High-Temperature Reactive Wetting of Natural Quartz by Liquid Magnesium

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

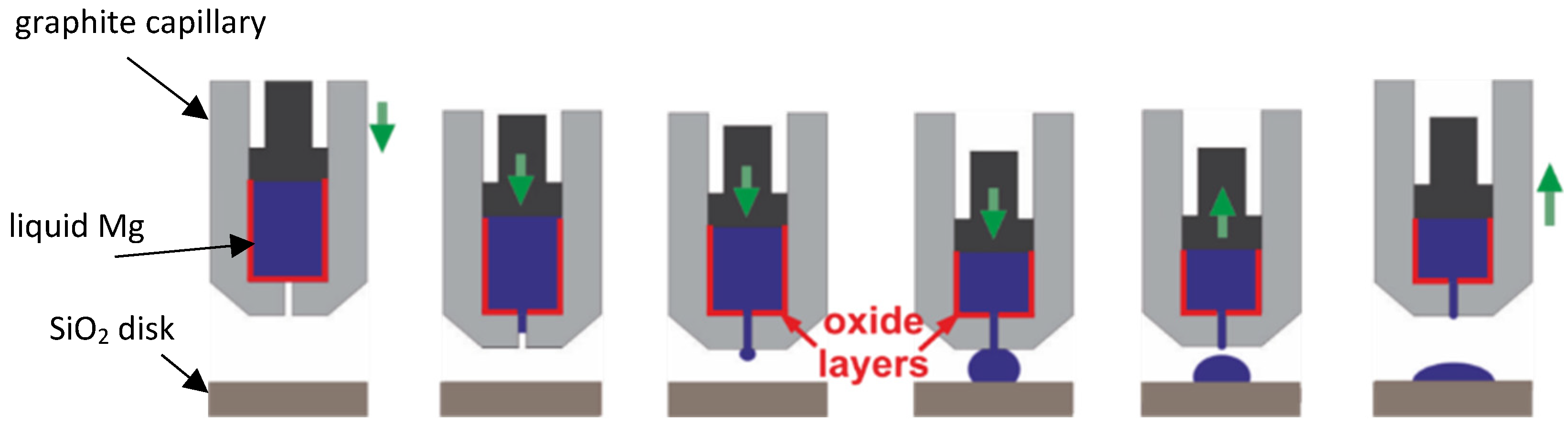

2.2. Procedure

2.3. Product Characterization

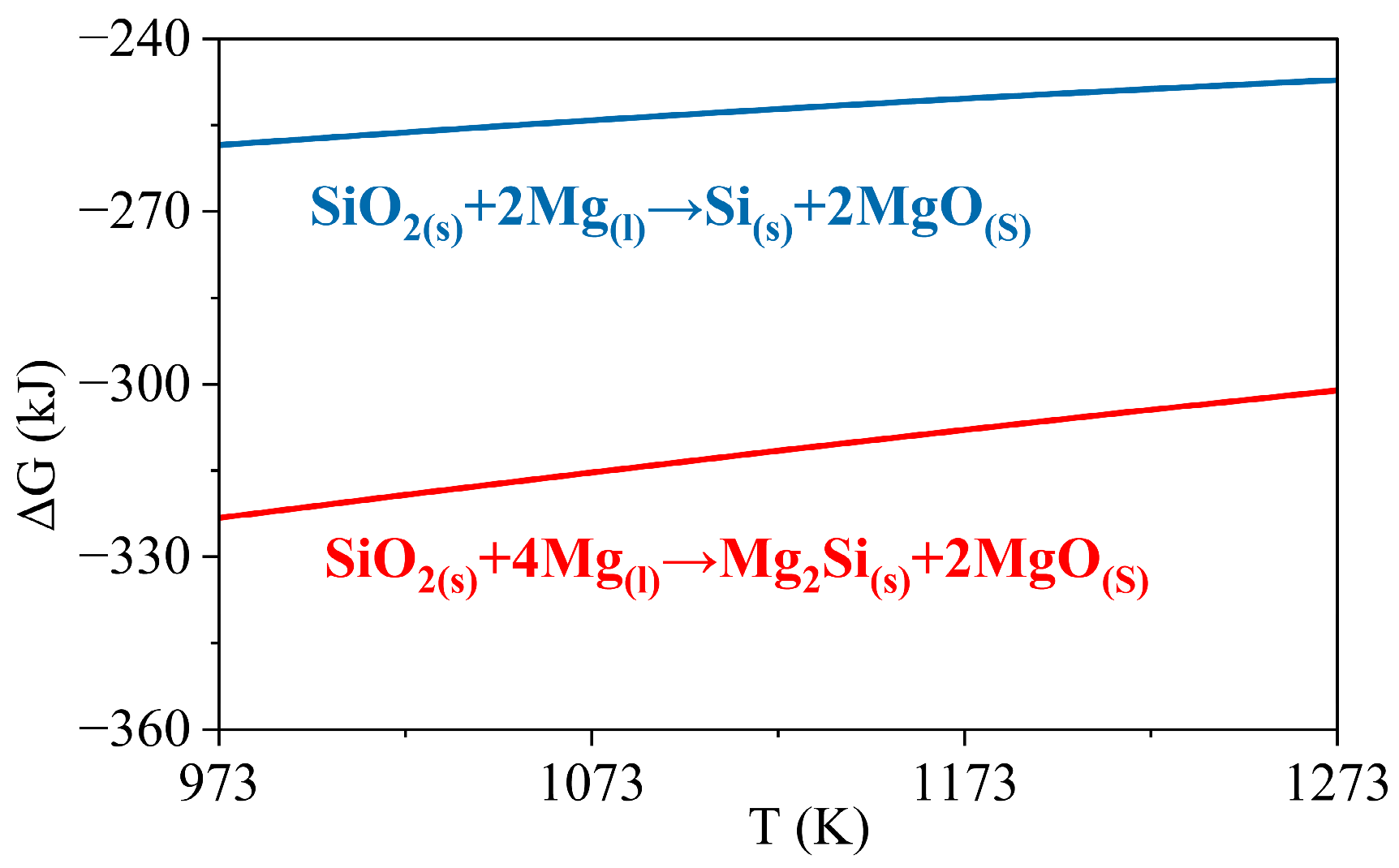

3. Results and Discussion

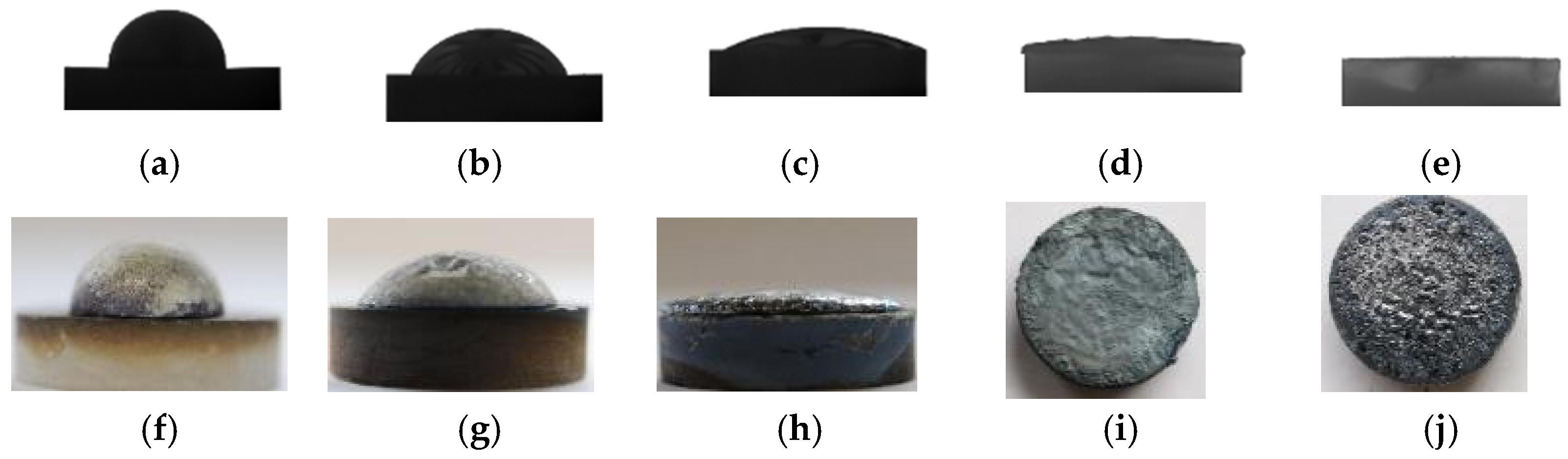

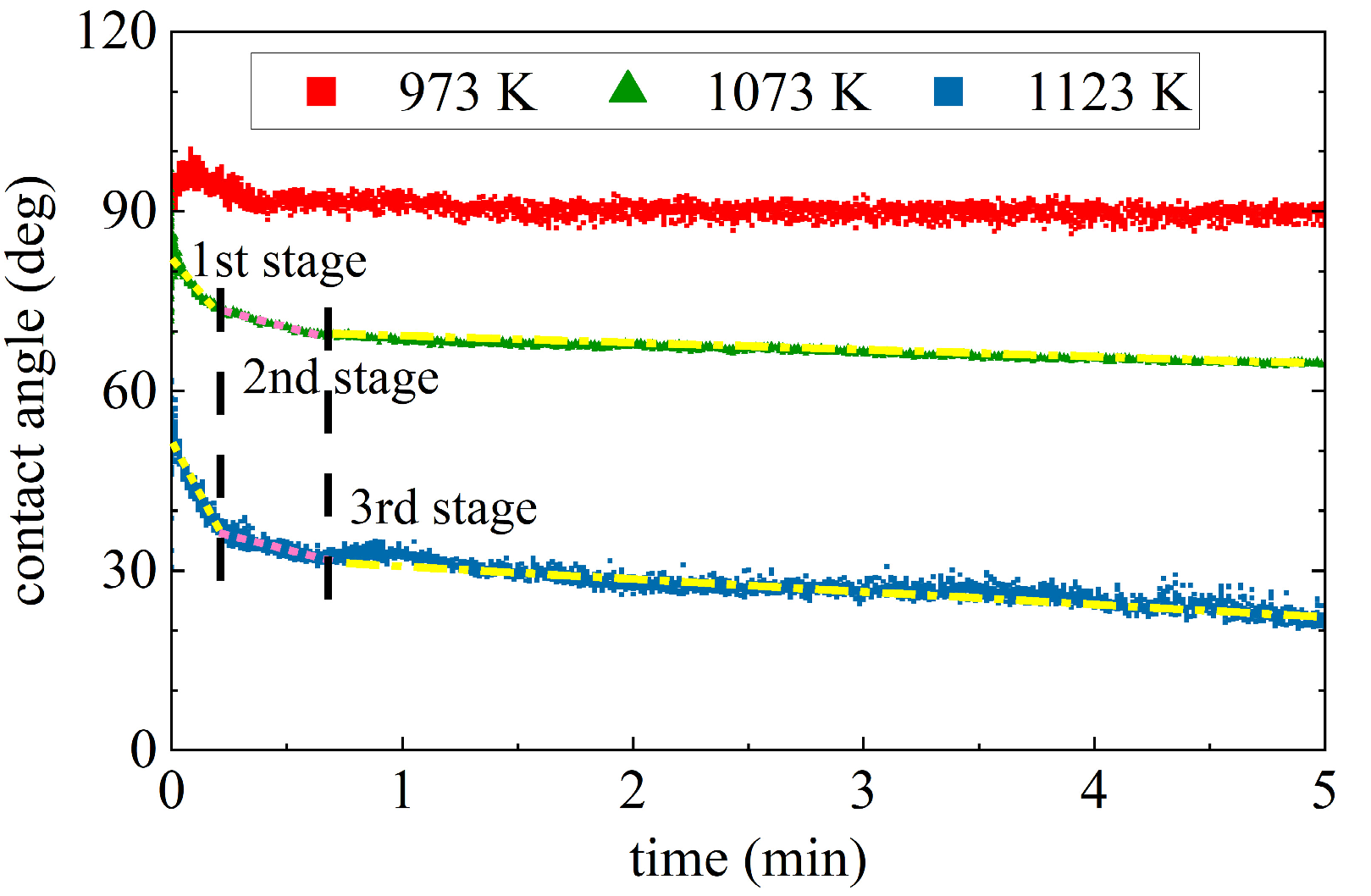

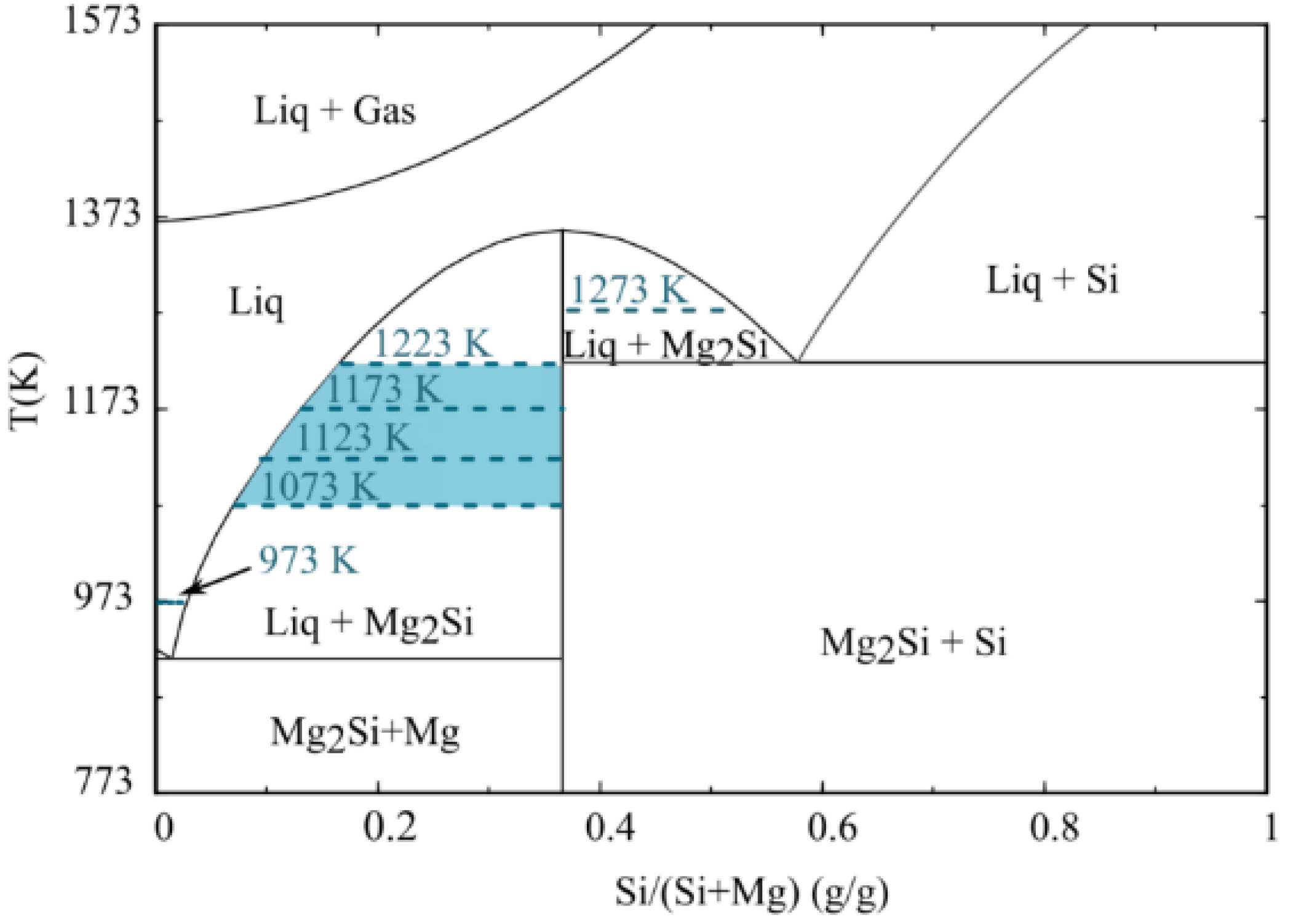

