Numerical Modeling of the Thermal Insulating Properties of Space Suits

Abstract

1. Introduction

1.1. Outer Space Conditions

1.2. Spacesuits

- Protects against the space environment;

- Enables mobility in outer space conditions;

- Contains a life support system;

- Maintains communication between the crew and the ISS base station.

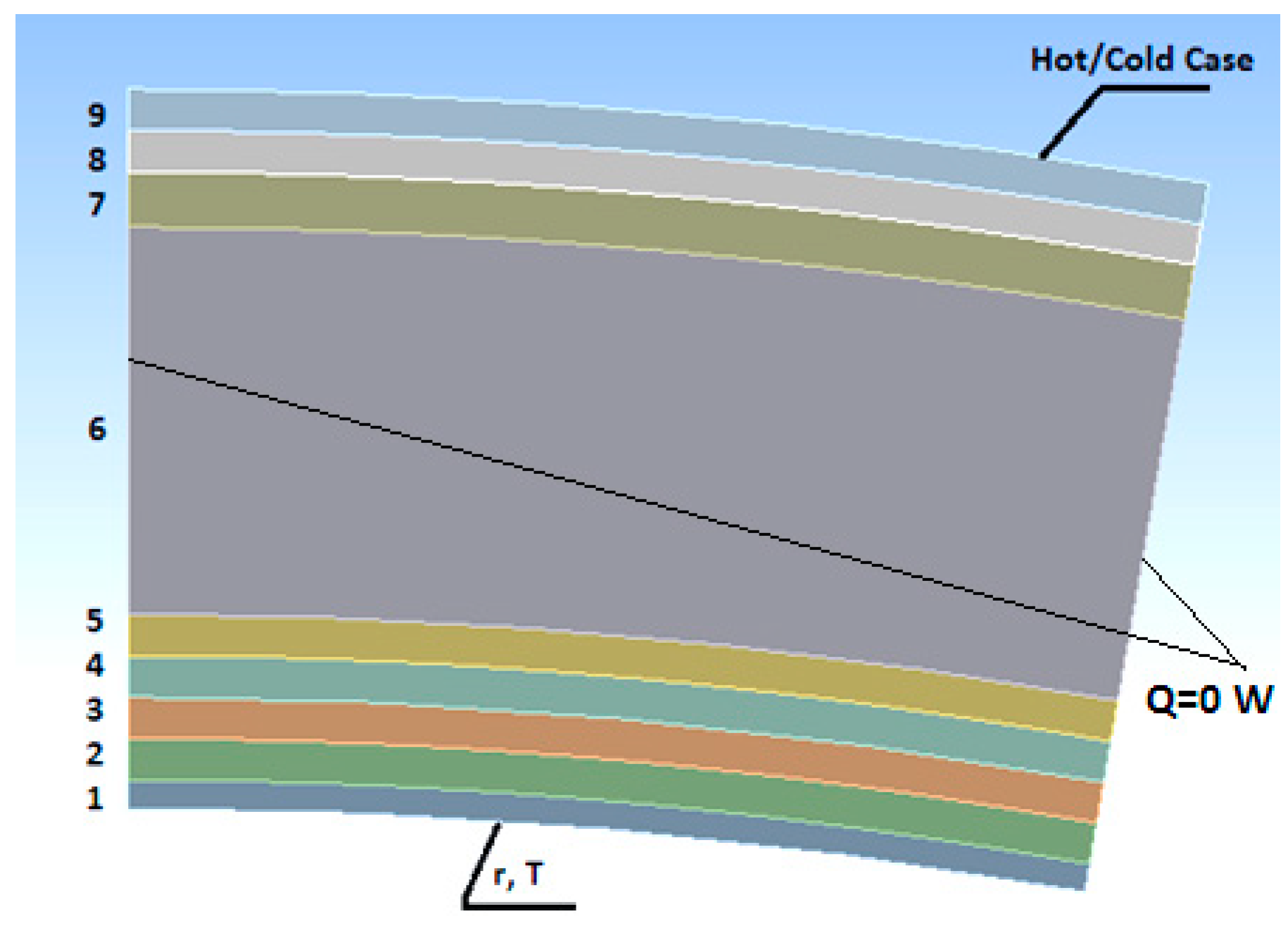

- Layer 1: Human skin.

