Temperature-Induced Variations in Slip Behavior of Single Crystal Aluminum: Microstructural Analysis

Abstract

1. Introduction

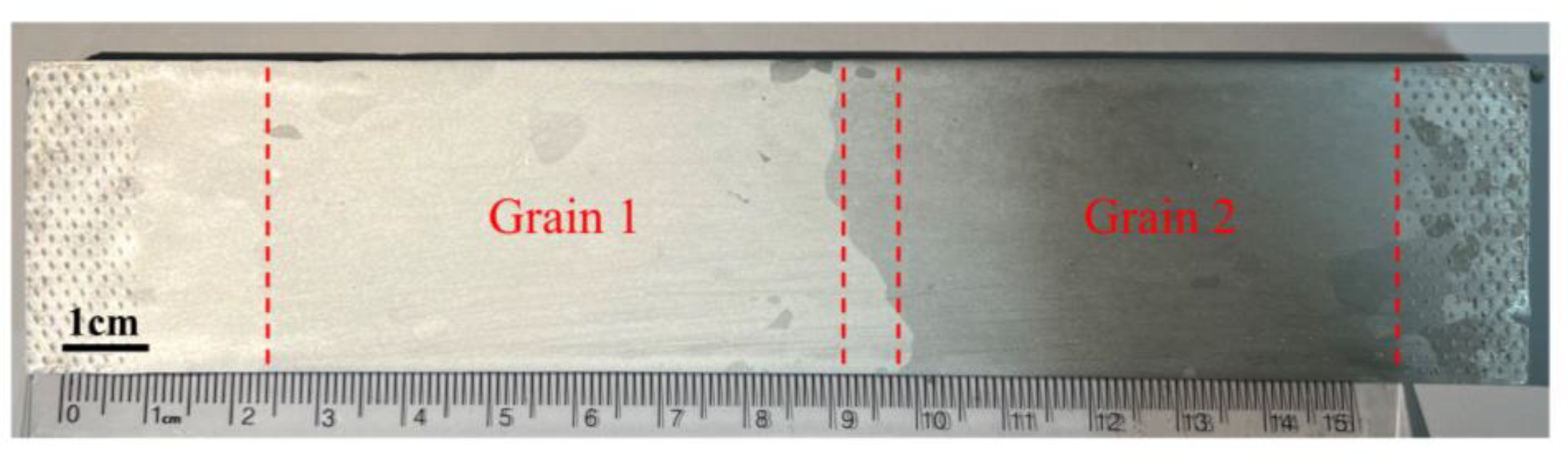

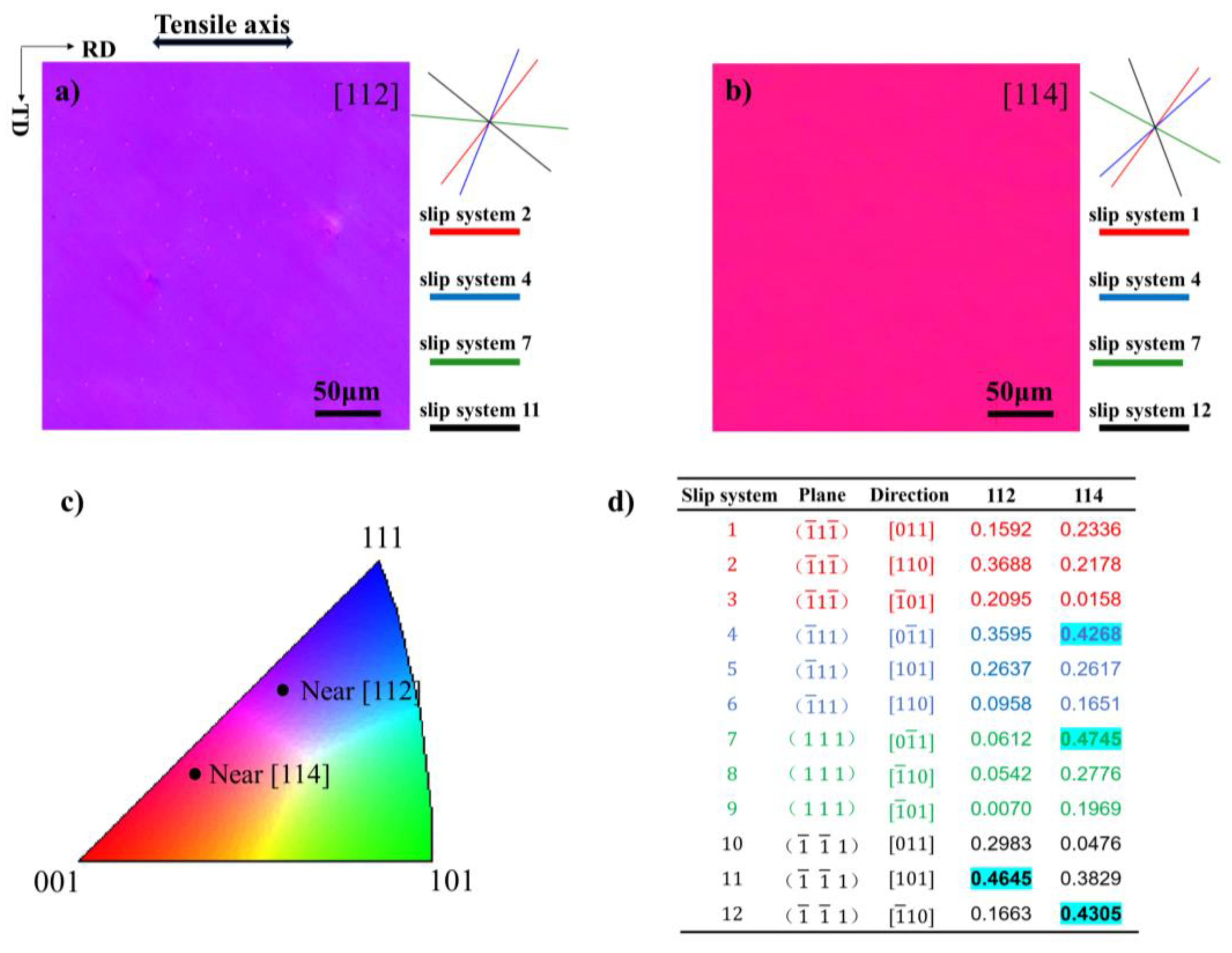

2. Materials and Methods

3. Results and Discussion

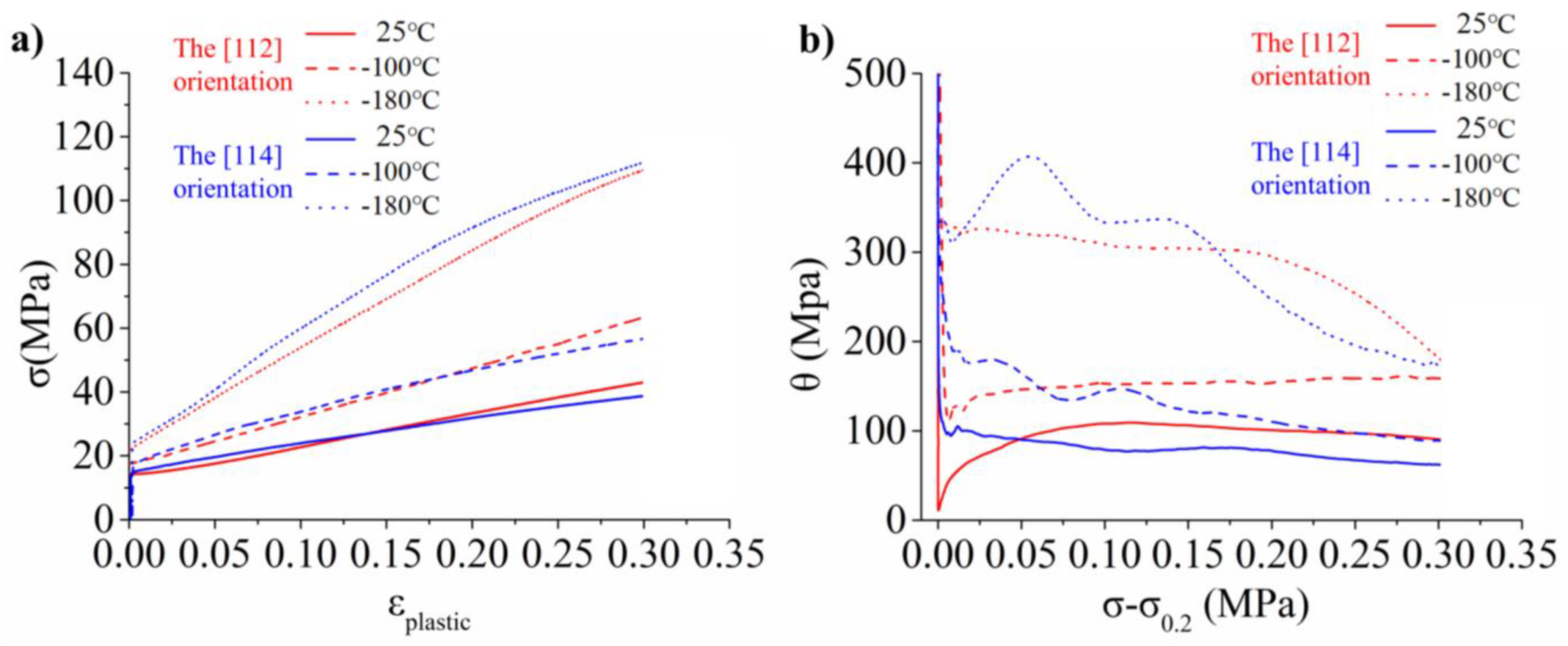

3.1. Mechanical Property

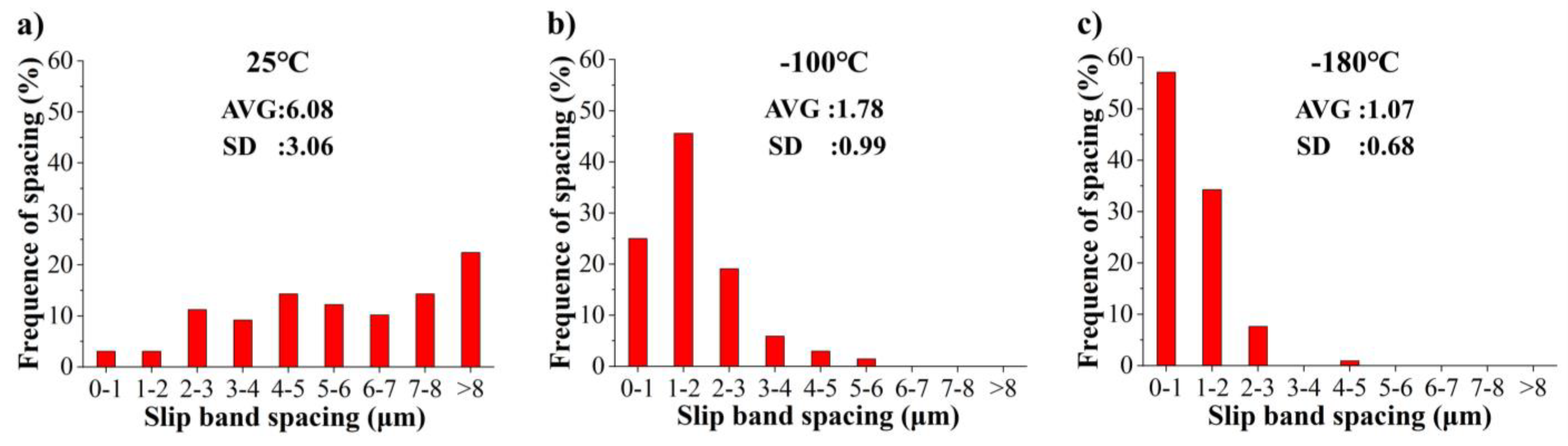

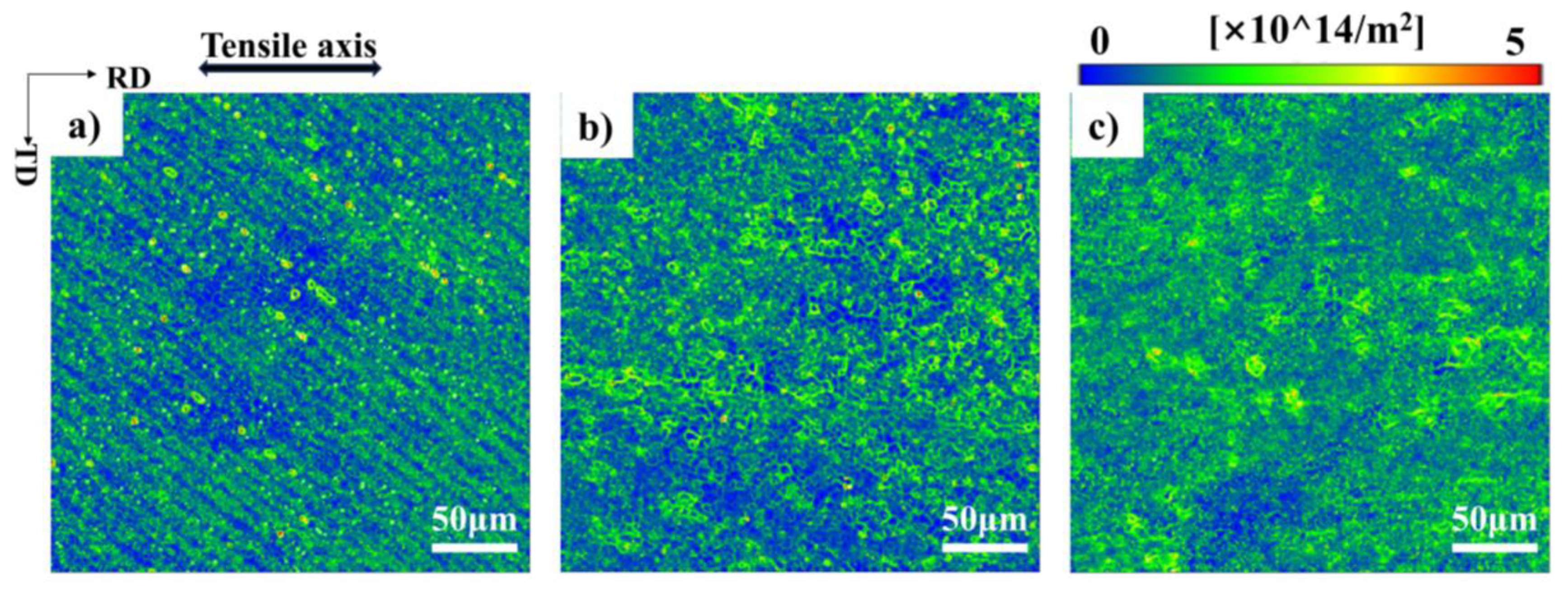

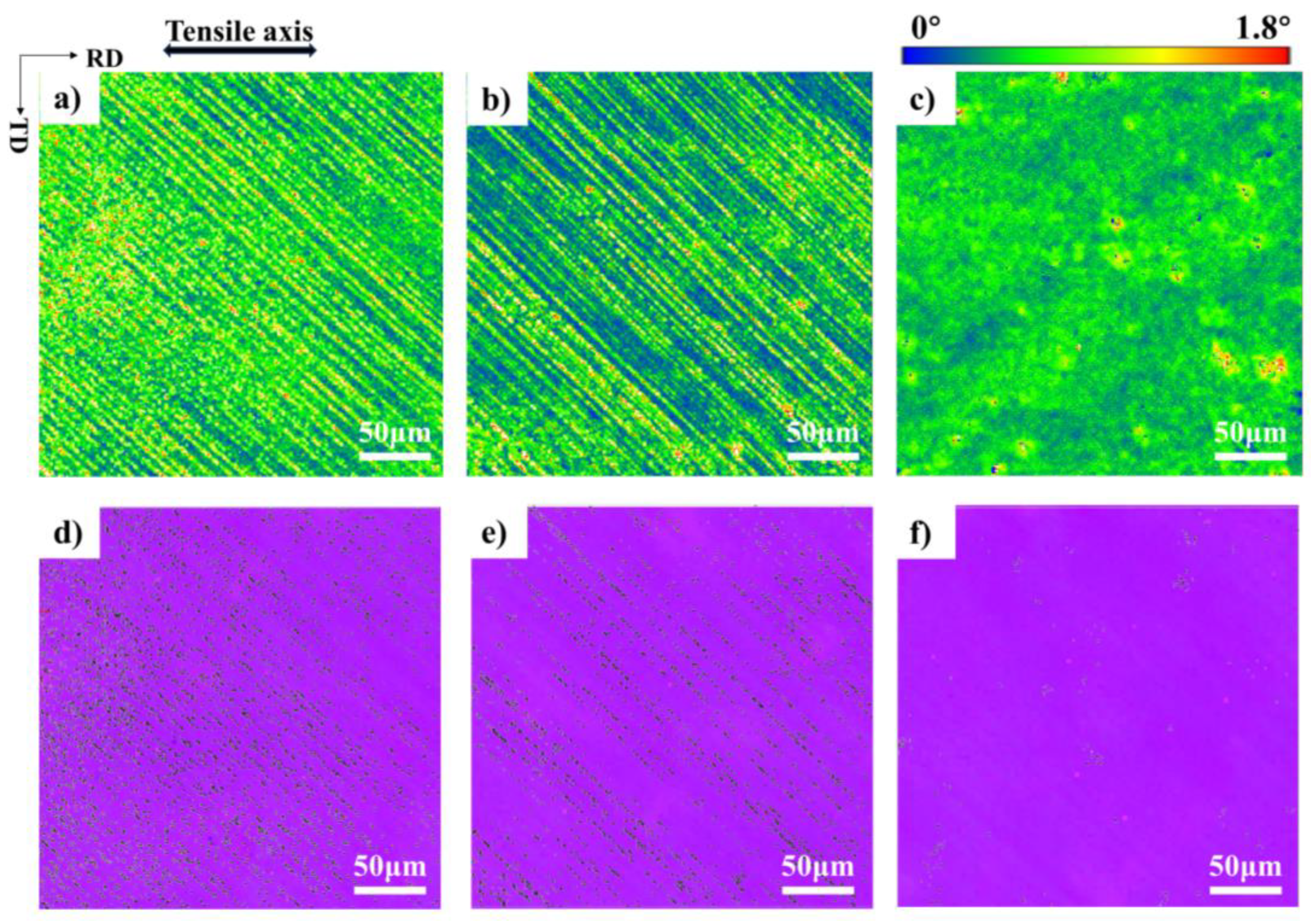

3.2. Microstructure Evolution of Al Single Crystals of the [112] Orientation with Strain

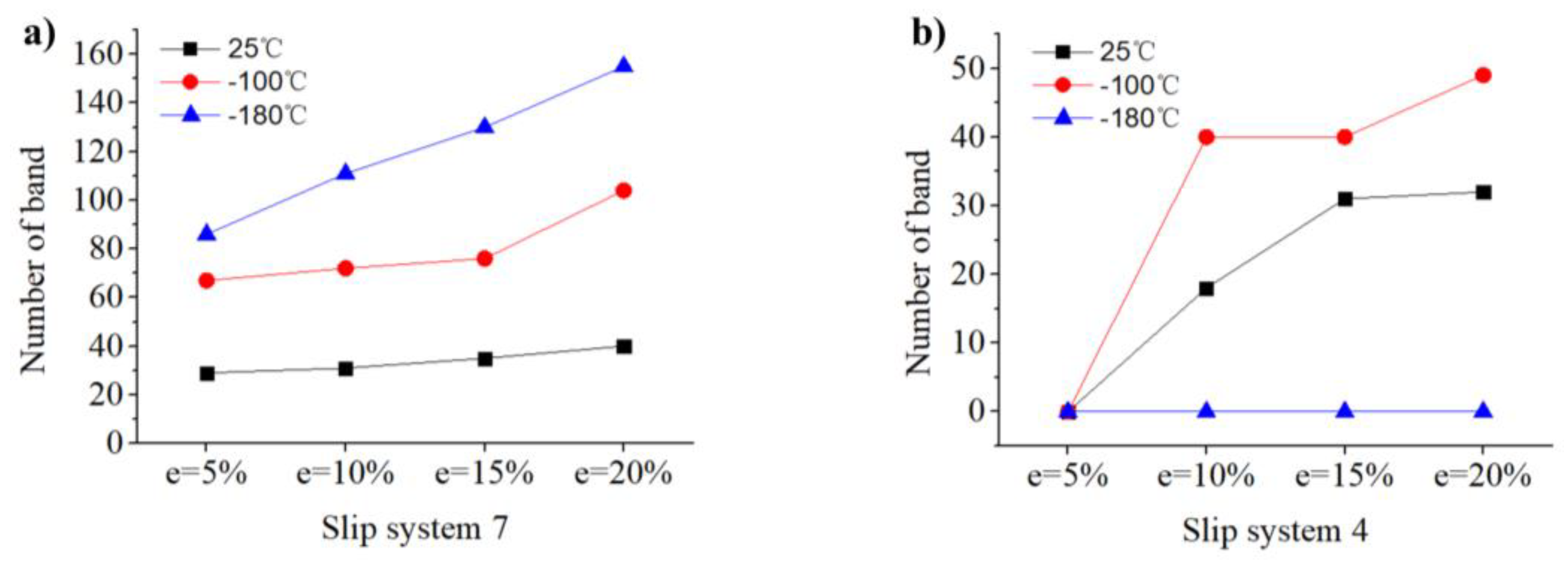

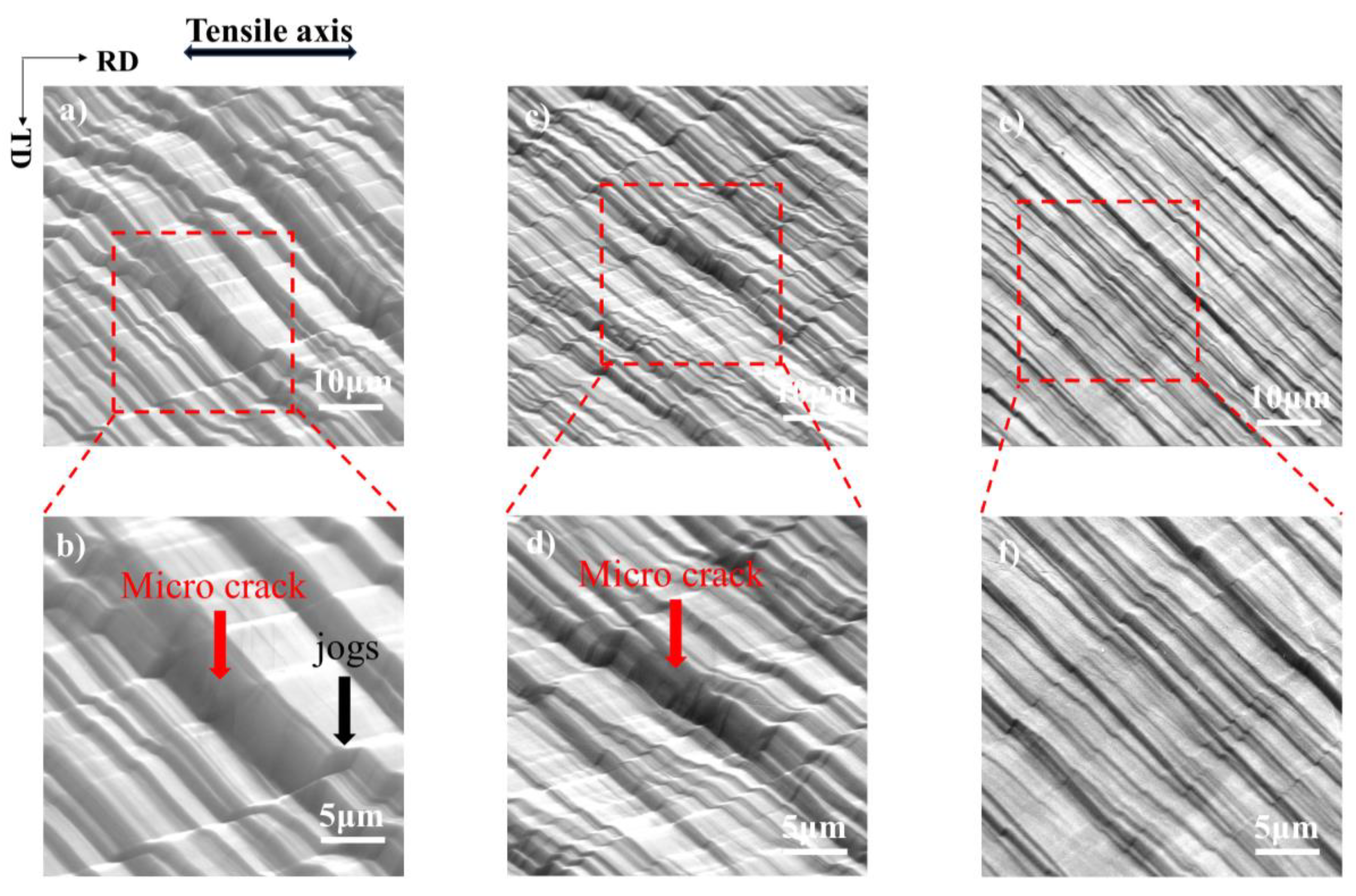

3.3. Slip Band Evolution of Al Single Crystals of the [114] Orientation

4. Summary and Conclusions

