Localised Electrochemical Impedance Spectroscopy of Gold Nanoparticles Labelled Antibodies Probed by Platinum Microstructured Ultramicroelectrode

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Antibody Immobilization

2.3. Measurements

2.4. Ultramicroelectrode Modification

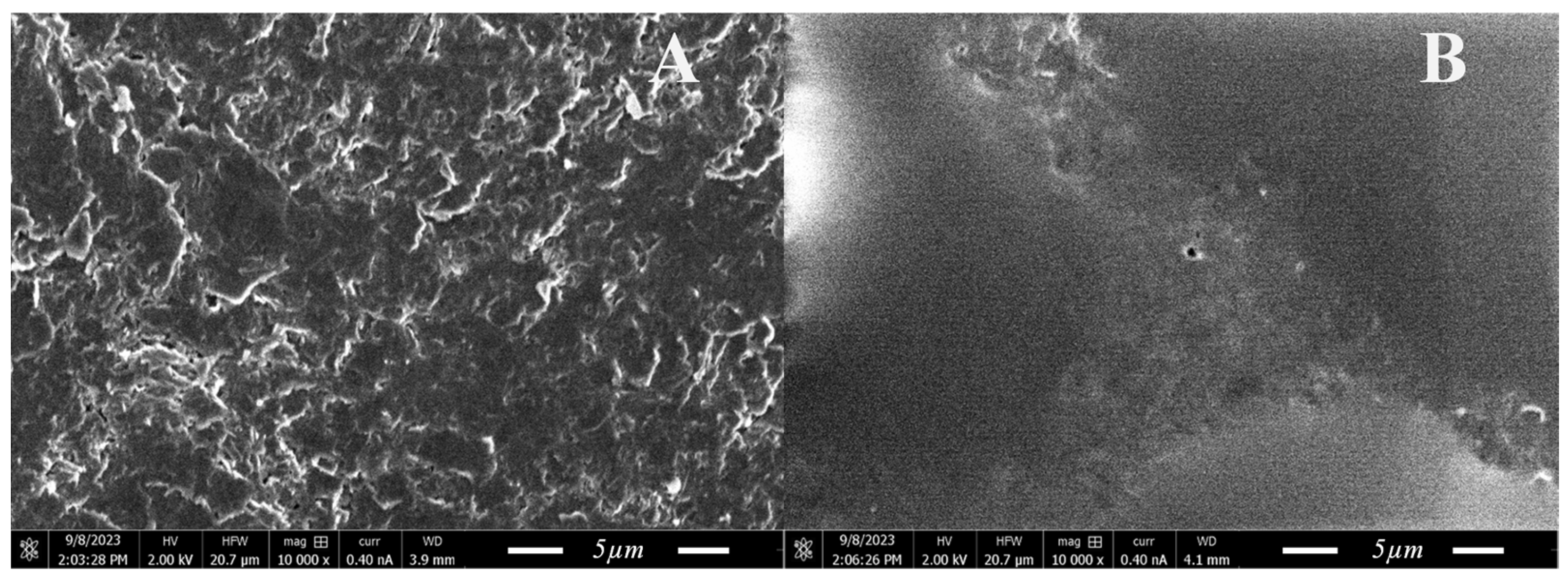

2.5. Scanning Electron Microscopy Analysis

3. Results

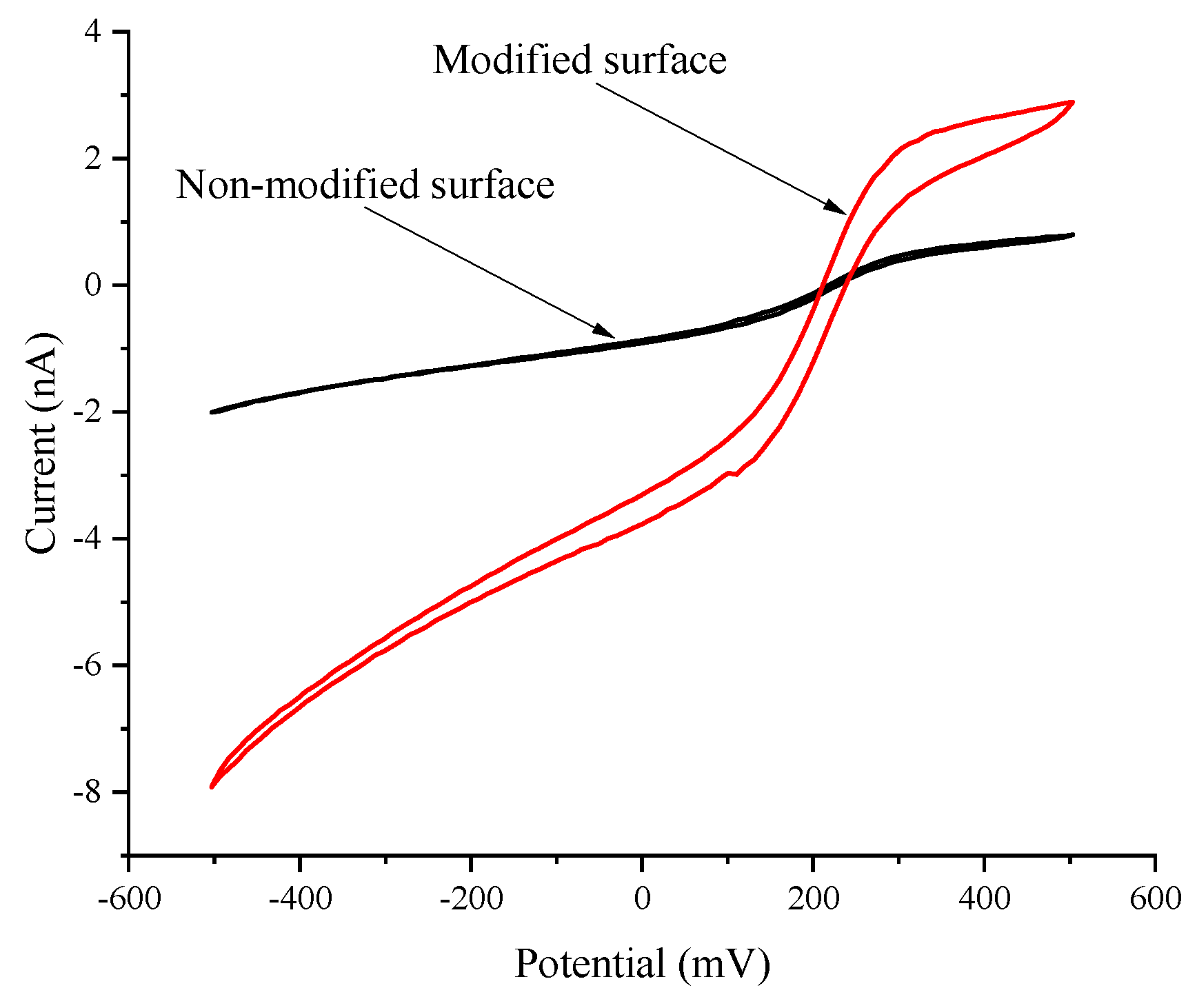

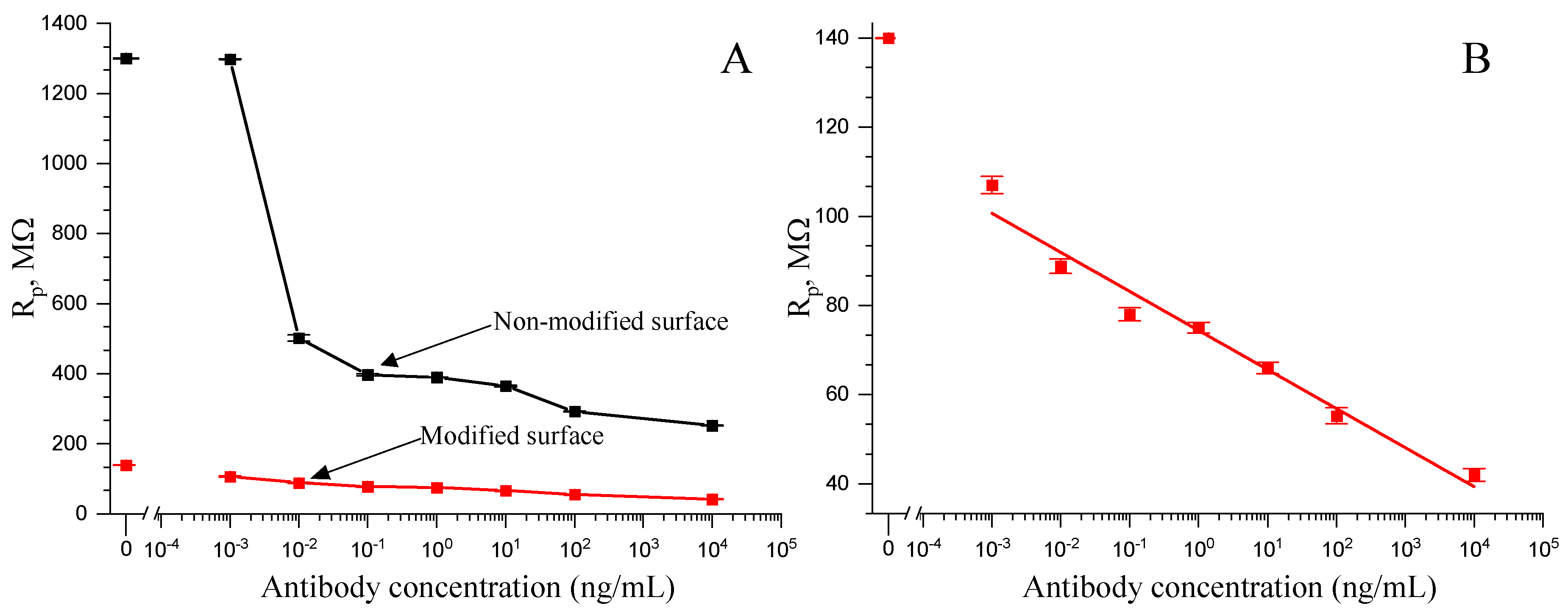

3.1. Ultramicroelectrode Comparison

