Impact of Ce Doping on the Relaxor Behavior and Electrical Properties of Sr0.4Ba0.6Nb2O6 Ferroelectric Ceramics

Abstract

1. Introduction

2. Materials and Methods

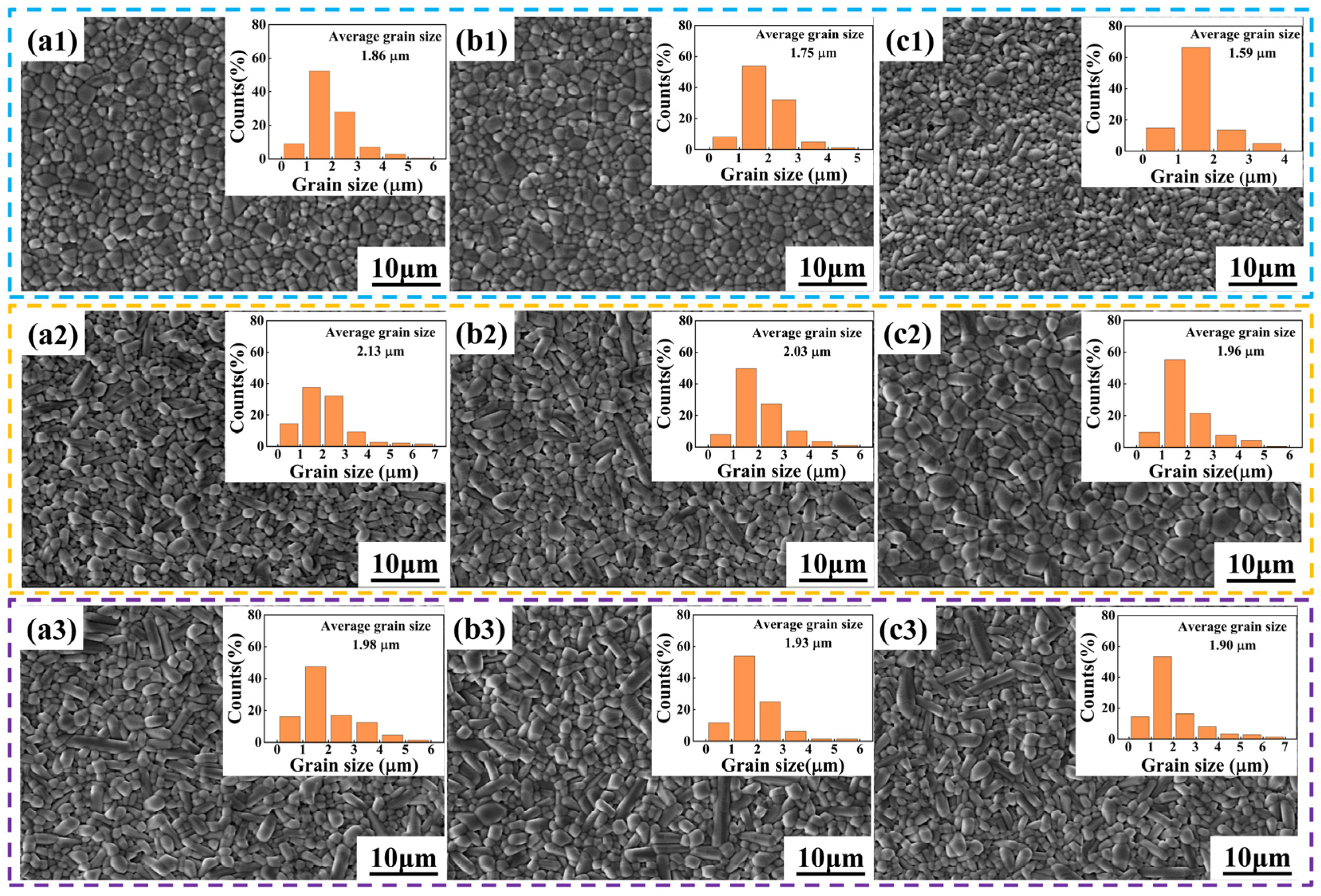

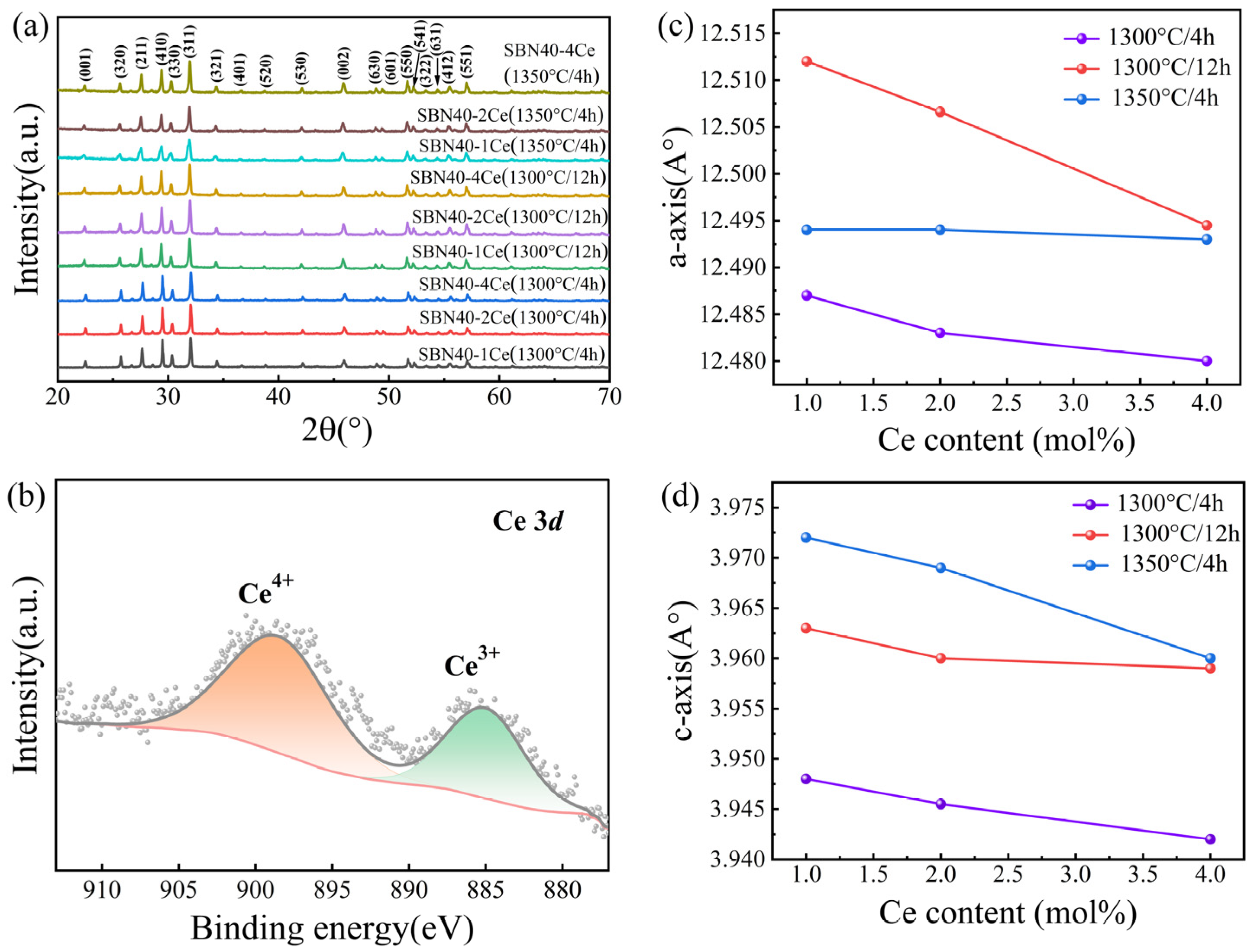

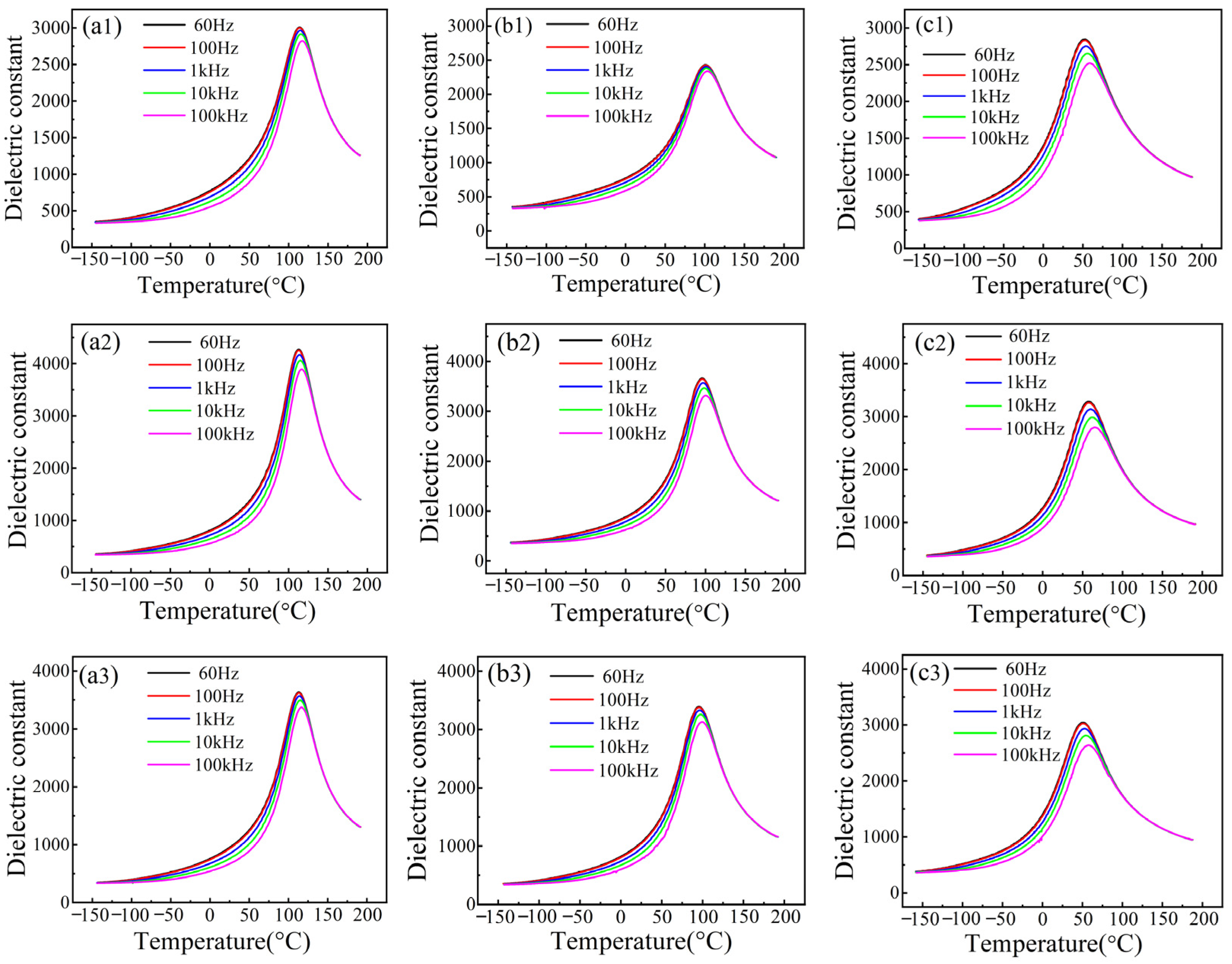

