Finite-Element Modeling of the Temperature Effect on Extended Avalanche Damage of Gas Main Pipelines

Abstract

1. Introduction

2. Materials and Methods

2.1. Mathematical Model of Dynamic Stress–Strain State and Fracture of Steel Pipelines with Consideration of Temperature Influence

- -

- Thermal stresses: Changes in the temperature cause the expansion and contraction of the materials that form the pipeline. This can generate stresses in the material, especially when it contains defects. Long-term thermal stresses can lead to the development of cracks and other damage.

- -

- Changes in the material’s mechanical properties: When the temperature changes, the physical properties of the materials, such as their strength, elasticity, and plasticity, change. This can influence the ability of the pipeline to resist mechanical loads and deformations.

- -

- Cryogenic effects: Sometimes, gases, such as liquefied natural gas, are transported at very low temperatures. This may cause cryogenic effects, such as ice formation and condensation, which can affect pipelines’ integrity.

- -

- Corrosion: High or low temperatures can increase the corrosion process of the pipeline material. For instance, wet conditions at low temperatures can promote ice formation and accelerate the corrosion process.

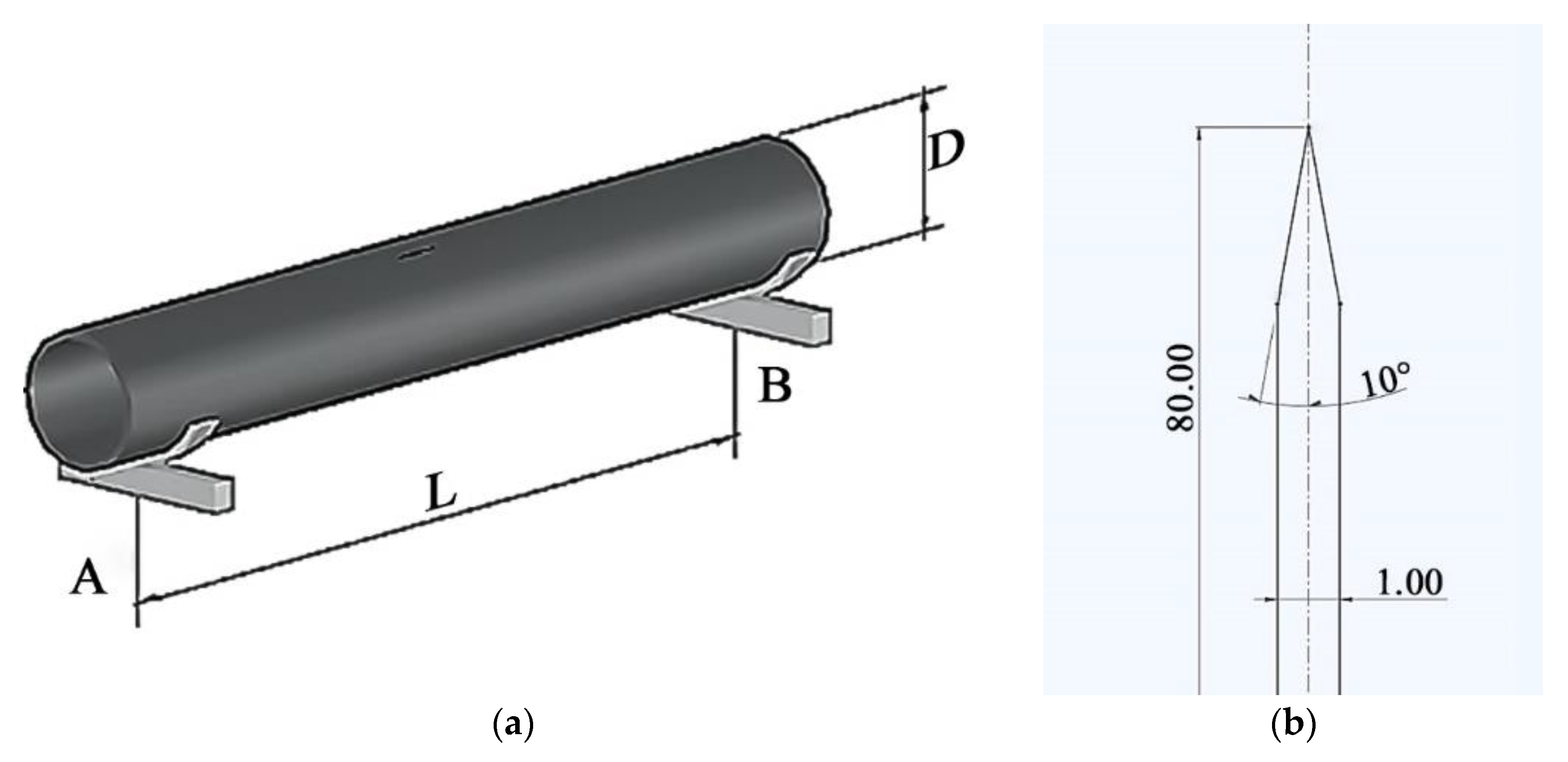

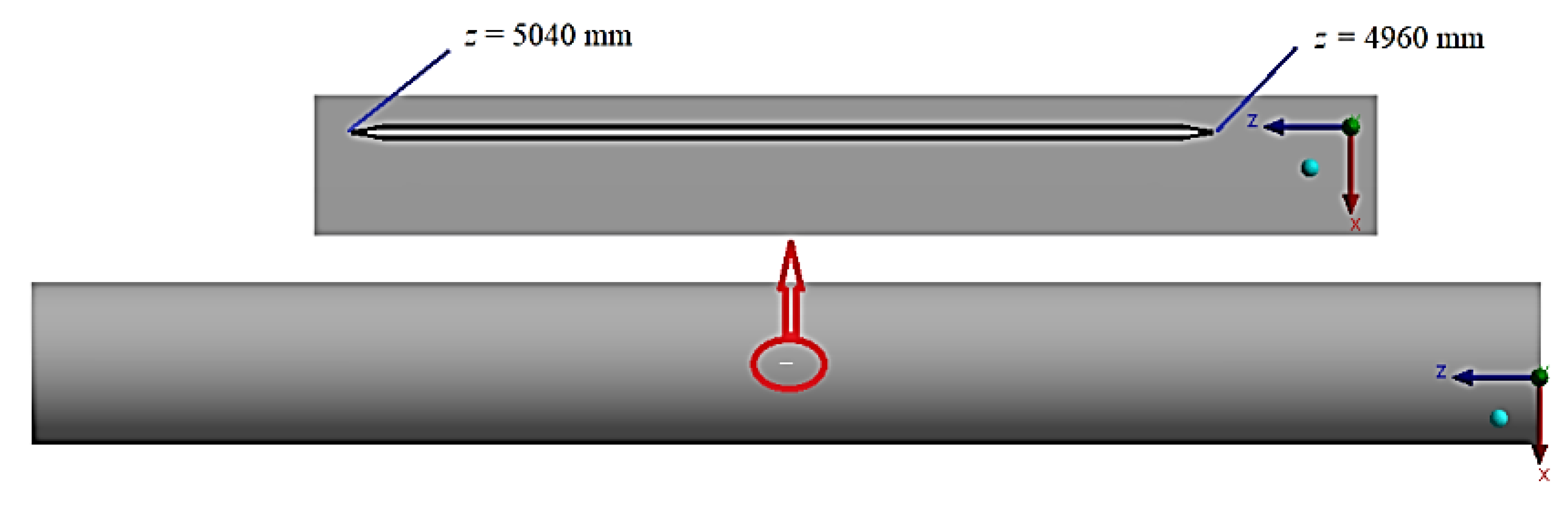

2.2. Finite-Element Model of Dynamic Stress–Strain State and Damage of a Steel Pipe Section with Regard to the Temperature Effect on the Mechanical Characteristics of the Material