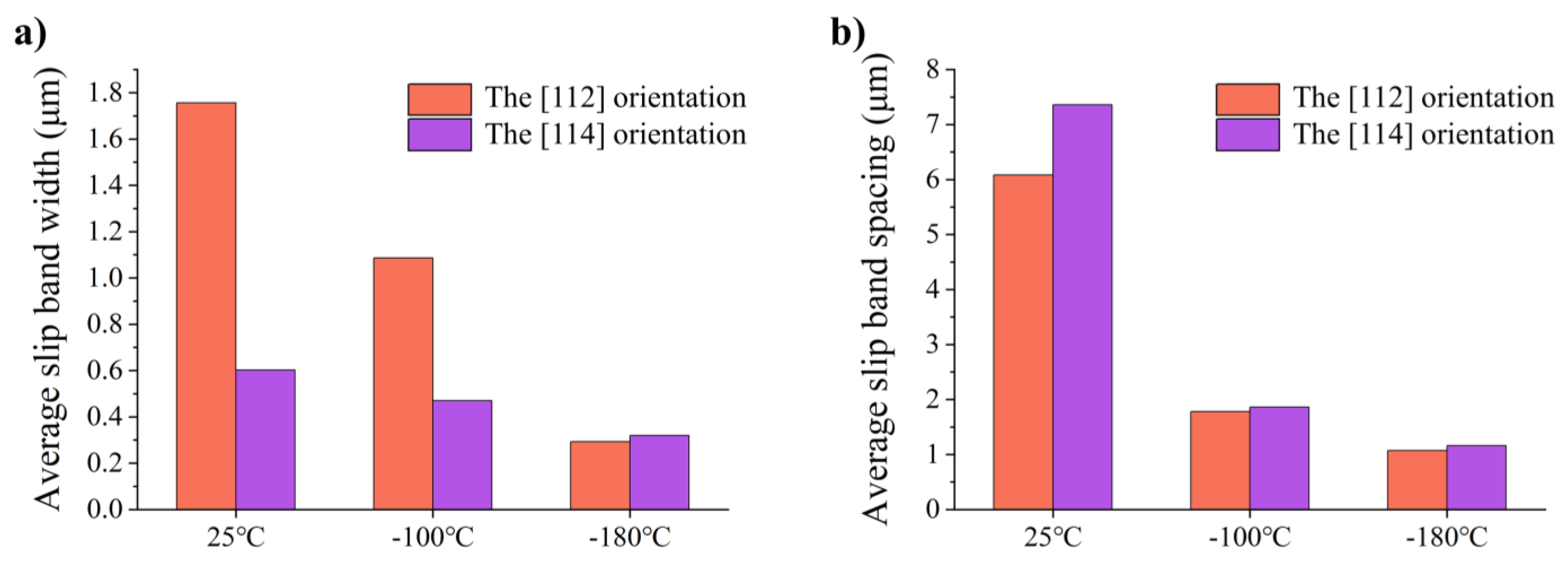

- The slip band width and spacing declined with the decrease in temperature, irrespective of the orientation. At −180 °C, high slip-plane density was found in the [112] and [114] orientations, and the samples showed excellent strain-hardening properties and a more homogeneous deformation during tensile tests.

- At room temperature, due to the slip plane’s softening and the dislocation multiplication mechanism, the slip bands became coarse with the increase in strain. When the temperature was decreased to −180 °C, dynamic slip band refinement occurred, which prevented slip localization and inhibited the generation of cracks.

