Mechanical and Ecological Properties of CO2 Curing Magnesium Slag Concrete

Highlights

- Investigates magnesium slag, a by-product of the magnesium industry, as an auxiliary cementitious material in concrete.

- Applies the carbon curing method to significantly improve the mechanical properties of magnesium slag concrete.

- Identifies the optimal concrete composition with 30% magnesium slag, achieving a compressive strength of 42.3 MPa.

- Analyzes the impact of different magnesium slag content and water–cement ratios on the mechanical properties and ecological aspects of carbon-cured concrete.

- Utilizes phase composition and thermogravimetric analysis to unveil the carbonization mechanism, revealing how magnesium slag content influences concrete reactions.

Abstract

1. Introduction

2. Experimental Raw Materials and Test Process

2.1. Experimental Raw Materials

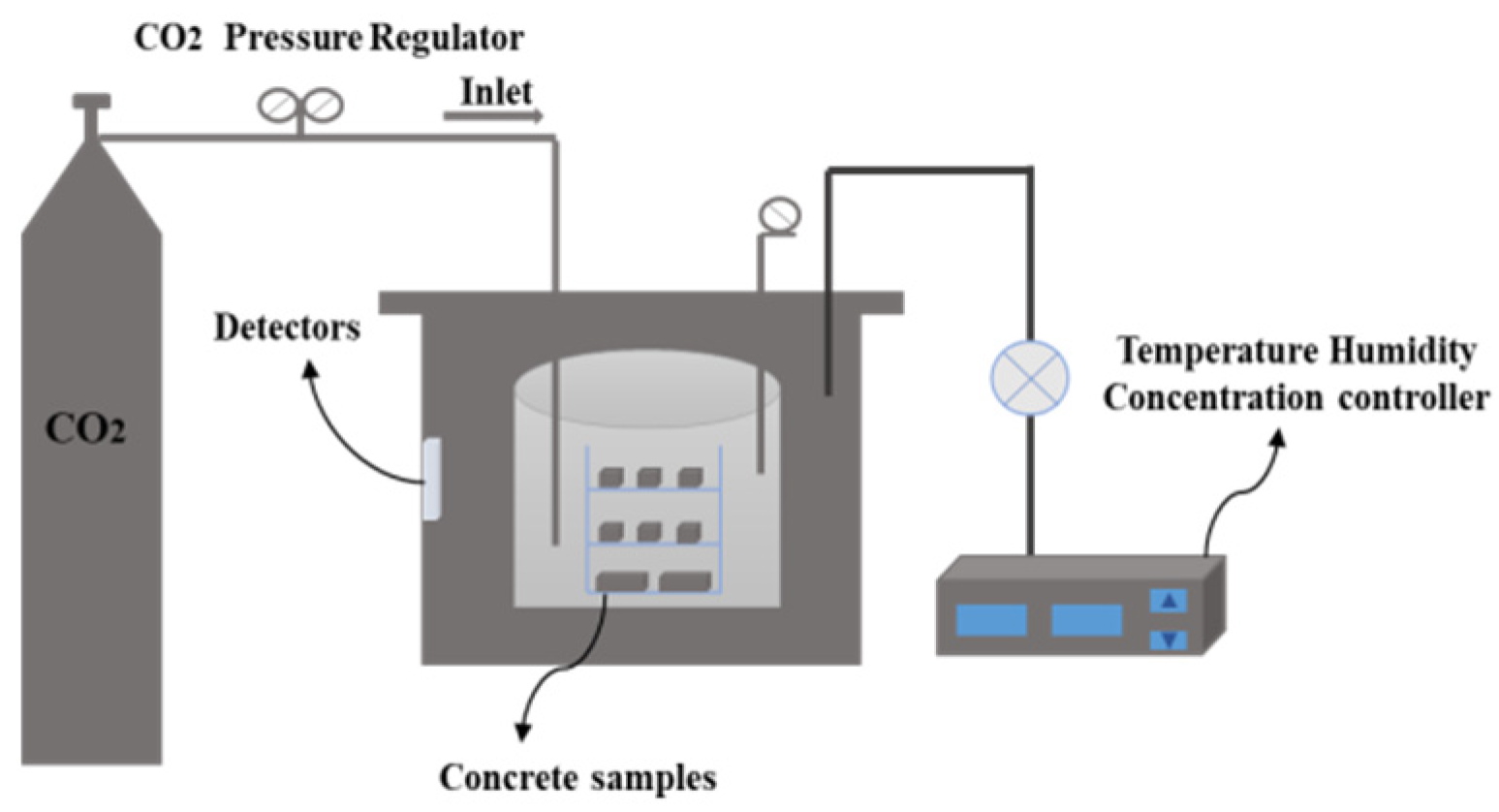

2.2. Preparation of Carbon Curing MSC

