Research on the Mechanical Properties of Concrete under Low Temperatures

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Design

2.2. Specimen Fabrication

- (1)

- Cement: P.O 42.5 Ordinary Portland cement produced by Harbin Yongxing Cement Products Co., Ltd., (Harbin, China).

- (2)

- Sand: with an absorption rate of 14.68%, a moisture content of 3.72%, a bulk density of 1386 kg/m3, an apparent density of 2287 kg/m3, and fineness modulus of 2.3.

- (3)

- Aggregate: Comprises two sizes, 5 mm to 9 mm and 9 mm to 16 mm, that were mixed in the ratio of 4:6 by mass. With an absorption rate of 1.01%, a moisture content of 0.52%, a bulk density of 1453 kg/m3, and an apparent density of 2558.5 kg/m3.

- (4)

- Water for mixing and curing concrete: ordinary tap water in (Harbin, China).

2.3. Experimental Methods

- Test specimens are rapidly removed from the low-temperature environmental chamber, the surface moisture is dried, and an external inspection is conducted to ensure no apparent defects are present.

- Before conducting the pressure test, the bearing surface is identified and undergoes abrasive treatment to ensure that the loading plate can adhere closely to the bearing surface and is parallel to the casting surface. The test specimen is placed at the center of the loading plate of the testing machine to ensure that the center of the specimen bears the pressure. Subsequently, the testing machine is activated, and the ball joint seat is adjusted when the upper pressing plate is about to contact the specimen to achieve a state of balance upon contact, thus minimizing eccentricity as much as possible. It is particularly noted that the casting surface must not serve as the bearing surface.

- The loading rate is to be continuous and uniform, with a rate of 1.5 mm/min employed. When the specimen approaches failure, adjustment of the throttle is ceased, and the test continues until the specimen fails, at which point the load is recorded.