- Layer 2: LCVG (Liquid Cooling and Ventilation Garment): a two-layered layup with a water-fed tube system. The flow of liquid facilitates the cooling of the body in extreme conditions. The first nylon-made layer ensures good adherence to the body. The second one made of spandex or nylon has polymer tubes.

- Layer 3: The Pressure Garment Layer contains the oxygen needed for breathing. Furthermore, the gas within this layer allows the astronauts to maintain normal blood pressure. It is a layer of nylon covered with thermoplastic urethane.

- Layer 4: The Dacron layer provides the stiffness of the gas-filled layer.

- Layer 5: The neoprene-covered nylon prevents the tearing of the material layers.

- Layer 6: Seven layers of aluminum-covered mylar create the main thermo-insulating layer. Mylar is the foil formed as a result of PET polyester stretching. It exhibits excellent thermal properties: the melting point is 254 °C, and in the temperature range from 50 to 200 °C, it maintains thermal stability. The aluminum coverage provides a safeguard from heat radiation between the layers. The distances between the layers are negligible. To simplify the calculations, the seven layers of aluminum-covered mylar are shown as one layer.

- Layers 7, 8, and 9: The three-layer external structure (Ortho-fabric) ensures protection from accelerated micrometeoroids (Kevlar) and fire (Goretex) and water (Nomex) resistance.

- A comparison of the results obtained using a computer simulation with the verification calculations for the simplified model of heat exchange. Two numerical models were analyzed: the verification model under simplified boundary conditions to assess the results’ credibility and the actual model with parameters similar to outer space conditions. This enabled an assessment of the model’s quality and of the possible discrepancies.

- An analysis of the thermo insulating properties of a space suit for a person in extreme outer space conditions. The specific conditions of outer space were defined by a variety of factors (i.e., the space vacuum, atomic oxygen, UV-radiation, temperature, micrometeoroids).

- The discussion on possible uses of the proposed model solution.

2. Materials and Methods

2.1. Metabolism and Heat Exchange

2.2. Numerical Modeling

- Approximation—the application of the material data and geometrical conditions to ensure similarity between the model and the actual object.

- Discretization—the transformation of a continuous mathematical model into a discrete model, divided into a finite number of elements.

- The solution—the determination of the temperature area and the heat flux density.

- Verification—the assessment of the quality of the obtained results, which will allow for the applied modifications.

