Microstructure and Properties of Aluminum–Graphene–SiC Matrix Composites after Friction Stir Processing

Abstract

1. Introduction

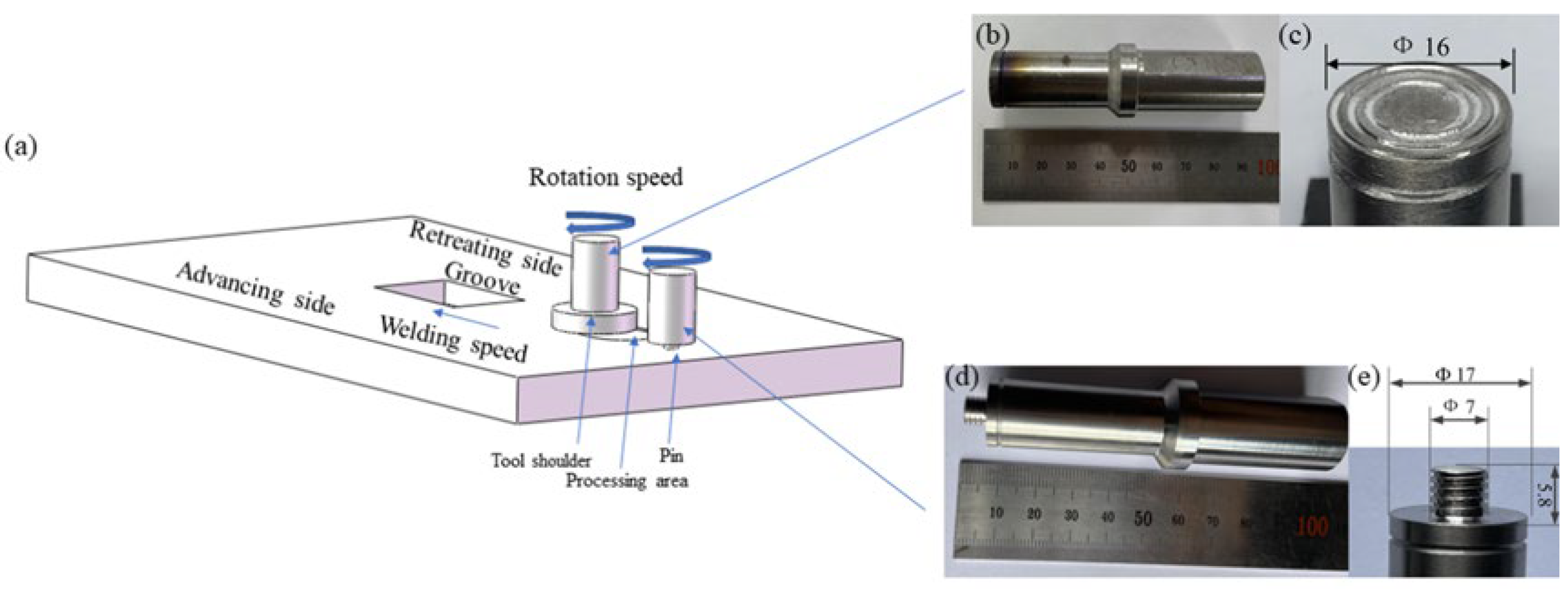

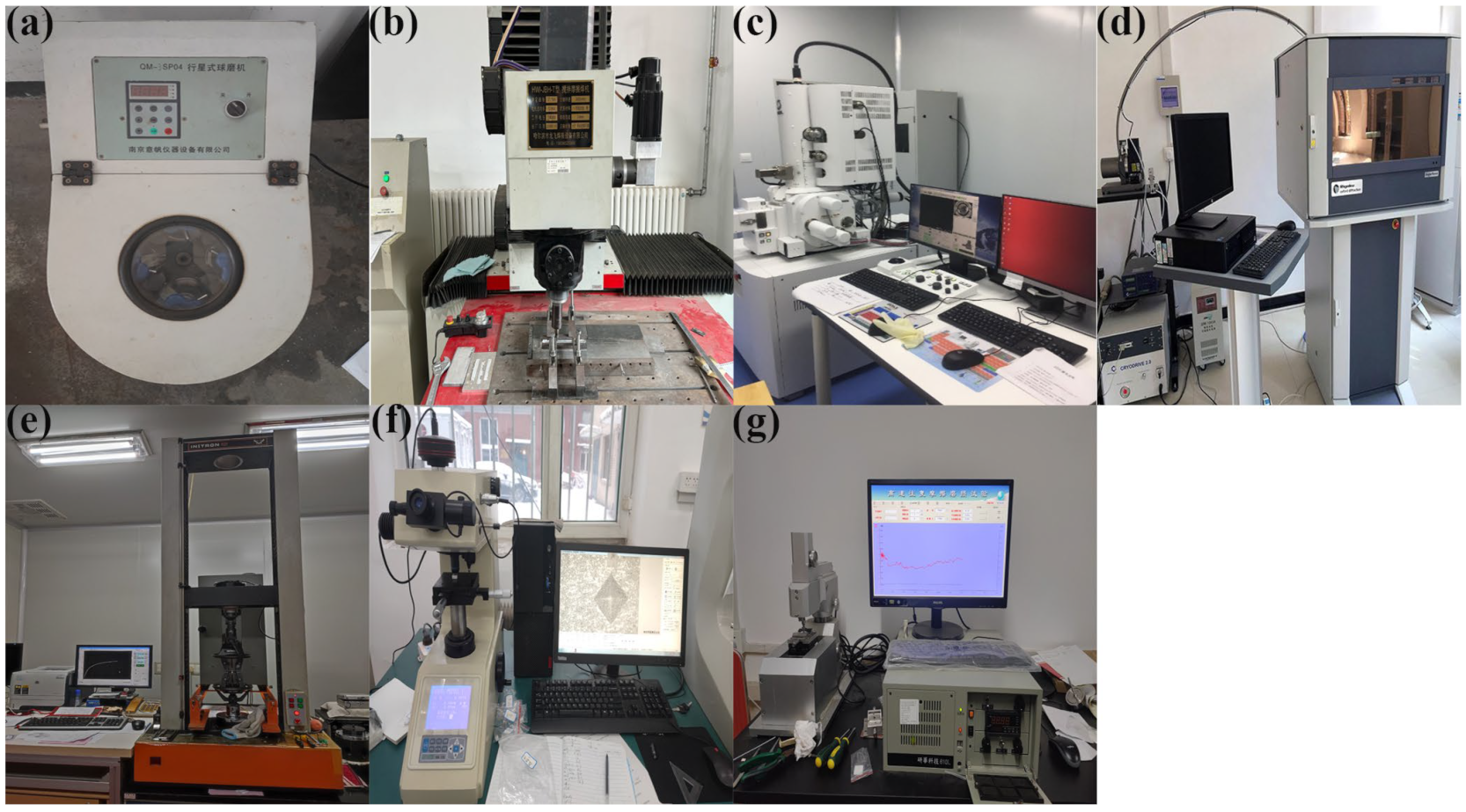

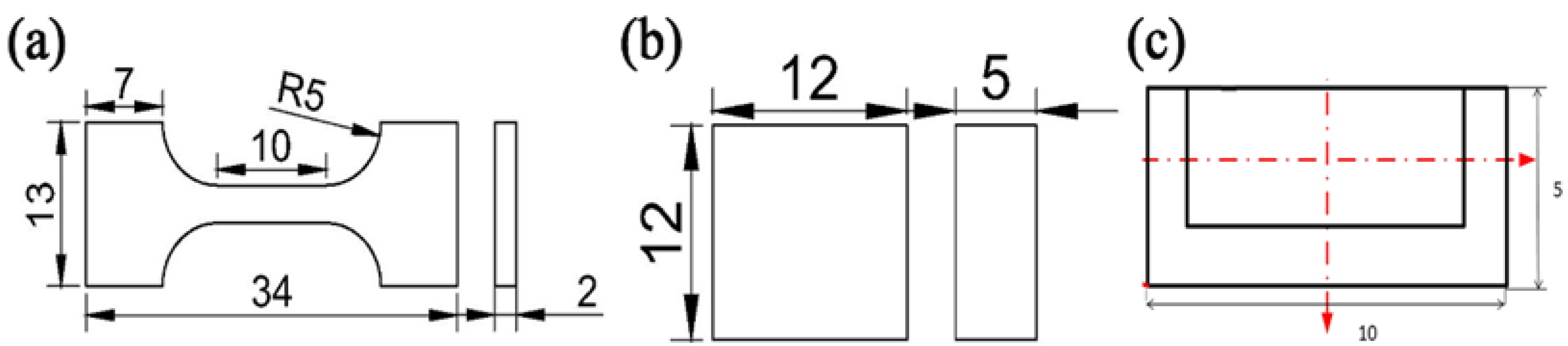

2. Materials and Methods

3. Results

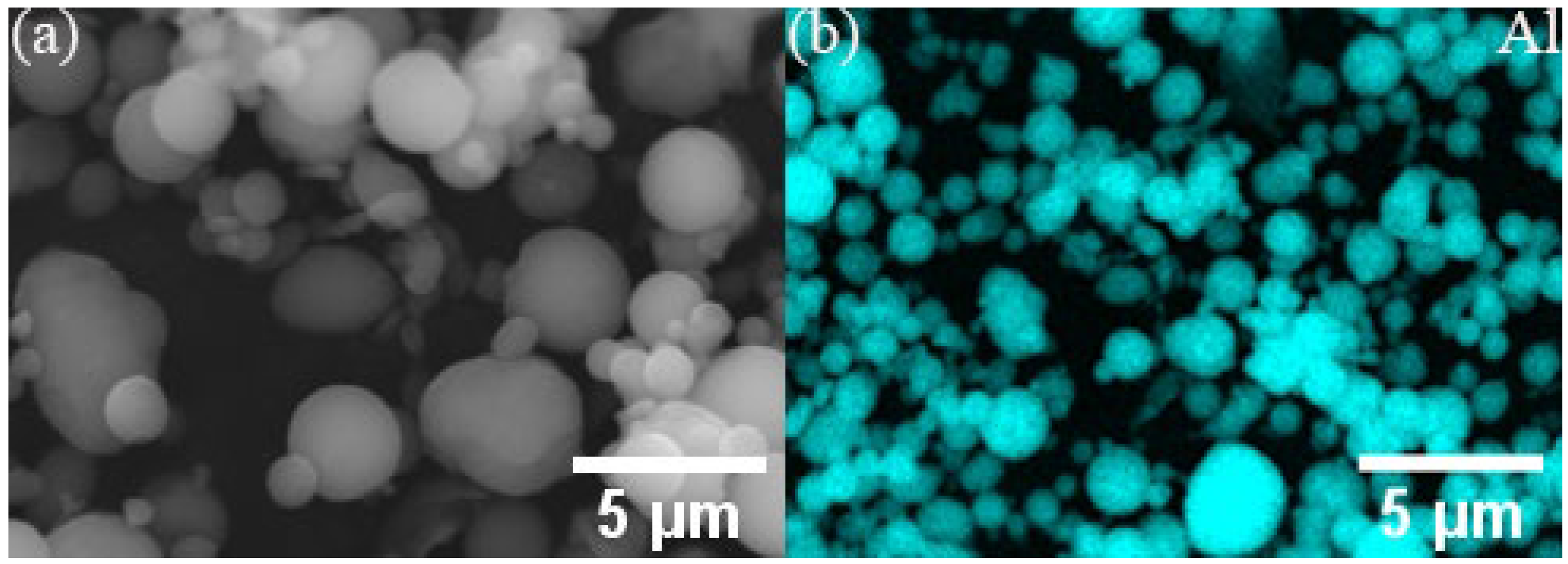

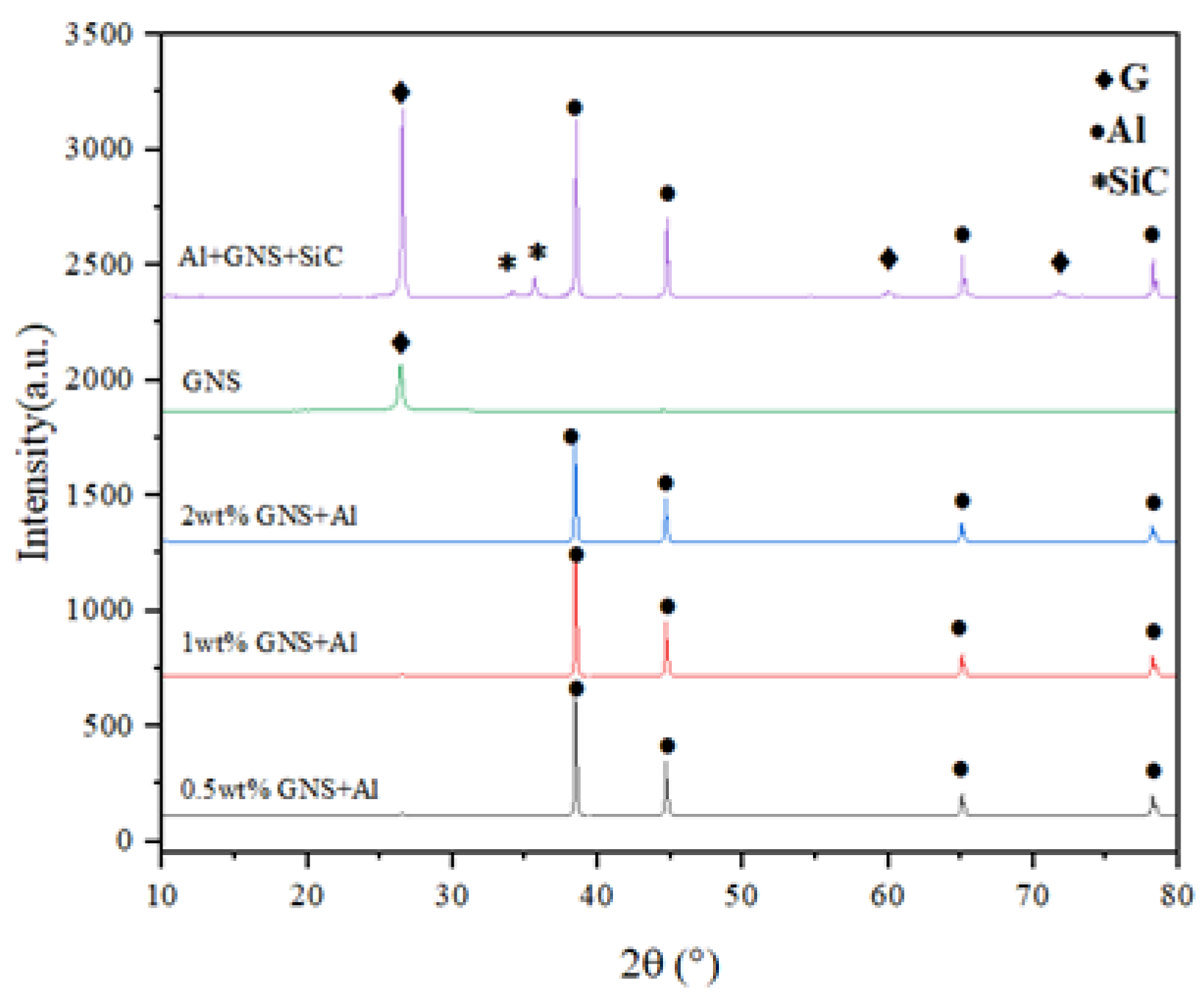

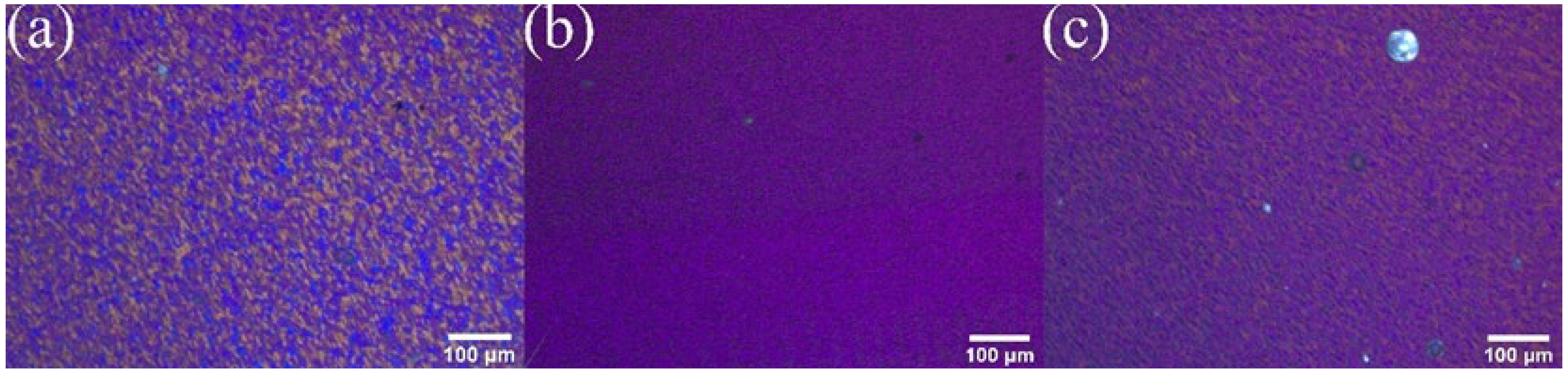

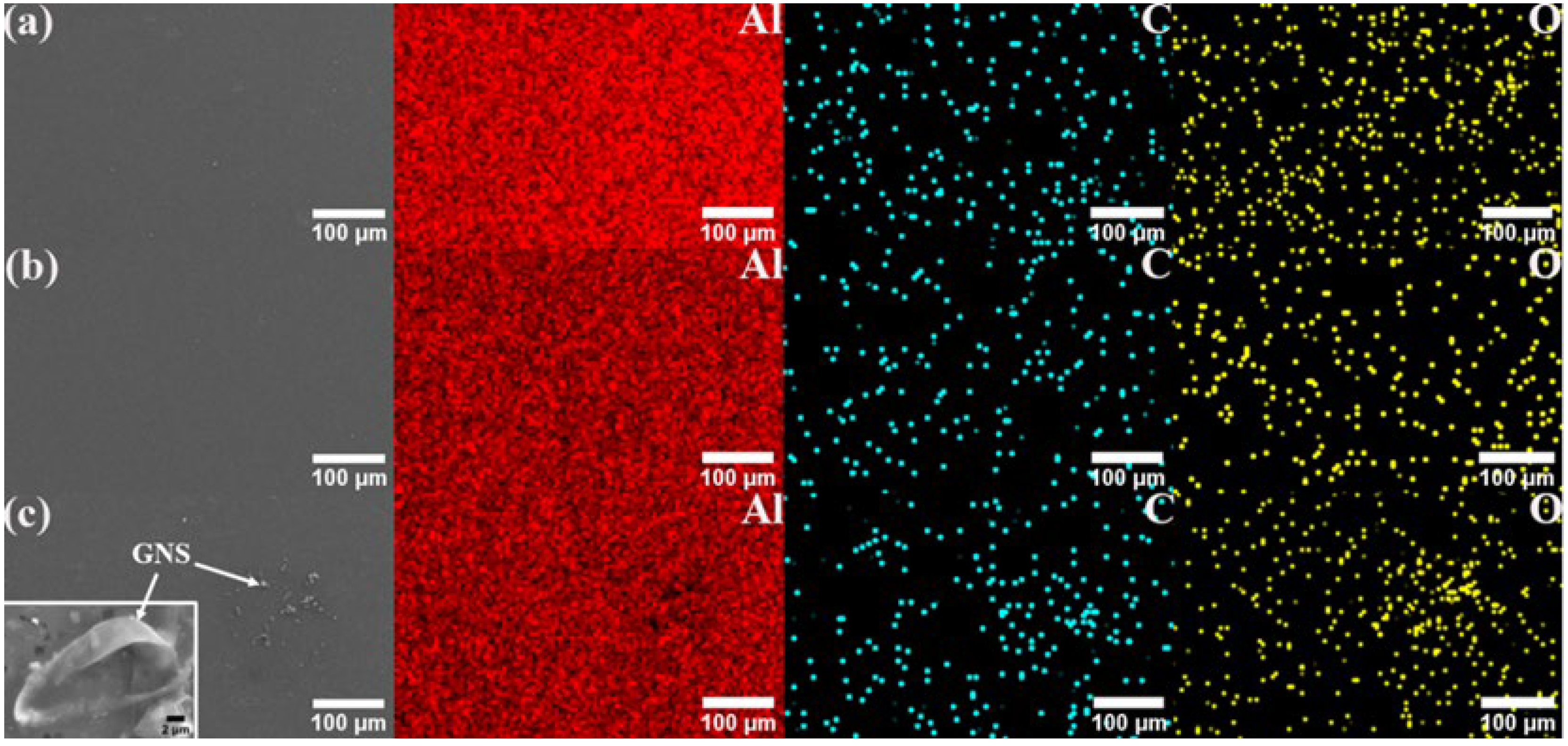

