Experimental Study on Dynamic Characteristics of Damaged Post-Tensioning Concrete Sleepers Using Impact Hammer

Abstract

1. Introduction

2. Materials and Methods

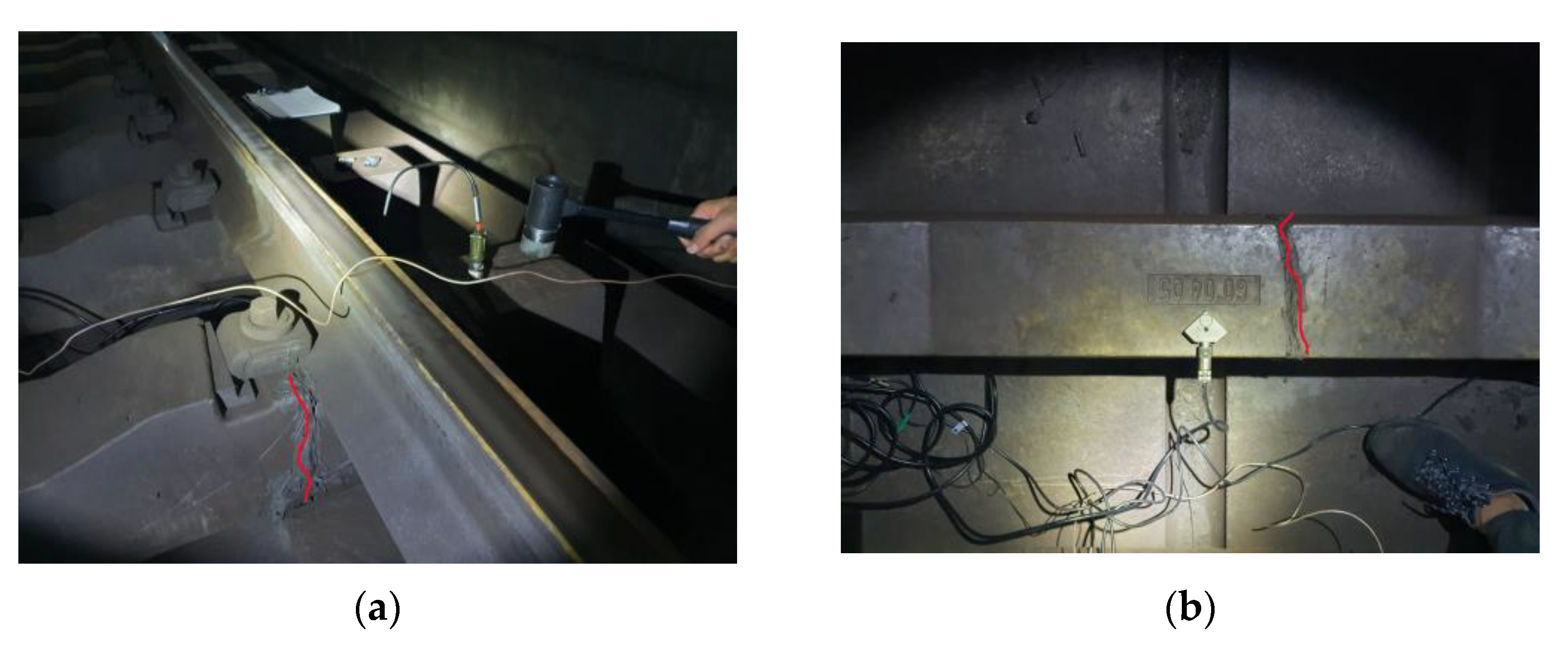

