Thermo-Mechanical Optimization of Die Casting Molds Using Topology Optimization and Numerical Simulations

Abstract

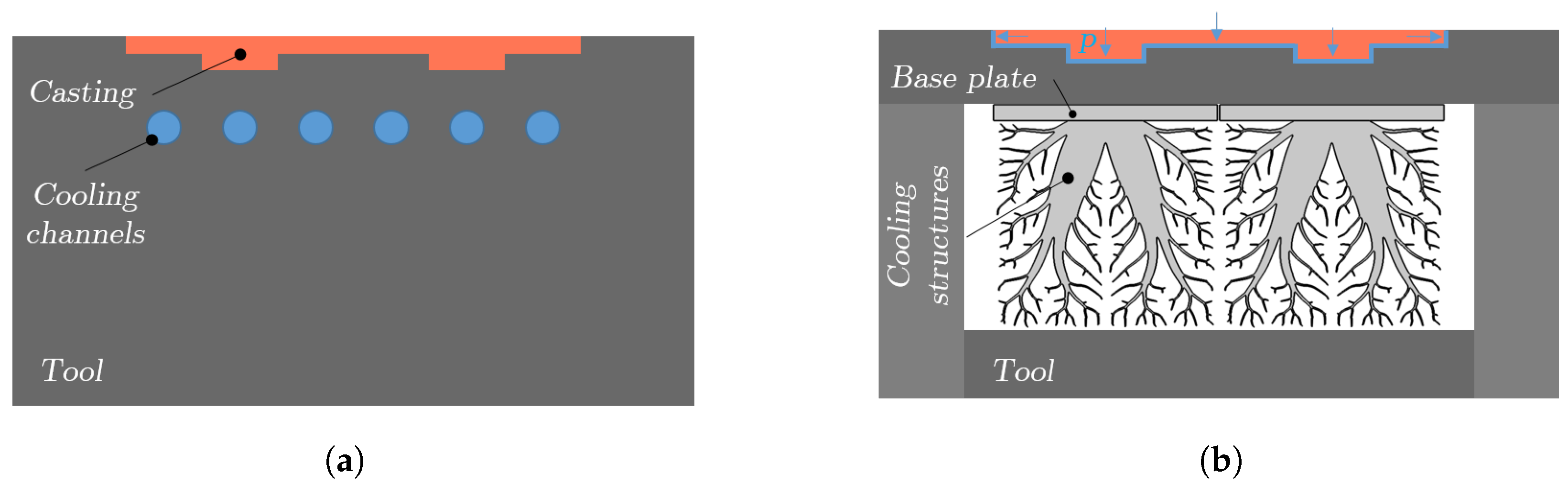

1. Introduction

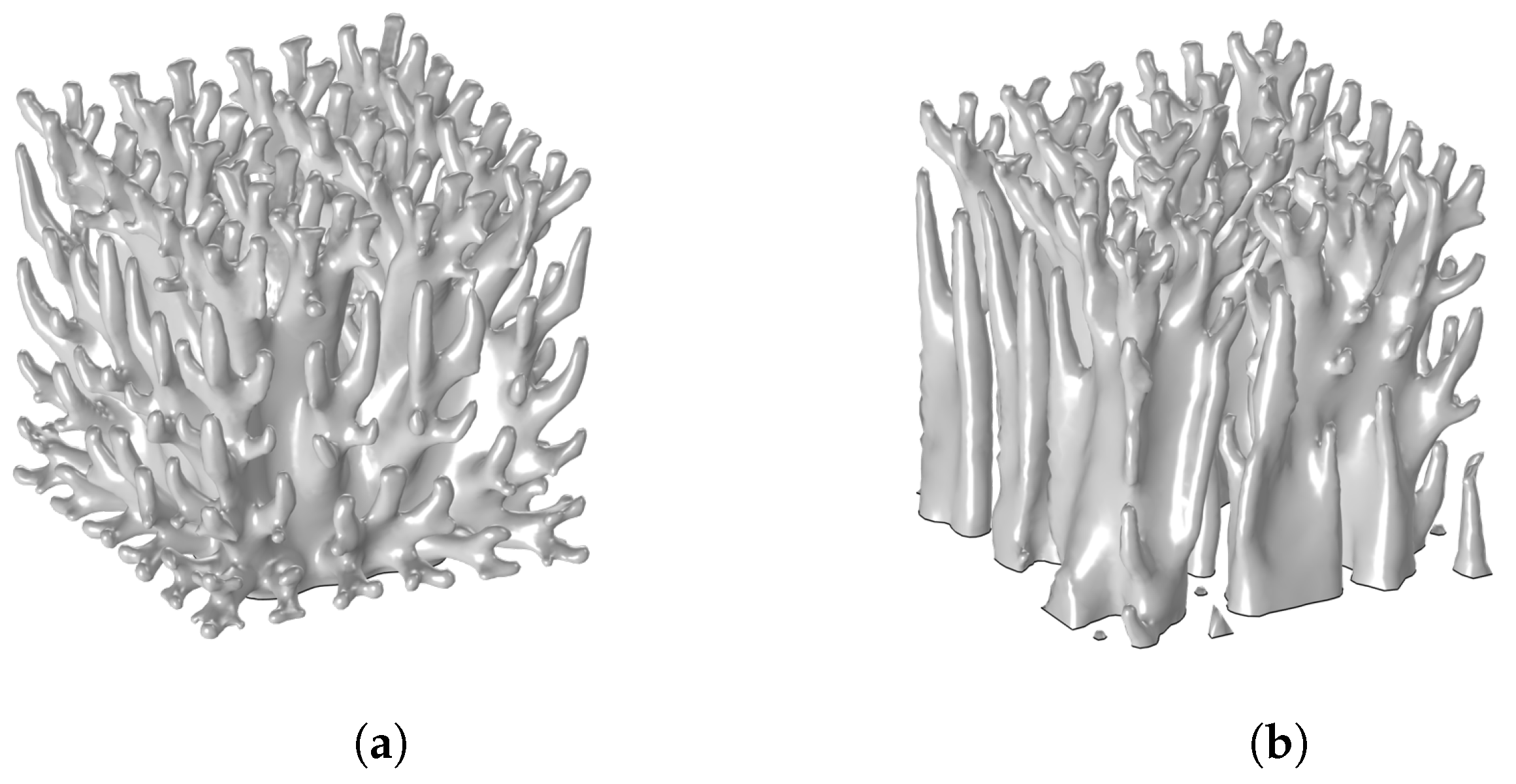

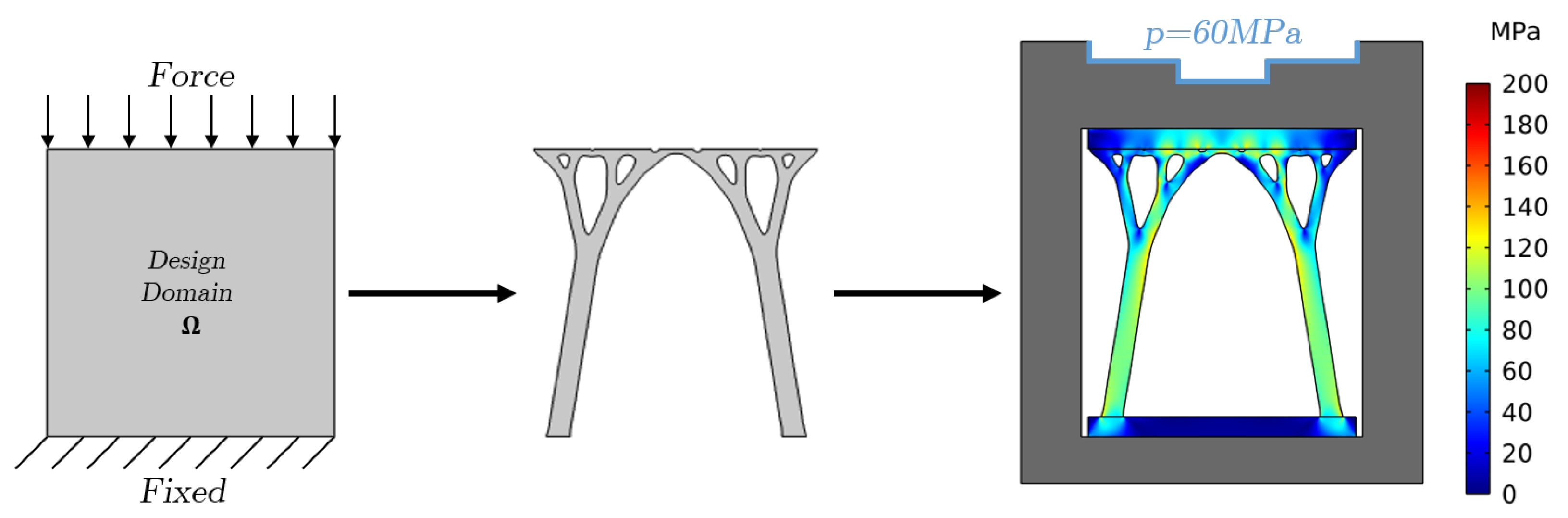

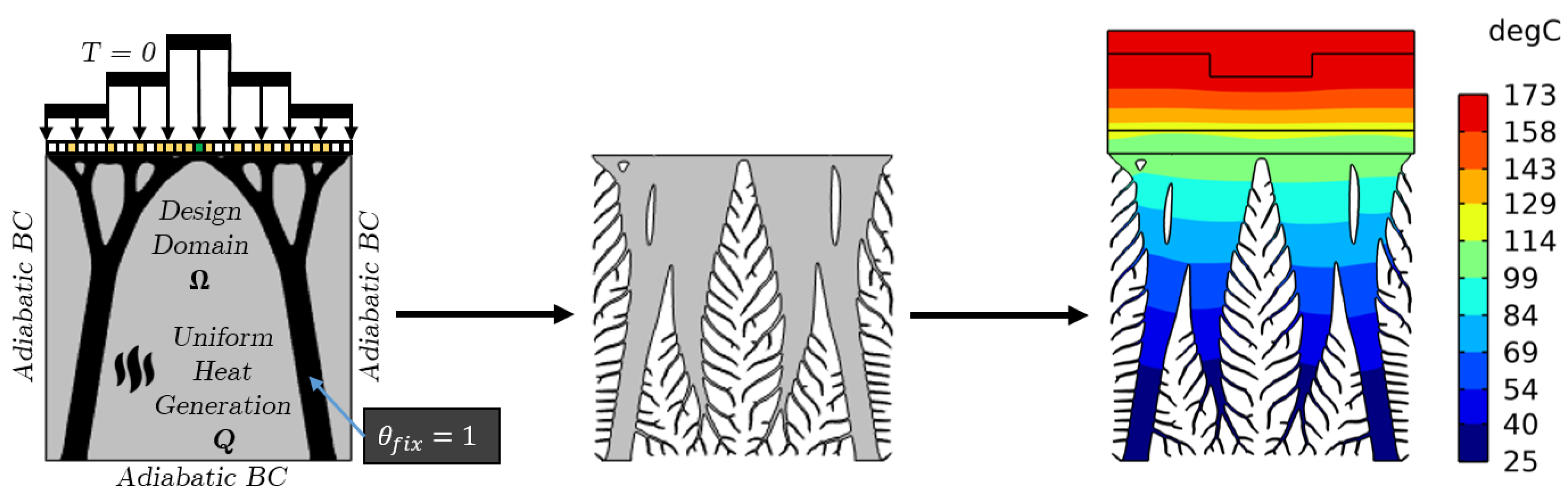

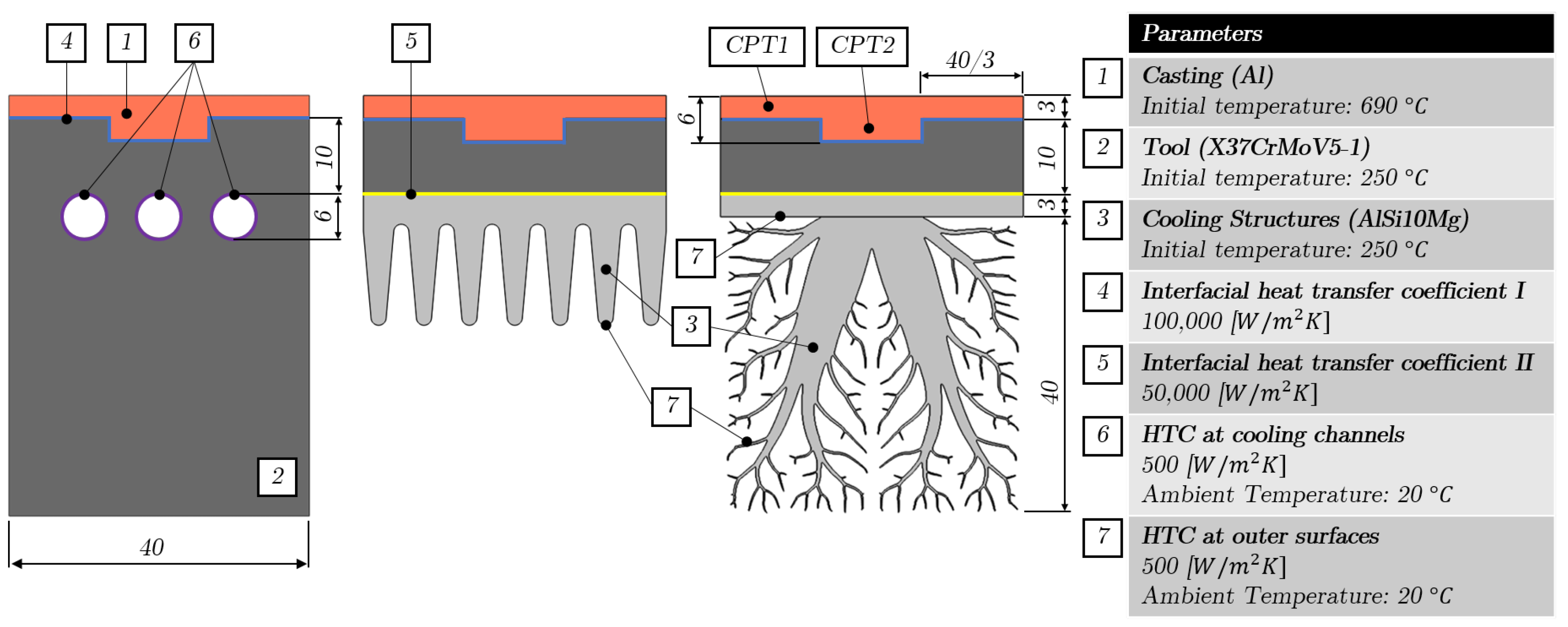

2. Methods and Computational Models

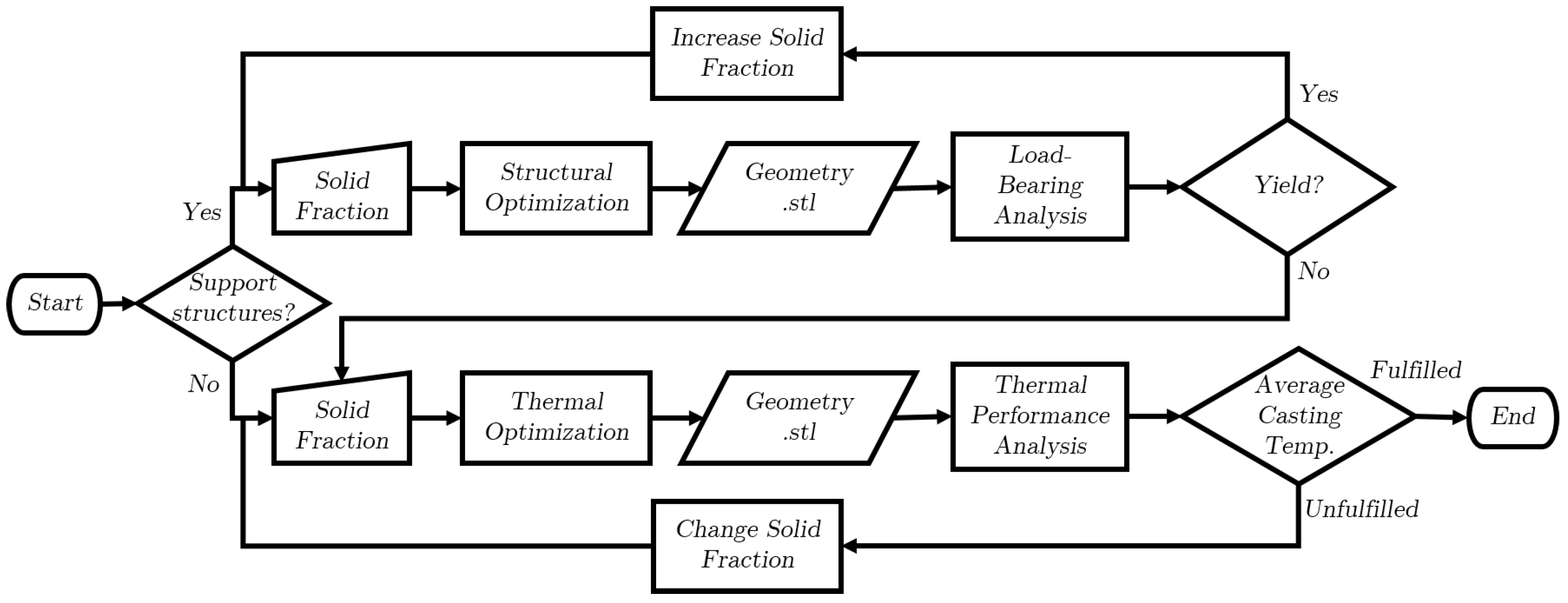

2.1. Method

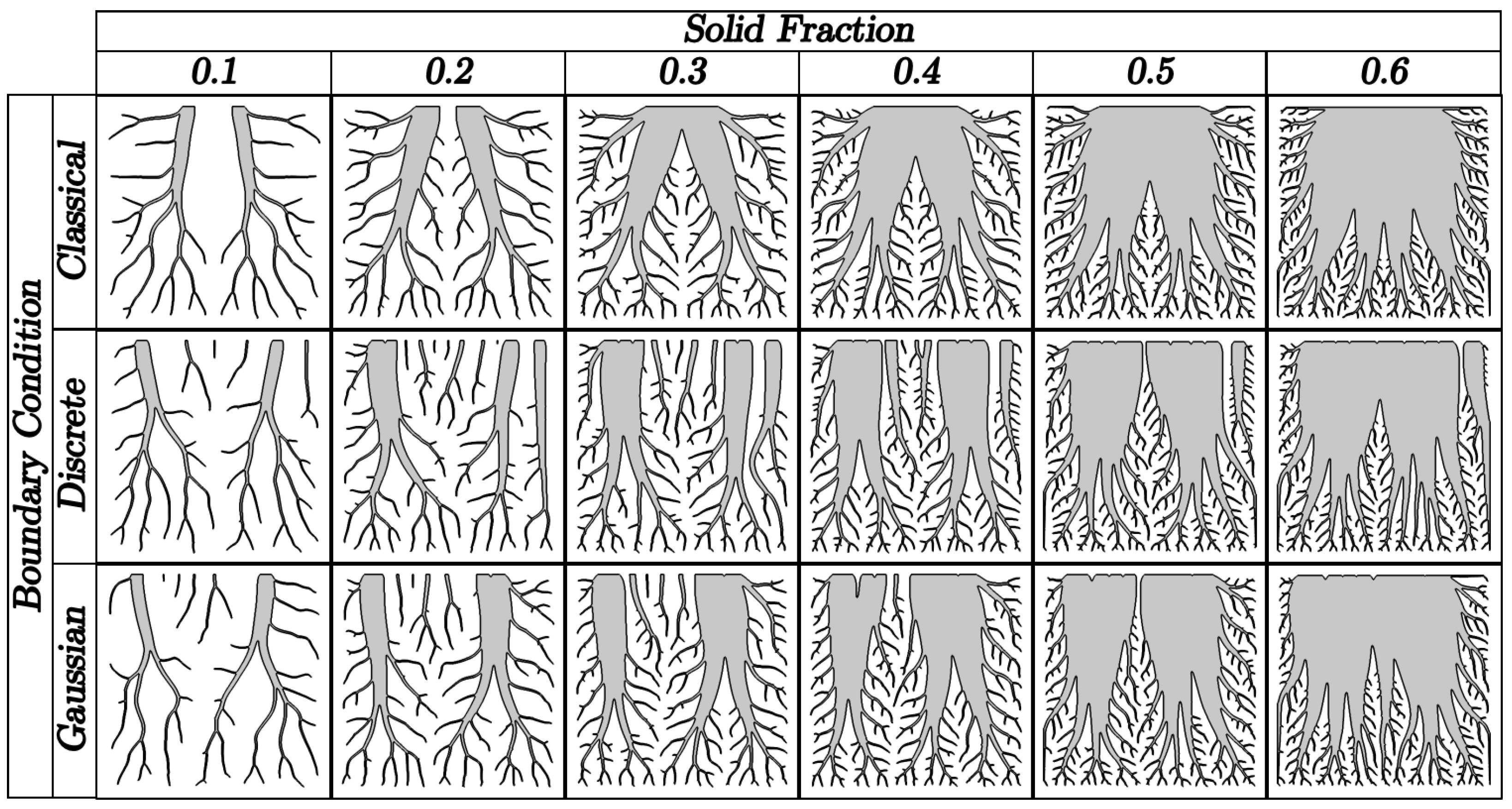

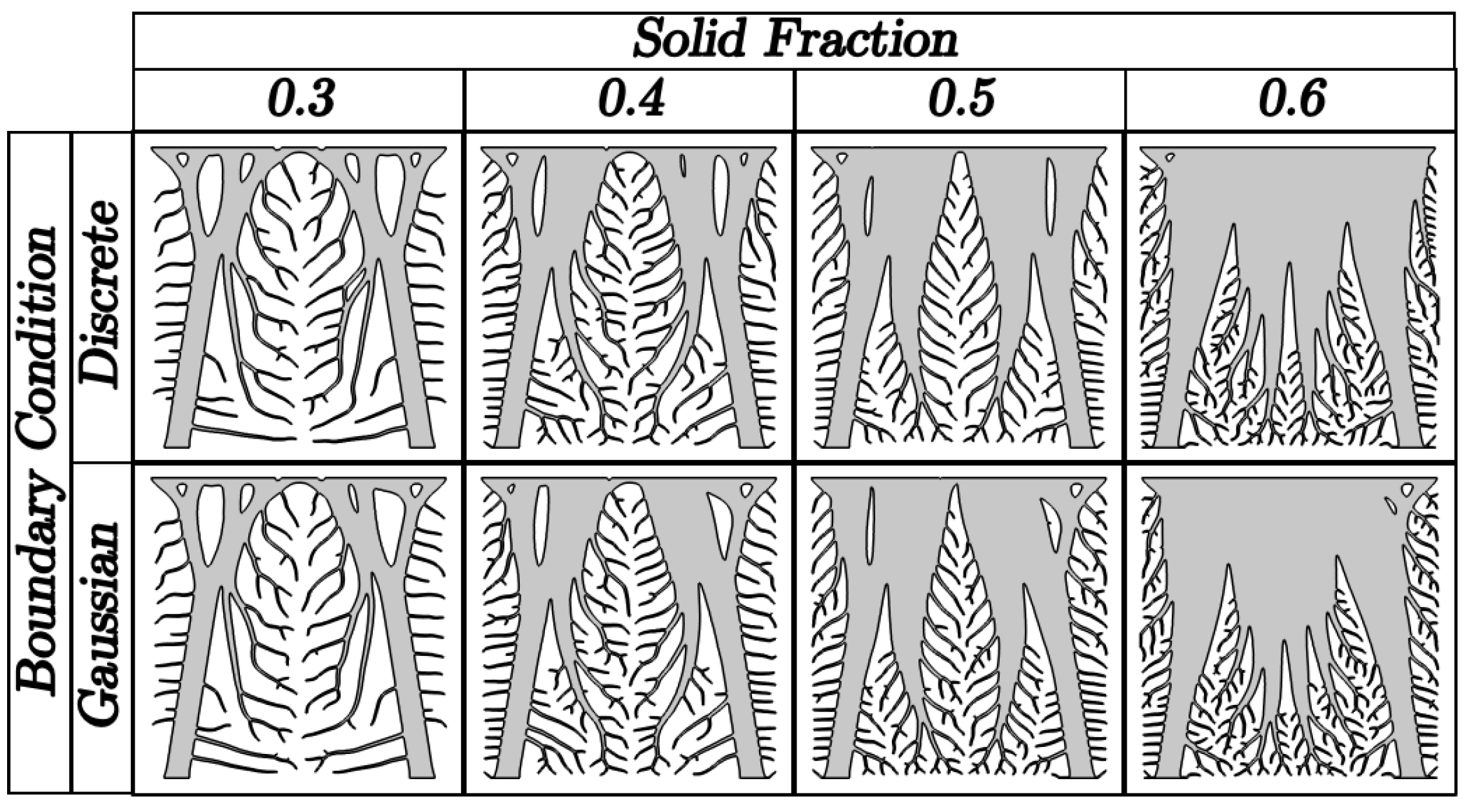

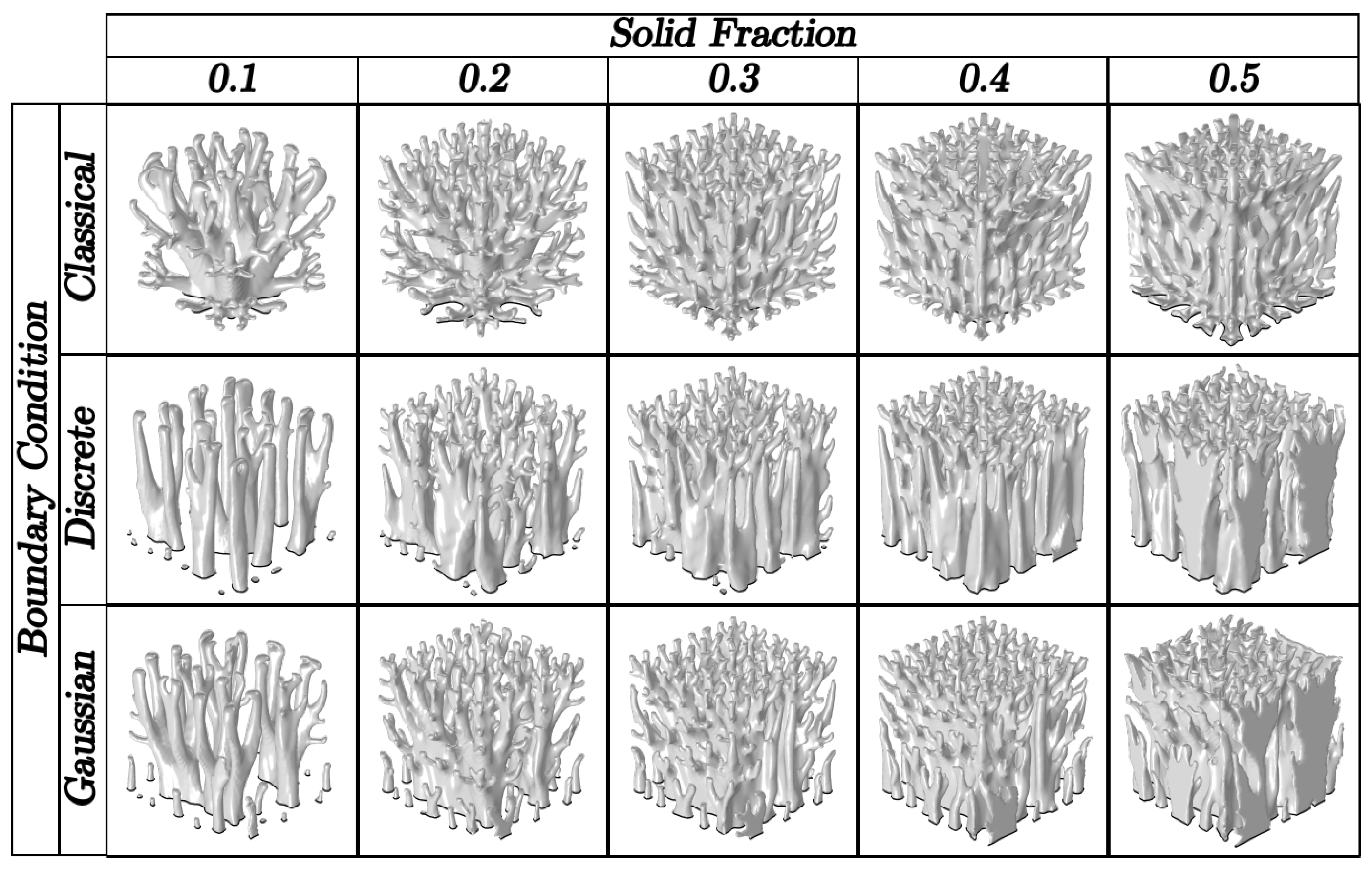

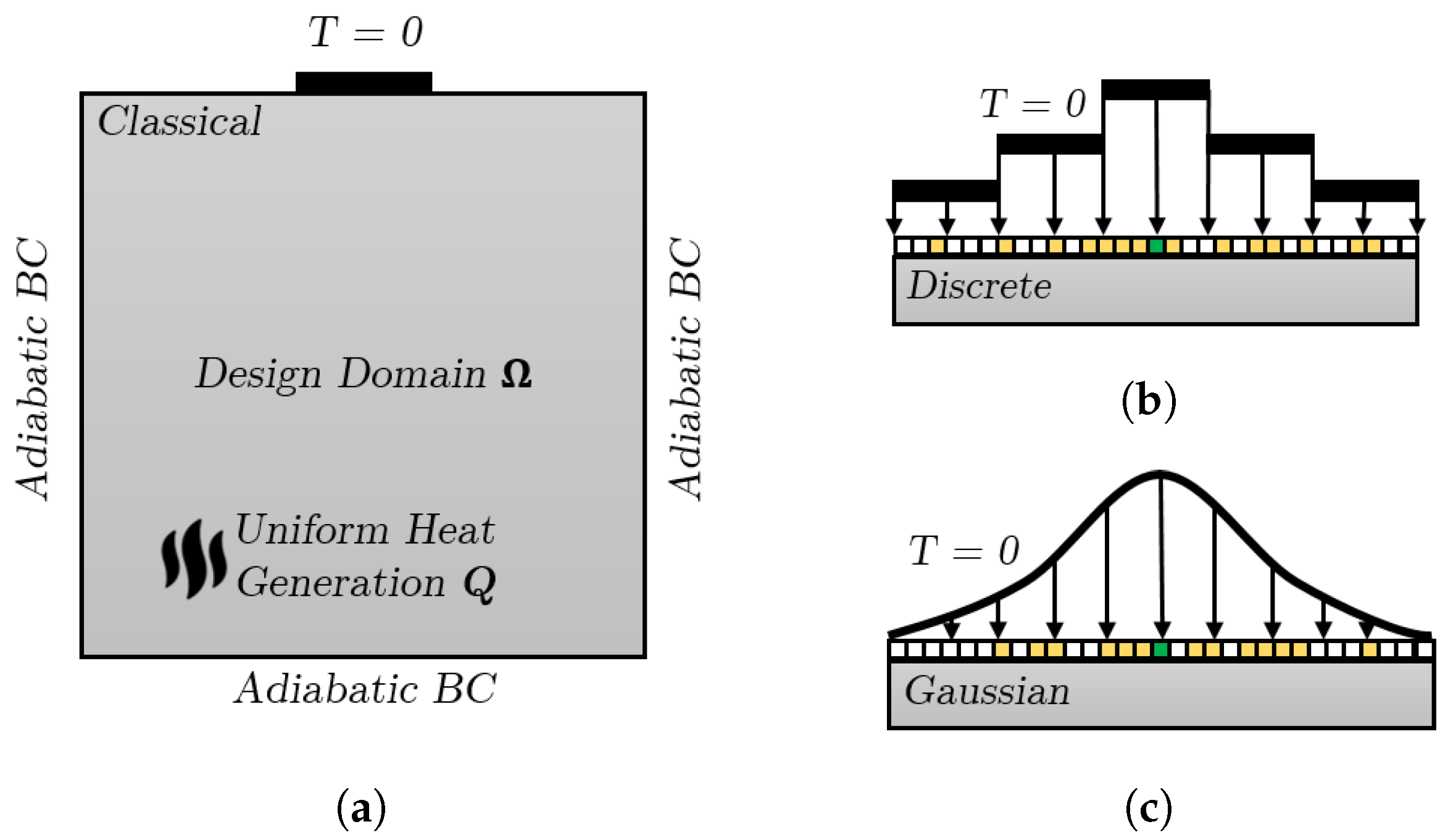

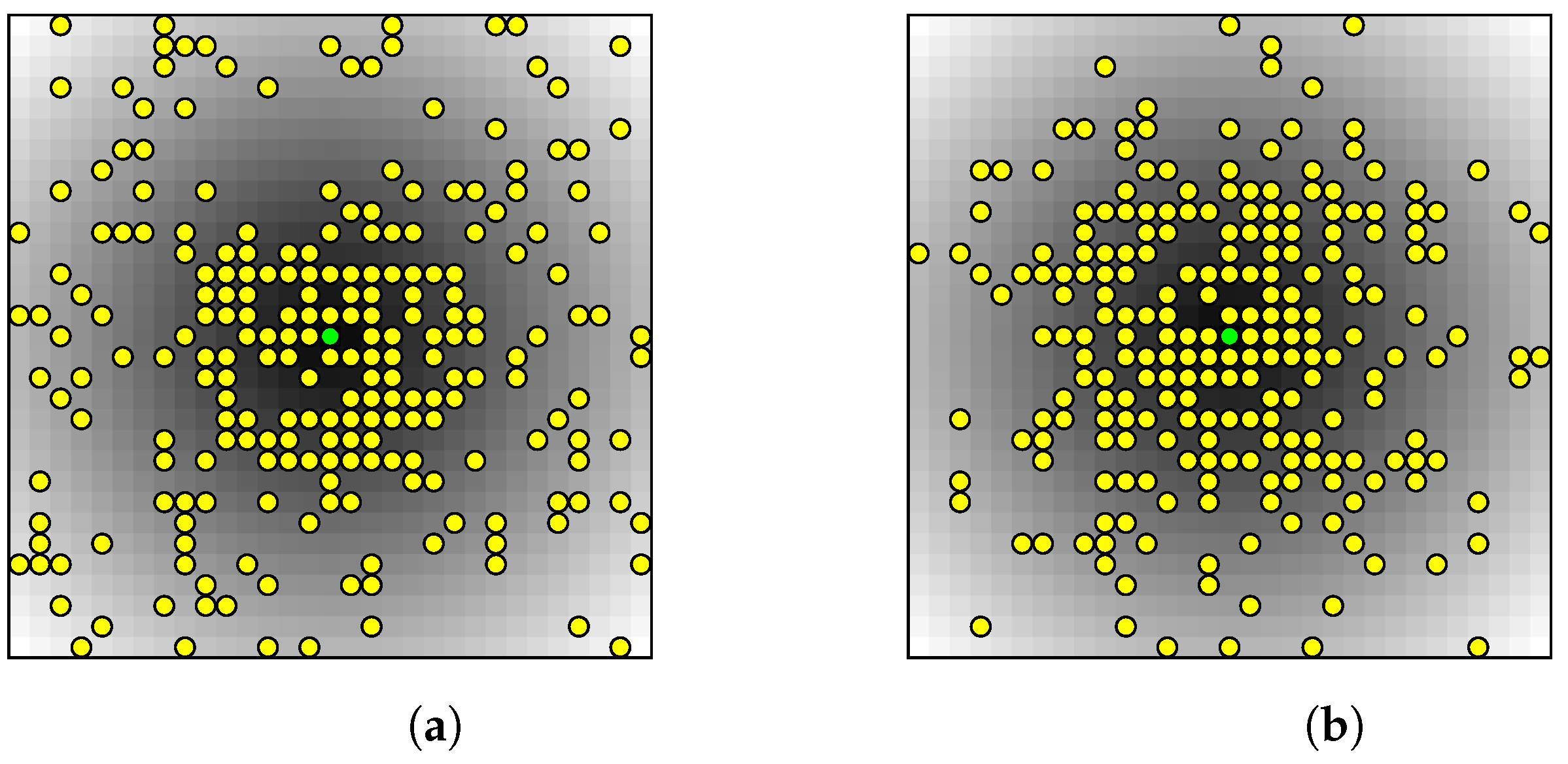

2.2. Thermal Topology Optimization

2.3. Thermomechanical Topology Optimization

2.4. Heat Transfer Simulations

3. Results and Discussion

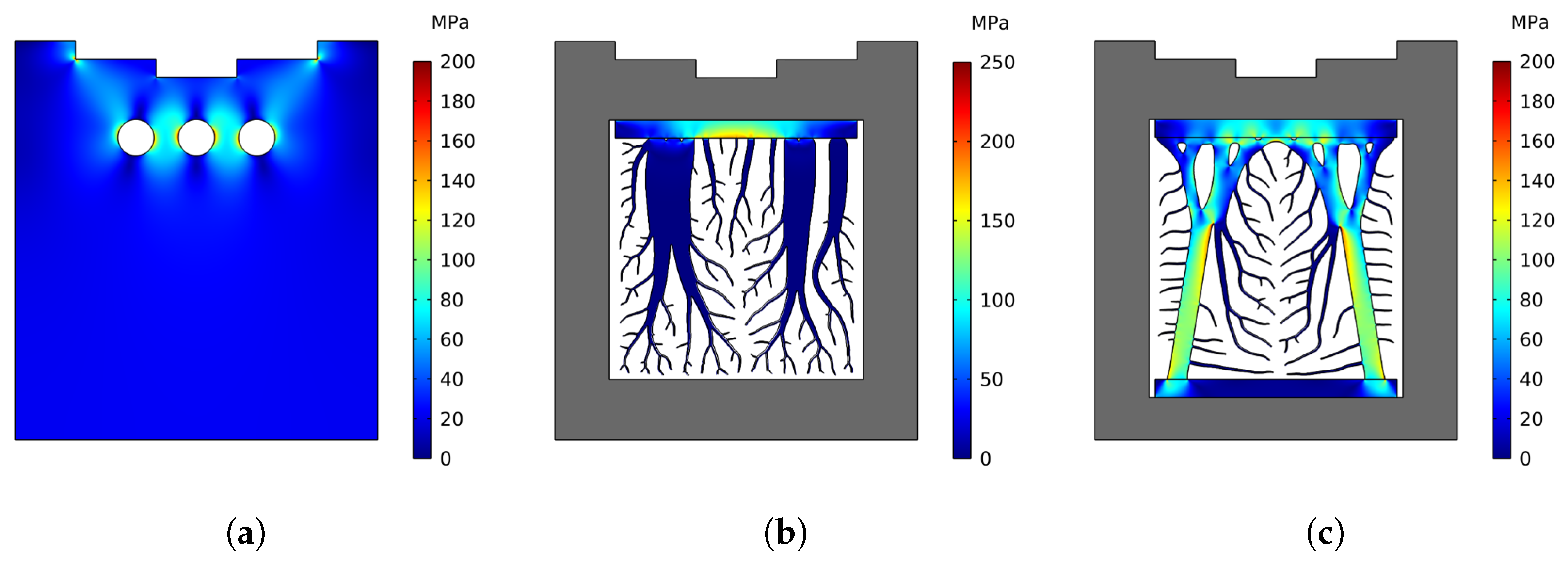

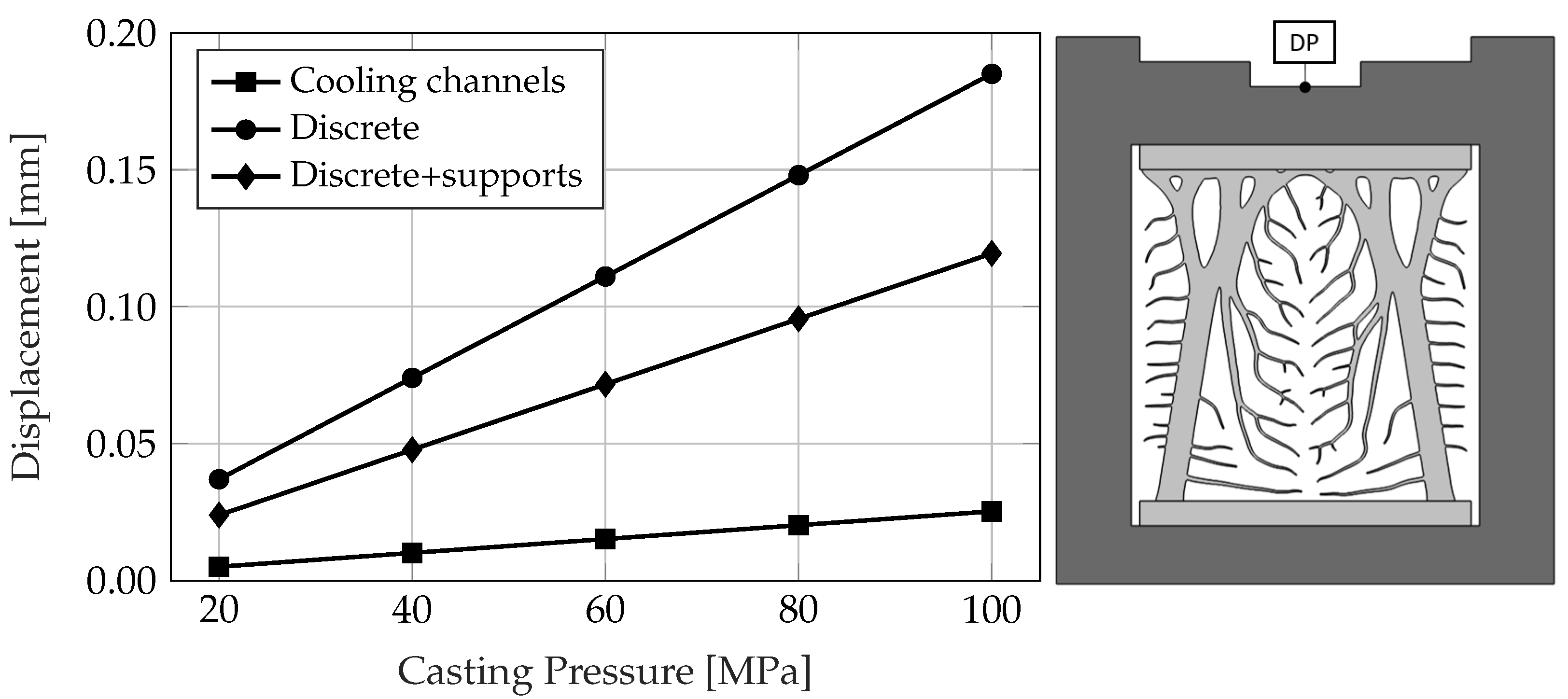

3.1. Load-Bearing Analysis

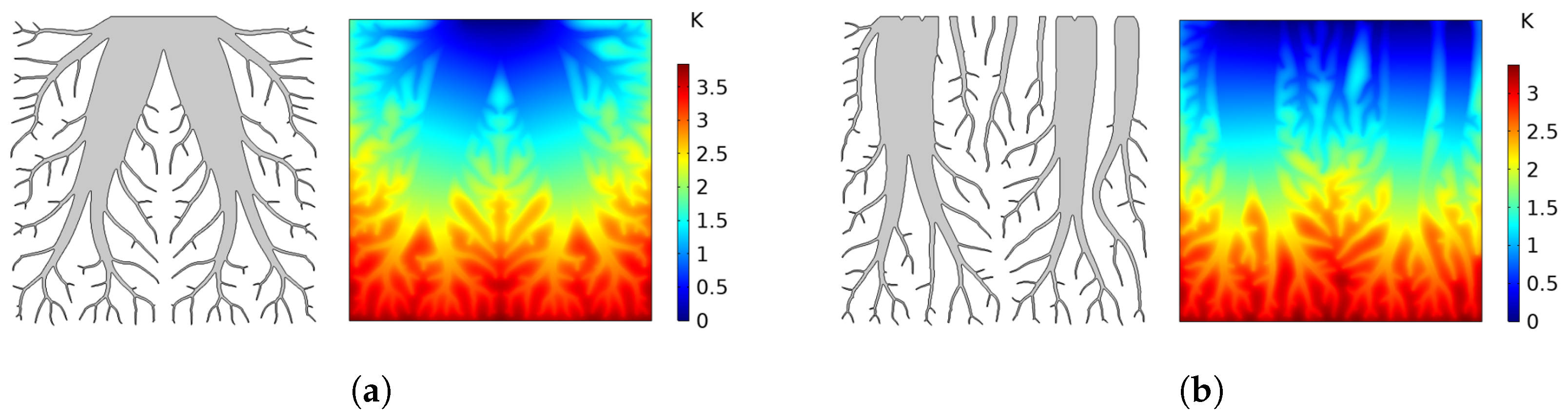

