1. Introduction

Biobased polymers have been the subject of many studies over the last decade because of the increasing need to reduce the carbon footprint [

1,

2,

3] of more traditional synthetic polymers. While biopolymers are often quite expansive with respect to traditional materials, their cost and potentially also their properties could be significantly improved upon employment of biobased fillers, and more precisely, agricultural wastes, in order to keep the carbon footprint limited, bringing several advantages, such as full circularity of resources, biodegradability, low specific gravity, and reduction of whole material cost [

2]. In this regard, poly(lactic acid) (PLA) appears as an optimal candidate as a biocomposite matrix [

4], owing to its large availability in comparison with other biobased thermoplastics, with 20.7% of the global production capacity in 2022 by material type [

5], its full biodegradability, and the wide range of applications that could benefit from lowering of the material’s cost. Additionally, PLA is largely adopted in additive manufacturing (AM), in particular in fused deposition modeling (FDM), where it actually represents a benchmark for household applications [

6]. Moreover, the feasibility of using PLA has already been demonstrated as a convenient matrix for producing reinforced 3D-printable filaments to obtain thermoplastic composites with enhanced characteristics [

7]. In FDM processing, the approach of using PLA-based biocomposites has been proposed and discussed in the scientific literature, which has investigated a wide range of natural fillers, which, on the commercial scale, are mostly declined as wood/PLA filaments [

8]. Several studies were focused on the development of biocomposite filaments using lignocellulosic fibers, such as wood [

9], flax [

10], bamboo [

11], hemp [

12], and kenaf [

13]. Concurrently, a great part of the research tried to valorize residues from industry or agriculture, often produced locally, using them as biofillers in 3D-printable filaments, such as sugarcane bagasse [

14] from sugar production, rice straw [

15], or coconut wastes [

16]. Indeed, FDM technology aims to take advantage of agricultural waste’s decreasing material cost [

17] and environmental impact [

18], which can also help reduce distortion after processing [

19] while preserving the mechanical properties of the material [

20]. Unfortunately, as reported in the literature, the majority of lignocellulosic biofillers provide materials with higher brittleness and lower tensile strength [

13]; higher mechanical properties were reported mainly in the cases of flax [

10], bamboo [

11], and hemp fiber [

12,

19] biocomposites. Such behavior can be due to many reasons, such as: a large internal void content in the filament (intrabead voids) [

13] because of the mixing process of heterogeneous materials; the well-known poor adhesion between biofillers and polymeric matrices, sometimes due to their different chemical natures, which does not allow for an efficient load transfer; phase segregation, which leads to inhomogeneous distribution and limited mechanical performance; and finally, high melt viscosity, which leads, in 3D printing, to low interlayer adhesion and high interbead void content. Some of these issues can be partially solved by surface treatments of biofillers and the use of compatibilizers.

In this context, we focused our interest on evaluating the possibility of using locally sourced agricultural wastes as biofillers for PLA in the production of polymeric filaments for FDM application. PLA was thus modified by the addition of wastes derived by the milling of wheat and rice, i.e., wheat middlings (WM) and rice husks (RH).

The wheat grain, i.e., wheat caryopsis, has a multi-layered structure. During the milling of wheat into flour, the starchy endosperm (precursor of edible flour) is separated from the bran material and embryo. The endosperm fraction is further ground while the bran material is a by-product, comprising different outer layers such as the embryo, aleurone layer, seed coat, and inner and outer pericarp layers [

21,

22]. These by-product fractions (called wheat middlings), however, do not have any specific applications and currently they are disposed of or sold at very low cost and mostly used for animal feed. Many studies dealing with the composition and nutritional value of wheat middlings [

23,

24,

25] were reported, but, to the best of the authors’ knowledge, no one has investigated the possibility of using this residual fraction, rich both in protein and starch, for the production of polymeric composites. In this regard, the research group has already achieved a viable biocomposite processed as filaments for additive manufacturing FDM [

26] with promising features.