2.3. Determination of MSC Performance

3. Mechanical Properties of Carbon Curing MSC

3.1. Compressive Strength of MSC

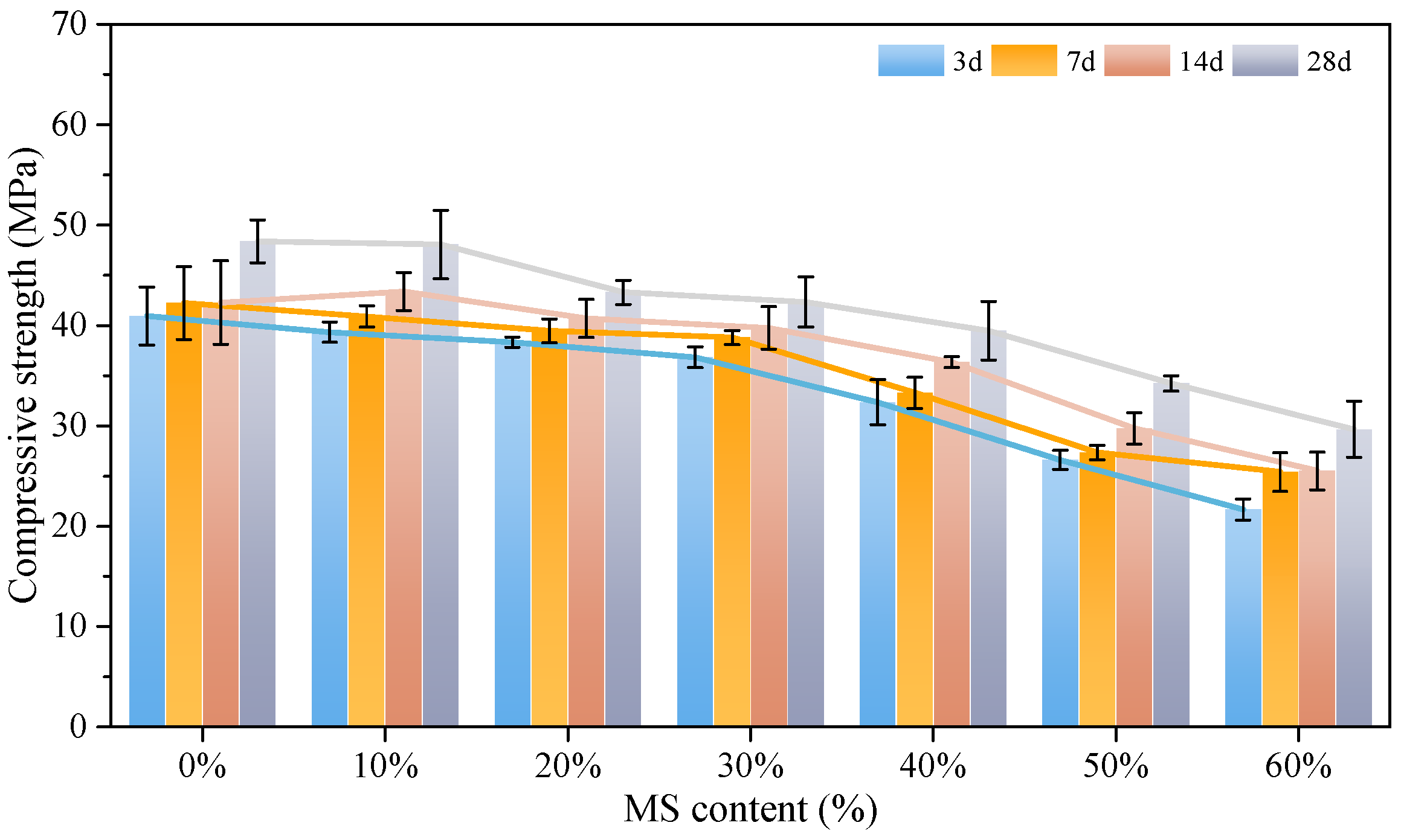

3.1.1. Influence of MS Content on Compressive Strength

3.1.2. Influence of Water-Cement Ratio on Compressive Strength

3.2. Flexural Strength of MSC

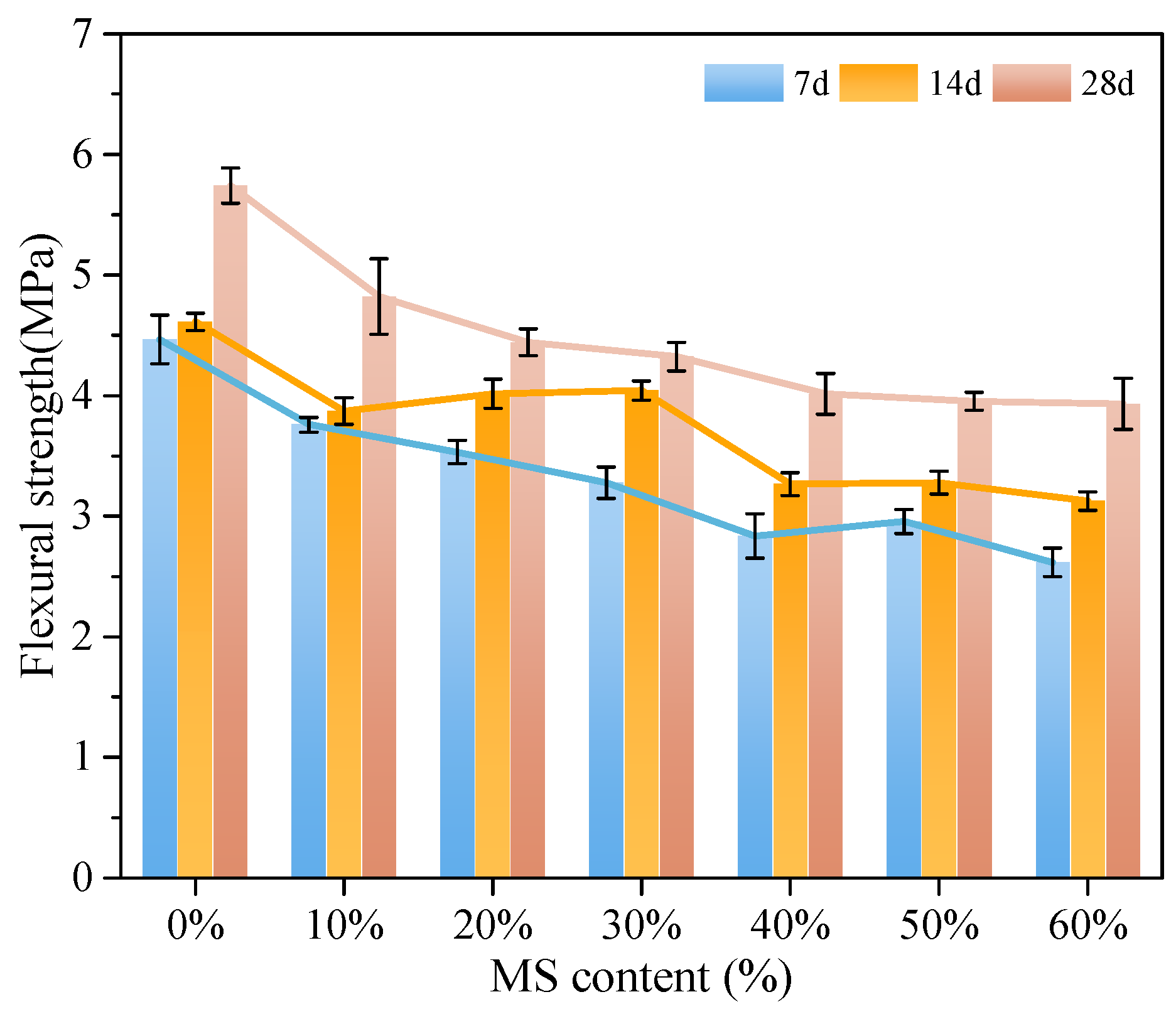

3.2.1. Influence of MS Content on Flexural Strength

3.2.2. Influence of Water-Cement Ratio on the Flexural Strength of MSC

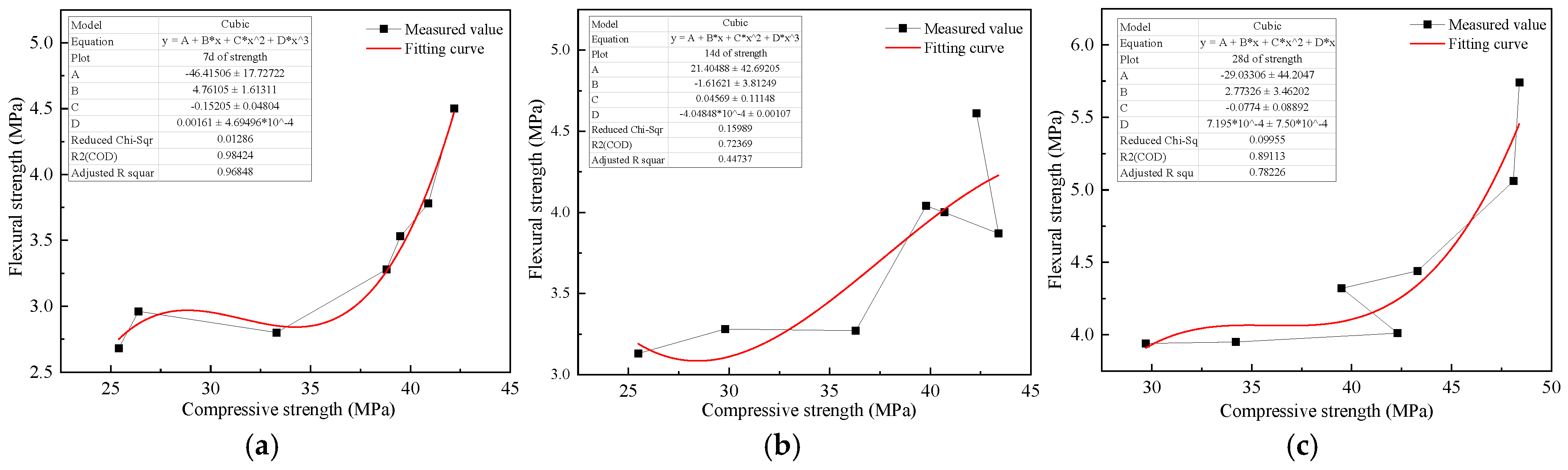

3.3. Mechanical Model of Carbon Cured MSC

3.4. The Relationship Between the Compressive Strength and the Flexural Strength of MSC

4. Microscopic Properties of MSC

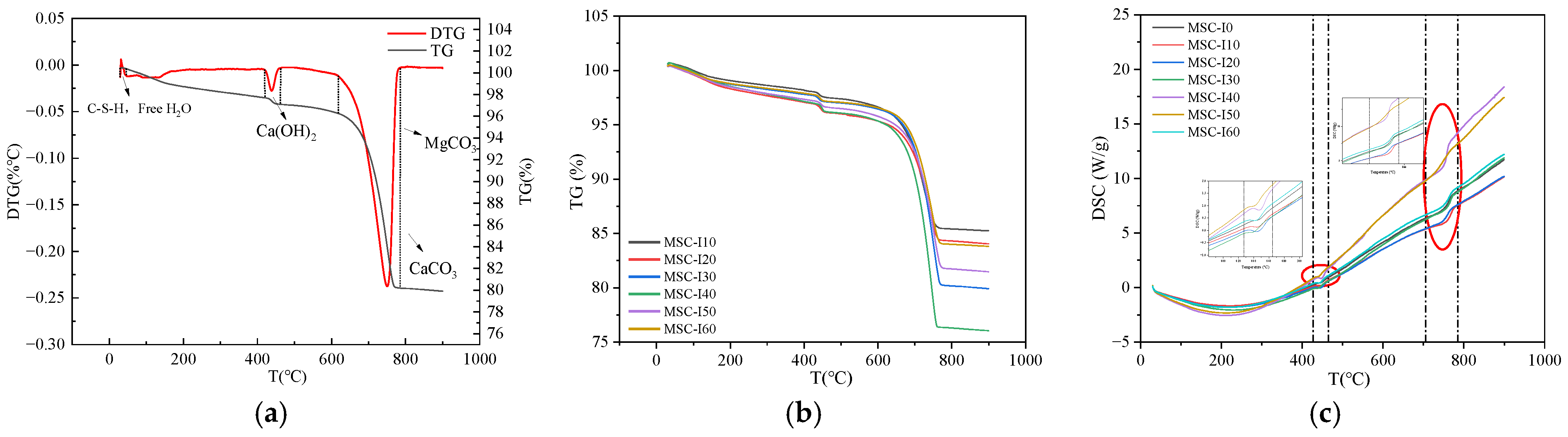

4.1. Thermal Weight Analysis of MSC

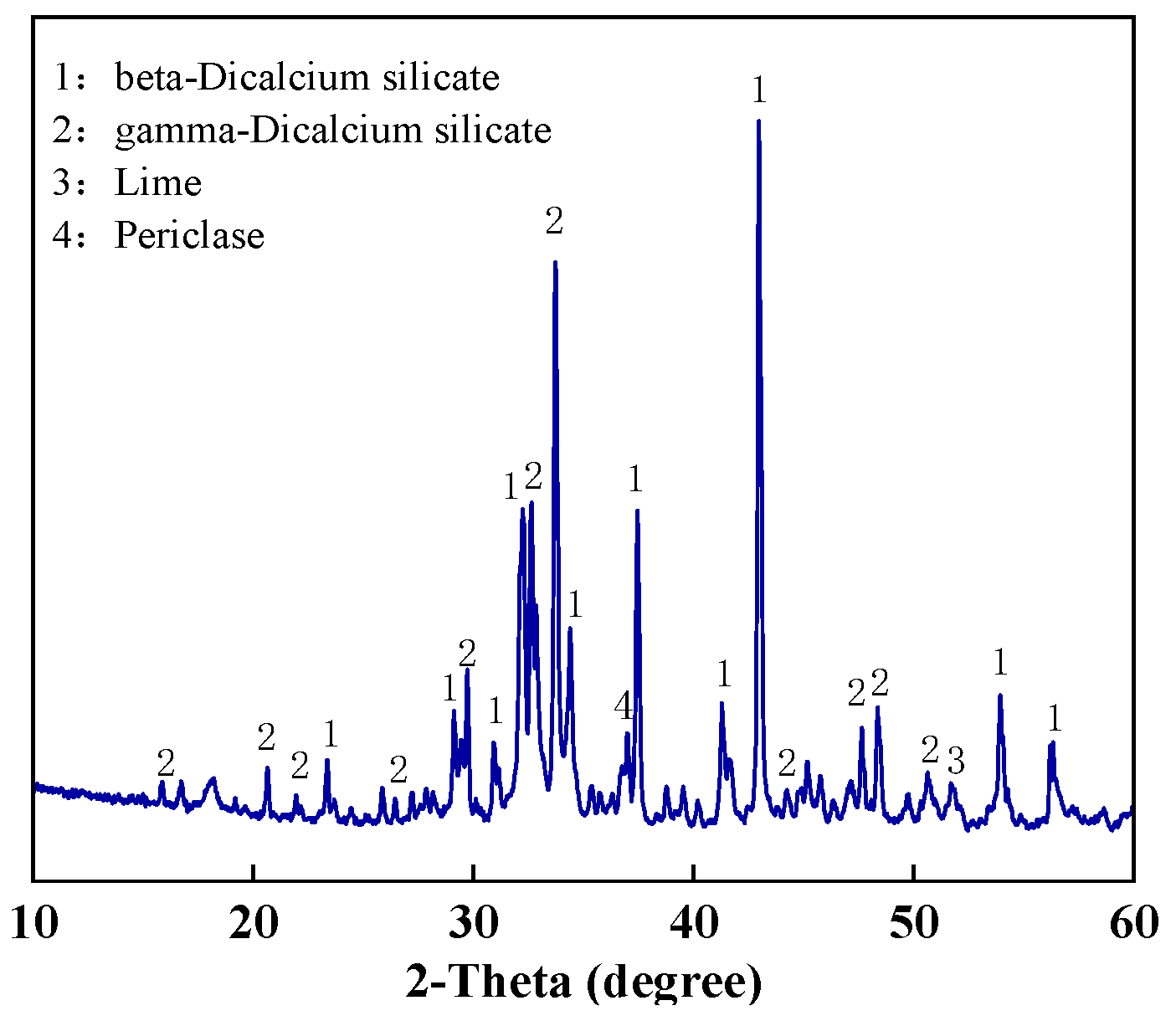

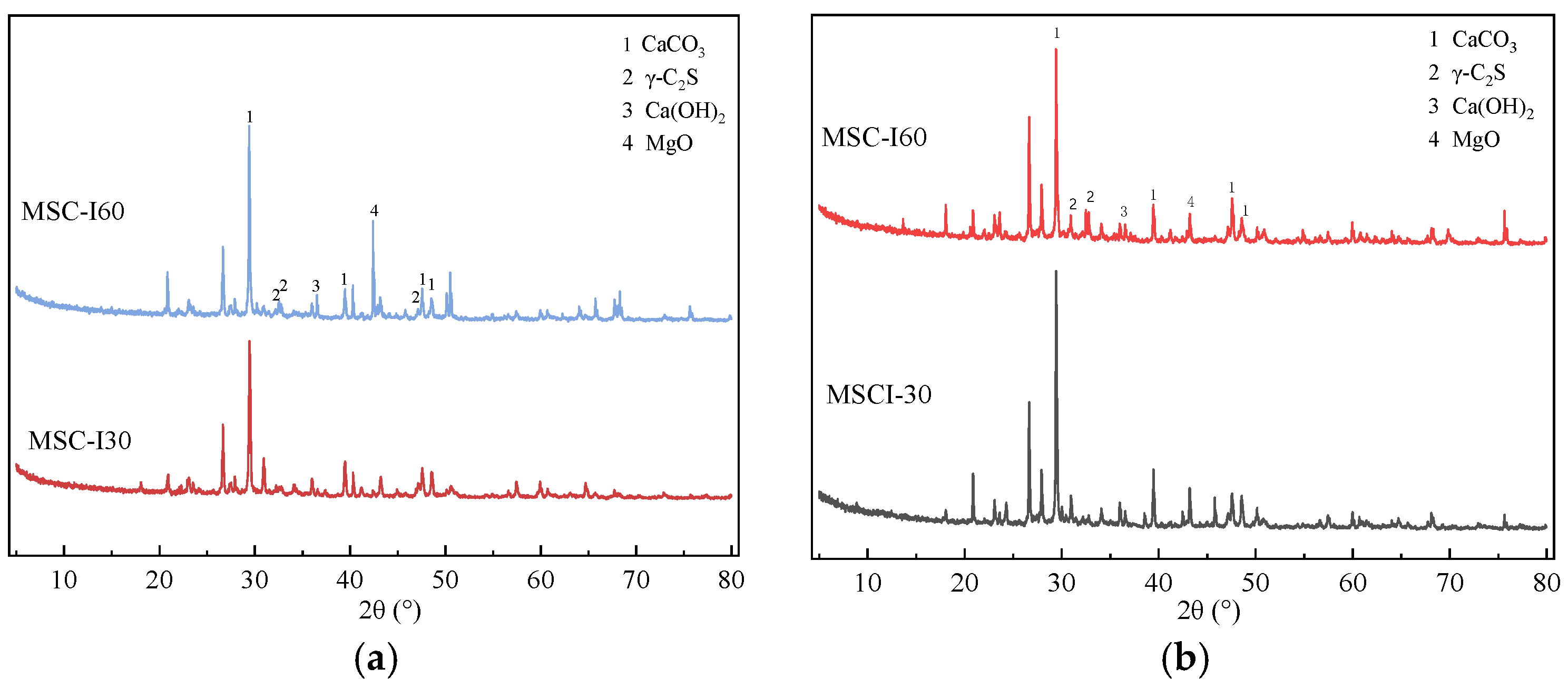

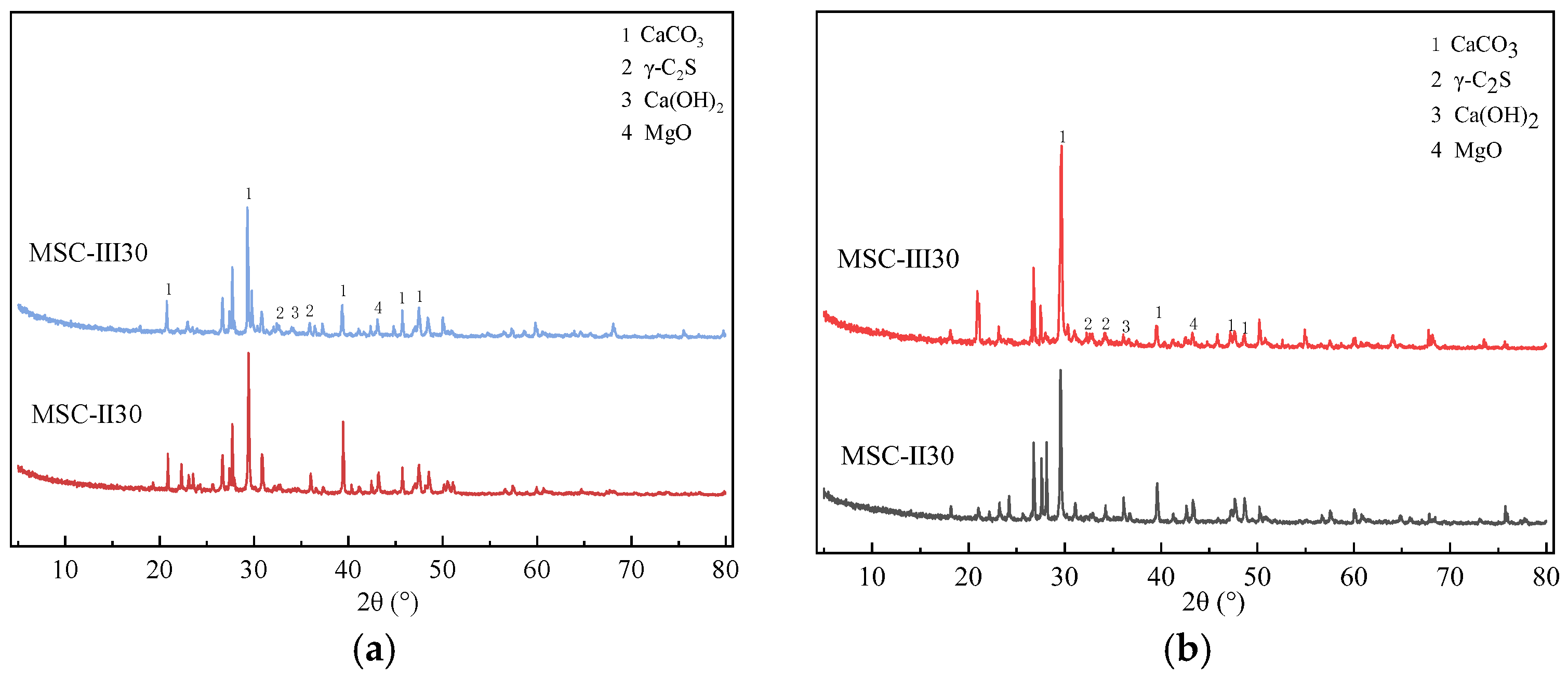

4.2. X-Ray Diffraction Analysis of MSC

5. Conclusions

- (1)