3.1. Microscopic Morphology of Mixed Powders of Different Types and Ratios

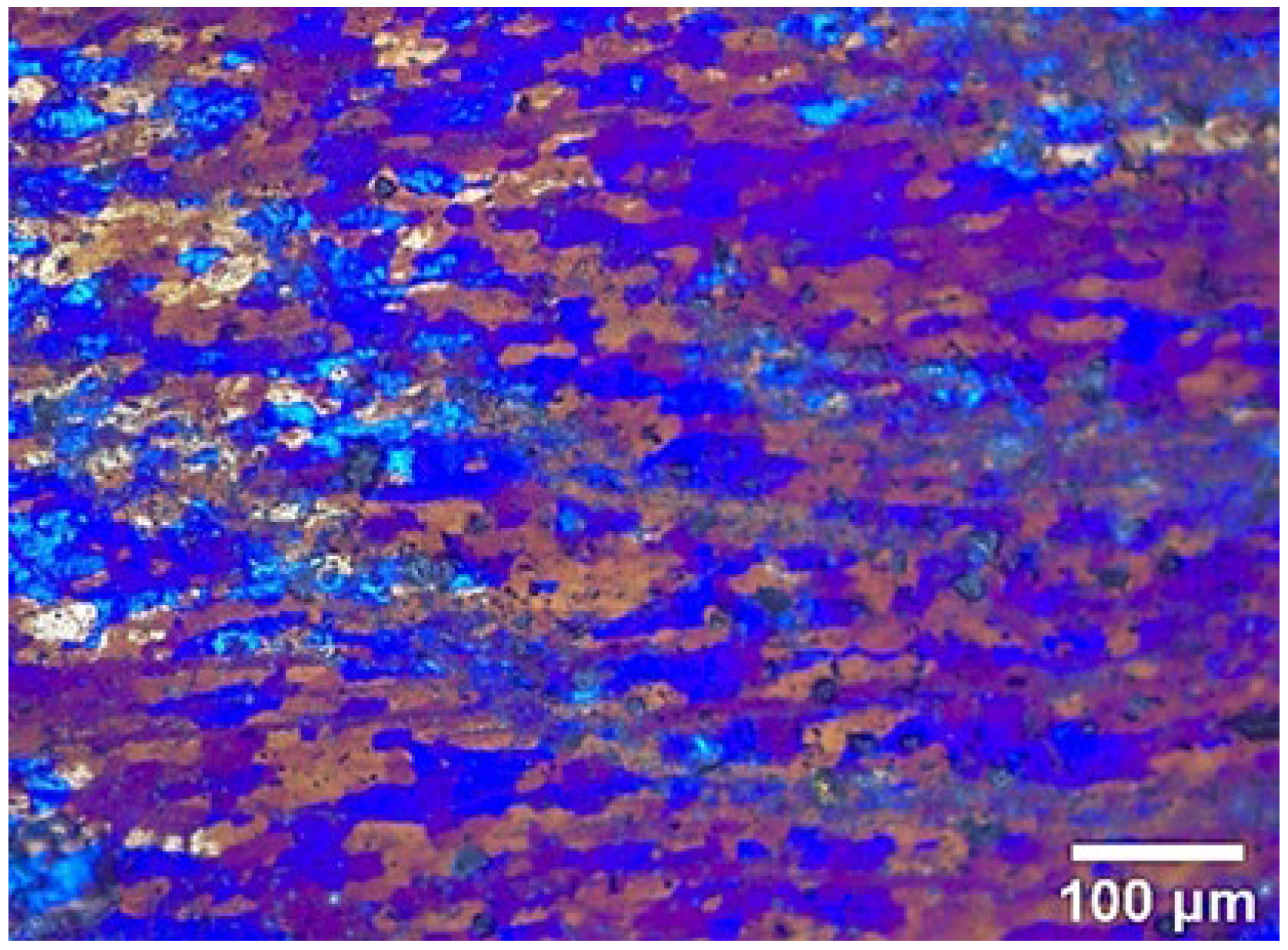

3.2. Microstructure

3.3. Tensile Strength

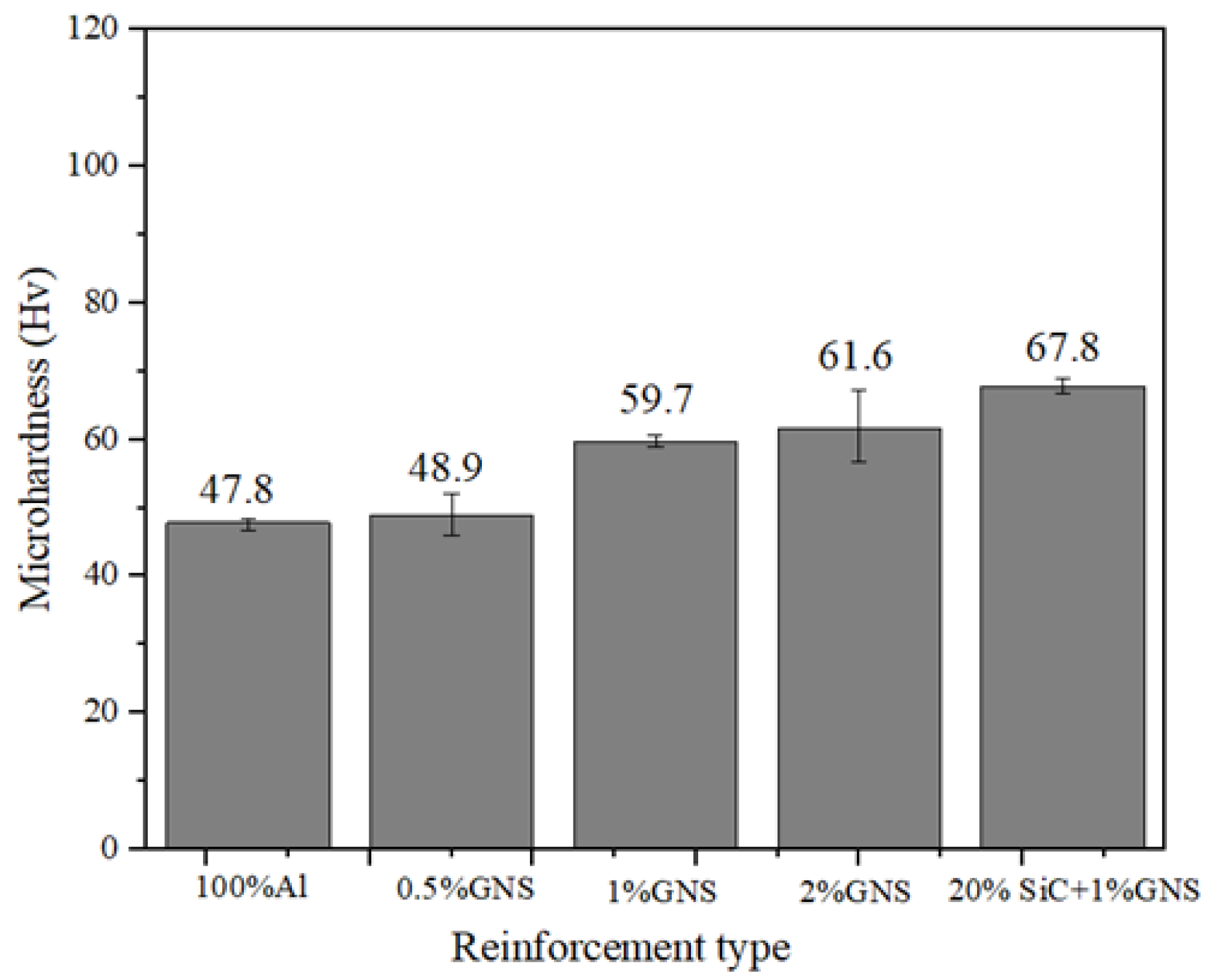

3.4. Hardness

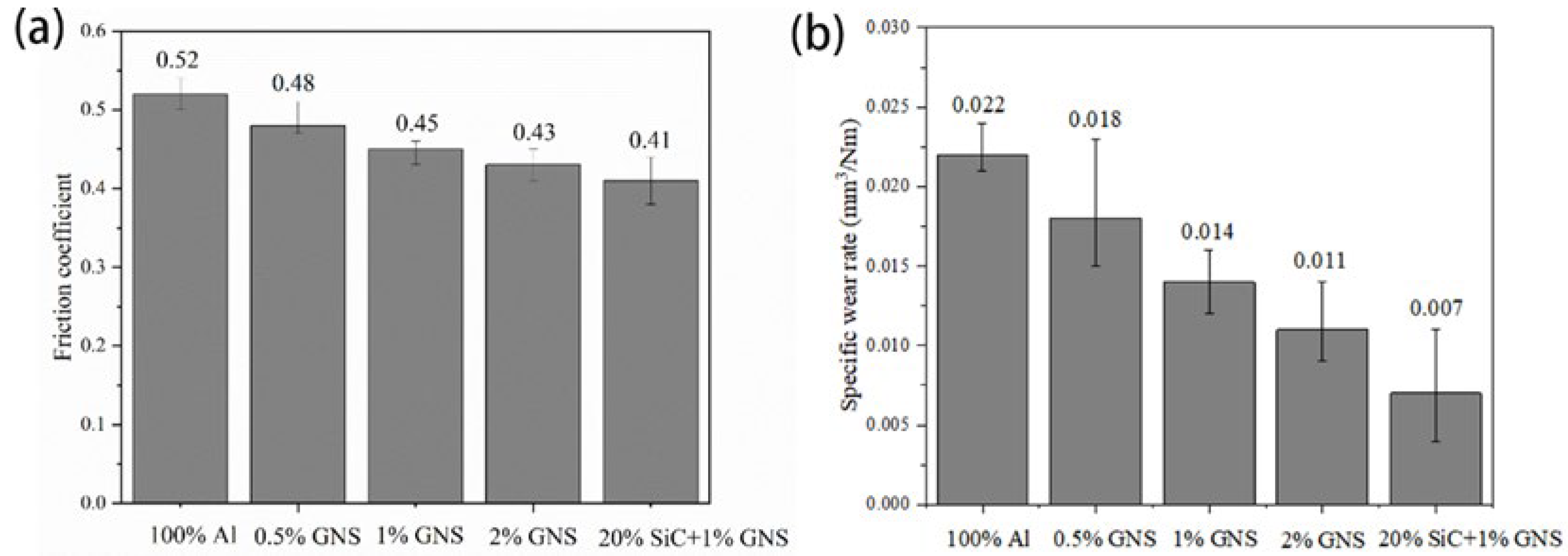

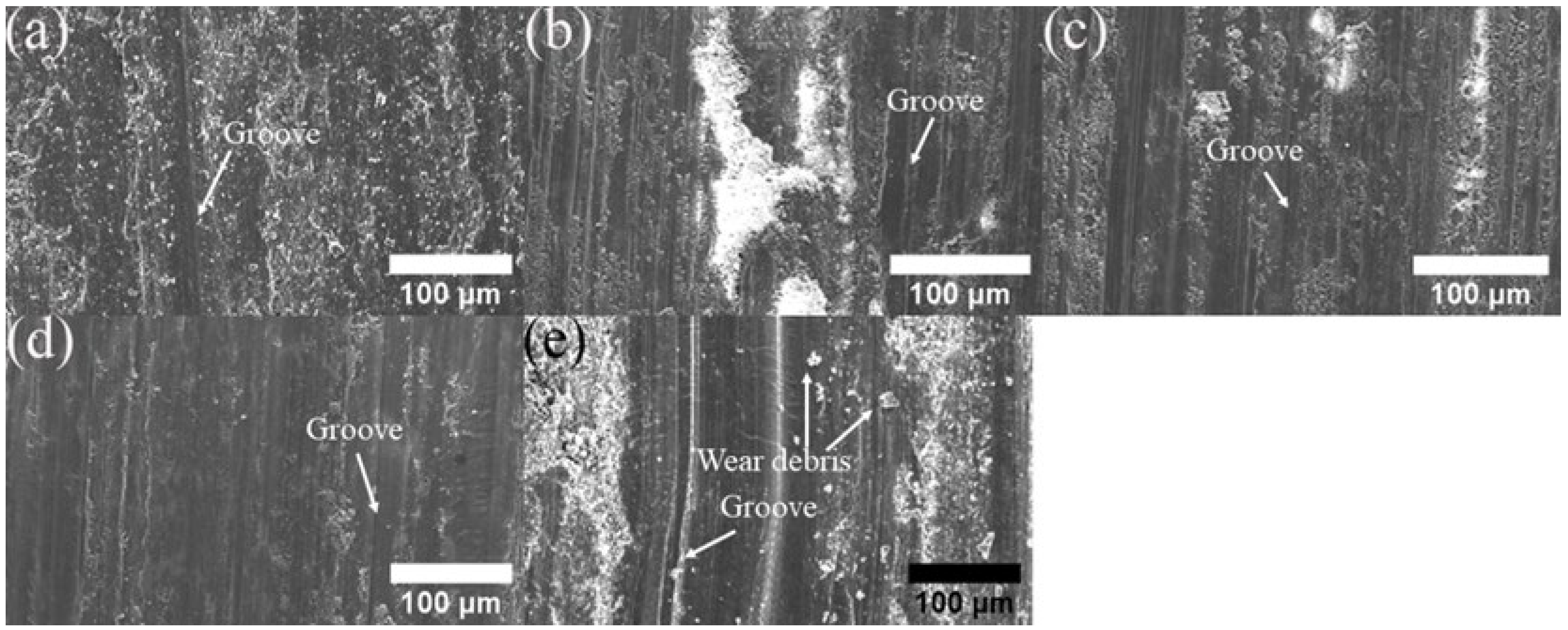

3.5. Friction and Wear Performance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, Z.; Bai, P.; Du, W.; Liu, B.; Pan, D.; Das, R.; Liu, C.; Guo, Z. An