2.1. Measurement Sections and System

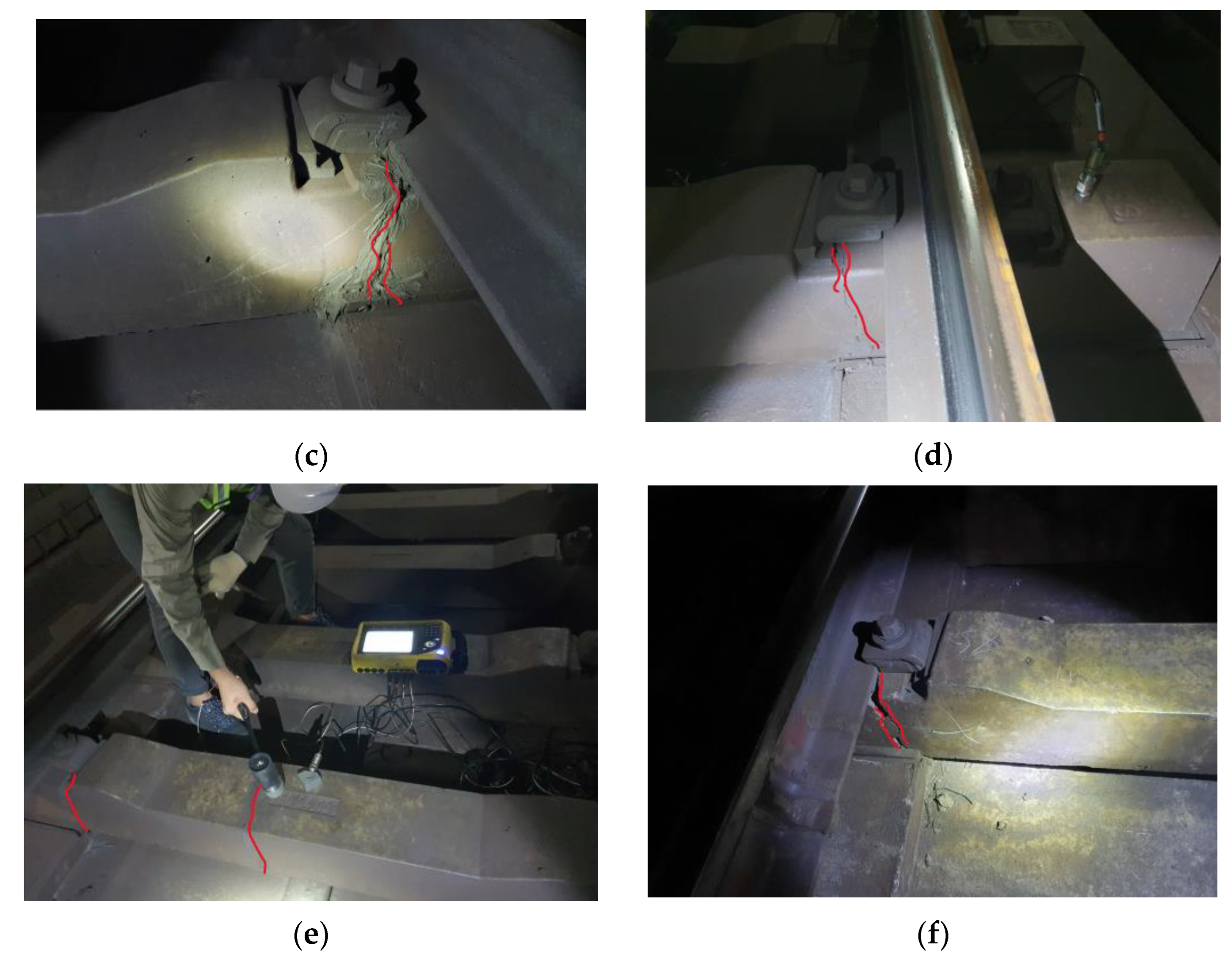

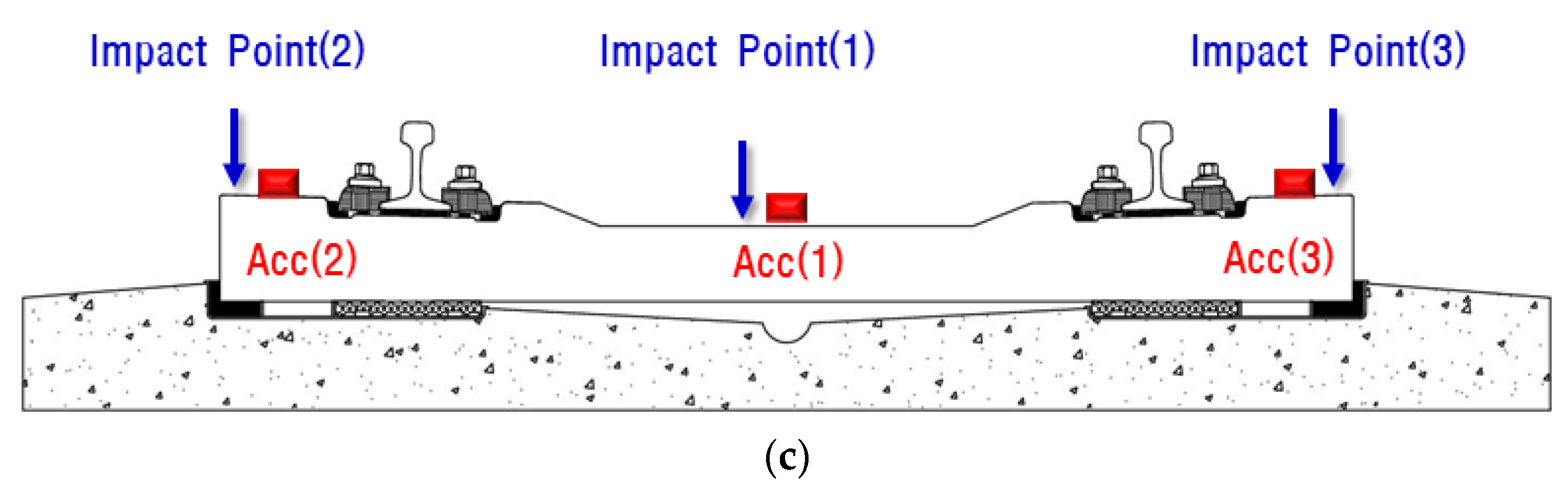

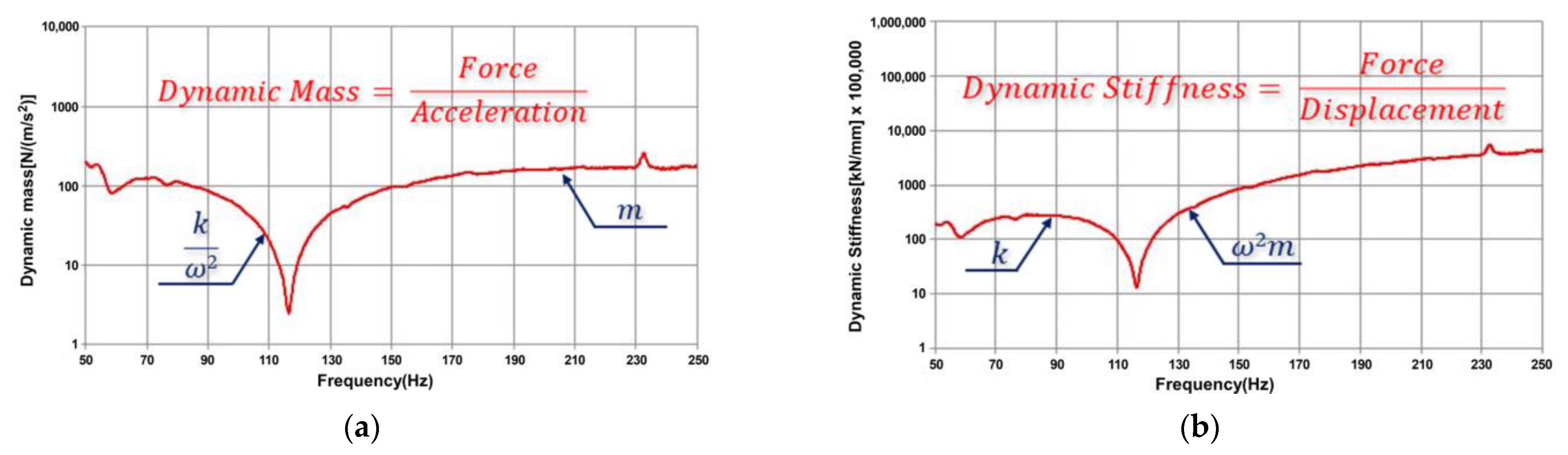

2.2. Dynamic Mass-and-Stiffness Estimation Using FRF

2.3. Numerical Analysis