Another potential alternative among locally sourced agro-wastes is represented by rice husks, which are the protective hulls of the rice grains and represent the main by-product of rice milling. Indeed, it is reported that for every ton of milled rice, about 0.23 tons of rice husks are generated [

27], and the global rice husk production is estimated to be between 128 and 148 million tons per year [

28]. Amongst the wide range of available lignocellulosic feedstocks, rice husks have gained interest due to their aforementioned abundancy, and their elevated content of inorganic ash, approximately 20–25 wt.%. This inorganic fraction was extensively investigated, confirming that 90–95 wt.% is composed of amorphous silica [

27,

29]. Such a significant inorganic content makes rice husks abrasive and characterized by a low content of nutritious substances, which in turn make them unsuitable as food. Moreover, differently from a lot of other agricultural residues, they cannot be used as raw materials for the paper production industry or as an efficient natural fertilizer [

28,

29], owing to their moisture, oxygen, and soil humification resistance, and they is often burnt in air, releasing large amounts of hazardous substances into the atmosphere [

25].

A preliminary evaluation of the ability to obtain a biocomposite filament suitable for 3D printing disclosed the versatility of WM as biofiller [

26]. In this work, hence, the application of such a biocomposite for FDM will be discussed and evaluated. Moreover, a similar approach was addressed for RH as biofiller. The optimized compounding process was then used to produce new 3D-printable filaments containing 10 and 20 wt.% of WM and RH. The morphological aspect of RH was compared to that of WM in order to evaluate its suitability for the FDM technique. Thus, the second stage of the work was focused on the thermal and mechanical properties of 3D-printed biocomposites and the effect of different biofiller concentrations on them. Initially, all biocomposite filaments were studied in terms of thermal properties, via DSC and TGA, and then processed by FDM to obtain 3D-printed specimens. Among the thermal behaviors,

CP and CLTE properties were studied. Thermomechanical and mechanical characterizations were carried out by means of DMA and tensile tests. Both CLTE measurements and tensile tests were conducted on two kinds of specimens with two distinct printing angles (0° and 90°) to assess the anisotropy of 3D-printed biocomposites.

3. Results and Discussion

Considering the Italian national wheat production of recent years, we can deduce that, every year in Italy, about 500,000 tons of wheat flour are produced. If we consider about 10% waste, there are about 450,000 tons of usable wheat middlings produced at a national level. The conservation of wheat meal and rice husks is not complex if the wastes are properly dried and then stored in a dry environment away from insects and fungi. So, the storage phase does not represent a complex problem. A preliminary evaluation of the feasibility of using 10% WM for 3D-printable filaments was reported by the authors, demonstrating the potential of such biofiller [

26]. In that case, different fractions of wheat waste, with different coarseness, were considered (

Figure S1 in Supplementary Information). The coarser ones, such as the so-called fine bran, comprising particles over 500 μm in size, were excluded, while the finer fraction, i.e., the middlings, was positively evaluated when used after sieving with a 200 μm mesh sieve [

26]. Concerning RH, the starting particle size of the residue as gathered from the producer (

Figure 1A) was reminiscent of the average dimension of the rice grain (a few mm up to more than a cm in length), which made this biomass unusable as biofiller in the 3D-printable filaments since the dimension is much higher than the nozzle diameter, i.e., 500 µm. Such a consideration imposed the downsizing of the biomass through planetary ball milling, reaching sub-millimeter dimensions (

Figure 1B,C), which was in the order of a few hundred microns. In this case, sieving was also applied, though this ended up being pointless with the particles all passing through the mesh with only a negligible fraction separated.

As widely reported in the literature, RH is differentiated from other lignocellulosic materials due to its moisture absorption resistance [

28]. This unique feature is conferred by its coating, mainly composed of silica. For this reason, a preliminary evaluation of the RH silica fraction within the biomass was carried out. Such a parameter has been reported to depend on crop region, weather, temperature, and nutritious substances, and the literature confirms that the silica amount ranges from 15 to 20 wt.% [

27,

28,

29]. Hence, RH powder was heated in a muffle oven in an air atmosphere up to 600 °C to fully remove the organic fraction of the biomass. The process led to a final inorganic residue of 16 wt.%, identified as silica via FT-IR spectroscopy (See

Figure S2 in Supplementary Information for the RH aspect before and after oxidation and the FT-IR spectrum of the residue), a fraction compatible with the ones reported in the literature [

27,

28,

29].

