NEPE Propellant Mesoscopic Modeling and Damage Mechanism Study Based on Inversion Algorithm

Abstract

1. Introduction

2. Mesoscopic Model

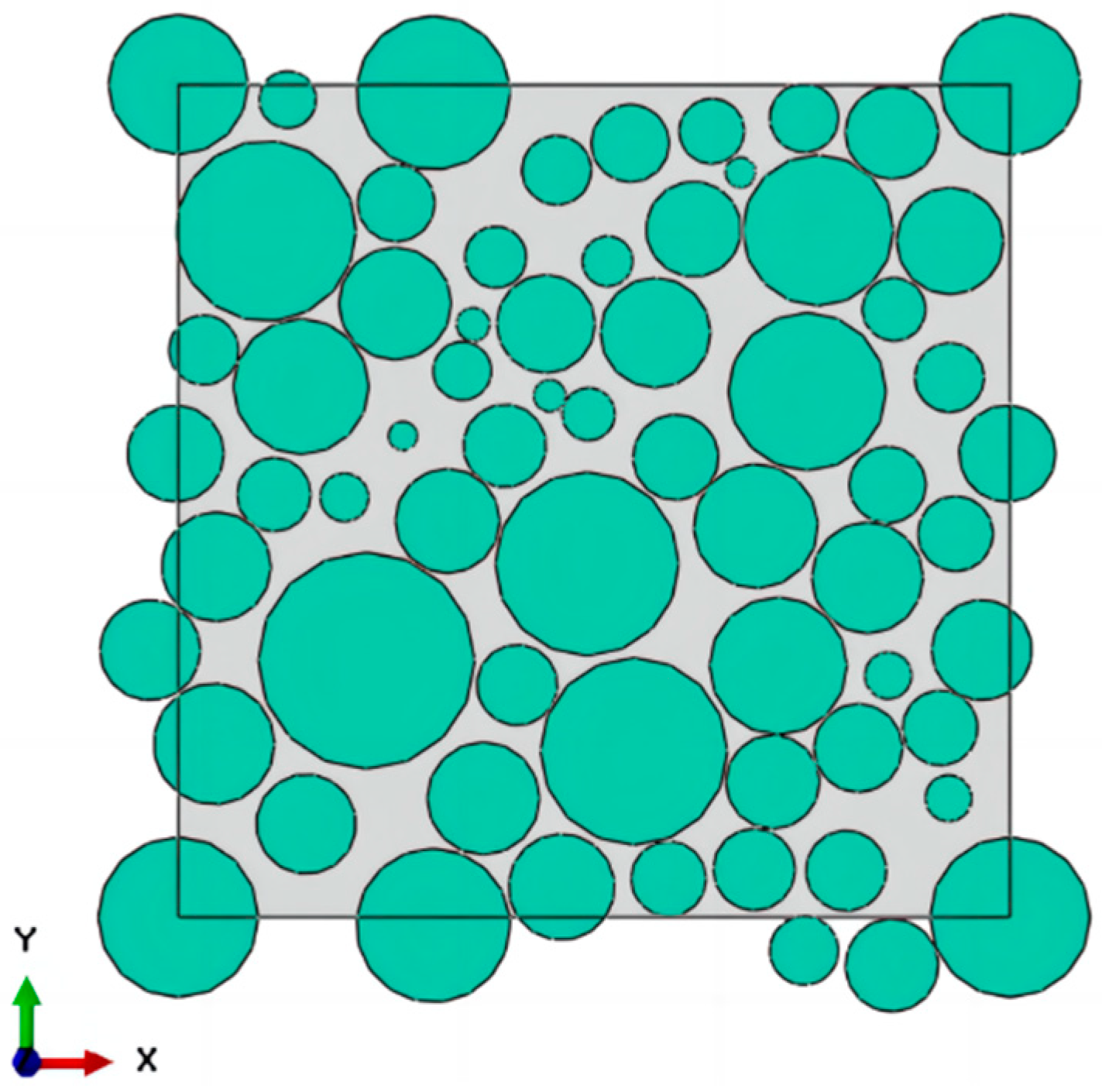

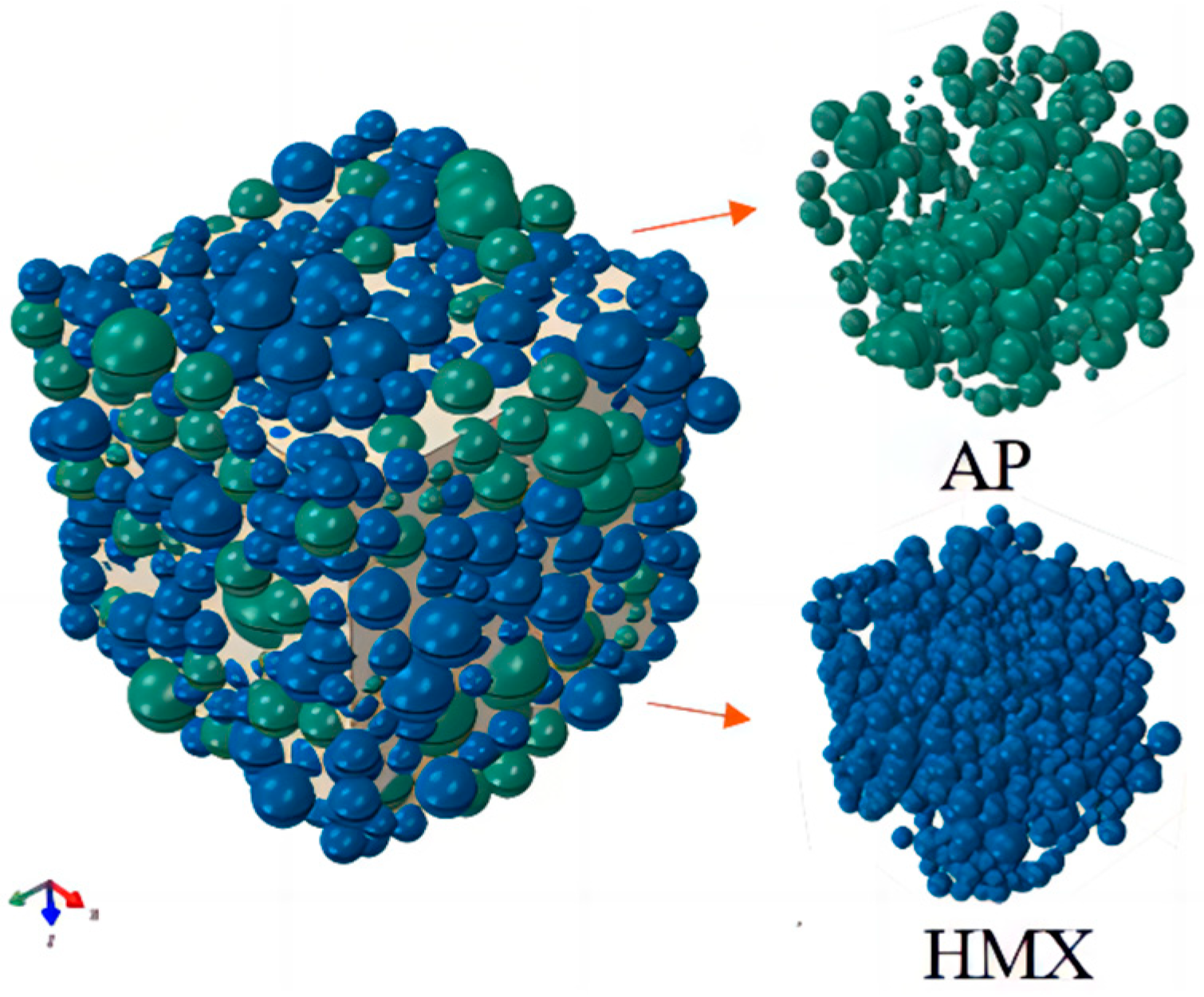

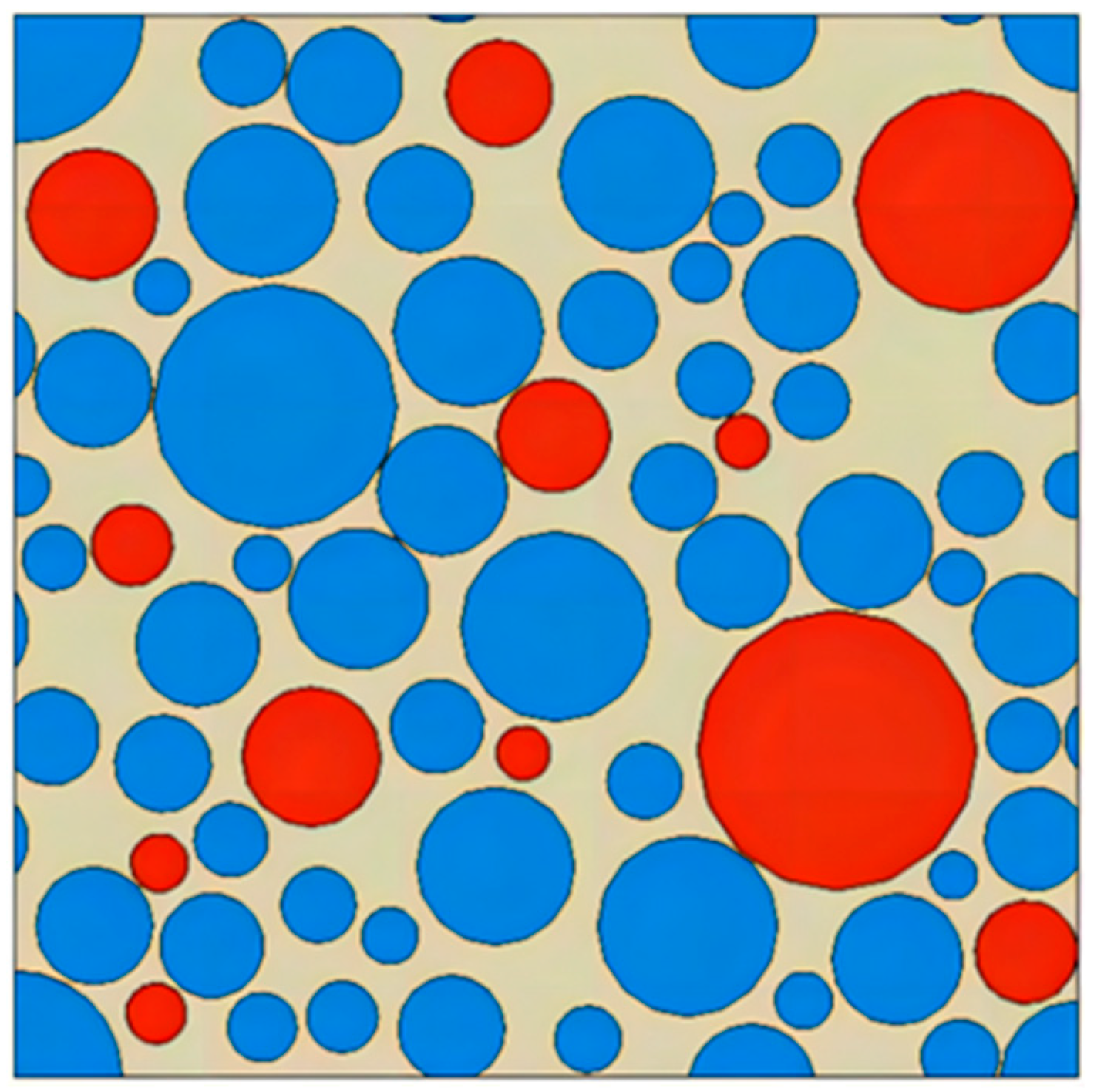

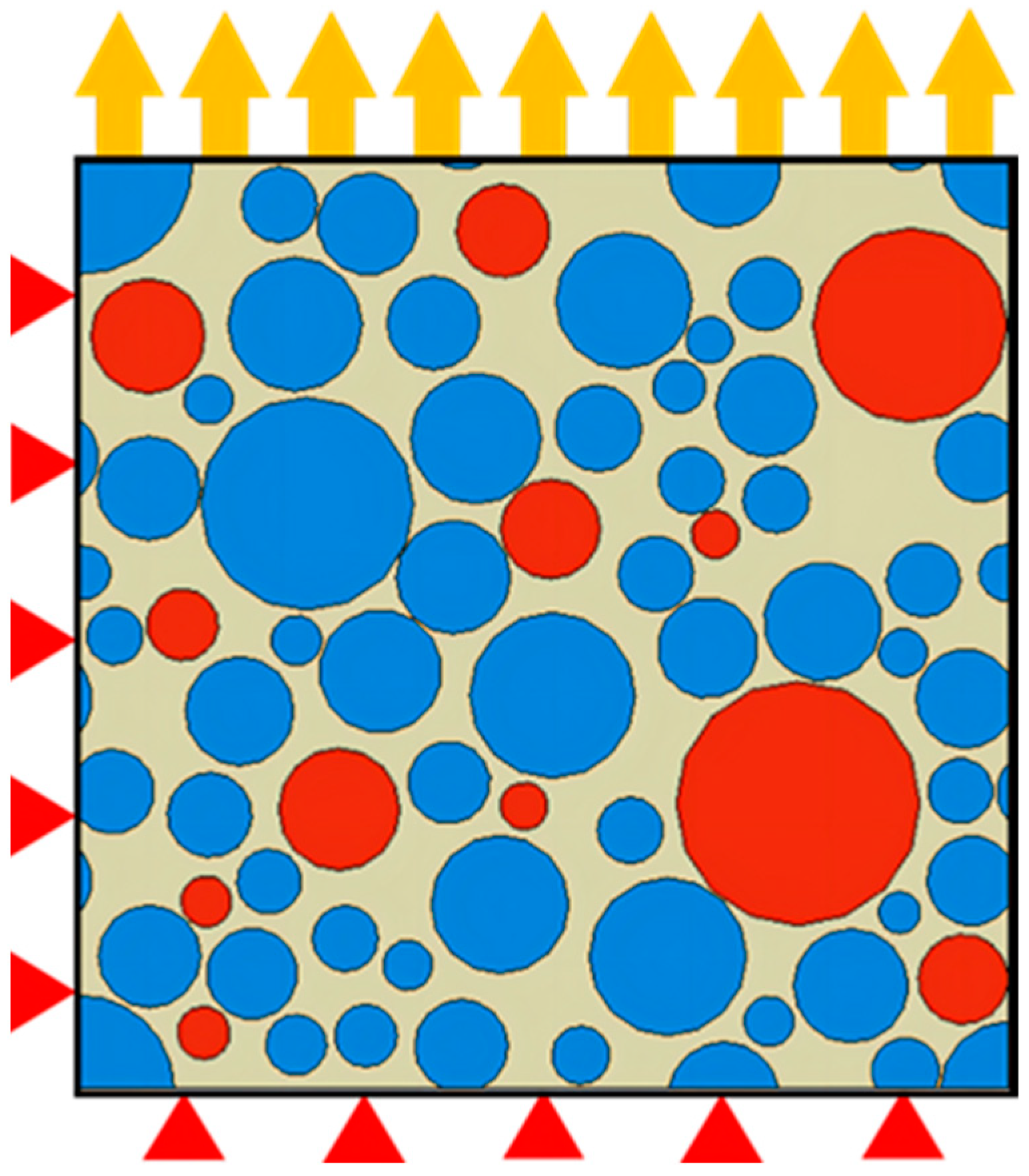

2.1. Representative Volume Element Model

2.2. Cohesive Zone Model

2.3. Numerical Computational Model of NEPE Propellants

- NEPE propellant mesoscopic modeling

- 2.