- The incorporation of MS significantly affects the carbonation curing and mechanical properties of concrete. As the proportion of MS increases, both compressive strength and flexural strength decrease. The turning point for changes in compressive strength occurs at approximately 30% MS content, while for flexural strength it appears at around 40%. Regarding the resistance to flexural strength after 14 d, an increase is observed with the addition of 10% to 30% MS, with growth rates of 3.36% and 0.99%, respectively, reaching a peak at 30%. With the further increase of MS content, the effect on the concrete turns to deterioration, resulting in a significant reduction in compressive strength, which is about 19% after 28 d.

- (2)

- The change of water-cement ratio on the strength of concrete is also very significant. When the water glue is relatively low, the proportion of water in the concrete is reduced, resulting in a reduction in the porosity of the concrete. In addition, it promotes the full hydration reaction of the cement, thereby improving the strength of the concrete. Therefore, with the increase of the water-cement ratio, the strength of the concrete gradually decreases. From the fitting model of the compressive strength of MSC, the amount of MS and water-cement ratio have more influence on the compressive strength than the curing age. For the flexural strength, the water-cement ratio and maintenance age have greater influence than that of MS.

- (3)

- Appropriately increasing the amount of MS can improve the absorption of CO2. The content of MS increased from 0% to 60%, and the carbon sequestration content was 14.60%, 11.87%, 11.69%, 16.90%, 19.80%, 14.78%, and 13.09%, respectively. When the content of MS is 40%, the carbon fixation of concrete is 19.8%. As for the water-cement ratio, the carbon fixation of concrete increases first and then decreases with the increase of water-cement ratio. Reducing the water-cement ratio from 0.59 to 0.47 increases carbon sequestration by 1.9%. However, a further reduction to 0.39 results in a decrease in carbon sequestration to 10.18%.