2.3. Initial Data for Finite-Element Modeling

3. Results and Discussion

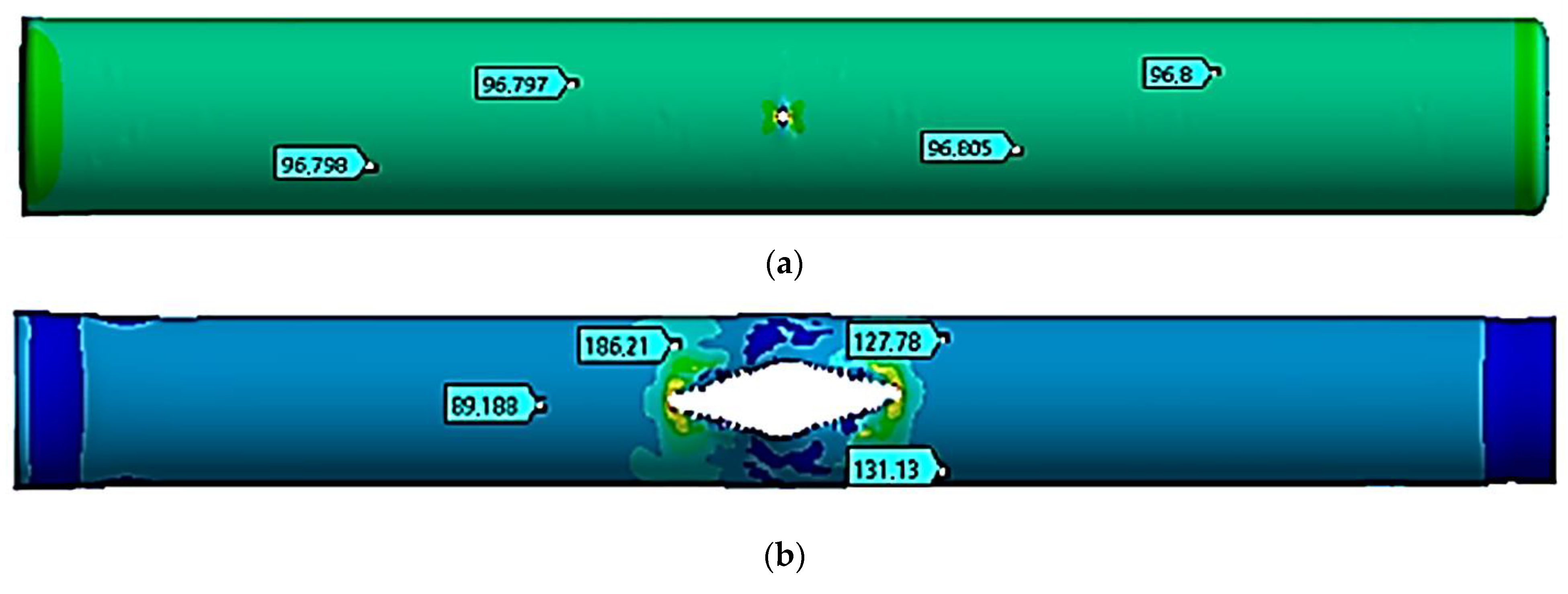

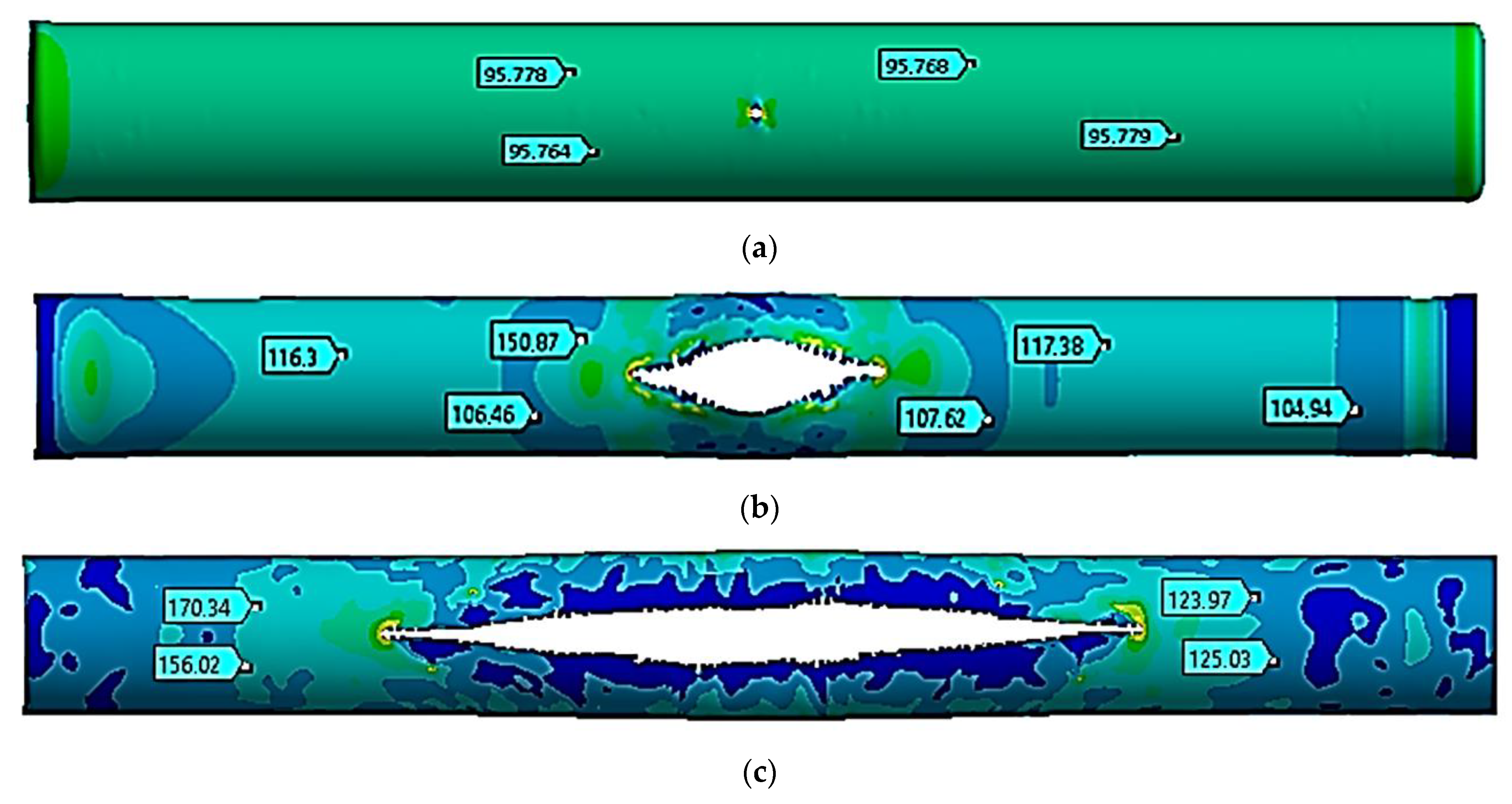

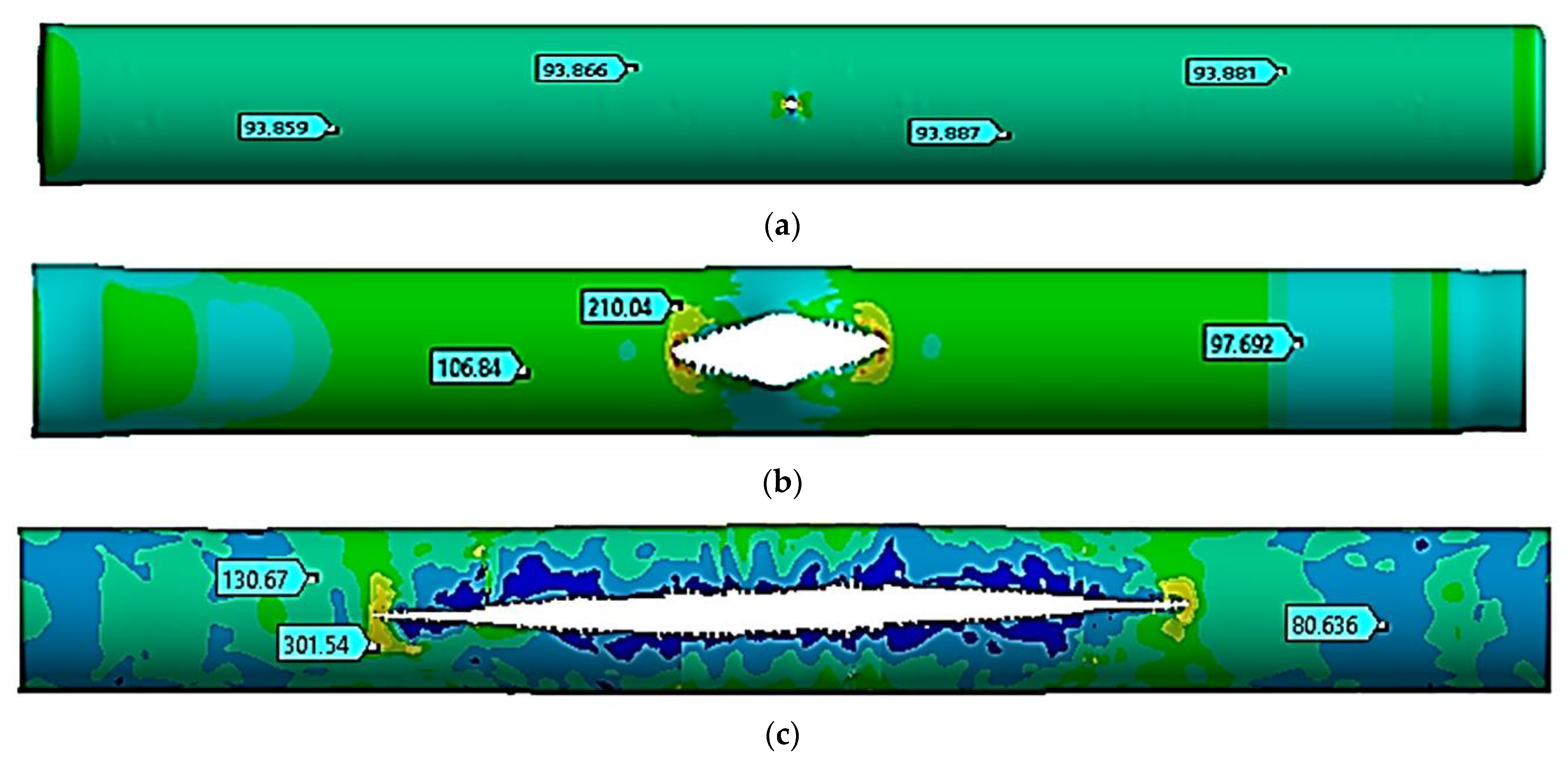

3.1. Study of a Rectilinear Section of a Gas Pipeline with a Crack at a Temperature of −40 °C

