Influence of Accelerators on Cement Mortars Using Fluid Catalytic Cracking Catalyst Residue (FCC): Enhanced Mechanical Properties at Early Curing Ages

Abstract

1. Introduction

2. Materials and Methods

3. Results

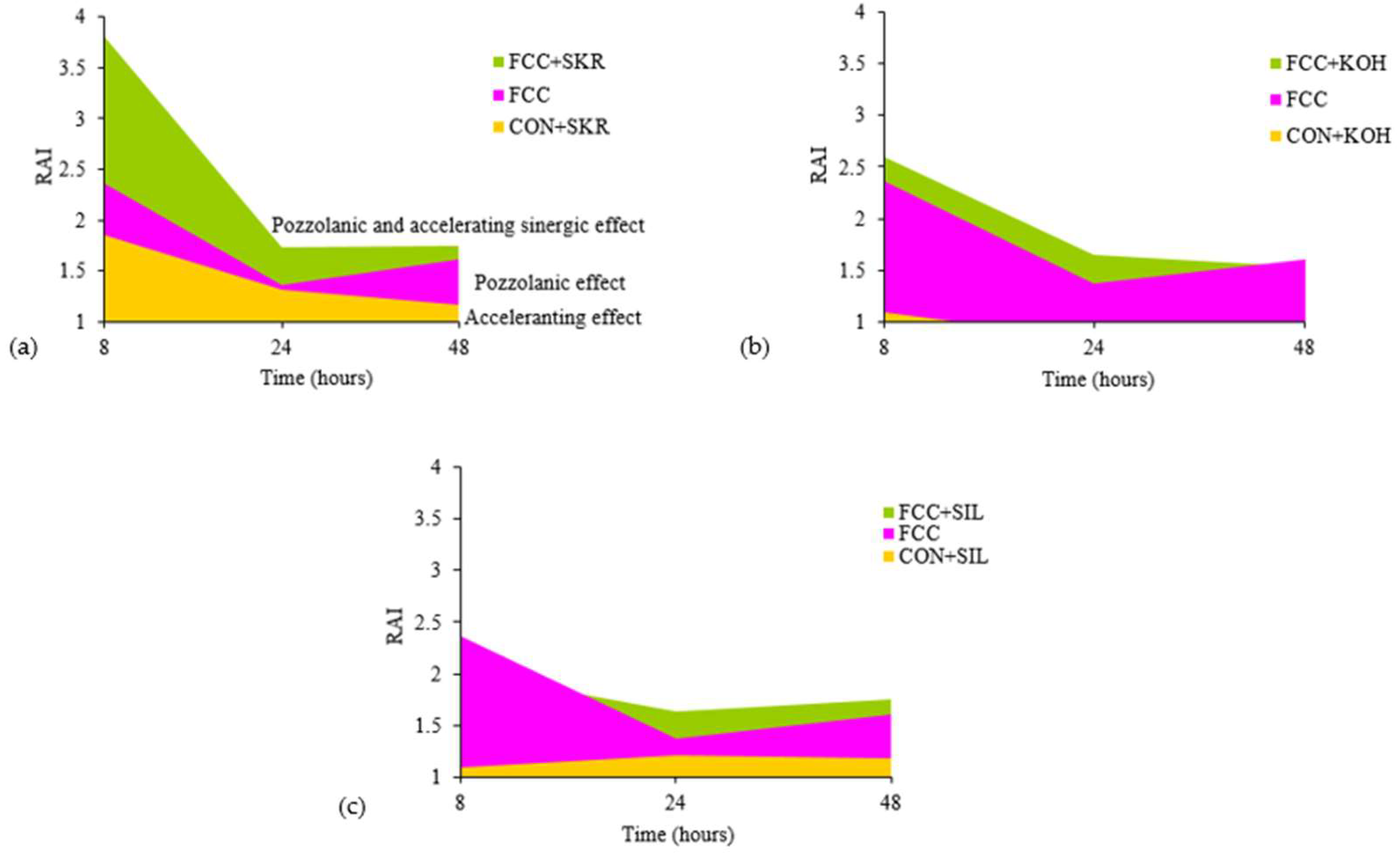

