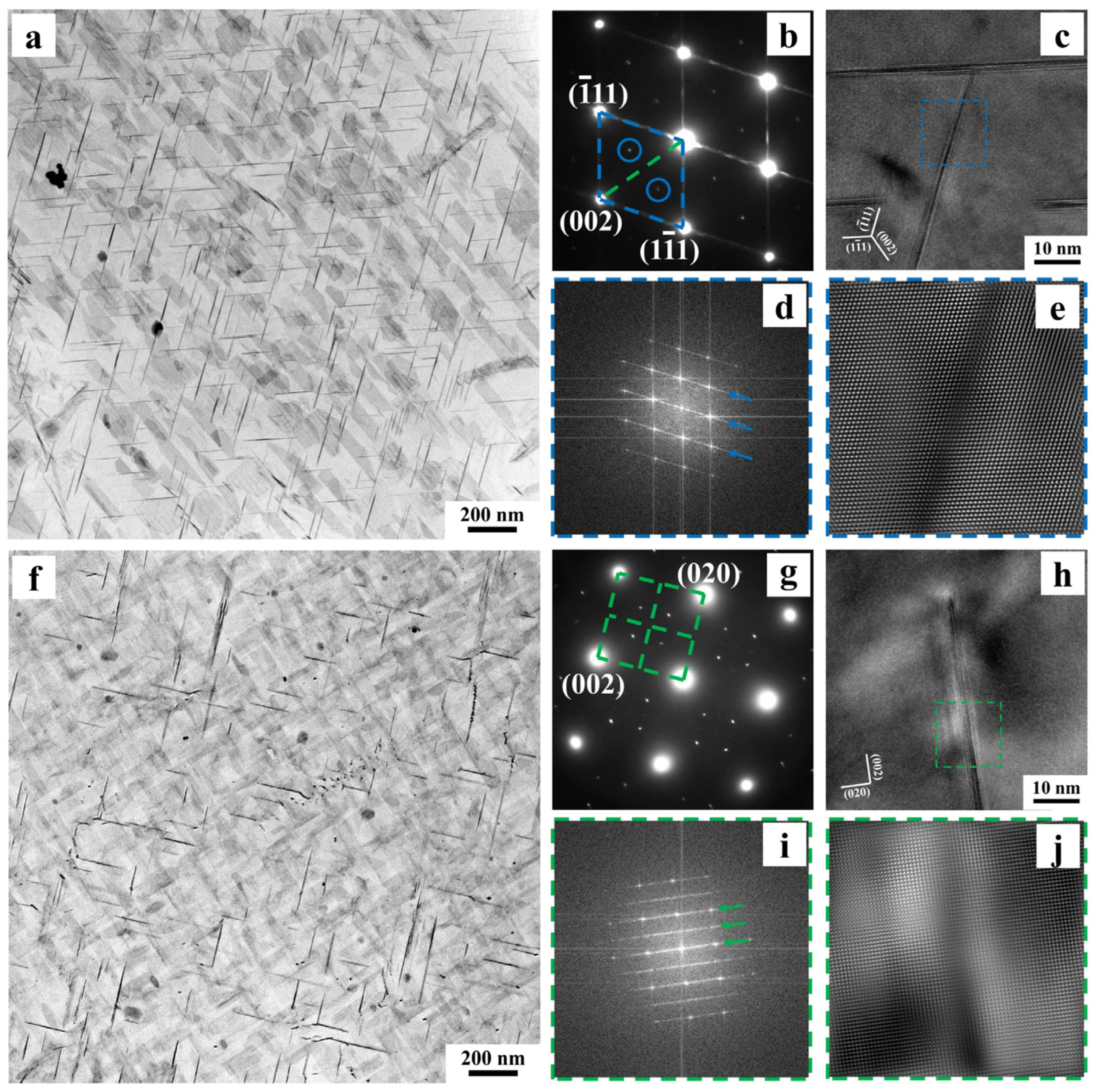

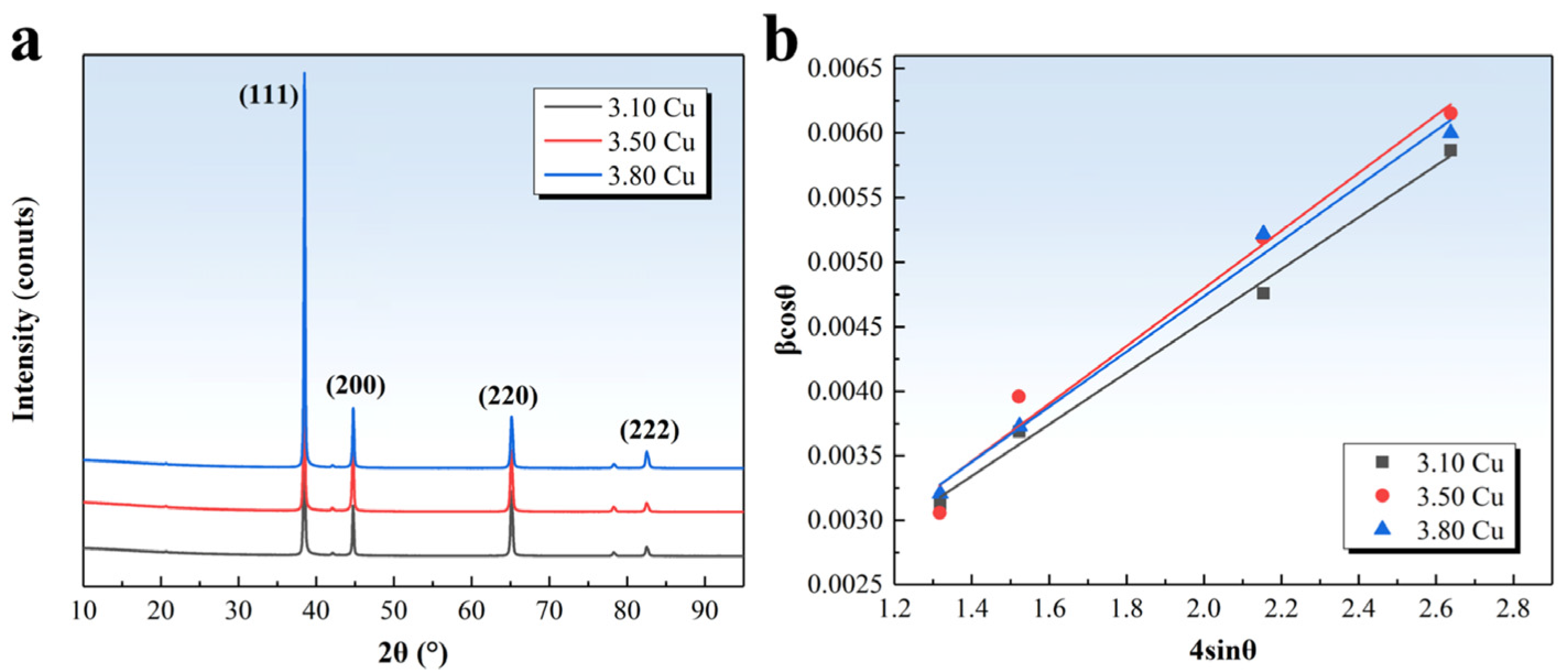

3.3. Precipitation Characterization

4. Discussion

5. Conclusions

- (1)