3.1. Wetting Behavior

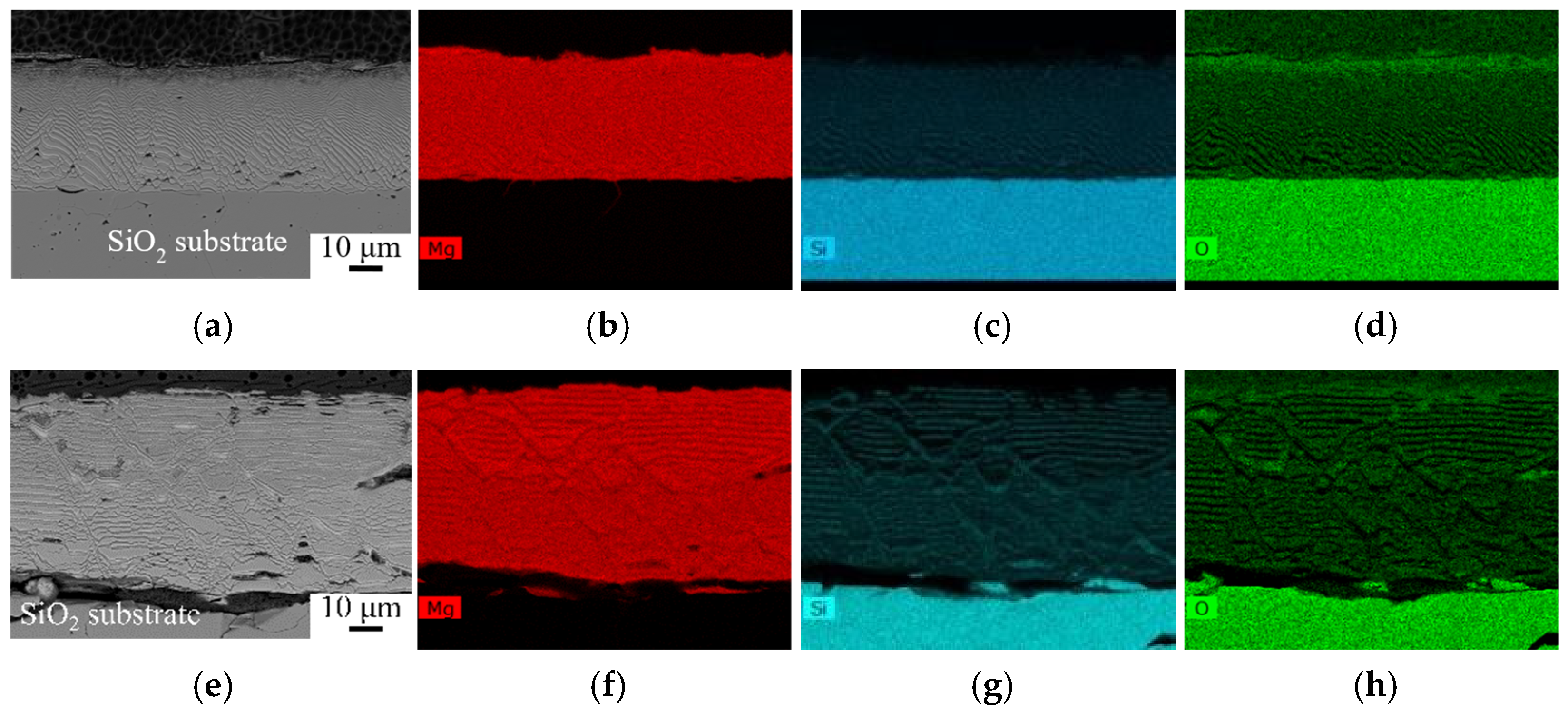

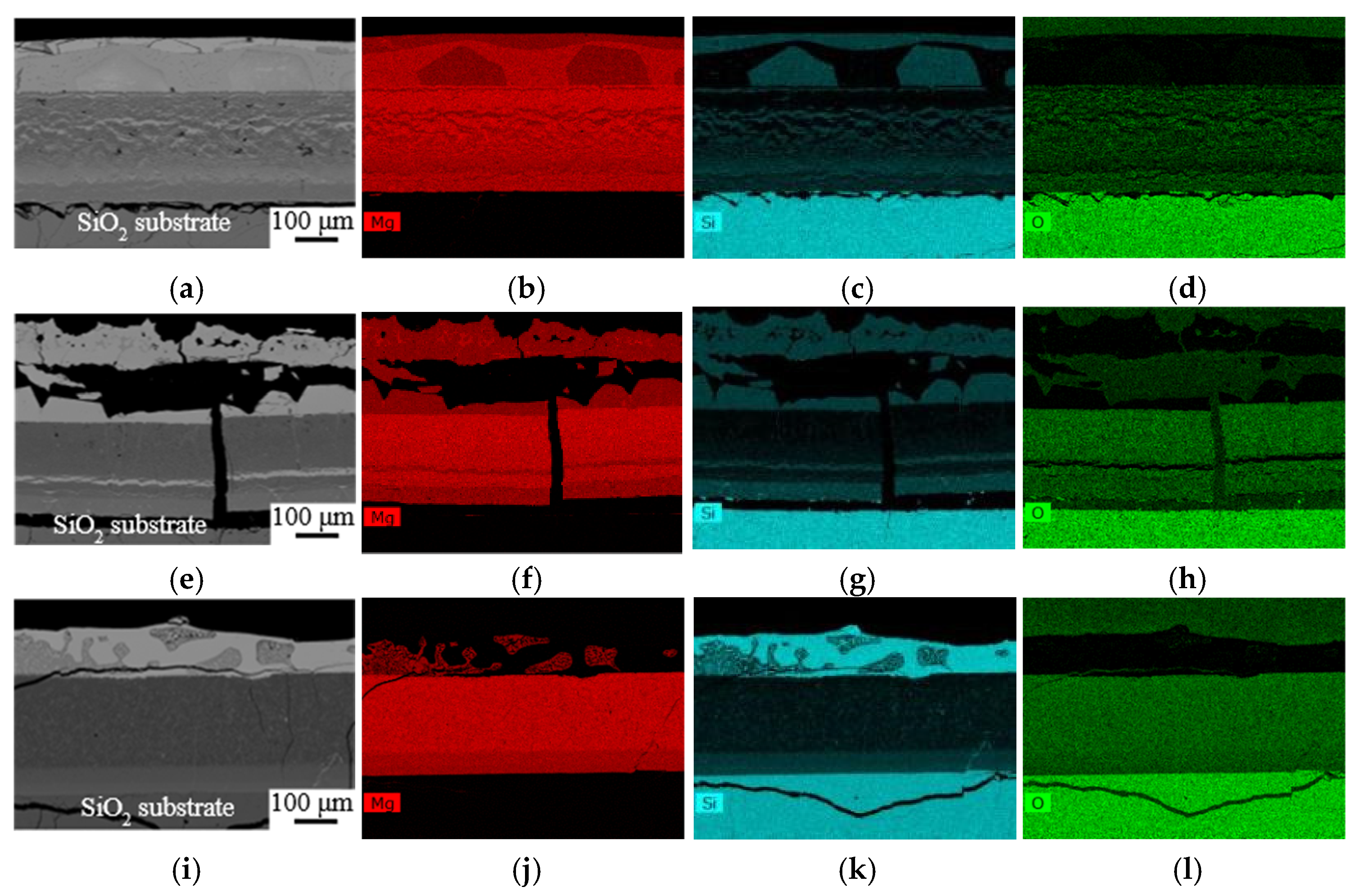

3.2. Microstructure Evaluation of the SiO2/Mg Interface

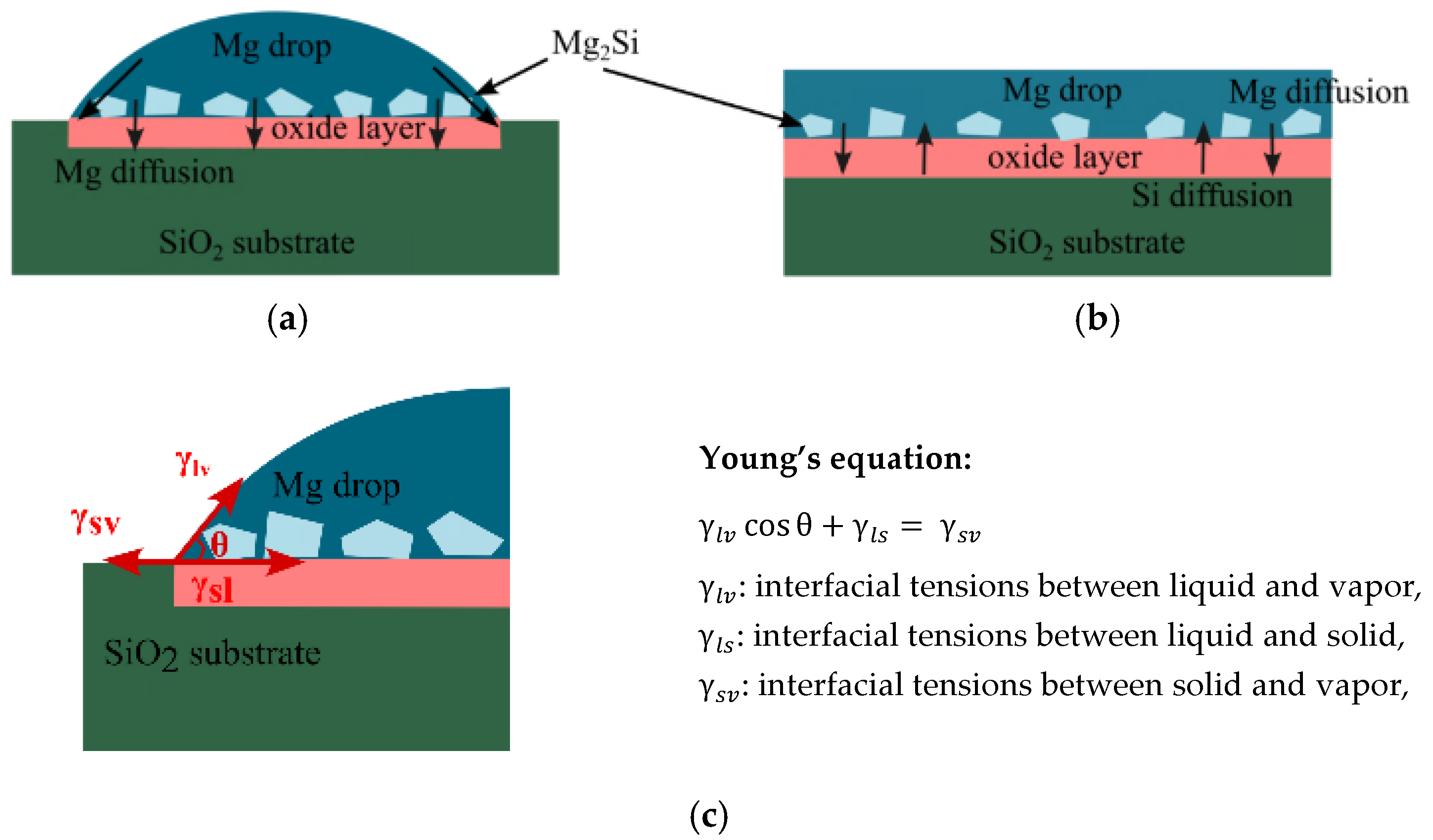

3.3. Wetting Mechanism

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tranell, G.; Wallin, M.; Safarian, J. SisAl-A New Process for Production of Silicon. In Proceedings of the