Hot Deformation Behavior of a Hot-Isostatically Pressed Ti-6Al-4V Alloy from Recycled Powder

Abstract

1. Introduction

2. Materials and Methods

2.1. As-Received Powders

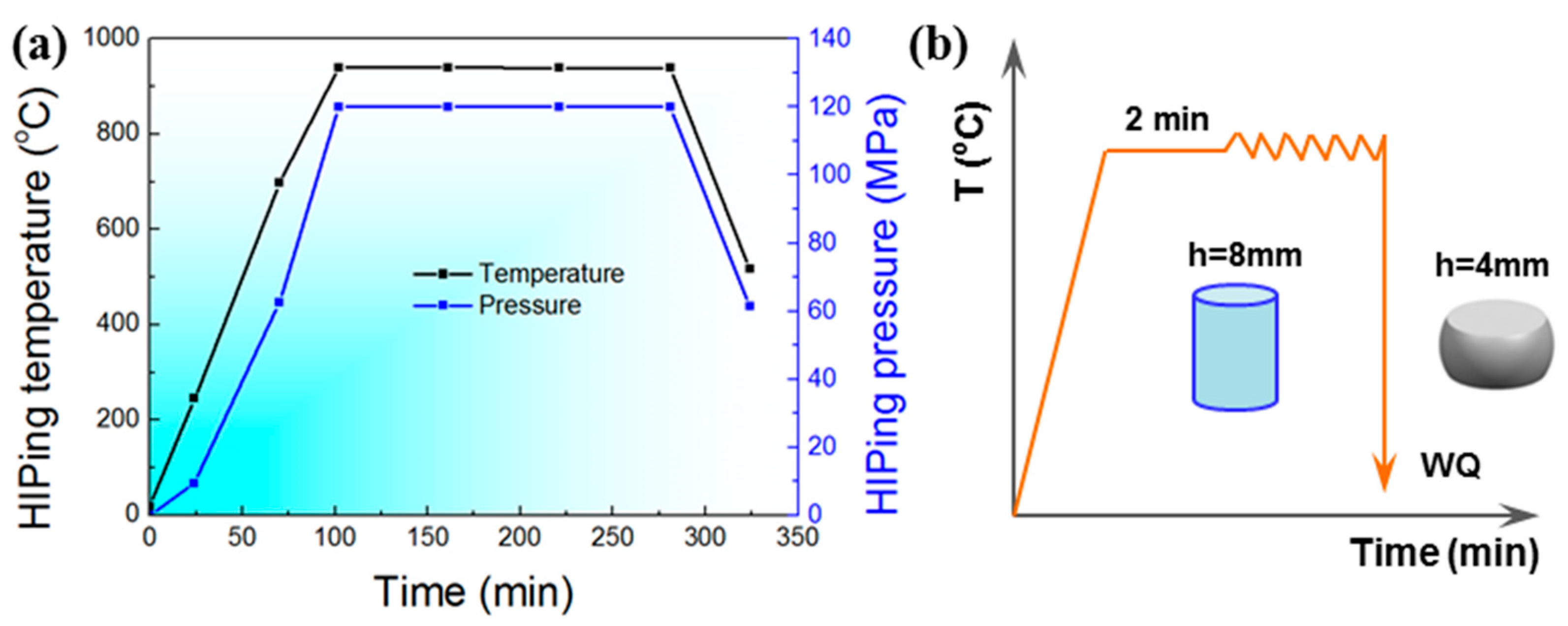