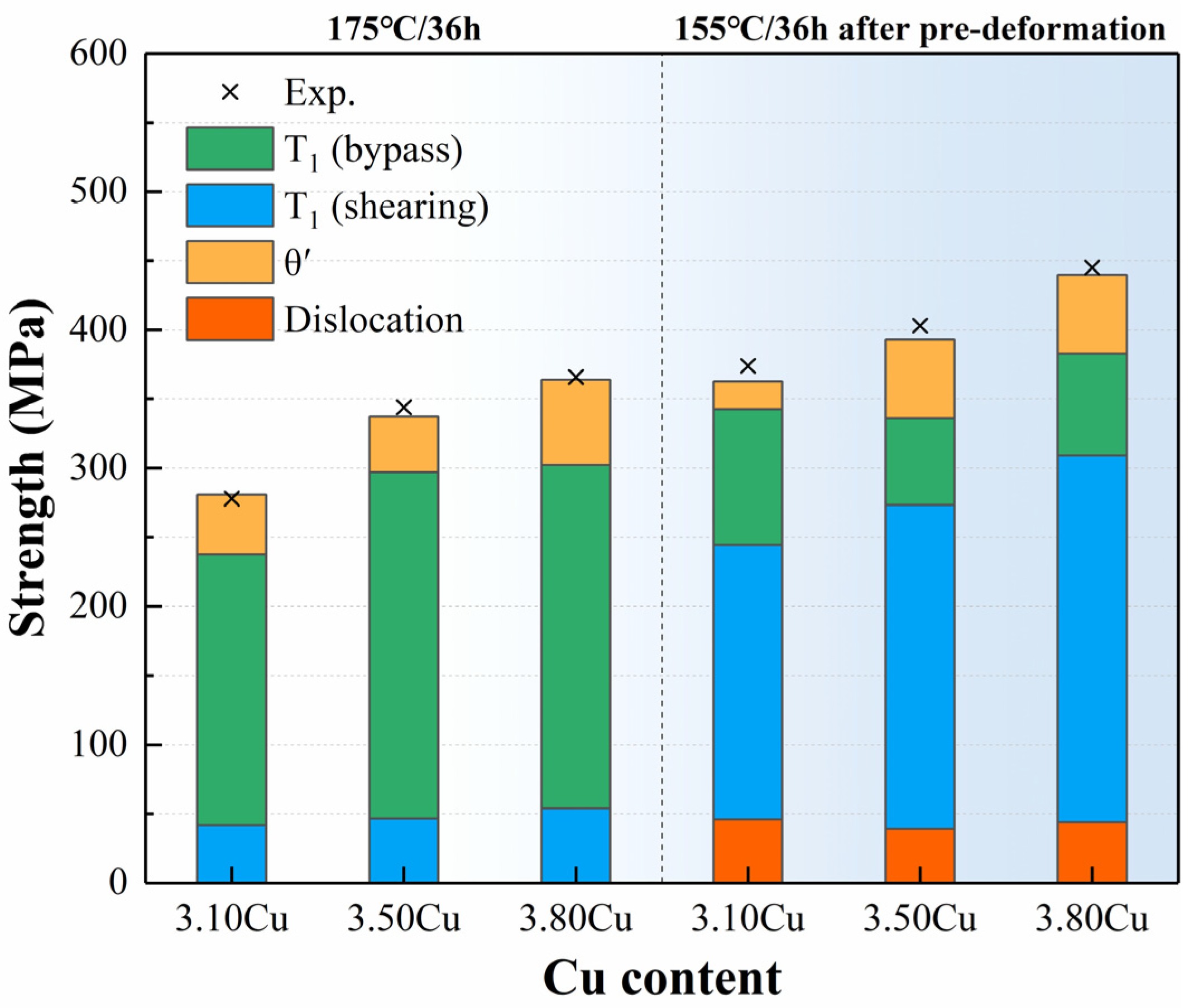

- Increased Cu content accelerated the hardening rate during initial aging stages while enhancing peak hardness and strength. Under 3.5% pre-deformation followed by aging at 155 °C, hardness and strength exhibited significant improvement, with a markedly greater disparity between the 3.80 Cu and 3.50 Cu alloys in these properties;

- (2)

- Under 175 °C/36 h aging conditions, the primary precipitates consisted of abundant T1 phases and minor θ′ phases. With the increase of Cu content, the enhancement effect on the precipitation of T1 and θ′ phases becomes more pronounced, gradually overshadowing the initial promotion effect on precipitate growth;

- (3)

- For pre-deformed samples aged at 155 °C/36 h, while maintaining identical precipitate types, significant refinement in precipitate diameter and thickness was observed alongside remarkable T1 phase proliferation. Elevated Cu content induced continuous reduction in T1 phase dimensions while promoting θ′ phase precipitation with slight diameter enlargement;

- (4)