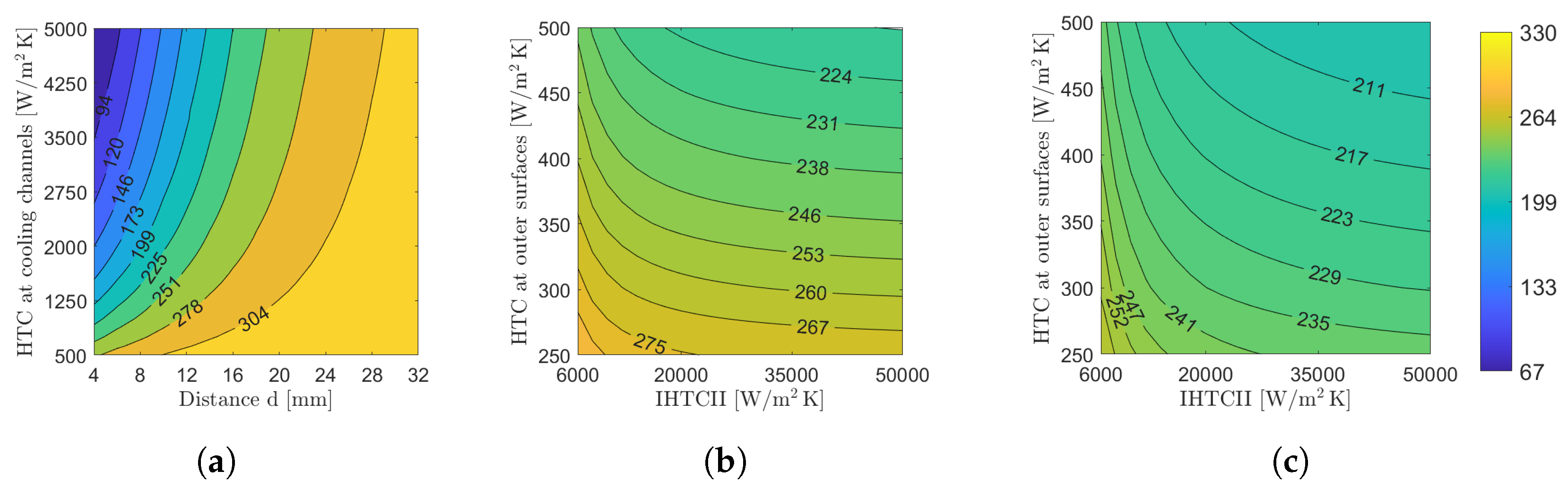

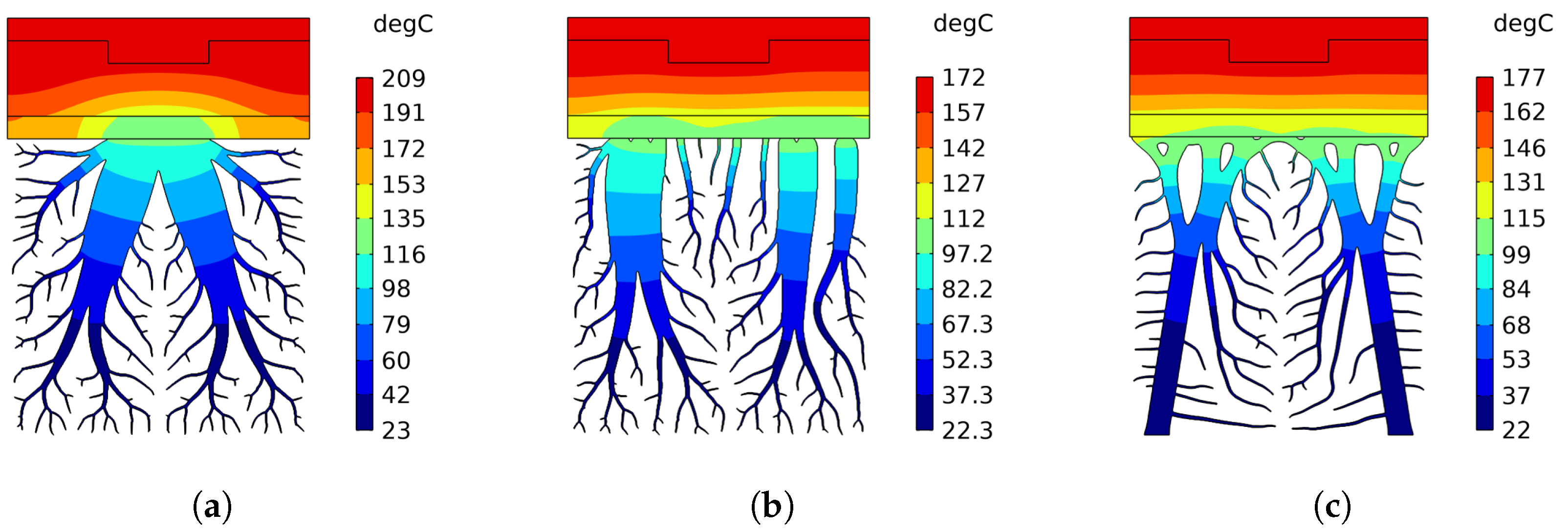

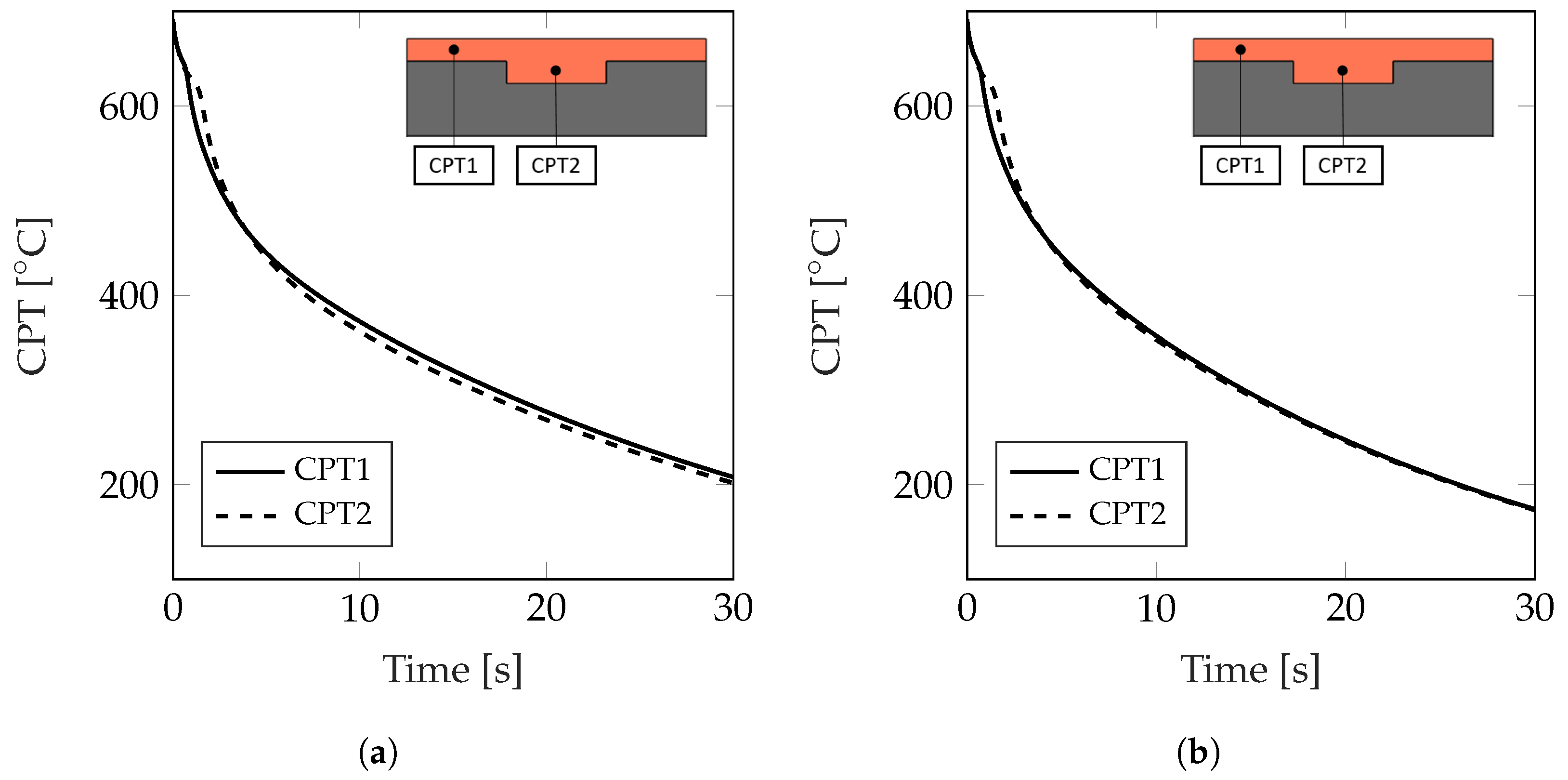

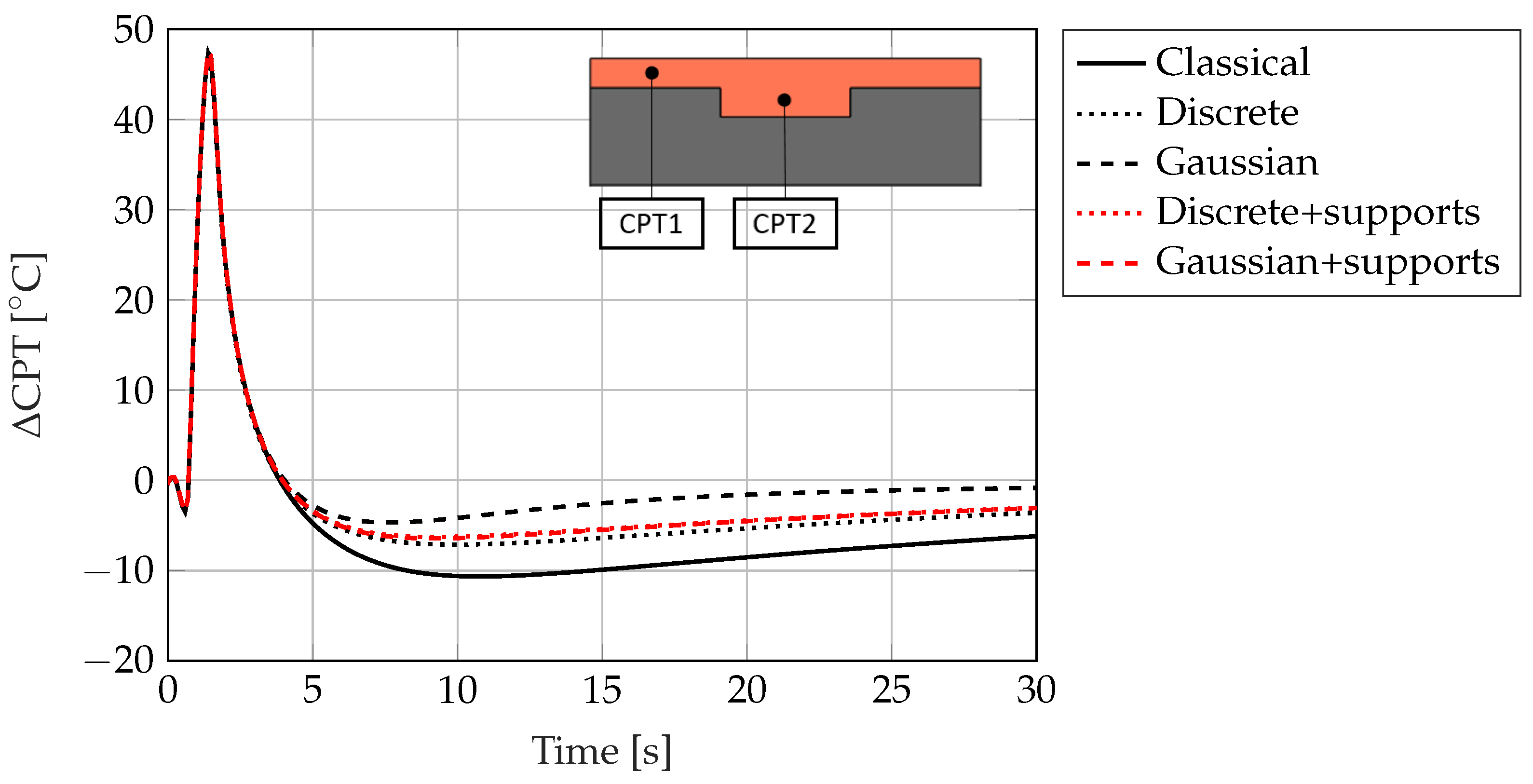

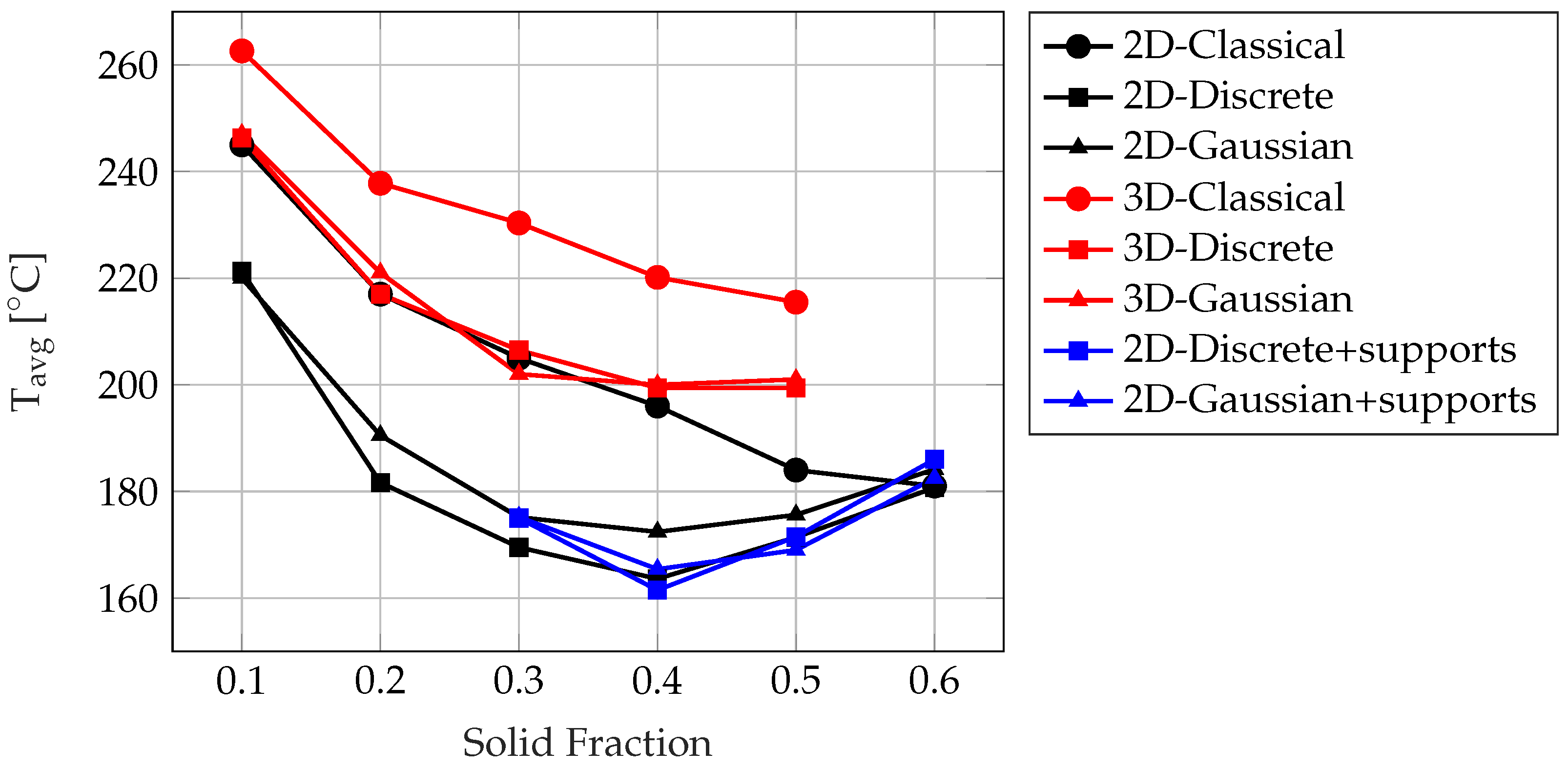

3.2. Thermal Performance Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Kurtulus, K.; Bolatturk, A.; Coskun, A.; Gürel, B. An experimental investigation of the cooling and heating performance of a gravity die casting mold with conformal cooling channels. Appl. Therm. Eng. 2021, 194, 117105. [Google Scholar] [CrossRef]

- Žbontar, M.; Petrič, M.; Mrvar, P. The influence of cooling rate on microstructure and mechanical properties of alsi9cu3. Metals 2021, 11, 186. [Google Scholar] [CrossRef]

- Sivertsen, S. Die Life Prediction Using High Pressure Die Casting Simulations. 2020. Available online: https://www.diva-portal.org/smash/record.jsf?pid=diva2%3A1452802&dswid=-6751 (accessed on 6 December 2023).