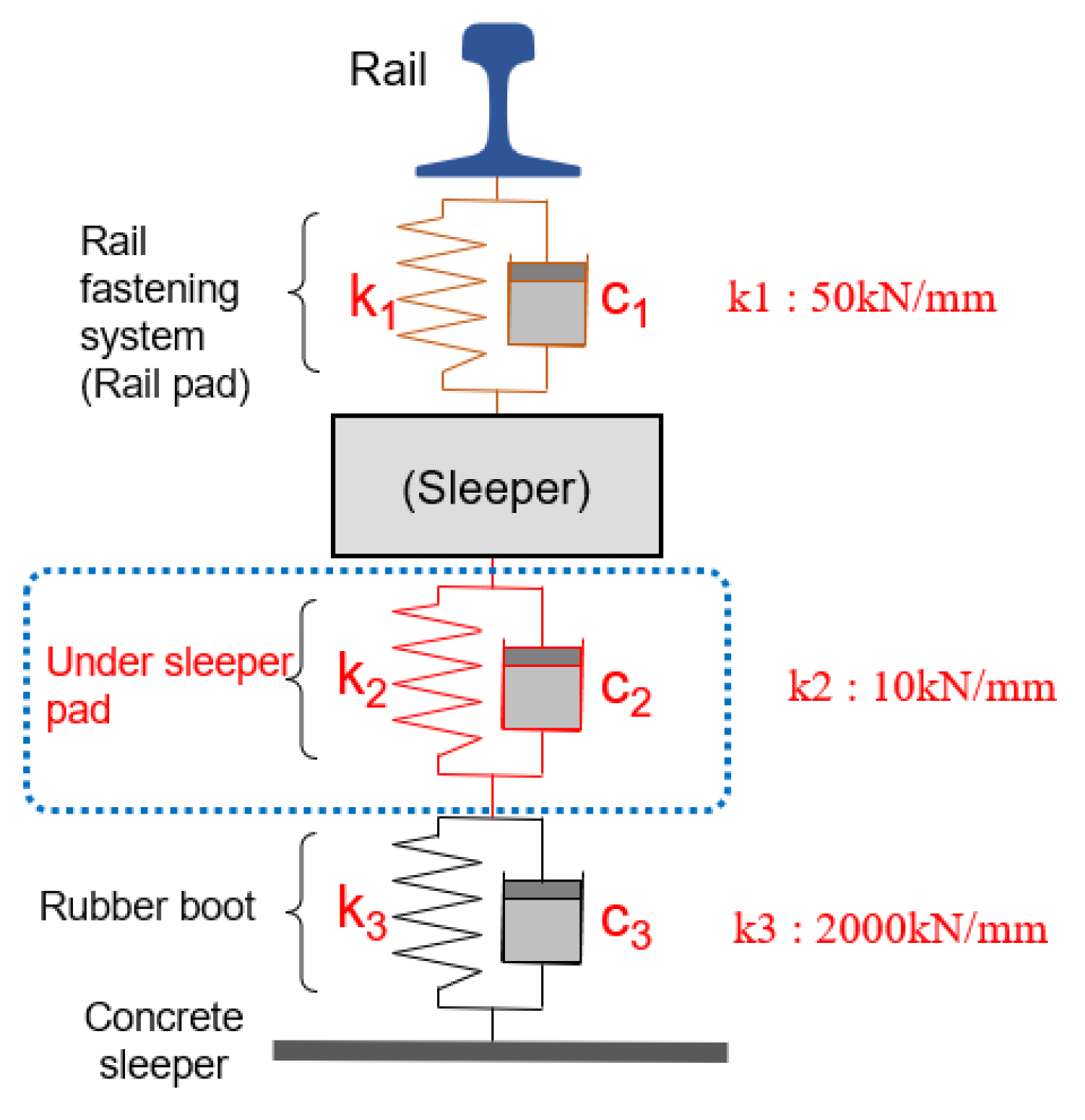

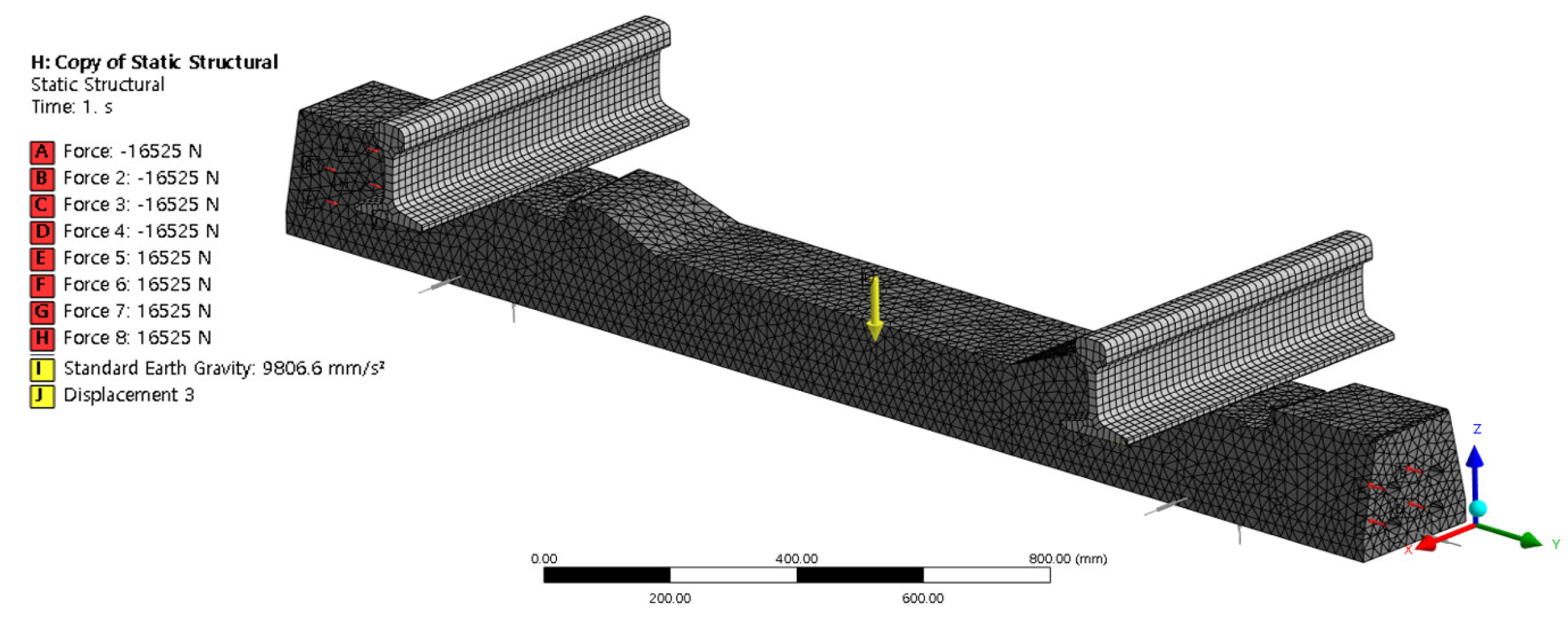

2.3.1. Numerical Analysis Conditions

2.3.2. Modeling

3. Results and Discussion

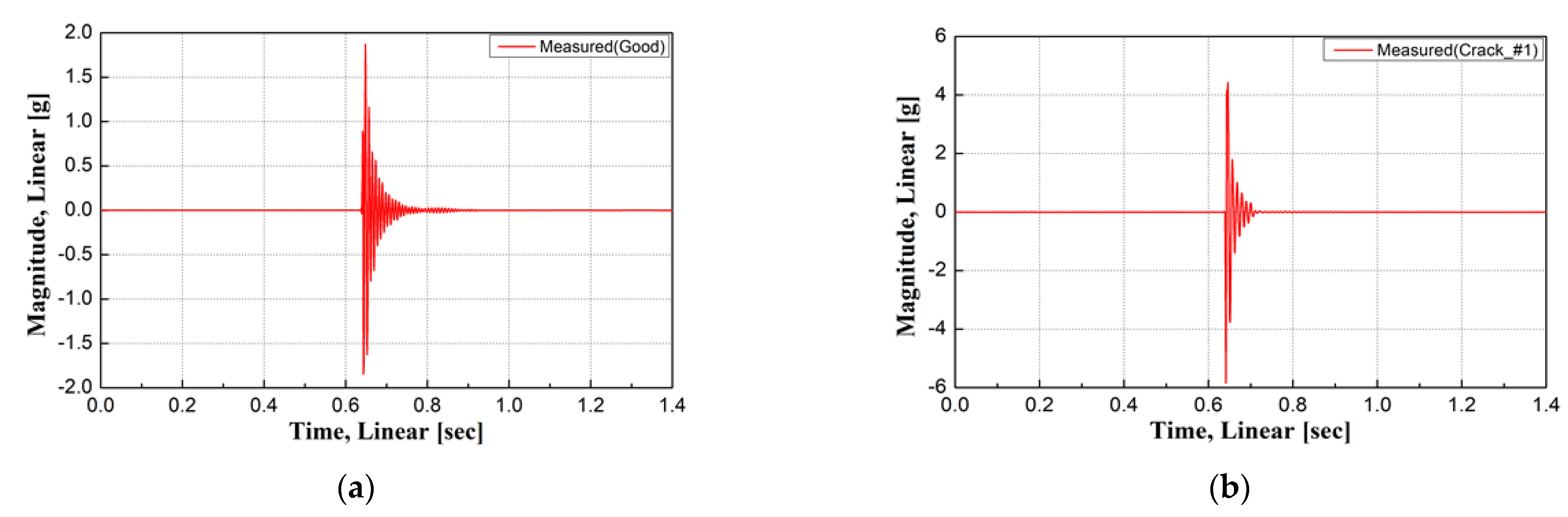