- Comparative analysis revealed that the strengthening mechanism of the T1 phase transitioned from bypass-dominated to shearing-dominated when comparing 175 °C/36 h with 155 °C/36 h aging after pre-deformation. Concurrently, enhanced Cu-induced refinement effects on T1 phases contributed to substantially improved strength in high-Cu alloys under the latter condition.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, S.S.; Yue, X.; Li, Q.Y.; Peng, H.L.; Dong, B.X.; Liu, T.S.; Yang, H.Y.; Fan, J.; Shu, S.L.; Qiu, F.; et al. Development and applications of Aluminum alloys for aerospace industry. J. Mater. Res. Technol. 2023, 27, 944–983. [Google Scholar] [CrossRef]

- Dursun, T.; Soutis, C. Recent developments in advanced aircraft aluminum alloys. Mater. Des. (1980–2015) 2014, 56, 862–871. [Google Scholar] [CrossRef]

- Xiao, G.; An, R.; Yang, J.; Ma, J. Research Progress of New Generation of Aluminum-Lithium Alloys Alloying. Adv. Eng. Mater. 2024, 26, 2301639. [Google Scholar] [CrossRef]

- Rioja, R.J.; Liu, J. The Evolution of Al-Li Base Products for Aerospace and Space Applications. Metall. Mater. Trans. A 2012, 43, 3325–3337. [Google Scholar] [CrossRef]

- Gumbmann, E.; De Geuser, F.; Sigli, C.; Deschamps, A. Influence of Mg, Ag and Zn minor solute additions on the precipitation kinetics and strengthening of an Al-Cu-Li alloy. Acta Mater. 2017, 133, 172–185. [Google Scholar] [CrossRef]

- Liu, Z.Z.; Li, J.F.; Liu, D.Y.; Ma, Y.L.; Du, Y.; Chen, Y.L.; Zhang, X.H.; Gupta, R.K.; Chen, X.B.; Zhang, R.F. Sluggish precipitation strengthening in Al-Li alloy with a high concentration of Mg. J. Mater. Res. Technol. 2021, 11, 1806–1815. [Google Scholar] [CrossRef]

- Noble, B.; Thompson, G.E. T1 (Al2CuLi) Precipitation in Aluminium-Copper-Lithium Alloys. Met. Sci. 1972, 6, 167–174. [Google Scholar] [CrossRef]

- Herring, R.A.; Gayle, F.W.; Pickens, J.R. High-resolution electron microscopy study of a high-copper variant of weldalite 049 and a high-strength AI-Cu-Ag-Mg-Zr alloy. J. Mater. Sci. 1993, 28, 69–73. [Google Scholar] [CrossRef]

- Gumbmann, E.; Lefebvre, W.; De Geuser, F.; Sigli, C.; Deschamps, A. The effect of minor solute additions on the precipitation path of an Al-Cu-Li alloy. Acta Mater. 2016, 115, 104–114. [Google Scholar] [CrossRef]

- Sun, J.; Wu, G.; Zhang, L.; Liu, W.; Zhang, J.; Shi, C.; Li, W. Role of Cu on the mechanical properties and microstructures evolution of Al-xCu-1Li-0.4Mg-1Zn-0.1Zr alloys. Mater. Sci. Eng. A 2020, 792, 139833. [Google Scholar] [CrossRef]

- Ning, H.; Du, Y.; Li, J.F.; Chen, Y.L.; Zhang, X.H.; You, W.; Guo, Y.L. Influence of Cu content on the hardenability of Al-xCu-1.1Li alloys. Mater. Charact. 2022, 194, 112407. [Google Scholar] [CrossRef]

- Li, J.F.; Liu, P.L.; Chen, Y.L.; Zhang, X.H.; Zheng, Z.Q. Microstructure and mechanical properties of Mg, Ag and Zn multi-microalloyed Al-(3.2-3.8)Cu-(1.0-1.4)Li alloys. Trans. Nonferrous Met. Soc. China 2015, 25, 2103–2112. [Google Scholar] [CrossRef]

- Rodgers, B.I.; Prangnell, P.B. Quantification of the influence of increased pre-stretching on microstructure-strength relationships in the Al-Cu-Li alloy AA2195. Acta Mater. 2016, 108, 55–67. [Google Scholar] [CrossRef]

- Araullo-Peters, V.; Gault, B.; De Geuser, F.; Deschamps, A.; Cairney, J.M. Microstructural evolution during ageing of Al–Cu–Li–x alloys. Acta Mater. 2014, 66, 199–208. [Google Scholar] [CrossRef]