An optimized processing method, made up of two subsequent extrusion steps, was used in order to obtain PLA-biocomposite filaments suitable for 3D printing (1.75 mm controlled diameter) containing 10 and 20 wt.% RH biofiller (

Table 1), according to previously published results [

26], as well as a PLA-biocomposite filaments containing 20 wt.% WM biofiller (

Table 1) to be used for the production of 3D-printed specimens. Moreover, the previously obtained filament made of PLA with 10% WM [

26] will be further discussed in comparison with the newly produced samples and finally used for 3D printing. In this context, considering the fraction of WM up to 20% wt in the biocomposite, theoretically about 2 million tons of biocomposite filament could be obtained every year only based on the Italian market. A comprehensive table of the biocomposites used in this work is reported in

Table 1.

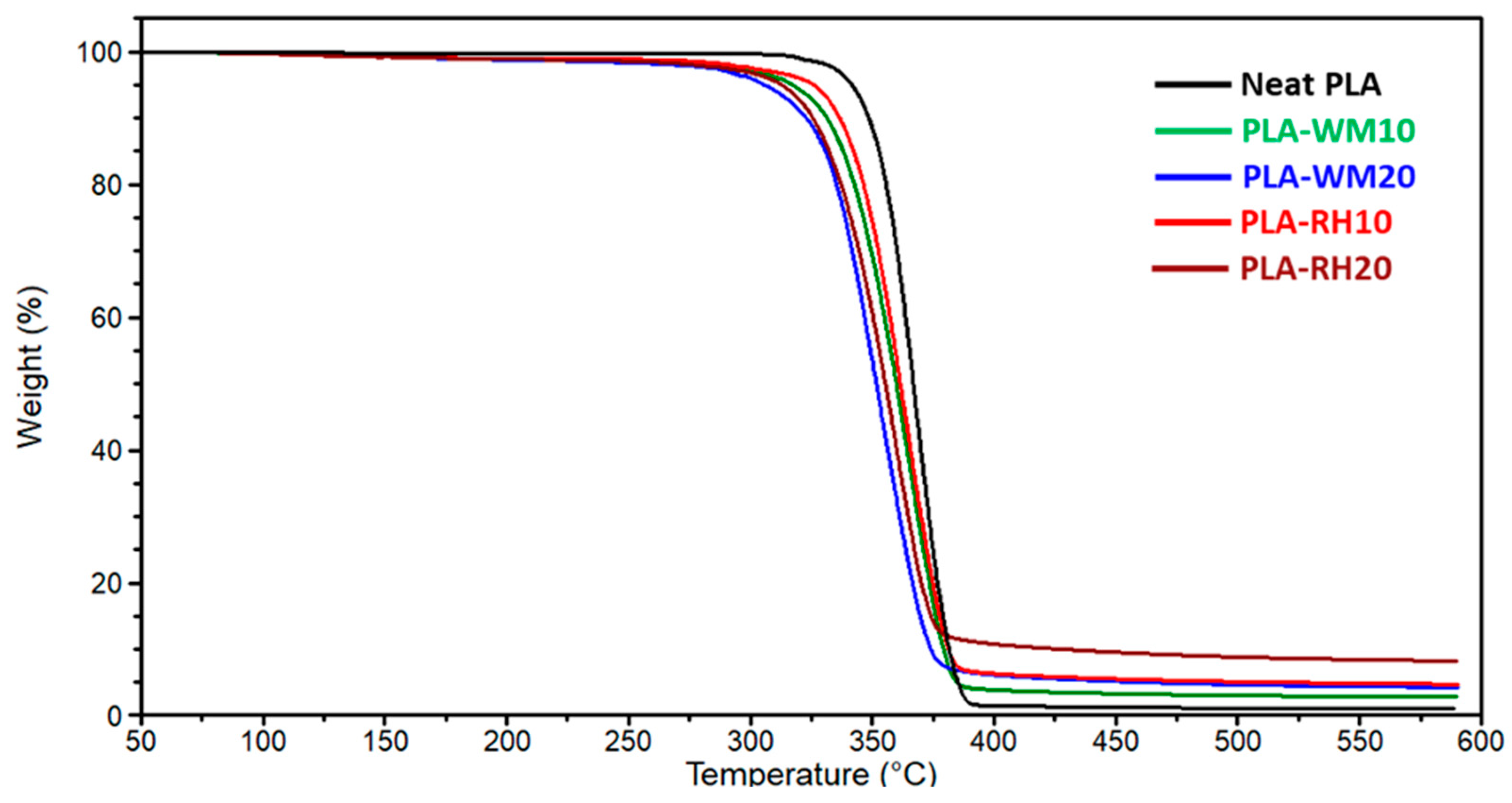

The thermal stability of the obtained biocomposite filaments was evaluated by TGA and compared with respect to PLA neat filament (

Figure 2). The presence of biofillers was already proved to slightly reduce the thermal stability of biocomposites [

26], and results from the present investigation confirmed (

Table 2) such behavior. Indeed,

Td values dropped from 352 °C of neat PLA filament down to about 330 °C for PLA-WM20 and PLA-RH20, with a stronger impact the higher the biofiller content. Similar results were reported for PLA-biocomposite containing natural fillers such as coconut waste [

16] or kenaf fibers [

33], and such a drop could be ascribed to the low thermal stability of lignocellulosic biofillers. Indeed, the principal constituents of biomass are lignin, hemicellulose, and cellulose, and their onset thermal decomposition temperatures (

Td) are established around 160, 220, and 315 °C, respectively [

34]. Nevertheless, such a decrease in thermal stability should not compromise the use of these materials in 3D printing applications since thermal degradation does not significantly proceed in conditions close to 3D printing processing temperatures (up to 220–230 °C).

