Alkali-Activated Permeable Concretes with Agro-Industrial Wastes for a Sustainable Built Environment

Highlights

- Air-cured alkali-activated permeable concrete was developed using agro-industrial wastes;

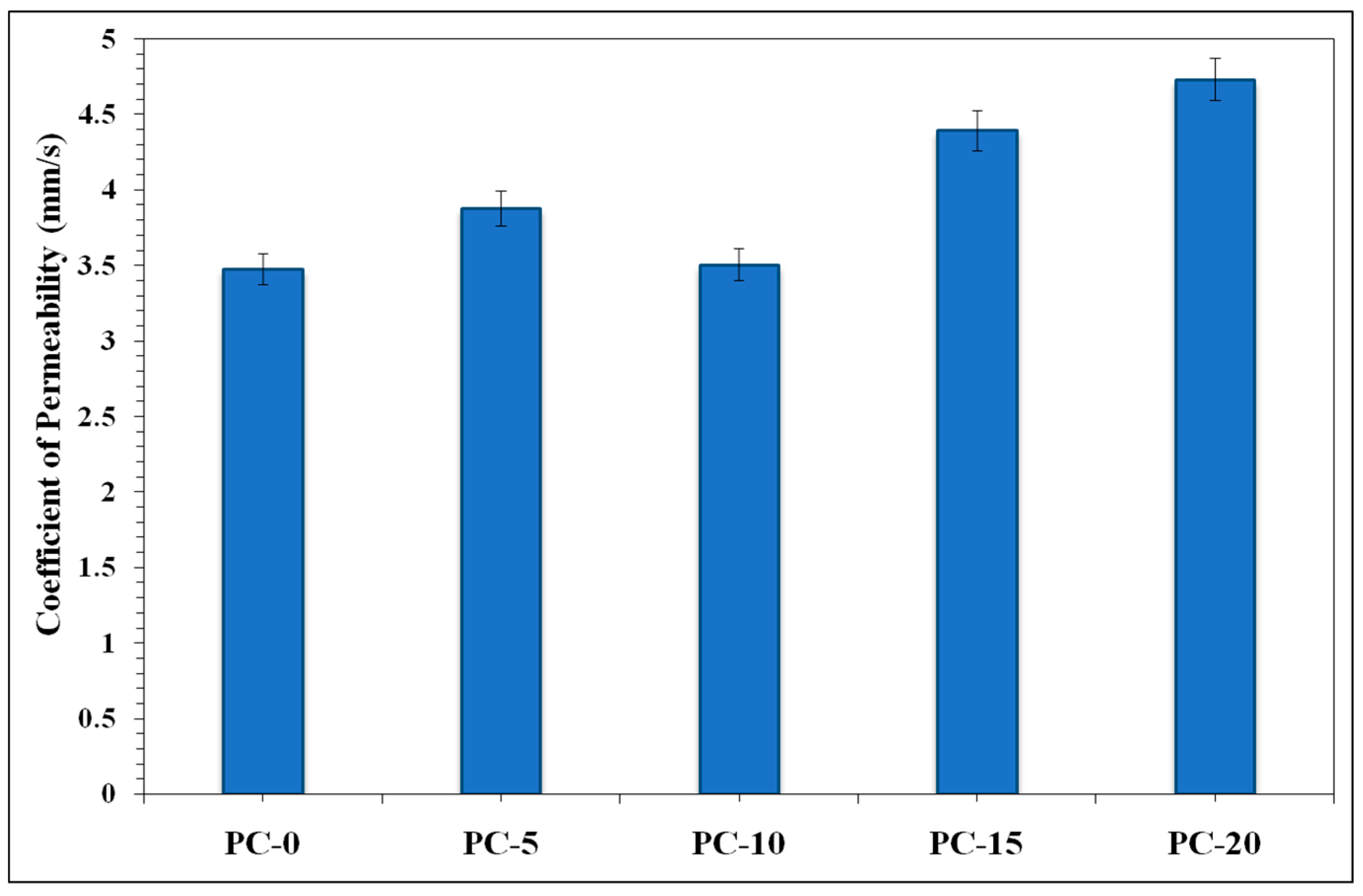

- Sugarcane bagasse ash (10%) enhanced the strength, durability, and hydraulic conductivity of the concrete;

- An optimized mix exhibited improved tensile, flexural strength, and reduced water absorption;