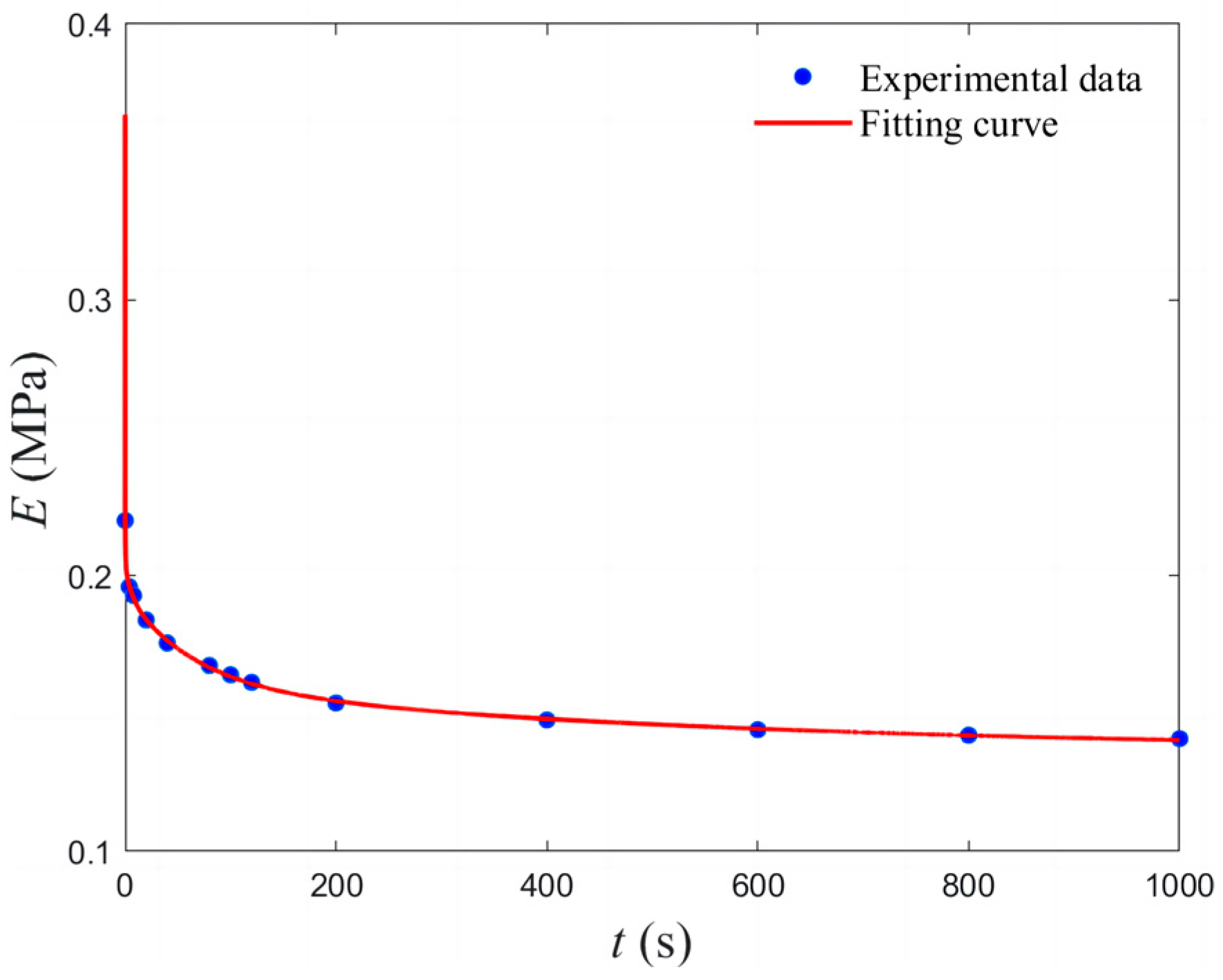

- Material parameters

- 3.

- Boundary conditions

- 4.