3.1. Study of Mechanical Strengths in Mortars

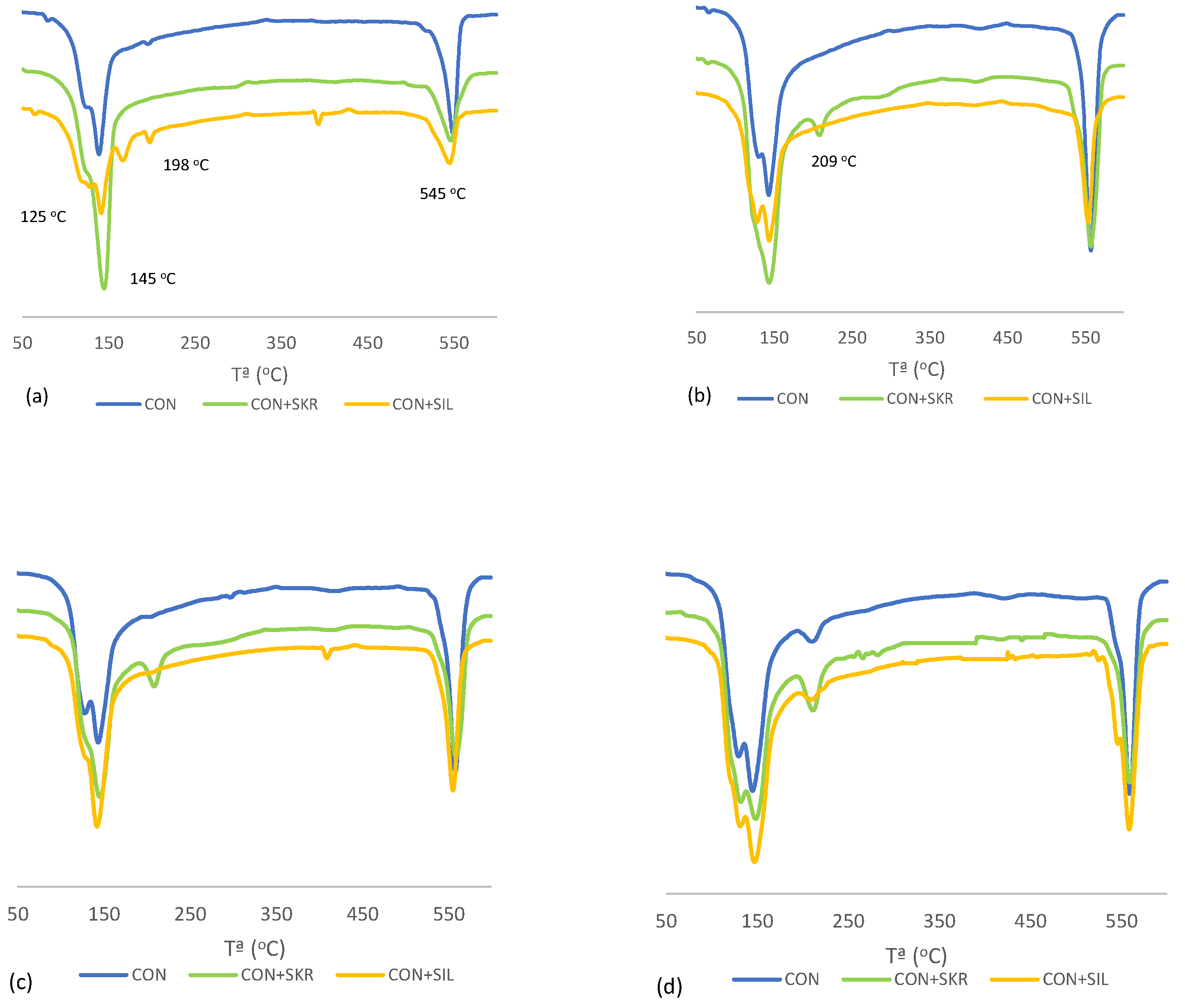

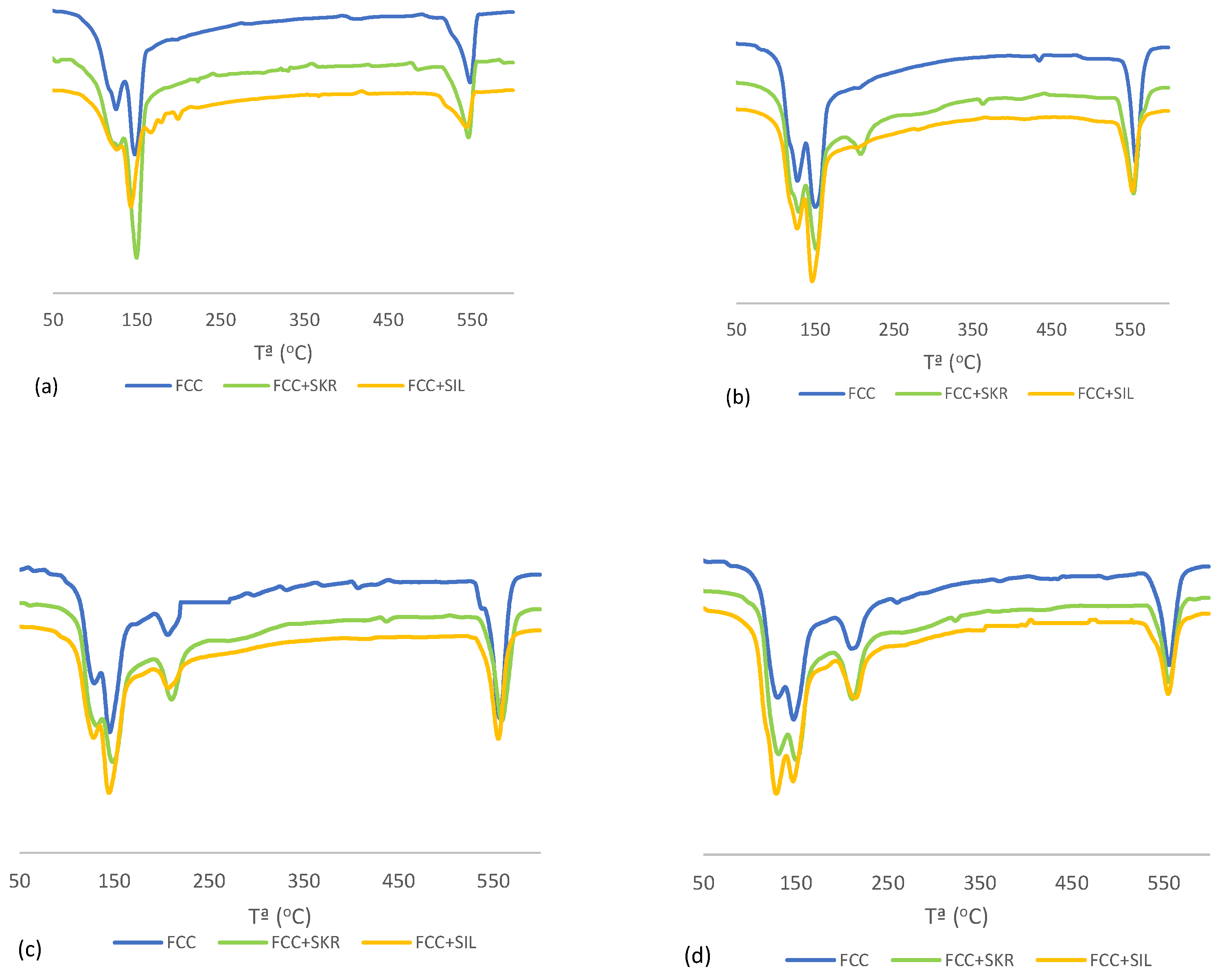

3.2. Thermogravimetric Analysis in Pastes

4. Discussion

5. Conclusions

- -

- The SKR commercial accelerator is the additive with the best behavior, especially during the first 8 curing hours, and no reduction in strength takes place for long curing ages (28 days). This indicates good compatibility between FCC and SKR.