Moreover, TGA showed that PLA-RH biocomposites had almost twice as much residue under nitrogen atmosphere as compared to PLA-WM biocomposites (

Figure 2 and

Table 2), probably caused by the high silica content of RH biofiller. This assumption was confirmed by the residues in air (

Wr,air), wherein only inorganic compounds were gathered after burning all of the organic fractions (

Table 2), and values related to PLA-RH biocomposites were 4.5 times higher than those of analog formulations of PLA-WM biocomposites. Considering 16 wt.% silica content in RH powder, as previously discussed, the silica contents in biocomposite filaments containing 10 and 20 wt.% RH were expected to be 1.6 and 3.2 wt.%, respectively. Despite TGA characterizing only a very small amount of sample, in the order of a few mg, the obtained silica residues (

Table 2) accurately matched the theoretical expected values. Such a result, along with the small scatter in the data from samples taken in regions very far away from each other in the filaments, confirmed that the employed compounding process led to good homogeneity of biocomposite filaments.

The intrinsic thermal properties of all of the produced filaments were tested by DSC with two subsequent heating scans: in this context, the 2nd heating scan (

Figure 3) was used, with the aim of first erasing the thermal history imparted by the filament extrusion process. As reported in

Table 3, the thermal properties of PLA, i.e., the glass transition and melting temperatures, were preserved in the biocomposites after the addition of biofillers. Nevertheless, the nucleating effect of biofillers, already seen in the preliminary studies [

26], led to higher enthalpies of cold crystallization (Δ

Hcc) and the lowering of the relative peak temperature, from 128 °C for neat PLA down to 115–118 °C for biocomposite filaments (

Figure 3 and

Table 3). However, the crystallinity of all biocomposites was close to zero, which represents an advantage for FDM applications, since highly crystalline filaments could provoke feeding troubles due to their excessive brittleness.