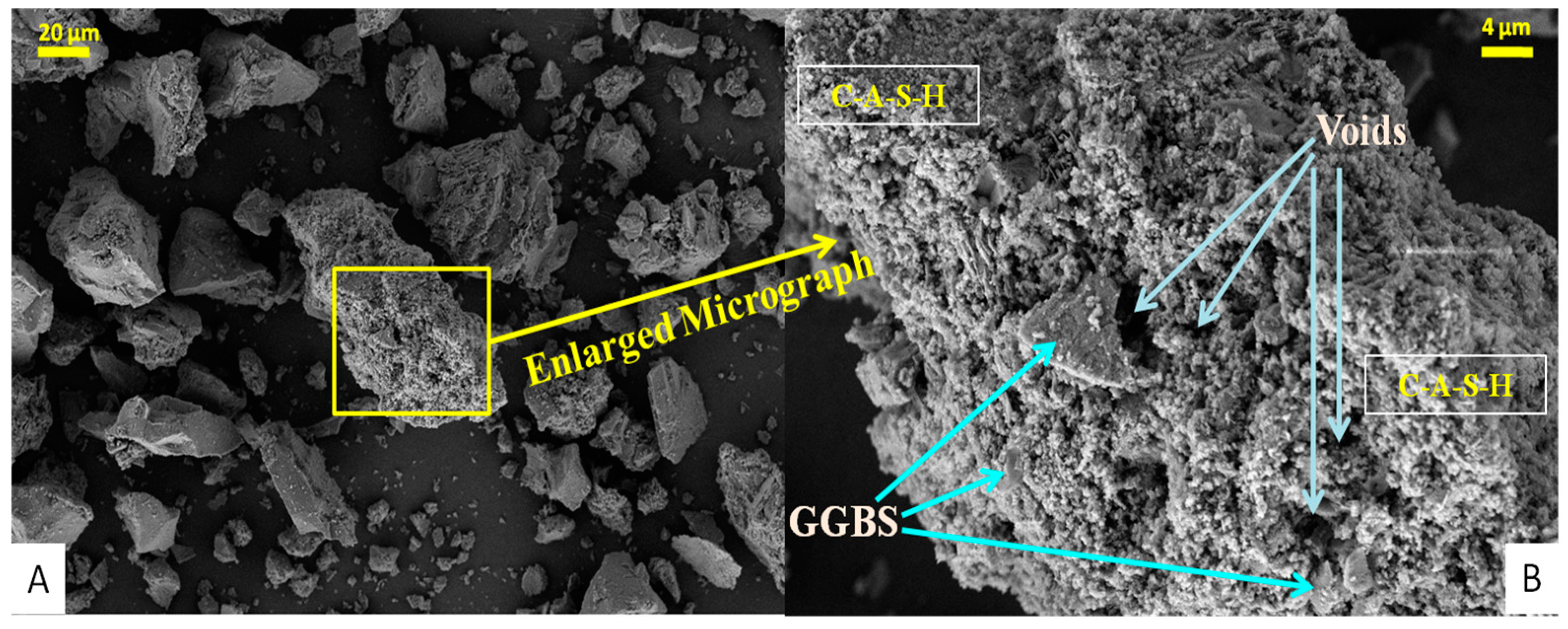

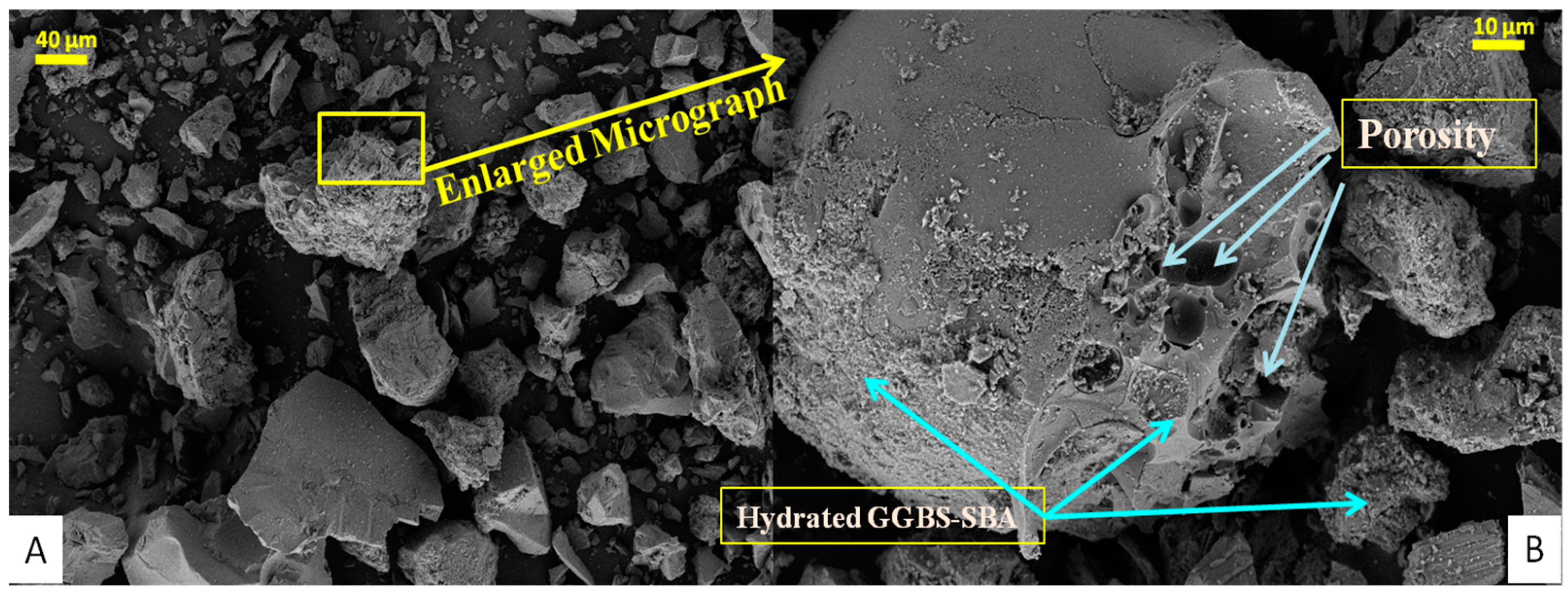

- Microstructural studies revealed denser hydration phases in optimized concrete mixes;

- These findings promote sustainable alkali-activated concretes for eco-friendly urban infrastructure.