Silicon for the Chemical and Solar Industry XV, Trondheim, Norway, 15–18 June 2020. [Google Scholar]

- Barati, M.; Sarder, S.; Mclean, A.; Roy, R. Recovery of Silicon from Silica Fume. J. Non-Cryst. Solids 2011, 357, 18–23. [Google Scholar] [CrossRef]

- Larbi, K.K.; Roy, R.; Barati, M.; Lakshmanan, V.I.; Sridhar, R.; McLean, A. Use of Rice Husk for Emission Neutral Energy Generation and Synthesis of Solar-Grade Silicon Feedstock. Biomass Convers. Biorefinery 2012, 2, 149–157. [Google Scholar] [CrossRef]

- Banerjee, H.D.; Sen, S.; Acharya, H.N. Investigations on the Production of Silicon from Rice Husks by the Magnesium Method. Mater. Sci. Eng. 1982, 52, 173–179. [Google Scholar] [CrossRef]

- Sandhage, K.H.; Dickerson, M.B.; Huseman, P.M.; Caranna, M.A.; Clifton, J.D.; Bull, T.A.; Heibel, T.J.; Overton, W.R.; Schoenwaelder, M.E.A. Novel, Bioclastic Route to Self-Assembled, 3D, Chemically Tailored Meso/Nanostructures: Shape-Preserving Reactive Conversion of Biosilica (Diatom) Microshells. Adv. Mater. 2002, 14, 429–433. [Google Scholar] [CrossRef]

- Cai, Y.; Allan, S.M.; Sandhage, K.H.; Zalar, F.M. Three-Dimensional Magnesia-Based Nanocrystal Assemblies via Low- Temperature Magnesiothermic Reaction of Diatom Microshells. J. Am. Ceram. Soc. 2005, 88, 2005–2010. [Google Scholar] [CrossRef]

- Bao, Z.; Weatherspoon, M.R.; Shian, S.; Cai, Y.; Graham, P.D.; Allan, S.M.; Ahmad, G.; Dickerson, M.B.; Church, B.C.; Kang, Z.; et al. Chemical Reduction of Three-Dimensional Silica Micro-Assemblies into Microporous Silicon Replicas. Nature 2007, 446, 172–175. [Google Scholar] [CrossRef]