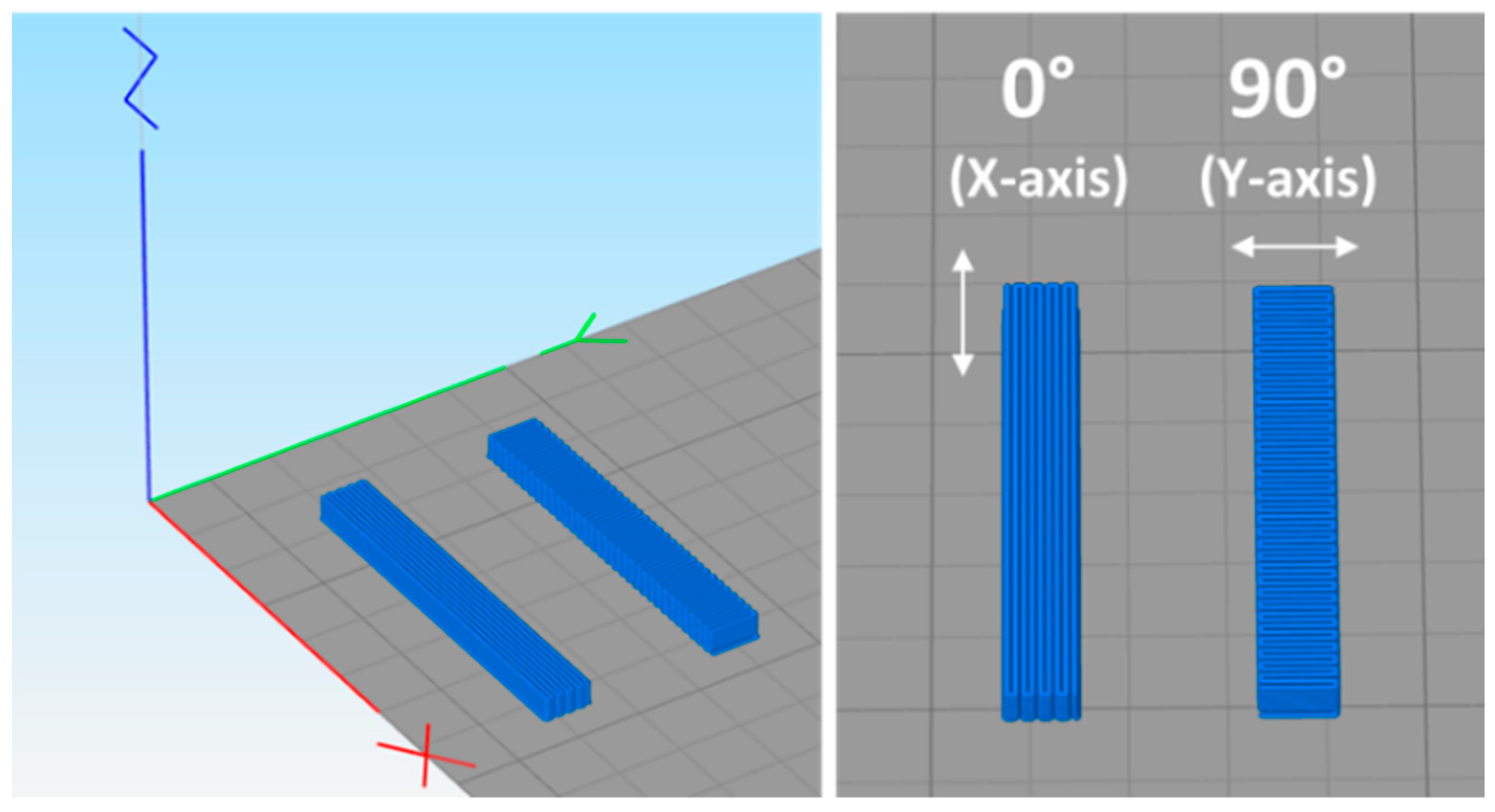

The obtained filaments were used to manufacture 3D-printed specimens for mechanical and thermomechanical characterizations, using a commercial 3D printer (

Figure 4A). In particular, bars were prepared for DMA and CLTE evaluation, instead, dogbone specimens (ASTM D638 Type V) were 3D printed to perform tensile tests (

Figure 4B,D). Tensile tests were performed using three different specimens for each formulation with three specific printing orientations along the

X-,

Y- and

Z-axes. The

X- and

Y-oriented specimens corresponded to 3D-printed samples with printing directions of 0° and 90° in the plane respectively, while

Z-axis specimens corresponded to vertically 3D-printed dogbone specimens.