- The slip mode was influenced by orientation and temperature. Single slip was the main slip mode of the [112] orientation at all the temperatures investigated. The slip behavior of the [114] orientation changed from multi slip at RT to single slip at −180 °C, which avoided the dislocation pile-up near the jogs and inhibited the generation of cracks.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Joost, W.J. Reducing Vehicle Weight and Improving U.S. Energy Efficiency Using Integrated Computational Materials Engineering. JOM 2012, 64, 1032–1038. [Google Scholar] [CrossRef]

- Scamans, G. Electric Vehicles Spike Demand for High Strength Aluminum Extrusions. Light Met Age 2018, 76, 6–12. [Google Scholar]

- Bałon, P.; Rejman, E.; Świątoniowski, A.; Kiełbasa, B.; Smusz, R.; Szostak, J.; Cieślik, J.; Kowalski, L. Thin-Walled Integral Constructions in Aircraft Industry. Procedia Manuf. 2020, 47, 498–504. [Google Scholar] [CrossRef]

- Cao, J.; Banu, M. Opportunities and Challenges in Metal Forming for Lightweighting: Review and Future Work. J. Manuf. Sci. Eng. 2020, 142, 110813. [Google Scholar] [CrossRef]

- Xu, Z.; Roven, H.J.; Jia, Z. Mechanical Properties and Surface Characteristics of an AA6060 Alloy Strained in Tension at Cryogenic and Room Temperature. Mater. Sci. Eng. A 2015, 648, 350–358. [Google Scholar] [CrossRef]

- Sotirov, N.; Falkinger, G.; Grabner, F.; Schmid, G.; Schneider, R.; Grant, R.J.; Kelsch, R.; Radlmayr, K.; Scheerer, M.; Reichl, C.; et