- Ebnesajjad, S. Fluoroplastics, Volume 2: Melt Processible Fluoropolymers—The Definitive User’s Guide and Data Book, 2nd ed.; William Andrew: Norwich, NY, USA, 2015. [Google Scholar] [CrossRef]

- Kent, R. Energy Management in Plastics Processing: Strategies, Targets, Techniques, and Tools; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar] [CrossRef]

- Pezzin, A.; Giansetti, M.; Ferri, A. Influence of Limescale on Heating Elements Efficiency. In Proceedings of the COMSOL Conference, Rotterdam, The Netherlands, 23–25 October 2013; pp. 23–25. [Google Scholar]

- Zink, B.; Kovács, J.G. The effect of limescale on heat transfer in injection molding. Int. Commun. Heat Mass Transf. 2017, 86, 101–107. [Google Scholar] [CrossRef]

- Campbell, J. Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design; Butterworth-Heinemann: Oxford, UK, 2015. [Google Scholar]

- Karakoc, C.; Dizdar, K.C.; Dispinar, D. Investigation of effect of conformal cooling inserts in high-pressure die casting of AlSi9Cu3. Int. J. Adv. Manuf. Technol. 2022, 121, 7311–7323. [Google Scholar] [CrossRef]

- Bendsoe, M.P.; Sigmund, O. Topology Optimization: Theory, Methods, and Applications; Springer Science & Business Media: Dordrecht, The Netherlands, 2003. [Google Scholar]

- Dede, E. Multiphysics topology optimization of heat transfer and fluid flow systems. In Proceedings of the COMSOL Users Conference, Boston, MA, USA, 8 October 2009; Volume 715. [Google Scholar]

- Lange, F.; Hein, C.; Li, G.; Emmelmann, C. Numerical optimization of active heat sinks considering restrictions of selective laser melting. In Proceedings of the COMSOL Conference 2018 Lausanne, Lausanne, Switzerland, 22–24 October 2018. [Google Scholar]

- Haertel, J.; Engelbrecht, K.; Lazarov, B.; Sigmund, O. Topology Optimization of Thermal Heat Sinks. In Proceedings of the COMSOL Conference, Grenoble, France, 14–16 October 2015. [Google Scholar]

