Radiation Damage Mitigation in FeCrAl Alloy at Sub-Recrystallization Temperatures

Abstract

1. Introduction

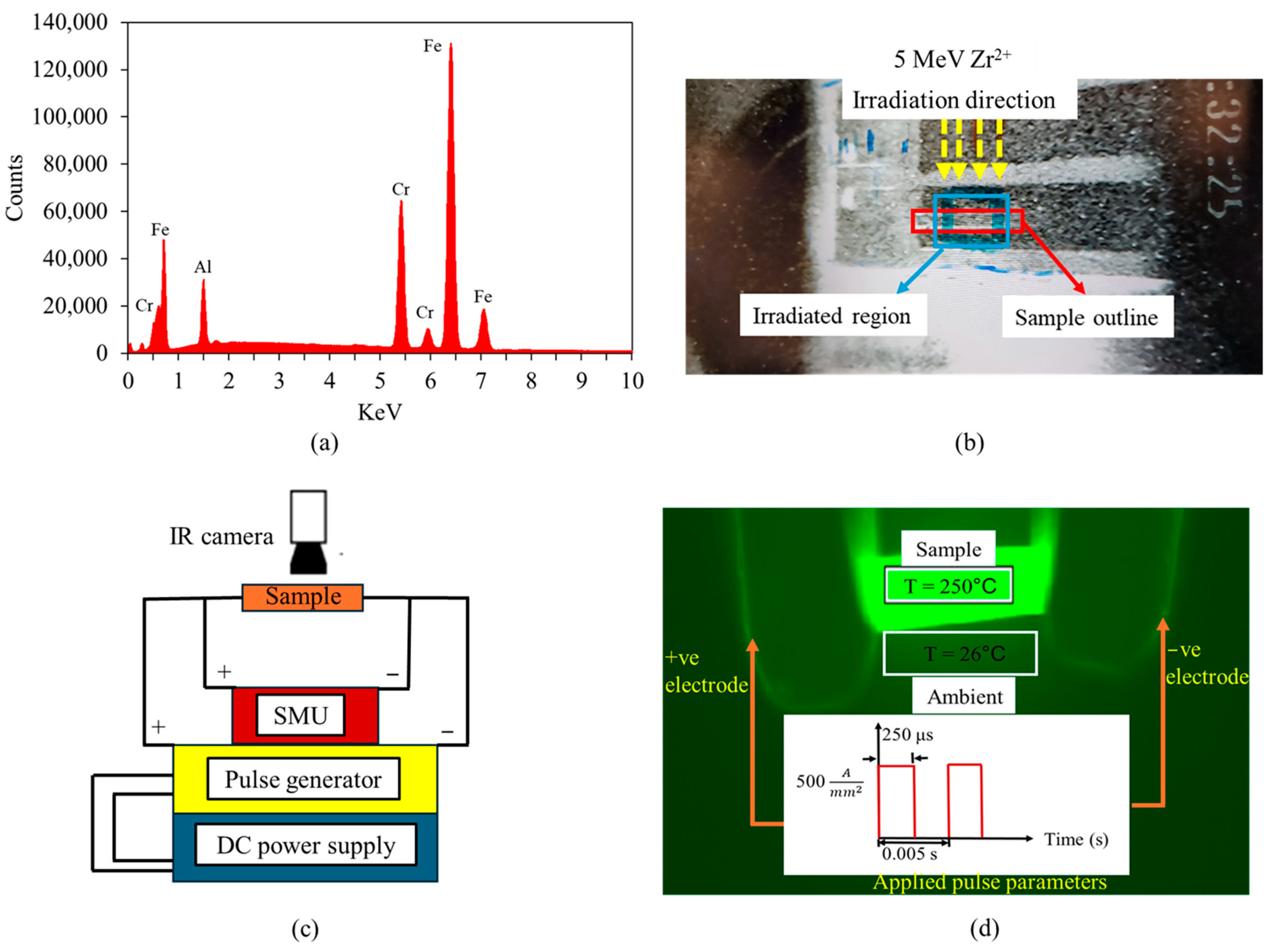

2. Materials and Methods

3. Results

3.1. Stopping and Range of Ions in Matter Simulations

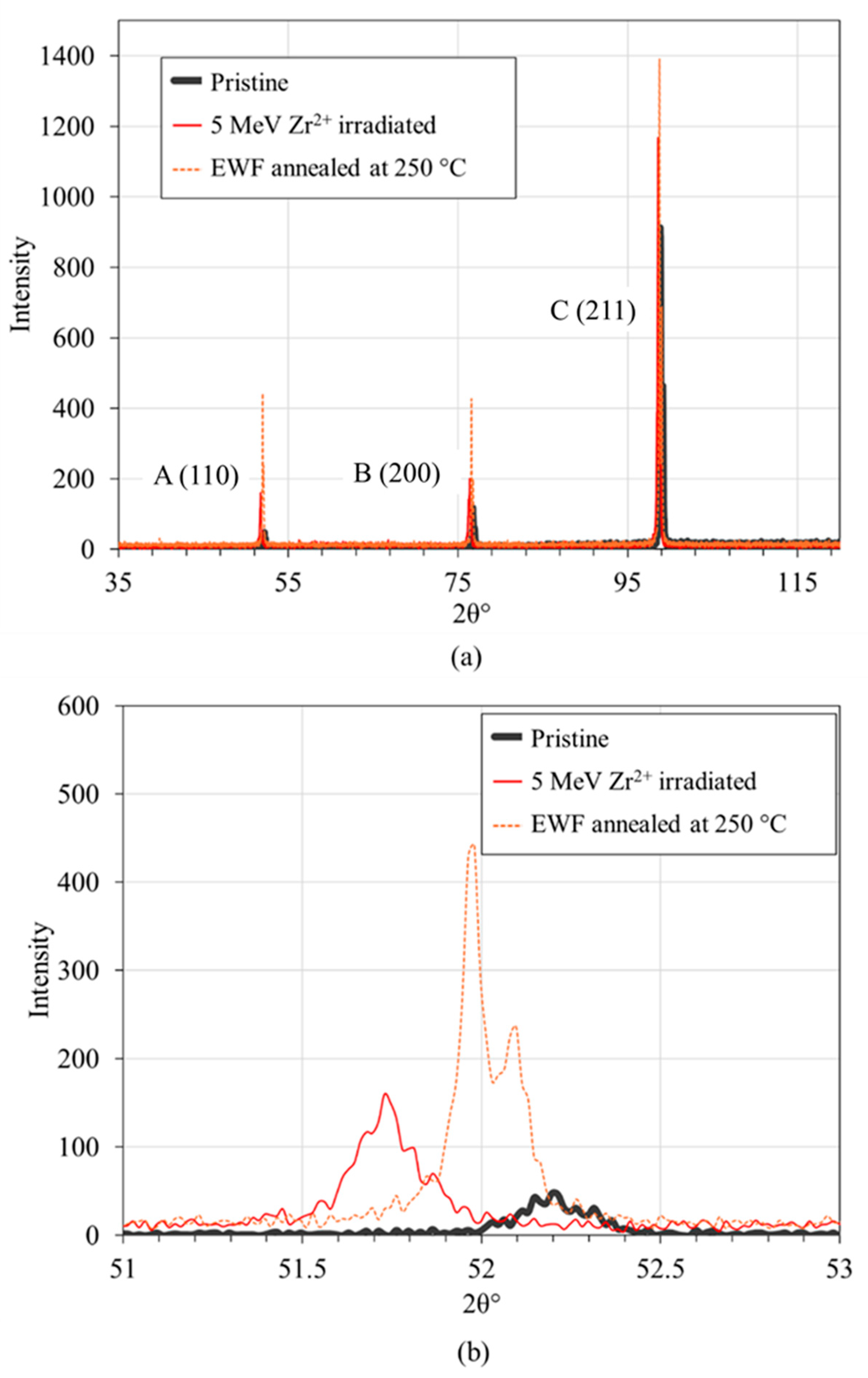

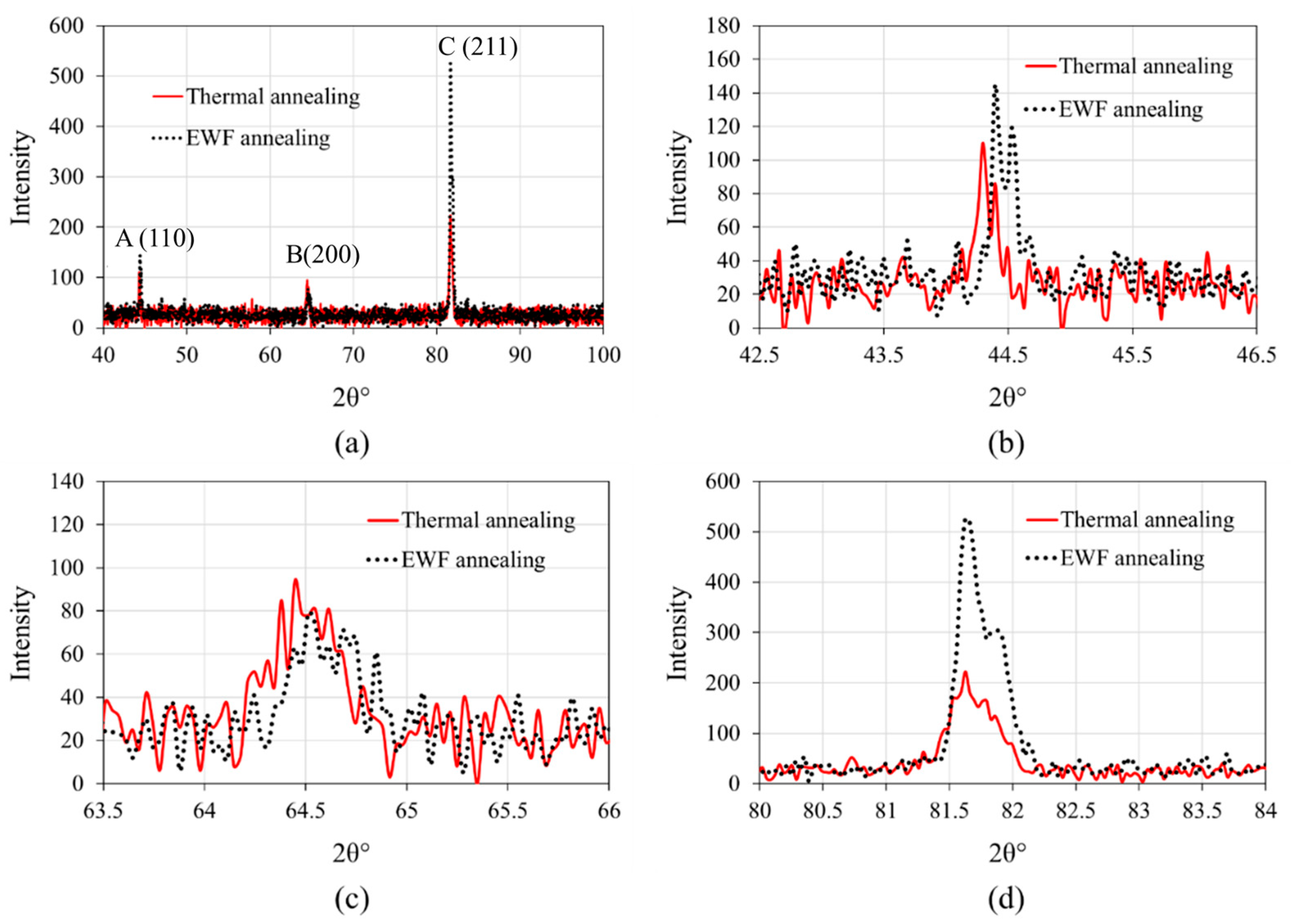

3.2. X-Ray Diffraction (XRD) Analysis

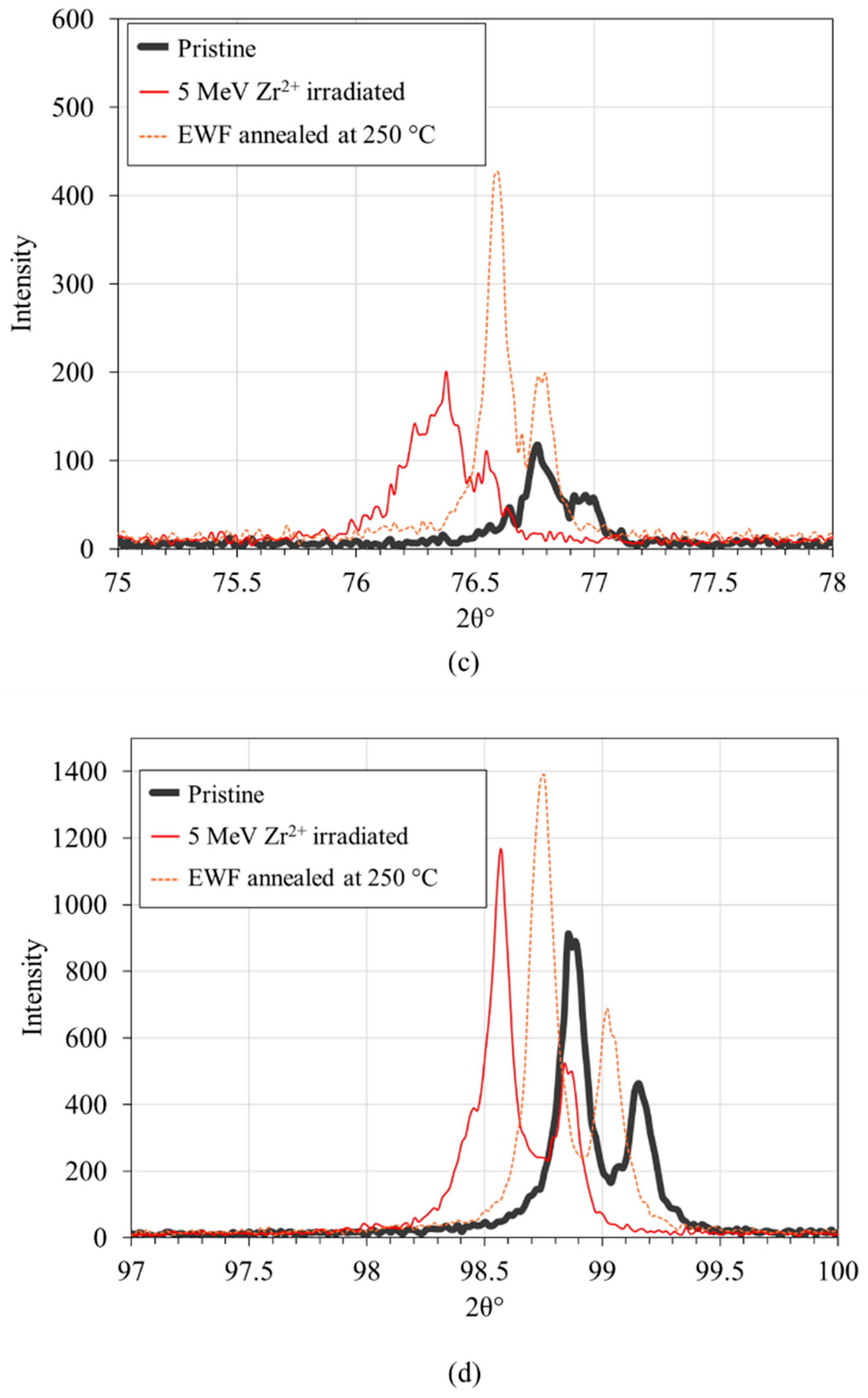

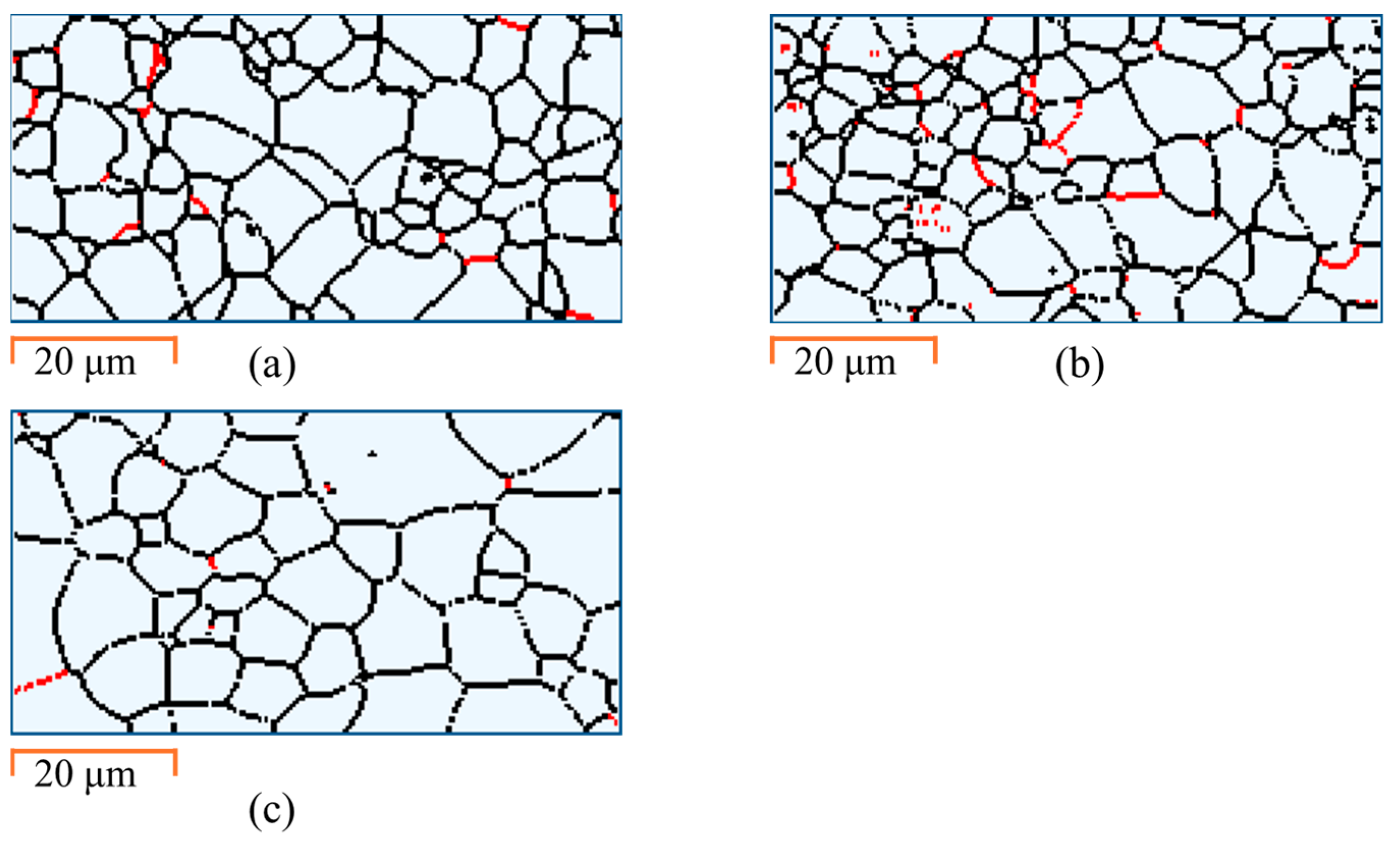

3.3. Electron Backscatter Diffraction Characterization

3.3.1. Kernel Average Misorientation (KAM) Maps

