Large Cyclability of Elastocaloric Effect in Highly Porous Ni-Fe-Ga Foams

Abstract

:1. Introduction

2. Experimental Details

3. Results and Discussion

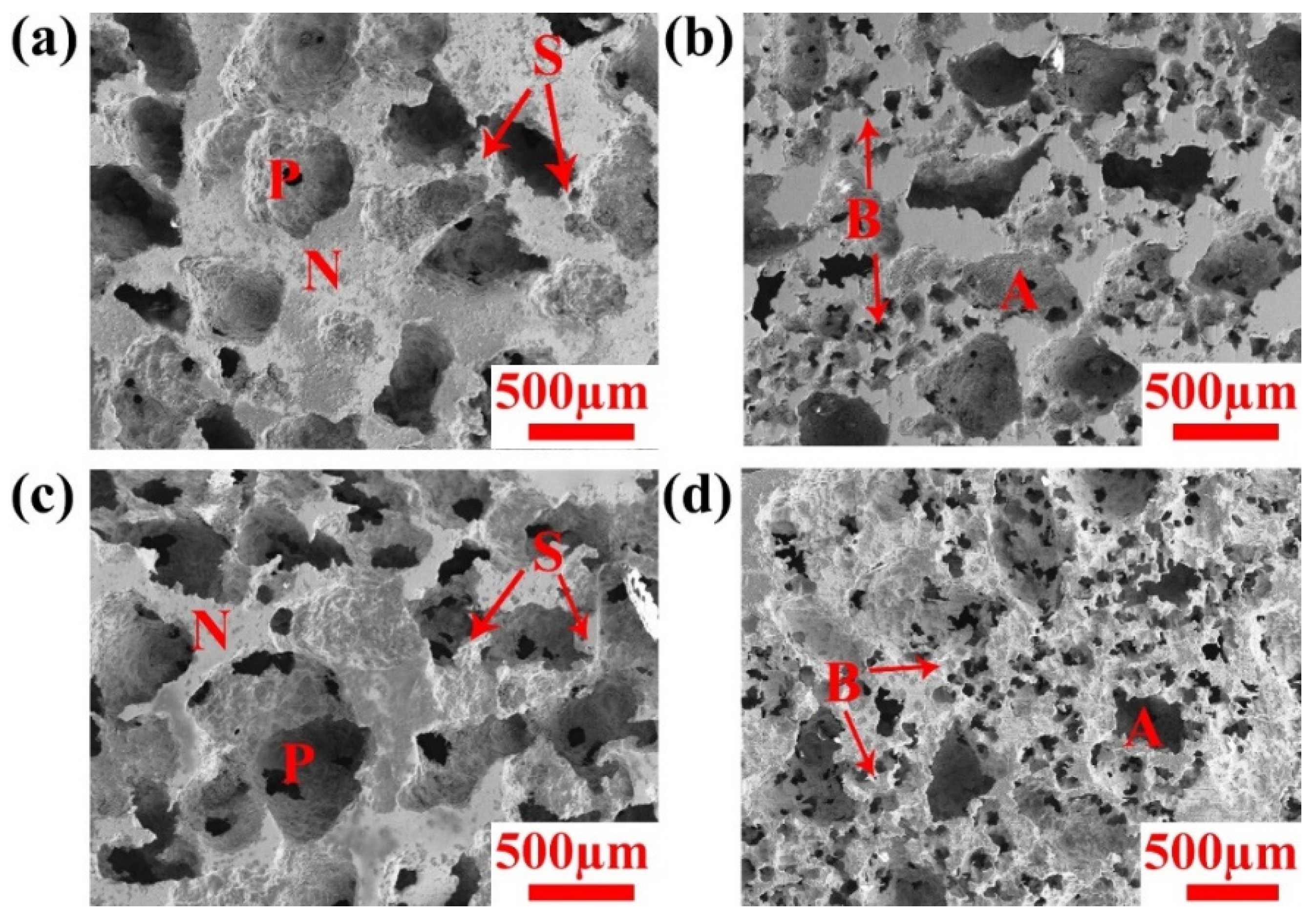

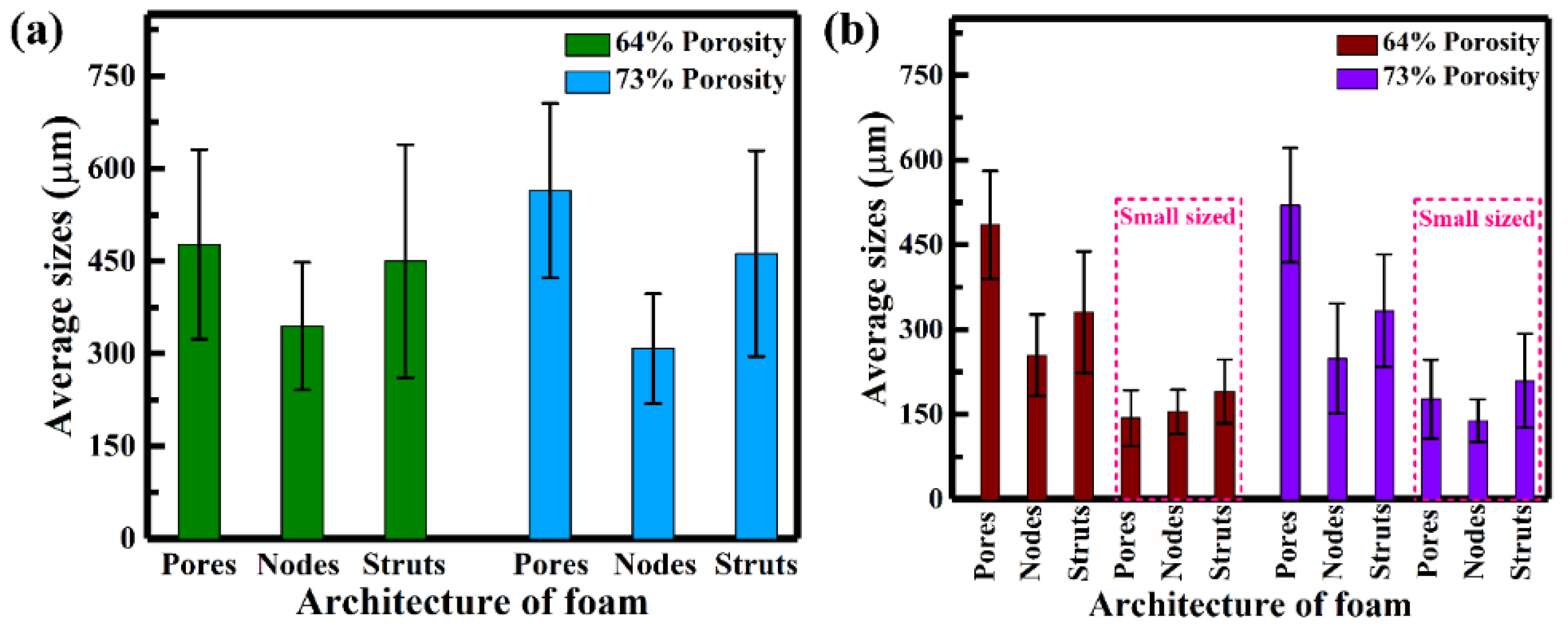

3.1. Structural Characterization of High-Porosity Foams

3.2. Martensitic Transformation Behavior

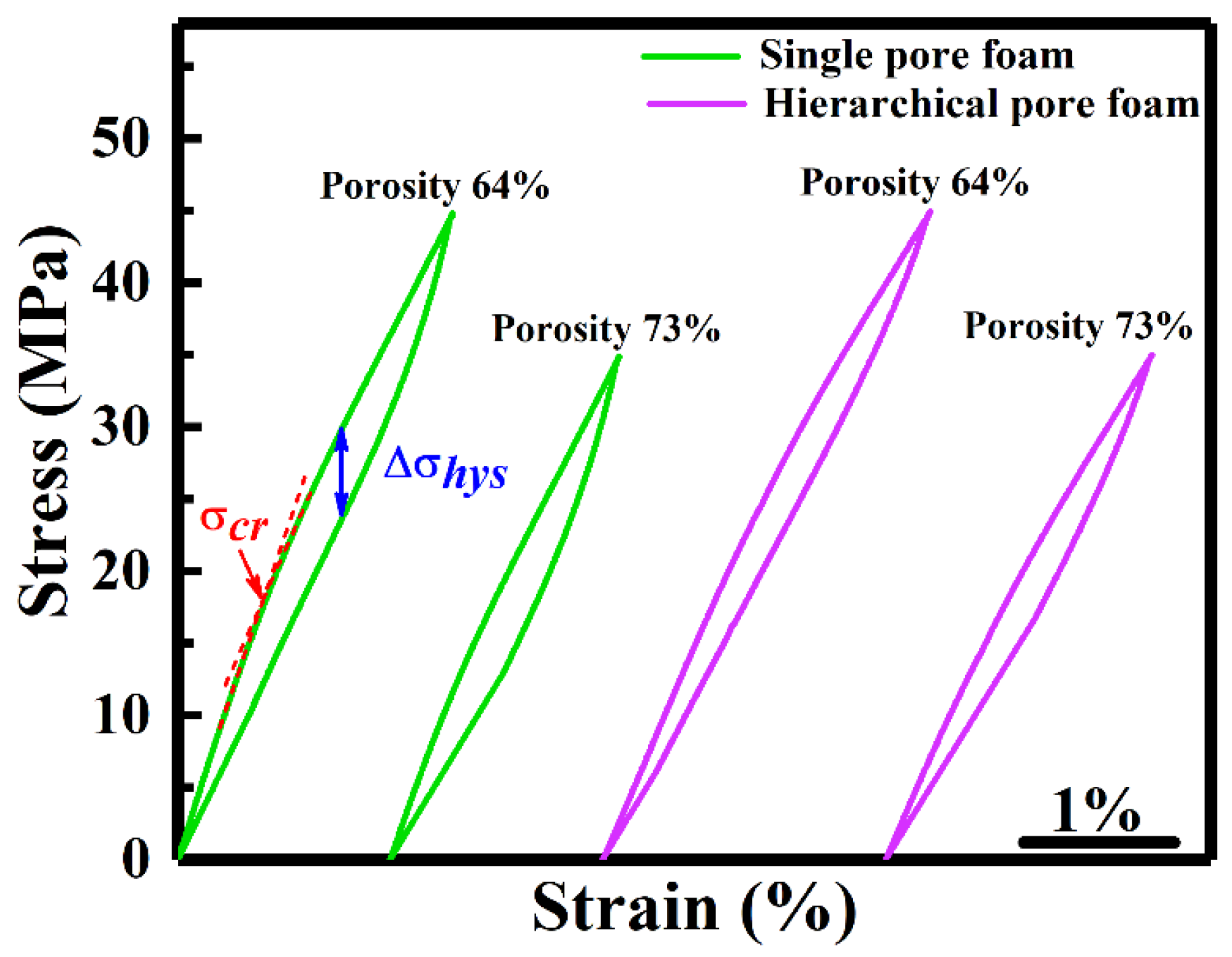

3.3. Superelastic Response

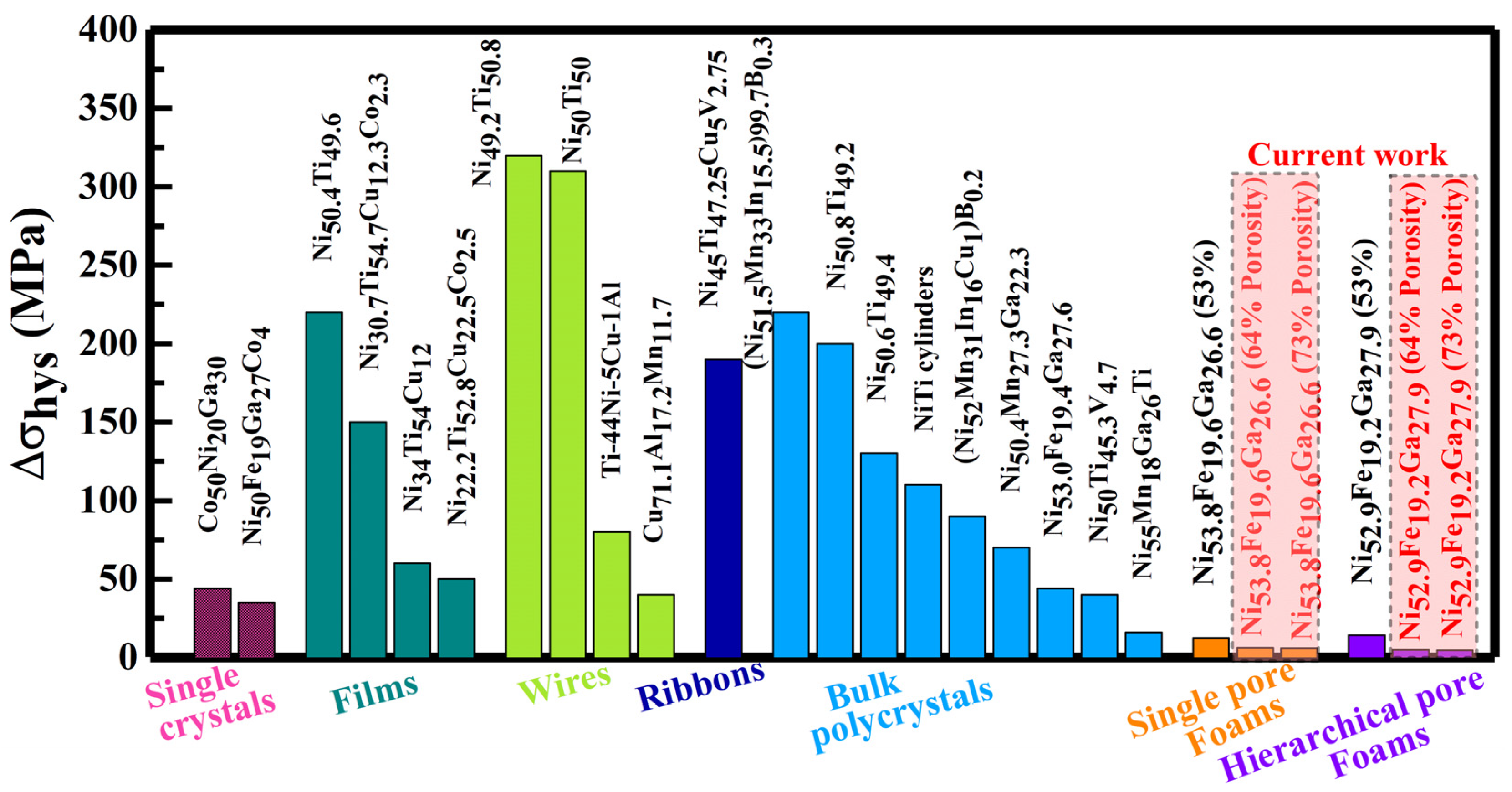

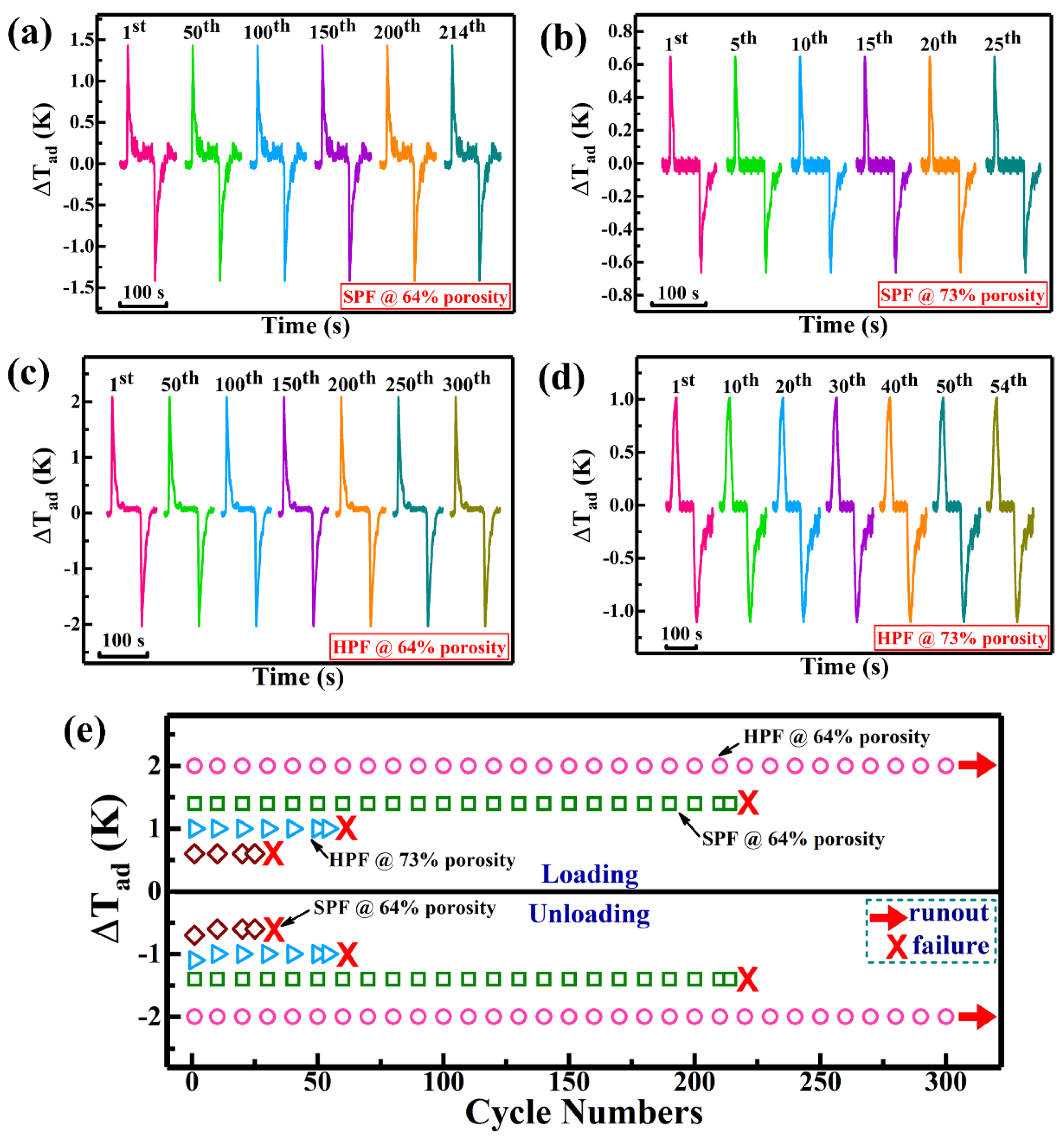

3.4. Evaluation of Elastocaloric Effect (eCE) and Its Cyclic Stability

4. Conclusions

- High-porosity (64–73%) foams at the mesoscopic level were successfully prepared by chemical etching in two acid baths (2% HF + 10% H2SO4 and 2% HF + 10% HNO3) under ultrasonic treatment. One needs to be very careful during the etching process, otherwise the mesoscopic level of the struts/nodes may be damaged, which are the main load-bearing structures in the Ni-Fe-Ga foams;