- -

- KOH appears beneficial in the mortar with FCC, but only for the first curing hours. When approaching 48 h, it exerts no benefit on the FCC mortar.

- -

- Unlike the mortar with KOH, the mortars with SIL containing FCC displayed improved compressive strength from 24 curing hours.

- -

- The mortars containing FCC for the 28-day curing age obtained higher compressive strength values than 88 MPa, except that containing KOH. These values confirm that FCC is an SCM with excellent pozzolanic activity.

- -

- Accelerators influence cement hydration by favoring the formation of Afm phases at early curing ages.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Andrew, R. Global CO2 emissions from cement production, 1928–2018. Earth Syst. Sci. Data 2019, 11, 1675–1710. [Google Scholar] [CrossRef]

- Juenger, M.C.G.; Snellings, R.; Bernal, S.A. Supplementary cementitious materials: New sources, characterization, and performance insights. Cem. Concr. Res. 2019, 122, 257–273. [Google Scholar] [CrossRef]

- Teara, A.; Ing, D.S. Mechanical properties of high strength concrete that replace cement partly by using fly ash and eggshell powder. Phys. Chem. Earth 2020, 120, 102942. [Google Scholar] [CrossRef]

- Hoang, K.; Justnes, H.; Geiker, M. Early age strength increase of fly ash blended cement by a ternary hardening accelerating admixture. Cem. Concr. Res. 2016, 81, 59–69. [Google Scholar] [CrossRef]

- Kocak, Y.; Nas, S. The effect of using fly ash on the strength and hydration characteristics of blended cements. Constr. Build. Mater. 2014, 73, 25–32. [Google Scholar] [CrossRef]

- Ashraf, M.; Iqbal, M.F.; Rauf, M.; Ashraf, M.U.; Ulhaq, A.; Muhammad, H.; Liu, Q. Developing a sustainable concrete incorporating bentonite clay and silica fume: Mechanical and durability performance. J. Clean. Prod. 2022, 337, 130315. [Google Scholar] [CrossRef]

- Liu, H.; Sun, X.; Wang, Y.; Lu, X.; Du, H.; Tian, Z. Study on the influence of silica fume (SF) on the rheology, fluidity, stability, time-varying characteristics, and mechanism of cement paste. Materials 2022, 15, 90. [Google Scholar] [CrossRef] [PubMed]

- Yuan, L.; Qiu, J.; Guo, Z.; Zhang, S.; Wan, X.; Sun, X. Microscale and macroscale strength behaviours of blast furnace slag-cement based materials: Modeling and analysis. Constr. Build. Mater. 2023, 376, 131016. [Google Scholar] [CrossRef]

- Kim, J.; Na, S.; Hama, Y. Effect of blast-furnace slag replacement ratio and curing method on pore structure change after carbonation on cement paste. Materials 2020, 13, 4787. [Google Scholar] [CrossRef]

- Al-Jabri, K.; Baawain, M.; Taha, R.; Al-Kamyani, Z.; Al-Shamsi, K.; Isthtieh, A. Potential use of FCC spent catalyst as partial replacement of cement or sand in cement mortars. Constr. Build. Mater. 2013, 39, 77–81. [Google Scholar] [CrossRef]

- Chen, H.; Tseng, Y.; Hsu, K. Spent FCC catalyst as a pozzolanic material for high-performance material for high-performance mortars. Cem. Concr. Compos. 2004, 26, 657–664. [Google Scholar] [CrossRef]