- Joo, Y.; Lee, I.; Kim, S.J. Topology optimization of heat sinks in natural convection considering the effect of shape-dependent heat transfer coefficient. Int. J. Heat Mass Transf. 2017, 109, 123–133. [Google Scholar] [CrossRef]

- Lohan, D.J.; Dede, E.M.; Allison, J.T. A study on practical objectives and constraints for heat conduction topology optimization. Struct. Multidiscip. Optim. 2020, 61, 475–489. [Google Scholar] [CrossRef]

- Xie, L.; Zhang, Y.; Ge, M.; Zhao, Y. Topology optimization of heat sink based on variable density method. Energy Rep. 2022, 8, 718–726. [Google Scholar] [CrossRef]

- Koga, A.A.; Lopes, E.C.C.; Nova, H.F.V.; Lima, C.R.; Silva, E.C.N. Development of heat sink device by using topology optimization. Int. J. Heat Mass Transf. 2013, 64, 759–772. [Google Scholar] [CrossRef]

- Yoon, G.H. Topological design of heat dissipating structure with forced convective heat transfer. J. Mech. Sci. Technol. 2010, 24, 1225–1233. [Google Scholar] [CrossRef]

- Lei, T.; Alexandersen, J.; Lazarov, B.S.; Wang, F.; Haertel, J.H.; De Angelis, S.; Sanna, S.; Sigmund, O.; Engelbrecht, K. Investment casting and experimental testing of heat sinks designed by topology optimization. Int. J. Heat Mass Transf. 2018, 127, 396–412. [Google Scholar] [CrossRef]

- Lazarov, B.S.; Sigmund, O.; Meyer, K.E.; Alexandersen, J. Experimental validation of additively manufactured optimized shapes for passive cooling. Appl. Energy 2018, 226, 330–339. [Google Scholar] [CrossRef]

- Zheng, S.; Ji, T.; Xie, G.; Sundén, B. On the improvement of the poor heat transfer lee-side regions of square cross-section ribbed channels. Numer. Heat Transf. Part A Appl. 2014, 66, 963–989. [Google Scholar] [CrossRef]

- Silvestri, A.T.; Astarita, A.; Hassanin, A.E.; Manzo, A.; Iannuzzo, U.; Iannuzzo, G.; de Rosa, V.; Acerra, F.; Squillace, A. Assessment of the mechanical properties of AlSi10Mg parts produced through selective laser melting under different conditions. Procedia Manuf. 