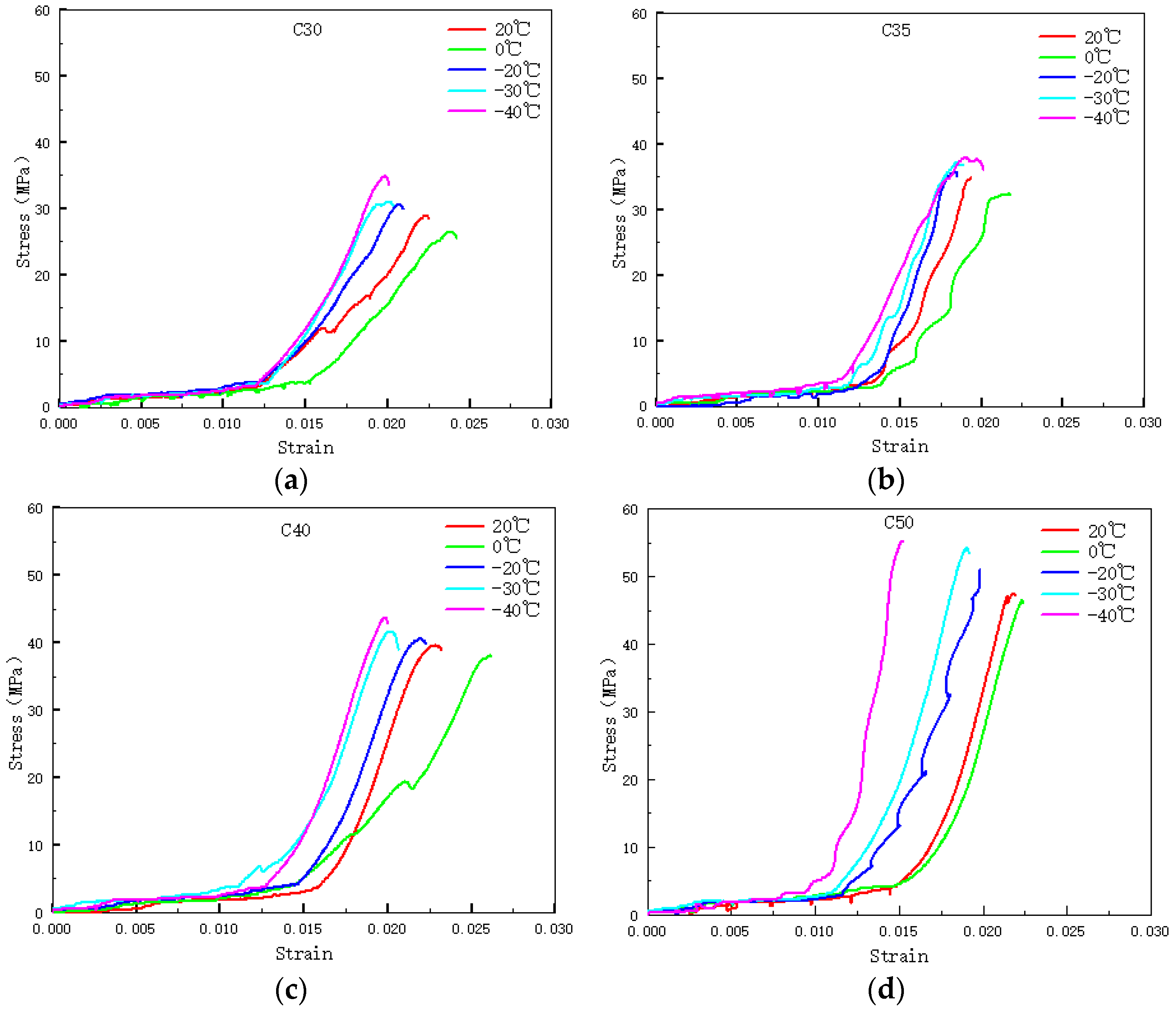

3. Results and Discussion

3.1. Experimental Phenomena

3.2. Analysis of Test Results

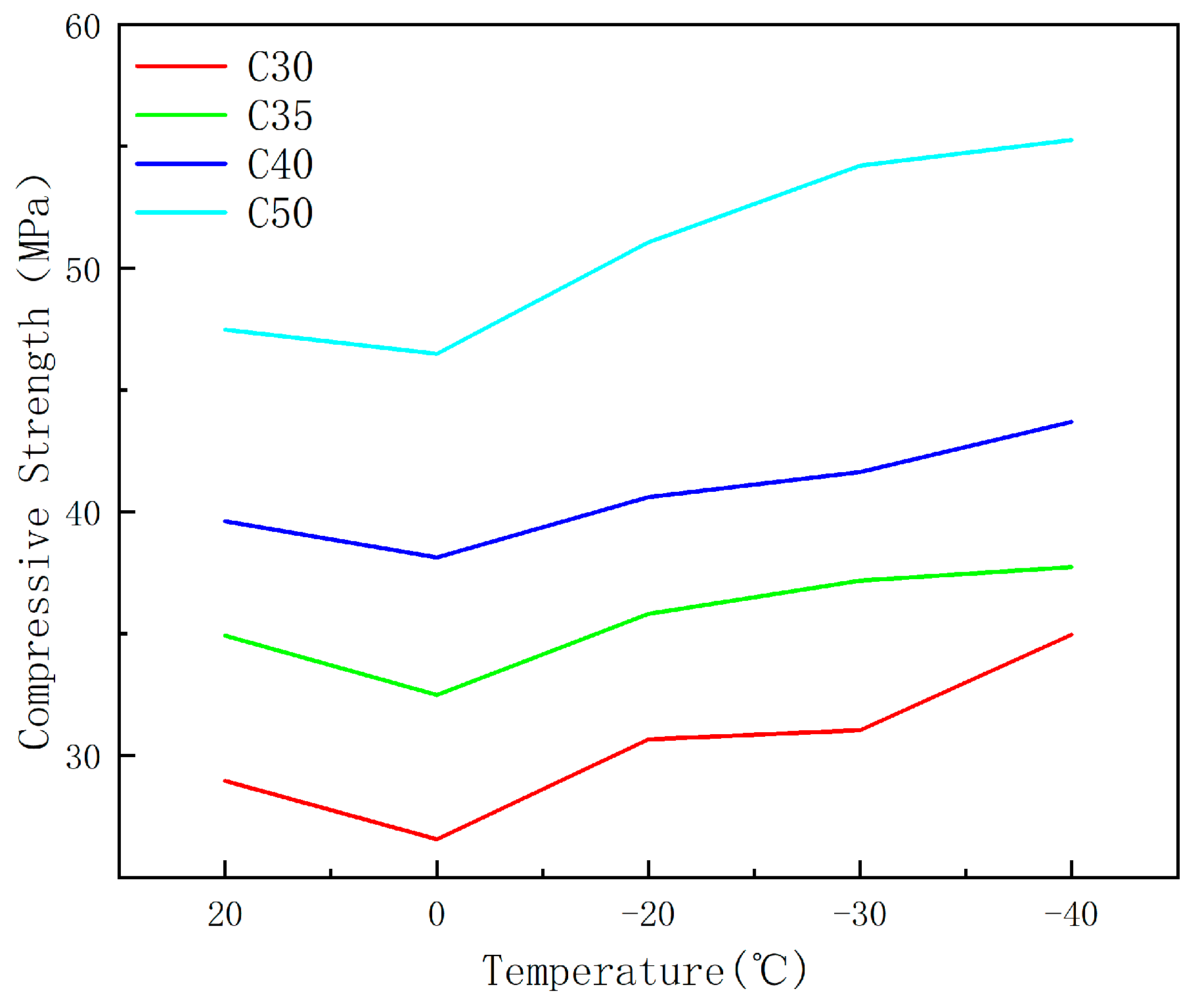

3.2.1. Compressive Strength