2.3. Verification Calculations

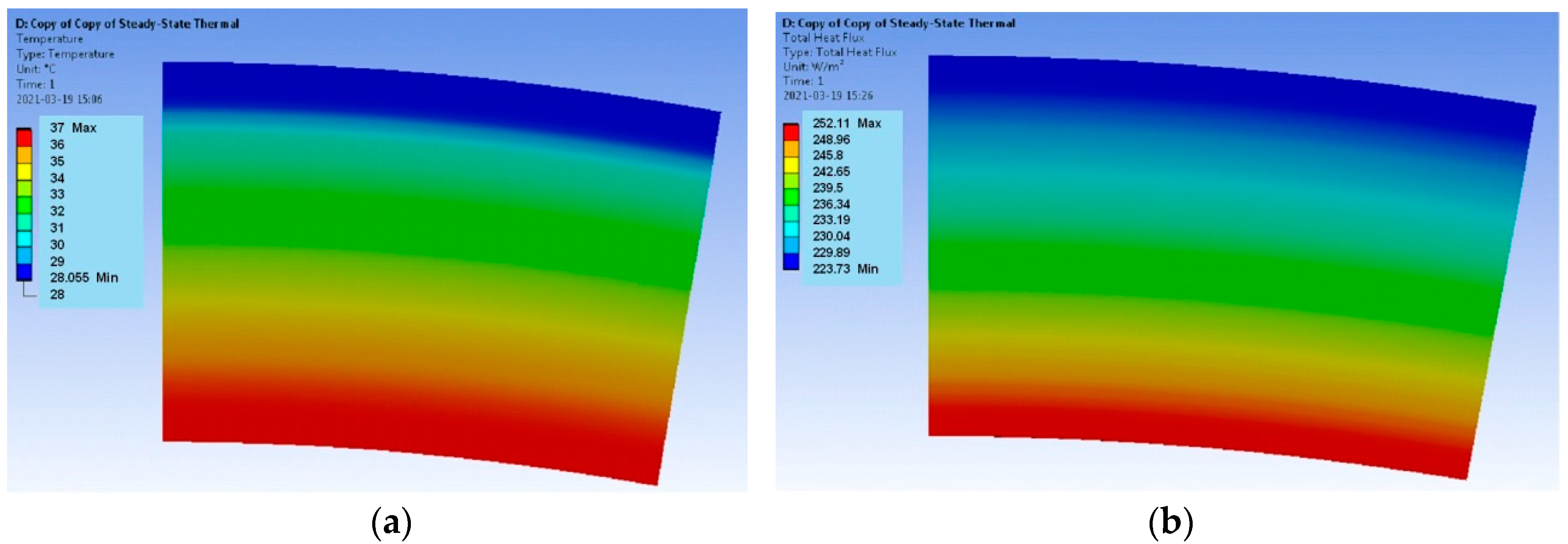

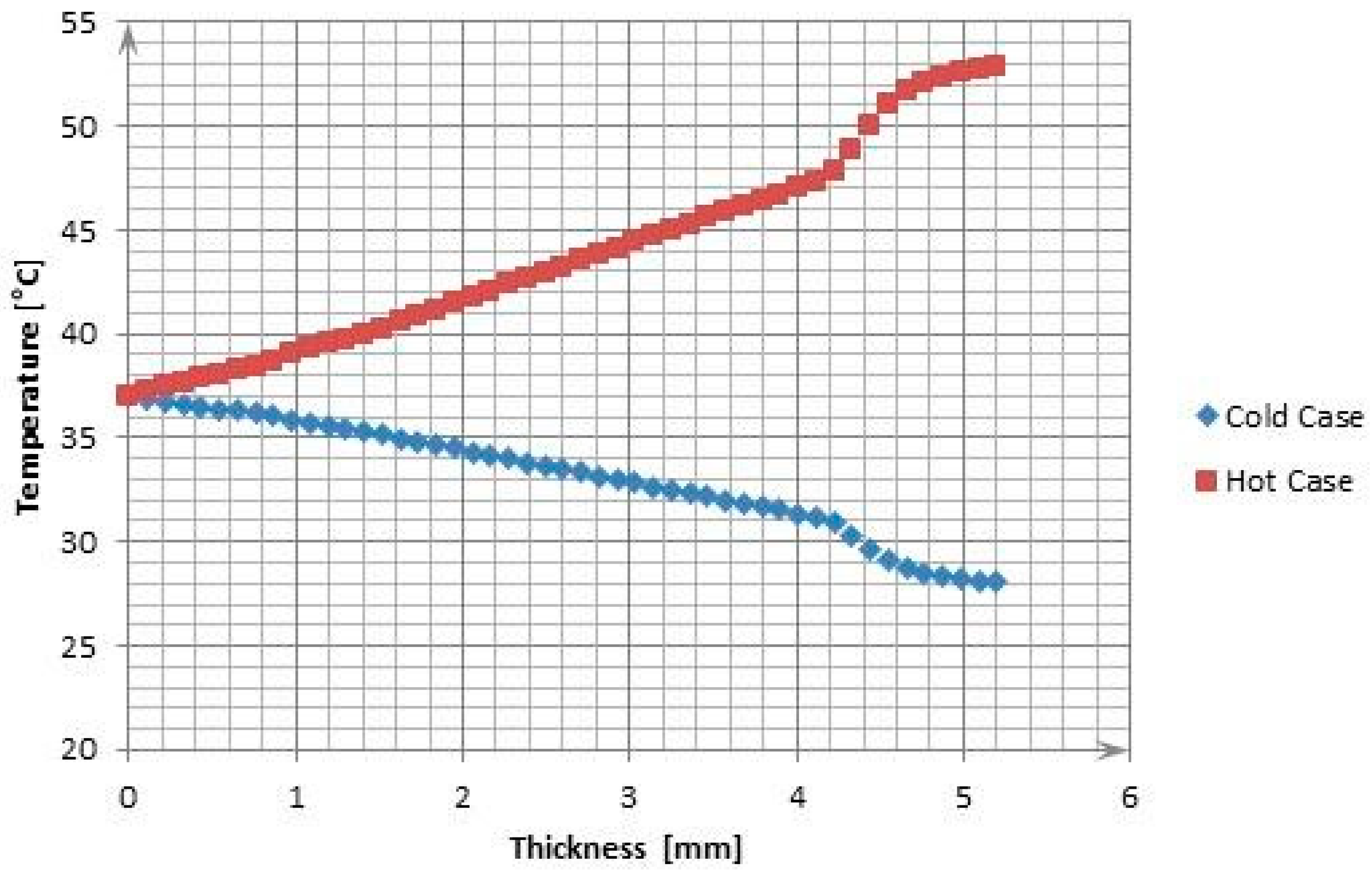

3. The Results of the Numerical Calculations

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| A | radiation surface, m2; |

| C | heat exchange on the skin by convection, W/m2; |

| CT | core temperature, K; |

| CTE | coefficient of thermal expansion, -; |

| CVCM | collected volatile condensable material in cosmic space, -; |

| h | convection coefficient, W/(m2K); |

| K | heat exchange on the skin by conduction, W/m2; |

| L | user’s height, m; |

| M | metabolic rate, W/m2; |

| Mb | user’s body weight, kg; |

| P | heat exchange on the skin by evaporation, W/m2; |

| Q | convective heat flux on the surface of the multilayer structure, W; |

| q | heat flux density of human heat loss, W/m2; |

| R | heat exchange on the skin by radiation, W/m2; |

| S | user’s skin surface, m2; |

| ri | radius of local curvature of the i-th layer of space suit, m; |

| Ta | surrounding/ambient temperature, K; |

| Ts | surface temperature, K; |

| Twi | surface temperature of the i-th layer of space suit, K; |

| TML | total mass loss in cosmic space, -; |

| V | heat exchange in the respiratory tract, W/m2; |

| ε | emissivity coefficient, -; |

| η | efficiency of converting thermal energy into work, -; |

| λi | thermal conductivity coefficient, W/(mK); |

| σ | Stefan–Boltzmann constant, 5.670367(13) × 10−8 W/(m2K4). |

References

- Finckenor, M.M.; de Groh, K.K. A Researcher’s Guide to: Space Environmental Effects. NASA Communications. Available online: https://www.nasa.gov/science-research/for-researchers/a-researchers-guide-to-space-environmental-effects (accessed on 28 October 2020).