Abstract

1. Introduction

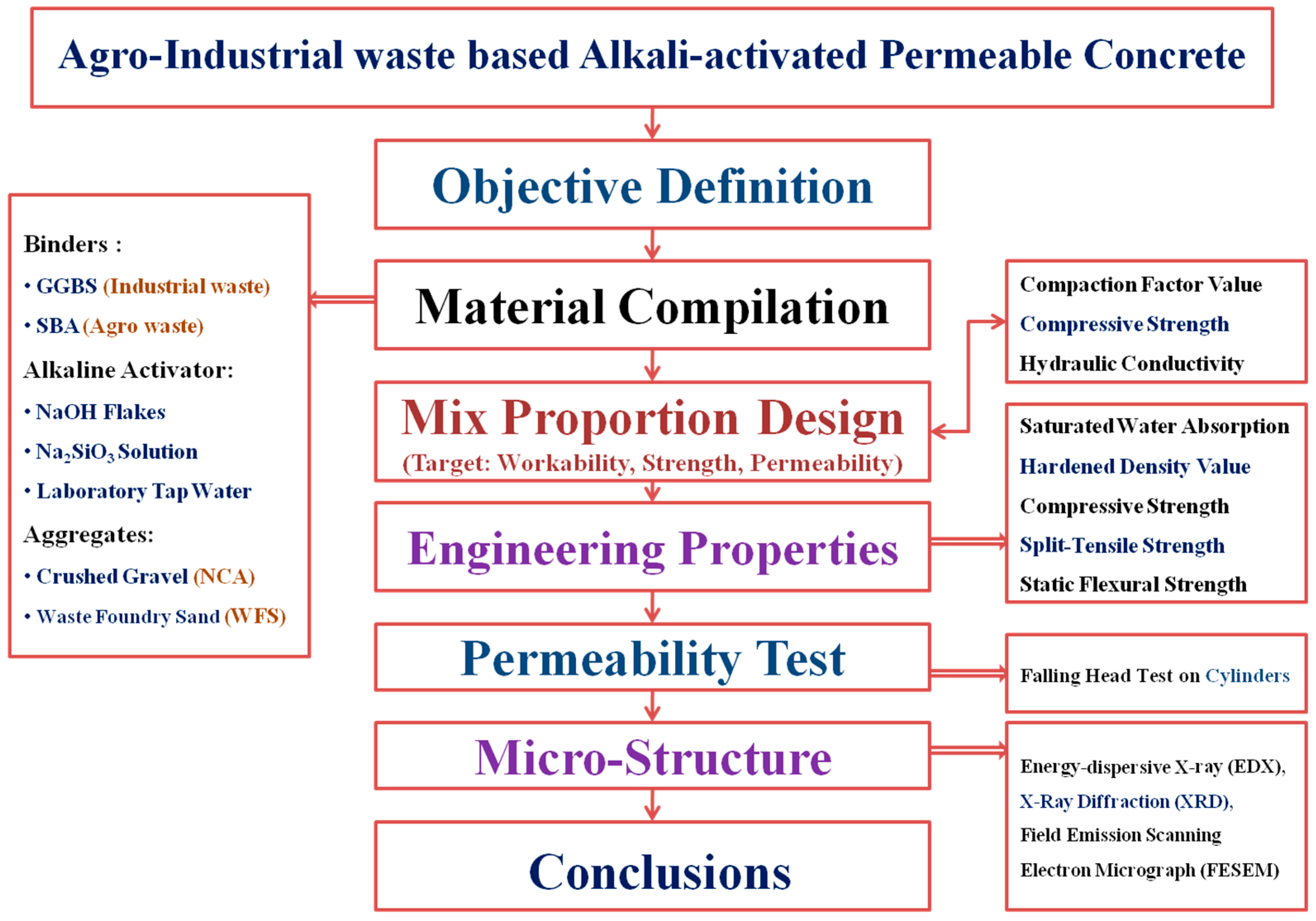

2. Materials and Experimental Methodology

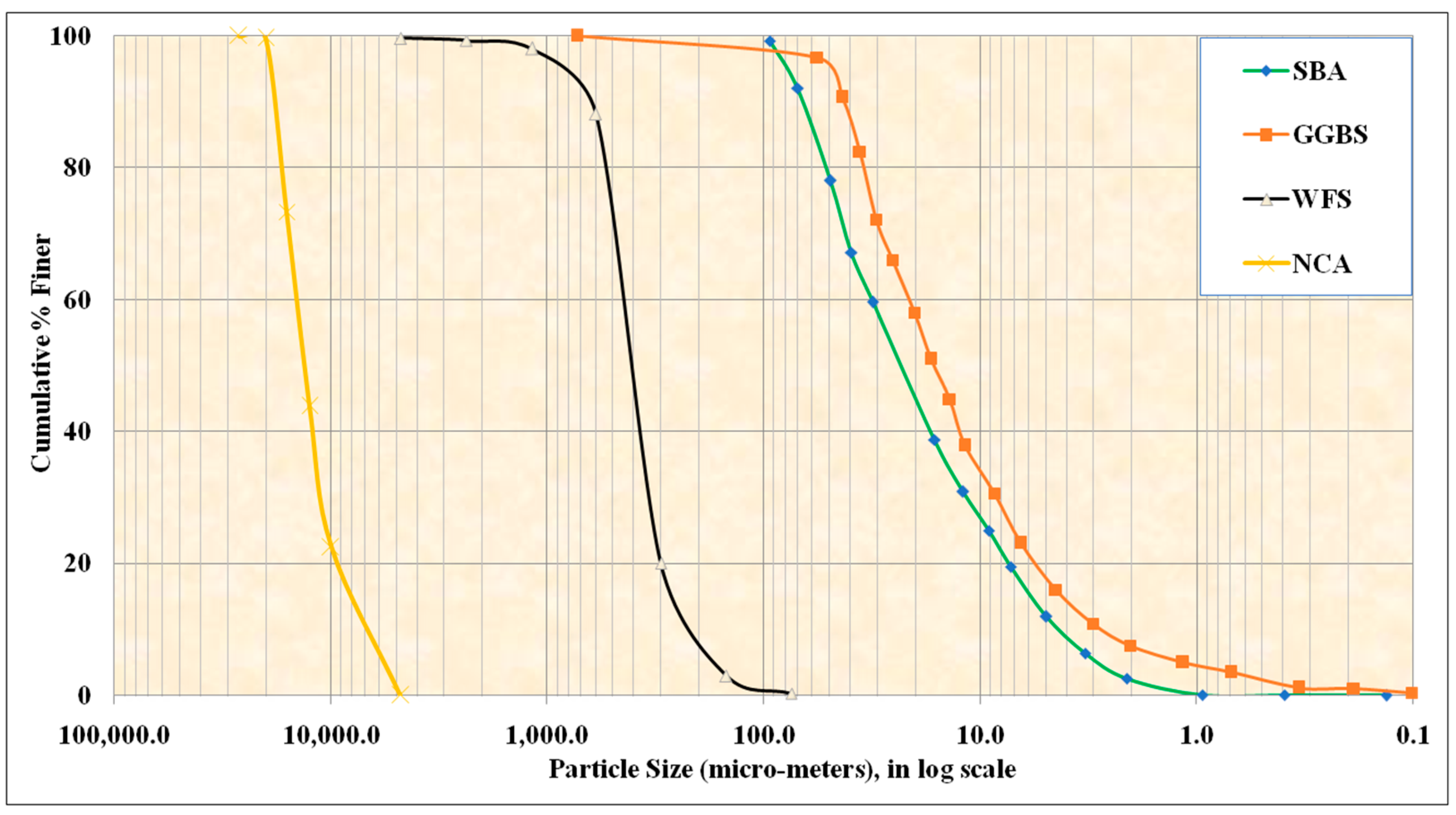

2.1. Materials and Design Mix

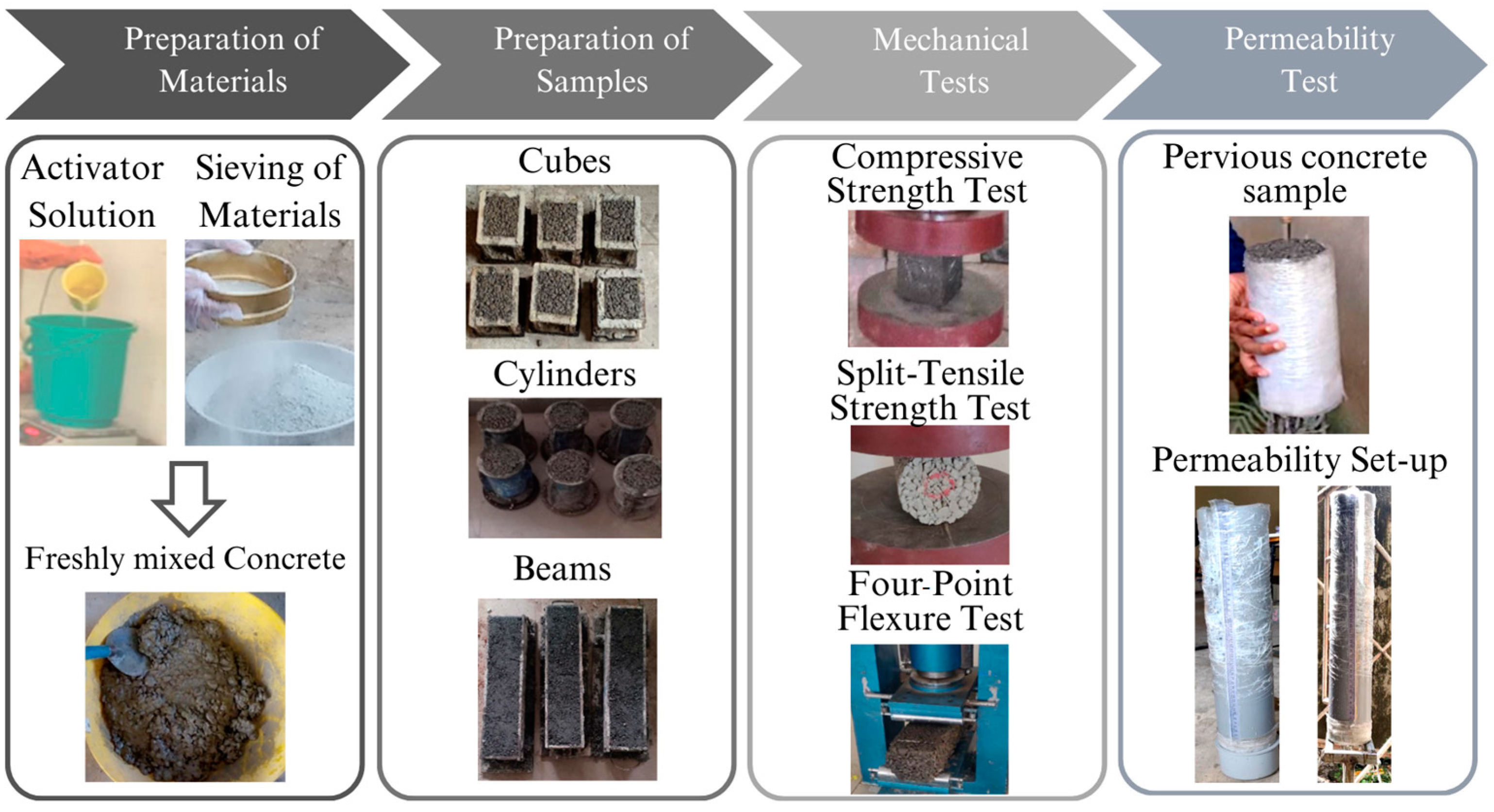

2.2. Experimental Methodology

