Freeze–Thaw Damage Characterization of Cement-Stabilized Crushed Stone Base with Skeleton Dense Gradation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Materials

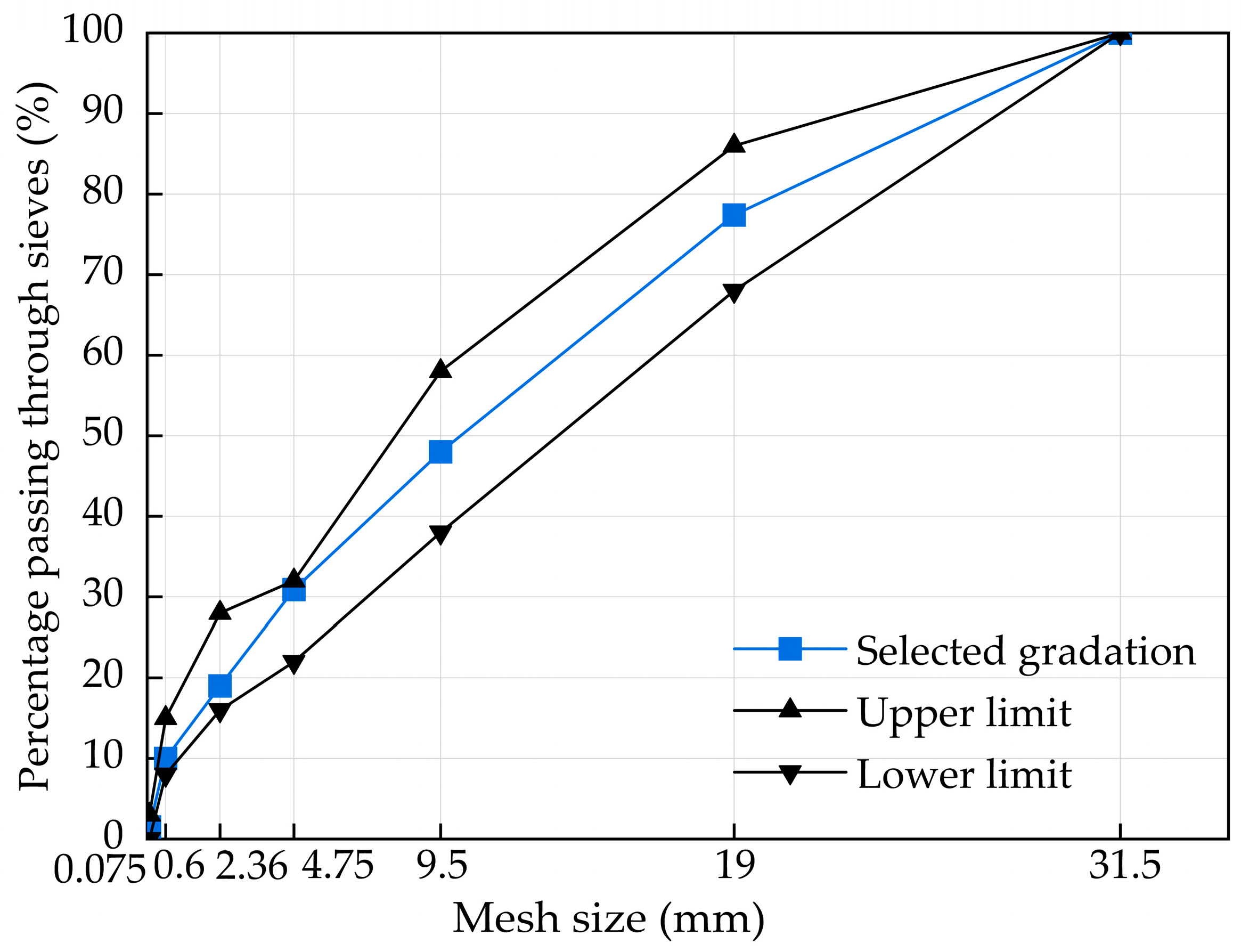

2.2. Material Gradations and Specimen Preparation

2.3. Experimental Methods

2.3.1. Freeze–Thaw Cycle Test

2.3.2. Mechanical Performance Test

2.3.3. Acoustic Detection Test

3. Results

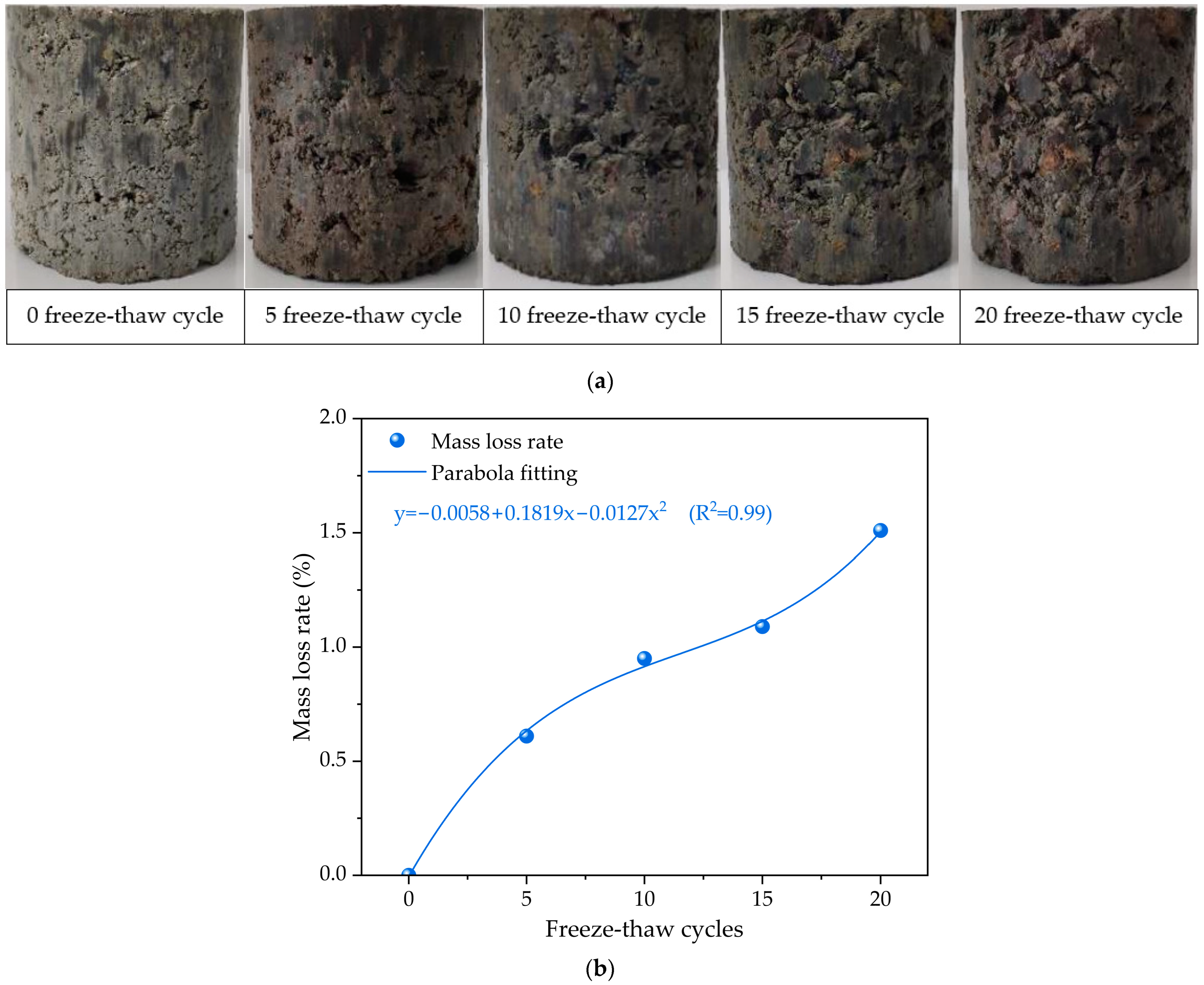