al. Improved Formability of AA5182 Aluminium Alloy Sheet at Cryogenic Temperatures. Mater. Today Proc. 2015, 2, S113–S118. [Google Scholar] [CrossRef]

- Cheng, W.; Liu, W.; Fan, X.; Yuan, S. Cooperative Enhancements in Ductility and Strain Hardening of a Solution-Treated Al–Cu–Mn Alloy at Cryogenic Temperatures. Mater. Sci. Eng. A 2020, 790, 139707. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, J.; Zhu, C.; Yi, Y. Multi Slip Activation Enabled Excellent Low-Temperature Strength-Ductility Synergy n Al–Cu–Li Alloy. Vacuum 2022, 204, 111328. [Google Scholar] [CrossRef]

- Greer, J.R.; Nix, W.D. Nanoscale Gold Pillars Strengthened through Dislocation Starvation. Phys. Rev. B 2006, 73, 245410. [Google Scholar] [CrossRef]

- Norfleet, D.M.; Dimiduk, D.M.; Polasik, S.J.; Uchic, M.D.; Mills, M.J. Dislocation Structures and Their Relationship to Strength in Deformed Nickel Microcrystals. Acta Mater. 2008, 56, 2988–3001. [Google Scholar] [CrossRef]

- Dong, F.; Huang, S.; Yi, Y.; He, H.; Huang, K.; Wang, C.; Gao, S.; Jia, Y.; Yu, W. Enhanced Deep Drawing Formability and Deformation Mechanism of Aluminum Alloy at Cryogenic Temperature. J. Alloys Compd. 2023, 968, 171992. [Google Scholar] [CrossRef]

- Rafael Velayarce, J.; Zamanzade, M.; Torrents Abad, O.; Motz, C. Influence of Single and Multiple Slip Conditions and Temperature on the Size Effect in Micro Bending. Acta Mater. 2018, 154, 325–333. [Google Scholar] [CrossRef]