- Riley, H.F. Micrometeoroids and Orbital Debris (MMOD). NASA Communications. Available online: https://www.nasa.gov/centers-and-facilities/white-sands/micrometeoroids-and-orbital-debris-mmod/ (accessed on 14 June 2016).

- Coonrod, J. What Is Outgassing and When Does It Matter? Microw. J. 2010. Available online: https://www.microwavejournal.com/blogs/1-rog-blog/post/16667-what-is-outgassing-and-when-does-it-matter (accessed on 19 October 2010).

- Springel, M. The Human Body in Space: Distinguishing Fact from Fiction. Science in the News. Available online: https://sitn.hms.harvard.edu/flash/2013/space-human-body/ (accessed on 20 July 2013).

- Health Effects of UV Radiation. United States Environmental Protection Agency. Available online: https://www.epa.gov/sunsafety/health-effects-uv-radiation (accessed on 27 November 2023).

- Spacewalk Spacesuit Basics. NASA Communications. Available online: https://www.nasa.gov/centers-and-facilities/johnson/spacewalk-spacesuit-basics/ (accessed on 4 October 2019).

- Launch and Entry Suit. Space Center Houston. Available online: https://spacecenter.org/exhibits-and-experiences/starship-gallery/launch-and-entry-suit/ (accessed on 1 January 2023).

- Anonymous. NASA Extravehicular Mobility Unit (EMU) LSS/SSA Data Book; UTC Aerospace Systems: Houston, TX, USA, 2017. [Google Scholar]

- Martin, P. NASA’S Development of Next-Generation Spacesuits. Available online: https://oig.nasa.gov/docs/IG-21-025.pdf (accessed on 10 August 2021).

- Wassmer, W. The Materials Used in Space Suits. AZO Materials. Available online: https://www.azom.com/article.aspx?ArticleID=12007 (accessed on 1 May 2015).