- Cui, S.; Zhang, C.; Liu, M.; Chen, L.; Zhao, G. Precipitation behavior of an Al–Cu–Li–X alloy and competing relationships among precipitates at different aging temperatures. Mater. Sci. Eng. A 2021, 814, 141125. [Google Scholar] [CrossRef]

- Xu, X.; Wu, G.; Zhang, L.; Tong, X.; Zhang, X.; Sun, J.; Li, L.; Xiong, X. Effects of heat treatment and pre-stretching on the mechanical properties and microstructure evolution of extruded 2050 Al-Cu-Li alloy. Mater. Sci. Eng. A 2022, 845, 143236. [Google Scholar] [CrossRef]

- Wang, X.M.; Shao, W.Z.; Jiang, J.T.; Li, G.A.; Wang, X.Y.; Zhen, L. Quantitative analysis of the influences of pre-treatments on the microstructure evolution and mechanical properties during artificial ageing of an Al-Cu-Li-Mg-Ag alloy. Mater. Sci. Eng. A 2020, 782, 139253. [Google Scholar] [CrossRef]

- Xie, B.; Huang, L.; Xu, J.; Su, H.; Zhang, H.; Xu, Y.; Li, J.; Wang, Y. Effect of the aging process and pre-deformation on the precipitated phase and mechanical properties of 2195 Al-Li alloy. Mater. Sci. Eng. A 2022, 832, 142394. [Google Scholar] [CrossRef]

- Zeng, G.J.; Li, H.R.; Deng, S.X.; Ma, P.C.; Chen, Y.L.; Liu, T.L.; Li, J.F.; Liu, D.Y.; Xu, G.F. Detailed investigation on microstructure and strengthening contribution of Al-xCu-1.3Li-X alloy sheets. Mater. Charact. 2023, 205, 113278. [Google Scholar] [CrossRef]

- Yan, S.; Wang, R.; Peng, C.; Cai, Z.; Peng, X.; Lv, P.; Li, X. Microstructural evolution and mechanical properties of the rapidly-solidified and hot-extruded 2196 Al-Li alloy. J. Alloys Compd. 2024, 988, 174285. [Google Scholar] [CrossRef]

- Wu, C.H.; Li, H.; Bian, T.J.; Lei, C.; Yang, Y.F.; Zhang, L.W. Effect of natural aging on formability and properties of Al-Cu-Li alloy during creep age forming. Mater. Today Commun. 2023, 36, 106633. [Google Scholar] [CrossRef]

- Ma, P.; Zhan, L.; Liu, C.; Wang, Q.; Li, H.; Liu, D.; Hu, Z. Pre-strain-dependent natural ageing and its effect on subsequent artificial ageing of an Al-Cu-Li alloy. J. Alloys Compd. 2019, 790, 8–19. [Google Scholar] [CrossRef]

- Deschamps, A.; Garcia, M.; Chevy, J.; Davo, B.; De Geuser, F. Influence of Mg and Li content on the microstructure evolution of Al-Cu-Li alloys during long-term ageing. Acta Mater. 2017, 122, 32–46. [Google Scholar] [CrossRef]

- Xie, Y.; Liu, S.; Guo, X.; Liang, C.; Deng, Y. Enhancing the strength of Sc-containing Al-Cu-Li alloys by modifying the precipitation behavior through plastic deformation and heat treatment. Mater. Charact. 2024, 207, 113558. [Google Scholar] [CrossRef]

- Nie, J.F.; Muddle, B.C. Strengthening of an Al-Cu-Sn alloy by deformation-resistant precipitate plates. Acta Mater. 2008, 56, 3490–3501. [Google Scholar] [CrossRef]

- Gu, C.; Yang, X.; Tang, W.; Xu, Y.; Tian, C. Texture features and strengthening mechanisms in welding nugget zone of SSFSWed thick-plate Al-Li alloy joint. Mater. Sci. Eng. A 2022, 848, 143459. [Google Scholar] [CrossRef]

- Liu, S.; Xu, G.; Li, Y.; Tang, L.; Li, H.; Peng, X. Enhanced strength and corrosion resistance of creep-aged AA2050 Al-Li alloy by pre-rolling deformation. Mater. Des. 2023, 226, 111621. [Google Scholar] [CrossRef]