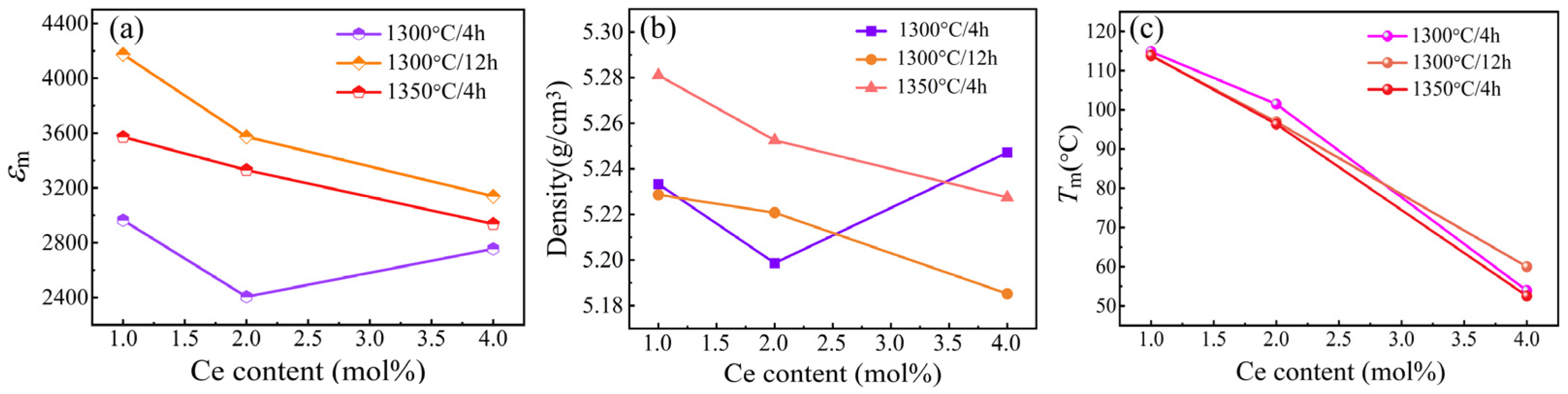

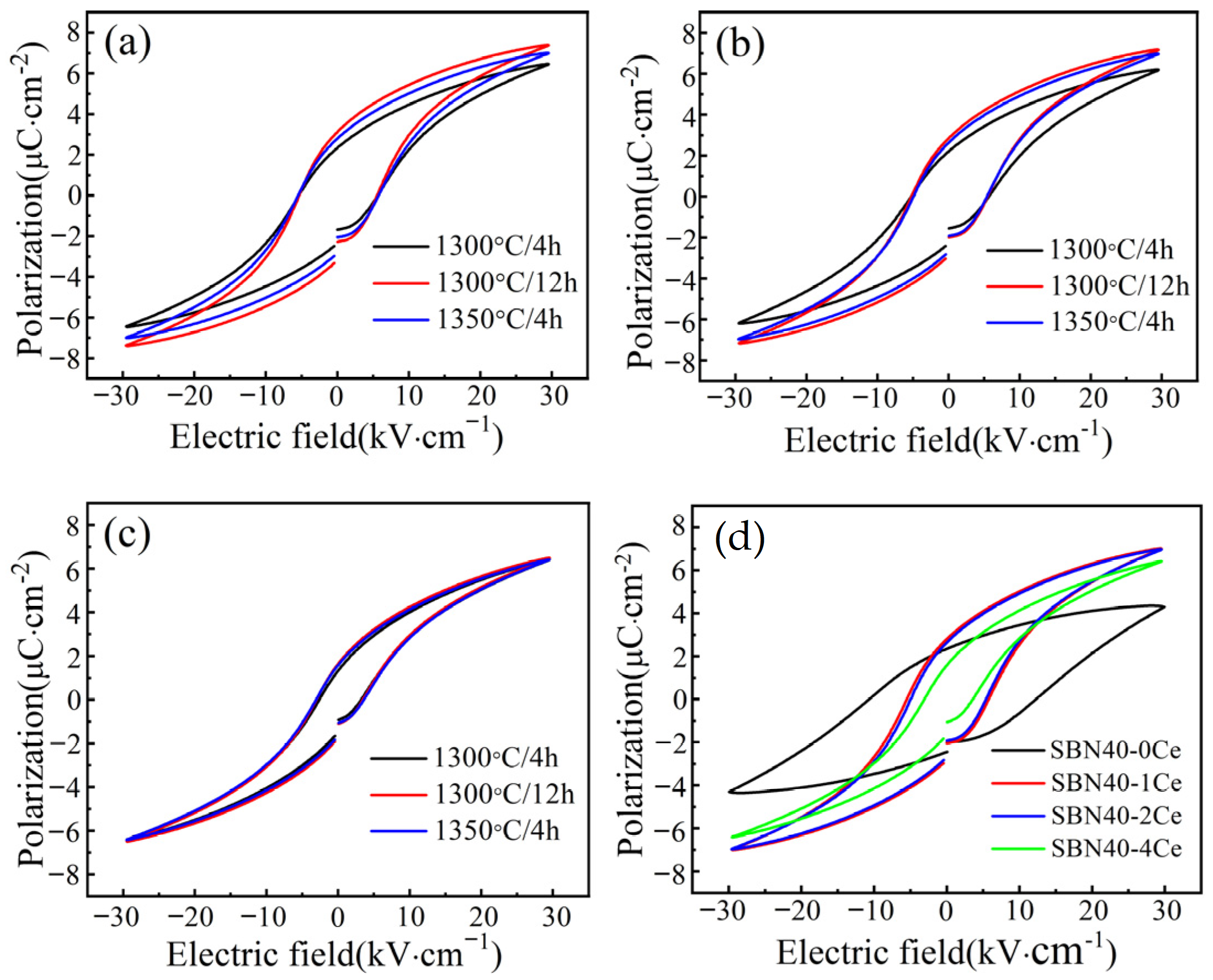

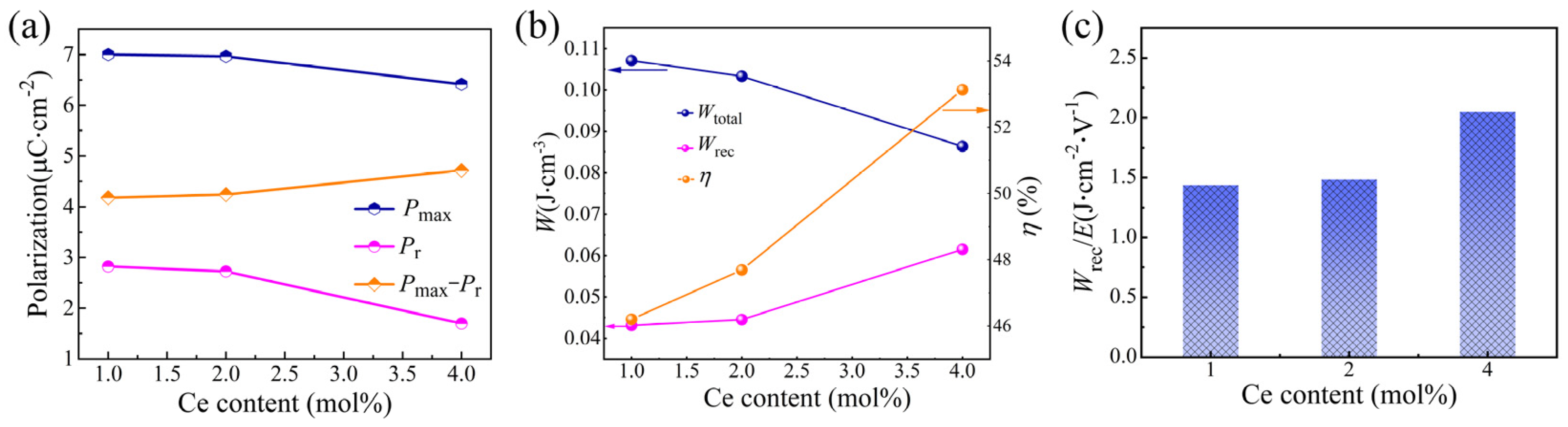

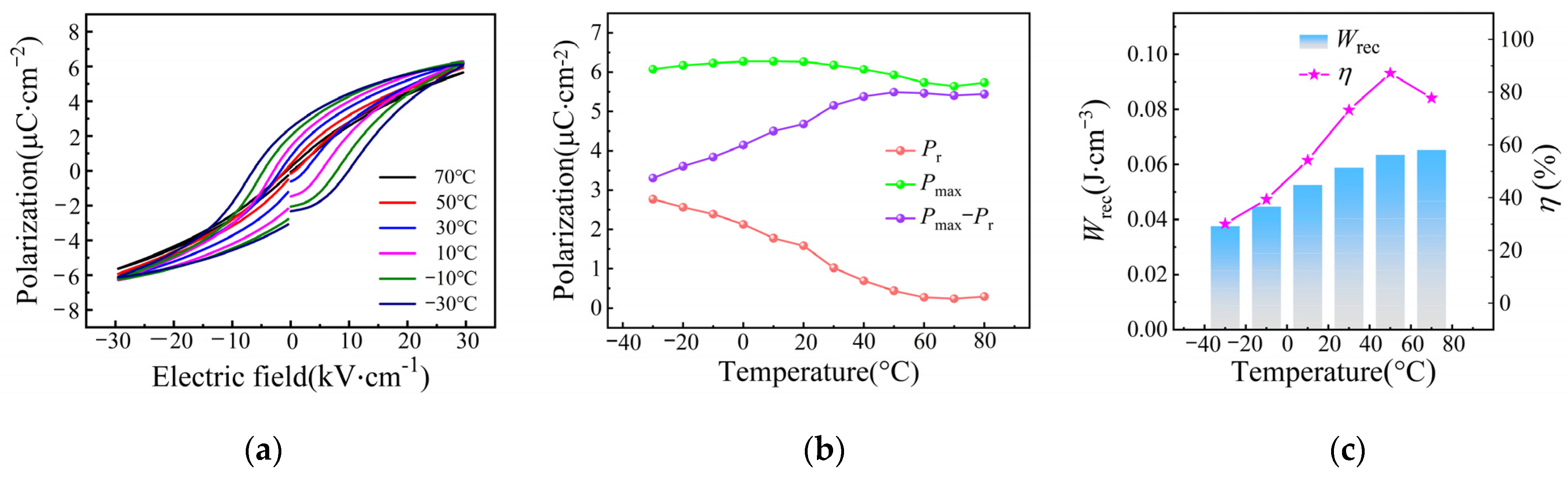

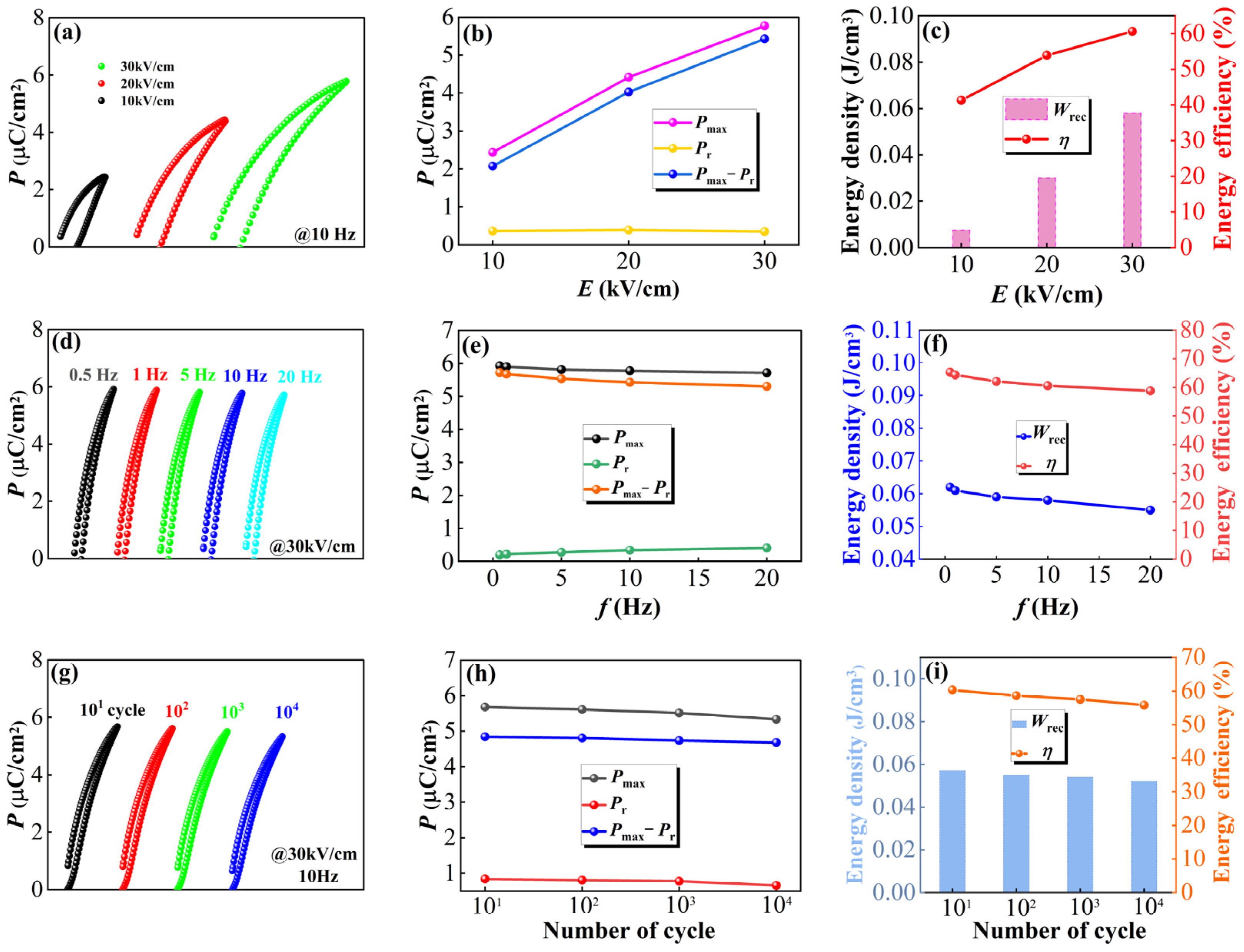

3. Results

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, Y.; Li, Z.; Du, H.; Liu, X.; Liu, J.; Kang, R.; Mao, P.; Zhang, L. Enhanced energy storage properties promoted by the synergistic effects of aging effects and relaxor behavior in Ce-Mn co-doped Sr0.4Ba0.6Nb2O6 ferroelectric ceramics. Ceram. Int. 2024, 50, 38462–38470. [Google Scholar] [CrossRef]

- Haertling, G.H. Ferroelectric ceramics: History and technology. J. Am. Ceram. Soc. 1999, 82, 797–818. [Google Scholar] [CrossRef]

- Bahri, F.; Simon, A.; Khemakhem, H.; Ravez, J. Classical or relaxor ferroelectric behaviour of ceramics with composition Ba1−xBi2x/3TiO3. Phys. Status Solidi 2001, 184, 459–464. [Google Scholar] [CrossRef]

- Kang, R.; Wang, Z.; Yang, W.; Zhao, Y.; Zhang, L.; Lou, X. Enhanced energy storage performance of Bi0.5Na0.5TiO3-based ceramics via grain tuning and relaxor construction. Chem. Eng. J. 2023, 455, 140924. [Google Scholar] [CrossRef]