3. Results and Discussions

3.1. Mechanical Properties of AAPC Mixes

3.2. Micro-Structural Behaviour of AAPC Mixes

3.2.1. Energy-Dispersive X-Ray Analysis (EDX)

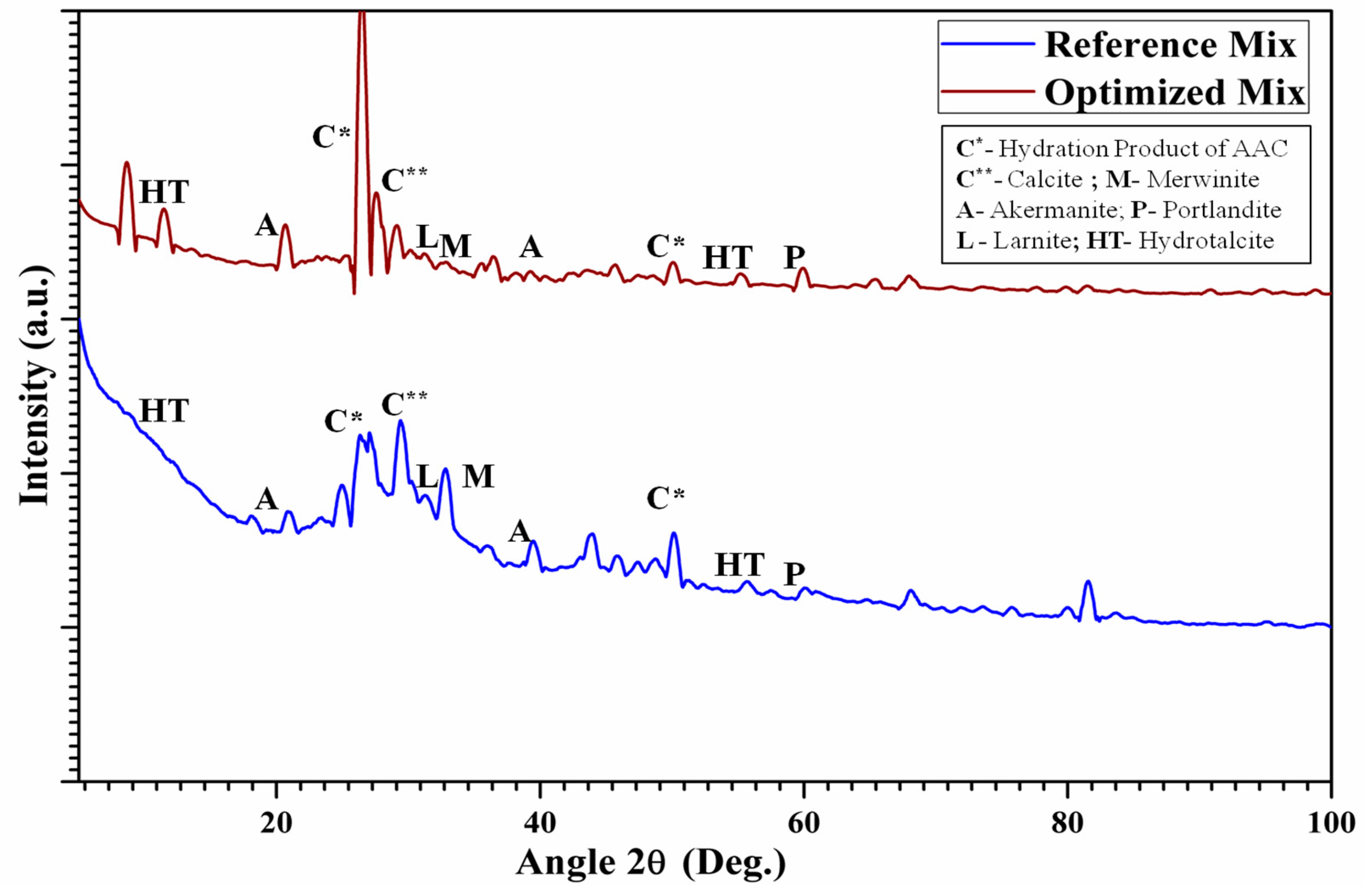

3.2.2. X-Ray Diffraction (XRD) Analysis

3.2.3. Analysis of Field Emission Scanning Electron Micrographs (FESEMs)

3.3. Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

References

- Montes, F.; Haselbach, L. Measuring Hydraulic Conductivity in Pervious Concrete. Environ. Eng. Sci. 2006, 23, 960–969. [Google Scholar] [CrossRef]