Very thin samples (with a 2 layer height) were also collected for the specific heat capacity (

CP) measurements. Considering that

CP accounts for 1 K of energy required for 1 °C of temperature increase for 1 g of material, its determination on a double-layered sample is useful to understand the impact of the layered structure on such a property, which, in turn, affects interlayer heat transfer during the printing process and can be responsible for the temperature gradient and inhomogeneous cooling within the printed object. All in all, no excessive deviations in

CP value were detected in the studied composites. Since lignocellulosic materials are not typically highly thermally conductive [

29,

30,

33,

35,

36], the addition of 10 wt.% both WM and RH provoked a slight increase in

CP (

Table 3). However, when the biofiller content was raised to 20 wt.%, an opposite trend in the two biomasses was recorded: while WM led to a fairly higher

CP value, PLA-RH20 showed a lower

CP than the same composite with just 10 wt.% RH, with an overall negligible variation along the series. In this regard, investigation of higher RH content would be interesting to assess whether a further reduction in

CP would occur, possibly owing to the presence of silica in the filler, thus lowering the probability of incurring warping troubles.

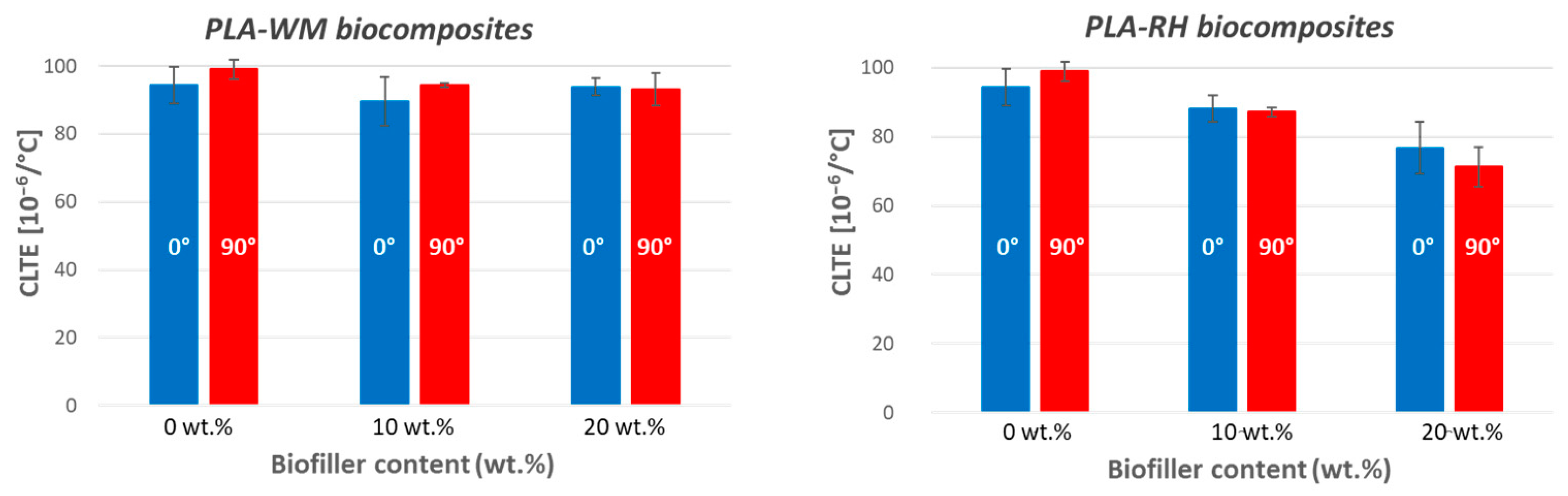

CLTE measurements are essential to assess the dimensional stability of 3D-printed samples and their tendency to warp during cooling. Indeed, a higher thermal expansion upon material heating entails a greater shrinkage upon cooling. In this context, CLTE values were calculated in the 10–50 °C range using samples produced with two filament deposition directions, namely 0° and 90° with respect to the assessment direction, as depicted in

Figure 5.