3.1. Mass Evolution Analysis of Cement-Stabilized Crushed Stone Base with Skeleton Dense Gradation

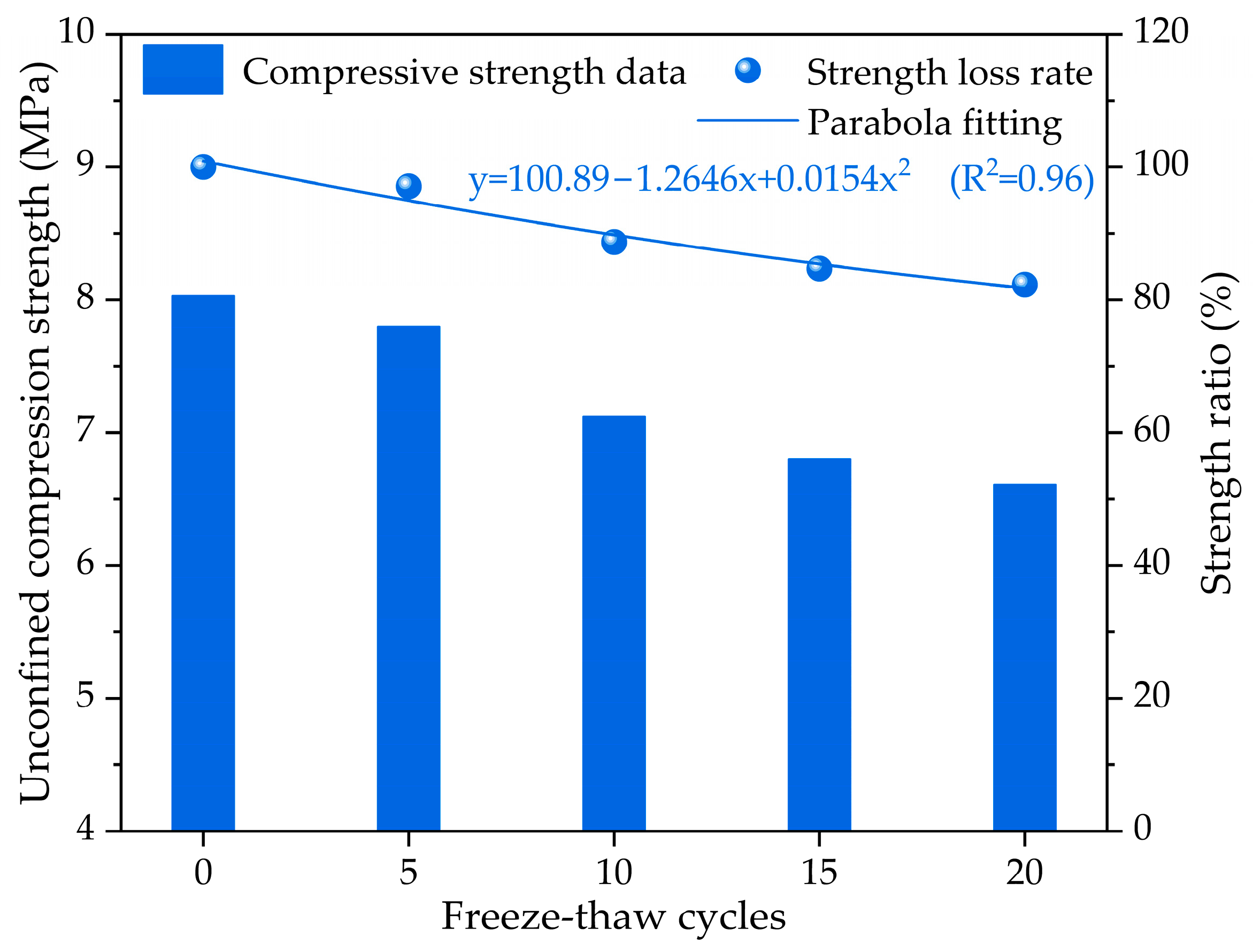

3.2. Compressive Strength Evolution of Cement-Stabilized Crushed Stone Base with Skeleton Dense Gradation

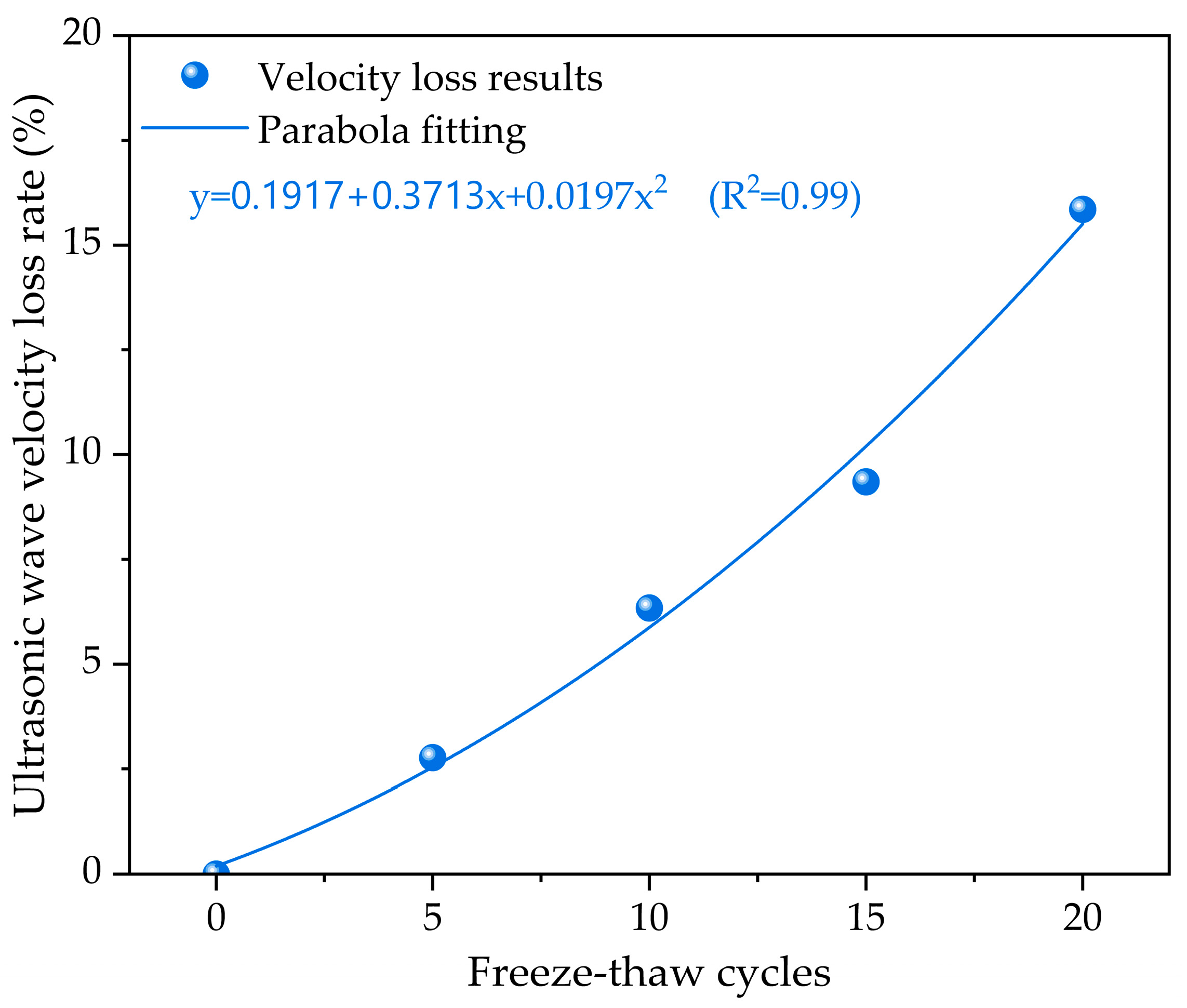

3.3. Ultrasonic Wave Velocity Analysis of Cement-Stabilized Crushed Stone Base with Skeleton Dense Gradation

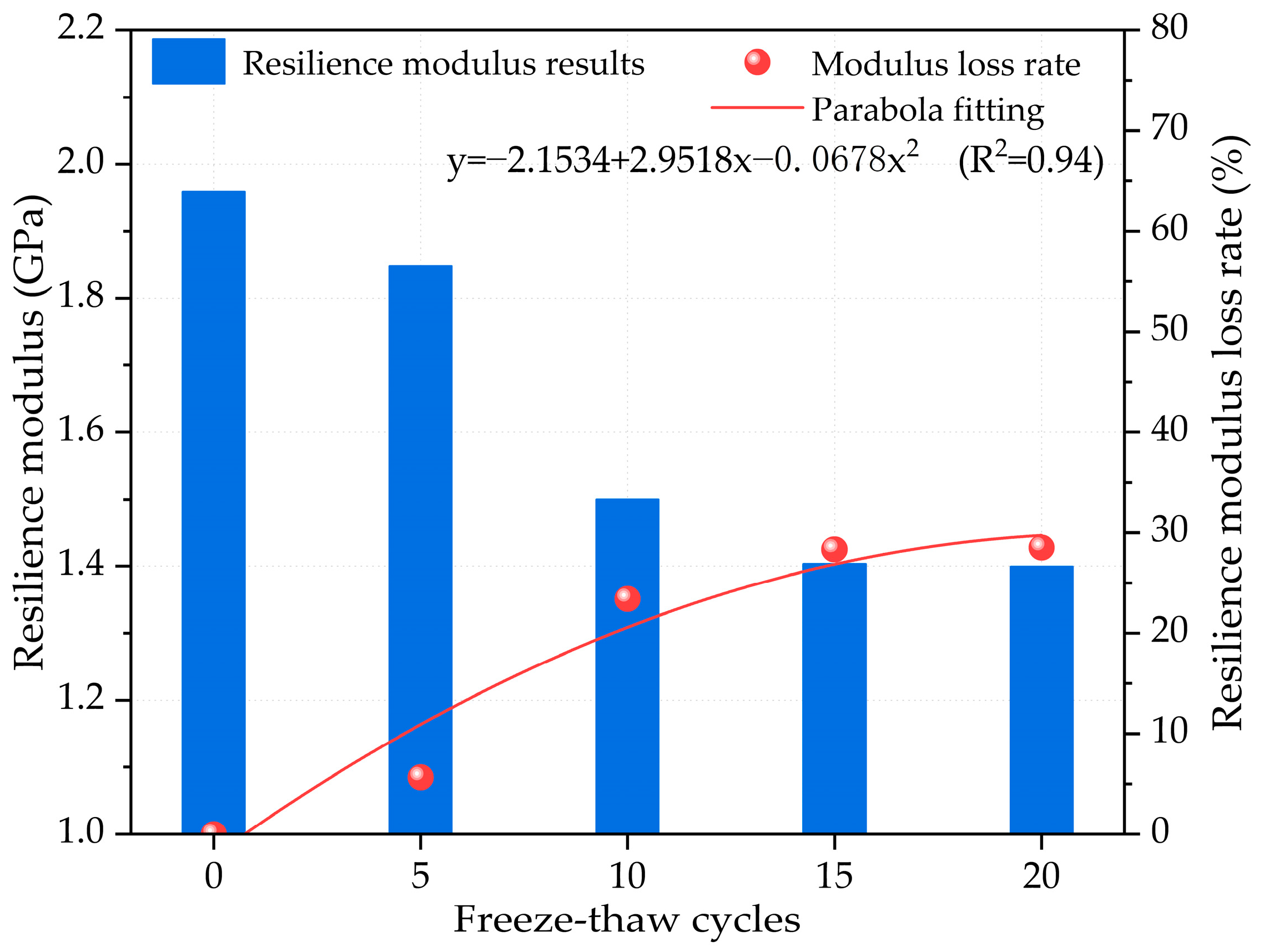