3.2. Study of a Rectilinear Section of a Gas Pipeline with a Crack at a Temperature of −10 °C

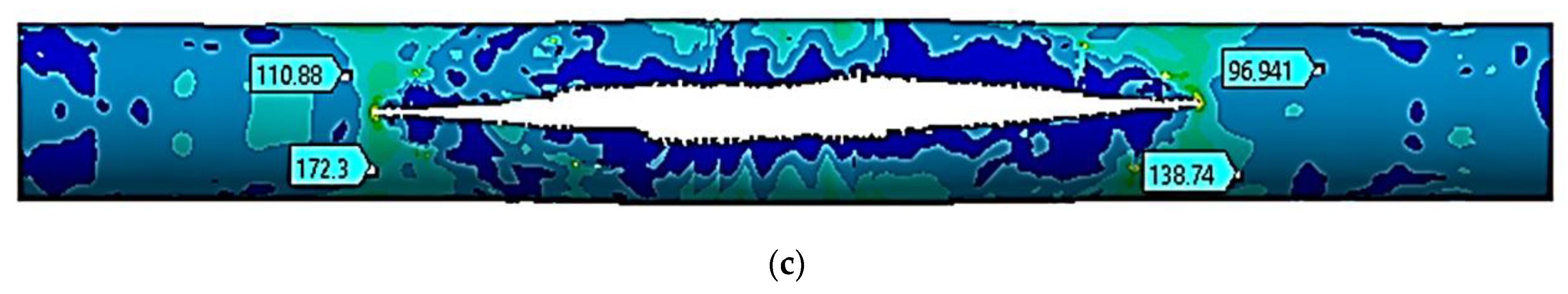

3.3. Study of a Rectilinear Section of a Gas Pipeline with a Crack at a Temperature of +20 °C

3.4. Study of a Rectilinear Section of a Gas Pipeline with a Crack at a Temperature of +50 °C

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Stepova, O.; Rassoha, I.; Blazhko, L.; Hanoshenko, O. Calculation of Lifetime of Steel Oil Pipelines with the Account of Corrosive Environment Affect; Lecture Notes in Civil Engineering; Springer: Berlin/Heidelberg, Germany, 2020; Volume 73. [Google Scholar] [CrossRef]