- Li, J.; Pu, Y.; Wang, Z.; Dai, J. A comparative study of Sr0.7Ba0.3Nb2O6 relaxor ferroelectric ceramics prepared by conventional and microwave sintering techniques. Ceram. Int. 2013, 39, 5069–5075. [Google Scholar] [CrossRef]

- Fang, T.T.; Chen, F.Y. The defect structure sintering behavior and dielectric responses of Cr2O3-doped Sr0.5Ba0.5Nb2O6. J. Appl. Phys. 2006, 100, 014110. [Google Scholar] [CrossRef]

- Paunovic, V.; Mitic, V.; Kocic, L. Dielectric characteristics of donor-acceptor modified BaTiO3 ceramics. Ceram. Int. 2016, 42, 11692–11699. [Google Scholar] [CrossRef]

- Li, Q.; Du, H.; Zhao, X.; Zhao, F.; Zhang, Y.; Hu, X.; Du, X. Densification and microstructure evolution of NaNbO3 ceramic via ultrafast high-temperature sintering. Ceram. Int. 2024, 50, 18907–18914. [Google Scholar] [CrossRef]

- Micard, Q.; Clementi, G.; Bartasyte, A.; Muralt, P.; Condorelli, G.G.; Malandrino, G. Self-poled heteroepitaxial Bi(1−x)DyxFeO3 films with promising pyroelectric properties. Adv. Mater. Int. 2022, 9, 2101539. [Google Scholar] [CrossRef]

- Morozov, M.I.; Einarsrud, M.A.; Tolchard, J.R.; Geiger, P.T.; Webber, K.G.; Damjanovic, D.; Grande, T. In-situ structural investigations of ferroelasticity in soft and hard rhombohedral and tetragonal PZT. J. Appl. Phys. 2015, 118, 164104. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, W.; Chen, W.; Ren, X.; Sun, J.; Gurdal, E.A.; Ural, S.O.; Uchino, K. Mn dopant on the “domain stabilization” effect of aged BaTiO3 and PbTiO3-based piezoelectrics. Appl. Phys. Lett. 2012, 101, 242903. [Google Scholar] [CrossRef]

- Li, Z.; Yu, J.; Hao, S.; Janolin, P. Enhancing properties of lead-free ferroelectric BaTiO3 through doping. J. Eur. Ceram. Soc. 2022, 42, 4693–4701. [Google Scholar] [CrossRef]

- Azadeh, M.; Zhao, C.; Pawadi, A.; Gao, S.; Frömling, T. Effect of iron acceptor doping and calcium donor doping in potassium sodium niobate-based lead-free piezoceramics. J. Am. Ceram. Soc. 2024, 107, 4949–4961. [Google Scholar] [CrossRef]

- Feng, Z.; Siu, W. Aging-induced, defect-mediated double ferroelectric hysteresis loops and large recoverable electrostrains in Mn-doped orthorhombic KNbO3-based ceramics. J. Alloys Compd. 2009, 480, 29–32. [Google Scholar] [CrossRef]

- Genenko, Y.A.; Glaum, J.; Hoffmann, M.J.; Albe, K. Mechanisms of aging and fatigue in ferroelectrics. Mater. Sci. Eng. B 2015, 192, 52–82. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, J.; Zhang, L.; Liu, S.; Zhang, D.; Wang, X. Large activation energy in aged Mn-doped Sr0.4Ba0.6Nb2O6 ferroelectric ceramics. RSC Adv. 2017, 7, 26894–26902. [Google Scholar] [CrossRef]

- Lv, P.P.; Huang, S.F.; Cheng, X.; Yang, C.H.; Yao, Q. Effect of donor W and acceptor Ni codoping at Ti site on the structure and electrical properties of Na0.5Bi0.5TiO3 thin film. Ceram. Int. 2018, 44, 15236–15242. [Google Scholar] [CrossRef]

- Li, M.; Li, L.; Zang, J.; Sinclair, D.C. Donor-doping and reduced leakage current in Nb-doped Na0.5Bi0.5TiO3. Appl. Phys. Lett. 2015, 106, 102904. [Google Scholar] [CrossRef]

- Huybrechts, B.; Ishizaki, K.; Takata, M. The positive temperature coefficient of resistivity in barium titanate. J. Mater. Sci. 1995, 30, 2463–2474. [Google Scholar] [CrossRef]

- Saburi, O. Properties of semiconductive of Barium titanates. J. Phys. Soc. Jpn. 1959, 14, 1159–1174. [Google Scholar] [CrossRef]

- Hagh, N.M.; Jadidian, B.; Ashbahian, E.; Safari, A. Lead-free piezoelectric ceramic transducer in the donor-doped K1/2Na1/2NbO3 solid solution system. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2008, 55, 214–224. [Google Scholar] [CrossRef] [PubMed]

- Pavlović, N.; Koval, V.; Dusza, J.; Srdić, V.V. Effect of Ce and La substitution on dielectric properties of bismuth titanate ceramics. Ceram. Int. 2011, 37, 487–492. [Google Scholar] [CrossRef]

- Ganguly, P. Influence of ionic radius of rare-earths on the structural and electrical properties of Ba5RTi3Nb7O30 (R=rare-earth) ferroelectric ceramics. J. Rare Earth 2015, 33, 1310–1315. [Google Scholar] [CrossRef]

- Li, J.; Pu, Y.; Wang, Z.; Dong, Z.; Dai, J. Microstructure and relaxor ferroelectric properties of Bi2O3-doped strontium barium niobate ceramics. Mater. Sci. Eng. B 2013, 178, 1178–1185. [Google Scholar] [CrossRef]