2.2. Experimental Procedures

3. Results and Discussion

3.1. Microstructures of As-HIPed Ti-6Al-4V

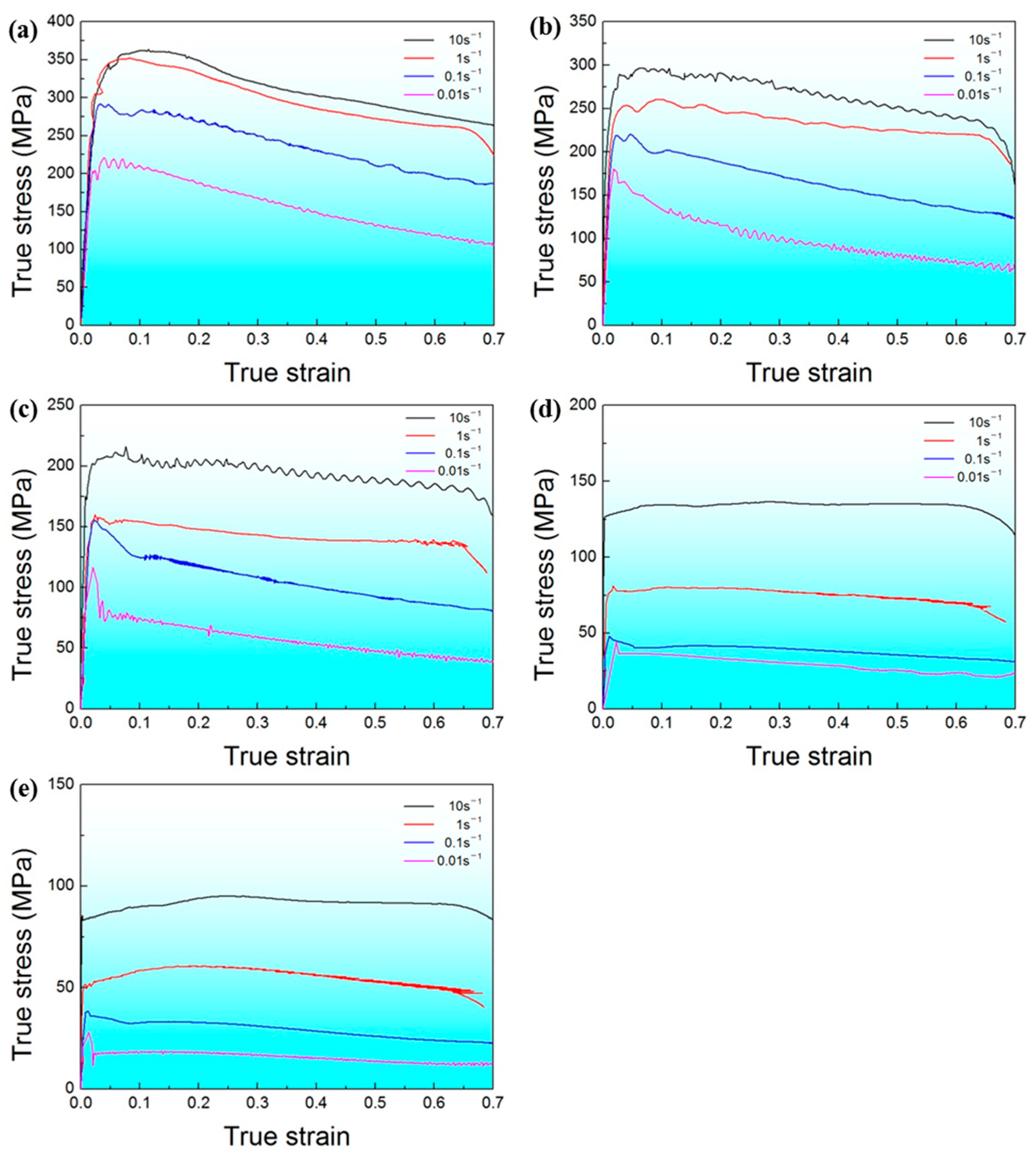

3.2. Isothermal Compression Tests