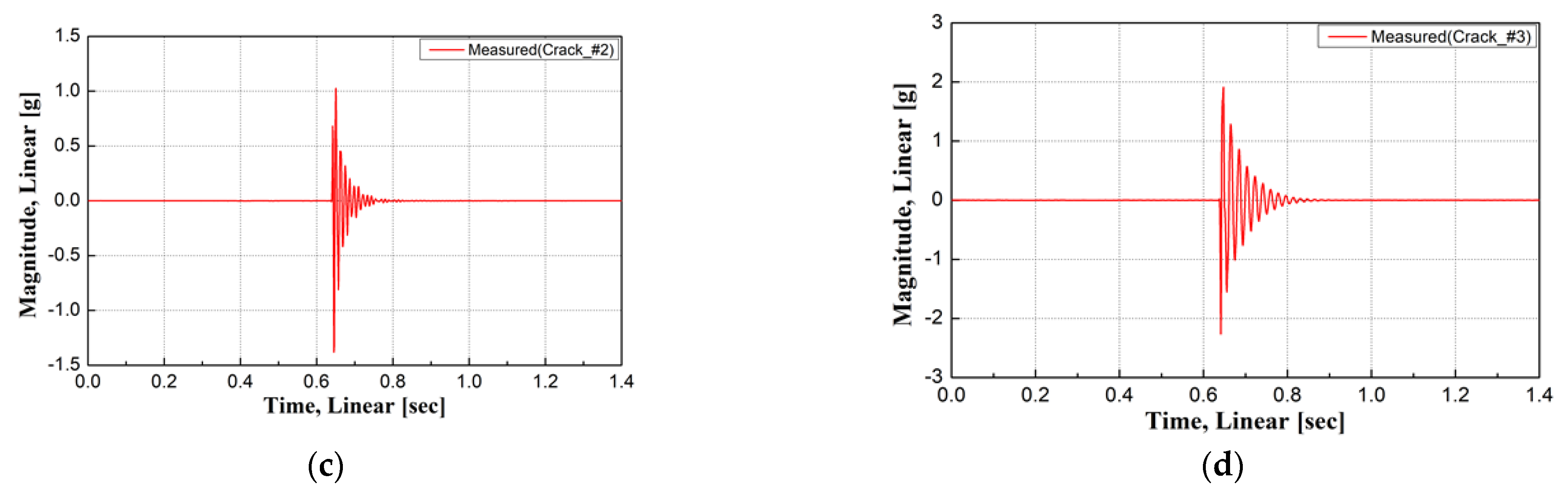

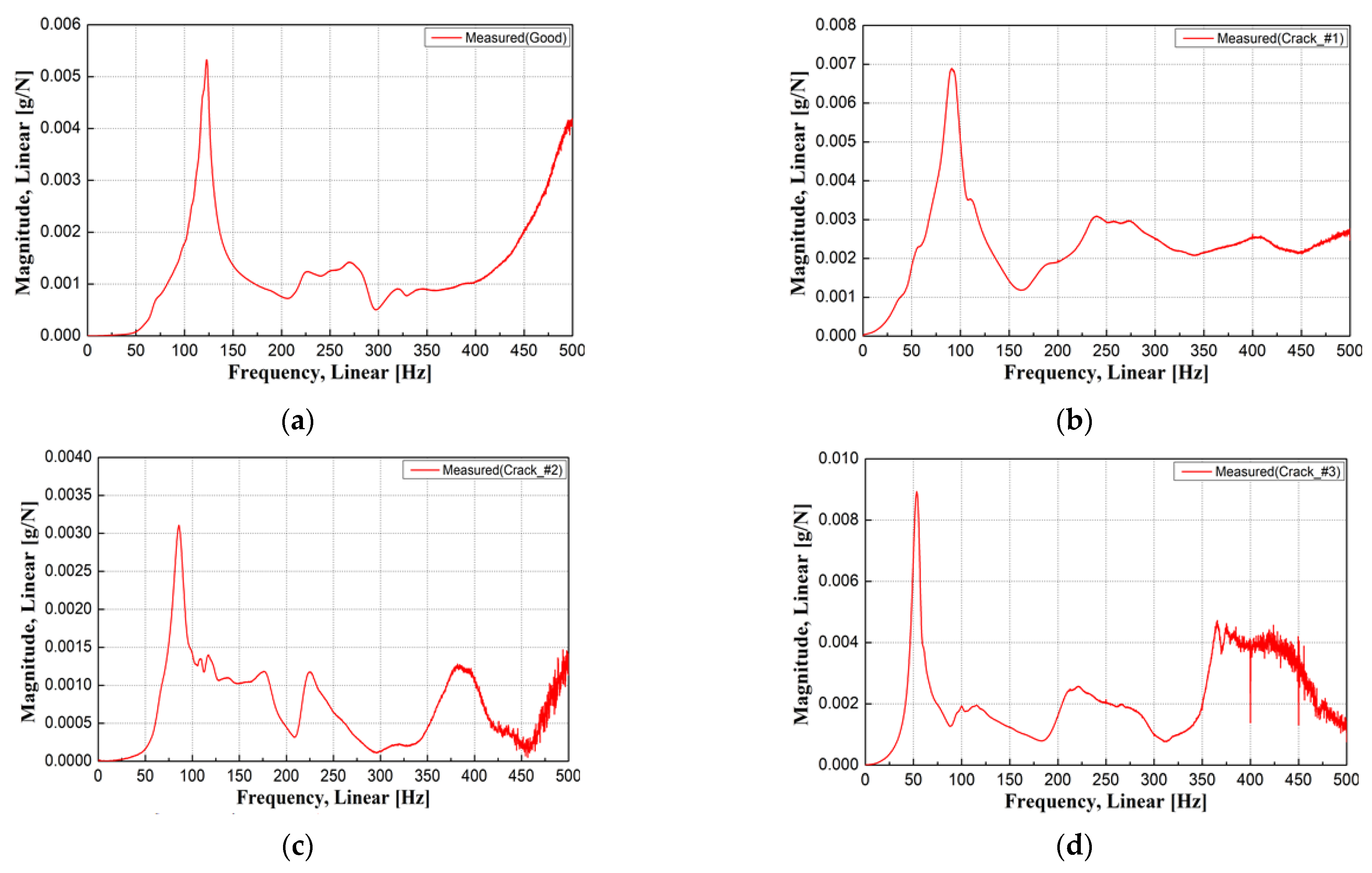

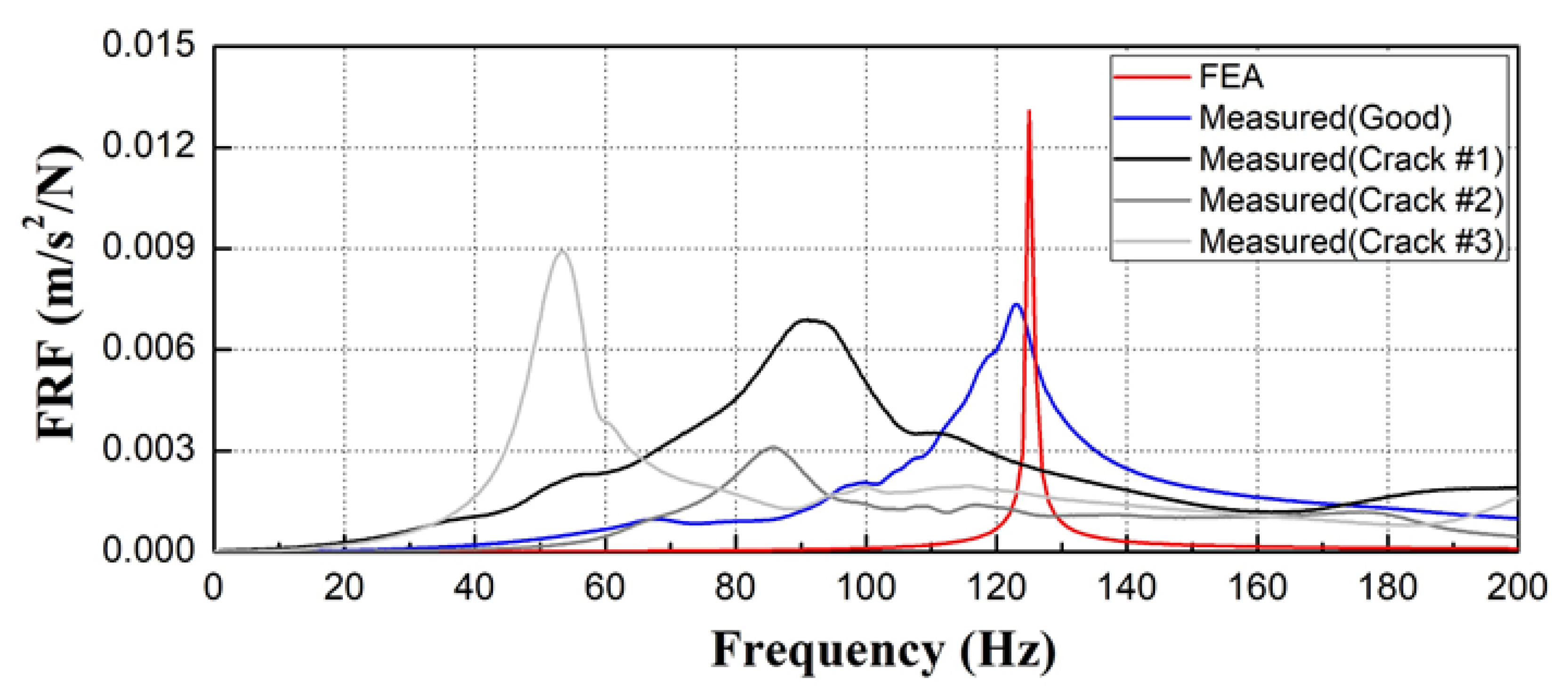

3.1. FRF Results

3.2. Dynamic Mass and Stiffness Prediction Using FRF