3.3.2. Low-Angle Grain Boundaries (LAGBs)

4. Comparative Analysis of EWF and Thermal Annealing

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Guérin, Y.; Was, G.S.; Zinkle, S.J. Materials Challenges for Advanced Nuclear Energy Systems. MRS Bull. 2009, 34, 10–19. [Google Scholar] [CrossRef]

- Klöwer, J. High temperature Corrosion behaviour of iron aluminides and iron-aluminium-chromium alloys. Mater. Corros. 1996, 47, 685–694. [Google Scholar] [CrossRef]

- Pint, B.A.; Terrani, K.A.; Brady, M.P.; Cheng, T.; Keiser, J.R. High temperature oxidation of fuel cladding candidate materials in steam–hydrogen environments. J. Nucl. Mater. 2013, 440, 420–427. [Google Scholar] [CrossRef]

- Lim, J.; Hwang, I.S.; Kim, J.H. Design of alumina forming FeCrAl steels for lead or lead–bismuth cooled fast reactors. J. Nucl. Mater. 2013, 441, 650–660. [Google Scholar] [CrossRef]

- Sun, T. Radiation Response and Mechanical Properties of FeCrAl Alloy. Ph.D. Dissertation, Purdue University, West Lafayette, IN, USA, 2022. [Google Scholar] [CrossRef]