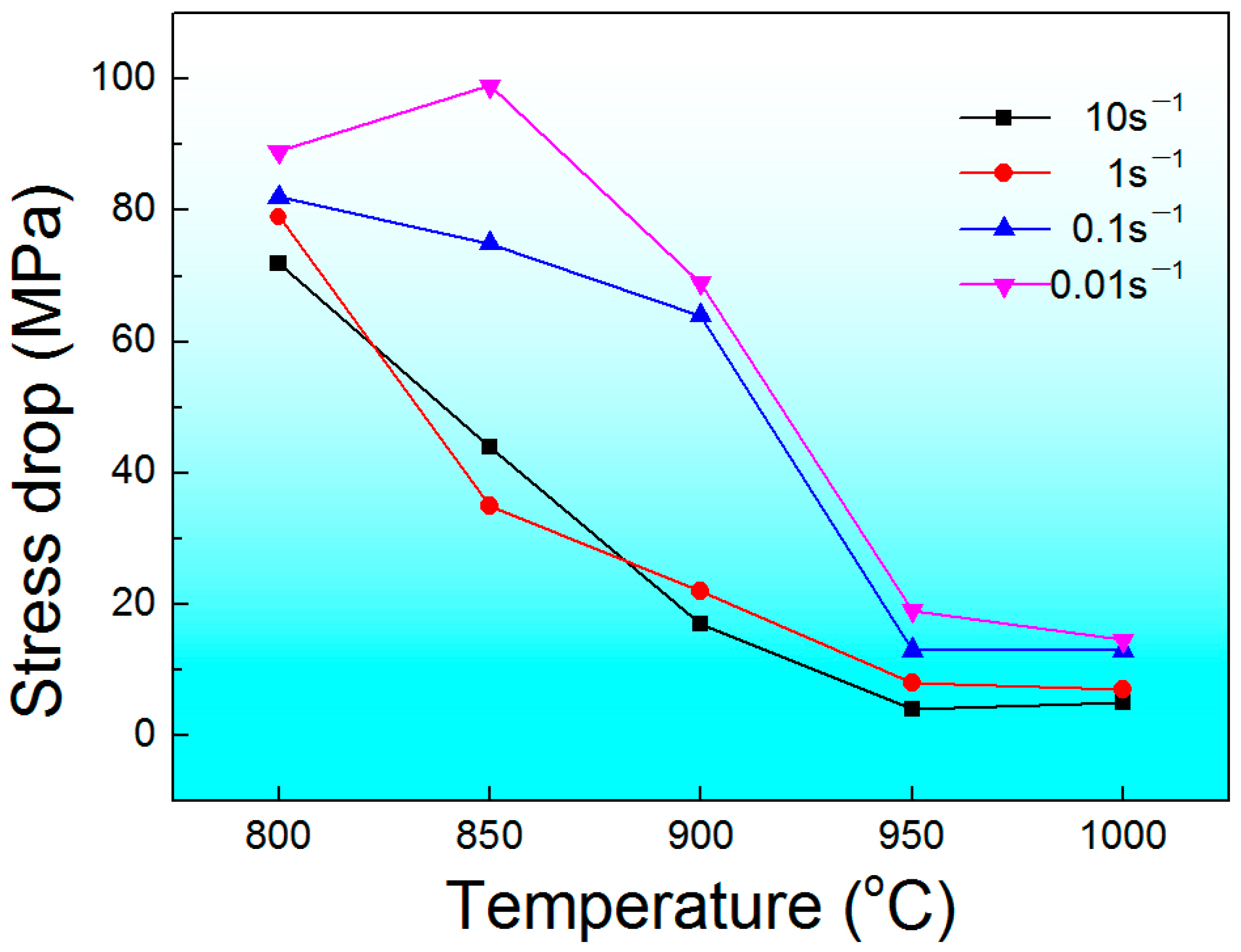

3.2.1. Stress–Strain Curves

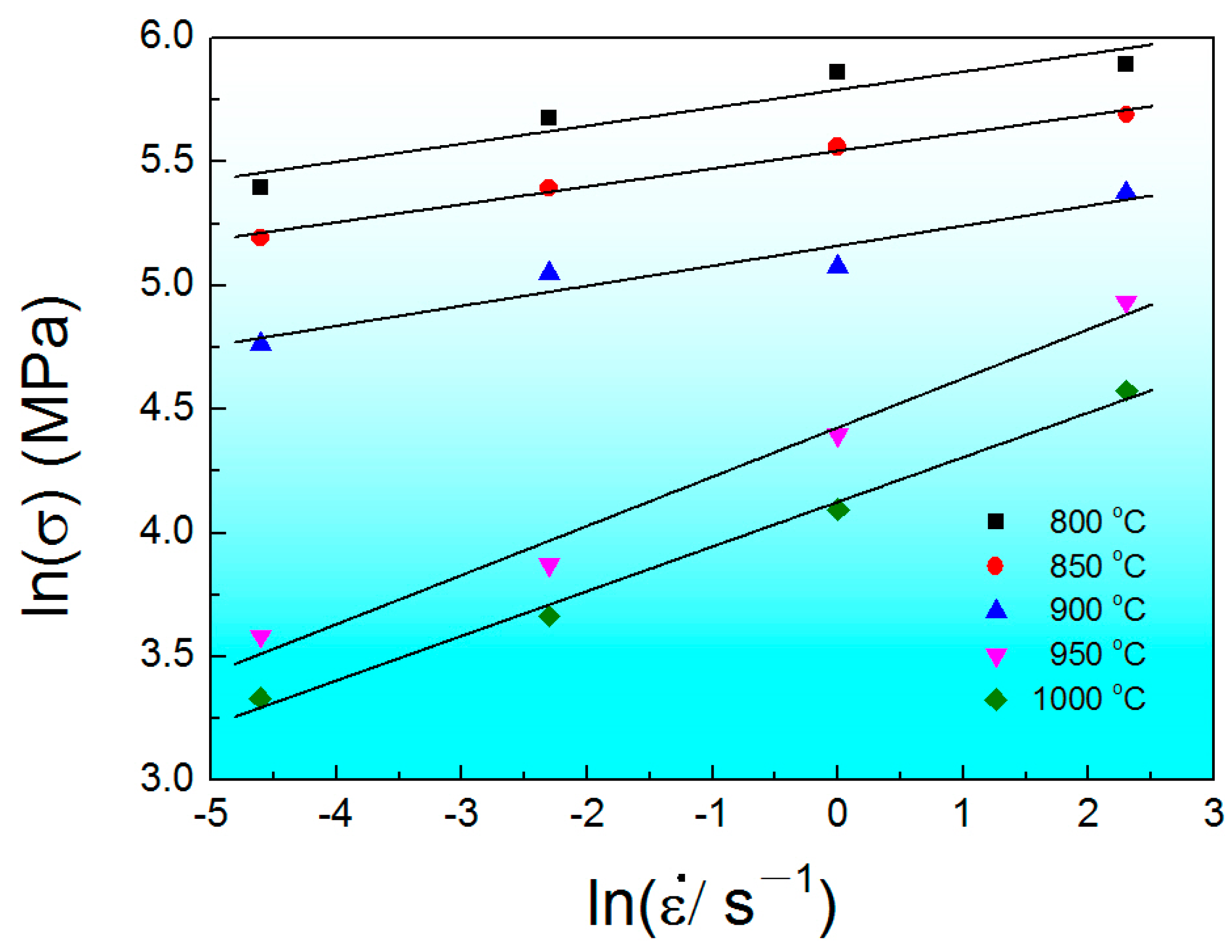

3.2.2. Kinetic Analysis

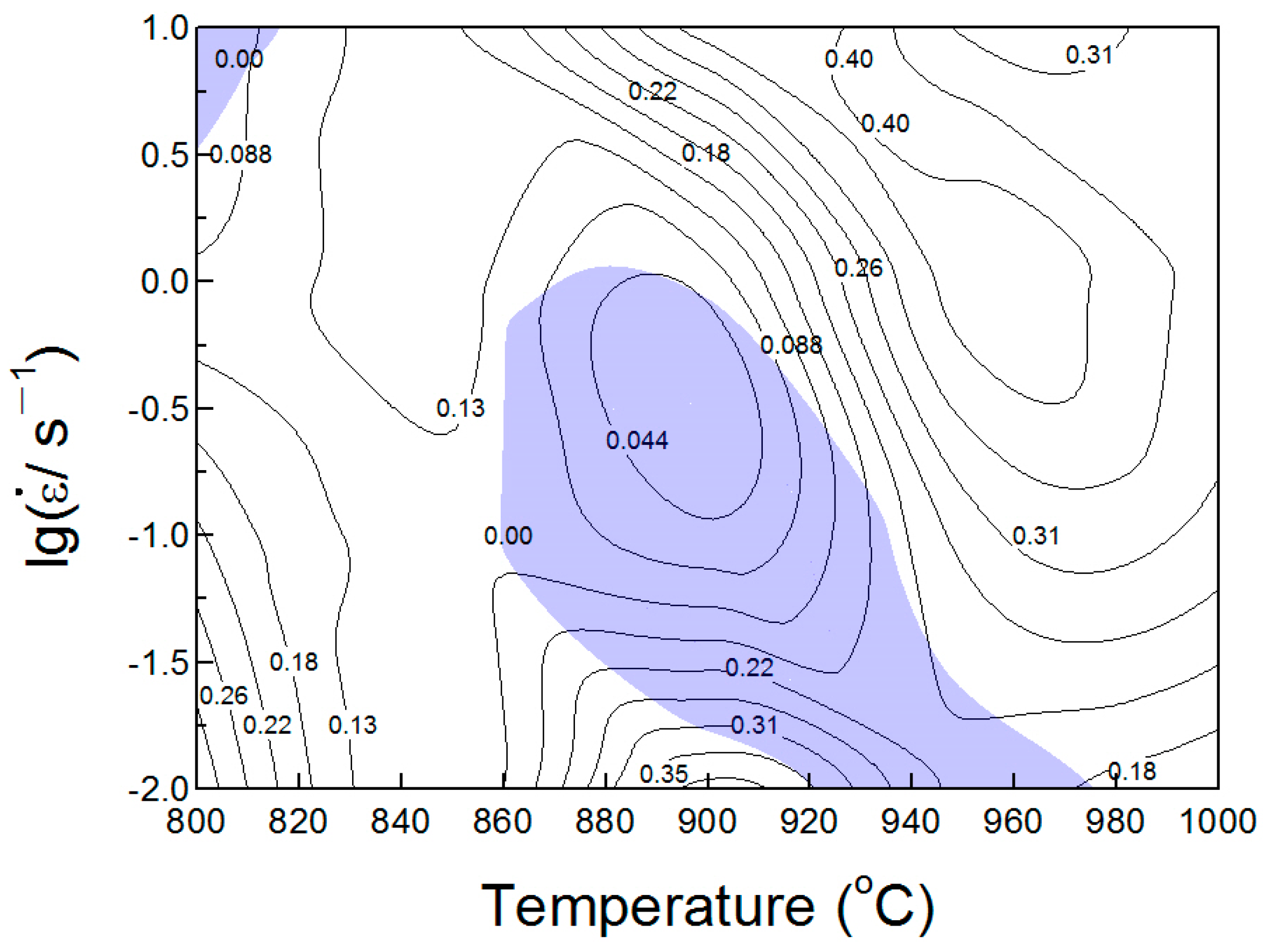

3.2.3. Processing Maps