- (4)

- With the increase of MS content, CaCO3 in MSC increased. With the increase of concrete age, the CaCO3 content and the intensity of reflection peak in concrete also increase gradually. This is because the cement inside the concrete constantly hydrates to release the Ca(OH)2 with the CO2 in the air, which reacts to generate CaCO3, thereby meaning that the CaCO3 was gradually increased.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Amini, O.; Ghasemi, M. Laboratory study of the effects of using magnesium slag on the geotechnical properties of cement stabilized soil. Constr. Build. Mater. 2019, 223, 409–420. [Google Scholar] [CrossRef]

- Wang, X.; Yan, X.; Li, X. Environmental risks for application of magnesium slag to soils in China. J. Integr. Agric. 2020, 19, 1671–1679. [Google Scholar] [CrossRef]

- Pappu, A.; Saxena, M.; Asolekar, S.R. Solid wastes generation in India and their recycling potential in building materials. Build. Environ. 2007, 42, 2311–2320. [Google Scholar] [CrossRef]

- Courtial, M.; Cabrillac, R.; Duval, R. Feasibility of the Manufacturing of Building Materials from Magnesium Slag; Elsevier: Amsterdam, The Netherlands, 1991; Volume 48, pp. 491–498. [Google Scholar] [CrossRef]

- Pang, Y.; Zhang, Z.; Wang, K.; Wang, C. Successful experience of calcining cement clinker with magnesium slag batching. Cement 2022, 4, 32–33. (In Chinese) [Google Scholar] [CrossRef]

- Qiang, Y.; Zhou, Y.; Peng, J.; Han, J.; Cui, J. Production practice of magnesia slag replacing limestone for clinker production. Cem. Eng. 2020, 5, 32–36. (In Chinese) [Google Scholar] [CrossRef]

- Li, H.; Huang, Y.; Yang, X.; Jiang, Z.; Yang, Z. Approach to the management of magnesium slag via the production of Portland cement clinker. J. Mater. Cycles Waste Manag. 2018, 20, 1701–1709. [Google Scholar] [CrossRef]