- Parida, B.N.; Das, P.R.; Padhee, R.; Choudhary, R.N. Phase transition and conduction mechanism of rare earth based tungsten-bronze compounds. J. Alloys Compd. 2012, 540, 267–274. [Google Scholar] [CrossRef]

- Shur, V.Y.; Shikhova, V.A.; Ievlev, A.V.; Zelenovskiy, P.S.; Neradovskiy, M.M.; Pelegov, D.V.; Ivleva, L.I. Nanodomain structures formation during polarization reversal in uniform electric field in strontium barium niobate single crystals. J. Appl. Phys. 2012, 112, 064117. [Google Scholar] [CrossRef]

- Arnold, D.C.; Morrison, F.D. B-cation effects in relaxor and ferroelectric tetragonal tungsten bronzes. J. Mater. Chem. 2009, 19, 6485. [Google Scholar] [CrossRef]

- Rotaru, A.; Arnold, D.C.; Daoud-Aladine, A.; Morrison, F.D. Origin and stability of the dipolar response in a family of tetragonal tungsten bronze relaxors. Phys. Rev. B 2011, 83, 184302. [Google Scholar] [CrossRef]

- Duan, J.; Wei, K.; Du, Q.; Ma, L.; Qi, H.; Li, H. High-entropy tungsten bronze ceramics for large capacitive energy storage with near-zero losses. Adv. Func. Mater. 2024, 2, 2409446. [Google Scholar] [CrossRef]

- Padhee, R.; Das, P.R.; Parida, B.N.; Choudhary, R.N. Dielectric and electrical properties of lanthanum modified electroceramics. Ferroelectrics 2017, 507, 109–120. [Google Scholar] [CrossRef]

- Gardner, J.; Morrison, F.D. A-site size effect in a family of unfilled ferroelectric tetragonal tungsten bronzes: Ba4R0.67Nb10O30 (R = La, Nd, Sm, Gd, Dy and Y). Dalton Trans. 2014, 43, 11687–11695. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Wang, J.; Zhang, L.; Shi, X.; Liu, S.; Zhang, D. Relaxor transition and properties of Mn-doped SrxBa1−xNb2O6 ferroelectric ceramics. Ceram. Int. 2016, 42, 16697–16702. [Google Scholar] [CrossRef]

- Jamieson, P.B.; Abrahams, S.C.; Bernstei, J.L. Ferroelectric tungsten bronze-type crystal structures. I. Barium strontium niobate Ba0.27Sr0.75Nb2O5.78. J. Chem. Phys. 1968, 48, 5048. [Google Scholar] [CrossRef]

- Huang, C.J.; Li, K.; Wu, S.Y.; Zhu, X.L.; Chen, X.M. Variation of ferroelectric hysteresis loop with temperature in (SrxBa1−x)Nb2O6 unfilled tungsten bronze ceramics. J. Mater. 2015, 1, 146–152. [Google Scholar] [CrossRef][Green Version]

- Huang, C.J.; Li, K.; Liu, X.Q.; Zhu, X.L.; Chen, X.M.; Johnson, D. Effects of A1/A2-sites occupancy upon ferroelectric transition in (SrxBa1−x)Nb2O6 tungsten bronze ceramics. J. Am. Ceram. Soc. 2014, 97, 507–512. [Google Scholar] [CrossRef]

- Jaiban, P.; Pisitpipathsin, N.; Wannasut, P.; Watcharapasorn, A. Dielectric and ferroelectric properties of Nb-doped Ba0.7Ca0.3TiO3 ceramics. Ferroelectrics 2019, 533, 165–172. [Google Scholar] [CrossRef]

- Jyh-Tzong, S.; Tsang-Tse, F. Charge-Compensating Defect in ceria-doped strontium barium niobate by electron energy-loss spectroscopy and X-ray photoelectron spectroscopy. J. Am. Ceram. Soc. 2004, 87, 391–394. [Google Scholar]

- Wang, L.; Sui, W.; Luan, S.; Song, R.; Tan, J. Sintering behavior and dielectric properties of Ce doped strontium barium niobate ceramics with silica sintering additive. Mater. Chem. Phys. 2012, 134, 531–535. [Google Scholar] [CrossRef]

- Awan, I.T.; Pinto, A.H.; Nogueira, I.C.; Bezzon, V.D.; Leite, E.R.; Balogh, D.T.; Mastelaro, V.R.; Ferreira, S.O.; Marega, E., Jr. Insights on the mechanism of solid state reaction between TiO2 and BaCO3 to produce BaTiO3 powders: The role of calcination, milling, and mixing solvent. Ceram. Int. 2020, 46, 2987–3001. [Google Scholar]

- Li, C.; Zhang, Y.; Liu, J.; Graetsch, H.A. Long-range and local structure of SrxBa1−xNb2O6 (x = 0.33 and 0.67) across the ferroelectric–relaxor transition. Chem. Mater. 2020, 32, 1844–1853. [Google Scholar] [CrossRef]

- Yang, H.; Yan, F.; Lin, Y.; Wang, T.; Wang, F.; Wang, Y.; Guo, L.; Tai, W.; Wei, H. Lead-free BaTiO3-Bi0.5Na0.5TiO3-Na0.73Bi0.09NbO3 relaxor ferroelectric ceramics for high energy storage. J. Eur. Ceram. Soc. 2017, 37, 3303–3311. [Google Scholar] [CrossRef]

- Lei, C.; Bokov, A.A.; Ye, Z.G. Ferroelectric to relaxor crossover and dielectric phase diagram in the BaTiO3-BaSnO3 system. J. Appl. Phys. 2007, 101, 084105. [Google Scholar] [CrossRef]