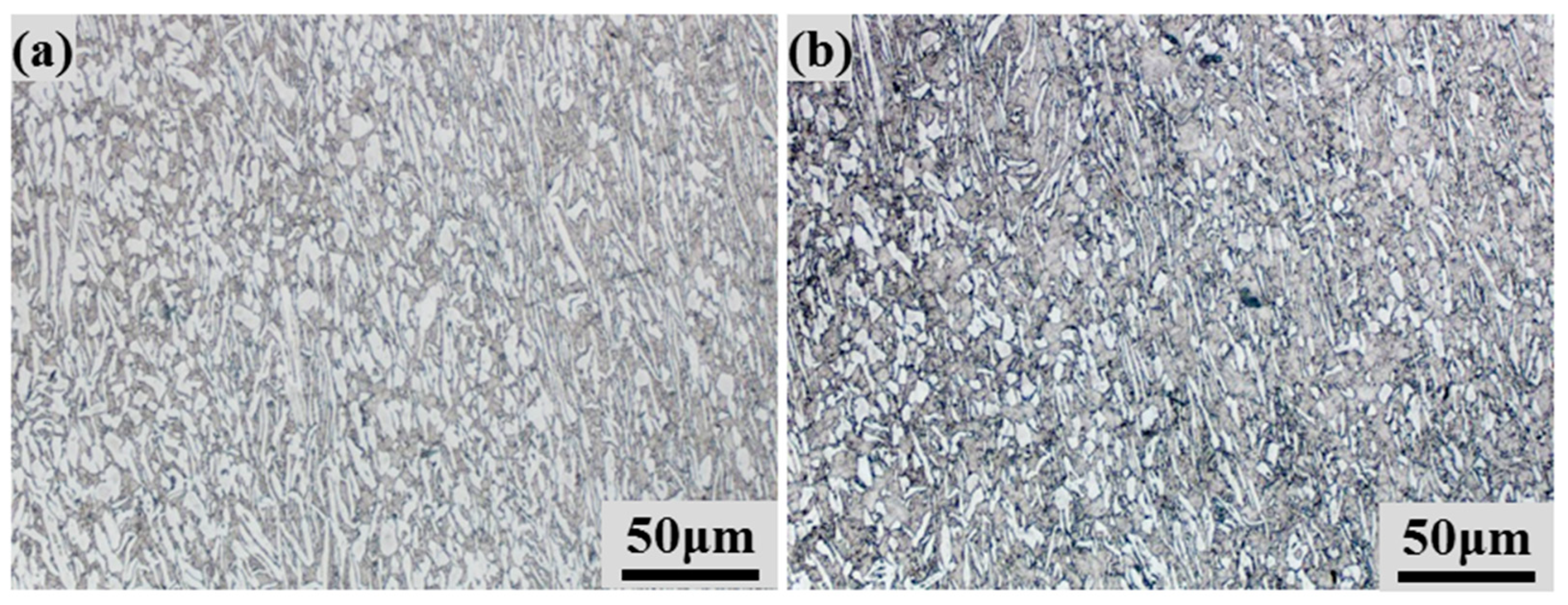

3.3. Deformed Microstructure

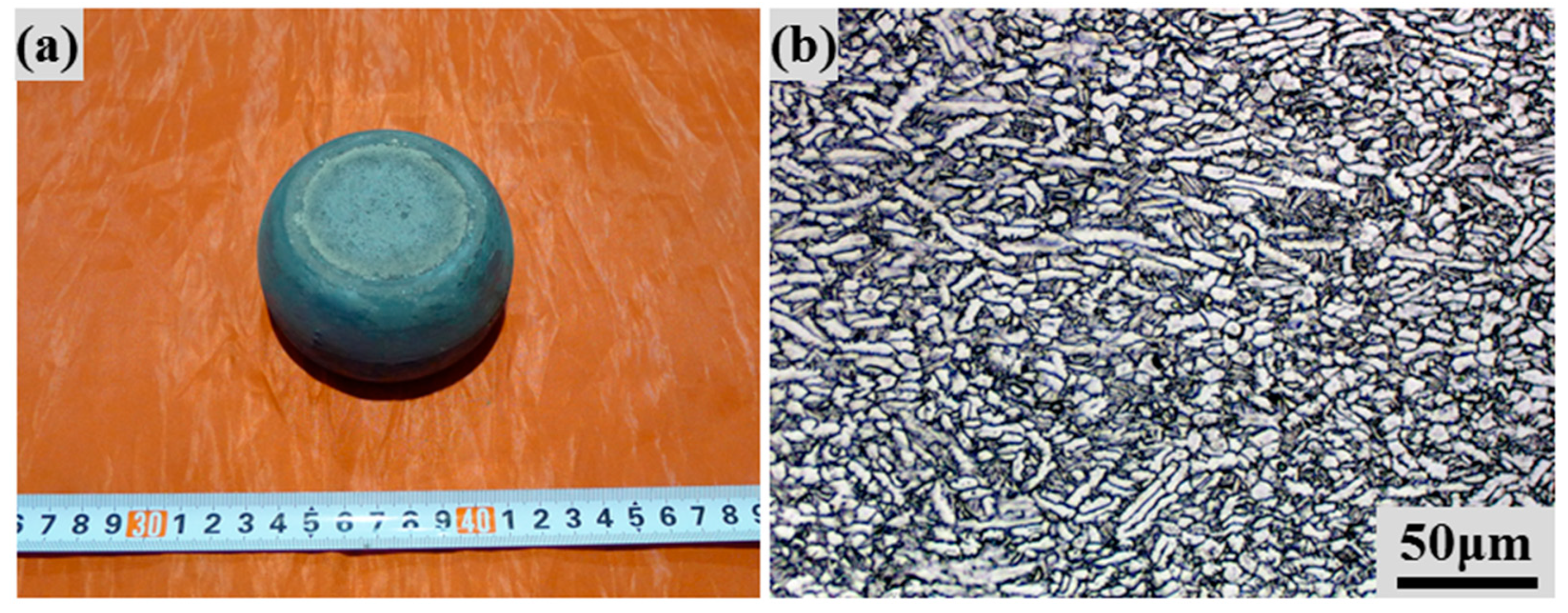

3.4. Upsetting Tests

4. Conclusions

- (1)

- The as-HIPed microstructure of Ti-6Al-4V powder compacts is fine and homogenous. The retained powder after screening for SLM and the recycled powder after SLM can be used to fabricate the powder compact by the HIP process.