- Liu, N.; Huo, K.; McDowell, M.T.; Zhao, J.; Cui, Y. Rice Husks as a Sustainable Source of Nanostructured Silicon for High Performance Li-Ion Battery Anodes. Sci. Rep. 2013, 3, 1919. [Google Scholar] [CrossRef]

- Yan, Z.; Guo, J. High-Performance Silicon-Carbon Anode Material via Aerosol Spray Drying and Magnesiothermic Reduction. Nano Energy 2019, 63, 103845. [Google Scholar] [CrossRef]

- Wynnyckyj, J.R.; Rao, D.B. The Mechanism of Reduction of Silica by Magnesium Vapor. High Temp. Sci. 1976, 8, 203–217. [Google Scholar]

- Shi, L.; Shen, P.; Zhang, D.; Jiang, Q. Reactive Wetting of Amorphous Silica by Molten Al-Mg Alloys and Their Interfacial Structures. Appl. Surf. Sci. 2016, 377, 340–348. [Google Scholar] [CrossRef]

- Shi, L.; Shen, P.; Zhang, D.; Dong, E.; Jiang, Q. Reactive Wetting in Liquid Magnesium/Silica and Magnesium/Silicon Systems. Appl. Surf. Sci. 2013, 274, 124–130. [Google Scholar] [CrossRef]

- Yuan, Z.; Huang, W.L.; Mukai, K. Wettability and Reactivity of Molten Silicon with Various Substrates. Appl. Phys. A 2004, 78, 617–622. [Google Scholar] [CrossRef]

- Shen, P.; Fujii, H.; Matsumoto, T.; Nogi, K. Wetting and Reaction of MgO Single Crystals by Molten Al at 1073–1473 K. Acta Mater. 2004, 52, 887–898. [Google Scholar] [CrossRef]

- Iyer, H.; Tafaghodi Khajavi, L.; Durlik, D.; Danaei, K.; Barati, M. Wettability of Al2O3, MgO, and TiB2 Inclusions with Liquid Silicon. Silicon 2018, 10, 2219–2226. [Google Scholar] [CrossRef]

- Fujii, H.; Yamamoto, M.; Hara, S.; Nogi, K. Effect of Gas Evolution at Solid-Liquid Interface on Contact Angle between Liquid Si and SiO2. J. Mater. Sci. 1999, 34, 3165–3168. [Google Scholar] [CrossRef]

- Li, J.G.; Hausner, H. Wetting and Adhesion in Liquid Silicon/Ceramic Systems. Mater. Lett. 1992, 14, 329–332. [Google Scholar] [CrossRef]

- Marumo, C.; Pask, J.A. Reactions and Wetting Behaviour in the Aluminium-Fused Silica System. J. Mater. Sci. 1977, 12, 223–233. [Google Scholar] [CrossRef]

- Shen, P.; Fujii, H.; Matsumoto, T.; Nogi, I. Reactive Wetting of SiO2 Substrates by Molten Al. Metall. Mater. Trans. A 2004, 35A, 583–588. [Google Scholar] [CrossRef]

- Zhou, X.B.; De Hosson, J.T.M. De Reactive Wetting of Liquid Metals on Ceramic Substrates. Acta Mater. 1996, 44, 421–426. [Google Scholar] [CrossRef]

- Laurent, V.; Chatain, D.; Eustathopoulos, N. Wettability of SiO2 and Oxidized SiC by Aluminium. Mater. Sci. Eng. A 1991, 135, 89–94. [Google Scholar] [CrossRef]

- Aksay, I.A.; Hoge, C.E.; Pask, J.A. Wetting under Chemical Equilibrium and Nonequilibrium Conditions. J. Phys. Chem. 1974, 78, 1178–1183. [Google Scholar] [CrossRef]

- Rasouli, A.; Herstad, K.E.; Safarian, J.; Tranell, G. Magnesiothermic Reduction of Natural Quartz. Metall. Mater. Trans. B 2022, 53, 2132–2142. [Google Scholar] [CrossRef]

- Rasouli, A.; Tsoutsouva, M.; Safarian, J.; Tranell, G. Kinetics of Magnesiothermic Reduction of Natural Quartz. Materials 2022, 15, 6535. [Google Scholar] [CrossRef] [PubMed]

- Jusnes, K.F. Phase Transformations and Thermal Degradation in Industrial Quartz. Doctoral Dissertation, Norwegian University of Science and Tehnology, Trondheim, Norway, 2020. [Google Scholar]

- Kudyba, A.; Sobczak, N.; Budzioch, J.; Polkowski, W.; Giuranno, D. Improvements in Experimental Investigation of Molten Mg-Based Materials. Mater. Des. 2018, 160, 915–917. [Google Scholar] [CrossRef]

- Kudyba, A.; Sobczak, N.; Polkowski, W.; Bruzda, G.; Polkowska, A.; Giuranno, D. Improved Methodological Concepts for Processing Liquid Mg at High Temperature. J. Magnes. Alloys 2021, 9, 183–191. [Google Scholar] [CrossRef]