- James, B.; Hudgins, A. Chapter 1—Failure analysis of oil and gas transmission pipelines. In Handbook of Materials Failure Analysis with Case Studies from the Oil and Gas Industry; Makhlouf, A.S.H., Aliofkhazraei, M., Eds.; Butterworth-Heinemann: Oxford, UK, 2016; pp. 1–38. [Google Scholar] [CrossRef]

- Mohamed Azzam, M. Failure Analysis of Pipelines in the Oil and Gas Industry. In Pipeline Engineering-Design, Failure, and Management; IntechOpen: London, UK, 2023. [Google Scholar] [CrossRef]

- Gerstein, M.S. Dynamics of Trunk Pipelines. 1992. Available online: https://search.rsl.ru/ru/record/01001652250 (accessed on 4 March 2024).

- Zhangabay, N.; Ibraimova, U.; Suleimenov, U.; Moldagaliyev, A.; Buganova, S.; Jumabayev, A.; Kolesnikov, A.; Tursunkululy, T.; Zhiyenkulkyzy, D.; Khalelova, A.; et al. Factors affecting extended avalanche destructions on long-distance gas pipe lines: Review. Case Stud. Constr. Mater. 2023, 19, e02376. [Google Scholar] [CrossRef]

- Wasim, M.; Djukic, M.B. External corrosion of oil and gas pipelines: A review of failure mechanisms and predictive preventions. J. Nat. Gas Sci. Eng. 2022, 100, 104467. [Google Scholar] [CrossRef]

- Chen, J.; Wang, H.; Salemi, M.; Balaguru, P.N. Finite Element Analysis of Composite Repair for Damaged Steel Pipeline. Coatings 2021, 11, 301. [Google Scholar] [CrossRef]

- Tursunkululy, T.; Zhangabay, N.; Suleimenov, U.; Abshenov, K.; Chernobryvko, M.; Utelbayeva, A. Analysis of strength and eigenfrequencies of a steel vertical cylindrical tank without liquid, reinforced by a plain composite thread. Case Stud. Constr. Mater. 2023, 18, e01776. [Google Scholar] [CrossRef]

- Marvin, C.W. Determining the Strength of Corroded Pipe. Mater. Prot. Perform. 1972, 11, 34–40. Available online: https://yandex.kz/search/?text=Marvin+C.+W.+Determining+the+Strength+of+Corroded+Pipe.+Materials+Protection+and+Performance.+1972.+№+11.+P.+34+–+40.&lr=162&clid=9582 (accessed on 4 March 2024).

- Nnoka, M.; Jack, T.A.; Szpunar, J. Effects of different microstructural parameters on the corrosion and cracking resistance of pipeline steels: A review. Eng. Fail. Anal. 2024, 159, 108065. [Google Scholar] [CrossRef]

- Arifin, H.; Zardasti, L.; Lim, K.; Noor, N.; Yahaya, N.; Mazlan, A.; Sam, A.R.M. Stress distribution analysis of composite repair with Carbon Nanotubes reinforced putty for damaged steel pipeline. Int. J. Press. Vessel. Pip. 2021, 194, 104537. [Google Scholar] [CrossRef]

- Olamide, A.; Bennecer, A.; Kaczmarczyk, S. Finite Element Analysis of Fatigue in Offshore Pipelines with Internal and External Circumferential Cracks. Appl. Mech. 2020, 1, 193–223. [Google Scholar] [CrossRef]

- Stepova, O.; Paraschienko, I. Modeling of the corrosion process in steel oil pipelines in order to improve environmental safety. East. Eur. J. Enterp. Technol. 2017, 2, 15–20. [Google Scholar] [CrossRef]

- Hutař, P.; Ševčík, M.; Náhlík, L.; Pinter, G.; Frank, A.; Mitev, I. A numerical methodology for lifetime estimation of HDPE pressure pipes. Eng. Fract. Mech. 2011, 78, 3049–3058. [Google Scholar] [CrossRef]