- Payá, J.; Monzó, J.; Borrachero, M. Fluid catalytic cracking catalyst residue (FC3R): An excellent mineral by product for improving early-strength development of cement mixtures. Cem. Concr. Res. 1999, 29, 1773–1779. [Google Scholar] [CrossRef]

- Lu, B.; Li, H.; Li, M.; Wong, T.; Qian, S. Mechanism and design of fluid catalytic cracking ash-blended cementitious composites for high performance printing. Addit. Manuf. 2023, 61, 103286. [Google Scholar] [CrossRef]

- Pacewska, B.; Wilinska, I.; Kubissa, J. Use of spent catalyst from catalytic cracking in fluidized bed as a new concrete additive. Thermochim. Acta 1998, 322, 175–181. [Google Scholar] [CrossRef]

- Serna, P.; López, J.A.; Coll, H.; Camacho, E.; Navarro-Gregori, J.; Galán, F. Ultra-high-performance fiber reinforced concrete footbridge over the Ovejas Ravine (Alicante). Hormig. Acero 2015, 66, 23–42. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, T.; Gao, X. Incorporation of self-ignited coal gangue in steam cured precast concrete. J. Clean. Prod. 2021, 292, 126004. [Google Scholar] [CrossRef]

- Zhao, Z.; Gao, L.; Zuo, J. How national policies facilitate low carbon city development: A China study. J. Clean. Prod. 2019, 234, 743–754. [Google Scholar] [CrossRef]

- Shi, J.; Liu, B.; He, Z.; Wu, X.; Tan, J.; Chen, J.; Jiang, J. Properties evolution of high early strength cement paste and interfacial transition zone during steam curing process. Constr. Build. Mater. 2020, 252, 119095. [Google Scholar] [CrossRef]

- Mustafa, T.Ç.; Mehmet, U. Effects of accelerator type and dosage on the mechanical and durability properties of rapid setting precast concrete. Sigma J. Eng. Nat. Sci. 2022, 40, 685–694. [Google Scholar]

- Tao, Y.; Rahul, A.V.; Lesage, K.; Yuan, Y.; Van Tittelboom, K.; De Schutter, G. Stiffening control of cement-based materials using accelerators in inline mixing processes: Possibilities and challenges. Cem. Com. Compos. 2021, 119, 103972. [Google Scholar] [CrossRef]

- Wang, Y.; Lei, L.; Liu, J.; Ma, Y.; Liu, Y.; Xiao, Z.; Shi, C. Accelerators for normal concrete: A critical review on hydration microstructure and properties of cement-based materials. Cem. Concr. Compos. 2022, 134, 104762. [Google Scholar] [CrossRef]

- Habib Lone, I.; Muneeb, A.; Ahmad, J.; Mohammad Jasmin, S.; Ali, M.; Ahmad Khan, M.; Hussain Malik, A.; Jasmin, M. Experimental study of effect of sodium silicate Na2SiO3 on properties of concrete. Int. J. Civ. Eng. Technol. 2015, 6, 39–47. [Google Scholar]

- Samoui, N.; Bérubé, M.A.; Fournier, B.; Bissonnette, B.; Durand, B. Effects of alkali addition on the mechanical properties and durability of concrete. Cem. Concr. Res. 2005, 35, 203–212. [Google Scholar] [CrossRef]

- Ananyachandran, P.; Vasugi, V. Development of a sustainable high early strength concrete incorporated with pozzolans, calcium nitrate and triethanolamine: An experimental study. Sustain. Energy Technol. Assess. 2022, 54, 102857. [Google Scholar] [CrossRef]

- UNE-EN 197-1; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. AENOR: Madrid, Spain, 2011.

- UNE-EN 196-1; Methods of Testing Cement—Part 1: Determination of Strength. AENOR: Madrid, Spain, 2018.