- (2)

- The flow stress is sensitive to the strain rate and the deformation temperature. The activation energies are calculated to be 359 kJ/mol in the α + β phase regime and 463 kJ/mol in the β phase regime, respectively. Based on the processing map of the as-HIPed billets, the optimal hot working parameters are a deformation temperature above 950 °C and a strain rate higher than 0.1 s−1.

- (3)

- The tensile properties of the as-deformed samples (YS-872 MPa, UTS-976 MPa) are better than those of the as-HIPed powder compacts (YS-842 MPa, UTS-930 MPa). The hot workability of as-HIPed powder compacts is better than that of as-cast Ti-6Al-4V billets, and the desired microstructure and mechanical properties can be achieved using the optimal thermo-mechanical processing treatment of powder compacts in the present work.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Banerjee, D.; Williams, J. Perspectives on Titanium Science and Technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Guo, R.P.; Cheng, M.; Zhang, C.J.; Qiao, J.W.; Cai, C.; Wang, Q.J.; Xu, D.S.; Xu, L.; Yang, R.; Shi, Y.S.; et al. Achieving superior fatigue strength in a powder-metallurgy titanium alloy via in-situ globularization during hot isostatic pressing. Scr. Mater. 2023, 228, 115345. [Google Scholar] [CrossRef]

- Wang, K.; Xiang, H.; Xu, L.; Feng, A.; Qu, S.; Wang, H.; Chen, D. The Effect of Nb Doping on the Properties of Ti-Al Intermetallic Compounds Using First-Principles Calculations. Materials 2024, 17, 358. [Google Scholar] [CrossRef]

- Bolzoni, L.; Ruiz-Navas, E.M.; Gordo, E. Flexural properties, thermal conductivity and electrical resistivity of prealloyed and master alloy addition powder metallurgy Ti–6Al–4V. Mater. Des. 2013, 52, 888–895. [Google Scholar] [CrossRef]

- Guo, R.; Xu, L.; Chen, Z.; Wang, Q.; Zong, B.Y.; Yang, R. Effect of powder surface state on microstructure and tensile properties of a novel near α-Ti alloy using hot isostatic pressing. Mater. Sci. Eng. A 2017, 706, 57–63. [Google Scholar] [CrossRef]

- Koike, M.; Krysiak, A.; Chan, K.S.; Guo, L.; Okabe, T. Effect of centrifugal rotational speed on wedge castability of titanium. J. Mater. Process. Technol. 2011, 211, 560–565. [Google Scholar] [CrossRef]

- Leyens, C.; Peters, M. Titanium and Titanium Alloys: Fundamentals and Applications; Wiley-VCH: Weinheim, Germany, 2003. [Google Scholar]

- Yang, Y.; Wang, X.; Li, X.; Zhou, R.; He, Z.; Jiang, Y. Numerical Simulation on Solidification during Vertical Centrifugal Casting Process for TC4 Alloy Wheel Hub with Enhanced Mechanical Properties. Materials 2024, 17, 184. [Google Scholar] [CrossRef]

- Jia, L.; Xu, D.; Li, M.; Guo, J.; Fu, H. Casting defects of Ti-6Al-4V alloy in vertical centrifugal casting processes with graphite molds. Met. Mater. Int. 2012, 18, 55–61. [Google Scholar] [CrossRef]

- Feng, X.; Qiu, J.; Ma, Y.; Lei, J.; Cui, Y.; Wu, X.; Yang, R. Influence of processing conditions on microstructure and mechanical properties of large thin-wall centrifugal Ti–6Al–4V casting. J. Mater. Sci. Technol. 2016, 32, 362–371. [Google Scholar] [CrossRef]

- Zhao, Z.; Gao, J.; Wang, Y.; Zhang, Y.; Hou, H. Effect of Equal Channel Angular Pressing on the Dynamic Softening Behavior of Ti-6Al-4V Alloy in the Hot Deformation Process. Materials 2021, 14, 232. [Google Scholar] [CrossRef]

- Weston, N.S.; Jackson, M. FAST-forge of Titanium Alloy Swarf: A Solid-State Closed-Loop Recycling Approach for Aerospace Machining Waste. Metals 2020, 10, 296. [Google Scholar] [CrossRef]

- Fernández, D.S.; Wynne, B.P.; Crawforth, P.; Fox, K.; Jackson, M. The effect of forging texture and machining parameters on the fatigue performance of titanium alloy disc components. Int. J. Fatigue 2021, 142, 105949. [Google Scholar] [CrossRef]

- Aizawa, T.; Yoshino, T.; Suzuki, Y.; Shiratori, T. Free-Forging of Pure Titanium with High Reduction of Thickness by Plasma-Carburized SKD11 Dies. Materials 2021, 14, 2536. [Google Scholar] [CrossRef] [PubMed]

- Chouhan, D.K.; Biswas, S. Multiaxial plane-strain forging and rolling of biomedical grade titanium: Evolution of microstructure, texture, and mechanical properties. Mater. Lett. 2021, 291, 129540. [Google Scholar] [CrossRef]

- Careau, S.G.; Ulate-Kolitsky, E.; Tougas, B. In-situ alloying of Ti-5Fe titanium alloy using direct powder forging and the effect of the powder mixing method. Materialia 2022, 24, 101471. [Google Scholar] [CrossRef]