3.2.2. Strength Grade

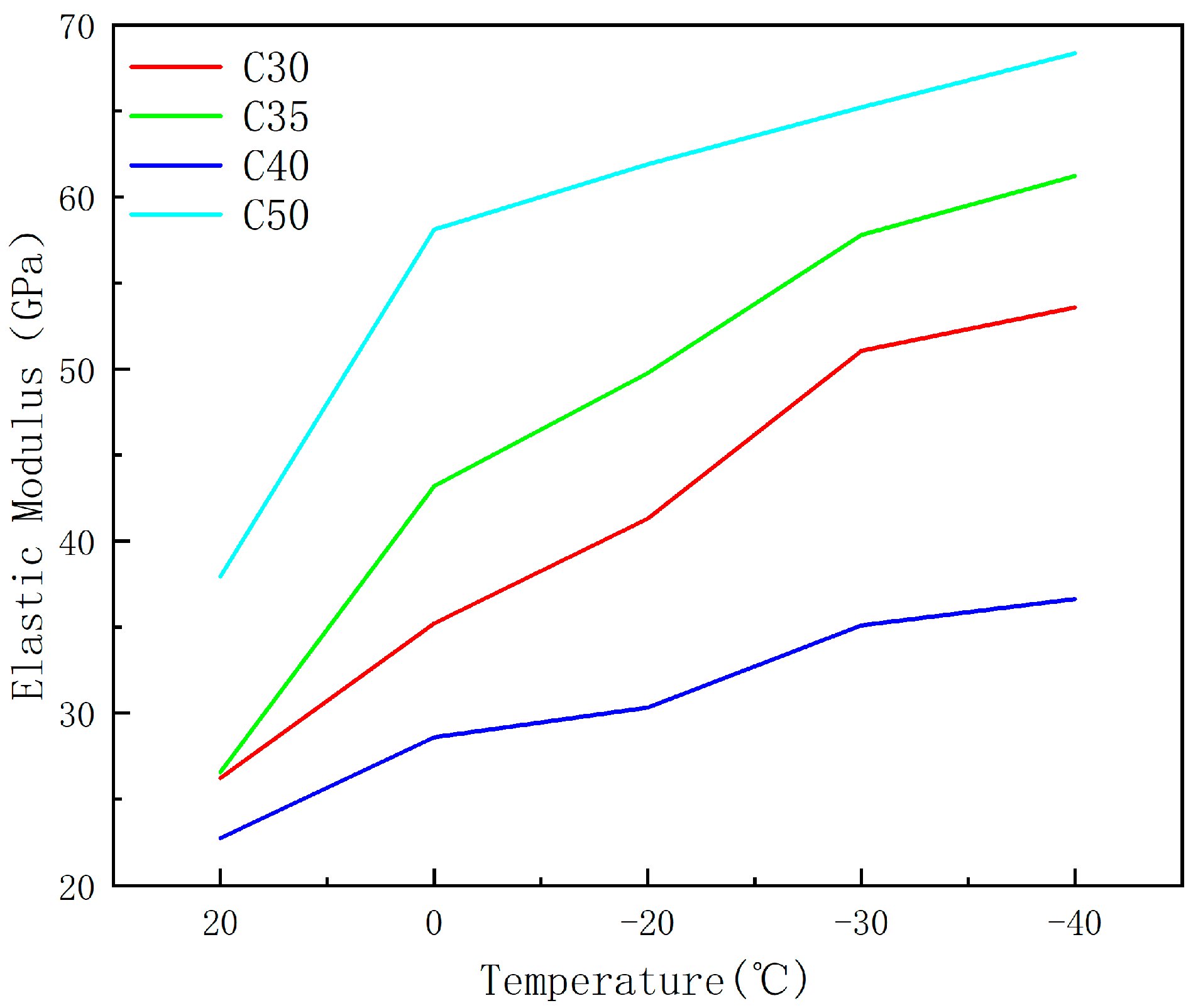

3.2.3. Elastic Modulus

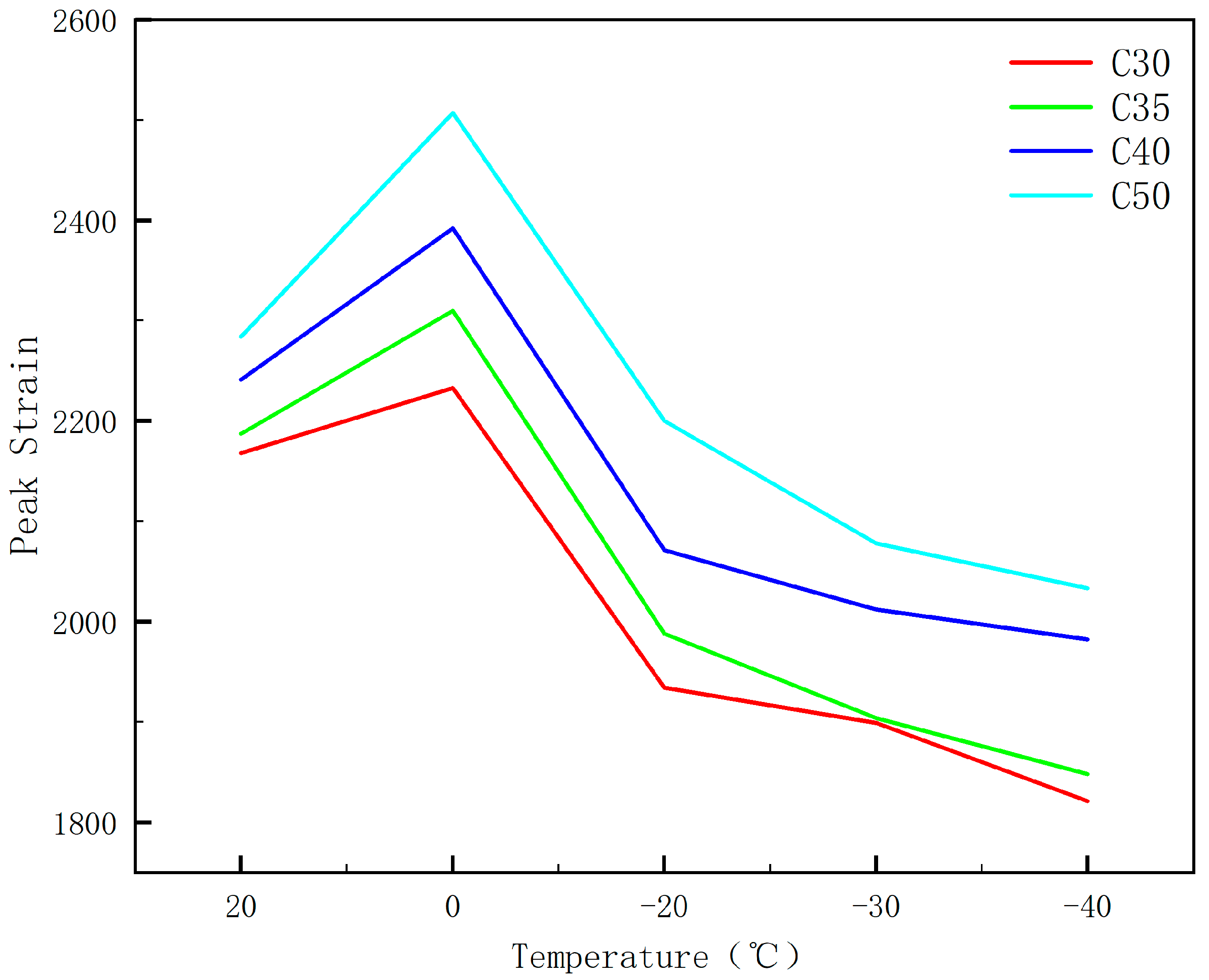

3.2.4. Peak Strain

3.3. Ontological Relationship

4. Conclusions

- (1)

- Under the same mix ratio, the concrete strength decreases as the temperature decreases from 20 °C to 0 °C, and increases as the temperature decreases from 0 °C to −40 °C.

