An Experimental Investigation of the Material Properties of the A356 Aluminum Alloy Power Fittings in the Vacuum Die-Casting Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material Specifications

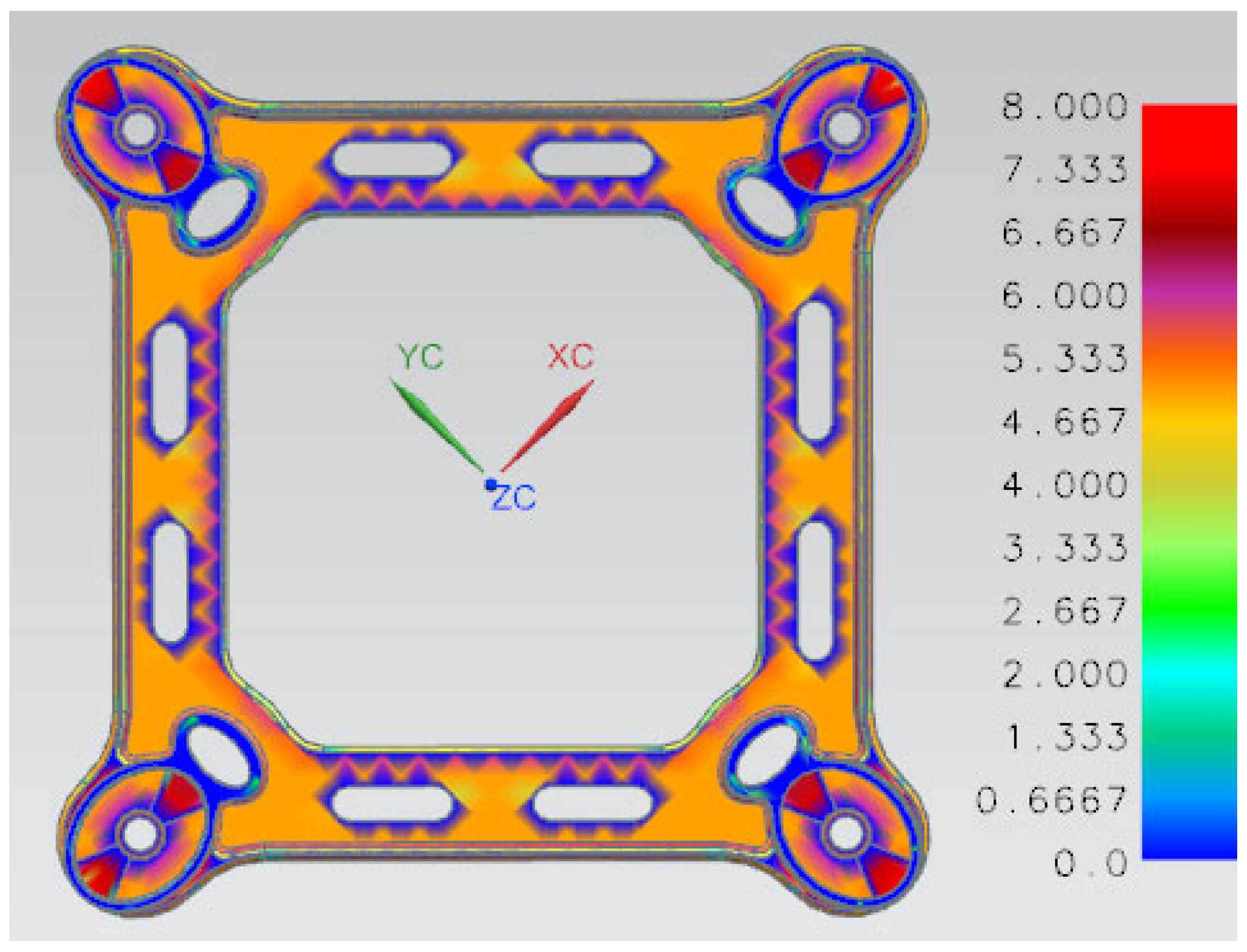

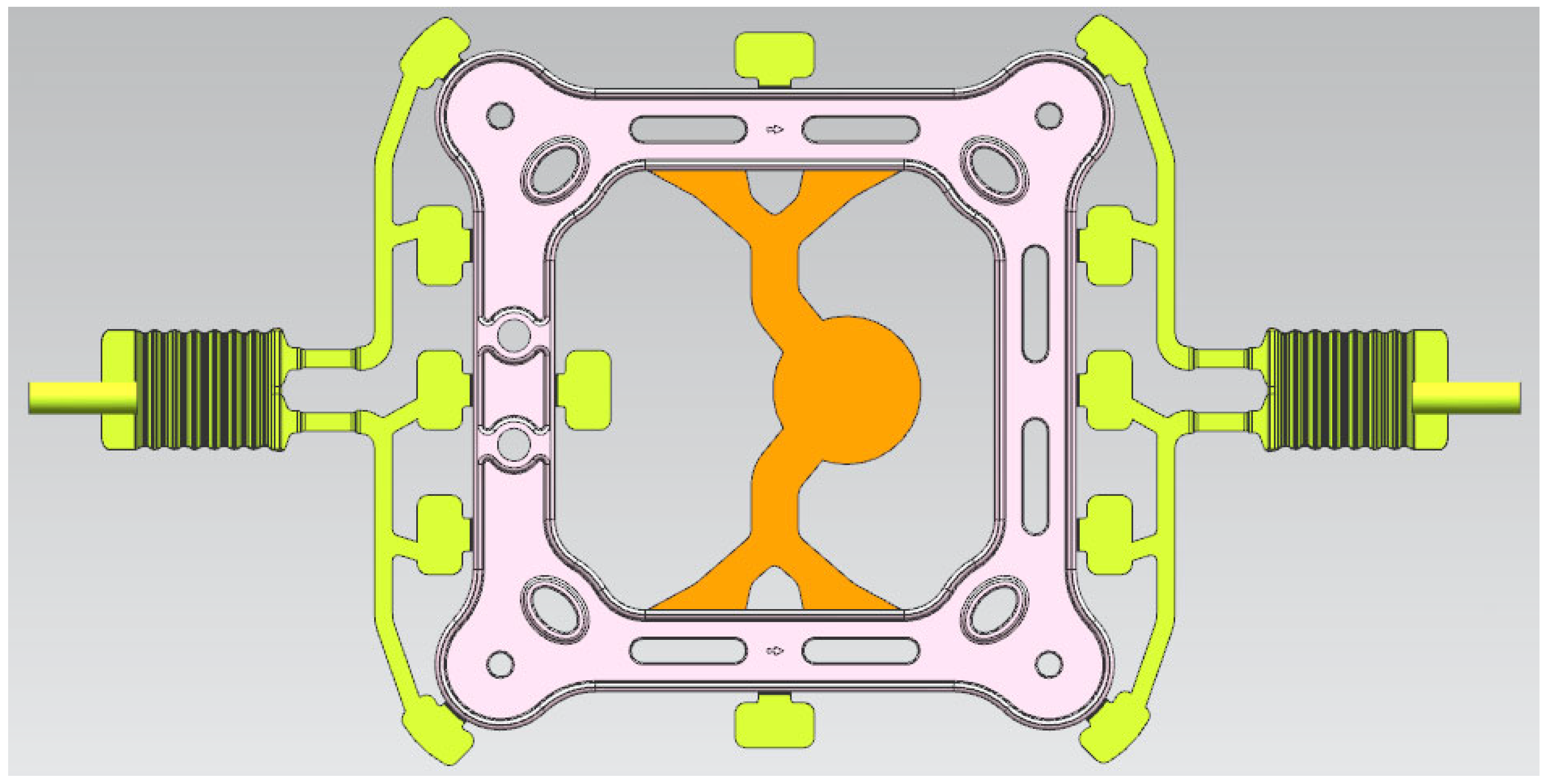

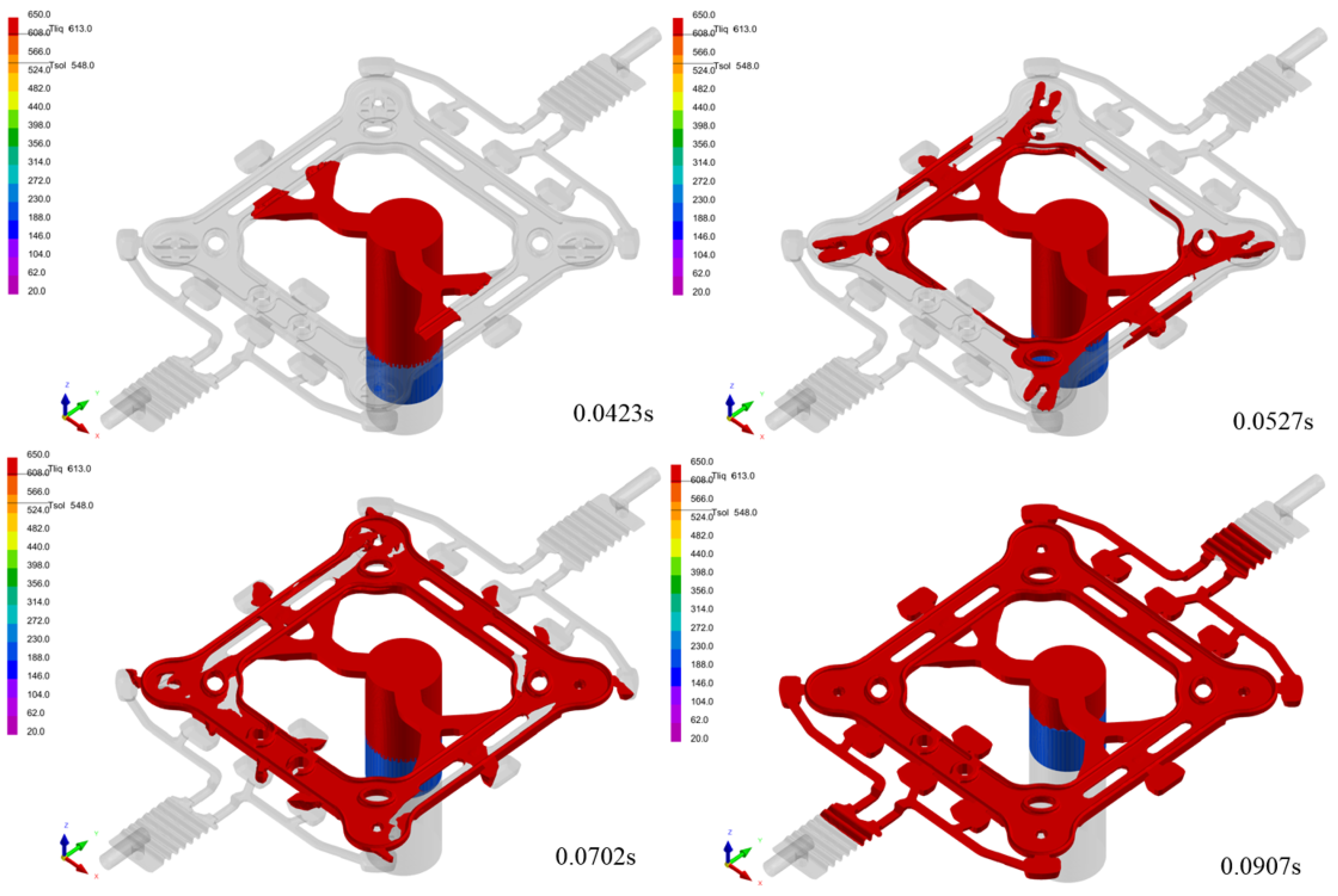

2.2. Process Design and Simulation

- ①

- Generate an STL model file through 3D CAD modeling;

- ②

- Import the STL model file into proCAST v.17.5.0 software and generate a mesh model with a minimum mesh size of 1.00 mm;

- ③

- Set the material parameters for material A356, including an alloy density of 2500 kg/m3;

- ④

- Set process parameters, including an initial temperature of 650 °C and a solidification time of 15 s;

- ⑤

- Finally, perform the computational simulation.