- Nnaji, C.C.; Udokpoh, U.U.; Ifeakor, A.R. Assessing the Efficiencies of Domestic Water Pumps and Distribution Systems for Household Water Supply in Enugu State, Nigeria. Indian J. Eng. 2024, 21, e5ije1680. [Google Scholar] [CrossRef]

- Singh, A.; Sampath, P.V.; Biligiri, K.P. A Review of Sustainable Pervious Concrete Systems: Emphasis on Clogging, Material Characterization, and Environmental Aspects. Constr. Build. Mater. 2020, 261, 120491. [Google Scholar] [CrossRef]

- Marathe, S.; Sadowski, Ł.; Shree, N. Geopolymer and Alkali-Activated Permeable Concrete Pavements: Bibliometrics and Systematic Current State of the Art Review, Applications, and Perspectives. Constr. Build. Mater. 2024, 421, 135586. [Google Scholar] [CrossRef]

- Dominković, D.F.; Bačeković, I.; Pedersen, A.S.; Krajačić, G. The Future of Transportation in Sustainable Energy Systems: Opportunities and Barriers in a Clean Energy Transition. Renew. Sustain. Energy Rev. 2018, 82, 1823–1838. [Google Scholar] [CrossRef]

- Sheshadri, A.; Marathe, S.; Sadowski, Ł. Development of Sustainable, High Strength Slag Based Alkali Activated Pavement Quality Concrete Using Agro-Industrial Wastes: Properties and Life Cycle Analysis. Int. J. Pavement Eng. 2024, 25, 2410953. [Google Scholar] [CrossRef]

- Muthu, M.; Sadowski, Ł. Evaluation of the Performance of Pervious Concrete Inspired by CO2-Curing Technology. Appl. Sci. 2024, 14, 4202. [Google Scholar] [CrossRef]

- Muthu, M.; Sadowski, Ł. Performance of Permeable Concrete Mixes Based on Cement and Geopolymer in Aggressive Aqueous Environments. J. Build. Eng. 2023, 76, 107143. [Google Scholar] [CrossRef]

- Marathe, S.; Rodrigues, A.P. Intelligent Models for Prediction of Compressive Strength of Geopolymer Pervious Concrete Hybridized with Agro-Industrial and Construction-Demolition Wastes. Stud. Geotech. Mech. 2024, 10, 1–28. [Google Scholar] [CrossRef]

- Marathe, S.; Shetty, T.S.; Mithun, B.M.; Ranjith, A. Strength and Durability Studies on Air Cured Alkali Activated Pavement Quality Concrete Mixes Incorporating Recycled Aggregates. Case Stud. Constr. Mater. 2021, 15, e00732. [Google Scholar] [CrossRef]

- Sheshadri, A.; Marathe, S.; Bettadapura Manjunath, M.; Jayasimhan, A.; Sadowski, Ł. Effective Utilization of Foundry Waste as Aggregates in Developing Eco-Friendly Alkali-Activated and Conventional Concretes for Sustainable Pavement Infrastructure. Pract. Period. Struct. Des. Constr. 2024, 29, 04024018. [Google Scholar] [CrossRef]

- Blesson, S.; Rao, A.U. Agro-Industrial-Based Wastes as Supplementary Cementitious or Alkali-Activated Binder Material: A Comprehensive Review. Innov. Infrastruct. Solut. 2023, 8, 125. [Google Scholar] [CrossRef]

- Kathirvel, P.; Gunasekaran, M.; Sreekumaran, S.; Krishna, A. Effect of Partial Replacement of Ground Granulated Blast Furnace Slag with Sugarcane Bagasse Ash as Source Material in the Production of Geopolymer Concrete. Medziagotyra 2020, 26, 477–481. [Google Scholar] [CrossRef]

- IS-2386; Part-I Indian Standard Method of Test for Aggregate for Concrete; Part I—Particle Size and Shape. Bureau of Indian Standards: New Delhi, India, 1963; pp. 1–26.

- IS:2386; Part III—Method of Test for Aggregate for Concrete. Bureau of Indian Standards: New Delhi, India, 1963; pp. 1–17.

- IS 2386; Part IV–Methods of Test for Aggregates for Concrete—Mechanical Properties. Bureau of Indian Standards: New Delhi, India, 1963; pp. 1–28.

- IS:383; Coarse and Fine Aggregate for Concrete—Specification. Bureau of Indian Standards: New Delhi, India, 2016; pp. 1–21.