- Watanabe, C.; Yamazaki, S.; Koga, N. Effects of Cross-Slip Activity on Low-Cycle Fatigue Behavior and Dislocation Structure in Pure Aluminum Single Crystals with Single-Slip Orientation. Mater. Sci. Eng. A 2021, 815, 141221. [Google Scholar] [CrossRef]

- Gruber, B.; Weißensteiner, I.; Kremmer, T.; Grabner, F.; Falkinger, G.; Schökel, A.; Spieckermann, F.; Schäublin, R.; Uggowitzer, P.J.; Pogatscher, S. Mechanism of Low Temperature Deformation in Aluminium Alloys. Mater. Sci. Eng. A 2020, 795, 139935. [Google Scholar] [CrossRef]

- Motz, C.; Weygand, D.; Senger, J.; Gumbsch, P. Initial Dislocation Structures in 3-D Discrete Dislocation Dynamics and Their Influence on Microscale Plasticity. Acta Mater. 2009, 57, 1744–1754. [Google Scholar] [CrossRef]

- Zelada-Lambri, G.I.; Lambri, O.A.; García, J.A. Mechanical Energy Losses Due to the Movement of Dislocations in Molybdenum at High Temperatures (0.3Tm). J. Nucl. Mater. 2006, 353, 127–134. [Google Scholar] [CrossRef]

- Glazer, J.; Verzasconi, S.L.; Sawtell, R.R.; Morris, J.W. Mechanical-behavior of aluminum-lithium alloys at cryogenic temperatures. Metall. Trans. A 1987, 18, 1695–1701. [Google Scholar] [CrossRef]

- Cheng, W.J.; Liu, W.; Yuan, S.J. Deformation behavior of Al-Cu-Mn alloy sheets under biaxial stress at cryogenic temperatures. Mater. Sci. Eng. A 2019, 759, 357–367. [Google Scholar] [CrossRef]

- Hu, W.; Chen, J.; Xu, J.; Ren, J.; Miao, J.; Xing, T.; Guan, R.; Ojo, O.A. Relationship between Precipitation Behavior and Loading Orientations of the Creep-Aged Al–Cu–Li Single Crystal. J. Mater. Res. Technol. 2023, 24, 689–702. [Google Scholar] [CrossRef]

- Shi, D.F.; Pérez-Prado, M.T.; Cepeda-Jiménez, C.M. Effect of Solutes on Strength and Ductility of Mg Alloys. Acta Mater. 2019, 180, 218–230. [Google Scholar] [CrossRef]

- Kuhlmann-Wilsdorf, D. Chapter 59 The LES theory of solid plasticity. Dislocat. Solids 2002, 11, 211–342. [Google Scholar]

- Blankenship, C.P.; Hornbogen, E.; Starke, E.A. Predicting Slip Behavior in Alloys Containing Shearable and Strong Particles. Mater. Sci. Eng. A 1993, 169, 33–41. [Google Scholar] [CrossRef]

- Csontos, A.A.; Starke, E.A. The Effect of Inhomogeneous Plastic Deformation on the Ductility and Fracture Behavior of Age Hardenable Aluminum Alloys. Int. J. Plast. 2005, 21, 1097–1118. [Google Scholar] [CrossRef]

- Gutierrez-Urrutia, I.; Raabe, D. Dislocation and Twin Substructure Evolution during Strain Hardening of an Fe–22wt.% Mn–0.6wt.% C TWIP Steel Observed by Electron Channeling Contrast Imaging. Acta Mater. 2011, 59, 6449–6462. [Google Scholar] [CrossRef]

- Efstathiou, C.; Sehitoglu, H. Strain Hardening and Heterogeneous Deformation during Twinning in Hadfield Steel. Acta Mater. 2010, 58, 1479–1488. [Google Scholar] [CrossRef]

- Asgari, S.; El-Danaf, E.; Kalidindi, S.R.; Doherty, R.D. Strain Hardening Regimes and Microstructural Evolution during Large Strain Compression of Low Stacking Fault Energy Fcc Alloys That Form Deformation Twins. Metall. Mater. Trans. A 1997, 28, 1781–1795. [Google Scholar] [CrossRef]

- Welsch, E.; Ponge, D.; Hafez Haghighat, S.M.; Sandlöbes, S.; Choi, P.; Herbig, M.; Zaefferer, S.; Raabe, D. Strain Hardening by Dynamic Slip Band Refinement in a High-Mn Lightweight Steel. Acta Mater. 2016, 116, 188–199. [Google Scholar] [CrossRef]

- Gil Sevillano, J.; Ocaña Arizcorreta, I.; Kubin, L.P. Intrinsic Size Effects in Plasticity by Dislocation Glide. Mater. Sci. Eng. A 2001, 309–310, 393–405. [Google Scholar] [CrossRef]

- Morris, J.W.; Klahn, D.H. Thermally Activated Dislocation Glide through a Random Array of Point Obstacles: Computer Simulation. J. Appl. Phys. 1974, 45, 2027–2038. [Google Scholar] [CrossRef]

- Kocks, U.F.; Mecking, H. Physics and Phenomenology of Strain Hardening: The FCC Case. Prog. Mater. Sci. 2003, 48, 171–273. [Google Scholar] [CrossRef]

- Levine, L.E.; Thomson, R. The Statistical Origin of Bulk Mechanical Properties and Slip Behavior in Fcc Metals. Mater. Sci. Eng. A 2005, 400–401, 202–205. [Google Scholar] [CrossRef]

- Cai, M.; Langford, S.C.; Thomas Dickinson, J. Orientation Dependence of Slip Band Formation in Single-Crystal Aluminum Studied by Photoelectron Emission. Acta Mater. 2008, 56, 5938–5945. [Google Scholar] [CrossRef]