- Kelly, P.M.; Jostons, A.; Blake, R.G.; Napier, J.G. The determination of foil thickness by scanning transmission electron microscopy. Phys. Stat. Sol. 1975, 31, 771–780. [Google Scholar] [CrossRef]

- Dorin, T.; Deschamps, A.; De Geuser, F.; Sigli, C. Quantification and modelling of the microstructure/strength relationship by tailoring the morphological parameters of the T1 phase in an Al-Cu-Li alloy. Acta Mater. 2014, 75, 134–146. [Google Scholar] [CrossRef]

- Nie, J.F.; Muddle, B.C. Microstructural design of high-strength aluminum alloys. J. Phase Equilib. 1998, 19, 543–551. [Google Scholar] [CrossRef]

- Lv, P.; Wang, R.; Peng, C.; Cai, Z.; Feng, Y.; Peng, X. The evolution of precipitates and mechanical properties in rapidly solidified 2195 Al-Cu-Li alloy during thermal exposure. J. Mater. Res. Technol. 2023, 27, 6159–6170. [Google Scholar] [CrossRef]

- Zhu, A.W.; Starke, E.A. Strengthening effect of unshearable particles of finite size: A computer experimental study. Acta Mater. 1999, 47, 3263–3269. [Google Scholar] [CrossRef]

- Dorin, T.; Deschamps, A.; De Geuser, F.; Lefebvre, W.; Sigli, C. Quantitative description of the T1 formation kinetics in an Al-Cu-Li alloy using differential scanning calorimetry, small-angle X-ray scattering and transmission electron microscopy. Philos. Mag. 2014, 94, 1012–1030. [Google Scholar] [CrossRef]

- Dorin, T.; De Geuser, F.; Lefebvre, W.; Sigli, C.; Deschamps, A. Strengthening mechanisms of T1 precipitates and their influence on the plasticity of an Al-Cu-Li alloy. Mater. Sci. Eng. A 2014, 605, 119–126. [Google Scholar] [CrossRef]

- Guo, G.; Li, Y.; Li, H.; Peng, X.; Li, J.; Xu, G. Quantitative effects of pre-deformation prior to non-isothermal aging on the mechanical properties-microstructure relationships in an Al-3.51Cu-1.01Li alloy. Mater. Des. 2022, 223, 111137. [Google Scholar] [CrossRef]

- Blankenship, C.P.; Hornbogen, E.; Starke, E.A. Predicting slip behavior in alloys containing shearable and strong particles. Mater. Sci. Eng. A 1993, 169, 33–41. [Google Scholar] [CrossRef]

- Calabrese, C.; Laird, C. Cyclic stress-strain response of two-phase alloys Part II. Particles not penetrated by dislocations. Mater. Sci. Eng. 1974, 13, 159–174. [Google Scholar] [CrossRef]

- Merle, P.; Fouquet, F.; Merlin, J.; Gobin, P.F. Research into a model for the evolution of the elastic limit of the alloy Al-4% Cu in the θ′ state. Acta Metall. 1979, 27, 327–336. [Google Scholar] [CrossRef]

- Hansen, N. Boundary strengthening over five length scales. Adv. Eng. Mater. 2005, 7, 815–821. [Google Scholar] [CrossRef]

- Smallman, R.E.; Westmacott, K.H. Stacking faults in face-centred cubic metals and alloys. Philos. Mag. 1957, 2, 669–683. [Google Scholar] [CrossRef]