- Both single- and hierarchical pore foams with high porosities (64–73%) exhibit reversible superelasticity (1.6–2.3% recoverable strain) at room temperature (297 K) with quite small stress hysteresis (9.6–18 MPa), which is favorable for reproducing multiple superelastic cycles under room temperature elastocaloric cooling;

- Hierarchical pore foam with 64% porosity yields a maximum reversible ∆Tad of 2.0 K at a compressive stress of 45 MPa with a strikingly large COPmat of 34, which is much higher than those in some well-known eCMs;

- Hierarchical pore foam with 64% porosity demonstrates stable elastocaloric behavior with insignificant degradation over >300 cycles (where ∆Tad~2.0 K remains constant), which is the largest number reported in Ni-Fe-Ga (β-phase) polycrystalline FMSMA;

- The outstanding reversible/reproducible superelastic and elastocaloric behavior in the presented hierarchical pore foams (with 64% porosity) can be explained well by the existence of pore hierarchies, which are processed by tailoring the approach to the material’s architecture. Such pore hierarchy effectively suppresses grain boundary constraints and/or limits the propagation of cracks, thereby reducing stress hysteresis and lowering the critical stress to induce multiple stress-induced MTs.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mañosa, L.; Planes, A. Materials with Giant Mechanocaloric Effects: Cooling by Strength. Adv. Mater. 2017, 29, 1603607. [Google Scholar] [CrossRef]

- Kabirifar, P.; Žerovnik, A.; Ahčin, Ž.; Porenta, L.; Brojan, M.; Tušek, J. Elastocaloric Cooling: State-of-the-art and Future Challenges in Designing Regenerative Elastocaloric Devices. Stroj. Vestn. J. Mech. Eng. 2019, 65, 16. [Google Scholar] [CrossRef]

- Imran, M.; Zhang, X. Recent developments on the cyclic stability in elastocaloric materials. Mater. Des. 2020, 195, 109030. [Google Scholar] [CrossRef]

- Xiao, F.; Fukuda, T.; Kakeshita, T.; Jin, X.J. Elastocaloric effect by a weak first-order transformation associated with lattice softening in an Fe-31.2Pd (at.%) alloy. Acta Mater. 2015, 87, 8–14. [Google Scholar] [CrossRef]

- Fukuda, T.; Kakeshita, T. Elastic-like deformation and elastocaloric effect of a partly ordered iron-platinum alloy exhibiting a weak first-order martensitic transformation. J. Phys. D Appl. Phys. 2017, 50, 404003. [Google Scholar] [CrossRef]

- Kawarada, Y.; Aimi, A.; Santos, A.; Nakata, G.; Takeuchi, I.; Fujimoto, K. Abnormal grain growth of 68Cu–16Al–16Zn alloys for elastocaloric cooling via cyclical heat treatments. J. Phys. Energy 2023, 5, 024012. [Google Scholar] [CrossRef]

- Lu, N.-H.; Chen, C.-H. Inhomogeneous martensitic transformation behavior and elastocaloric effect in a bicrystal Cu-Al-Mn shape memory alloy. Mater. Sci. Eng. A 2021, 800, 140386. [Google Scholar] [CrossRef]