- Field, K.G.; Snead, M.A.; Yamamoto, Y.; Terrani, K.A. Handbook on the Material Properties of FeCrAl Alloys for Nuclear Power Production Applications (FY18 Version: Revision 1); Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2018. [Google Scholar] [CrossRef]

- Field, K.G.; Hu, X.; Littrell, K.C.; Yamamoto, Y.; Snead, L.L. Radiation tolerance of neutron-irradiated model Fe–Cr–Al alloys. J. Nucl. Mater. 2015, 465, 746–755. [Google Scholar] [CrossRef]

- Ye, T.; Yao, H.; Wu, Y.; Zhang, J.; Wu, J.; Wang, M.; Tian, W.; Su, G.H.; Qiu, S. Primary radiation damage characteristics in displacement cascades of FeCrAl alloys. J. Nucl. Mater. 2021, 549, 152909. [Google Scholar] [CrossRef]

- Li, F.; Long, Y.; Guo, D.; Guo, L.; Lin, W.; Chen, Y.; Li, L.; Ren, Q.; Liao, Y. Ion Irradiation Defects and Hardening in FeCrAl Alloy. Metals 2022, 12, 1645. [Google Scholar] [CrossRef]

- Wang, P.; Bowman, J.; Bachhav, M.; Kammenzind, B.; Smith, R.; Carter, J.; Motta, A.; Lacroix, E.; Was, G. Emulation of neutron damage with proton irradiation and its effects on microstructure and microchemistry of Zircaloy-4. J. Nucl. Mater. 2021, 557, 153281. [Google Scholar] [CrossRef]