3.4. Resilience Modulus Analysis of Cement-Stabilized Crushed Stone Base with Skeleton Dense Gradation

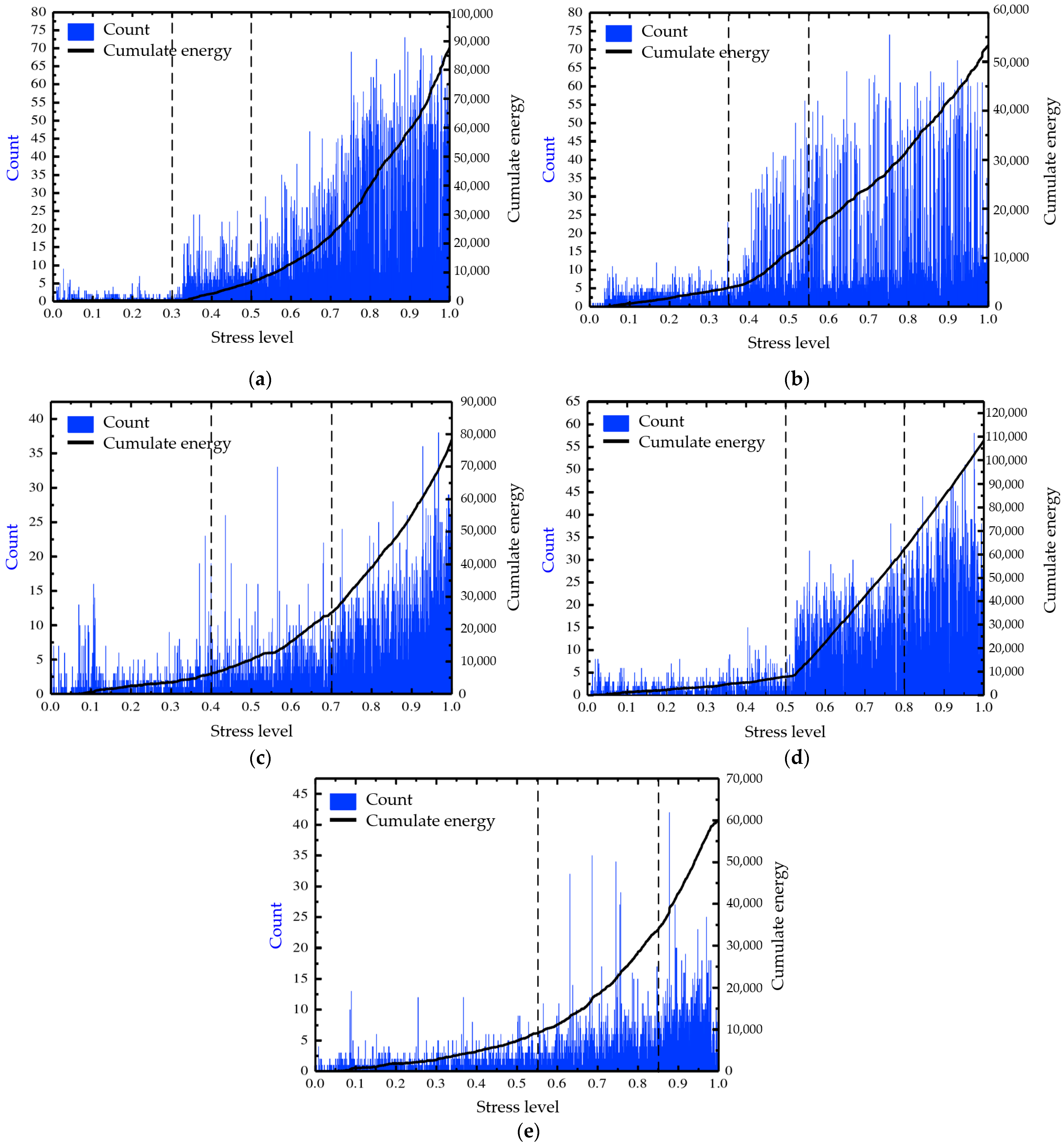

3.5. Acoustic Emission Parameter Analysis of Cement-Stabilized Crushed Stone Base under Freeze–Thaw Cycles

4. Discussions

5. Conclusions

- (1)

- The mass loss rate of the cement-stabilized crushed stone base shows a gradually increasing trend with freezing–thawing cycles increasing, in which the curve steepens significantly after 15 freeze–thaw cycles, following a parabola-fitting pattern relationship.

- (2)

- The compressive strength of the cement-stabilized crushed stone base with skeleton dense gradation decreases with freezing–thawing cycle increasing, following a parabola-fitting pattern. The decrease rate may accelerate as the cycles increase.

- (3)

- The ultrasonic wave velocity of the cement-stabilized crushed stone base decreases with increasing freeze–thaw cycles, exhibiting a parabolic trend. This decline can be attributed to microcracks and defects, offering insights for monitoring and predicting the structure’s service life.

- (4)

- The resilience modulus decreases with increasing freeze–thaw cycles for the cement-stabilized crushed stone base, following a parabolic trend. This reduction can be attributed to microcracking and debonding within the material.