- Zhu, X.; Zhang, X.; Qian, M.; Zhong, S.; Muhammad, I.; Geng, L. Enhanced elastocaloric stability in NiTi alloys under shear stress. Mater. Sci. Eng. A 2022, 838, 142787. [Google Scholar] [CrossRef]

- Kordizadeh, F.; Safaei, K.; Mohajerani, S.; Elahinia, M. Investigation of the elastocaloric effect in laser powder bed fusion NiTi porous structures. Addit. Manuf. Lett. 2023, 6, 100131. [Google Scholar] [CrossRef]

- Villa, E.; Villa, F.; Crespo, B.R.; Lazpita, P.; Salazar, D.; Hosoda, H.; Chernenko, V. Shape memory and elastocaloric properties of melt-spun NiMn-based Heusler alloys. J. Alloys Compd. 2023, 965, 171437. [Google Scholar] [CrossRef]

- Navarro-García, J.D.; Camarillo-Garcia, J.P.; Alvarado-Hernández, F.; Sánchez Llamazares, J.L.; Flores-Zúñiga, H. Elastocaloric and Magnetocaloric Effects Linked to the Martensitic Transformation in Bulk Ni55Fe11Mn7Ga27 Alloys Produced by Arc Melting and Spark Plasma Sintering. Metals 2022, 12, 273. [Google Scholar] [CrossRef]

- Masdeu, F.; Pons, J.; Torrens-Serra, J.; Chumlyakov, Y.; Cesari, E. Superelastic behavior and elastocaloric effect in a Ni51.5Fe21.5Ga27.0 ferromagnetic shape memory single crystal under compression. Mater. Sci. Eng. A 2022, 833, 142362. [Google Scholar] [CrossRef]

- Eftifeeva, A.; Panchenko, E.; Yanushonite, E.; Kurlevskaya, I.; Timofeeva, E.; Tokhmetova, A.; Surikov, N.; Tagiltsev, A.; Chumlyakov, Y. Superelasticity and elastocaloric cooling capacity in stress-induced martensite aged [001]A-oriented Ni54Fe19Ga27 single crystals. Mater. Sci. Eng. A 2022, 855, 143855. [Google Scholar] [CrossRef]

- Bonnot, E.; Romero, R.; Mañosa, L.; Vives, E.; Planes, A. Elastocaloric Effect Associated with the Martensitic Transition in Shape-Memory Alloys. Phys. Rev. Lett. 2008, 100, 125901. [Google Scholar] [CrossRef]

- Chu, R.C.; Simons, R.E.; Ellsworth, M.J.; Schmidt, R.R.; Cozzolino, V. Review of cooling technologies for computer products. IEEE Trans. Device Mater. Reliab. 2004, 4, 568–585. [Google Scholar] [CrossRef]

- Imran, M.; Zhang, X. Reduced dimensions elastocaloric materials: A route towards miniaturized refrigeration. Mater. Des. 2021, 206, 109784. [Google Scholar] [CrossRef]

- Bruederlin, F.; Ossmer, H.; Wendler, F.; Miyazaki, S.; Kohl, M. SMA foil-based elastocaloric cooling: From material behavior to device engineering. J. Phys. D Appl. Phys. 2017, 50, 424003. [Google Scholar] [CrossRef]

- Schmidt, M.; Schütze, A.; Seelecke, S. Scientific test setup for investigation of shape memory alloy based elastocaloric cooling processes. Int. J. Refrig. 2015, 54, 88–97. [Google Scholar] [CrossRef]

- Kirsch, S.-M.; Welsch, F.; Michaelis, N.; Schmidt, M.; Wieczorek, A.; Frenzel, J.; Eggeler, G.; Schuetze, A.; Seelecke, S. NiTi-Based Elastocaloric Cooling on the Macroscale: From Basic Concepts to Realization. Energy Technol.-Ger. 2018, 6, 1567–1587. [Google Scholar] [CrossRef]

- Kalizan, J.; Tušek, J. Caloric Micro-Cooling: Numerical modelling and parametric investigation. Energy Convers. Manag. 2020, 225, 113421. [Google Scholar] [CrossRef]

- Sasso, C.P.; Zheng, P.; Basso, V.; Muellner, P.; Dunand, D.C. Enhanced field induced martensitic phase transition and magnetocaloric effect in Ni55Mn20Ga25 metallic foams. Intermetallics 2011, 19, 952–956. [Google Scholar] [CrossRef]

- Imran, M.; Zhang, X. Ferromagnetic shape memory Ni-Fe-Ga alloy foams for elastocaloric cooling. J. Phys. D Appl. Phys. 2020, 53, 245503. [Google Scholar] [CrossRef]

- Villa, E.; Aguilar-Ortiz, C.O.; Nespoli, A.; Alvarez-Alonso, P.; Camarillo-Garcia, J.P.; Salazar, D.; Passaretti, F.; Flores-Zuniga, H.; Hosoda, H.; Chernenko, V.A. Tailoring thermomechanical treatment of Ni-Fe-Ga melt-spun ribbons for elastocaloric applications. J. Mater. Res. Technol. JMRT 2019, 8, 4540–4546. [Google Scholar] [CrossRef]

- Imran, M.; Zhang, X.; Qian, M.; Geng, L. Enhancing the Elastocaloric Cooling Stability of Ni-Fe-Ga Alloys via Introducing Pores. Adv. Eng. Mater. 2020, 22, 1901140. [Google Scholar] [CrossRef]