- Zinkle, S.J. Microstructures and Mechanical Properties of Irradiated Metals and Alloys. In Materials Issues for Generation IV Systems; Ghetta, V., Gorse, D., Mazière, D., Pontikis, V., Eds.; Springer: Dordrecht, The Netherlands, 2008; pp. 227–244. [Google Scholar]

- Rao, S.G.; Shu, R.; Wang, J.; Chai, J.; Zhu, Y.; le Febvrier, A.; Eklund, P. Mechanical properties of Xe-ion-irradiated high-entropy-alloy-based multilayers. Appl. Phys. Lett. 2024, 124, 61906. [Google Scholar] [CrossRef]

- Pathak, A. Interaction of Radiation with Matter. In Tools and Techniques in Radiation Biophysics; Pathak, A., Ed.; Springer Nature: Singapore, 2023; pp. 75–92. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, D.; Weaver, J.; Gigax, J.; Wang, Y.; Mara, N.A.; Fensin, S.; Maloy, S.A.; Misra, A.; Li, N. Heavy ion irradiation effects on CrFeMnNi and AlCrFeMnNi high entropy alloys. J. Nucl. Mater. 2023, 574, 154163. [Google Scholar] [CrossRef]

- Aydogan, E.; Weaver, J.S.; Maloy, S.A.; El-Atwani, O.; Wang, Y.Q.; Mara, N.A. Microstructure and mechanical properties of FeCrAl alloys under heavy ion irradiations. J. Nucl. Mater. 2018, 503, 250–262. [Google Scholar] [CrossRef]

- Dhanunjaya, M.; Avasthi, D.K.; Pathak, A.P.; Khan, S.A.; Nageswara Rao, S.V.S. Grain fragmentation and phase transformations in hafnium oxide induced by swift heavy ion irradiation. Appl. Phys. A 2018, 124, 587. [Google Scholar] [CrossRef]

- Lian, J.; Zhang, J.; Namavar, F.; Zhang, Y.; Lu, F.; Haider, H.; Garvin, K.; Weber, W.J.; Ewing, R.C. Ion beam-induced amorphous-to-tetragonal phase transformation and grain growth of nanocrystalline zirconia. Nanotechnology 2009, 20, 245303. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Z.; Huang, H.; Liu, J.; Ye, L.; Zhu, Z. Nanoindentation Study on the Creep Characteristics and Hardness of Ion-Irradiated Alloys. Materials 2020, 13, 3132. [Google Scholar] [CrossRef]

- Sáez-Maderuelo, A.; Castro, L.; de Diego, G. Plastic strain characterization in austenitic stainless steels and nickel alloys by electron backscatter diffraction. J. Nucl. Mater. 2011, 416, 75–79. [Google Scholar] [CrossRef]

- Fincher, C.; Turman, H.; French, A.; Chancey, M.; Gigax, J.; Aydogan, E.; Zhao, D.; Yadav, D.; Xie, K.; Wang, Y.; et al. Damage relief of ion-irradiated Inconel alloy 718 via annealing. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2020, 479, 157–162. [Google Scholar] [CrossRef]

- Ogorodnikova, O.V.; Gasparyan, Y.; Efimov, V.; Ciupiński, Ł.; Grzonka, J. Annealing of radiation-induced damage in tungsten under and after irradiation with 20MeV self-ions. J. Nucl. Mater. 2014, 451, 379–386. [Google Scholar] [CrossRef]

- Druzhkov, A.P.; Arbuzov, V.L.; Perminov, D.A. Radiation-induced defects and low-temperature hardening in the Fe–Cr alloy. Phys. Met. Metallogr. 2011, 111, 212–219. [Google Scholar] [CrossRef]

- Niu, M.; Wang, H.; Huang, X. Positron annihilation investigation of hardening behavior induced by Fe2+ irradiation in low-Cr FeCrAl alloys. J. Mater. Res. Technol. 2023, 24, 7291–7301. [Google Scholar] [CrossRef]

- Zha, X.-Q.; Xiong, Y.; Gao, L.-Q.; Zhang, X.-Y.; Ren, F.-Z.; Wang, G.-X.; Cao, W. Effect of annealing on microstructure and mechanical properties of cryo-rolled 316LN austenite stainless steel. Mater. Res. Express 2019, 6, 96506. [Google Scholar] [CrossRef]

- Bianchi, I.; Forcellese, A.; Simoncini, M.; Vita, A. Effect of in situ and furnace thermal annealing on the mechanical properties and sustainability of 3D printed carbon-peek composites. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2024, 238, 1794–1804. [Google Scholar] [CrossRef]