- Wen, X.; Zhang, J.; Liao, H.; Cheng, F. Study on crystal phase transformation of fiber feedstock mixed with fly ash and magnesium slag during temperature rise. Compr. Util. Fly Ash 2019, 6, 11–16. (In Chinese) [Google Scholar] [CrossRef]

- Gao, L. Study on porosity control of porous ceramic filter balls made from magnesium slag. China Met. Bull. 2021, 7, 183–184. (In Chinese) [Google Scholar] [CrossRef]

- Ge, T.; Fan, Y.; Li, H.; Cheng, F. Effects of magnesium slag silica-potassium fertilizer on salinity soil fertility and rape growth. Guangdong Agric. Sci. 2015, 42, 45–51. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, X. Application of metal magnesium slag in cement production. Cem. Technol. 2023, 62–67+73. (In Chinese) [Google Scholar] [CrossRef]

- Xiao, L.; Wang, S.; Luo, F. Application status and prospect analysis of industrial waste slag such as magnesium slag. J. Jilin Univ. Civ. Eng. Archit. 2008, 25, 1–7. (In Chinese) [Google Scholar] [CrossRef]

- Sun, R.; Wu, Z.; Wang, D.; Ding, Y. Properties and hydration mechanism of ultrafine magnesium slag and cement composite cementing materials. Mater. Rev. 2023, 37, 98–108. (In Chinese) [Google Scholar] [CrossRef]

- Ruan, Y.; Pan, G.; Gao, Q. Study on preparation of ultra-high strength concrete by ultrafine pulverized fly ash. J. Dalian Univ. Technol. 1997, 137, 140. (In Chinese) [Google Scholar]

- Luo, F. Research and Application of Magnesium Slag Gelling Materials with Less Clinker. Master’s Thesis, Jilin Institute of Civil Engineering, Changchun, China, 2010. (In Chinese). [Google Scholar]

- Peng, X.; Wang, K.; Li, J.; Yu, Z. Activation of magnesium slag and preparation of Magnesium slag brick. J. Chongqing Univ. (Nat. Sci. Ed.) 2013, 36, 48–52+58. [Google Scholar]

- Wang, Y.; Zhang, Z. Study on alkali activated magnesium slag cementing materials. China Pet. Chem. Stand. Qual. 2011, 31, 64. (In Chinese) [Google Scholar] [CrossRef]

- Lu, G.; Han, J.; Ma, Z. Experimental design of gelling characteristics of alkali excited magnesium slag. Exp. Technol. Manag. 2022, 39, 31–36. (In Chinese) [Google Scholar] [CrossRef]

- Yang, T.; Zhang, Z.; Zhu, H.; Gao, X.; Dai, C.; Wu, Q. Re-examining the suitability of high magnesium nickel slag as precursors for alkali-activated materials. Constr. Build. Mater. 2019, 213, 109–120. [Google Scholar] [CrossRef]

- Meng, L.; Wang, Z.; Guo, Z. Effective separation of fusing agent from refined magnesium slag by supergravity technology. Chem. Eng. Process.—Process Intensif. 2022, 175, 108915. [Google Scholar] [CrossRef]

- Zhou, J.; Cui, Z.; Zhou, K.; Zheng, H. Study on the effect of magnesium slag replacing some fine aggregate on compressive strength of concrete. Concrete 2012, 9, 54–56. (In Chinese) [Google Scholar] [CrossRef]

- Longarini, N.; Crespi, P.; Zucca, M.; Giordano, N.; Silvestro, G.D. The Advantages of Fly Ash Use in Concrete Structures. J. Pol. Miner. Eng. Soc. 2014, 15, 141–145. [Google Scholar]

- Heng, X.; Lu, J.; Li, X.; Qing, P.; Xin, C. Progress in Research of Effect of Silica Fume on the Performance of Cement Concrete. Bull Ceramic. 2013, 32, 423–428. [Google Scholar] [CrossRef]

- Liu, X.; Wu, P.; Liu, X.; Zhang, Z.; Ai, X. The Utilization of Carbonated Steel Slag as a Supplementary Cementitious Material in Cement. Materials 2024, 17, 4574. [Google Scholar] [CrossRef]

- Zhang, D.; Ghouleh, Z.; Shao, Y. Review on carbonation curing of cement-based materials. J. CO2 Util. 2017, 21, 119–131. [Google Scholar] [CrossRef]

- Liu, Z.; Meng, W. Fundamental understanding of carbonation curing and durability of carbonation-cured cement-based composites: A review. J. CO2 Util. 2021, 44, 101428. [Google Scholar] [CrossRef]

- Hao, Y.; Mo, L.; Yun, J. Effect of carbonization on strength and microstructure of magnesium slag mortar. Bull. Silic. 2016, 35, 3047–3052. [Google Scholar] [CrossRef]

- Ye, J.; Liu, S.; Zhao, Y.; Li, Y.; Fang, J.; Zhang, H.; Guan, X. Development of Ultrafine Mineral Admixture from Magnesium Slag and Sequestration of CO2. Buildings 2023, 13, 204. [Google Scholar] [CrossRef]

- Mo, L.; Hao, Y.; Liu, Y.; Wang, F.; Deng, M. Preparation of calcium carbonate binders via CO2 activation of magnesium slag. Cem. Concr. Res. 2019, 121, 81–90. [Google Scholar] [CrossRef]