- Elyasi, N.; Shahzamanian, M.; Lin, M.; Westover, L.; Li, Y.; Kainat, M.; Yoosef-Ghodsi, N.; Adeeb, S. Prediction of Tensile Strain Capacity for X52 Steel Pipeline Materials Using the Extended Finite Element Method. Appl. Mech. 2021, 2, 209–225. [Google Scholar] [CrossRef]

- Arumugam, T.; Vijaya Kumar, S.D.; Karuppanan, S.; Ovinis, M. The Influence of Axial Compressive Stress and Internal Pressure on a Pipeline Network: A Review. Appl. Sci. 2023, 13, 3799. [Google Scholar] [CrossRef]

- Kantor, M.M.; Vorkachev, K.G.; Bozhenov, V.A.; Solntsev, K.A. The Role of Splitting Phenomenon under Fracture of Low-Carbon Microalloyed X80 Pipeline Steels during Multiple Charpy Impact Tests. Appl. Mech. 2022, 3, 740–756. [Google Scholar] [CrossRef]

- Martynenko, G.; Avramov, K.; Martynenko, V.; Chernobryvko, M.; Tonkonozhenko, A.; Kozharin, V. Numerical simulation of warhead transportation. Def. Technol. 2021, 17, 478–494. [Google Scholar] [CrossRef]

- Sarker, S.; Sarker, T. Spectral Properties of Water Hammer Wave. Appl. Mech. 2022, 3, 799–814. [Google Scholar] [CrossRef]

- Nordhagen, H.O.; Kragset, S.; Berstad, T.; Morin, A.; Dorum, C.; Munkejord, S.T. A new coupled fluid-structure modelling methodology for running ductile fracture. Comput. Struct. 2017, 94, 13–21. [Google Scholar] [CrossRef]

- Zhangabay, N.; Ibraimova, U.; Bonopera, M.; Suleimenov, U.; Avramov, K.; Chernobryvko, M.; Utelbayeva, A.; Uspenskyi, B. Finite-Element Modeling of the Dynamic Behavior of a Crack-like Defect in an Internally Pressurized Thin-Walled Steel Cylinder. Appl. Sci. 2024, 14, 1790. [Google Scholar] [CrossRef]

- Chernobryvko, M.; Kruszka, L.; Vorobiev, Y. Thermo-Elastic-Plastic Constitutive Model for Numerical Analysis of Metallic Structures under Local Impulsive Loadings. Appl. Mech. Mater. 2014, 566, 493–498. [Google Scholar] [CrossRef]

- Ben-Dor, G.; Dubinsky, A.; Elperin, T. High-Speed Penetration Dynamics: Engineering Models and Methods; World Scientific Publishing: Singapore, 2013. [Google Scholar] [CrossRef]

- Anderson Ted, L. Fracture Mechanics: Fundamentals and Applications, 4th ed.; CRC Press: Boca Raton, FL, USA, 2017; 684p. [Google Scholar] [CrossRef]

- Hallquist, J.O. LS-DYNA Theory Manual; Livermore Software Technology Corporation (LSTC): Livermore, CA, USA, 2006; 680p, Available online: https://www.academia.edu/23076592/LS_DYNA_Theory_Manual_LIVERMORE_SOFTWARE_TECHNOLOGY_CORPORATION_LSTC (accessed on 3 March 2024).

- Martynenko, G.; Chernobryvko, M.; Avramov, K.; Martynenko, V.; Tonkonozhenko, A.; Kozharin, V.; Klymenko, D. Numerical simulation of missile warhead operation. Adv. Eng. Softw. 2021, 123, 93–103. [Google Scholar] [CrossRef]

- Altenbach, H.; Breslavsky, D.; Chernobryvko, M.; Senko, A.; Tatarinova, O. Fast Fracture of Conic Shell Under the Action of Belt Explosive Charge. In Advances in Mechanical and Power Engineering, CAMPE 2021; Lecture Notes in Mechanical Engineering; Springer International Publishing: Cham, Switzerland, 2023. [Google Scholar] [CrossRef]

- State Standard 14959-2016; Metal Products Made of Spring-Spring Non-Alloy and Alloy Steel. Technical Conditions. 2016; 32p. Available online: https://files.stroyinf.ru/Data2/1/4293747/4293747278.pdf (accessed on 2 March 2024).