- (5)

- The damage to the cement-stabilized crushed stone base progresses through three stages: initial, stationary, and failure according to AE parameters. The stage I duration increases with freeze–thaw cycles, while the stage III duration decreases, reflecting internal defects and crack growth under freeze–thaw cycling.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jumassultan, A.; Sagidullina, N.; Kim, J.; Ku, T.; Moon, S.W. Performance of cement-stabilized sand subjected to freeze-thaw cycles. Geomech. Eng. 2021, 25, 41–48. [Google Scholar] [CrossRef]

- Jiang, W.Q.; Liu, S.T.; Wu, C.; Wang, C.H.; Liang, J.; Zhou, X.L. Impact Factors of Performance of Rubber Particle Cement Stabilized Gravel Base. J. Munic. Technol. 2023, 41, 118–123. [Google Scholar] [CrossRef]

- Park, D.W.; Vo, H.V. Evaluation of air-foam stabilized soil of dredged soil waste as a pavement subgrade layer. KSCE J. Civ. Eng. 2015, 19, 2091–2097. [Google Scholar] [CrossRef]

- Fan, Y.B.; Wei, F.; Wu, Q.; Tang, K.; Zhang, J. Study on Compaction Properties of Cement Stabilized Macadam in Gobi Saline Soil Area. Highw. Eng. J. 2023, 48, 128–135. [Google Scholar] [CrossRef]

- Ahmed, A.; Ugai, K. Environmental effects on durability of soil stabilized with recycled gypsum. Cold Reg. Sci. Technol. 2011, 66, 84–92. [Google Scholar] [CrossRef]

- Su, P.L.; Bi, J.Y.; Pei, Y.; Zhu, D.J. Analysis of Performance Improvement of Carbide Slag Stabilized Loess by Adding Fly Ash. Highw. Eng. J. 2022, 47, 146–152. [Google Scholar] [CrossRef]

- Zhang, Y.; Johnson, A.E.; White, D.J. Freeze-thaw performance of cement and fly ash stabilized loess. Transp. Geotech. 2019, 21, 100279. [Google Scholar] [CrossRef]

- Zhang, X.; Fan, X.Y.; Ni, Z.T.; Liu, Y.Q. Study on Influence Mechanism of Gradation of Porous Basalt Macadam Subgrade Filling on Resilient Modulus. J. Munic. Technol. 2023, 41, 138–142. [Google Scholar] [CrossRef]

- Jamshidi, R.J.; Lake, C.B.; Barnes, C.L. Evaluating Impact Resonance Testing As a Tool for Predicting Hydraulic Conductivity and Strength Changes in Cement-Stabilized Soils. J. Mater. Civ. Eng. 2015, 27, 04015051. [Google Scholar] [CrossRef]

- Kalpokaite-Dickuviene, R.; Pitak, I.; Baltusnikas, A.; Cesniene, J.; Kriukiene, R.; Lukosiute, S.I. Functional and microstructural alterations in hydrated and freeze-thawed cement-oil shale ash composites. Case Stud. Constr. Mat. 2023, 19, e02302. [Google Scholar] [CrossRef]

- Pham, N.P.; Toumi, A.; Turatsinze, A. Effect of an enhanced rubber-cement matrix interface on freeze-thaw resistance of the cement-based composite. Constr. Build. Mater. 2019, 207, 528–534. [Google Scholar] [CrossRef]

- del Bosque, I.F.S.; Van den Heede, P.; De Belie, N.; de Rojas, M.I.S.; Medina, C. Freeze-thaw resistance of concrete containing mixed aggregate and construction and demolition waste-additioned cement in water and de-icing salts. Constr. Build. Mater. 2020, 259, 119772. [Google Scholar] [CrossRef]

- Lu, J.G.; Tan, L.L.; Yang, H.H.; Wan, X.S.; Wang, Y.D.; Yan, Z.R. Experimental study on the hydro-thermal-deformation characteristics of cement-stabilized soil exposed to freeze-thaw cycles. Front. Earth Sci. 2023, 10, 1041249. [Google Scholar] [CrossRef]

- Wang, T.L.; Song, H.F.; Yue, Z.R.; Hu, T.F.; Sun, T.C.; Zhang, H.B. Freeze-thaw durability of cement-stabilized macadam subgrade and its compaction quality index. Cold Reg. Sci. Technol. 2019, 160, 13–20. [Google Scholar] [CrossRef]

- Li, S.A.; Zhang, C.Z.; Zhang, T.B.; Li, W.T.; Jia, P.J. Experimental study on the strength, collapsibility, and microstructure of cement and micro-silica-stabilized saline soil under freeze-thaw cycles. Case Stud. Constr. Mat. 2023, 19, e02518. [Google Scholar] [CrossRef]

- Rhardane, A.; Sleiman, S.A.; Alam, S.Y.; Grondin, F. A quantitative assessment of the parameters involved in the freeze-thaw damage of cement-based materials through numerical modelling. Constr. Build. Mater. 2021, 272, 121838. [Google Scholar] [CrossRef]

- Mardani-Aghabaglou, A.; Kalipcilar, I.; Sezer, G.I.; Sezer, A.; Altun, S. Freeze-thaw resistance and chloride-ion penetration of cement-stabilized clay exposed to sulfate attack. Appl. Clay Sci. 2015, 115, 179–188. [Google Scholar] [CrossRef]

- Sahlabadi, S.H.; Bayat, M.; Mousivand, M.; Saadat, M. Freeze-Thaw Durability of Cement-Stabilized Soil Reinforced with Polypropylene/Basalt Fibers. J. Mater. Civ. Eng. 2021, 33, 04021232. [Google Scholar] [CrossRef]

- Abbaszadeh, R.; Modarres, A. Freeze-thaw durability of non-air-entrained roller compacted concrete designed for pavement containing cement kiln dust. Cold Reg. Sci. Technol. 2017, 141, 16–27. [Google Scholar] [CrossRef]