- Williamson, G.K.; Hall, W.H. X-ray line broadening from filed aluminium and wolfram. Acta Metall. 1953, 1, 22–31. [Google Scholar] [CrossRef]

| Alloy | Cu | Li | Mg | Ag | Zn | Mn | Zr | Al |

|---|---|---|---|---|---|---|---|---|

| 3.10 Cu | 3.14 | 0.84 | 0.33 | 0.36 | 0.12 | 0.42 | 0.09 | Bal. |

| 3.50 Cu | 3.54 | 0.88 | 0.37 | 0.39 | 0.13 | 0.41 | 0.13 | Bal. |

| 3.80 Cu | 3.76 | 0.82 | 0.34 | 0.38 | 0.12 | 0.42 | 0.09 | Bal. |

| Alloy | 3.10 Cu | 3.50 Cu | 3.80 Cu | |||

|---|---|---|---|---|---|---|

| Phase | T1 | θ′ | T1 | θ′ | T1 | θ′ |

| dt (nm) | 139.39 | 97.93 | 147.49 | 121.79 | 132.07 | 92.78 |

| t (nm) | 1.96 | 3.54 | 1.93 | 3.45 | 1.98 | 3.34 |

| fV (%) | 1.88 | 0.53 | 2.42 | 0.47 | 2.63 | 0.88 |

| Alloy | 3.10 Cu | 3.50 Cu | 3.80 Cu | |||

|---|---|---|---|---|---|---|

| Phase | T1 | θ′ | T1 | θ′ | T1 | θ′ |

| dt (nm) | 58.47 | 68.36 | 48.51 | 77.97 | 46.85 | 79.36 |

| t (nm) | 1.42 | 2.73 | 1.49 | 2.67 | 1.34 | 3.15 |

| fV (%) | 1.80 | 0.11 | 3.20 | 0.63 | 2.94 | 0.74 |

| Alloy | 3.10 Cu | 3.50 Cu | 3.80 Cu | |||

|---|---|---|---|---|---|---|

| Phase | T1 (bypass) | T1 (shearing) | T1 (bypass) | T1 (shearing) | T1 (bypass) | T1 (shearing) |

| dt (nm) | 193.02 | 63.51 | 203.70 | 64.15 | 179.70 | 64.98 |

| t (nm) | 1.96 | 1.96 | 1.93 | 1.93 | 1.98 | 1.98 |

| fV (%) | 2.14 | 0.16 | 2.79 | 0.18 | 2.88 | 0.26 |

| 2.30 | 2.97 | 3.14 | ||||

| Alloy | 3.10 Cu | 3.50 Cu | 3.80 Cu | |||

|---|---|---|---|---|---|---|

| Phase | T1 (bypass) | T1 (shearing) | T1 (bypass) | T1 (shearing) | T1 (bypass) | T1 (shearing) |

| dt (nm) | 135.63 | 53.19 | 133.25 | 47.29 | 134.85 | 45.43 |

| t (nm) | 1.42 | 1.42 | 1.49 | 1.49 | 1.34 | 1.34 |

| fV (%) | 0.64 | 1.39 | 0.35 | 2.99 | 0.40 | 2.72 |

| 2.03 | 3.34 | 3.12 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, P.; Li, X.; Lin, H.; Wen, K.; Li, Y.; Wang, S.; Xun, C.; Li, C.; Yan, L.; Zhang, Y.; et al. Influence of Cu Content on Precipitation Behavior and Mechanical Properties Under Aging Treatment of Al-Cu-Li Alloys. Materials 2025, 18, 2172. https://doi.org/10.3390/ma18102172

Chen P, Li X, Lin H, Wen K, Li Y, Wang S, Xun C, Li C, Yan L, Zhang Y, et al. Influence of Cu Content on Precipitation Behavior and Mechanical Properties Under Aging Treatment of Al-Cu-Li Alloys. Materials. 2025; 18(10):2172. https://doi.org/10.3390/ma18102172

Chicago/Turabian StyleChen, Pengcheng, Xiwu Li, Haitao Lin, Kai Wen, Ying Li, Shuyan Wang, Chenyang Xun, Changlin Li, Lizhen Yan, Yongan Zhang, and et al. 2025. "Influence of Cu Content on Precipitation Behavior and Mechanical Properties Under Aging Treatment of Al-Cu-Li Alloys" Materials 18, no. 10: 2172. https://doi.org/10.3390/ma18102172

APA StyleChen, P., Li, X., Lin, H., Wen, K., Li, Y., Wang, S., Xun, C., Li, C., Yan, L., Zhang, Y., & Xiong, B. (2025). Influence of Cu Content on Precipitation Behavior and Mechanical Properties Under Aging Treatment of Al-Cu-Li Alloys. Materials, 18(10), 2172. https://doi.org/10.3390/ma18102172