Overview of Graphene and Its Derivatives Reinforced Metal Matrix Composites: Preparation, Properties and Applications. Carbon 2020, 170, 302–326. [Google Scholar] [CrossRef]

- Owa, T.; Shimizu, Y.; Kaiume, S.; Hashimoto, Y. Mechanical Behavior of Graphite-Reinforced Aluminum Alloy Composite via Friction Stir Processing. Mater. Trans. 2021, 62, 519–525. [Google Scholar] [CrossRef]

- Mohammed, M.H.; Subhi, A.D. Exploring the Influence of Process Parameters on the Properties of SiC/A380 Al Alloy Surface Composite Fabricated by Friction Stir Processing. Eng. Sci. Technol. Int. J. 2021, 24, 1272–1280. [Google Scholar] [CrossRef]

- Mishra, R.R.; Panda, A.; Sahoo, A.K.; Kumar, R. Research Progress on Nano-Metal Matrix Composite (NMMC) Fabrication Method: A Comprehensive Review. Mater. Today: Proc. 2022, 56, 2104–2109. [Google Scholar] [CrossRef]

- Hosseinzadeh, A.; Yapici, G.G. High Temperature Characteristics of Al2024/SiC Metal Matrix Composite Fabricated by Friction Stir Processing. Mater. Sci. Eng. A 2018, 731, 487–494. [Google Scholar] [CrossRef]

- Zheng, Z.; Zhang, X.; Li, J.; Geng, L. High-Content Graphene Nanoplatelet Reinforced Aluminum Composites Produced by Ball Milling and Hot Extrusion. Sci. China Technol. Sci. 2020, 63, 1426–1435. [Google Scholar] [CrossRef]

- Lou, S.M.; Qu, C.D.; Guo, G.X.; Ran, L.W.; Liu, Y.Q.; Zhang, P.P.; Su, C.J.; Wang, Q.B. Effect of Fabrication Parameters on the Performance of 0.5 Wt.% Graphene Nanoplates-Reinforced Aluminum Composites. Materials 2020, 13, 3483. [Google Scholar] [CrossRef] [PubMed]

- Shin, S.E.; Bae, D.H. Deformation Behavior of Aluminum Alloy Matrix Composites Reinforced with Few-Layer Graphene. Compos. Part A Appl. Sci. Manuf. 2015, 78, 42–47. [Google Scholar] [CrossRef]