- Marathe, S.; Prashanth, L.D.; Sadowski, Ł. Engineering of Alkali-Activated Permeable Pavement Composites with Agro-Industrial Wastes. Int. J. Pavement Eng. 2024, 25, 2431600. [Google Scholar] [CrossRef]

- IRC:44 Guidelines for Cement Concrete Mix Design for Pavements; Indian Roads Congress (IRC): New Delhi, India, 2017; pp. 1–60.

- Marathe, S.; Mithanthaya, I.R.; Shenoy, R.Y. Durability and Microstructure Studies on Slag-Fly Ash-Glass Powder Based Alkali Activated Pavement Quality Concrete Mixes. Constr. Build. Mater. 2021, 287, 123047. [Google Scholar] [CrossRef]

- Marathe, S.; Mithanthaya, I.R.; Mithun, B.M.; Shetty, S.; Akarsh, P.A. Performance of Slag-Fly Ash Based Alkali Activated Concrete for Paver Applications Utilizing Powdered Waste Glass as a Binding Ingredient. Int. J. Pavement Res. Technol. 2020, 14, 196–203. [Google Scholar] [CrossRef]

- IS-1199; Part-2—Fresh Concrete- Methods of Sampling, Testing and Analysis; Part 2 Determination of Consistency of Fresh Concrete. Bureau of Indian Standards: New Delhi, India, 2018; pp. 1–15.

- IS:516; Part 2/Sec 2—Hardened Concrete—Methods of Test: Part 2 Properties of Hardened Concrete Other than Strengt: Section 2 Initial Surface Absorption. Bureau of Indian Standards: New Delhi, India, 2020; pp. 1–6.

- IS 516; Part 2:Sec 1—Hardened Concrete- Methods of Test: Part 2-Properties of Hardened Concrete Other than Strength, Section 1 Density of Hardened Concrete and Depth of Water Penetration Under Pressure. Bureau of Indian Standards: New Delhi, India, 2018; pp. 1–6.

- IS 516; Part 1-Sec 1—Hardened Concrete- Methods of Test: Part 1 Testing of Strength of Hardened Concrete, Section 1 Compressive, Flexural and Split Tensile Strength. Bureau of Indian Standards: New Delhi, India, 2021; pp. 1–9.

- ASTM:D2434-22; Standard Test Methods for Measurement of Hydraulic Conductivity of Coarse-Grained Soils. ASTM International: West Conshohocken, PA, USA, 2022; pp. 1–16.

- Kevern, J.T.; Biddle, D.; Cao, Q. Effects of Macrosynthetic Fibers on Pervious Concrete Properties. J. Mater. Civ. Eng. 2015, 27, 06014031. [Google Scholar] [CrossRef]

- ASTM C1723-16; Standard Guide for Examination of Hardened Concrete Using Scanning Electron Microscopy. ASTM International: West Conshohocken, PA, USA, 2022.

- Marathe, S.; Sheshadri, A.; Sadowski, Ł. Agro-Industrial Waste Utilization in Air-Cured Alkali-Activated Pavement Composites: Properties, Micro-Structural Insights and Life Cycle Impacts. Clean. Mater. 2024, 14, 100281. [Google Scholar] [CrossRef]

- Bahurudeen, A.; Vaisakh, K.S.; Santhanam, M. Availability of Sugarcane Bagasse Ash and Potential for Use as a Supplementary Cementitious Material in Concrete. Indian Concr. J. 2015, 89, 41–50. [Google Scholar]

- Shetty, M.S.; Jain, A.K. Concrete Technology: Theory and Practice; S. Chand Publishing House: New Delhi, India, 2018. [Google Scholar]

- Sales, A.; Lima, S.A. Use of Brazilian Sugarcane Bagasse Ash in Concrete as Sand Replacement. Waste Manag. 2010, 30, 1114–1122. [Google Scholar] [CrossRef] [PubMed]

- Sinyoung, S.; Asavapisit, S.; Kunchariyakun, K. Investigation of Bagasse Ash as an Alternative Raw Material in Clinker Production. J. Mater. Civ. Eng. 2022, 34, 04021433. [Google Scholar] [CrossRef]

- Filho, E.L.C.; Dos Santos Ferreira, G.C.; Nogarotto, D.C.; Pozza, S.A. Pervious Concrete with Waste Foundry Sand: Mechanical and Hydraulic Properties. Rev. Mater. 2022, 27, e13154. [Google Scholar] [CrossRef]

- Kunther, W.; Ferreiro, S.; Skibsted, J. Influence of the Ca/Si Ratio on the Compressive Strength of Cementitious Calcium-Silicate-Hydrate Binders. J. Mater. Chem. A 2017, 5, 17401–17412. [Google Scholar] [CrossRef]

- Pelisser, F.; Gleize, P.J.P.; Mikowski, A. Effect of the Ca/Si Molar Ratio on the Micro/Nanomechanical Properties of Synthetic C-S-H Measured by Nanoindentation. J. Phys. Chem. C 2012, 116, 17219–17227. [Google Scholar] [CrossRef]

- Ghorbani, S.; Stefanini, L.; Sun, Y.; Walkley, B.; Provis, J.L.; Schutter, G.D.; Matthys, S. Characterisation of Alkali-Activated Stainless Steel Slag and Blast-Furnace Slag Cements. Cem. Concr. Compos. 2023, 143, 105230. [Google Scholar] [CrossRef]

- Stefanini, L.; Ansari, D.; Walkley, B.; Provis, J.L. Characterisation of Calcined Waste Clays from Kaolinite Extraction in Alkali-Activated GGBFS Blends. Mater. Today Commun. 2024, 38, 107777. [Google Scholar] [CrossRef]

- JCPDS-Index to the Powder Diffraction File. Available online: https://www.icdd.com/pdfsearch/ (accessed on 10 September 2024).