- Imran, M.; Zhang, X. Elastocaloric effects in polycrystalline Ni-Fe-Ga foams with hierarchical pore architecture. Phy. Rev. Mater. 2020, 4, 065403. [Google Scholar] [CrossRef]

- Lu, N.-H.; Chen, C.-H. Improving the functional stability of TiNi-based shape memory alloy by multi-principal element design. Mater. Sci. Eng. A 2023, 872, 144999. [Google Scholar] [CrossRef]

- Yuan, B.; Zhong, S.; Qian, M.; Zhang, X.; Geng, L. Elastocaloric effect in bamboo-grained Cu71.1Al17.2Mn11.7 microwires. J. Alloys Compd. 2021, 850, 156612. [Google Scholar] [CrossRef]

- Xu, Y.; Lu, B.; Sun, W.; Yan, A.; Liu, J. Large and reversible elastocaloric effect in dual-phase Ni54Fe19Ga27 superelastic alloys. Appl. Phys. Lett. 2015, 106, 201903. [Google Scholar] [CrossRef]

- Lyubina, J.; Schafer, R.; Martin, N.; Schultz, L.; Gutfleisch, O. Novel Design of La(Fe, Si)(13) Alloys Towards High Magnetic Refrigeration Performance. Adv. Mater. 2010, 22, 3735–3739. [Google Scholar] [CrossRef]

- Gibson, L.J. Mechanical Behavior of Metallic Foams. Annu. Rev. Mater. Sci. 2000, 30, 191–227. [Google Scholar] [CrossRef]

- Chmielus, M.; Zhang, X.X.; Witherspoon, C.; Dunand, D.C.; Mullner, P. Giant magnetic-field-induced strains in polycrystalline Ni-Mn-Ga foams. Nat. Mater. 2009, 8, 863–866. [Google Scholar] [CrossRef]

- Boonyongmaneerat, Y.; Chmielus, M.; Dunand, D.C.; Müllner, P. Increasing Magnetoplasticity in Polycrystalline Ni-Mn-Ga by Reducing Internal Constraints through Porosity. Phys. Rev. Lett. 2007, 99, 247201. [Google Scholar] [CrossRef]

- Wei, L.S.; Zhang, X.X.; Geng, L. Microstructure and properties of NiTi foams with 69% porosity. Vacuum 2019, 162, 15–19. [Google Scholar] [CrossRef]

- Li, H.; Yuan, B.; Gao, Y. Achieving high oligocrystalline degree via strut architecture tailoring to increase the damping and mechanical properties of spherical porous CuAlMn SMAs. J. Alloys Compd. 2018, 767, 690–702. [Google Scholar] [CrossRef]

- Yuan, B.; Zhu, M.; Chung, C.Y. Biomedical Porous Shape Memory Alloys for Hard-Tissue Replacement Materials. Materials 2018, 11, 1716. [Google Scholar] [CrossRef]

- Porenta, L.; Kabirifar, P.; Žerovnik, A.; Čebron, M.; Žužek, B.; Dolenec, M.; Brojan, M.; Tušek, J. Thin-walled Ni-Ti tubes under compression: Ideal candidates for efficient and fatigue-resistant elastocaloric cooling. Appl. Mater. Today. 2020, 20, 100712. [Google Scholar] [CrossRef]

- Zhang, X.X.; Witherspoon, C.; Mullner, P.; Dunand, D.C. Effect of pore architecture on magnetic-field-induced strain in polycrystalline Ni-Mn-Ga. Acta Mater. 2011, 59, 2229–2239. [Google Scholar] [CrossRef]

- Tong, H.; Wayman, C. Characteristic temperatures and other properties of thermoelastic martensites. Acta Metallurgica 1974, 22, 887–896. [Google Scholar] [CrossRef]

- Alvarez-Alonso, P.; Aguilar-Ortiz, C.O.; Villa, E.; Nespoli, A.; Flores-Zuniga, H.; Chernenko, V.A. Conventional and inverse elastocaloric effect in Ni-Fe-Ga and Ni-Mn-Sn ribbons. Scr. Mater. 2017, 128, 36–40. [Google Scholar] [CrossRef]

- Soto-Parra, D.; Vives, E.; Manosa, L.; Matutes-Aquino, J.A.; Flores-Zuniga, H.; Planes, A. Elastocaloric effect in Ti-Ni shape-memory wires associated with the B2 <-> B19’ and B2 <-> R structural transitions. Appl. Phys. Lett. 2016, 108, 071902. [Google Scholar]

- Wu, Y.; Ertekin, E.; Sehitoglu, H. Elastocaloric cooling capacity of shape memory alloys—Role of deformation temperatures, mechanical cycling, stress hysteresis and inhomogeneity of transformation. Acta Mater. 2017, 135, 158–176. [Google Scholar] [CrossRef]

- Guyomar, D.; Li, Y.; Sebald, G.; Cottinet, P.J.; Ducharne, B.; Capsal, J.F. Elastocaloric modeling of natural rubber. Appl. Therm. Eng. 2013, 57, 33–38. [Google Scholar] [CrossRef]

- Chluba, C.; Ge, W.W.; de Miranda, R.L.; Strobel, J.; Kienle, L.; Quandt, E.; Wuttig, M. Ultralow-fatigue shape memory alloy films. Science 2015, 348, 1004–1007. [Google Scholar] [CrossRef] [PubMed]

- Xiao, F.; Jin, M.J.; Liu, J.; Jin, X.J. Elastocaloric effect in Ni50Fe19Ga27Co4 single crystals. Acta Mater. 2015, 96, 292–300. [Google Scholar] [CrossRef]