- (2)

- At the same temperature, and without considering other factors such as moisture content, the stronger the concrete sample’s strength grade, the greater its strength will be. However, considering only the impact of strength grade cannot yield accurate results, as conclusions vary depending on the other variables. Therefore, it is necessary to include these other variables in the consideration scope to provide a more comprehensive and accurate conclusion.

- (3)

- Similar to the trend of concrete strength, the elastic modulus of low-temperature concrete increases as the temperature decreases.

- (4)

- Consistent with the behavior at room temperature, the peak strain of concrete increases slightly with the improvement in strength grade at low temperatures. Taking 0 °C as a dividing point, the peak strain increases with temperature decrease from 20 °C to 0 °C, and decreases with the increase of negative temperatures from 0 °C to −40 °C, although the amplitude of increase is smaller than that of strength. With the advancement of strength grade, the peak strain of concrete also experiences a slight increase.

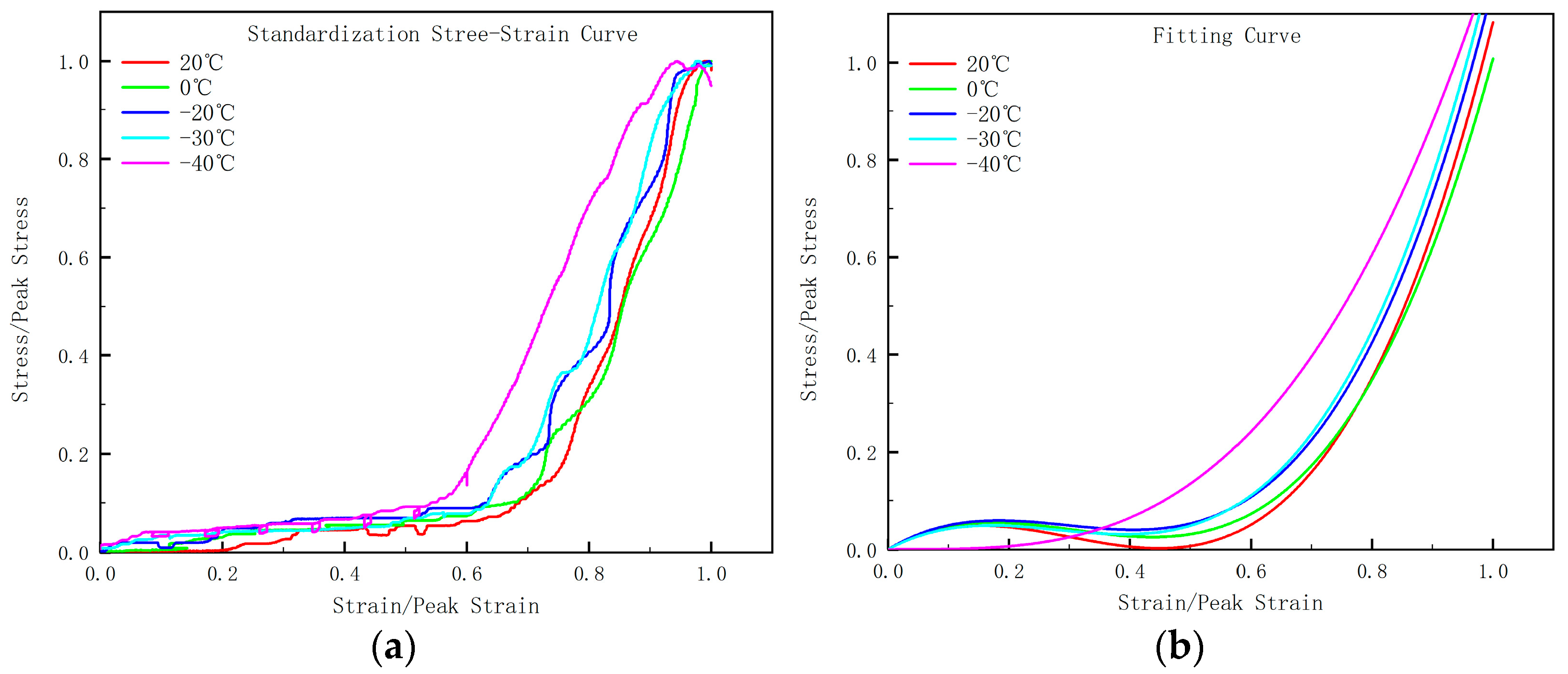

- (5)