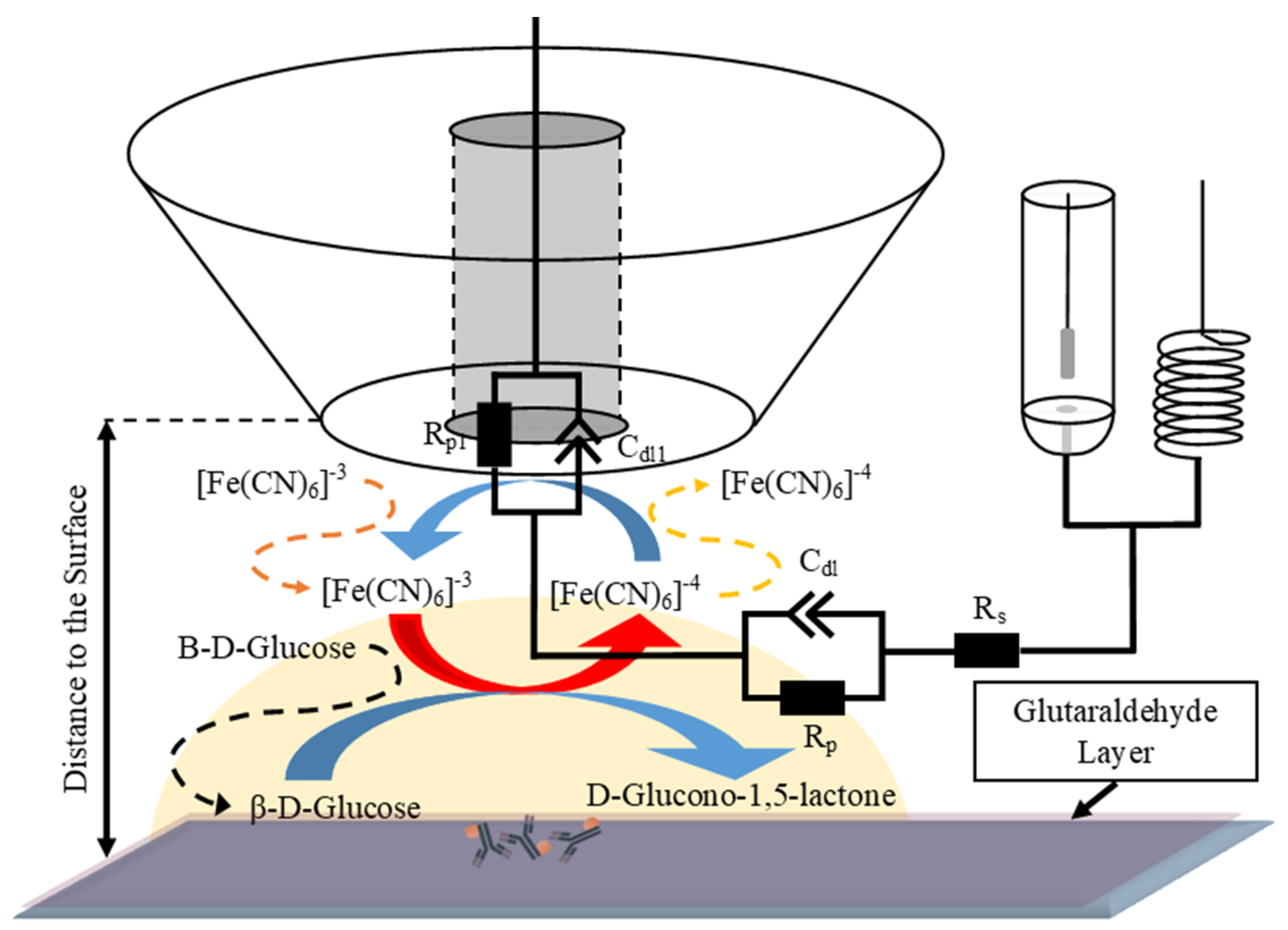

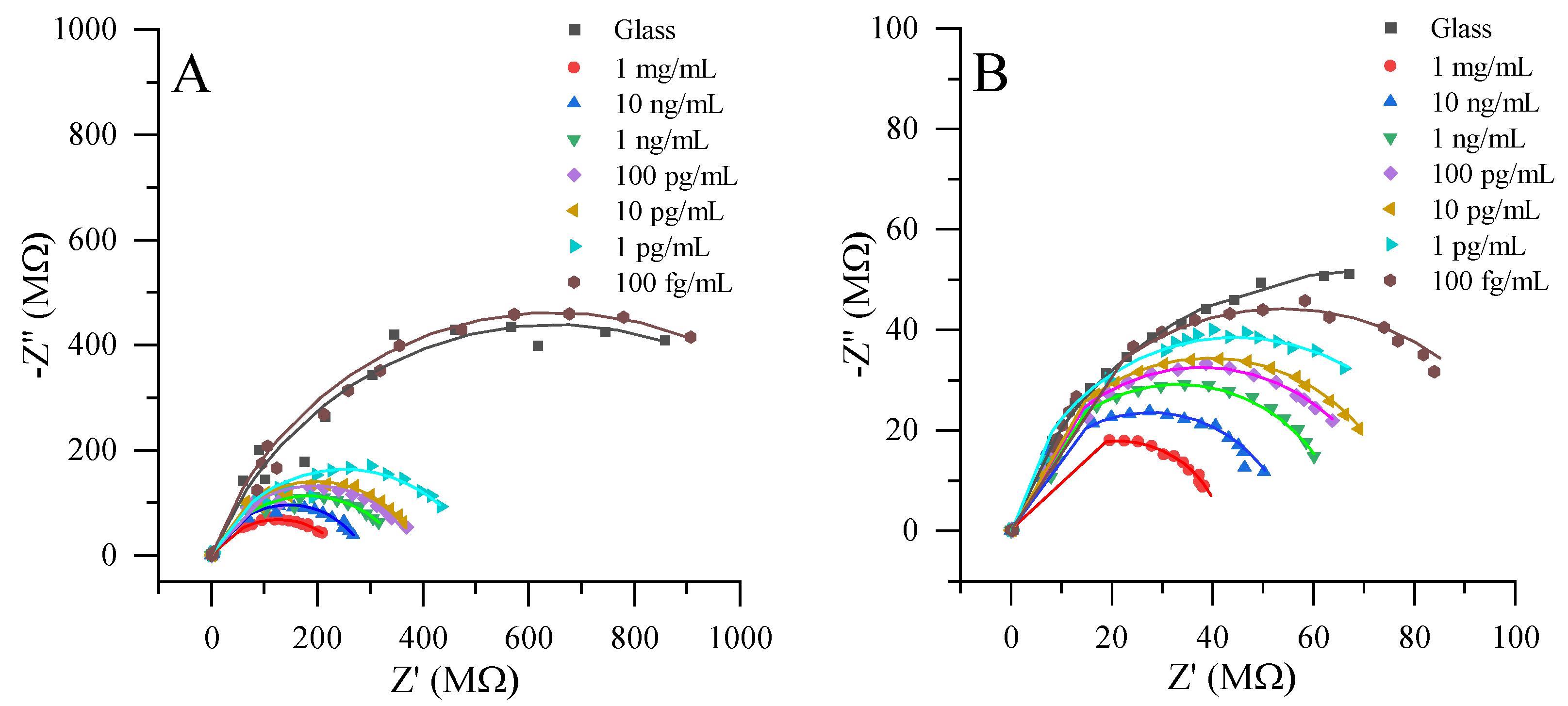

3.2. Local Electrochemical Impedance Measurement

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Manasa, G.; Mascarenhas, R.J.; Malode, S.J.; Shetti, N.P. Graphene-based electrochemical immunosensors for early detection of oncomarker carcinoembryonic antigen. Biosens. Bioelectron. X 2022, 11, 100189. [Google Scholar] [CrossRef]

- An, Y.; Song, L.; Chen, X.; Ni, C.; Mao, K.; Zhu, L.; Gu, Y.; Miao, Y.; Song, B.; Ma, H. 3D Biomimetic Hydrangea-Like