As reported in the literature, in most cases, the addition of biofillers decreases the shrinkage effect during 3D printing due to macromolecular mobility inhibition [

8]. An interesting point is that the 0° and 90° printing orientation results displayed a similar trend. The biocomposites with WM displayed only a slight decrease in CLTE, with a negligible effect of the filler content (

Figure 6). On the other hand, when RH was used, decreasing CLTE values were recorded for both

X- and

Y-printed samples. This effect increased with increasing biofiller fraction. Such a different behavior when using WM or RH was already evidenced in the

CP analysis. Such results could be ascribed to the presence of aggregates of biofillers, which formed at high WM concentration (20 wt.%). The resulting partial phase inhomogeneity did not allow for a strong reinforcing effect of WM toward PLA. The finer morphology of RH, instead, seemed to allow for a more homogeneous dispersion of the biofiller even when the RH concentration was 20 wt.%. In this way, RH biofiller positively impacted the thermal expansion of the biocomposite. Such results, along with the improved heat transfer properties reported in the

CP analysis (

Table 3), defined RH biomass as a promising biofiller for the prevention of some printing troubles, e.g., excessive shrinkage and warping.

DMA in tensile mode was used to evaluate the conservative modulus (

E′) of 3D-printed samples as a function of temperature. Specimens were 3D printed with a linear deposition pattern in the same direction as the applied force during the analysis (

X-axis direction), since in CLTE measurements no significant differences in trends were observed between

X- and

Y-deposited samples. The DMA spectra of all samples showed a single dissipative phenomenon ascribed to the

Tg of PLA (

Figure 7), after which the

E′ dropped to very low values since samples were left almost totally amorphous, as revealed by the DSC analysis (

Table 3).

It is worth noting that the addition of 10 wt.% WM did not provide a significant effect on the storage modulus, giving results comparable to those of neat PLA (

Table 4), whereas the addition of twice the WM amount (PLA-WM20) led to some decrease in the mechanical performance. Such a behavior was already tentatively hypothesized within the CLTE measurements, wherein 20 wt.% WM filling hinted at agglomerate formation. The effect of RH led to a similar behavior at the lowest load (PLA-RH10), where no significant mechanical improvement was detected, while on the other hand, 20 wt.% RH significantly boosted the conservative modulus of the biocomposite.

Finally, the mechanical properties were investigated by tensile tests using three different classes of specimens designed with the slicing software (Simplify3D V 5.0) and produced by growing the dogbone specimens along the three axes of the building platform (

Figure 8) with 100% infill. In this regard, no actual perimeter was applied in the necked section of the dogbone to avoid influences on the stress/strain measurements. Hence, the printing direction was maintained on the

X-axis for all specimens, while the testing direction varied according to the building orientation of the specimens, namely the

X-,

Y- and

Z-axes, as depicted in

Figure 8. During the deposition, the filament orientation was inverted at each layer by 180°. As

X-axis specimens were made of extruded filaments (beads) parallelly disposed to the testing direction,

X-specimens were helpful to evaluate the tensile properties of biocomposites;

Y- and

Z-specimens, instead, were produced for evaluating the extent of the interbead and interlayer adhesion, respectively. Indeed,

Y-specimens were tested on the in-plane orthogonal direction (

Y-axis) with respect to the bead deposition (

X-axis). In this regard, we referred to the “bead” as the main filament section after deposition. Such a feature implied the load application on the interbead surface, and, consequently, the maximal stress achieved during the tensile test outlined the interbead adhesion. Similarly,

Z-specimens were vertically manufactured and thus their characterization involved the load application on the orthogonal axis to the

X–Y plane. In this way, interfaces between layers were forced and the ultimate strength reached during the analysis defined the interlayer strength or adhesion. All of the evaluated mechanical properties are summarized in

Figure 9.