- Under different temperatures, the stress–strain curve of concrete can be fitted by a cubic polynomial with variable parameters for the ascending portion. With the decrease in temperature, the parameters of the fitted curve for the ascending portion gradually decrease.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sun, X. Effect of Low Temperature Environment on Compressive and Tensile Strength of C25 Desert Sand Concrete. Master’s Thesis, Ningxia University, Yinchuan, China, 2020. [Google Scholar]

- Wu, C. Study on Axial Compression Rate Effect of Freeze-Thaw Deteriorated Concrete under Frozen Condition. Master’s Thesis, Three Gorges University, Yichang, China, 2019. [Google Scholar]

- Van de Veen, V. Properties of Concrete at Very Low Temperatures: A Survey of the Literature; Civil Engineering and Geosciences; Delft University of Technology, Faculty Civil Engineering: Delft, The Netherlands, 1987. [Google Scholar]

- Dahmani, L.; Khenane, A.; Kaci, S. Behavior of the reinforced concrete at cryogenic temperatures. Cryogenics 2006, 47, 517–525. [Google Scholar] [CrossRef]

- Bairagi, N.K.; Dubal, N.S. Effects of thermal cycles on concrete. Int. J. Struct. 1996, 16, 23–37. [Google Scholar]

- Kim, M.-J.; Kim, S.; Lee, S.-K.; Kim, J.-H.; Lee, K.; Yoo, D.-Y. Mechanical properties of ultra-high-performance fiber-reinforced concrete at cryogenic temperatures. Constr. Build. Mater. 2017, 157, 498–508. [Google Scholar] [CrossRef]

- Xie, J.; Li, X.; Wu, H.J.C.; Materials, B. Experimental study on the axial-compression performance of concrete at cryogenic temperatures. Constr. Build. Mater. 2014, 72, 380–388. [Google Scholar] [CrossRef]

- Lee, G.C.; Shih, T.S.; Chang, K.C. Mechanical Properties of Concrete at Low Temperature. J. Cold Reg. Eng. 1988, 2, 13–24. [Google Scholar] [CrossRef]

- Kogbara, R.B.; Iyengar, S.R.; Grasley, Z.C.; Masad, E.A.; Zollinger, D.G. A review of concrete properties at cryogenic temperatures: Towards direct LNG containment. Constr. Build. Mater. 2013, 47, 760–770. [Google Scholar] [CrossRef]

- Browne, R.D.; Bamforth, P.B. The use of concrete for cryogenic storage: A summary of research past and present. In Proceedings of the 1st International Conference on Cryogenic Concrete, Newcastle upon Tyne, UK, 27–31 March 1981. [Google Scholar]

- Krstulovic-Opara, N. Liquefied natural gas storage: Material behavior of concrete at cryogenic temperatures. ACI Mater. J. 2007, 104, 297–306. [Google Scholar]

- Longarini, N.; Crespi, P.; Zucca, M.; Giordano, N.; Silvestro, G. The advantages of fly ash use in concrete structures. Inz. Miner. 2014, 15, 141–145. [Google Scholar]

- Zhang, D.; Zhang, T.; Yang, Q. Mechanical Properties and Damage Layer Thickness of Green Concrete under a Low-Temperature Environment. Materials 2022, 15, 7409. [Google Scholar] [CrossRef]

- Shi, X.; Ma, C.; Zhang, T.; Li, J.; Wang, W. Experimental study on compressive strength properties of concrete of different strength grades at −190 °C. Eng. Mech. 2017, 34, 61–67. [Google Scholar]

- Qian, L. Experimental Research on Basic Stress Performance of Concrete at Low Temperature. Master’s Thesis, Tsinghua University, Beijing, China, 2019. [Google Scholar]

- München, R.M.; Ehrenbring, H.Z.; Wirth, A.; Medeiros, D.R.; Tutikian, B.F.J.M. Impact on the mechanical properties of concrete cured at low temperatures. Matéria 2019, 24, e12346. [Google Scholar]