- Nagase, T.; Rack, P.D.; Egami, T. Irradiation damage in multicomponent equimolar alloys and high entropy alloys (HEAs). Microscopy 2014, 63, i22. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Rahman, M.H.; Todaro, S.; Warner, L.; Waryoba, D.; Haque, A. Elimination of Low-Angle Grain Boundary Networks in FeCrAl Alloys with the Electron Wind Force at a Low Temperature. Metals 2024, 14, 331. [Google Scholar] [CrossRef]

- Yi, K.; Xiang, S.; Zhou, M.; Zhang, X.; Du, F. Altering the Residual Stress in High-Carbon Steel through Promoted Dislocation Movement and Accelerated Carbon Diffusion by Pulsed Electric Current. Acta Metall. Sin. (Engl. Lett.) 2023, 36, 1511–1522. [Google Scholar] [CrossRef]

- Xiang, S.; Zhang, X. Residual Stress Removal Under Pulsed Electric Current. Acta Metall. Sin. (Engl. Lett.) 2020, 33, 281–289. [Google Scholar] [CrossRef]

- Long, P. Influence of electropulsing treatment on residual stresses and tensile strength of as-quenched medium carbon steel. J. Phys. Conf. Ser. 2019, 1187, 32054. [Google Scholar] [CrossRef]

- Lienig, J.; Thiele, M. Fundamentals of Electromigration-Aware Integrated Circuit Design; Springer: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Sheng, Y.; Hua, Y.; Wang, X.; Zhao, X.; Chen, L.; Zhou, H.; Wang, J.; Berndt, C.C.; Li, W. Application of High-Density Electropulsing to Improve the Performance of Metallic Materials: Mechanisms, Microstructure and Properties. Materials 2018, 11, 185. [Google Scholar] [CrossRef]

- Rahman, M.H.; Todaro, S.; Waryoba, D.; Haque, A. Synergistic Thermal and Electron Wind Force-Assisted Annealing for Extremely High-Density Defect Mitigation. Materials 2024, 17, 3188. [Google Scholar] [CrossRef] [PubMed]

- Was, G.; Averback, R.S. Radiation Damage Using Ion Beams. Compr. Nucl. Mater. 2012, 1, 195–221. [Google Scholar] [CrossRef]

- Qin, X.; Zhang, R.; Du, P.; Pei, J.; Pan, Q.; Cao, Y.; Liu, H. Recrystallization and texture evolution of cold pilgered FeCrAl cladding tube during annealing at 700 °C∼1000 °C. J. Nucl. Mater. 2023, 577, 154303. [Google Scholar] [CrossRef]

- Palaniappan, S.; Joshi, S.S.; Sharma, S.; Radhakrishnan, M.; Krishna, K.V.M.; Dahotre, N.B. Additive manufacturing of FeCrAl alloys for nuclear applications—A focused review. Nucl. Mater. Energy 2024, 40, 101702. [Google Scholar] [CrossRef]

- Trimby, P.; Anderson, I.; Larsen, K.; Hjelmstad, M.; Thomsen, K.; Mehnert, K. Advanced Classification of Microstructures in EBSD Datasets Using AZtecCrystal. Microsc. Microanal. 2020, 26, 112–113. [Google Scholar] [CrossRef]

- Holmes-Siedle, A.; van Lint, V.A.J. Radiation Effects in Electronic Materials and Devices. In Encyclopedia of Physical Science and Technology, 3rd ed.; Meyers, R.A., Ed.; Academic Press: New York, NY, USA, 2003; pp. 523–559. [Google Scholar] [CrossRef]

- Krawczyk, B.; Cook, P.; Hobbs, J.; Engelberg, D.L. Corrosion behavior of cold rolled type 316L stainless steel in HCl-containing environments. Corrosion 2017, 73, 1346–1358. [Google Scholar] [CrossRef] [PubMed]

- Mudali, U.K.; Shankar, P.; Ningshen, S.; Dayal, R.K.; Khatak, H.S.; Raj, B. On the pitting corrosion resistance of nitrogen alloyed cold worked austenitic stainless steels. Corros. Sci. 2002, 44, 2183–2198. [Google Scholar] [CrossRef]

- Alam, K. Open air X-ray diffractometer for crystallography, compression, contraction, and structural phase transitions with variable temperature capabilities. MethodsX 2024, 12, 102703. [Google Scholar] [CrossRef] [PubMed]