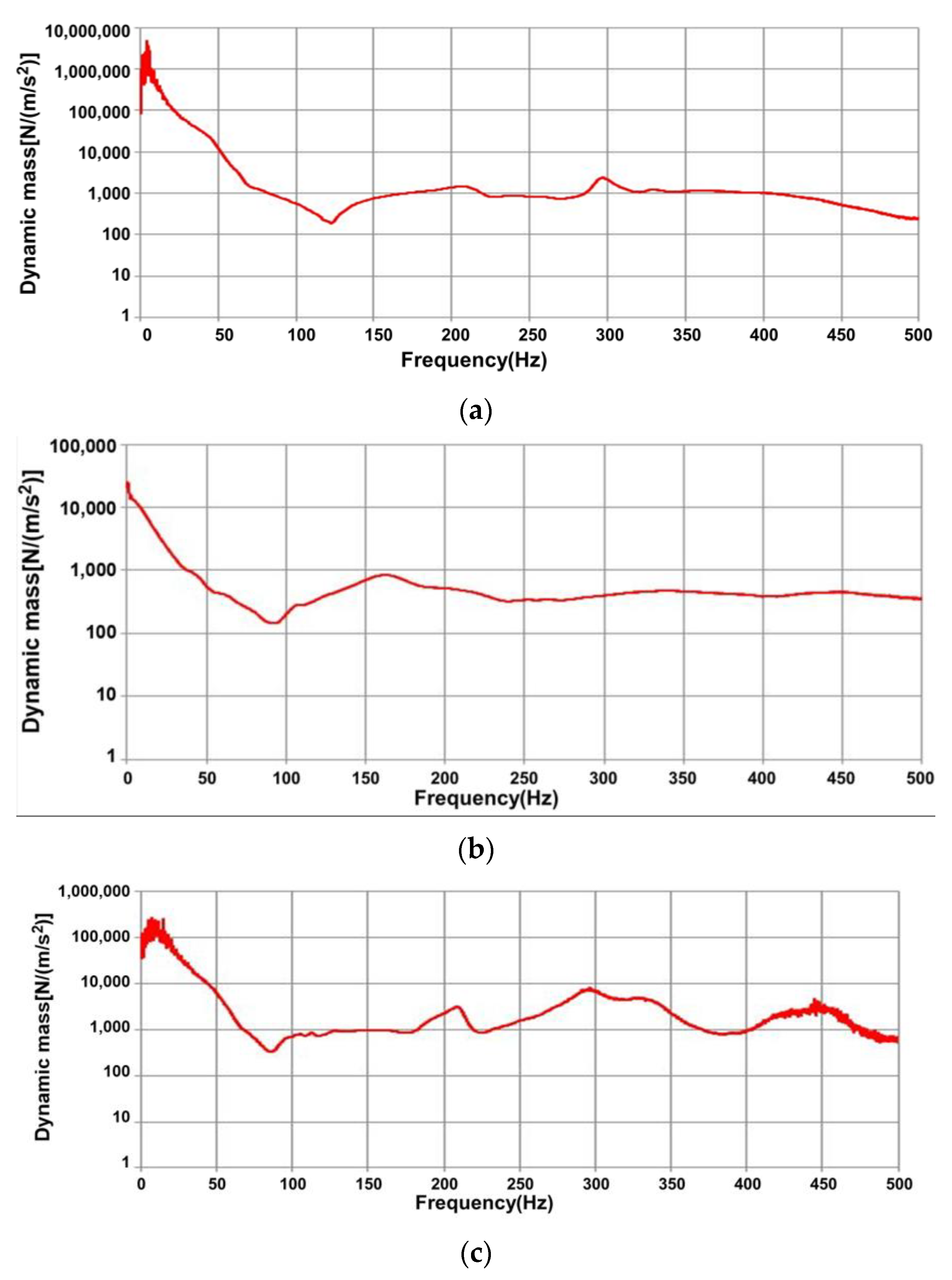

3.2.1. Dynamic Mass-Prediction Results

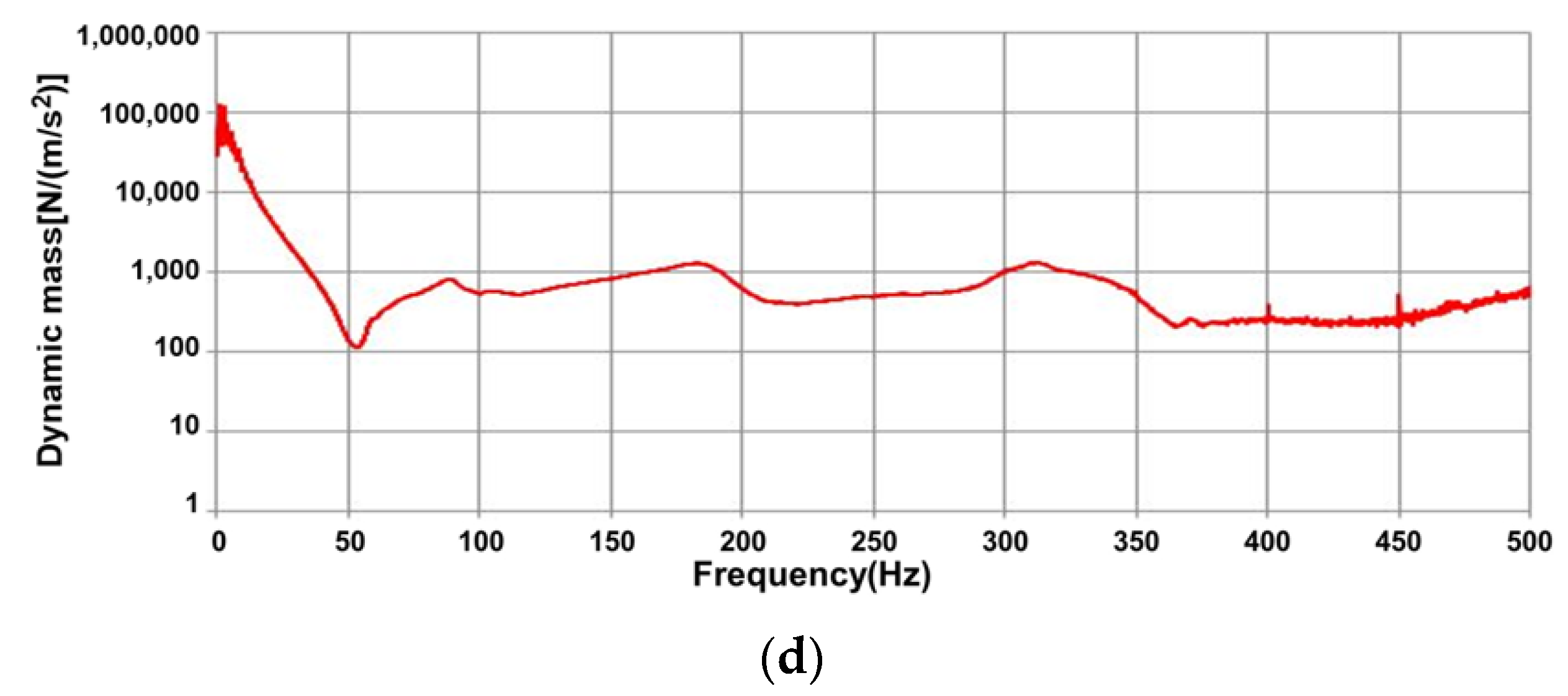

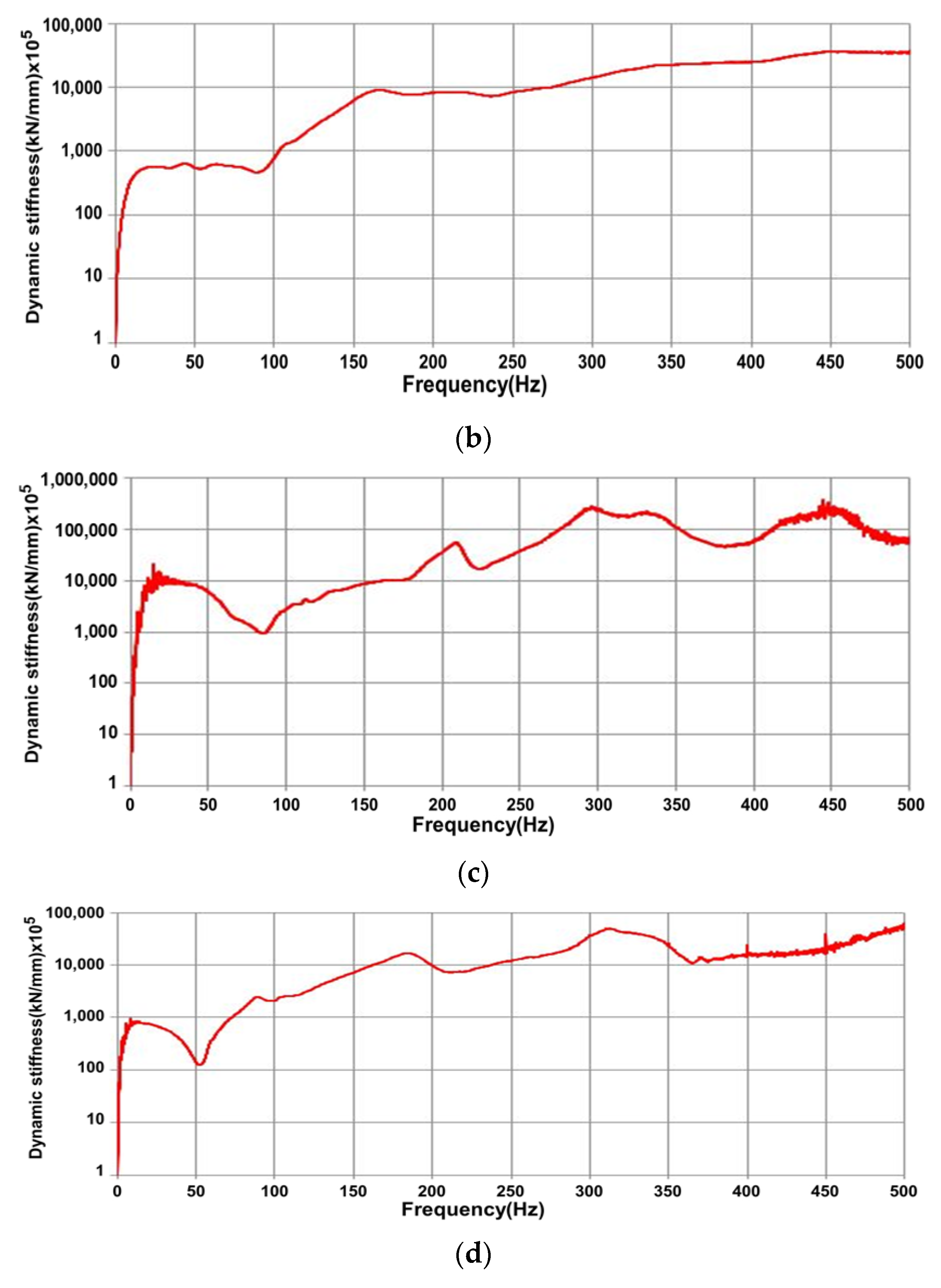

3.2.2. Dynamic Stiffness Prediction Results for Concrete Sleepers