- Das, D.; Kumar Thakur, R.; Kumar Chaubey, A.; Kumar Sahoo, A. Optimization of Machining Parameters and Development of Surface Roughness Models during Turning Al-Based Metal Matrix Composite. Mater. Today Proc. 2018, 5, 4431–4437. [Google Scholar] [CrossRef]

- Mishra, P.C.; Das, D.K.; Ukamanal, M.; Routara, B.C.; Sahoo, A.K. Multi-Response Optimization of Process Parameters Using Taguchi Method and Grey Relational Analysis during Turning AA 7075/SiC Composite in Dry and Spray Cooling Environments. Int. J. Ind. Eng. Comput. 2015, 6, 445–456. [Google Scholar] [CrossRef]

- Swain, P.K.; Mohapatra, K.D.; Das, R.; Sahoo, A.K.; Panda, A. Experimental Investigation into Characterization and Machining of Al + SiCp Nano-Composites Using Coated Carbide Tool. Mech. Ind. 2020, 21, 307. [Google Scholar] [CrossRef]

- Mohanty, S.; Routara, B.C.; Nanda, B.K.; Das, D.K.; Sahoo, A.K. Study of Machining Characteristics of Al-SiCp12% Composite in Nano Powder Mixed Dielectric Electrical Discharge Machining Using RSM. Mater. Today: Proc. 2018, 5, 25581–25590. [Google Scholar] [CrossRef]

- Ravinath, H.; Ahammed, I.I.; Harigovind, P.; Devan, S.A.; Senan, V.R.A.; Shankar, K.V.; Nandakishor, S. Impact of Aging Temperature on the Metallurgical and Dry Sliding Wear Behaviour of LM25/Al2O3 Metal Matrix Composite for Potential Automotive Application. Int. J. Lightweight Mater. Manuf. 2023, 6, 416–433. [Google Scholar] [CrossRef]

- Sharma, A.; Narsimhachary, D.; Sharma, V.M.; Sahoo, B.; Paul, J. Surface Modification of Al6061-SiC Surface Composite through Impregnation of Graphene, Graphite & Carbon Nanotubes via FSP: A Tribological Study. Surf. Coat. Technol. 2019, 368, 175–191. [Google Scholar] [CrossRef]

- Khare, M.; Gupta, R.K.; Ghosh, S.S.; Bhardwaj, B. Effect of Reinforcements (B4C & Al2O3) and Rotational Speed on Tribological Properties of Aluminum Alloy 7075 Hybrid Composites through Friction Stir Processing. In Proceedings of the 1st International Conference on Advances in Mechanical Engineering and Nanotechnology (ICAMEN 2019), Jaipur, India, 8–9 March 2019; p. 030008. [Google Scholar] [CrossRef]

- Akbari, M.; Asadi, P.; Zolghadr, P.; Khalkhali, A. Multicriteria Optimization of Mechanical Properties of Aluminum Composites Reinforced with Different Reinforcing Particles Type. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2018, 232, 323–337. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, B.; Gao, Q.; Song, J.; Han, G. A Review on Microstructures and Properties of Graphene-Reinforced Aluminum Matrix Composites Fabricated by Friction Stir Processing. J. Manuf. Process. 2021, 68, 126–135. [Google Scholar] [CrossRef]

- Sharma, D.K.; Patel, V.; Badheka, V.; Mehta, K.; Upadhyay, G. Different Reinforcement Strategies of Hybrid Surface Composite AA6061/(B4C+MoS2) Produced by Friction Stir Processing. Materialwiss. Werkstofftech. 2020, 51, 1493–1506. [Google Scholar] [CrossRef]

- Rhodes, C.G.; Mahoney, M.W.; Bingel, W.H.; Calabrese, M. Fine-Grain Evolution in Friction-Stir Processed 7050 Aluminum. Scr. Mater. 2003, 48, 1451–1455. [Google Scholar] [CrossRef]

- Das, D.; Pradhan, S.K.; Sahoo, A.K.; Panda, A.; Satpathy, M.P.; Samal, C. Tool Wear and Cutting Force Investigations during Turning 15 Wt% SiCp-Al 7075 Metal Matrix Composite. Mater. Today: Proc. 2020, 26, 854–859. [Google Scholar] [CrossRef]

- Bahrami, M.; Besharati Givi, M.K.; Dehghani, K.; Parvin, N. On the Role of Pin Geometry in Microstructure and Mechanical Properties of AA7075/SiC Nano-Composite Fabricated by Friction Stir Welding Technique. Mater. Des. 2014, 53, 519–527. [Google Scholar] [CrossRef]

- Sahraeinejad, S.; Izadi, H.; Haghshenas, M.; Gerlich, A.P. Fabrication of Metal Matrix Composites by Friction Stir Processing with Different Particles and Processing Parameters. Mater. Sci. Eng. A 2015, 626, 505–513. [Google Scholar] [CrossRef]

- Zhang, L.-J.; Qiu, F.; Wang, J.-G.; Wang, H.-Y.; Jiang, Q.-C. Microstructures and Mechanical Properties of the Al2014 Composites Reinforced with Bimodal Sized SiC Particles. Mater. Sci. Eng. A 2015, 637, 70–74. [Google Scholar] [CrossRef]

- Khodabakhshi, F.; Simchi, A.; Kokabi, A.H.; Gerlich, A.P.; Nosko, M.; Švec, P. Influence of Hard Inclusions on Microstructural Characteristics and Textural Components during Dissimilar Friction-Stir Welding of an PM Al–Al2O3–SiC Hybrid Nanocomposite with AA1050 Alloy. Sci. Technol. Weld. Join. 2017, 22, 412–427. [Google Scholar] [CrossRef]

- Manjunath Naik, H.R.; Manjunath, L.H.; Malik, V.; Patel Gc, M.; Saxena, K.K.; Lakshmikanthan, A. Effect of Microstructure, Mechanical and Wear on Al-CNTs/Graphene Hybrid MMC’S. Adv. Mater. Process. Technol. 2022, 8 (Suppl. S2), 366–379. [Google Scholar] [CrossRef]

- Şenel, M.C.; Gürbüz, M.; Koç, E. Fabrication and Characterization of Synergistic Al-SiC-GNPs Hybrid Composites. Compos. Part B Eng. 2018, 154, 1–9. [Google Scholar] [CrossRef]