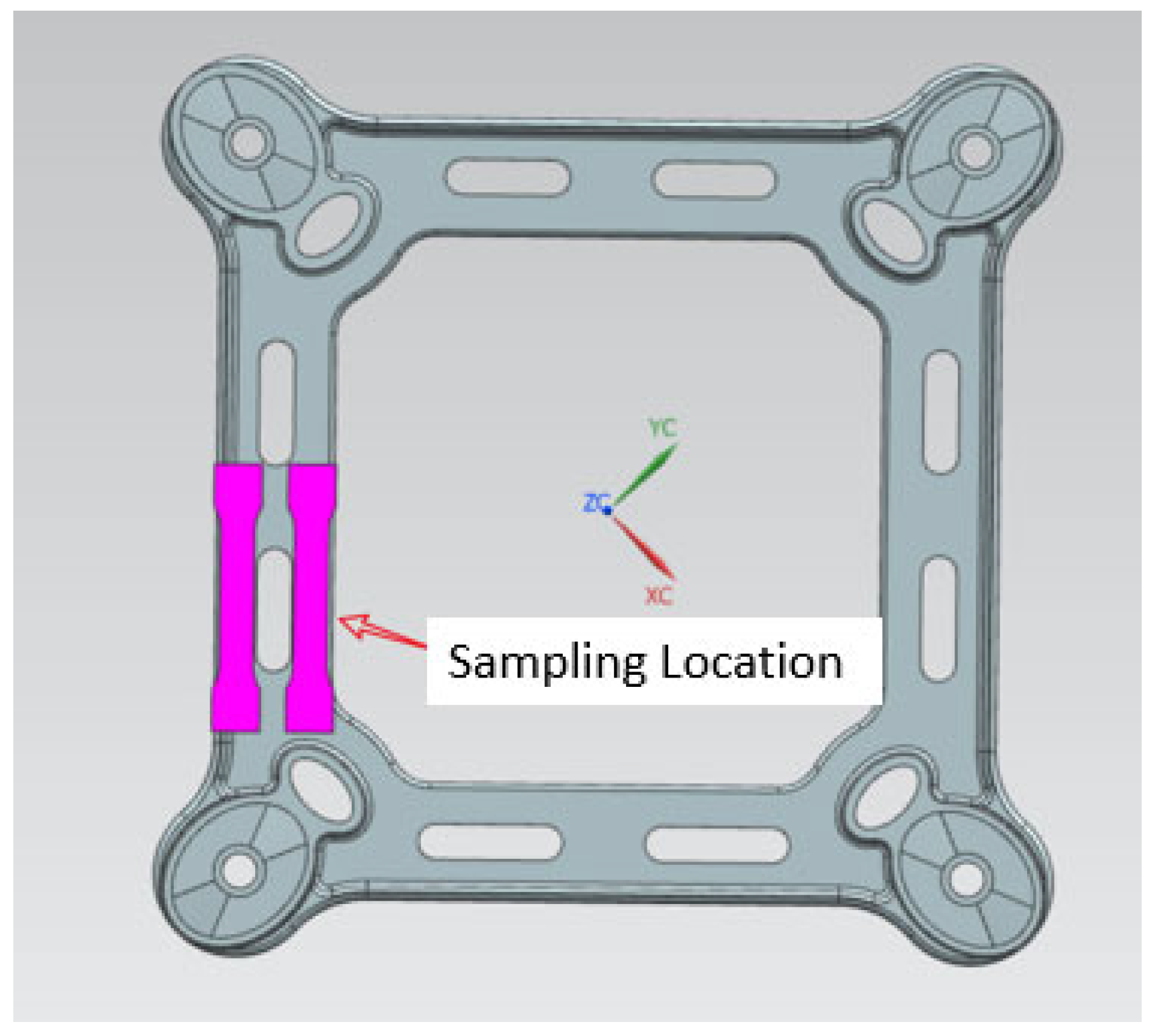

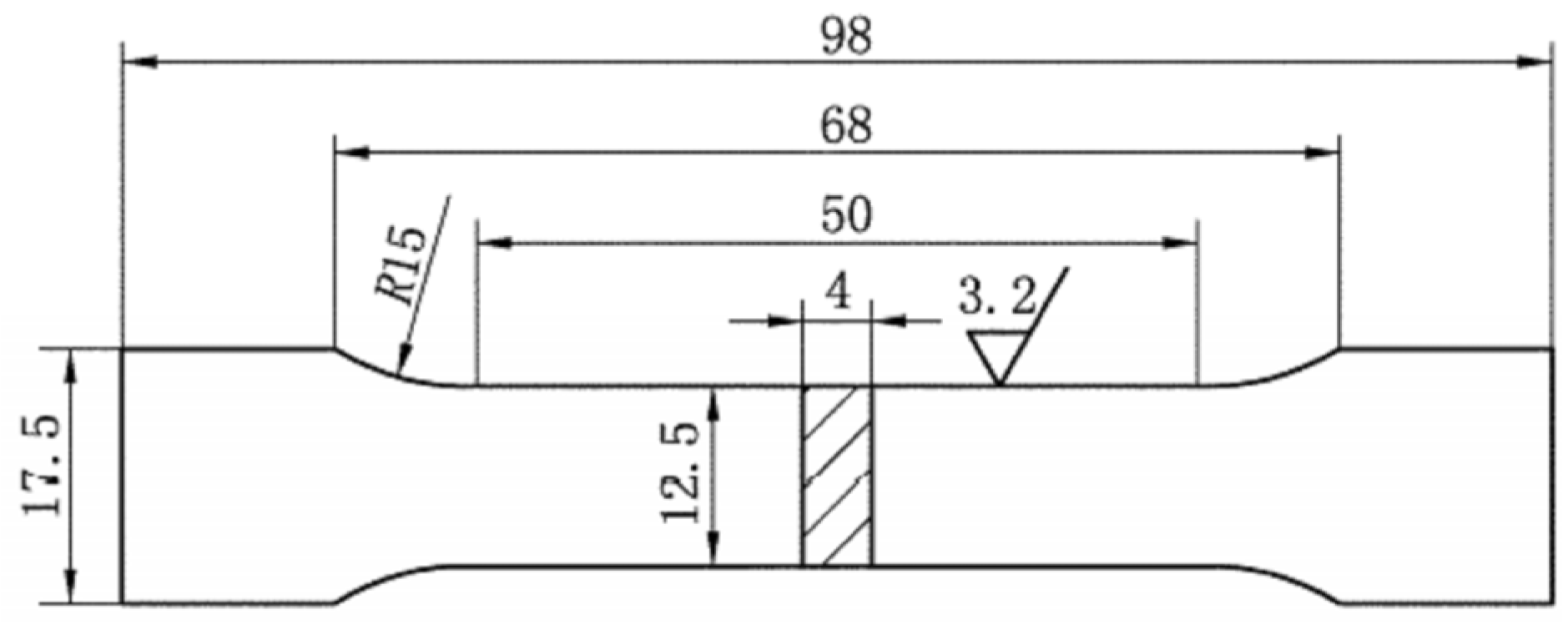

2.3. Trial Production and Performance Testing

3. Results and Discussion

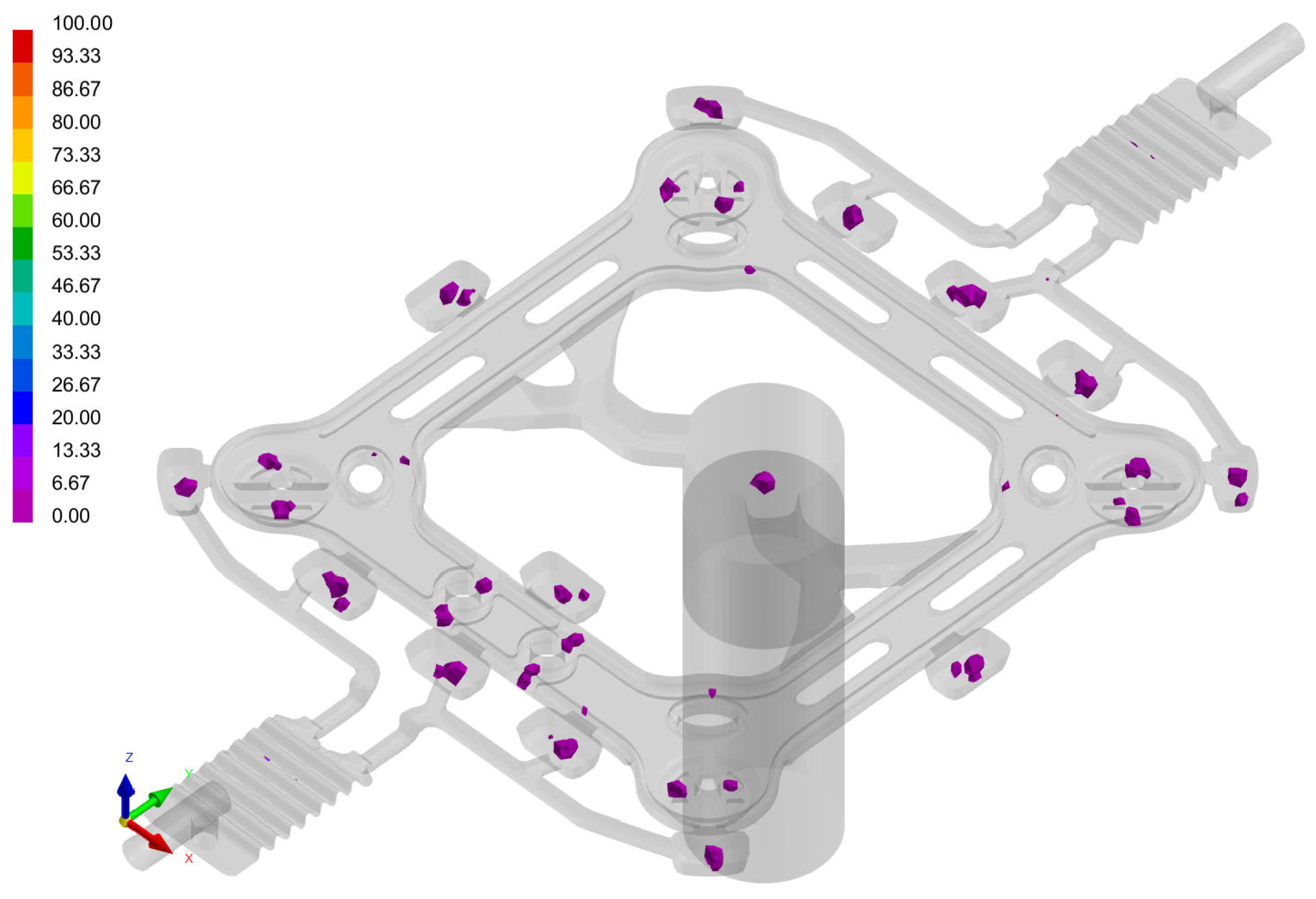

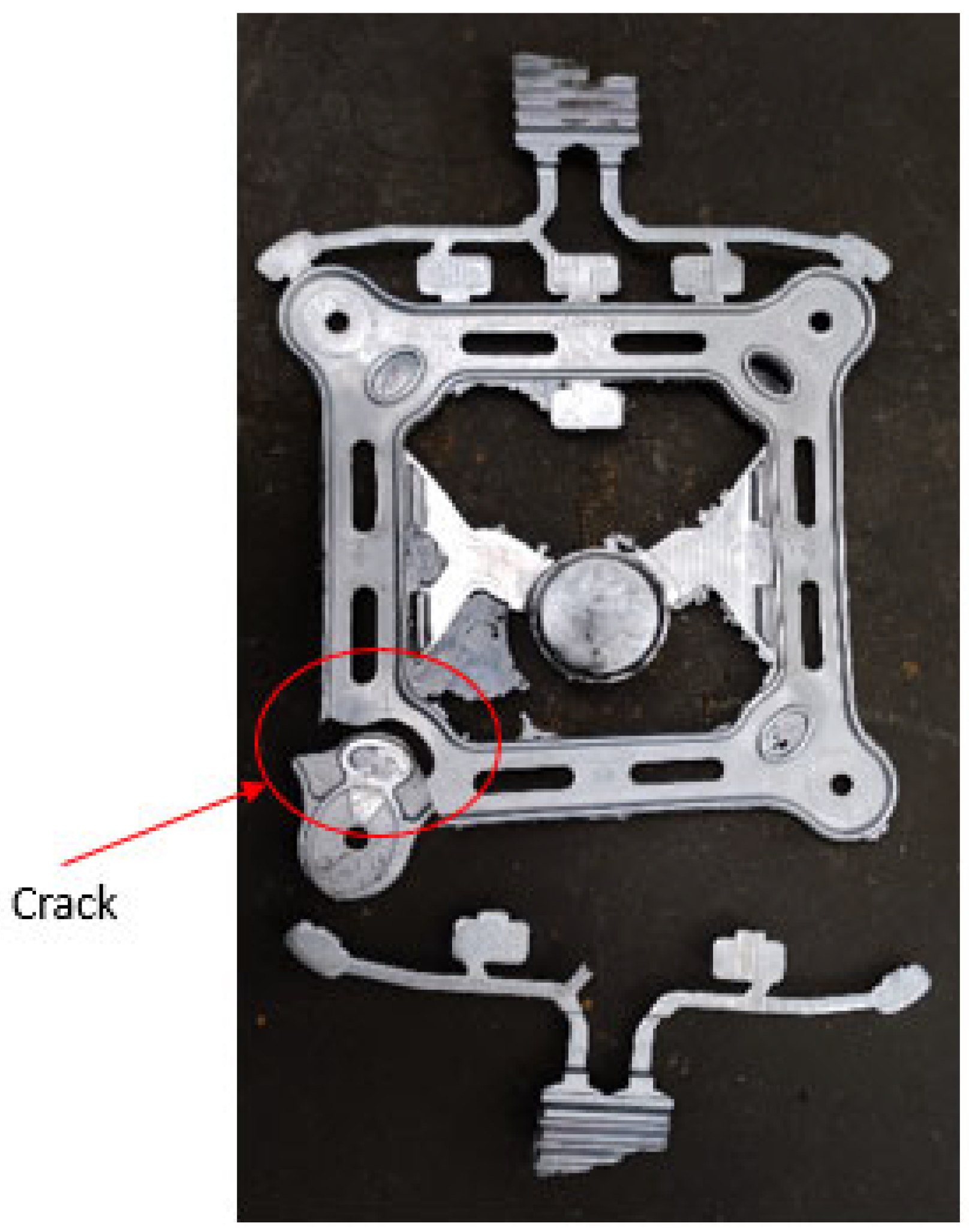

3.1. Optimizing the Casting System through Finite Element Simulation

3.2. Control of the Vacuum Die-Casting Process

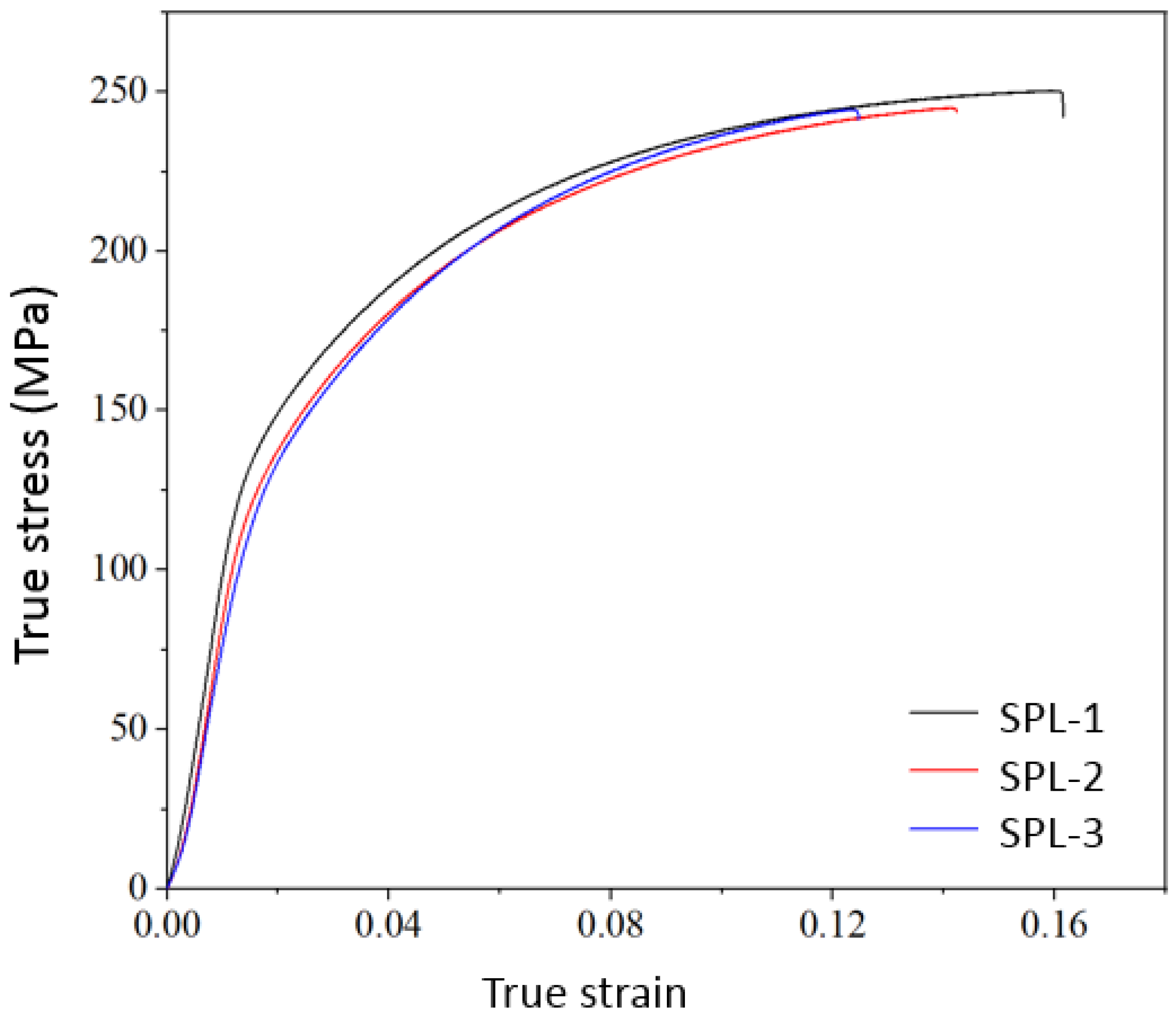

3.3. Influence of the Vacuum Die-Casting Process on the Mechanical Properties of a Die-Cast Aluminum Alloy

4. Conclusions

- (1)

- The results of the process test indicate that the VDCP can significantly reduce the formation of porosity defects during the die-casting process, thereby improving the quality and reliability of the parts. By utilizing high-strength materials and advanced molding processes, the surface quality