- Baghini, M.S.; Ismail, A.; Naseralavi, S.S.; Firoozi, A.A. Freeze-thaw performance of base course treated with carboxylated styrene-butadiene emulsion-Portland cement. Int. J. Pavement Eng. 2018, 19, 1087–1095. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Tan, Y.Q.; Guo, M.; Wang, X.L. Influence of Emulsified Asphalt on the Mechanical Property and Microstructure of Cement-Stabilized Gravel under Freezing and Thawing Cycle Conditions. Materials 2017, 10, 504. [Google Scholar] [CrossRef]

- Ding, M.T.; Zhang, F.; Ling, X.Z.; Lin, B. Effects of freeze-thaw cycles on mechanical properties of polypropylene Fiber and cement stabilized clay. Cold Reg. Sci. Technol. 2018, 154, 155–165. [Google Scholar] [CrossRef]

- Ding, P.C.; Hou, Y.B.; Han, D.; Zhang, X.; Cao, S.X.; Li, C.Q. Effect of Freeze-Thaw Cycles on Mechanical and Microstructural Properties of Tailings Reinforced with Cement-Based Material. Minerals 2022, 12, 413. [Google Scholar] [CrossRef]

- Ying, L.B.; Wang, Y.X.; Wang, W. Strength and freeze-thaw cycle resistance of cement stabilized coastal clay mixed with shell powder. Mater. Res. Express 2023, 10, 065509. [Google Scholar] [CrossRef]

- Zhang, Y.; Johnson, A.E.; White, D.J. Laboratory freeze-thaw assessment of cement, fly ash, and fiber stabilized pavement foundation materials. Cold Reg. Sci. Technol. 2016, 122, 50–57. [Google Scholar] [CrossRef]

- Maji, V.; Murton, J.B. Experimental Observations and Statistical Modeling of Crack Propagation Dynamics in Limestone by Acoustic Emission Analysis During Freezing and Thawing. J. Geophys. Res.-Earth 2021, 126, e2021JF006127. [Google Scholar] [CrossRef]

- Shields, Y.; Garboczi, E.; Weiss, J.; Farnam, Y. Freeze-thaw crack determination in cementitious materials using 3D X-ray computed tomography and acoustic emission. Cem. Concr. Comp. 2018, 89, 120–129. [Google Scholar] [CrossRef]

- El-Mir, A.; El-Zahab, S. Assessment of the Compressive Strength of Self-Consolidating Concrete Subjected to Freeze-Thaw Cycles Using Ultrasonic Pulse Velocity Method. Russ. J. Nondestruct. 2022, 58, 108–117. [Google Scholar] [CrossRef]

- Liu, Z.X.; Han, Z.J.; Qin, L.; Cao, D.F.; Guo, C.C.; Wang, F.M.; Ma, B.S.; Wu, J.H. Identification of bending fracture characteristics of cement-stabilized coral aggregate in four-point bending tests based on acoustic emission. Constr. Build. Mater. 2023, 402, 132999. [Google Scholar] [CrossRef]

- GB 175-2007; Common Portland Cement. Standards Press of China: Beijing, China, 2007.

- JTG E 51-2009; Test Methods of Materials Stabilized with Inorganic Binders for Highway Engineering. China Communications Press: Beijing, China, 2009.

- Wu, H.R.; Jin, W.L.; Yan, Y.D.; Xia, P. Environmental zonation and life prediction of concrete in frost environments. J. Zhejiang Univ. (Eng. Sci.) 2012, 46, 650–657. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Tan, Y.Q.; Guo, M.; Liu, Z.Y.; Wang, X.L. Study on the dynamic compressive resilient modulus and frost resistance of semi-rigid base materials. Road Mater. Pavement 2017, 18, 259–269. [Google Scholar] [CrossRef]

- Rashidi, Y.; Korayem, A.H.; Farsi, S.; Sadeghi, J. Utilizing halloysite nanotube to enhance the properties of cement mortar subjected to freeze-thaw cycles. J. Build. Eng. 2023, 75, 106832. [Google Scholar] [CrossRef]

- Vegas, I.; Urreta, J.; Frías, M.; García, R. Freeze-thaw resistance of blended cements containing calcined paper sludge. Constr. Build. Mater. 2009, 23, 2862–2868. [Google Scholar] [CrossRef]

- Haghnejad, M.; Modarres, A. Effect of freeze-thaw cycles on the response of roller compacted concrete pavement reinforced by recycled polypropylene fibre under monotonic and cyclic loadings. Road Mater. Pavement 2021, 22, 2704–2720. [Google Scholar] [CrossRef]

- Bozbey, I.; Kelesoglu, M.K.; Demir, B.; Komut, M.; Comez, S.; Ozturk, T.; Mert, A.; Ocal, K.; Oztoprak, S. Effects of soil pulverization level on resilient modulus and freeze and thaw resistance of a lime stabilized clay. Cold Reg. Sci. Technol. 2018, 151, 323–334. [Google Scholar] [CrossRef]

- Bidgoli, M.A.; Naderi, K.; Moghadas Nejad, F. Effect of Filler Type on Moisture Susceptibility of Asphalt Mixtures Using Mechanical and Thermodynamic Properties. J. Mater. Civ. Eng. 2019, 31. [Google Scholar] [CrossRef]