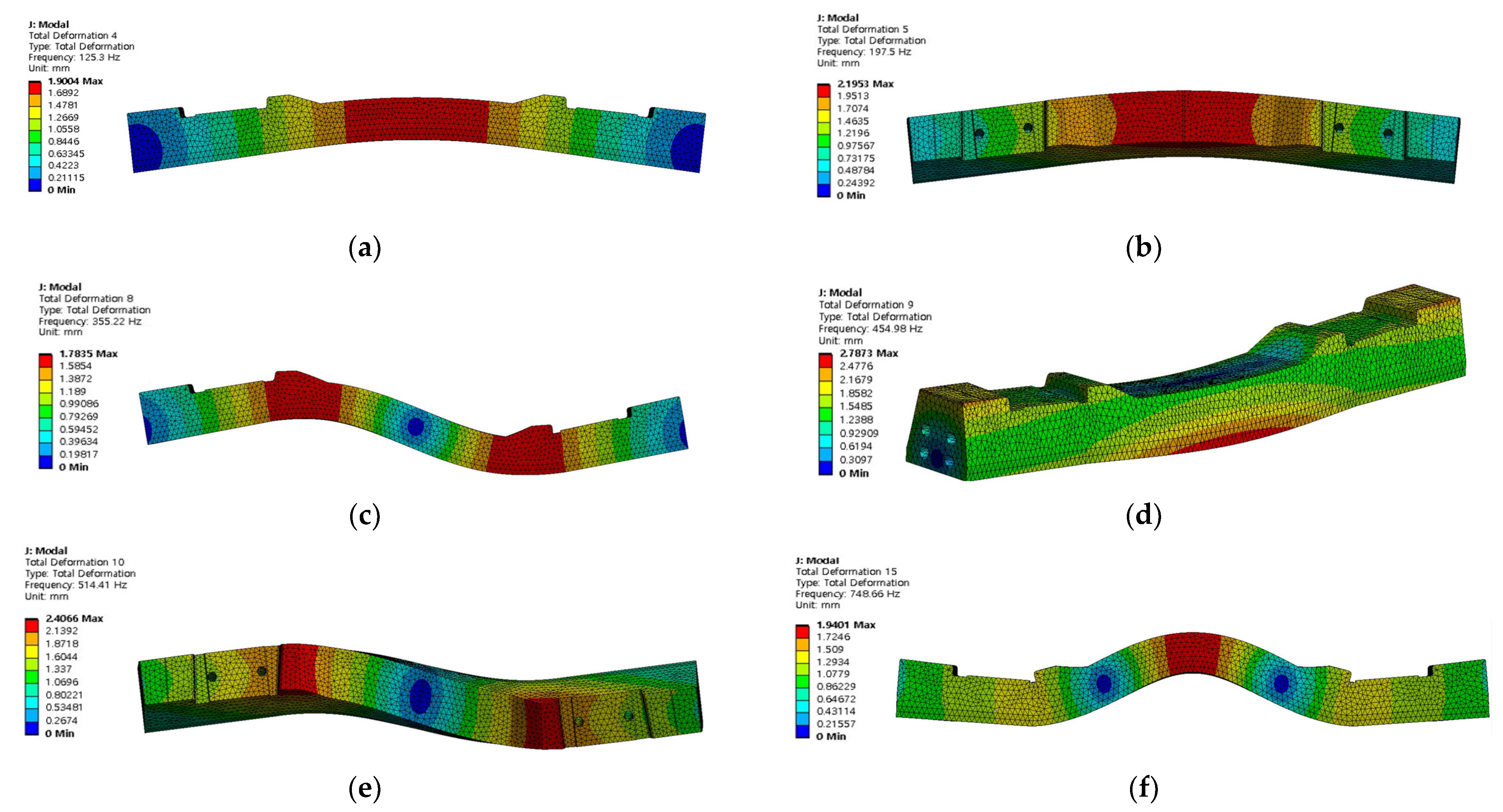

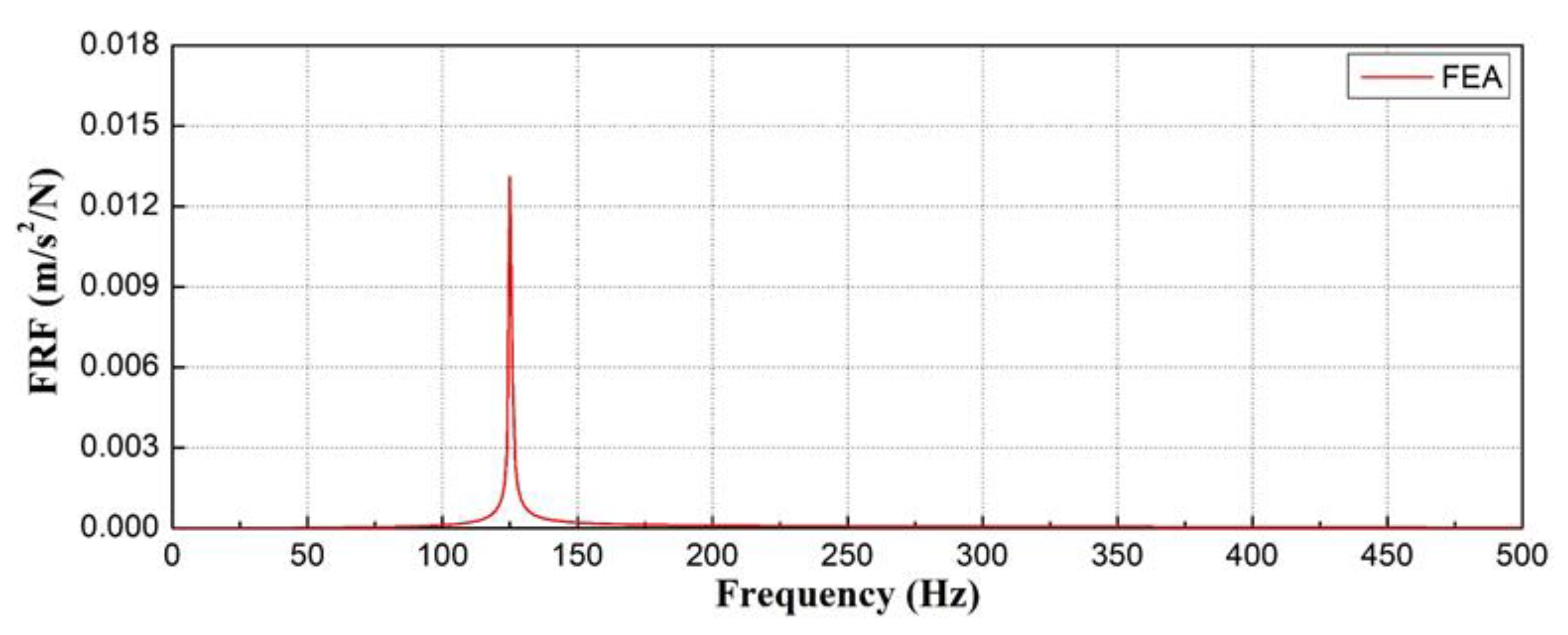

3.3. Numerical Analysis Results

3.4. Correlation between Concrete Sleeper Damage and Natural Frequency

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Korea National Railway. Guidelines for Track Facility Performance Evaluation; Korea Ministry of Land Infrastructure and Transport (MOLIT): Sejong, Republic of Korea, 2022. (In Korean) [Google Scholar]