of the parts can be improved, leading to enhanced anti-fatigue mechanical properties and increased reliability of the entire transmission line project.

- (2)

- The test results indicate that the A356 aluminum alloy vacuum die-casting spacer bar has an average tensile strength of 246.52 MPa and an average elongation of 10.18%, with elongation exceeding 7%. Its STP value of 2509.57 MPa% is much higher than the typical value of the ZL102 aluminum alloy, and it greatly improved the strength and toughness of the product.

- (3)

- The utilization of water-based mold release agents that are more environmentally friendly can resolve the challenges of releasing A356 aluminum alloy die-casting molds, thereby meeting the requirements for mass production.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, S.; He, W.; Du, T.; Liao, J.; Li, X.; Wang, L.; Zong, L. Research progress on materials for transmission line fittings and their process technology. Electr. Eng. 2019, 15, 149–153. [Google Scholar]

- Cai, X.; Huang, Y.; Li, Y. Production process and technology development of hotdip galvanizing. Appl. Mech. Mater. 2014, 488–489, 61–65. [Google Scholar] [CrossRef]

- Yetim, A.F.; Kovaci, H.; Yildiz, F.; Bayrak, O.; Çelik, A. The effect of post aging on wear properties of a plasma nitrided ferromagnetic steel under DC magnetic field. Wear 2015, 332–333, 988–994. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, R.; Du, Z.; Yuan, D.; Du, H. Hysteretic and Loss Modeling of Grain Oriented Silicon Steel Lamination under AC-DC Hybrid Magnetization. Trans. China Electrotech. Soc. 2021, 13, 2791–2800. [Google Scholar]