BiOCl and PtNi Nanocube-Based Electrochemical Immunosensor for Quantitative Detection of CA19–9. J. Electrochem. Soc. 2022, 169, 056520. [Google Scholar] [CrossRef]

- Halima, H.B.; Zine, N.; Nemeir, I.A.; Pfeiffer, N.; Heuberger, A.; Bausells, J.; Elaissari, A.; Jaffrezic-Renault, N.; Errachid, A. An ImmunoFET Coupled with an Immunomagnetic Preconcentration Technique for the Sensitive EIS Detection of HF Biomarkers. Micromachine 2024, 15, 296. [Google Scholar] [CrossRef]

- Liao, R. Recent progress in electrochemical immunosensors for SARS-CoV-2 detection. J. Phys. Conf. Ser. 2023, 2608, 012040. [Google Scholar] [CrossRef]

- Sharma, A.; Angnes, L.; Sattarahmady, N.; Negahdary, M.; Heli, H. Electrochemical Immunosensors Developed for Amyloid-Beta and Tau Proteins, Leading Biomarkers of Alzheimer’s Disease. Biosensors 2023, 13, 742. [Google Scholar] [CrossRef]

- Tortolini, C.; Gigli, V.; Angeloni, A.; Galantini, L.; Tasca, F.; Antiochia, R. Disposable Voltammetric Immunosensor for D-Dimer Detection as Early Biomarker of Thromboembolic Disease and of COVID-19 Prognosis. Biosensors 2023, 13, 43. [Google Scholar] [CrossRef] [PubMed]

- Felemban, S.; Vazquez, P.; Balbaied, T.; Moore, E. Lab-on-a-Chip Electrochemical Immunosensor Array Integrated with Microfluidics: Development and Characterisation. Electrochem 2022, 3, 570–580. [Google Scholar] [CrossRef]

- Lobnik, A.; Turel, M.; Urek, Š.K.; Košak, A. Nanostructured materials use in sensors: Their benefits and drawbacks. Adv. Struct. Mater. 2011, 5, 307–354. [Google Scholar] [CrossRef]