- Payá, J.; Borrachero, M.V.; Mónzó, J.; Soriano, L. Studies on the behaviour of different spent fluidized-bed catalytic cracking catalysts on Portland cement. Mater. Constr. 2009, 59, 37–52. [Google Scholar] [CrossRef]

- Soriano, L.; Tashima, M.M.; Bonilla, M.; Payá, J.; Monzó, J.; Borrachero, M.V. Use of high-resolution thermogravimetric analysis (HRTG) technique in spent FCC catalyst/Portland cement pastes. J. Therm. Anal. Calorim. 2015, 120, 1511–1517. [Google Scholar] [CrossRef]

- Wang, K.; Shah, S.P.; Mishulovich, A. Effects of curing temperature and NaOH addition on hydration and strength development of clinker-free CKD-fly ash binders. Cem. Concr. Res. 2004, 34, 299–309. [Google Scholar] [CrossRef]

- Coppola, L.; Buoso, A.; Coffetti, D.; Kara, P.; Lorenzi, S.; D’Alessandro, F. The effect of sodium silicate on the behaviour of shotcretes for tunnel lining. Sci. Res. Rep. 2017, 14, 1–8. [Google Scholar] [CrossRef]

- Xu, Y.; He, T.; Ma, X. The influence of calcium nitrate/sodium nitrate on the hydration process of cement paste mixed with alkali free liquid accelerator. Constr. Build. Mater. 2022, 347, 128555. [Google Scholar] [CrossRef]

- Wise, T.; Ramachandran, V.S.; Polomark, G.M. The effect of thiocyanates on the hydration of portland cement at low temperatures. Thermochim. Acta 1995, 264, 157–171. [Google Scholar] [CrossRef]

- Salvador, R.P.; Cavalaro, S.H.P.; Cano, M.; Figueiredo, A.D. Influence of spraying on the early hydration of accelerated cement pastes. Cem. Concr. Res. 2016, 88, 7–19. [Google Scholar] [CrossRef]

- Shi, Y.; Wang, T.; Li, H.; Wu, S. Exploring the influence factors of early hydration of ultrafine cement. Materials 2021, 14, 5677. [Google Scholar] [CrossRef] [PubMed]

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | Na2O + K2O | P2O5 | TiO2 | LOI * | |

|---|---|---|---|---|---|---|---|---|---|---|

| CEM | 19.29 | 5.22 | 3.51 | 61.75 | 2.07 | 3.55 | 1.23 | 0.26 | 0.27 | 1.96 |

| FCC | 47.76 | 49.25 | 0.60 | 0.11 | 0.17 | 0.03 | 0.33 | 0.02 | 1.22 | 0.51 |

| Cem (g) | Sand (g) | FCC (g) | Accel. (g) | H2O (g) | Superplast. (g) | Work. (mm) | |