- Stein, J.; Lenczowski, B.; Frety, N.; Anglaret, E. Mechanical reinforcement of a high -performance aluminium alloy AA5083 with homogeneously dispersed multi-walled carbon nanotubes. Carbon 2012, 50, 2264–2272. [Google Scholar] [CrossRef]

- Pertz-Bustamante, R.; Estrada-Guel, I.; Amezaga-Madrid, P.; Miki-Yoshida, M.; Herrera-Ramírez, J.M.; Martínez-Sánchez, R. Microstructural characterization of Al-MWCNT composites produced by mechanical milling and hot extrusion. J. Alloys Compd. 2010, 495, 399–402. [Google Scholar] [CrossRef]

- Cheng, Y.; Qian, N.; Chen, S.; Wang, J.; Wang, C. Analysis on Simulation and Test of Energy Consumption of Composite Power Fittings. Zhejiang Electr. Power 2015, 34, 27–30. [Google Scholar]

- Li, T.; Tian, W.; Liu, L. Simulation and experiment research of fittings power loss in high voltage transmission line. In Proceedings of the 1st International Conference on Electrical Materials and Power Equipment (ICEMPE), Xi’an, China, 14–17 May 2017; pp. 151–154. [Google Scholar]

- Nikiforov, E.P. Raising the reliability of overhead transmission lines under the action of atmospheric loads. Power Technol. Eng. 2004, 38, 49–53. [Google Scholar] [CrossRef]

- Sawaitov, D.S.; Timashova, L.V. Technical state of basic equipment of substations and overhead transmission lines and measures for raising their reliability. Power Technol. Eng. 2004, 38, 285–290. [Google Scholar]

- Li, J.; Liao, Z.; Zhang, L.; Xiong, X.; Liang, N.; Zhang, Y.; Kang, Y.; Zhou, E. Operation and maintenance techniques for 750 kV transmission lines under severe wind and sand-dust weather in Xinjiang. Power Syst. Prot. Control 2017, 45, 123–130. [Google Scholar]