- Joudeh, N.; Linke, D. Nanoparticle classification, physicochemical properties, characterization, and applications: A comprehensive review for biologists. J. Nanobiotechnol. 2022, 20, 1–29. [Google Scholar] [CrossRef]

- Pan, M.; Gu, Y.; Yun, Y.; Li, M.; Jin, X.; Wang, S. Nanomaterials for electrochemical immunosensing. Sensors 2017, 17, 1041. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, X.; Li, D.; Wei, Q. A laccase based biosensor on AuNPs-MoS2 modified glassy carbon electrode for catechol detection. Colloids Surf. B Biointerfaces 2020, 186, 110683. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Ma, Q.; Li, M.; Chao, D.; Huang, L.; Wu, W.; Fang, Y.; Dong, S. Glucose-oxidase like catalytic mechanism of noble metal nanozymes. Nat. Commun. 2021, 12, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Zhang, J.; Huang, R.; Wang, D.; Deng, D.; Zhang, Q.; Luo, L. The Applications of Electrochemical Immunosensors in the Detection of Disease Biomarkers: A Review. Molecules 2023, 28, 3605. [Google Scholar] [CrossRef] [PubMed]

- Morkvenaite-Vilkonciene, I.; Kisieliute, A.; Nogala, W.; Popov, A.; Brasiunas, B.; Kamarauskas, M.; Ramanavicius, A.; Linfield, S.; Ramanaviciene, A. Scanning electrochemical microscopy: Glucose oxidase as an electrochemical label in sandwich format immunoassay. Electrochim. Acta 2023, 463, 142790. [Google Scholar] [CrossRef]

- Drobysh, M.; Liustrovaite, V.; Baradoke, A.; Rucinskiene, A.; Ramanaviciene, A.; Ratautaite, V.; Viter, R.; Chen, C.F.; Plikusiene, I.; Samukaite-bubniene, U.; et al. Electrochemical Determination of Interaction between SARS-CoV-2 Spike Protein and Specific Antibodies. Int. J. Mol. Sci. 2022, 23, 6768. [Google Scholar] [CrossRef] [PubMed]

- Kongkaew, S.; Cotchim, S.; Kanatharana, P.; Thavarungkul, P.; Limbut, W. Disposable label-free electrochemical immunosensor based on prussian blue nanocubes for four breast cancer tumor markers. Talanta 2023, 255, 124229. [Google Scholar] [CrossRef] [PubMed]

- Carneiro, P.; Loureiro, J.A.; Delerue-Matos, C.; Morais, S.; Pereira, M. do C. Nanostructured label–free electrochemical immunosensor for detection of a Parkinson’s disease biomarker. Talanta 2022, 252, 123838. [Google Scholar] [CrossRef] [PubMed]

- Drobysh, M.; Liustrovaite, V.; Kanetski, Y.; Brasiunas, B.; Zvirbliene, A.; Rimkute, A.; Gudas, D.; Kucinskaite-Kodze, I.; Simanavicius, M.; Ramanavicius, S.; et al. Electrochemical biosensing based comparative study of monoclonal antibodies against SARS-CoV-2 nucleocapsid protein. Sci. Total Environ. 2024, 908, 168154. [Google Scholar] [CrossRef]

- Aydın, E.B.; Aydın, M.; Sezgintürk, M.K. A novel electrochemical impedance immunosensor for the quantification of CYFRA 21-1 in human serum. Microchim. Acta 2023, 190, 1–13. [Google Scholar] [CrossRef]

- Shoute, L.C.T.; Abdelrasoul, G.N.; Ma, Y.; Duarte, P.A.; Edwards, C.; Zhuo, R.; Zeng, J.; Feng, Y.; Charlton, C.L.; Kanji, J.N.; et al. Label-free impedimetric immunosensor for point-of-care detection of COVID-19 antibodies. Microsyst. Nanoeng. 2023, 9, 3. [Google Scholar] [CrossRef]

- Ullah, S.F.; Moreira, G.; Datta, S.P.A.; McLamore, E.; Vanegas, D. An Experimental Framework for Developing Point-of-Need Biosensors: Connecting Bio-Layer Interferometry and Electrochemical Impedance Spectroscopy. Biosensors 2022, 12, 938. [Google Scholar] [CrossRef] [PubMed]