|---|---|---|---|---|---|---|---|

| CON | 450.0 | 1350.0 | _ | _ | 202.5 | _ | 110 |

| FCC | 450.0 | 1215.0 | 135.0 * | _ | 202.5 | 3.2 | 110 |

| CON + KOH | 450.0 | 1350.0 | _ | 9.0 | 202.5 | 1.1 | 111 |

| FCC + KOH | 450.0 | 1215.0 | 135.0 * | 9.0 | 202.5 | 6.2 | 119 |

| CON + SIL | 450.0 | 1350.0 | _ | 9.0 | 202.5 | 1.2 | 112 |

| FCC + SIL | 450.0 | 1215.0 | 135.0 * | 9.0 | 202.5 | 5.7 | 113 |

| CON + SKR | 450.0 | 1350.0 | _ | 9.0 | 202.5 | _ | 113 |

| FCC + SKR | 450.0 | 1215.0 | 135.0 * | 9.0 | 202.5 | 3.2 | 116 |

| 8 h | 24 h | 48 h | 28 d | |

|---|---|---|---|---|

| CON | 6.85 ± 0.51 | 29.23 ± 1.17 | 34.47 ± 2.06 | 56.96 ± 1.31 |

| FCC | 16.18 ± 1.24 | 39.93 ± 2.15 | 55.44 ± 2.23 | 88.54 ± 2.61 |

| CON + KOH | 7.51 ± 0.82 | 24.60 ± 1.76 | 28.86 ± 0.45 | 48.13 ± 0.86 |

| FCC + KOH | 17.86 ± 1.05 | 48.13 ± 1.25 | 52.98 ± 1.75 | 68.10 ± 2.05 |

| CON + SIL | 7.56 ± 0.79 | 35.42 ± 2.03 | 40.69 ± 0.35 | 61.25 ± 1.67 |

| FCC + SIL | 13.83 ± 0.85 | 47.72 ± 0.52 | 60.38 ± 2.10 | 89.30 ± 1.92 |

| CON + SKR | 12.76 ± 1.32 | 38.67 ± 1.25 | 40.40 ± 0.97 | 64.16 ± 1.23 |

| FCC + SKR | 26.03 ± 0.65 | 50.61 ± 0.79 | 60.43 ± 1.56 | 91.60 ± 1.46 |

| 8 h | 24 h | 48 h | 28 d | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TML | CH | BW | TML | CH | BW | TML | CH | BW | TML | CH | BW | |

| CON | 6.8 | 1.0 | 5.8 | 13.2 | 2.3 | 10.9 | 15.9 | 2.7 | 13.2 | 21.1 | 3.4 | 17.7 |

| CON + SIL | 5.4 | 0.7 | 4.7 | 9.6 | 2.2 | 7.4 | 13.8 | 2.0 | 11.8 | 20.2 | 3.5 | 16.7 |

| CON + SKR | 8.1 | 0.8 | 7.3 | 15.6 | 1.3 | 14.3 | 16.9 | 2.4 | 14.5 | 22.4 | 3.4 | 19.0 |

| FCC | 7.8 | 0.9 | 6.9 | 13.5 | 1.2 | 12.3 | 15.7 | 2.2 | 13.5 | 23.5 | 2.3 | 21.2 |

| FCC + SIL | 5.9 | 0.5 | 5.4 | 11.6 | 1.1 | 10.5 | 14.6 | 1.6 | 13.0 | 22.8 | 1.8 | 21.0 |

| FCC + SKR | 8.6 | 1.0 | 7.6 | 14.9 | 1.4 | 13.5 | 17.6 | 1.8 | 15.8 | 25.1 | 1.8 | 23.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soriano, L.; Borrachero, M.V.; Giménez-Carbo, E.; Tashima, M.M.; Monzó, J.M.; Payá, J. Influence of Accelerators on Cement Mortars Using Fluid Catalytic Cracking Catalyst Residue (FCC): Enhanced Mechanical Properties at Early Curing Ages. Materials 2024, 17, 1219. https://doi.org/10.3390/ma17051219

Soriano L, Borrachero MV, Giménez-Carbo E, Tashima MM, Monzó JM, Payá J. Influence of Accelerators on Cement Mortars Using Fluid Catalytic Cracking Catalyst Residue (FCC): Enhanced Mechanical Properties at Early Curing Ages. Materials. 2024; 17(5):1219. https://doi.org/10.3390/ma17051219

Chicago/Turabian StyleSoriano, Lourdes, María Victoria Borrachero, Ester Giménez-Carbo, Mauro M. Tashima, José María Monzó, and Jordi Payá. 2024. "Influence of Accelerators on Cement Mortars Using Fluid Catalytic Cracking Catalyst Residue (FCC): Enhanced Mechanical Properties at Early Curing Ages" Materials 17, no. 5: 1219. https://doi.org/10.3390/ma17051219

APA StyleSoriano, L., Borrachero, M. V., Giménez-Carbo, E., Tashima, M. M., Monzó, J. M., & Payá, J. (2024). Influence of Accelerators on Cement Mortars Using Fluid Catalytic Cracking Catalyst Residue (FCC): Enhanced Mechanical Properties at Early Curing Ages. Materials, 17(5), 1219. https://doi.org/10.3390/ma17051219