- Gao, Y. Experimental Study on the Deterioration Law of Mechanical Properties of Early Frozen Concrete. Master’s Thesis, North China University of Water Resources and Electric Power, Zhengzhou, China, 2019. [Google Scholar]

- Yu, X.; Chen, L.; Fang, Q.; Ruan, Z.; Hong, J.; Xiang, H. A concrete constitutive model considering coupled effects of high temperature and high strain rate. Int. J. Impact Eng. 2016, 101, 66–77. [Google Scholar] [CrossRef]

- Xu, H.; Wen, H.M. A computational constitutive model for concrete subjected to dynamic loadings. Int. J. Impact Eng. 2016, 91, 116–125. [Google Scholar] [CrossRef]

- Li, Z.; Xie, J.; Wu, H. Experimental study on constitutive relationship of concrete under ultra-low temperature environment. Eng. Mech. 2014, 31 (Suppl. S1), 195–200. [Google Scholar] [CrossRef]

- Su, H.; Zhu, Z.; Li, T.; Xiang, H. Experimental studies and numerical analysis of the dynamic mechanical properties of concrete at low temperatures. Constr. Build. Mater. 2023, 404, 133221. [Google Scholar] [CrossRef]

- Masad, N.; Zollinger, D.; Kim, S.M.; Grasley, Z. Meso-scale model for simulations of concrete subjected to cryogenic temperatures. Mater. Struct. 2015, 49, 2141–2159. [Google Scholar] [CrossRef]

- Gong, F.; Ueda, T.; Zhang, D. Two-dimensional rigid body spring method based micro-mesoscale study of mechanical strengthening/damaging effects to concrete by frost action. Struct. Concr. 2018, 19, 1131–1145. [Google Scholar] [CrossRef]

- GB51081-2015; Technical Specification for Concrete Application in Low Temperature Environment. China Planning Press: Beijing, China, 2015.

- Ji, H. Experimental Study on Mechanical Properties of Concrete at Low Temperature. Master’s Thesis, North West Agriculture and Forestry University, Xi’an, China, 2003. [Google Scholar]

- Wang, C.; Xie, J.; Li, H. Experimental study on the performance of concrete in low temperature environment. In Proceedings of the 19th National Structural Engineering Conference, Jinan, China, 5–8 November 2010; Structural Engineering Committee of Chinese Mechanics Society, Shandong University of Architecture: Jinan, China; Editorial Committee of Engineering Mechanics of Chinese Mechanics Society, Department of Civil Engineering, Tsinghua University: Beijing, China; State Key Laboratory of Water and Sand Science and Hydropower Engineering, Tsinghua University: Beijing, China, 2010; Volume II, pp. 146–151. [Google Scholar]

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. China Architecture & Building Press: Beijing, China, 2019. (In Chinese)

- GB/T 50082-2010; Test Method for Long-term Perfomance and Durability of Ordinary Concrete. China Construction Industry Press: Beijing, China, 2010.

- JGJ55-2011; Specification for the Design of Mix Ratio of Ordinary Concrete. China Construction Industry Press: Beijing, China, 2011.

- Liu, C. Experimental Study on Low Temperature Stress Performance of Concrete. Master’s Thesis, Tsinghua University, Beijing, China, 2011. [Google Scholar]

- Wu, B. Experimental Study of Concrete Stress-Strain Curve with Random Damage Principal Model. Master’s Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2015. [Google Scholar]

- Ji, W.; Zhang, T.; Wang, B.; Zhang, N.; Liao, J. Research on mechanical properties of concrete in ultra-low temperature environment. Concrete 2014, 45–47+58. [Google Scholar]

- Berner, D.E. Behavior of Prestressed Concrete Subjected to Low Temperatures and Cyclic Loading; University of California: Berkeley, CA, USA, 1984. [Google Scholar]

- Marshall, A.L.J.C. Cryogenic concrete. Cryogenics 1982, 22, 555–565. [Google Scholar] [CrossRef]

- Monfore, G.E.; Lentz, A.E. Physical Properties of Concrete at Very Low Temperatures. J. PCA 1962, 22, 21–28. [Google Scholar]

- Wu, H. Experimental Study on Axial Compression Performance of Hoop-Restrained Concrete Under Ultra-Low Temperature Environment. Master’s Thesis, Tianjin University, Tianjin, China, 2012. [Google Scholar]