- Manshadi, M.K.D.; Mansoorifar, A.; Chiao, J.C.; Beskok, A. Impedance-Based Neutralizing Antibody Detection Biosensor with Application in SARS-CoV-2 Infection. Anal. Chem. 2023, 95, 836–845. [Google Scholar] [CrossRef] [PubMed]

- Bard, A.J.; Mirkin, M.V.; Unwin, P.R.; Wipf, D. Scanning Electrochemical Microscopy. 12. Theory and Experiment of the Feedback Mode with Finite Heterogeneous Electron-Transfer Kinetics and Arbitrary Substrate Size. J. Phys. Chem. 1992, 96, 1861–1868. [Google Scholar] [CrossRef]

- Traxler, I.; Singewald, T.D.; Schimo-Aichhorn, G.; Hild, S.; Valtiner, M. Scanning electrochemical microscopy methods (SECM) and ion-selective microelectrodes for corrosion studies. Corros. Rev. 2022, 40, 515–542. [Google Scholar] [CrossRef]

- Nasri, Z.; Memari, S.; Striesow, J.; Weltmann, K.D.; von Woedtke, T.; Wende, K. Application of scanning electrochemical microscopy for topography imaging of supported lipid bilayers. Anal. Methods 2022, 14, 1077–1082. [Google Scholar] [CrossRef] [PubMed]

- Morkvenaite-Vilkonciene, I.; Genys, P.; Ramanaviciene, A.; Ramanavicius, A. Scanning electrochemical impedance microscopy for investigation of glucose oxidase catalyzed reaction. Colloids Surf. B Biointerfaces 2015, 126, 598–602. [Google Scholar] [CrossRef] [PubMed]

- Ballesteros Katemann, B.; Schulte, A.; Calvo, E.J.; Koudelka-Hep, M.; Schuhmann, W. Localised electrochemical impedance spectroscopy with high lateral resolution by means of alternating current scanning electrochemical microscopy. Electrochem. Commun. 2002, 4, 134–138. [Google Scholar] [CrossRef]

- Zinovicius, A.; Morkvenaite-Vilkonciene, I.; Ramanaviciene, A.; Rozene, J.; Popov, A.; Ramanavicius, A. Scanning electrochemical impedance microscopy in redox-competition mode for the investigation of antibodies labelled with horseradish peroxidase. Materials 2021, 14, 4301. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, J.; Gharbi, O.; Vivier, V.; Gao, M.; Orazem, M.E. Electrochemical impedance spectroscopy. Nat. Rev. Methods Prim. 2021, 1, 41. [Google Scholar] [CrossRef]

- El Alami El Hassani, N.; Baraket, A.; Boudjaoui, S.; Taveira Tenório Neto, E.; Bausells, J.; El Bari, N.; Bouchikhi, B.; Elaissari, A.; Errachid, A.; Zine, N. Development and application of a novel electrochemical immunosensor for tetracycline screening in honey using a fully integrated electrochemical Bio-MEMS. Biosens. Bioelectron. 2019, 130, 330–337. [Google Scholar] [CrossRef]

- Shaikh, M.O.; Zhu, P.Y.; Wang, C.C.; Du, Y.C.; Chuang, C.H. Electrochemical immunosensor utilizing electrodeposited Au nanocrystals and dielectrophoretically trapped PS/Ag/ab-HSA nanoprobes for detection of microalbuminuria at point of care. Biosens. Bioelectron. 2019, 126, 572–580. [Google Scholar] [CrossRef] [PubMed]

- Nawaz, M.H.; Hayat, A.; Catanante, G.; Latif, U.; Marty, J.L. Development of a portable and disposable NS1 based electrochemical immunosensor for early diagnosis of dengue virus. Anal. Chim. Acta 2018, 1026, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Hosu, O.; Tertiș, M.; Melinte, G.; Feier, B.; Săndulescu, R.; Cristea, C. Mucin 4 detection with a label-free electrochemical immunosensor. Electrochem. Commun. 2017, 80, 39–43. [Google Scholar] [CrossRef]