- Dolabella, S.; Borzì, A.; Dommann, A.; Neels, A. Lattice Strain and Defects Analysis in Nanostructured Semiconductor Materials and Devices by High-Resolution X-Ray Diffraction: Theoretical and Practical Aspects. Small Methods 2022, 6, 2100932. [Google Scholar] [CrossRef] [PubMed]

- Kamaya, M.; Kubushiro, K.; Sakakibara, Y.; Suzuki, S.; Morita, H.; Yoda, R.; Kobayashi, D.; Yamagiwa, K.; Nishioka, T.; Yamazaki, Y.; et al. Round robin crystal orientation measurement using EBSD for damage assessment. Mech. Eng. J. 2016, 3, 16–77. [Google Scholar] [CrossRef]

- Hou, J.; Shoji, T.; Lu, Z.P.; Peng, Q.J.; Wang, J.Q.; Han, E.-H.; Ke, W. Residual strain measurement and grain boundary characterization in the heat-affected zone of a weld joint between Alloy 690TT and Alloy 52. J. Nucl. Mater. 2010, 397, 109–115. [Google Scholar] [CrossRef]

- Shen, R.R.; Ström, V.; Efsing, P. Spatial correlation between local misorientations and nanoindentation hardness in nickel-base alloy 690. Mater. Sci. Eng. A 2016, 674, 171–177. [Google Scholar] [CrossRef]

- Gussev, M.N.; Leonard, K.J. In situ SEM-EBSD analysis of plastic deformation mechanisms in neutron-irradiated austenitic steel. J. Nucl. Mater. 2019, 517, 45–56. [Google Scholar] [CrossRef]

- Rui, S.-S.; Niu, L.-S.; Shi, H.-J.; Wei, S.; Tasan, C.C. Diffraction-based misorientation mapping: A continuum mechanics description. J. Mech. Phys. Solids 2019, 133, 103709. [Google Scholar] [CrossRef]

- Shi, Y.; Cui, S.; Zhu, T.; Gu, S.; Shen, X. Microstructure and intergranular corrosion behavior of HAZ in DP-TIG welded DSS joints. J. Mater. Process. Technol. 2018, 256, 254–261. [Google Scholar] [CrossRef]

- Haque, A.; Sherbondy, J.; Warywoba, D.; Hsu, P.; Roy, S. Room-temperature stress reduction in welded joints through electropulsing. J. Mater. Process. Technol. 2022, 299, 117391. [Google Scholar] [CrossRef]

- Liang, X.; Wang, H.; Pan, Q.; Zheng, J.; Liu, H.; Zhang, R.; Xu, Y.; Xu, Y.; Yi, D. Recrystallization and mechanical properties of cold-rolled FeCrAl alloy during annealing. J. Iron Steel Res. Int. 2020, 27, 549–565. [Google Scholar] [CrossRef]

| Peak A | Peak B | Peak C | |

|---|---|---|---|

| Pristine | 52.194 | 76.764 | 98.861 |

| 5 MeV Zr2+ irradiated | 51.729 | 76.37 | 98.569 |

| EWF annealed at 250 °C | 51.99 | 76.6 | 98.76 |

| Peak A | Peak B | Peak C | |

|---|---|---|---|

| Pristine | 0.189 | 0.22 | 0.133 |

| 5 MeV Zr2+ irradiated | 0.21 | 0.515 | 0.166 |

| EWF annealed at 250 °C | 0.128 | 0.135 | 0.133 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahman, M.H.; Rasel, M.A.J.; Smyth, C.M.; Waryoba, D.; Haque, A. Radiation Damage Mitigation in FeCrAl Alloy at Sub-Recrystallization Temperatures. Materials 2025, 18, 124. https://doi.org/10.3390/ma18010124

Rahman MH, Rasel MAJ, Smyth CM, Waryoba D, Haque A. Radiation Damage Mitigation in FeCrAl Alloy at Sub-Recrystallization Temperatures. Materials. 2025; 18(1):124. https://doi.org/10.3390/ma18010124

Chicago/Turabian StyleRahman, Md Hafijur, Md Abu Jafar Rasel, Christopher M. Smyth, Daudi Waryoba, and Aman Haque. 2025. "Radiation Damage Mitigation in FeCrAl Alloy at Sub-Recrystallization Temperatures" Materials 18, no. 1: 124. https://doi.org/10.3390/ma18010124

APA StyleRahman, M. H., Rasel, M. A. J., Smyth, C. M., Waryoba, D., & Haque, A. (2025). Radiation Damage Mitigation in FeCrAl Alloy at Sub-Recrystallization Temperatures. Materials, 18(1), 124. https://doi.org/10.3390/ma18010124