- Dong, F.; Yi, Y.; Huang, S.; Wang, B.; He, H.; Huang, K.; Wang, C. Cryogenic Formability and Deformation Behavior of 2060 Al–Li Alloys with Water-Quenched and T4 Aged Temper. Mater. Sci. Eng. A 2021, 823, 141722. [Google Scholar] [CrossRef]

- Feng, B.; Gu, B.; Li, S. Cryogenic Deformation Behavior and Failure Mechanism of AA7075 Alloy Sheets Tempered at Different Conditions. Mater. Sci. Eng. A 2022, 848, 143396. [Google Scholar] [CrossRef]

- Rui, S.-S.; Han, Q.-N.; Wang, X.; Li, S.; Ma, X.; Su, Y.; Cai, Z.; Du, D.; Shi, H.-J. Correlations between Two EBSD-Based Metrics Kernel Average Misorientation and Image Quality on Indicating Dislocations of near-Failure Low Alloy Steels Induced by Tensile and Cyclic Deformations. Mater. Today Commun. 2021, 27, 102445. [Google Scholar] [CrossRef]

- Chen, J.; Zhu, Y.; Huang, M.; Zhao, L.; Liang, S.; Li, Z. Study on Hydrogen-Affected Interaction between Dislocation and Grain Boundary by MD Simulation. Comput. Mater. Sci. 2021, 196, 110562. [Google Scholar] [CrossRef]

- Li, S.; Guo, C.; Hao, L.; Kang, Y.; An, Y. In-Situ EBSD Study of Deformation Behaviour of 600 MPa Grade Dual Phase Steel during Uniaxial Tensile Tests. Mater. Sci. Eng. A 2019, 759, 624–632. [Google Scholar] [CrossRef]

- Saeidi, N.; Ashrafizadeh, F.; Niroumand, B.; Barlat, F. EBSD Study of Micromechanisms Involved in High Deformation Ability of DP Steels. Mater. Des. 2015, 87, 130–137. [Google Scholar] [CrossRef]

- Mesbah, M.; Faraji, G.; Bushroa, A.R. Electron Back-Scattered Diffraction and Nanoindentation Analysis of Nanostructured Al Tubes Processed by Multipass Tubular-Channel Angular Pressing. Met. Mater. Int. 2016, 22, 288–294. [Google Scholar] [CrossRef]

- Chen, S.; Yu, Q. The Role of Low Angle Grain Boundary in Deformation of Titanium and Its Size Effect. Scr. Mater. 2019, 163, 148–151. [Google Scholar] [CrossRef]

- Vattré, A.; Devincre, B.; Roos, A. Orientation Dependence of Plastic Deformation in Nickel-Based Single Crystal Superalloys: Discrete–Continuous Model Simulations. Acta Mater. 2010, 58, 1938–1951. [Google Scholar] [CrossRef]

- Fan, Z.; Li, J.; Ma, Y.; Zhang, Z. Effect of temperature on tensile behavior of nickel-based single crystal Superalloy DD13, Xiyou Jinshu Cailiao Yu Gongcheng/Rare Met. Mater. Eng. 2019, 48, 1288–1292. [Google Scholar]

- Sun, Z.; Li, F.; Zhu, J. Radial Micro-Cracks in Pile-up Region of Single-Crystal Cu in Spherical Indentation: Experimental Observation and Crystal Plastic Simulation. J. Mater. Sci. 2019, 54, 9875–9886. [Google Scholar] [CrossRef]

- Stroh, A.N. The Formation of Cracks as a Result of Plastic Flow. Proc. R. Soc. Lond. A 1954, 223, 404–414. [Google Scholar] [CrossRef]

- Kreins, M.; Schilli, S.; Seifert, T.; Iyer, A.H.S.; Colliander, M.H.; Wesselmecking, S.; Krupp, U. Bauschinger Effect and Latent Hardening under Cyclic Micro-Bending of Ni-Base Alloy 718 Single Crystals: Part I. Experimental Analysis of Single and Multi Slip Plasticity. Mater. Sci. Eng. A 2021, 827, 142027. [Google Scholar] [CrossRef]

| Average Slip Band Widths (μm) | Average Slip Band Spacings (μm) | |||

|---|---|---|---|---|

| [112] | [114] | [112] | [114] | |

| 25 °C | 1.76 | 0.60 | 6.08 | 7.36 |

| −100 °C | 1.09 | 0.47 | 1.78 | 1.86 |

| −180 °C | 0.29 | 0.32 | 1.07 | 1.16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, C.; Shi, D.; Zhang, J. Temperature-Induced Variations in Slip Behavior of Single Crystal Aluminum: Microstructural Analysis. Materials 2024, 17, 2084. https://doi.org/10.3390/ma17092084

Tang C, Shi D, Zhang J. Temperature-Induced Variations in Slip Behavior of Single Crystal Aluminum: Microstructural Analysis. Materials. 2024; 17(9):2084. https://doi.org/10.3390/ma17092084

Chicago/Turabian StyleTang, Cheng, Dongfeng Shi, and Jin Zhang. 2024. "Temperature-Induced Variations in Slip Behavior of Single Crystal Aluminum: Microstructural Analysis" Materials 17, no. 9: 2084. https://doi.org/10.3390/ma17092084

APA StyleTang, C., Shi, D., & Zhang, J. (2024). Temperature-Induced Variations in Slip Behavior of Single Crystal Aluminum: Microstructural Analysis. Materials, 17(9), 2084. https://doi.org/10.3390/ma17092084