- Wu, G.; Yu, Z.; Jiang, L.; Zhou, C.; Deng, G.; Deng, X.; Xiao, Y. A Novel Method for Preparing Graphene Nanosheets/Al Composites by Accumulative Extrusion-Bonding Process. Carbon 2019, 152, 932–945. [Google Scholar] [CrossRef]

- Gao, X.; Yue, H.; Guo, E.; Zhang, S.; Wang, B.; Guan, E.; Song, S.; Zhang, H. Preparation and Tribological Properties of Homogeneously Dispersed Graphene-Reinforced Aluminium Matrix Composites. Mater. Sci. Technol. 2018, 34, 1316–1322. [Google Scholar] [CrossRef]

- Moustafa, E.B.; Abushanab, W.S.; Melaibari, A.; Yakovtseva, O.; Mosleh, A.O. The Effectiveness of Incorporating Hybrid Reinforcement Nanoparticles in the Enhancement of the Tribological Behavior of Aluminum Metal Matrix Composites. JOM 2021, 73, 4338–4348. [Google Scholar] [CrossRef]

- Liu, J.; Cao, G.; Zhu, X.; Zhao, K.; An, L. Optimization of the Microstructure and Mechanical Properties of Heterogeneous Al-Al2O3 Nanocomposites. Mater. Today Commun. 2020, 25, 101199. [Google Scholar] [CrossRef]

- Zhang, X.; Li, S.; Pan, B.; Pan, D.; Liu, L.; Hou, X.; Chu, M.; Kondoh, K.; Zhao, M. Regulation of Interface between Carbon Nanotubes-Aluminum and Its Strengthening Effect in CNTs Reinforced Aluminum Matrix Nanocomposites. Carbon 2019, 155, 686–696. [Google Scholar] [CrossRef]

- Guo, S.; Gao, J.B.; Du, X.M.; Fang, G.S.; Qi, H.T.; Li, N.; Zhang, G. Wear Properties of Aluminum Matrix Composites Reinforced by Graphene Encapsulated Sic Nanoparticles. DJNB 2021, 16, 249–259. [Google Scholar] [CrossRef]

- Mazaheri, Y.; Karimzadeh, F.; Enayati, M.H. Tribological Behavior of A356/Al2O3 Surface Nanocomposite Prepared by Friction Stir Processing. Met. Mat Trans. A 2014, 45, 2250–2259. [Google Scholar] [CrossRef]

- Zheng, K.; Du, X.; Qi, H.; Zhao, T.; Liu, F.; Sun, B. Sliding-Wear Behavior of Aluminum-Matrix Composites Reinforced with Graphene and SiC Nanoparticles. Mater. Tehnol. 2020, 54, 41–48. [Google Scholar] [CrossRef]

| Materials | Mg | Cu | V | Zn | Mn | Si | Fe | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| Al 1060 | 0.03 | 0.05 | 0.05 | 0.05 | 0.03 | 0.25 | 0.35 | 0.03 | Bal. |

| Material | YSσ0.2/MPa | UTS/MPa | El/% | Hardness/HV |

|---|---|---|---|---|

| Al 1060 | 60 | 90 | 42 | 30 |

| Material | 100% Al | 0.5% GNS | 1% GNS | 2% GNS | 1% GNS + 20% SiC |

|---|---|---|---|---|---|

| Average grain size (μm) | 20.2 ± 3.3 | 9.3 ± 1.5 | 6.6 ± 0.5 | 11.4 ± 0.8 | 4.9 ± 1 |

| Material | YSσ0.2/MPa | UTS/MPa | El/% |

|---|---|---|---|

| Al 1060 | 60 | 90 | 42 |

| 100% Al powder | 70.7 | 107 | 47 |

| 0.5% GNS | 71.1 | 121 | 48.8 |

| 1% GNS | 71.2 | 121.1 | 55.6 |

| 2% GNS | 67.4 | 117.3 | 41.1 |

| 20% SiC + 1% GNS | 42.4 | 171.3 | 50.8 |

| Material | RZ of AS/HV a | RZ/HV b | RZ of RS/HV c |

|---|---|---|---|

| Al 1060 | 30 ± 0.2 | 30 ± 0.2 | 30 ± 0.2 |

| 100%Al powder | 47.8 ± 0.2 | 47.8 ± 0.2 | 47.8 ± 0.2 |

| 0.5% GNS | 48.9 ± 3.9 | 48.9 ± 3.1 | 48.9 ± 5.1 |

| 1% GNS | 59.7 ± 1.3 | 59.7 ± 0.9 | 59.7 ± 2 |

| 2% GNS | 61.6 ± 7 | 61.6 ± 5.6 | 61.6 ± 9.9 |

| 20% SiC + 1% GNS | 67.8 ± 1.8 | 67.8 ± 1.1 | 67.8 ± 2.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Zhu, X.; Fan, Y.; Liu, J.; Xie, L.; Jiang, C.; Xiao, X.; Wu, P.; You, X. Microstructure and Properties of Aluminum–Graphene–SiC Matrix Composites after Friction Stir Processing. Materials 2024, 17, 979. https://doi.org/10.3390/ma17050979

Wang C, Zhu X, Fan Y, Liu J, Xie L, Jiang C, Xiao X, Wu P, You X. Microstructure and Properties of Aluminum–Graphene–SiC Matrix Composites after Friction Stir Processing. Materials. 2024; 17(5):979. https://doi.org/10.3390/ma17050979

Chicago/Turabian StyleWang, Chen, Xianyong Zhu, Yuexiang Fan, Jiaan Liu, Liangwen Xie, Cheng Jiang, Xiong Xiao, Peng Wu, and Xiangmi You. 2024. "Microstructure and Properties of Aluminum–Graphene–SiC Matrix Composites after Friction Stir Processing" Materials 17, no. 5: 979. https://doi.org/10.3390/ma17050979

APA StyleWang, C., Zhu, X., Fan, Y., Liu, J., Xie, L., Jiang, C., Xiao, X., Wu, P., & You, X. (2024). Microstructure and Properties of Aluminum–Graphene–SiC Matrix Composites after Friction Stir Processing. Materials, 17(5), 979. https://doi.org/10.3390/ma17050979