2020, 47, 1058–1064. [Google Scholar] [CrossRef]

- Svanberg, K. The method of moving asymptotes—A new method for structural optimization. Int. J. Numer. Methods Eng. 1987, 24, 359–373. [Google Scholar] [CrossRef]

- Wang, M.Y.; Wang, X.; Guo, D. A level set method for structural topology optimization. Comput. Methods Appl. Mech. Eng. 2003, 192, 227–246. [Google Scholar] [CrossRef]

| Domain | Mesh Size (mm) | |||||||

|---|---|---|---|---|---|---|---|---|

| 2D | 0.1 | 2 × meshsize | 8 | 0.5 | 3 | 0.001 | 1 | 0.001 |

| 3D | 0.6 | 2 × meshsize | 6 | 0.5 | 3 | 0.001 | 1000 | 1 |

| Material | [kg/m3] | k [W/(m · K)] | [J/(kg· K)] | E [GPa] | |

|---|---|---|---|---|---|

| Al | COMSOL | COMSOL | COMSOL | N/A | N/A |

| X37CrMoV5-1 | 7716 | 28.7 | 511.5 | 171.8 | 0.3 |

| AlSi10Mg | 2640 | 115 | 968 | 65 | 0.33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Djabraian, S.; Teichmann, F.; Müller, S. Thermo-Mechanical Optimization of Die Casting Molds Using Topology Optimization and Numerical Simulations. Materials 2024, 17, 2114. https://doi.org/10.3390/ma17092114

Djabraian S, Teichmann F, Müller S. Thermo-Mechanical Optimization of Die Casting Molds Using Topology Optimization and Numerical Simulations. Materials. 2024; 17(9):2114. https://doi.org/10.3390/ma17092114

Chicago/Turabian StyleDjabraian, Serouj, Fabian Teichmann, and Sebastian Müller. 2024. "Thermo-Mechanical Optimization of Die Casting Molds Using Topology Optimization and Numerical Simulations" Materials 17, no. 9: 2114. https://doi.org/10.3390/ma17092114

APA StyleDjabraian, S., Teichmann, F., & Müller, S. (2024). Thermo-Mechanical Optimization of Die Casting Molds Using Topology Optimization and Numerical Simulations. Materials, 17(9), 2114. https://doi.org/10.3390/ma17092114