- Bin, T. Study on the Full Curve of Stress-Strain of Activated Powder Concrete under Compression. Master’s Thesis, Hunan University, Changsha, China, 2007. [Google Scholar]

- Guo, Z. Strength and Deformation of Concrete-Test Fundamentals and Constitutive Relations; Tsinghua University Press: Beijing, China, 1997; pp. 31–35. [Google Scholar]

- Duan, P.; Bi, X.; Li, Y.; Liu, J.; Zhou, D. Study on mechanical properties and constitutive relationship of concrete at ultra-low temperature. Mater. Guide 2022, 36, 73–77. [Google Scholar]

- Wang, X. Research on Frost Resistance and Constitutive Relationship of Air-Entraining Lightweight Aggregate Concrete. Master’s Thesis, Inner Mongolia Agricultural University, Hohhot, China, 2008. [Google Scholar]

| Strength Grade | Composition (kg/m3) | Serial Number | |||

|---|---|---|---|---|---|

| Cement | Water | Sand | Aggregate | ||

| C30 | 24.60 | 14.76 | 41.21 | 73.31 | A1~A15 |

| C35 | 24.8 | 12.40 | 41.54 | 73.90 | B1~B15 |

| C40 | 25.4 | 11.43 | 42.55 | 75.69 | C1~C15 |

| C50 | 25.60 | 7.68 | 42.88 | 76.29 | D1~D15 |

| Strength Grade | Temperature (°C) | Average Compressive Strength (MPa) | Average Elastic Modulus (GPa) | Average Peak Strain (×10−6) |

|---|---|---|---|---|

| C30 | 20 | 28.96 | 21.68 | 22.75 |

| 0 | 26.56 | 21.94 | 23.43 | |

| −20 | 30.67 | 22.09 | 20.29 | |

| −30 | 30.76 | 22.16 | 19.93 | |

| −40 | 31.22 | 22.25 | 19.11 | |

| C35 | 20 | 34.91 | 21.87 | 26.22 |

| 0 | 32.47 | 22.18 | 27.69 | |

| −20 | 37.04 | 22.29 | 24.10 | |

| −30 | 37.18 | 22.36 | 22.84 | |

| −40 | 37.74 | 22.44 | 22.16 | |

| C40 | 20 | 39.61 | 22.41 | 26.57 |

| 0 | 38.10 | 22.66 | 28.35 | |

| −20 | 42.18 | 22.77 | 24.55 | |

| −30 | 42.43 | 22.95 | 23.86 | |

| −40 | 43.69 | 23.02 | 23.49 | |

| C50 | 20 | 47.47 | 22.84 | 37.57 |

| 0 | 46.47 | 23.18 | 41.25 | |

| −20 | 51.08 | 23.30 | 36.18 | |

| −30 | 54.21 | 23.34 | 34.19 | |

| −40 | 55.26 | 23.42 | 33.44 |

| Parametric | Strength Class | Temperature | ||||

|---|---|---|---|---|---|---|

| 20 °C | 0 °C | −20 °C | −30 °C | −40 °C | ||

| a | C30 | 2.21 | 2.18 | 2.07 | 1.85 | 1.72 |

| C35 | 2.37 | 2.32 | 2.19 | 2.03 | 1.84 | |

| C40 | 2.48 | 2.39 | 2.27 | 2.11 | 1.98 | |

| C50 | 2.62 | 2.58 | 2.39 | 2.22 | 2.02 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Qin, L.; Guo, L.; Li, Y. Research on the Mechanical Properties of Concrete under Low Temperatures. Materials 2024, 17, 1882. https://doi.org/10.3390/ma17081882

Li X, Qin L, Guo L, Li Y. Research on the Mechanical Properties of Concrete under Low Temperatures. Materials. 2024; 17(8):1882. https://doi.org/10.3390/ma17081882

Chicago/Turabian StyleLi, Xiangyi, Lihui Qin, Lina Guo, and Yan Li. 2024. "Research on the Mechanical Properties of Concrete under Low Temperatures" Materials 17, no. 8: 1882. https://doi.org/10.3390/ma17081882

APA StyleLi, X., Qin, L., Guo, L., & Li, Y. (2024). Research on the Mechanical Properties of Concrete under Low Temperatures. Materials, 17(8), 1882. https://doi.org/10.3390/ma17081882