- Baghini, M.S.; Ismail, A. Freeze-Thaw Performance and Moisture-Induced Damage Resistance of Base Course Stabilized with Slow Setting Bitumen Emulsion-Portland Cement Additives. Adv. Mater. Sci. Eng. 2015, 2015, 348691. [Google Scholar] [CrossRef]

- Korouzhdeh, T.; Eskandari-Naddaf, H. Evolution of different microstructure and influence on the characterization of pore structure and mechanical properties of cement mortar exposed to freezing-thawing: The role of cement fineness. Eng. Fail. Anal. 2022, 140, 106588. [Google Scholar] [CrossRef]

- Kim, I.S.; Choi, S.Y.; Choi, Y.S.; Yang, E.I. An experimental study on absorptivity measurement of superabsorbent polymers (SAP) and effect of SAP on freeze-thaw resistance in mortar specimen. Constr. Build. Mater. 2021, 267, 120974. [Google Scholar] [CrossRef]

- Frazier, S.D.; Lobo, A.J.; Matar, M.G.; Srubar, W.V. Biomimetic ice recrystallization inhibition-active poly(vinyl alcohol) enhances the freeze-thaw resistance of cement paste. Cem. Concr. Res. 2022, 160, 106905. [Google Scholar] [CrossRef]

- Smith, S.H.; Qiao, C.Y.; Suraneni, P.; Kurtis, K.E.; Weiss, W.J. Service-life of concrete in freeze-thaw environments: Critical degree of saturation and calcium oxychloride formation. Cem. Concr. Res. 2019, 122, 93–106. [Google Scholar] [CrossRef]

- Jafari, K.; Heidarnezhad, F.; Moammer, O.; Jarrah, M. Experimental investigation on freeze-thaw durability of polymer concrete. Front. Struct. Civ. Eng. 2021, 15, 1038–1046. [Google Scholar] [CrossRef]

| Performance Indexes | Results | Standard (GB 175-2007) [30] |

|---|---|---|

| Initial setting time (h) | 2 | ≥0.75 |

| Final setting time (h) | 3 | ≤10 |

| 3 d compressive strength (MPa) | 25 | ≥21 |

| 28 d compressive strength (MPa) | 53 | ≥42.5 |

| 3 d flexural strength (MPa) | 5.2 | ≥4.0 |

| 28 d flexural strength (MPa) | 8.5 | ≥6.5 |

| Performance Indexes | Results | Standard (GB 175-2007) [30] |

|---|---|---|

| Apparent relative density | 2.766 | / |

| Water absorption (%) | 1.24 | / |

| Needle-like content (%) | 10.6 | ≤18 |

| Crushing value (%) | 21.5 | ≤22 |

| Performance Indexes | Results | Standard (GB 175-2007) [30] |

|---|---|---|

| Apparent relative density | 2.682 | / |

| Fineness modulus | 2.85 | / |

| Water absorption (%) | 1.72 | / |

| Plasticity index | 10.6 | ≤17 |

| Liquid limit (%) | 23.2 | / |

| Plastic limit (%) | 12.6 | / |

| Sieve Size (mm) | 20~30 mm (%) | 10~20 mm (%) | 5~10 mm (%) | 0~5 mm (%) |

|---|---|---|---|---|

| 31.5 | 100 | 100 | 100 | 100 |

| 26.5 | 82.19 | 100 | 100 | 100 |

| 19 | 33.63 | 75.67 | 100 | 100 |

| 16 | 1.27 | 58.01 | 100 | 100 |

| 13.2 | 0.38 | 36.45 | 100 | 100 |

| 9.5 | 0 | 9.73 | 100 | 100 |

| 4.75 | 0 | 0.44 | 50.93 | 92.28 |

| 2.36 | 0 | 0 | 23.36 | 74.66 |

| 1.18 | 0 | 0 | 15.31 | 46.15 |

| 0.6 | 0 | 0 | 10.85 | 29.12 |

| 0.3 | 0 | 0 | 6.11 | 19.01 |

| 0.15 | 0 | 0 | 4.15 | 7.72 |

| 0.075 | 0 | 0 | 2.65 | 2.97 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, R.; An, B.; Wu, F.; Wang, W.; Sui, Y.; Wang, Y. Freeze–Thaw Damage Characterization of Cement-Stabilized Crushed Stone Base with Skeleton Dense Gradation. Materials 2024, 17, 1228. https://doi.org/10.3390/ma17061228

Xiao R, An B, Wu F, Wang W, Sui Y, Wang Y. Freeze–Thaw Damage Characterization of Cement-Stabilized Crushed Stone Base with Skeleton Dense Gradation. Materials. 2024; 17(6):1228. https://doi.org/10.3390/ma17061228

Chicago/Turabian StyleXiao, Rui, Baoping An, Fei Wu, Wensheng Wang, Yi Sui, and Yinghan Wang. 2024. "Freeze–Thaw Damage Characterization of Cement-Stabilized Crushed Stone Base with Skeleton Dense Gradation" Materials 17, no. 6: 1228. https://doi.org/10.3390/ma17061228