- Fang, Z.Z.; Paramore, J.D.; Sun, P.; Chandran, K.R.; Zhang, Y.X.; Cao, F.; Koopman, M.; Free, M. Powder metallurgy of titanium–past, present, and future. Int. Mater. Rev. 2018, 63, 407–459. [Google Scholar] [CrossRef]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Van Humbeeck, J.; Kruth, J.P. A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Kumar, P.; Ramamurty, U. High cycle fatigue in selective laser melted Ti-6Al-4V. Acta Mater. 2020, 194, 305–320. [Google Scholar] [CrossRef]

- Yan, Q.; Chen, B.; Kang, N.; Lin, X.; Lv, S.; Kondoh, K.; Li, S.; Li, J. Comparison study on microstructure and mechanical properties of Ti-6Al-4V alloys fabricated by powder-based selective-laser-melting and sintering methods. Mater. Character. 2020, 164, 110358. [Google Scholar] [CrossRef]

- Attar, H.; Ehtemam-Haghighi, S.; Kent, D.; Dargusch, M.S. Laser Additive Manufacturing of Low-Cost Ti–Mo Alloys: Microstructural Evolution, Phase Analysis, and Mechanical Properties. Adv. Eng. Mater. 2023, 25, 2201265. [Google Scholar] [CrossRef]

- Distefano, F.; Pasta, S.; Epasto, G. Titanium Lattice Structures Produced via Additive Manufacturing for a Bone Scaffold: A Review. J. Funct. Biomater. 2023, 14, 125. [Google Scholar] [CrossRef]

- Schaal, H.; Castany, P.; Gloriant, T. Outstanding strain-hardening of a new metastable β-titanium alloy elaborated by in situ additive manufacturing L-PBF process. Mater. Sci. Eng. A 2023, 875, 145117. [Google Scholar] [CrossRef]

- Wu, Q.; Qiao, C.; Wu, Y.; Liu, Z.; Li, X.; Wang, J.; An, X.; Huang, A.; Lim, C.V.S. Numerical investigation on the reuse of recycled powders in powder bed fusion additive manufacturing. Addit. Manuf. 2023, 77, 103821. [Google Scholar] [CrossRef]

- Ghods, S.; Schultz, E.; Wisdom, C.; Schur, R.; Pahuja, R.; Montelione, A.; Arola, D.; Ramulu, M. Electron beam additive manufacturing of Ti6Al4V: Evolution of powder morphology and part microstructure with powder reuse. Materialia 2020, 9, 100631. [Google Scholar] [CrossRef]

- Tang, H.P.; Qian, M.; Liu, N.; Zhang, X.Z.; Yang, G.Y.; Wang, J. Effect of powder reuse times on additive manufacturing of Ti-6Al-4V by selective electron beam melting. JOM 2015, 67, 555–563. [Google Scholar] [CrossRef]

- Guo, R.P.; Xu, L.; Zong, B.Y.P.; Yang, R. Characterization of prealloyed Ti–6Al–4V powders from EIGA and PREP process and mechanical properties of HIPed powder compacts. Acta Metall. Sin. (Engl. Lett.) 2017, 30, 735–744. [Google Scholar] [CrossRef]

- Cheng, M.; Lu, Z.; Wu, J.; Guo, R.; Qiao, J.; Xu, L.; Yang, R. Effect of thermal induced porosity on high-cycle fatigue and very high-cycle fatigue behaviors of hot-isostatic-pressed Ti-6Al-4V powder components. J. Mater. Sci. Technol. 2022, 98, 177–185. [Google Scholar] [CrossRef]

- Soltani-Tehrani, A.; Isaac, J.P.; Tippur, H.V.; Silva, D.F.; Shao, S.; Shamsaei, N. Ti-6Al-4V powder reuse in laser powder bed fusion (L-PBF): The effect on porosity, microstructure, and mechanical behavior. Int. J. Fatigue 2023, 167, 107343. [Google Scholar] [CrossRef]

- He, X.; Kong, D.; Zhou, Y.; Wang, L.; Ni, X.; Zhang, L.; Wu, W.; Li, R.; Li, X.; Dong, C. Powder recycling effects on porosity development and mechanical properties of Hastelloy X alloy during laser powder bed fusion process. Addit. Manuf. 2022, 55, 102840. [Google Scholar] [CrossRef]

- Guo, R.P.; Xu, L.; Zong, B.Y.; Yang, R. Preparation and ring rolling processing of large size Ti-6Al-4V powder compact. Mater. Des. 2016, 99, 341–348. [Google Scholar] [CrossRef]

- Zhang, K.; Mei, J.; Wain, N.; Wu, X. Effect of hot-isostatic-pressing parameters on the microstructure and properties of powder Ti-6Al-4V hot-isostatically-pressed samples. Metall. Mater. Trans. A 2010, 41, 1033–1045. [Google Scholar] [CrossRef]

- Cai, C.; Song, B.; Xue, P.; Wei, Q.; Wu, J.; Li, W.; Shi, Y. Effect of hot isostatic pressing procedure on performance of Ti6Al4V: Surface qualities, microstructure and mechanical properties. J. Alloys Compd. 2016, 686, 55–63. [Google Scholar] [CrossRef]