- Du, H.; Zhou, W.; Zhu, D.; Fa, L.; Qu, S.; Li, Y.; Pei, Z. Sintering characteristic, microstructure, and dielectric relaxor behavior of (K0.5Na0.5)NbO3-(Bi0.5Na0.5)TiO3 lead-free ceramics. J. Am. Ceram. Soc. 2008, 91, 2903–2909. [Google Scholar] [CrossRef]

- Du, H.; Zhou, W.; Luo, F.; Zhu, D.; Qu, S.; Pei, Z. Phase structure, dielectric properties, and relaxor behavior of (K0.5Na0.5)NbO3–(Ba0.5Sr0.5)TiO3 lead-free solid solution for high temperature applications. J. Appl. Phys. 2009, 105, 124104. [Google Scholar] [CrossRef]

- Sun, E.; Qi, X.; Yuan, Z.; Sang, S.; Zhang, R.; Yang, B.; Cao, W.; Zhao, L. Relaxation behavior in 0.24Pb(In1/2Nb1/2)O3-0.49Pb(Mg1/3Nb2/3)O3-0.27PbTiO3 ferroelectric single crystal. Ceram. Int. 2016, 42, 4893–4898. [Google Scholar] [CrossRef]

- Kallel, M.; Kriaa, I.; Khemakhem, H. Effect of doping by bismuth on dielectric properties and relaxor behavior in the Ba1−xBi2x/3(Yb0.5Nb0.5)0.05Ti0.95O3 solid solution. Ceram. Int. 2016, 42, 1379–1383. [Google Scholar] [CrossRef]

- Bokov, A.A.; Ye, Z.G. Dielectric relaxation in relaxor ferroelectrics. J. Adv. Dielectr. 2012, 2, 1241010. [Google Scholar] [CrossRef]

- Wang, C.; Lou, X. High energy storage properties of 0.94Bi0.5Na0.5TiO3-0.06BaTiO3 ceramics by incorporating Sr0.8Bi0.1γ0.1Ti0.8Zr0.2O2.95. Microstructures 2023, 3, 2023023. [Google Scholar]

- Kshirsagar, S.H.; Jigajeni, S.R.; Tarale, A.N.; Salunkhe, D.J.; Joshi, P.B. Investigations on Fe-doped strontium barium niobate, single phase ferroelectric and magnetodielectric compounds. J. Adv. Dielectr. 2015, 05, 1550001. [Google Scholar] [CrossRef]

- Kim, M.S.; Wang, P.; Lee, J.H.; Kim, J.J.; Lee, H.Y.; Cho, S.H. Site occupancy and dielectric characteristics of Strontium Barium Niobate ceramics: Sr/Ba ratio dependence. Jpn. J. Appl. Phys. 2002, 41, 7042–7047. [Google Scholar] [CrossRef]

- Yu, Z.; Ang, C.; Guo, R.; Bhalla, A.S. Ferroelectric-relaxor behavior of Ba(Ti0.7Zr0.3)O3 ceramics. J. Appl. Phys. 2002, 92, 2655–2657. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, X.; Zhang, X.; Du, H. Enhanced energy storage properties of La-doped Sr0.6Ba0.4Nb2O6 relaxor ferroelectric ceramics prepared by spark plasma sintering. Materials 2022, 15, 4360. [Google Scholar] [CrossRef] [PubMed]

- Kang, R.; Wang, Z.; Wu, M.; Cheng, S.; Mi, S.; Hu, Y.; Zhang, L.; Wang, D.; Lou, X. Superior energy storage capacity of a Bi0.5Na0.5TiO3-based dielectric capacitor under moderate electric field by constructing multiscale polymorphic domains. Nano Energy 2023, 112, 108477. [Google Scholar] [CrossRef]

| Composition | Tm/K | TB/K | T/K | /K | |

|---|---|---|---|---|---|

| SBN40-1Ce | 387 | 402 | 15 | 3.36 | 1.80 |

| SBN40-2Ce | 370 | 389 | 19 | 4.25 | 1.89 |

| SBN40-4Ce | 326 | 348 | 22 | 7.22 | 1.71 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Mao, P.; Kang, R.; Li, Z.; Kang, F. Impact of Ce Doping on the Relaxor Behavior and Electrical Properties of Sr0.4Ba0.6Nb2O6 Ferroelectric Ceramics. Materials 2025, 18, 74. https://doi.org/10.3390/ma18010074

Zhao Y, Mao P, Kang R, Li Z, Kang F. Impact of Ce Doping on the Relaxor Behavior and Electrical Properties of Sr0.4Ba0.6Nb2O6 Ferroelectric Ceramics. Materials. 2025; 18(1):74. https://doi.org/10.3390/ma18010074

Chicago/Turabian StyleZhao, Yingying, Pu Mao, Ruirui Kang, Ziao Li, and Fang Kang. 2025. "Impact of Ce Doping on the Relaxor Behavior and Electrical Properties of Sr0.4Ba0.6Nb2O6 Ferroelectric Ceramics" Materials 18, no. 1: 74. https://doi.org/10.3390/ma18010074

APA StyleZhao, Y., Mao, P., Kang, R., Li, Z., & Kang, F. (2025). Impact of Ce Doping on the Relaxor Behavior and Electrical Properties of Sr0.4Ba0.6Nb2O6 Ferroelectric Ceramics. Materials, 18(1), 74. https://doi.org/10.3390/ma18010074