- Li, D.; Li, Z.; Zhang, X.; Yang, B.; Wang, D.; Zhao, X.; Zuo, L. Enhanced cyclability of elastocaloric effect in a directionally solidified Ni55Mn18Ga26Ti1 alloy with low hysteresis. Scr. Mater. 2020, 189, 78–83. [Google Scholar] [CrossRef]

- Zhang, G.; Li, D.; Liu, C.; Li, Z.; Yang, B.; Yan, H.; Zhao, X.; Zuo, L. Giant low-field actuated caloric effects in a textured Ni43Mn47Sn10 alloy. Scr. Mater. 2021, 201, 113947. [Google Scholar] [CrossRef]

- Hamilton, R.F.; Sehitoglu, H.; Efstathiou, C.; Maier, H.; Chumlyakov, Y. Pseudoelasticity in Co–Ni–Al single and polycrystals. Acta Mater. 2006, 54, 587–599. [Google Scholar] [CrossRef]

- Tusek, J.; Engelbrecht, K.; Mikkelsen, L.P.; Pryds, N. Elastocaloric effect of Ni-Ti wire for application in a cooling device. J. Appl. Phys. 2015, 117, 124901. [Google Scholar] [CrossRef]

- Shen, A.; Zhao, D.W.; Sun, W.; Liu, J.; Li, C.J. Elastocaloric effect in a Co50Ni20Ga3 single crystal. Scr. Mater. 2017, 127, 1–5. [Google Scholar] [CrossRef]

- Bechtold, C.; Chluba, C.; De Miranda, R.L.; Quandt, E. High cyclic stability of the elastocaloric effect in sputtered TiNiCu shape memory films. Appl. Phys. Lett. 2012, 101, 091903. [Google Scholar] [CrossRef]

- Ossmer, H.; Chluba, C.; Gueltig, M.; Quandt, E.; Kohl, M. Local Evolution of the Elastocaloric Effect in TiNi-Based Films. Shape Mem. Superelasticity 2015, 1, 142–152. [Google Scholar] [CrossRef]

- Bumke, L.; Zamponi, C.; Jetter, J.; Quandt, E. Cu-rich Ti52.8Ni22.2Cu22.5Co2.5 shape memory alloy films with ultra-low fatigue for elastocaloric applications. J. Appl. Phys. 2020, 127, 225105. [Google Scholar] [CrossRef]

- Cui, J.; Wu, Y.M.; Muehlbauer, J.; Hwang, Y.H.; Radermacher, R.; Fackler, S.; Wuttig, M.; Takeuchi, I. Demonstration of high efficiency elastocaloric cooling with large Delta T using NiTi wires. Appl. Phys. Lett. 2012, 101, 073904. [Google Scholar] [CrossRef]

- Liang, X.; Xiao, F.; Jin, M.; Jin, X.; Fukuda, T.; Kakeshita, T. Elastocaloric effect induced by the rubber-like behavior of nanocrystalline wires of a Ti-50.8Ni (at.%) alloy. Scr. Mater. 2017, 134, 42–46. [Google Scholar] [CrossRef]

- Xiao, F.; Li, Z.; Chen, H.; Li, Z.; Huang, K.; Jin, X.; Fukuda, T. Martensitic transformation and elastocaloric effect of Ti–Ni–Cu–Al microwire. Materialia 2020, 9, 100547. [Google Scholar] [CrossRef]

- Schmidt, M.; Schutze, A.; Seelecke, S. Elastocaloric cooling processes: The influence of material strain and strain rate on efficiency and temperature span. Apl. Mater. 2016, 4, 064107. [Google Scholar] [CrossRef]

- Wei, L.; Zhang, X.; Liu, J.; Geng, L. Orientation dependent cyclic stability of the elastocaloric effect in textured Ni-Mn-Ga alloys. Aip. Adv. 2018, 8, 055312. [Google Scholar] [CrossRef]

- Yang, Z.; Cong, D.Y.; Sun, X.M.; Nie, Z.H.; Wang, Y.D. Enhanced cyclability of elastocaloric effect in boron-microalloyed Ni-Mn-In magnetic shape memory alloys. Acta Mater. 2017, 127, 33–42. [Google Scholar] [CrossRef]

- Tang, X.; Feng, Y.; Wang, H.; Wang, P. Enhanced elastocaloric effect and cycle stability in B and Cu co-doping Ni-Mn-In polycrystals. Appl. Phys. Lett. 2019, 114, 033901. [Google Scholar] [CrossRef]

- Zhang, K.; Kang, G.; Sun, Q. High fatigue life and cooling efficiency of NiTi shape memory alloy under cyclic compression. Scr. Mater. 2019, 159, 62–67. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, K.; Kan, Q.; Yin, H.; Sun, Q. Ultra-high fatigue life of NiTi cylinders for compression-based elastocaloric cooling. Appl. Phys. Lett. 2019, 115, 093902. [Google Scholar] [CrossRef]

- Chen, H.; Xiao, F.; Liang, X.; Li, Z.; Li, Z.; Jin, X.; Min, N.; Fukuda, T. Improvement of the stability of superelasticity and elastocaloric effect of a Ni-rich Ti-Ni alloy by precipitation and grain refinement. Scr. Mater. 2019, 162, 230–234. [Google Scholar] [CrossRef]

- Kim, Y.; Jo, M.-G.; Park, J.-W.; Park, H.-K.; Han, H.N. Elastocaloric effect in polycrystalline Ni50Ti45.3V4.7 shape memory alloy. Scr. Mater. 2018, 144, 48–51. [Google Scholar] [CrossRef]

- Imran, M.; Zhang, X.; Qian, M.; Geng, L. Enhanced working stability of elastocaloric effects in polycrystalline Ni-Fe-Ga dual phase alloy. Intermetallics 2021, 136, 107255. [Google Scholar] [CrossRef]