- Wu, G. Cause Analysis and Preventive Measures of Line Hardware Frost Crack. Electr. Power Constr. 2007, 2, 73–75. [Google Scholar]

- Fachri, P.N.; Svein, S.; Stig, B. Experimental and finite element analysis of fatigue strength for 300 mm2 copper power conductor. Mar. Struct. 2014, 39, 225–254. [Google Scholar]

- Martina, G.; Urban, W. Wear and electrical performance of a slip-ring system with silver–graphite in continuous sliding against PVD coated wires. Wear 2016, 348–349, 138–147. [Google Scholar]

- Łągiewka, M.; Konopka, Z.; Nadolski, M.; Zyska, A. The effect of vacuum assistance on the quality of castings produced by high pressure die casting method. Arch. Foundry Eng. 2014, 14, 23–26. [Google Scholar] [CrossRef]

- Niu, X.P.; Hua, B.H.; Pinwilla, I.; Li, H. Vacuum assisted high pressure die casting of aluminium alloys. J. Mater. Process. Technol. 2000, 105, 119–127. [Google Scholar] [CrossRef]

- Dudeka, P.; Biało’na, J.; Piwowo’nskaa, J.; Walczakb, W.; Wrzałab, K. The impact on the cost of making high pressure die castings with multi-cavity die and vacuum assistance. Vacuum 2023, 210, 111859. [Google Scholar] [CrossRef]

- Yoo, M.; Song, J.; Oh, J.; Kang, S.; Kim, K.; Yang, S.; Moon, M. Development of a bus armrest fabrication process with a high-vacuum, high-pressure die-casting process using the AM60 alloy. Robot. Comput. Integr. Manuf. 2019, 55, 154–159. [Google Scholar] [CrossRef]

- Das, P.; Bhuniya, B.; Samanta, S.K.; Dutta, P. Studies on die filling of A356 Al alloy and development of a steering knuckle component using rheo pressure die casting system. J. Mater. Process. Technol. 2019, 271, 293–311. [Google Scholar] [CrossRef]

- Ali, Z.; Muthuraman, V.; Rathnakumar, P.; Gurusamy, P.; Nagaral, M. Studies on mechanical properties of 3 wt% of 40 and 90 mm size B4C particulates reinforced A356 alloy composites. Mater. Today Proc. 2022, 52, 494–499. [Google Scholar] [CrossRef]

- Lakshmikanthan, A.; Prabhu, T.; Babu, U.; Koppad, P.; Gupta, M.; Krishna, M.; Bontha, S. The effect of heat treatment on the mechanical and tribological properties of dual size SiC reinforced A357 matrix composites. J. Mater. Res. Technol. 2020, 9, 34–52. [Google Scholar] [CrossRef]

- Eshaghi, A.; Ghasemi, H.M.; Rassizadehghani, J. Effect of heat treatment on microstructure and wear behavior of Al-Si alloys with various iron contents. Mater. Des. 2011, 32, 1520–1525. [Google Scholar] [CrossRef]

- Hu, C.; Zhao, H.; Wang, X.; Zheng, B. Effect of Mg on age hardening of high vacuum die casting AlSi10MgMn alloys. Chin. J. Nonferrous Met. 2020, 30, 1481–1490. [Google Scholar]

| Si | Fe | Cu | Mn | Mg | Ti | Zn | Al |

|---|---|---|---|---|---|---|---|

| 10.0~13.0 | 0~1.00 | ≤0.30 | ≤0.50 | ≤0.10 | ≤0.20 | ≤0.10 | Bal |

| Si | Fe | Cu | Mn | Mg | Ti | Zn | Al |

|---|---|---|---|---|---|---|---|

| 6.5~7.5 | 0~0.12 | ≤0.10 | ≤0.05 | 0.30~0.45 | ≤0.20 | ≤0.05 | Bal |

| Material | Process | Tensile Strength (MPa) | Elongation (%) | STP (MPa%) |

|---|---|---|---|---|

| ZL102 | VDCP | 157.67 | 3.5 | 551.84 |

| A356 | VDCP | 246.52 | 10.18 | 2509.57 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, J.; Wang, Y.; Wang, X.; Zhang, Y. An Experimental Investigation of the Material Properties of the A356 Aluminum Alloy Power Fittings in the Vacuum Die-Casting Process. Materials 2024, 17, 1242. https://doi.org/10.3390/ma17061242

Zhao J, Wang Y, Wang X, Zhang Y. An Experimental Investigation of the Material Properties of the A356 Aluminum Alloy Power Fittings in the Vacuum Die-Casting Process. Materials. 2024; 17(6):1242. https://doi.org/10.3390/ma17061242

Chicago/Turabian StyleZhao, Jianli, Yilin Wang, Xiaowei Wang, and Yisheng Zhang. 2024. "An Experimental Investigation of the Material Properties of the A356 Aluminum Alloy Power Fittings in the Vacuum Die-Casting Process" Materials 17, no. 6: 1242. https://doi.org/10.3390/ma17061242