- Eustathopoulos, N.; Sobczak, N.; Passerone, A.; Nogi, K. Measurement of Contact Angle and Work of Adhesion at High Temperature. J. Mater. Sci. 2005, 40, 2271–2280. [Google Scholar] [CrossRef]

- Kudyba, A.; Polkowski, W.; Bruzda, G.; Polkowska, A.; Giuranno, D. Enhancement of Wettability in AZ91/B4C System by a Mechanical Purification of Liquid Alloy. J. Magnes. Alloys 2022, 10, 3133–3142. [Google Scholar] [CrossRef]

- Sobczak, N.; Singh, M.; Asthana, R. High-Temperature Wettability Measurements in Metal/Ceramic Systems—Some Methodological Issues. Curr. Opin. Solid State Mater. Sci. 2005, 9, 241–253. [Google Scholar] [CrossRef]

- Liggieri, L.; Passerone, A. ASTRA Reference Book, IENI Report; National Research Council of Italy: Genova, Italy, 2007. [Google Scholar]

- FactSage. Available online: https://www.factsage.com (accessed on 15 May 2023).

- Gutman, I.; Klinger, L.; Gotman, I.; Shapiro, M. Experimental Observation of Periodic Structure Formation in SiO2 ± Mg System. Scr. Mater. 2001, 45, 363–367. [Google Scholar] [CrossRef]

- Gutman, I.; Gotman, I.; Shapiro, M. Kinetics and Mechanism of Periodic Structure Formation at SiO2/Mg Interface. Acta Mater. 2006, 54, 4677–4684. [Google Scholar] [CrossRef]

- Gutman, I.; Klinger, L.; Gotman, I.; Shapiro, M. Model for Evolution of Periodic Layered Structure in the SiO2/Mg System. Solid State Ion. 2009, 180, 1350–1355. [Google Scholar] [CrossRef]

- Chen, Y.C.; Xu, J.; Fan, X.H.; Zhang, X.F.; Han, L.; Lin, D.Y.; Li, Q.H.; Uher, C. The Mechanism of Periodic Layer Formation during Solid-State Reaction between Mg and SiO2. Intermetallics 2009, 17, 920–926. [Google Scholar] [CrossRef]

- Guo, X.L.; Liu, Z.G.; Chen, X.Y.; Zhu, S.N.; Xiong, S.B.; Hu, W.S.; Lin, C.Y. Pulsed Laser Deposition of Pulsed Laser Deposition of SrxBa1−x Nb2O6/MgO Bilayered Films on Si Wafer in Waveguide Form. J. Phys. D Appl. Phys. 1996, 29, 1632–1635. [Google Scholar] [CrossRef]

- Dezellus, O.; Eustathopoulos, N. Fundamental Issues of Reactive Wetting by Liquid Metals. J. Mater. Sci. 2010, 45, 4256–4264. [Google Scholar] [CrossRef]

- Gale, W.F.; Totemeier, T.C. (Eds.) Chapter 14. General Physical Properties. In Smithells Metals Reference Book; Butterworth-Heinemann: Oxford, UK, 2004; ISBN 9780750675093. [Google Scholar]

- Chase, M.W. Journal of Physical and Chemical Reference Data: No. 9 Pt. 2: Monograph NIST-JANAF Thermochemical Tables Cr-Zr: Vol. No. 9 Pt. 2, 4th ed.; American Chemical Society and the American Institute of Physics for the National Institute of Standards and Technology: New York, NY, USA, 1998. [Google Scholar]

- Young, T., III. An Essay on the Cohesion of Fluids. Philos. Trans. R. Soc. Lond. 1805, 95, 171–172. [Google Scholar] [CrossRef]

| Temperature (K) | 973 | 1073 | 1123 | 1173 | 1223 | 1273 |

|---|---|---|---|---|---|---|

| Vapor pressure (atm) | 9.4 × 10−3 | 4.3 × 10−2 | 8.4 × 10−2 | 1.5 × 10−1 | 2.6 × 10−1 | 4.32 × 10−1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rasouli, A.; Kudyba, A.; Bruzda, G.; Safarian, J.; Tranell, G. High-Temperature Reactive Wetting of Natural Quartz by Liquid Magnesium. Materials 2024, 17, 1302. https://doi.org/10.3390/ma17061302

Rasouli A, Kudyba A, Bruzda G, Safarian J, Tranell G. High-Temperature Reactive Wetting of Natural Quartz by Liquid Magnesium. Materials. 2024; 17(6):1302. https://doi.org/10.3390/ma17061302

Chicago/Turabian StyleRasouli, Azam, Artur Kudyba, Grzegorz Bruzda, Jafar Safarian, and Gabriella Tranell. 2024. "High-Temperature Reactive Wetting of Natural Quartz by Liquid Magnesium" Materials 17, no. 6: 1302. https://doi.org/10.3390/ma17061302

APA StyleRasouli, A., Kudyba, A., Bruzda, G., Safarian, J., & Tranell, G. (2024). High-Temperature Reactive Wetting of Natural Quartz by Liquid Magnesium. Materials, 17(6), 1302. https://doi.org/10.3390/ma17061302