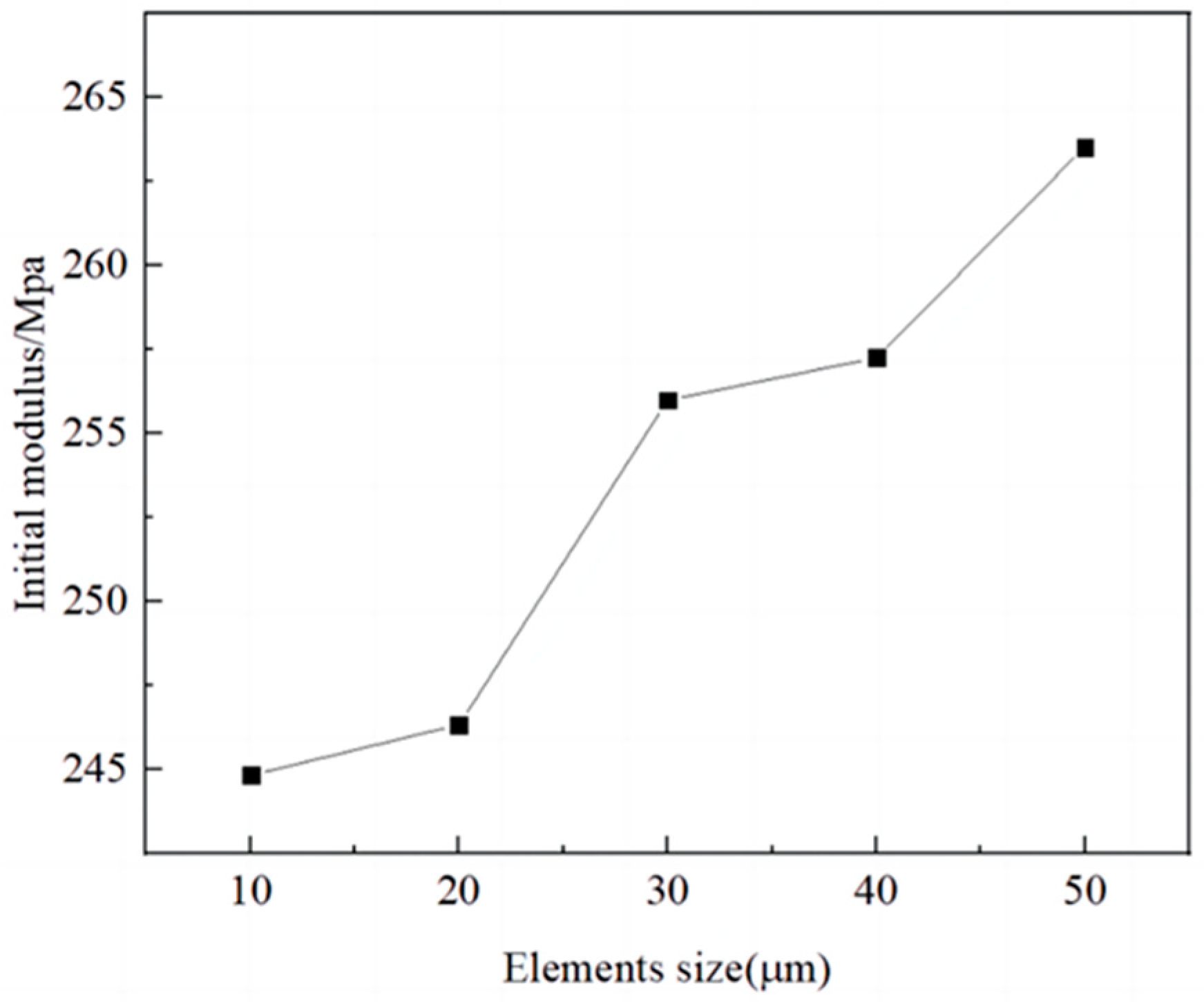

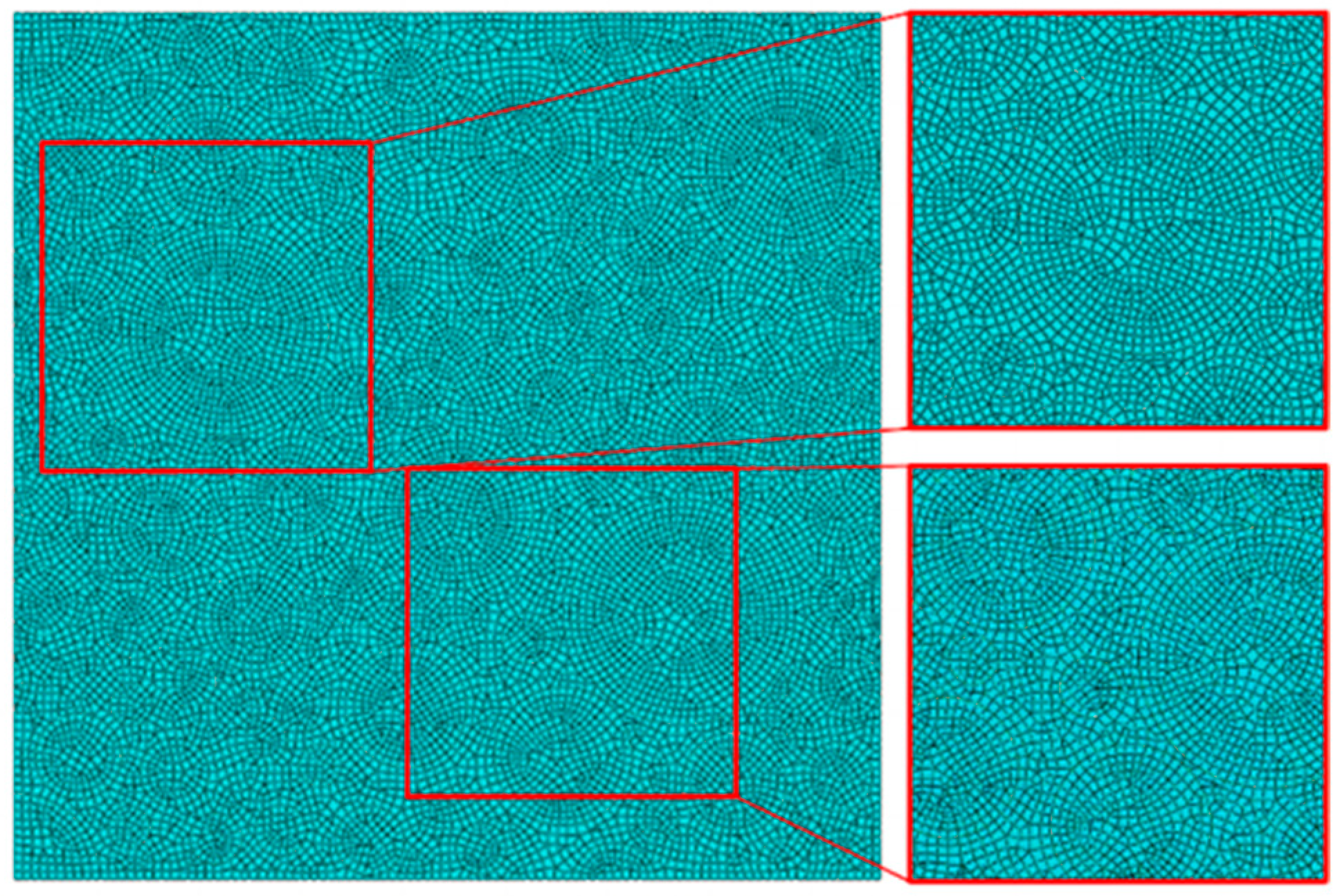

- Grid-independent verification

3. Numerical Calculations and Inversion of Interface Parameters

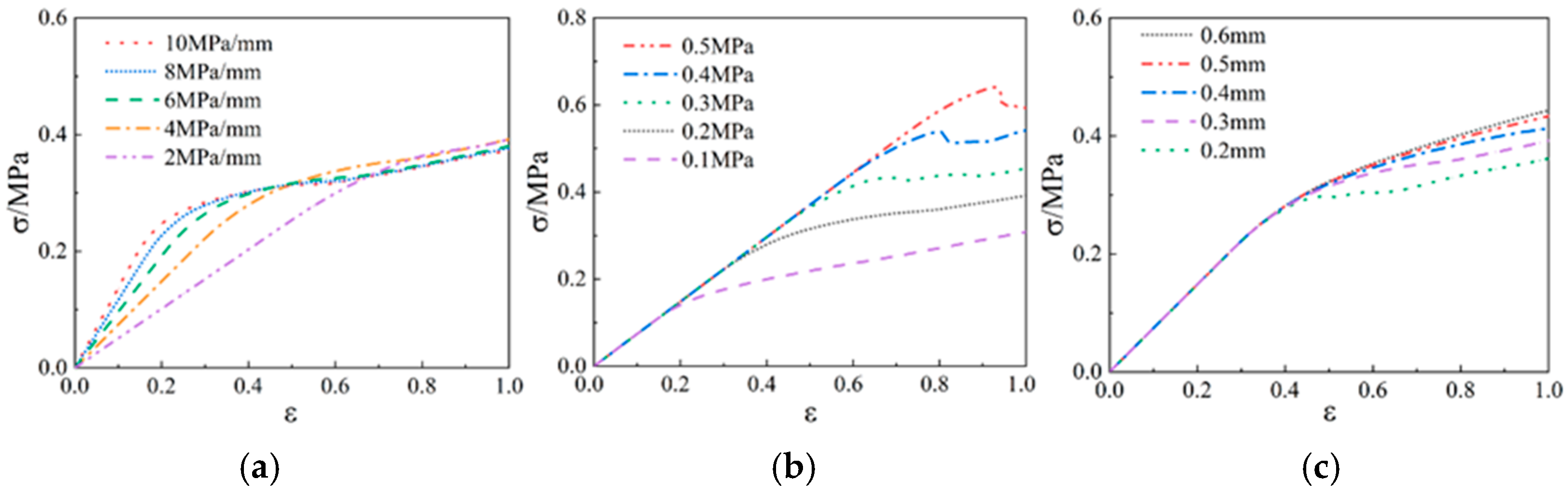