- Mo, L.; Zhang, F.; Panesar, D.K.; Deng, M. Development of low-carbon cementitious materials via carbonating Portland cement–fly ash–magnesia blends under various curing scenarios: A comparative study. J. Clean. Prod. 2017, 163, 252–261. [Google Scholar] [CrossRef]

- Dai, Y.; Ma, J.; Guo, C.; Xu, X. Experimental Study on Carbonization of Magnesium Slag Cement. E3S Web Conf. 2020, 198, 01022. [Google Scholar] [CrossRef]

- Gao, Y.-H.; Liu, L.; Fang, Z.-Y.; He, W. A backfill material without cementitious material: Carbonation curing magnesium slag based full solid waste backfill material. J. Cent. South Univ. 2024, 31, 1507–1525. [Google Scholar] [CrossRef]

- Li, Z. Research on Carbonization Characteristics of Magnesium Slag Concrete. Master’s Thesis, Ningxia University, Yinchuan, China, 2016. [Google Scholar]

- Cui, Z.; Li, S.; Zhang, C.; Chen, D. Drying shrinkage characteristics of magnesium slag and fly ash composite concrete. Adv. Eng. Sci. 2015, 34, 14–19. [Google Scholar] [CrossRef]

| Water Requirement of Normal Consistency/% | Specific Area/m2·kg−1 | Stability | Loss on Ignition/% | Setting Time/h | Compressive Strength/MPa | Flexural Strength/MPa | |||

|---|---|---|---|---|---|---|---|---|---|

| Initial Set | Final Set | 3 d | 28 d | 3 d | 28 d | ||||

| 25.8 | 334 | qualified | 2.79 | 2.3 | 3.4 | 28.8 | 48.6 | 6.4 | 8.6 |

| Composition/Content/% | CaO | SiO2 | MgO | Fe2O3 | Al2O3 | SO3 | MnO2 | CuO | Other |

|---|---|---|---|---|---|---|---|---|---|

| Cement | 63.42 | 21.18 | 5.02 | 3.14 | 5.02 | 2.3 | - | - | 1.82 |

| MS | 60.93 | 28.67 | 5.10 | 3.42 | 0.73 | 0.032 | 0.058 | 0.012 | 1.048 |

| Number | Cement | MS | Coarse Aggregate | Fine Aggregate | Water | Water Reducer | ||

|---|---|---|---|---|---|---|---|---|

| 5–10 mm | 10–16 mm | >16 mm | ||||||

| MSC-I0 | 366 | 0 | 581.5 | 523.3 | 58.1 | 683 | 161 | 3.66 |

| MSC-I10 | 329.4 | 36.6 | 581.5 | 523.3 | 58.1 | 683 | 161 | 3.66 |

| MSC-I20 | 292.8 | 73.2 | 581.5 | 523.3 | 58.1 | 683 | 161 | 3.66 |

| MSC-I30 | 256.2 | 109.8 | 581.5 | 523.3 | 58.1 | 683 | 161 | 3.66 |

| MSC-I40 | 219.6 | 146.4 | 581.5 | 523.3 | 58.1 | 683 | 161 | 3.66 |

| MSC-I50 | 183 | 183 | 581.5 | 523.3 | 58.1 | 683 | 161 | 3.66 |

| MSC-I60 | 146.4 | 219.6 | 581.5 | 523.3 | 58.1 | 683 | 161 | 3.66 |

| MSC-II30 | 277.2 | 118.8 | 581.8 | 523.6 | 58.2 | 683.4 | 150.4 | 3.96 |

| MSC-III30 | 338.1 | 144.9 | 513.1 | 461.8 | 51.3 | 774.1 | 140.0 | 4.83 |

| Age/Coefficients | A | B | C | D |

|---|---|---|---|---|

| 7 d | 0.0016 | −0.15 | −4.76 | −46.42 |

| 14 d | −0.0004 | −0.05 | −1.62 | 21.4 |

| 28 d | 0.0007 | 2.77 | 2.77 | −29.03 |

| Number | MSC-I0 | MSC-I10 | MSC-I20 | MSC-I30 | MSC-I40 | MSC-I50 | MSC-I60 |

|---|---|---|---|---|---|---|---|

| Carbon sequestration (%) | 14.60 | 11.87 | 11.69 | 16.90 | 19.80 | 14.78 | 13.09 |

| Water-cement ratio | 0.39 | 0.47 | 0.59 |

| Carbon sequestration (%) | 10.18 | 18.80 | 16.90 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Zhang, Y.; Zhang, F.; Liang, H.; Niu, D.; Li, H. Mechanical and Ecological Properties of CO2 Curing Magnesium Slag Concrete. Materials 2025, 18, 109. https://doi.org/10.3390/ma18010109

Zhang L, Zhang Y, Zhang F, Liang H, Niu D, Li H. Mechanical and Ecological Properties of CO2 Curing Magnesium Slag Concrete. Materials. 2025; 18(1):109. https://doi.org/10.3390/ma18010109

Chicago/Turabian StyleZhang, Lu, Yilong Zhang, Fan Zhang, Haonan Liang, Ditao Niu, and Hui Li. 2025. "Mechanical and Ecological Properties of CO2 Curing Magnesium Slag Concrete" Materials 18, no. 1: 109. https://doi.org/10.3390/ma18010109

APA StyleZhang, L., Zhang, Y., Zhang, F., Liang, H., Niu, D., & Li, H. (2025). Mechanical and Ecological Properties of CO2 Curing Magnesium Slag Concrete. Materials, 18(1), 109. https://doi.org/10.3390/ma18010109