- Chen, Y.; Schuh, C.A. Size effects in shape memory alloy microwires. Acta Mater. 2011, 59, 537–553. [Google Scholar] [CrossRef]

- Hamilton, R.F.; Sehitoglu, H.; Chumlyakov, Y.; Maier, H.J. Stress dependence of the hysteresis in single crystal NiTi alloys. Acta Mater. 2004, 52, 3383–3402. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F. Cellular Solids: Structure and Properties, 2nd ed.; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar] [CrossRef]

- Ossmer, H.; Wendler, F.; Gueltig, M.; Lambrecht, F.; Miyazaki, S.; Kohl, M. Energy-efficient miniature-scale heat pumping based on shape memory alloys. Smart Mater. Struct. 2016, 25, 085037. [Google Scholar] [CrossRef]

- Czernuszewicz, A.; Griffith, L.; Slaughter, J.; Pecharsky, V. Low-force compressive and tensile actuation for elastocaloric heat pumps. Appl. Mater. Today 2020, 19, 100557. [Google Scholar] [CrossRef]

- Panchenko, E.; Tokhmetova, A.; Surikov, N.; Eftifeeva, A.; Tagiltsev, A.; Timofeeva, E.; Chumlyakov, Y.; Gerstein, G.; Maier, H.J. Temperature dependence of martensite variant reorientation in stress-induced martensite aged Ni49Fe18Ga27Co6 single crystals. Scr. Mater. 2021, 194, 113618. [Google Scholar] [CrossRef]

- Hou, H.; Simsek, E.; Ma, T.; Johnson, N.S.; Qian, S.; Cissé, C.; Stasak, D.; Al Hasan, N.; Zhou, L.; Hwang, Y. Fatigue-resistant high-performance elastocaloric materials made by additive manufacturing. Science 2019, 366, 1116–1121. [Google Scholar] [CrossRef]

- Aaltio, I.; Fukuda, T.; Kakeshita, T. Elastocaloric cooling and heating using R-phase transformation in hot rolled Ni-Ti-Fe shape memory alloys with 2 and 4 at% Fe content. J. Alloys Compd. 2019, 780, 930–936. [Google Scholar] [CrossRef]

- Chmielus, M.; Witherspoon, C.; Wimpory, R.C.; Paulke, A.; Hilger, A.; Zhang, X.; Dunand, D.C.; Müllner, P. Magnetic-field-induced recovery strain in polycrystalline Ni–Mn–Ga foam. J. Appl. Phys. 2010, 108, 123526. [Google Scholar] [CrossRef]

- Li, D.; Li, Z.; Yang, J.; Li, Z.; Yang, B.; Yan, H.; Wang, D.; Hou, L.; Li, X.; Zhang, Y.; et al. Large elastocaloric effect driven by stress-induced two-step structural transformation in a directionally solidified Ni55Mn18Ga27 alloy. Scr. Mater. 2019, 163, 116–120. [Google Scholar] [CrossRef]

- Cao, T.; Xuan, H.; Liu, S.; Wang, L.; Xie, Z.; Liang, X.; Chen, F.; Han, P.; Wang, D.; Du, Y. Enhanced elastocaloric effect and mechanical properties of Fe-doped Ni-Mn-Al ferromagnetic shape memory alloys. Intermetallics 2019, 112, 106529. [Google Scholar] [CrossRef]

- Villa, F.; Tamandi, M.; Passaretti, F.; Bassani, E.; Villa, E. Promising elastocaloric properties of sintered polycrystalline NiMnGa produced by open die pressing. J. Mater. Sci. 2023, 58, 15240–15250. [Google Scholar] [CrossRef]

- Manosa, L.; Jarque-Farnos, S.; Vives, E.; Planes, A. Large temperature span and giant refrigerant capacity in elastocaloric Cu-Zn-Al shape memory alloys. Appl. Phys. Lett. 2013, 103, 211904. [Google Scholar] [CrossRef]

- Lu, N.-H.; Chen, C.-H. Compressive stress-induced martensitic transformation and elastocaloric effect in Cu-Al-Mn single-crystal alloy. Mater. Sci. Eng. A 2022, 840, 142945. [Google Scholar] [CrossRef]

- Gottschall, T.; Skokov, K.P.; Frincu, B.; Gutfleisch, O. Large reversible magnetocaloric effect in Ni-Mn-In-Co. Appl. Phys. Lett. 2015, 106, 021901. [Google Scholar] [CrossRef]

- Dang, P.; Ye, F.; Zhou, Y.; Ding, L.; Pang, J.; Zhang, L.; Ding, X.; Sun, J.; Dai, S.; Lookman, T.; et al. Low-fatigue and large room-temperature elastocaloric effect in a bulk Ti49.2Ni40.8Cu10 alloy. Acta Mater. 2022, 229, 117802. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Imran, M.; Qian, M.; Zhang, X.; Geng, L. Large Cyclability of Elastocaloric Effect in Highly Porous Ni-Fe-Ga Foams. Materials 2024, 17, 1272. https://doi.org/10.3390/ma17061272

Imran M, Qian M, Zhang X, Geng L. Large Cyclability of Elastocaloric Effect in Highly Porous Ni-Fe-Ga Foams. Materials. 2024; 17(6):1272. https://doi.org/10.3390/ma17061272

Chicago/Turabian StyleImran, Muhammad, Mingfang Qian, Xuexi Zhang, and Lin Geng. 2024. "Large Cyclability of Elastocaloric Effect in Highly Porous Ni-Fe-Ga Foams" Materials 17, no. 6: 1272. https://doi.org/10.3390/ma17061272