3.1. Effects of Interface Parameters

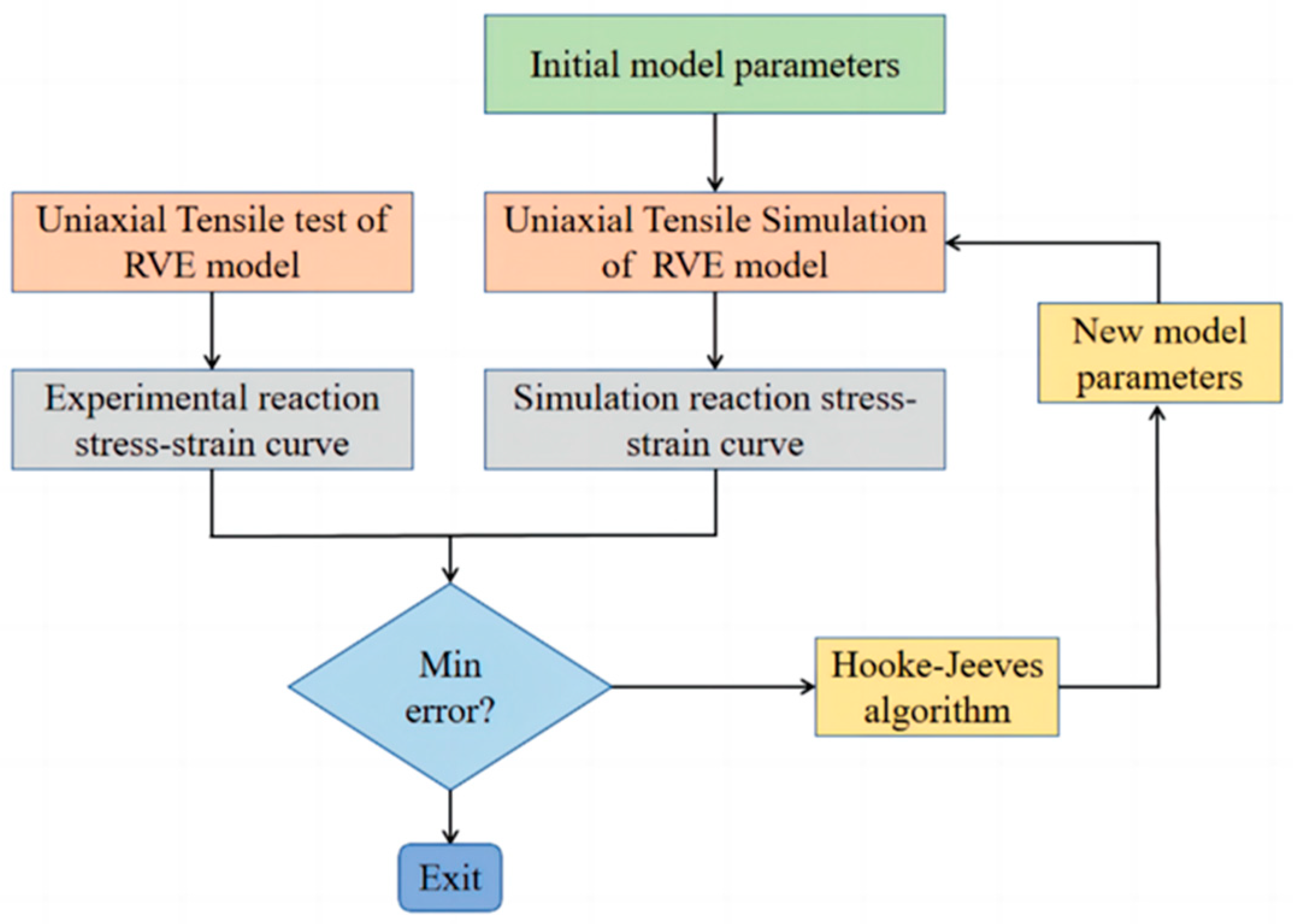

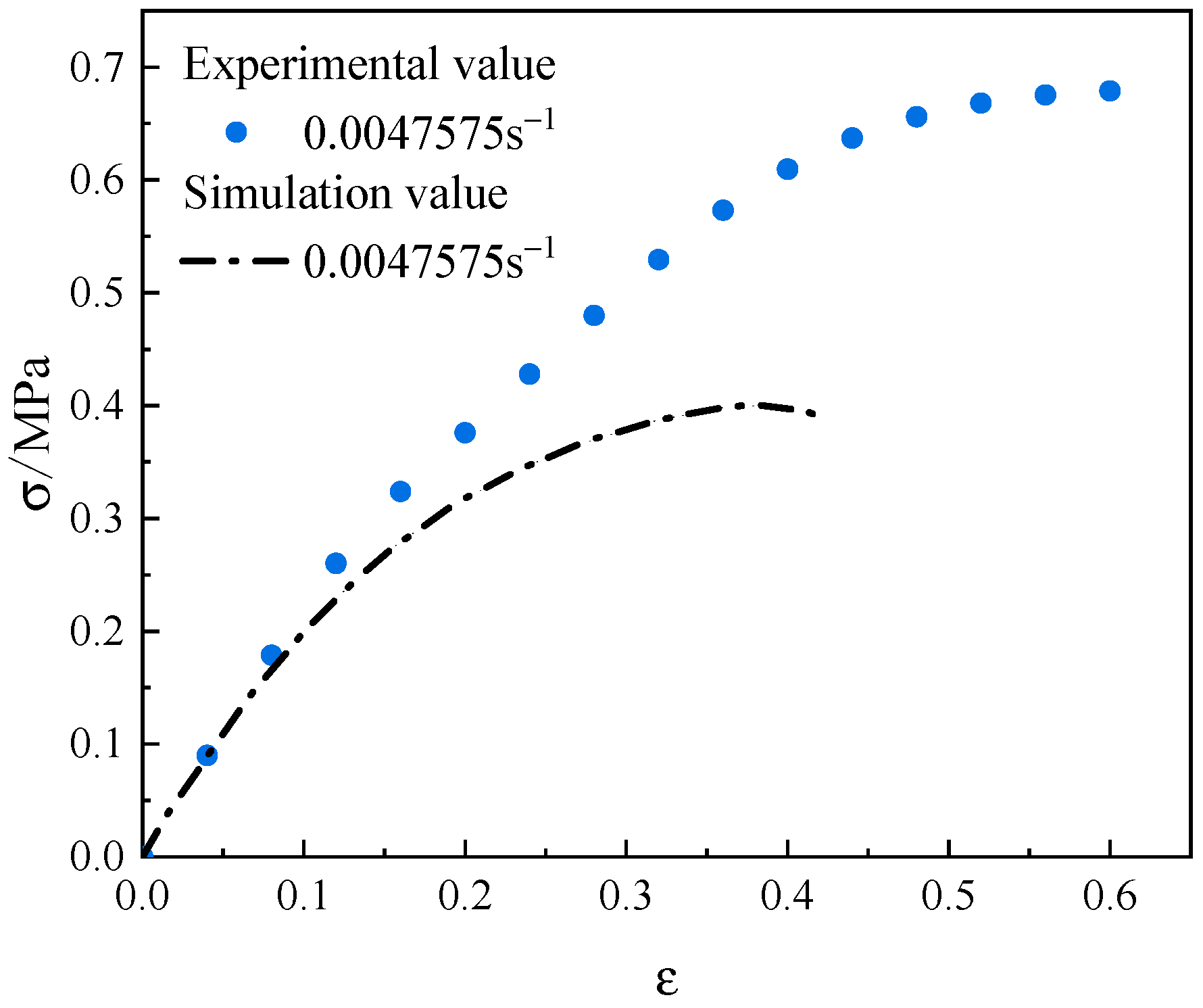

3.2. Inversion of Interface Parameters

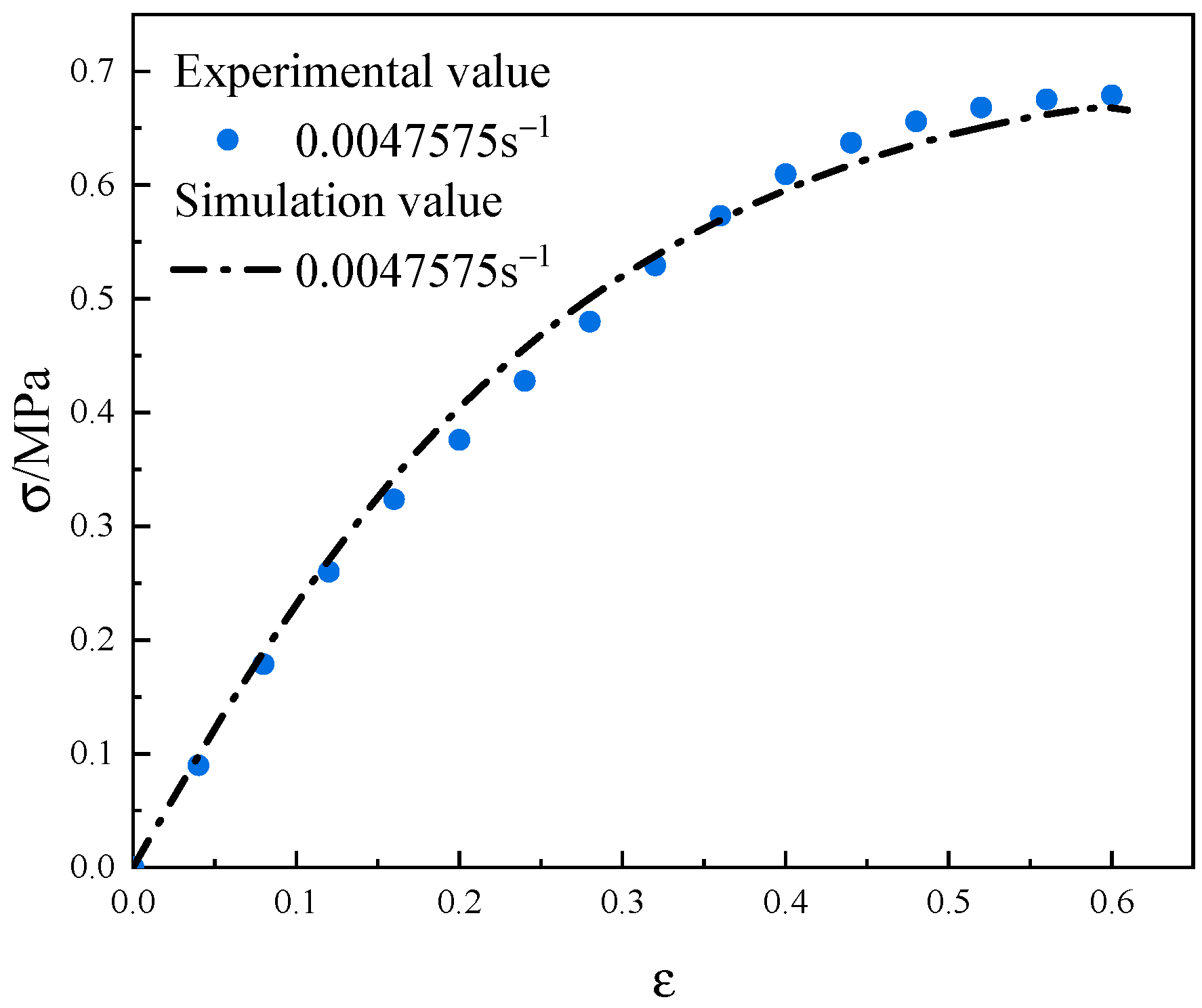