- Clark, A.; Kaewunruen, S.; Janeliukstis, R.; Papaelias, M. Damage detection in railway prestressed concrete sleepers using acoustic emission. In Proceedings of the IOP Conference Series: Materials Science and Engineering, IMST 2017, Riga, Latvia, 27–29 September 2017; Volume 251, p. 012068. [Google Scholar]

- Choi, J.Y. Qualitative Analysis for Dynamic Behavior of Railway Ballasted Track. Ph.D. Thesis, Technical University of Berlin, Berlin, Germany, February 2014. [Google Scholar]

- Kim, J.W.; Jung, H.Y. Vibrational characteristics of the deteriorated railway plate girder bridge by full-scale experimental modal analysis. J. Korean Soc. Steel Constr. 2012, 24, 119–128. [Google Scholar] [CrossRef]

- Esmaeili, M.; Majidi-Parast, S.; Hosseini, A. Comparison of dynamic lateral resistance of railway concrete, wooden and steel sleepers subjected to impact loading. Road Mater. Pavement Des. 2019, 20, 1779–1806. [Google Scholar] [CrossRef]

- Braunfelds, J.; Senkans, U.; Skels, P.; Porins, J.; Haritonovs, V.; Spolitis, S.; Bobrovs, V. Development of the strain measurement calibration technique for road pavement structural health monitoring applications using optical FBG sensors. In Proceedings of the 2023 PhotonIcs & Electromagnetics Research Symposium (PIERS), Prague, Czech Republic, 3–7 July 2023; pp. 1060–1065. [Google Scholar]

- Chung, J.S.; Lee, J.S.; Choi, J.Y. A study on estimation method of concrete sleeper strength for sleeper floating track using rebound hardness test method. J. Converg. Cult. Technol. (JCCT) 2022, 8, 277–282. [Google Scholar]

- Choi, J.Y.; Park, S.W.; Chung, J.S. Estimation method of resilience pads spring stiffness for sleeper floating tracks based on track vibration. J. Converg. Cult. Technol. (JCCT) 2023, 9, 1057–1063. [Google Scholar]

- Sapidis, G.M.; Kansizoglou, I.; Naoum, M.C.; Papadopoulos, N.A.; Chalioris, C.E. A deep learning approach for autonomous compression damage identification in fiber-reinforced concrete using piezoelectric lead zirconate titanate transducers. Sensors 2023, 24, 386. [Google Scholar] [CrossRef]

- Nielsen, D.; Palmer, E. Modal analysis experiments on prestressed concrete sleepers. In Proceedings of the 16th East Asian-Pacific Conference on Structural Engineering and Construction, Brisban, Australia, 3–6 December 2019. [Google Scholar]

- Kaewunruen, S.; Remennikov, A.M. Sensitivity analysis of free vibration characteristics of an in situ railway concrete sleeper to variations of rail pad parameters. J. Sound Vib. 2006, 298, 453–461. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Remennikov, A. Non-destructive evaluation for dynamic integrity of railway track structure. In Proceedings of the International Conference on Structural Integrity and Failure—SIF2006, Sydney, Australia, 27–29 September 2006; pp. 294–299. [Google Scholar]

- Shin, T.H. Integrity Assessment of Concrete Sleeper Using Modal Test Technique. Ph.D. Thesis, Dongyang University, Yeongju-si, Republic of Korea, February 2022. [Google Scholar]

- Lam, H.F.; Wong, M.T. Railway ballast diagnose through impact hammer test. Procedia Eng. 2011, 14, 185–194. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Remennikov, A.M. Dynamic effect on vibration signatures of cracks in railway prestressed concrete sleepers. Adv. Mater. Res. 2008, 41, 233–239. [Google Scholar] [CrossRef]

- You, R.; Wang, J.; Ning, N.; Wang, M.; Zhang, J. The typical damage form and mechanism of a railway prestressed concrete sleeper. Materials 2022, 15, 8074. [Google Scholar] [CrossRef] [PubMed]

- Real, J.J.; Sanchez, M.E.; Real, T.; Sanchez, F.J. Experimental modal analysis of railway concrete sleepers with cracks. Struct. Eng. Mech. 2012, 44, 51–60. [Google Scholar] [CrossRef]

- Hassan, M.H.M. Advances in Structural Health Monitoring; IntechOpen: London, UK, 2019; Chapter 6. [Google Scholar]

- ANSYS. ANSYS® 2007 ANSYS Workbench, version 2021 R2; ANSYS Inc.: Cannonsberg, PA, USA, 2021. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions, and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions, or products referred to in the content. |

| Sensor Type | Impact Hammer | Accelerometer | ||

|---|---|---|---|---|

| Channels | Ch.1 | Ch.2 | Ch.3 | Ch.4 |

| Sensitivity | 0.2301 mV/N | 1024.0 mV/g | 1018.0 mV/g | 993.2 mV/g |

| Response | Inverse FRF | Standard FRF |

|---|---|---|

| Acceleration | / | |

| Velocity | / | |

| Displacement | /u() | u()/ |

| Dynamic Mass (m) | Dynamic Stiffness (k) | |

|---|---|---|

| Items | Properties | ||

|---|---|---|---|

| Rail weight (kg/m) | 60 | ||

| Sleeper type | Post-tensioning Sleeper | ||

| Sleeper size (mm) | 212 × 240 × 2300 | ||

| Compressive strength (MPa) | 59 | ||

| Post-tensioning steel bar | Tensile strength (MPa) | Diameter (mm) | Length (mm) |

| 1230 | Ø9.2 | 2240 | |

| Post-tensioning force (kN/EA) | 66.1 | ||

| Spring stiffness of rail pad (kN/mm) | 50 | ||

| Spring stiffness of under sleeper pad (kN/mm) | 10 | ||

| Spring stiffness of rubber boot (kN/mm) | 2000 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, J.-Y.; Shin, T.-H.; Kim, S.-H.; Chung, J.-S. Experimental Study on Dynamic Characteristics of Damaged Post-Tensioning Concrete Sleepers Using Impact Hammer. Materials 2024, 17, 1581. https://doi.org/10.3390/ma17071581

Choi J-Y, Shin T-H, Kim S-H, Chung J-S. Experimental Study on Dynamic Characteristics of Damaged Post-Tensioning Concrete Sleepers Using Impact Hammer. Materials. 2024; 17(7):1581. https://doi.org/10.3390/ma17071581

Chicago/Turabian StyleChoi, Jung-Youl, Tae-Hyung Shin, Sun-Hee Kim, and Jee-Seung Chung. 2024. "Experimental Study on Dynamic Characteristics of Damaged Post-Tensioning Concrete Sleepers Using Impact Hammer" Materials 17, no. 7: 1581. https://doi.org/10.3390/ma17071581

APA StyleChoi, J.-Y., Shin, T.-H., Kim, S.-H., & Chung, J.-S. (2024). Experimental Study on Dynamic Characteristics of Damaged Post-Tensioning Concrete Sleepers Using Impact Hammer. Materials, 17(7), 1581. https://doi.org/10.3390/ma17071581