- Steels and Alloys; Vintage: Reference edition; Sorokin, V.G., Gervasyev, M.A., Eds.; Intermet Engineering: Moscow, Russia, 2001; 608p, Available online: https://djvu.online/file/Elzj1ecA8fz4Z (accessed on 2 March 2024).

- Zhangabay, N.; Suleimenov, U.; Utelbayeva, A.; Buganova, S. Experimental research of the stress-strain state of prestressed cylindrical shells taking into account temperature effects. Case Stud. Constr. Mater. 2022, 18, e01776. [Google Scholar] [CrossRef]

- Tursunkululy, T.; Zhangabay, N.; Avramov, K.; Chernobryvko, M.; Kambarov, M.; Abildabekov, A.; Narikov, K.; Azatkulov, O. Oscillation frequencies of the reinforced wall of a steel vertical cylindrical tank for petroleum products depending on winding pre-tension. East. Eur. J. Enterp. Technol. 2023, 3, 14–25. [Google Scholar] [CrossRef]

| t, ms | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 22 | 30 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| P(t), MPa | 7.5 | 9.8 | 9.8 | 9.1 | 7.5 | 5.0 | 3.5 | 3.2 | 2.5 | 2.5 | 1.5 |

| Temperature, T, °C | −40 | −10 | +20 | +50 |

|---|---|---|---|---|

| Tensile strength, , MPa | 574 | 572 | 570 | 568 |

| Yield strength, , MPa | 525 | 515 | 505 | 495 |

| Modulus of elasticity, E, GPa | 211 | 209 | 206 | 203.5 |

| Moment in Time t, ms | 0 | 1 | 10 | 20 |

|---|---|---|---|---|

| Right end z coordinate, mm | 4960 | 4920 | 3580 | 2290 |

| Left end z coordinate, mm | 5040 | 5080 | 6420 | 7710 |

| Distance between ends, mm | 80 | 160 | 2840 | 5420 |

| Moment in Time t, ms | 0 | 1 | 8 | 20 |

|---|---|---|---|---|

| Right end z coordinate, mm | 4960 | 4920 | 3640 | 2280 |

| Left end z coordinate, mm | 5040 | 5080 | 6360 | 7720 |

| Distance between ends, mm | 80 | 160 | 2720 | 5440 |

| Moment in Time t, ms | 0 | 1 | 6 | 19.5 |

|---|---|---|---|---|

| Right end z coordinate, mm | 4960 | 4920 | 4080 | 2270 |

| Left end z coordinate, mm | 5040 | 5080 | 5920 | 7730 |

| Distance between ends, mm | 80 | 160 | 1840 | 5460 |

| Moment in Time t, ms | 0 | 1 | 5 | 20 |

|---|---|---|---|---|

| Right end z coordinate, mm | 4960 | 4920 | 4240 | 2260 |

| Left end z coordinate, mm | 5040 | 5080 | 5760 | 7740 |

| Distance between ends, mm | 80 | 160 | 1520 | 5480 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhangabay, N.; Ibraimova, U.; Ainabekov, A.; Buganova, S.; Moldagaliev, A. Finite-Element Modeling of the Temperature Effect on Extended Avalanche Damage of Gas Main Pipelines. Materials 2024, 17, 1963. https://doi.org/10.3390/ma17091963

Zhangabay N, Ibraimova U, Ainabekov A, Buganova S, Moldagaliev A. Finite-Element Modeling of the Temperature Effect on Extended Avalanche Damage of Gas Main Pipelines. Materials. 2024; 17(9):1963. https://doi.org/10.3390/ma17091963

Chicago/Turabian StyleZhangabay, Nurlan, Ulzhan Ibraimova, Alpysbay Ainabekov, Svetlana Buganova, and Arman Moldagaliev. 2024. "Finite-Element Modeling of the Temperature Effect on Extended Avalanche Damage of Gas Main Pipelines" Materials 17, no. 9: 1963. https://doi.org/10.3390/ma17091963

APA StyleZhangabay, N., Ibraimova, U., Ainabekov, A., Buganova, S., & Moldagaliev, A. (2024). Finite-Element Modeling of the Temperature Effect on Extended Avalanche Damage of Gas Main Pipelines. Materials, 17(9), 1963. https://doi.org/10.3390/ma17091963