- Cheng, M.; Wu, J.; Lu, Z.G.; Guo, R.P.; Xu, L.; Yang, R. Effect of Argon-Induced Porosity on Mechanical Properties of Powder Metallurgy Titanium Alloy Components using Hot Isostatic Pressing. Acta Metall. Sin. (Engl. Lett.) 2021, 34, 1386–1394. [Google Scholar] [CrossRef]

- Raynova, S.; Yang, F.; Bolzoni, L. The effect of thermomechanical treatments on the properties of powder metallurgy Ti–5Fe alloy. Mater. Sci. Eng. A 2021, 801, 140389. [Google Scholar] [CrossRef]

- Zhang, D. Ultrafine grained metals and metal matrix nanocomposites fabricated by powder processing and thermomechanical powder consolidation. Prog. Mater. Sci. 2022, 123, 100853. [Google Scholar] [CrossRef]

- Murty, S.N.; Rao, B.N. On the flow localization concepts in the processing maps of titanium alloy Ti–24Al–20Nb. J. Mater. Process. Technol. 2000, 104, 103–109. [Google Scholar] [CrossRef]

- Tan, Y.; Liu, W.; Yuan, H.; Liu, R.; Zhang, X. On the phenomenon of stress drop during hot deformation of ZrTiAlV alloy. Metall. Mater. Trans. A 2013, 44, 5284–5288. [Google Scholar] [CrossRef]

- Sellars, C.M.; McTegart, W.J. On the mechanism of hot deformation. Acta Metall. 1966, 14, 1136–1138. [Google Scholar] [CrossRef]

- Front, H.J.; Ashby, M.E. Deformation Maps; Pergamon Press: New York, NY, USA, 1982. [Google Scholar]

- Warchomicka, F.; Poletti, C.; Stockinger, M. Study of the hot deformation behaviour in Ti–5Al–5Mo–5V–3Cr–1Zr. Mater. Sci. Eng. A 2011, 528, 8277–8285. [Google Scholar] [CrossRef]

- Prasad, Y.; Gegel, H.L.; Doraivelu, S.M.; Malas, J.C.; Morgan, J.T.; Lark, K.A.; Barker, D.R. Modeling of dynamic material behavior in hot deformation: Forging of Ti-6242. Metall. Trans. A 1984, 15, 1883–1892. [Google Scholar] [CrossRef]

- Zhao, H.Z.; Xiao, L.; Ge, P.; Sun, J.; Xi, Z.P. Hot deformation behavior and processing maps of Ti-1300 alloy. Mater. Sci. Eng. A 2014, 604, 111–116. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K.; Seshacharyulu, T. Processing maps for hot working of titanium alloys. Mater. Sci. Eng. A 1998, 243, 82–88. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K.; Sasidhara, S. Hot Working Guide: A Compendium of Processing Maps; ASM International: Materials Park, OH, USA, 1997. [Google Scholar]

- Roy, S.; Suwas, S. The influence of temperature and strain rate on the deformation re-sponse and microstructural evolution during hot compression of a titanium alloy Ti–6Al–4V–0.1B. J. Alloys Compd. 2013, 548, 110–125. [Google Scholar] [CrossRef]

- Wang, M.; Zhou, J.; Yin, Y.; Nan, H.; Xue, P.; Tu, Z. Hot deformation behavior of the Ti6Al4V alloy prepared by powder hot isostatic pressing. J. Alloys Compd. 2017, 721, 320–332. [Google Scholar] [CrossRef]

| Samples | Al | V | Fe | C | O | N |

|---|---|---|---|---|---|---|

| PI | 6.1 | 4.0 | 0.14 | 0.03 | 0.09 | 0.01 |

| PV | 6.2 | 3.9 | 0.15 | 0.05 | 0.13 | 0.01 |

| Samples | YS | UTS | El. | A |

|---|---|---|---|---|

| As-HIPed | 842 ± 3 | 930 ± 1 | 15.7 ± 0.2 | 39 ± 1 |

| As-deformed | 878 ± 1 | 976 ± 2 | 15.5 ± 0.3 | 43 ± 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, R.; Wang, N.; Cheng, M. Hot Deformation Behavior of a Hot-Isostatically Pressed Ti-6Al-4V Alloy from Recycled Powder. Materials 2024, 17, 990. https://doi.org/10.3390/ma17050990

Guo R, Wang N, Cheng M. Hot Deformation Behavior of a Hot-Isostatically Pressed Ti-6Al-4V Alloy from Recycled Powder. Materials. 2024; 17(5):990. https://doi.org/10.3390/ma17050990

Chicago/Turabian StyleGuo, Ruili, Naixu Wang, and Min Cheng. 2024. "Hot Deformation Behavior of a Hot-Isostatically Pressed Ti-6Al-4V Alloy from Recycled Powder" Materials 17, no. 5: 990. https://doi.org/10.3390/ma17050990

APA StyleGuo, R., Wang, N., & Cheng, M. (2024). Hot Deformation Behavior of a Hot-Isostatically Pressed Ti-6Al-4V Alloy from Recycled Powder. Materials, 17(5), 990. https://doi.org/10.3390/ma17050990