- Freitas, M.; Correr, W.; Cancino-Bernardi, J.; Barroso, M.F.; Delerue-Matos, C.; Zucolotto, V. Impedimetric immunosensors for the detection of Cry1Ab protein from genetically modified maize seeds. Sens. Actuators B Chem. 2016, 237, 702–709. [Google Scholar] [CrossRef]

- Chen, L.; Jiang, J.; Shen, G.; Yu, R. A label-free electrochemical impedance immunosensor for the sensitive detection of aflatoxin B1. Anal. Methods 2015, 7, 2354–2359. [Google Scholar] [CrossRef]

- Jin, W.; Yang, G.; Shao, H.; Qin, A. A label-free impedimetric immunosensor for detection of 1-aminohydantoin residue in food samples based on sol-gel embedding antibody. Food Control 2014, 39, 185–191. [Google Scholar] [CrossRef]

| Analyte | Used Electrode | Linear Range | LOD | Analysis Time, min | Ref. |

|---|---|---|---|---|---|

| Human IgG | platinum-based UME modified with platinum microstructures | 0.001–103 ng/mL | 0.001 ng/mL | 20 | This research |

| Tetracycline | eight gold microelectrodes functionalised with 4-aminophenylacetic acid, the structure of magnetic nanoparticles coated with poly (pyrrole-co-pyrrole-2-carboxylic acid and crosslinked with specific polyclonal antibody for tetracycline | 0.0001–1 ng/mL | 0.0012 ng/mL | 60 | [30] |

| Microalbuminuria | carbon interdigitated microelectrode modified with gold nanocrystals with trapped nanoprobes (polystyrene nanoparticle core with silver nano-shells covalently conjugated to HSA antibodies) | 30–300 μg/mL | 30 μg/mL | - | [31] |

| Dengue virus | screen-printed carbon electrodes coated with oxidised bovine serum albumen and functionalised by anti-non-structural monoclonal antibodies | 1–200 ng/mL | 0.3 ng/mL | 30 | [32] |

| Mucin 4 | carbon-based screen-printed electrode functionalised with phenylacetic acid with immobilised human partial recombinant MUC4 protein and mouse monoclonal antibody | 1–15 μg/mL | 0.33 μg/mL | 30 | [33] |

| Cry1Ab | indium tin oxide electrodes modified by 3-aminopropyltrimethoxysilane monolayer with covalently immobilised Anti-Cry1Ab polyclonal antibodies | 1–10 ng/mL | 0.37 ng/mL | 60 | [34] |

| Aflatoxin B1 | gold electrode modified by 1,6-hexanedithiol and coated with gold nanoparticles and functionalised with Aflatoxin B1-bovine serum albumin (BSA) | 0.08–100 ng/mL | 0.05 ng/mL | 50 | [35] |

| 1-Aminohydantoin | glassy carbon electrode modified with sol-gel-monoclonal anti-body against 1-Aminohydantoin | 2–103 ng/mL | 2 ng/mL | 160 | [36] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zinovicius, A.; Morkvenaite-Vilkonciene, I.; Ramanavicius, A. Localised Electrochemical Impedance Spectroscopy of Gold Nanoparticles Labelled Antibodies Probed by Platinum Microstructured Ultramicroelectrode. Materials 2024, 17, 1339. https://doi.org/10.3390/ma17061339

Zinovicius A, Morkvenaite-Vilkonciene I, Ramanavicius A. Localised Electrochemical Impedance Spectroscopy of Gold Nanoparticles Labelled Antibodies Probed by Platinum Microstructured Ultramicroelectrode. Materials. 2024; 17(6):1339. https://doi.org/10.3390/ma17061339

Chicago/Turabian StyleZinovicius, Antanas, Inga Morkvenaite-Vilkonciene, and Arunas Ramanavicius. 2024. "Localised Electrochemical Impedance Spectroscopy of Gold Nanoparticles Labelled Antibodies Probed by Platinum Microstructured Ultramicroelectrode" Materials 17, no. 6: 1339. https://doi.org/10.3390/ma17061339