- Haha, M.; Ben; Lothenbach, B.; Le Saout, G.; Winnefeld, F. Influence of Slag Chemistry on the Hydration of Alkali-Activated Blast-Furnace Slag—Part I: Effect of MgO. Cem. Concr. Res. 2011, 41, 955–963. [Google Scholar] [CrossRef]

- Walkley, B.; San Nicolas, R.; Sani, M.-A.; Rees, G.J.; Hanna, J.V.; van Deventer, J.S.J.; Provis, J.L. Phase Evolution of C-(N)-A-S-H/N-A-S-H Gel Blends Investigated via Alkali-Activation of Synthetic Calcium Aluminosilicate Precursors. Cem. Concr. Res. 2016, 89, 120–135. [Google Scholar] [CrossRef]

- Ramezani, S.J.; Toufigh, M.M.; Toufigh, V. Utilization of Glass Powder and Silica Fume in Sugarcane Bagasse Ash-Based Geopolymer for Soil Stabilization. J. Mater. Civ. Eng. 2023, 35, 04023042. [Google Scholar] [CrossRef]

- Öz, A. Optimization of Mechanical Properties and Embodied Energy of Polyvinyl Alcohol Fiber-Reinforced High-Strength Alkali-Activated Slag Mortars: Comparative Study. J. Mater. Civ. Eng. 2023, 35, 4023465. [Google Scholar] [CrossRef]

- Chen, J.; Zhu, Z.; Zhou, L.; Zhuang, J.; Wang, M.; Ma, L. Study on Mechanical Properties of (1% PVA Fiber +1% Steel Fiber) PS-ECC under the Coupling Effects of Elevated Temperature and Dynamic Loads. Struct. Concr. 2023, 24, 4126–4144. [Google Scholar] [CrossRef]

| Mix ID | PC-0 | PC-5 | PC-10 | PC-15 | PC-20 |

|---|---|---|---|---|---|

| Waste-Foundry Fine Aggregates (WFS) | 199.7 | 199.3 | 198.9 | 198.6 | 198.3 |

| Granite Coarse Aggregates (NCA) | 1881.3 | 1878.13 | 1874.89 | 1871.65 | 1868.42 |

| Sodium Silicate Liquid (LSS) | 44.207 | 44.207 | 44.207 | 44.207 | 44.207 |

| Sodium Hydroxide Solids (NaOH) | 6.583 | 6.583 | 6.583 | 6.583 | 6.583 |

| Water | 92.791 | 92.791 | 92.791 | 92.791 | 92.791 |

| Sugarcane Bagasse Ash (SBA) | 0 | 14.5 | 29 | 43.5 | 58 |

| Ground Granulated Blast-Furnace Slag (GGBS) | 290 | 275.5 | 261 | 246.5 | 232 |

| Mix ID | PC-0 | PC-5 | PC-10 | PC-15 | PC-20 |

|---|---|---|---|---|---|

| % GGBS | 100 | 95 | 90 | 85 | 80 |

| % SBA | 0 | 5 | 10 | 15 | 20 |

| Compressive Strength (MPa) | 32.2 | 34.2 | 37.5 | 30.2 | 27.8 |

| Split Tensile Strength (MPa) | 2.14 | 2.31 | 2.47 | 2.02 | 1.99 |

| Flexural Strength (MPa) | 3.92 | 4.02 | 4.1 | 3.87 | 3.41 |

| Element | C | O | Fe | Na | Mg | Al | Si | S | Ca | Mn |

|---|---|---|---|---|---|---|---|---|---|---|

| PC-0 | 5.36 | 34.0 | 0 | 5.39 | 4.13 | 9.82 | 21.44 | 3.68 | 15.81 | 0.35 |

| PC-10 | 3.32 | 42.91 | 1.13 | 1.8 | 6.5 | 9.55 | 14.97 | 4.87 | 14.91 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marathe, S.; Nieświec, M.; Gronostajska, B. Alkali-Activated Permeable Concretes with Agro-Industrial Wastes for a Sustainable Built Environment. Materials 2025, 18, 87. https://doi.org/10.3390/ma18010087

Marathe S, Nieświec M, Gronostajska B. Alkali-Activated Permeable Concretes with Agro-Industrial Wastes for a Sustainable Built Environment. Materials. 2025; 18(1):87. https://doi.org/10.3390/ma18010087

Chicago/Turabian StyleMarathe, Shriram, Martyna Nieświec, and Barbara Gronostajska. 2025. "Alkali-Activated Permeable Concretes with Agro-Industrial Wastes for a Sustainable Built Environment" Materials 18, no. 1: 87. https://doi.org/10.3390/ma18010087

APA StyleMarathe, S., Nieświec, M., & Gronostajska, B. (2025). Alkali-Activated Permeable Concretes with Agro-Industrial Wastes for a Sustainable Built Environment. Materials, 18(1), 87. https://doi.org/10.3390/ma18010087