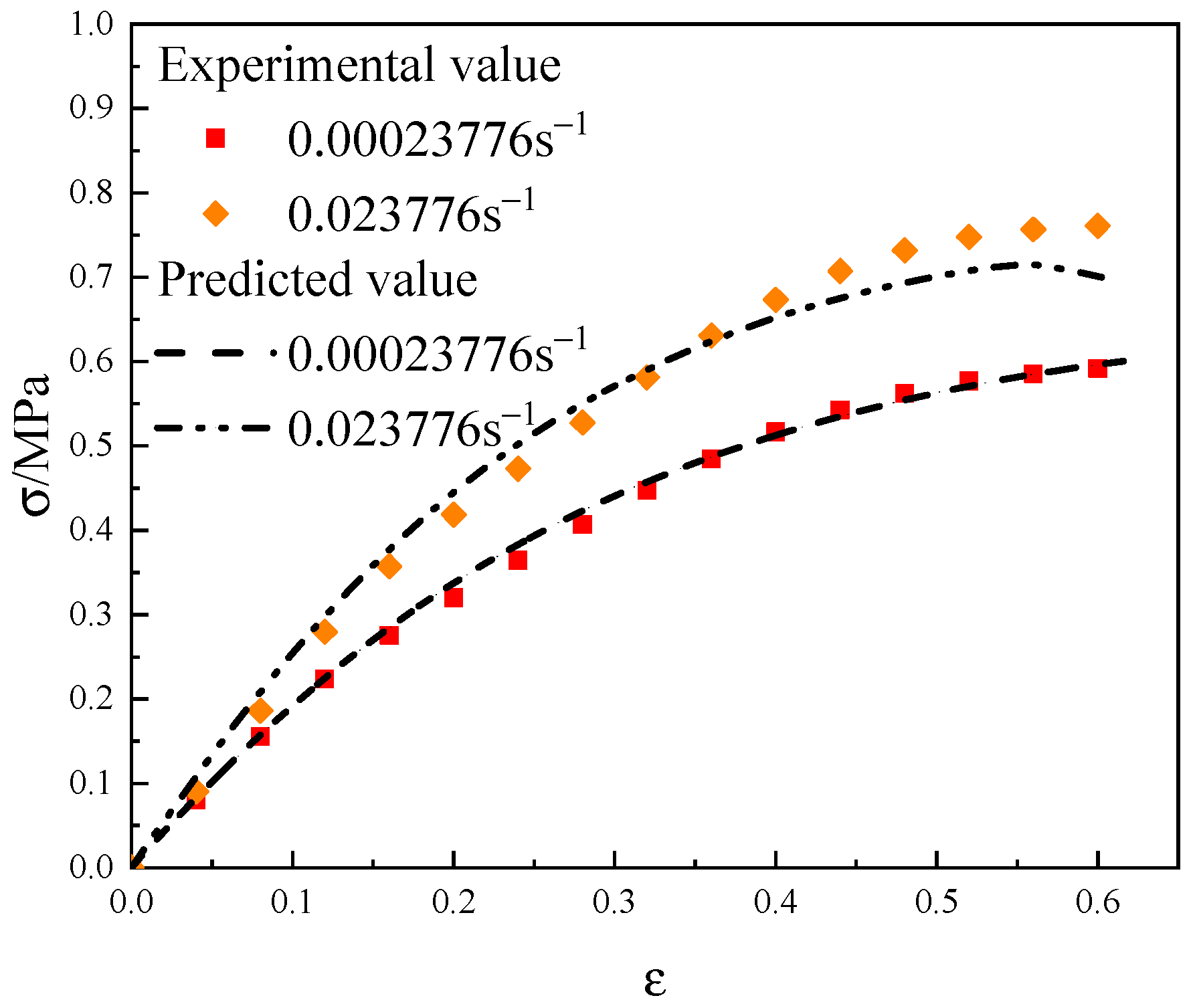

3.3. Interface Parameter Validation

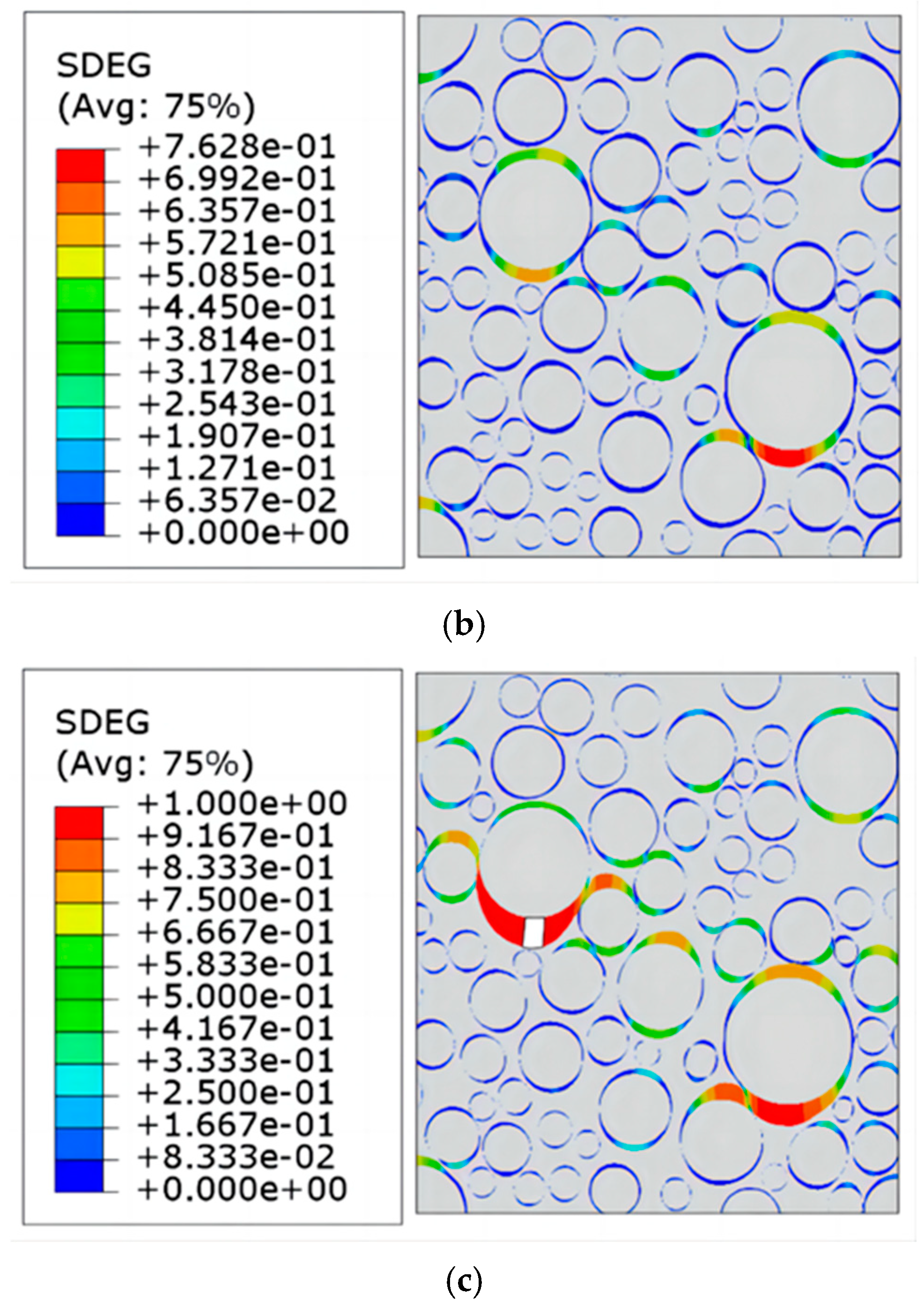

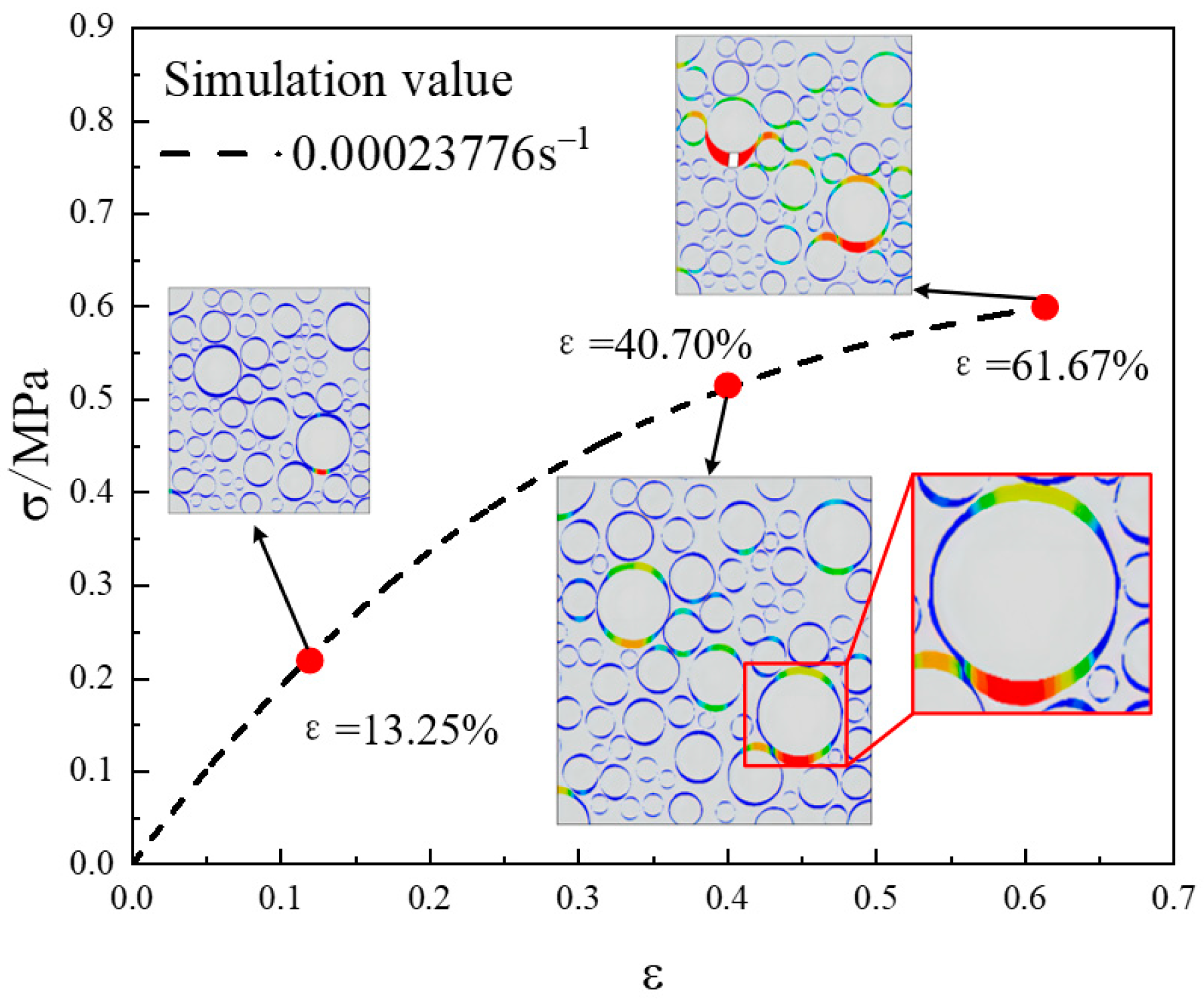

4. The Damage Fracture Evolution of the Propellant

5. Conclusions

- The NEPE composite solid propellant mesoscopic model established based on the mechanical contraction method and bilinear cohesion unit can effectively reflect the mesoscopic characteristics of the propellant.