Considering the in-plane mechanical properties of 3D-printed biocomposites (X- and Y-specimens), the addition of WM led to a slight decrease in the elastic modulus with a concurrent drop in UTS and embrittlement with smaller elongation at break (εbreak). These observations substantially confirmed the previously discussed data, wherein wheat middlings seemed to hardly homogenize with PLA, with a possible lack of adhesion between the biofiller and matrix that did not allow for proper load transfer between the two phases. Such an observation suggests that a surface treatment would probably be required to make the biofiller compatible with the thermoplastic matrix. RH, instead, led to some better moduli, strengthening the material, in particular when the X-printed sample was analyzed. Indeed, DMA tests were run in the very same specimen configuration. Concurring with the WM results, however, and as expected in the presence of a filler, both UTS and εbreak dropped, with a behavior similar to WM-modified samples. All test results of Y-specimen biocomposites showed reductions in σmax and εbreak with biofiller content, thus indicating a decrease in the interbead strength. Such a behavior seemed to suggest that the presence of biofillers hampered the macromolecular diffusion across the bead interface, thus leading to lower bead welding during 3D printing.

The interlayer adhesion was evaluated by tensile tests on

Z-specimens. As shown in

Figure 9, all of the samples, even neat PLA, displayed overall lower mechanical properties with respect to the in-plane specimens (

X- and

Y-printed), while only the elastic modulus was reported to be similar to that of

Y-printed samples. These characteristics suggested the

Z-axis being the weak direction of the 3D-printed part. Such a behavior is already reported in literature [

37], ascribed to the lowered diffusion of polymeric chains caused by the presence of a heterogeneous agent onto the layer–layer interface, and was already partially highlighted in the

Y-direction (see similarities in the elastic modulus). This phenomenon was more evident with RH addition, which led to a more significant drop in ultimate stress, namely the interlayer strength, with respect to neat PLA (

Figure 9B). WM biocomposites, instead, displayed interlayer strength values fairly close to the unfilled material. As a final result, the time in which the superficial section of the layer was in the molten state was fairly short, thus not achieving the optimal interlayer diffusion of macromolecules.

In terms of absolute performance, it is not an easy task to compare such results with other corresponding products owing to the limited literature and the fact that agro-wastes can be profoundly different and often details on their characterization and even simply dimensions are lacking. As a matter of fact, the use of agro-wastes, without any further modification, is significantly affected by the quality, type, and region of sourcing of the wastes themselves. A recent review paper [

38] put forward a systematic approach for being able to compare many different products in AM starting from agro-wastes. Even in the review, only 57 papers were considered encompassing all of the areas of biomasses (fisheries, forests, as well as agriculture). Concerning wheat middlings, no reference other than the authors’ previously published note was considered, while for rice residues, only rice straw or rice husks isolated fibers were used, but with polypropylene as a polymeric matrix. The presently obtained results, however, encourage the future investigation of such an approach, possibly suggesting superficial treatment of biofillers or the employment of compatibilizers in order to enhance the filler/matrix adhesion and reach the maximum attainable mechanical properties.

A preliminary market survey shows, nonetheless, that wheat middlings and rice husks are currently listed on the Italian national market at a few Euro cents per kilo, i.e., 0.20–0.30 €/kg [

39]. From an economic analysis, the authors determined that the cost of the operations necessary to select and mill these natural materials and to extrude filaments of biocomposite PLA-organic material can be obtained in a range from 3 to 5 € per kilo of extruded filament. Thus, the reduction of the cost of the whole material for printing, for example for filaments containing 20 wt.% WM, could be estimated in a range from 15% to 17%, with respect to the cost of neat PLA.