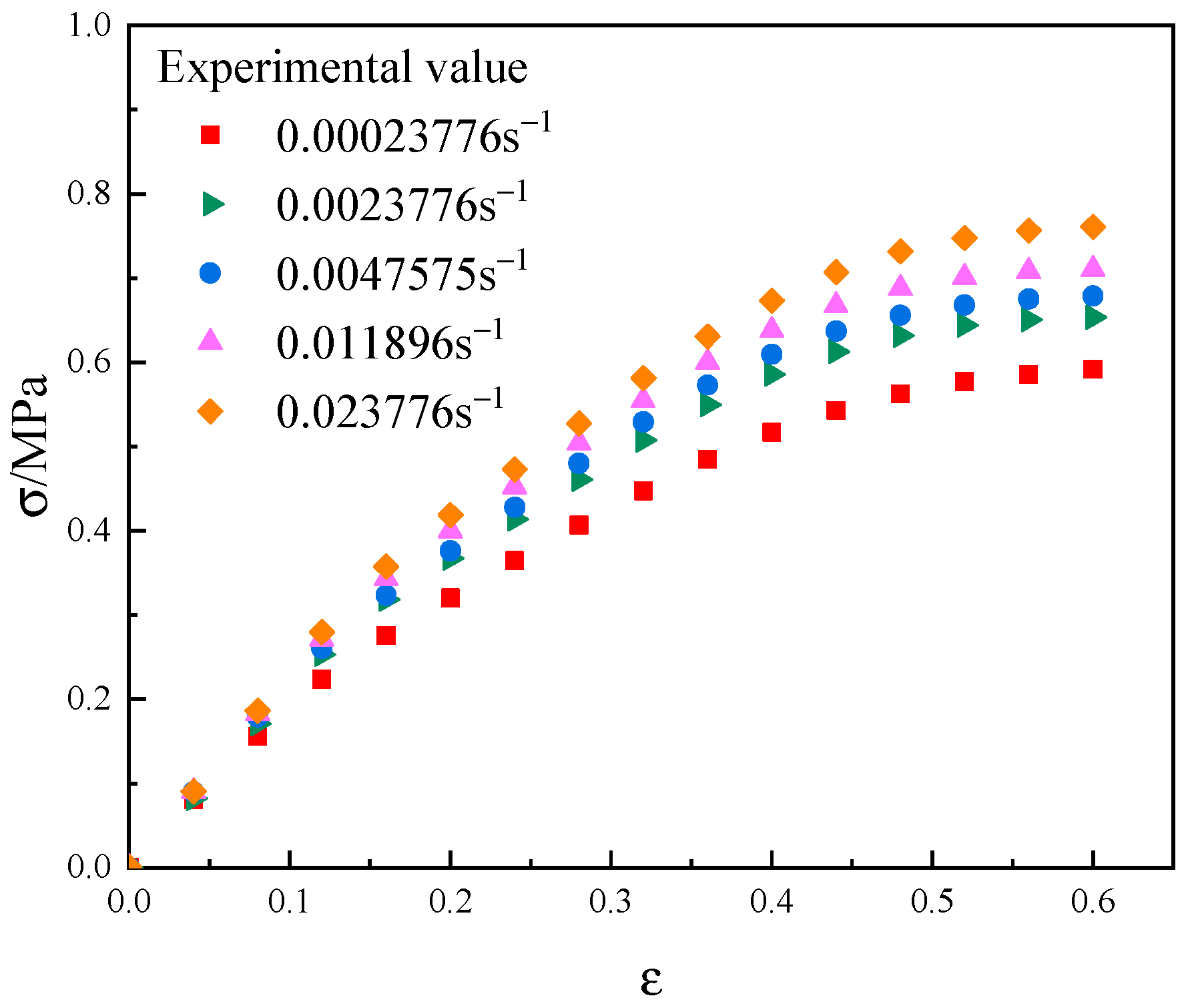

- The constructed mesoscopic simulation model can effectively reflect the strain rate correlation of the mechanical properties of NEPE composite solid propellants. The macroscopic stress–strain relationship of NEPE propellants can be effectively predicted in the range of 0.00023776 s−1~0.023776 s−1 strain rate.

- The damage mechanism of NEPE propellants under external loading can be obtained by analyzing the evolution of NEPE propellant mesoscopic damage. At the early stage of loading, the strain is small, there is no damage in the mesoscopic interior, and the stress–strain curve is linear. When continuing loading, damage occurs at some positions. With further loading, the damage at the interface between the particles and the substrate increases, with some interfacial failures and microcracks appearing. The matrix cracks further and the propellant fractures and fails.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Poryazov, V.A.; Moiseeva, K.M.; Krainov, A.Y. Combustion of a Composite Solid Propellant with Addition of Boron Powder. Combust. Explos. Shock Waves 2022, 58, 602–609. [Google Scholar] [CrossRef]

- Schapery, R.A. On a Thermodynamic Constitutive Theory and Its Application to Various Nonlinear Materials. In Proceedings of the IUTAM Symposium, East Killbride, UK, 25–28 June 1968; pp. 259–285. [Google Scholar] [CrossRef]

- Park, S.W.; Schapery, R.A. A viscoelastic constitutive model for particulate composites with growing damage. Int. J. Solids Struct. 1997, 34, 931–947. [Google Scholar] [CrossRef]

- Ho, S.-Y. High Strain-Rate Constitutive Models for Solid Rocket Propellants. J. Propuls. Power 2002, 18, 1106–1111. [Google Scholar] [CrossRef]

- Swanson, S.R.; Christensen, L.W. A constitutive formulation for high-elongation propellants. J. Spacecr. Rocket. 1983, 20, 559–566. [Google Scholar] [CrossRef]

- Rao, S.; Krishna, Y.; Rao, B.N. Fracture toughness of nitramine and composite solid propellants. Mater. Sci. Eng. A 2005, 403, 125–133. [Google Scholar] [CrossRef]

- Tigănescu, T.-V.; Grigoriu, N.; Ginghină, R.-E.; Epure, G.; Iorga, O.; Oncioiu, R.; Dîrloman, F.-M. Analysis of unaged and aged composite rocket propellant formulations by FTIR and SEM/EDX. Univ. Politeh. Buchar. Sci. Bull. Ser. B Chem. Mater. Sci. 2022, 84, 217–226. [Google Scholar]

- Deng, K.; Li, H.; Shen, Z.; Zhang, X.; Weng, J. Low strain rate yield characteristics and failure modes of solid composite propellant. Eng. Fail. Anal. 2023, 150, 107364. [Google Scholar] [CrossRef]

- Hwang, J.-M.; Go, E.-S.; Jo, H.-J.; Kim, I.-G.; Kim, J.-H. Study on the Dynamic Stress-Strain Behavior of Solid Propellant Using Low-Velocity Impact Test. J. Korean Soc. Aeronaut. Space Sci. 2021, 49, 813–820. [Google Scholar] [CrossRef]

- Sun, Z.; Fan, X.; Liu, J. Research on NEPE Propellant at High Strain Rates. J. Phys. Conf. Ser. 2023, 2478, 032074. [Google Scholar] [CrossRef]

- Tan, H.; Liu, C.; Huang, Y.; Geubelle, P. The cohesive law for the particle/matrix interfaces in high explosives. J. Mech. Phys. Solids 2005, 53, 1892–1917. [Google Scholar] [CrossRef]

- Tan, H.; Huang, Y.; Liu, C.; Geubelle, P. The Mori–Tanaka method for composite materials with nonlinear interface debonding. Int. J. Plast. 2005, 21, 1890–1918. [Google Scholar] [CrossRef]

- Tan, H.; Huang, Y.; Liu, C.; Ravichandran, G.; Inglis, H.; Geubelle, P. The uniaxial tension of particulate composite materials with nonlinear interface debonding. Int. J. Solids Struct. 2007, 44, 1809–1822. [Google Scholar] [CrossRef]

- Brassart, L.; Inglis, H.; Delannay, L.; Doghri, I.; Geubelle, P. An extended Mori–Tanaka homogenization scheme for finite strain modeling of debonding in particle-reinforced elastomers. In Proceedings of the 17th International Workshop on Computational Mechanics of Materials, Paris, France, 22–24 August 2007; Volume 45, pp. 611–616. [Google Scholar] [CrossRef]

- Chang, W.J.; Ju, Y.T.; Han, B.; Hu, S.Q.; Wang, Z.S. Numerical simulation of particle /matrix interface failure in composite propellant. Def. Technol. 2012, 3, 146–153. [Google Scholar]

- Mortazavi, B.; Baniassadi, M.; Bardon, J.; Ahzi, S. Modeling of two-phase random composite materials by finite element, Mori–Tanaka and strong contrast methods. Compos. Part B Eng. 2013, 45, 1117–1125. [Google Scholar] [CrossRef]

- Cui, H.-R.; Li, H.-Y.; Shen, Z.-B. Cohesive zone model for mode-I fracture with viscoelastic-sensitivity. Eng. Fract. Mech. 2019, 221, 106578. [Google Scholar] [CrossRef]

- Cerrone, A.; Wawrzynek, P.; Nonn, A.; Paulino, G.H.; Ingraffea, A. Implementation and verification of the Park–Paulino–Roesler cohesive zone model in 3D. Eng. Fract. Mech. 2014, 120, 26–42. [Google Scholar] [CrossRef]

- Ding, W.; Xu, J.; Zhou, C.; Wang, T.; Hou, Y. Type Ⅰ Failure Temperature-dependent Properties of HTPB Propellant/Liner Interface. Chin. J. Energetic Mater. 2022, 30, 146–154. [Google Scholar]

- Zhao, J. Research on microscopic damage and fracture of composite propellant based on global CZM. Solid Rocket Technol. 2019, 42, 269–274. [Google Scholar]

- de Francqueville, F.; Diani, J.; Gilormini, P.; Vandenbroucke, A. Use of a micromechanical approach to understand the mechanical behavior of solid propellants. Mech. Mater. 2020, 153, 103656. [Google Scholar] [CrossRef]

- Xing, R.; Wang, L.; Zhang, F.; Hou, C. Mechanical behavior and constitutive model of NEPE solid propellant in finite deformation. Mech. Mater. 2022, 172, 104383. [Google Scholar] [CrossRef]

- Li, H.; Wang, S.; Li, M.; Xu, J.; Fan, X.; Chen, X. Experimental Research on Tensile Mechanical Properties of NEPE Propellant under Confining Pressure. Propellants Explos. Pyrotech. 2020, 45, 1769–1779. [Google Scholar] [CrossRef]

- Knott, G.M.; Jackson, T.L.; Buckmaster, J. Random Packing of Heterogeneous Propellants. AIAA J. 2001, 39, 678–686. [Google Scholar] [CrossRef]

- Kochevets, S.; Buckmaster, J.; Jackson, T. Random propellant packs and the flames they support. In Proceedings of the 36th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Las Vegas, NV, USA, 24–28 July 2000. [Google Scholar] [CrossRef]

- Xu, W.X.; Chen, H.S. Quantitative characterization of the microstructure of fresh cement paste via random packing of polydispersed Platonic cement particles. Model. Simul. Mater. Sci. Eng. 2012, 20, 075003. [Google Scholar] [CrossRef]

- Donev, A.; Torquato, S.; Stillinger, F.H. Neighbor list collision-driven molecular dynamics simulation for nonspherical hard particles. I. Algorithmic details. J. Comput. Phys. 2005, 202, 737–764. [Google Scholar] [CrossRef]

- Abreu, C.R.; Tavares, F.W.; Castier, M. Influence of particle shape on the packing and on the segregation of spherocylinders via Monte Carlo simulations. Powder Technol. 2003, 134, 167–180. [Google Scholar] [CrossRef]

- Williams, S.R.; Philipse, A.P. Random packings of spheres and spherocylinders simulated by mechanical contraction. Phys. Rev. E 2003, 67, 051301. [Google Scholar] [CrossRef]

- Dartois, S.; Nadot-Martin, C.; Halm, D.; Dragon, A.; Fanget, A.; Contesse, G. Micromechanical modelling of damage evolution in highly filled particulate composites—Induced effects at different scales. Int. J. Damage Mech. 2012, 22, 927–966. [Google Scholar] [CrossRef]

- Dugdale, D.S. Yielding of steel sheets containing slits. J. Mech. Phys. Solids 1960, 8, 100–104. [Google Scholar] [CrossRef]

- Espinosa, H.D.; Zavattieri, P.D. A grain level model for the study of failure initiation and evolution in polycrystalline brittle materials. Part II: Numerical examples. Mech. Mater. 2003, 35, 365–394. [Google Scholar] [CrossRef]

- Wu, P.; Li, G.; Han, Y.; Wang, Z.; Qian, R. Parameter Inverse Identification and Damage Failure Process Simulation of Adhesive Interface of Solid Rocket Motor. Chin. J. Energetic Mater. 2021, 29, 211–219. [Google Scholar]

- Feng, T. Numerical Simulation of Meso-mechanics Damage in Composite Solid Propellant Based on Mesoscopic Model. Master’s Thesis, Nanjing University of Science & Technology, Nanjing, China, December 2017. [Google Scholar]

- Hooke, R.; Jeeves, T.A. “Direct Search” Solution of Numerical and Statistical Problems. J. ACM 1961, 8, 212–229. [Google Scholar] [CrossRef]

- The Ministry of Aerospace Industry of the People’s Republic of China. QJ 2487-93; The Determination Method of Uniaxial Tensile Stress Relaxation Modulus and Principal Curve of Composite Solid Propellant. The 708th Institute of the Ministry of Aerospace Industry: Beijing, China, 1993.

- Wang, J.; Cao, P.; Wang, X. Review of the Mechanical Properties and Numerical Simulation of Composite Solid Propellants. Materials 2023, 16, 6875. [Google Scholar] [CrossRef]

| Components | AP | HMX |

|---|---|---|

| Average size (μm) | 120 | 75 |

| Interval size (μm) | 50~190 | 25~130 |

| Components | Young’s Modulus (MPa) | Poisson’s Ratio | Density (kg/m3) |

|---|---|---|---|

| AP | 32,450 | 0.130 | 1950 |

| HMX | 29,500 | 0.300 | 1900 |

| Matrix | E(t) | 0.495 | 1200 |

| i | ∞ | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|---|

| Ei/MPa | 0.3679 | 0.0788 | 0.0645 | 0.0205 | 0.0100 | 0.0330 | 0.0238 |

| τi/s | – | 0.0041 | 0.0231 | 0.3948 | 6.1445 | 64.6894 | 542.4027 |

| Components | Number of Grids |

|---|---|

| AP particle | 1905 |

| HMX particle | 5456 |

| Matrix | 5645 |

| Particle/matrix interface bonding unit | 1553 |

| Matrix neighboring unit interface bonding unit | 10,443 |

| Components | σmax/MPa | K/(MPa/mm) | δf/mm |

|---|---|---|---|

| Particle/matrix interface | 0.50 | 400 | 2.0 |

| Matrix | 0.65 | 300 | 2.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, Z.; Zhang, K.; Liu, Q.; Wang, C. NEPE Propellant Mesoscopic Modeling and Damage Mechanism Study Based on Inversion Algorithm. Materials 2024, 17, 1289. https://doi.org/10.3390/ma17061289

Hu Z, Zhang K, Liu Q, Wang C. NEPE Propellant Mesoscopic Modeling and Damage Mechanism Study Based on Inversion Algorithm. Materials. 2024; 17(6):1289. https://doi.org/10.3390/ma17061289

Chicago/Turabian StyleHu, Zhenyuan, Kaining Zhang, Qiqi Liu, and Chunguang Wang. 2024. "NEPE Propellant Mesoscopic Modeling and Damage Mechanism Study Based on Inversion Algorithm" Materials 17, no. 6: 1289. https://doi.org/10.3390/ma17061289

APA StyleHu, Z., Zhang, K., Liu, Q., & Wang, C. (2024). NEPE Propellant Mesoscopic Modeling and Damage Mechanism Study Based on Inversion Algorithm. Materials, 17(6), 1289. https://doi.org/10.3390/ma17061289