- Freudenrich, C. How Space Suits Work. AZoM.com. Available online: https://science.howstuffworks.com/space-suit.htm (accessed on 13 July 2021).

- Mylar Polyester Film—Product Information. DuPont Teijin Films. Available online: https://usa.dupontteijinfilms.com/wp-content/uploads/2017/01/Mylar_Physical_Properties.pdf (accessed on 1 June 2003).

- Maslanka, P.; Aleksieiev, A.; Korycki, R.; Szafranska, H.; Dabrowska, A. Experimental and Numerical Determination of Strength Characteristics Related to Paraglider Wing with Fourier Transform Infrared Spectroscopy of Applied Materials. Materials 2022, 15, 7291. [Google Scholar] [CrossRef] [PubMed]

- Li, Y. The science of clothing comfort. Text. Prog. 2001, 15, 1–135. [Google Scholar] [CrossRef]

- Li, Y.; Zhu, Q. Simultaneous heat and moisture transfer with moisture sorption, condensation and capillary liquid diffusion in porous textiles. Text. Res. J. 2003, 73, 515–524. [Google Scholar] [CrossRef]

- Wang, Z.P.; Turteltaub, S.; Abdalla, M. Shape optimization and optimal control for transient heat conduction problems using an isogeometric approach. Compos. Struct. 2017, 185, 59–74. [Google Scholar] [CrossRef]

- Ghazy, A.; Bergstrom, D.J. Influence of the air gap between protective clothing and skin on clothing performance during flash fire exposure. Heat Mass Transf. 2011, 47, 1275–1288. [Google Scholar] [CrossRef]

- Korycki, R. Determination of Material Thicknesses in Protective Clothing for Firefighters. Fibres Text. East. Eur. 2018, 26, 93–99. [Google Scholar] [CrossRef]

- Dems, K.; Korycki, R. Sensitivity analysis and optimal design for steady conduction problem with radiative heat transfer. J. Therm. Stress. 2005, 28, 213–232. [Google Scholar] [CrossRef]

- Fanger, P.O. Thermal Comfort, 1st ed.; McGraw-Hill: New York, NY, USA, 1972. [Google Scholar]

- EN-ISO 8996:2022; Ergonomics of the Thermal Environment—Determination of Metabolic Rate. ISO: Geneva, Switzerland, 2022.

- Junker, J.; Klaus, D. Parametric Analysis of Internal Heat Transfer for Full-Body Radiative-Cooled Space Suit Concepts. Available online: https://ttu-ir.tdl.org/items/ce87707f-04c3-4018-ba1b-f40125e0e092 (accessed on 7 July 2019).

- Conduction, Cylindrical Coordinates, Heat Transfer. Engineers Edge. Available online: https://www.engineersedge.com/heat_transfer/conduction_cylidrical_coor.htm (accessed on 1 January 2023).

- Martinez, I. Spacecraft Thermal Modelling and Testing. Available online: http://imartinez.etsiae.upm.es/~isidoro/tc3/Spacecraft%20Thermal%20Modelling%20and%20Testing.pdf (accessed on 1 January 2023).

- Korycki, R.; Wiezowska, A. Modeling of the Temperature Field within Knitted Fur Fabrics. Fibres Text. East. Eur. 2011, 19, 55–59. [Google Scholar]

- Korycki, R.; Szafranska, H. Modeling of the Temperature Field within Textile lnlayers of Clothing Laminates. Fibres Text. East. Eur. 2013, 21, 118–122. [Google Scholar]

- Bathe, K.J. Finite Element Procedures, 1st ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2014. [Google Scholar]

- Frei, W. Meshing Your Geometry: When to Use the Various Element Types. COMSOL, Inc. Available online: https://www.comsol.com/blogs/meshing-your-geometry-various-element-types/ (accessed on 4 November 2013).

- Wang, E.; Nelson, T.; Rauch, R. Back to Elements—Tetrahedra vs. Hexahedra. Research Gate. Available online: https://www.researchgate.net/publication/242616030_Back_to_Elements_-_Tetrahedra_vs_Hexahedra (accessed on 1 January 2004).

- Zienkiewicz, O.C.; Morgan, K.; Morgan, K. Finite Elements and Approximation; Dover Publications: Mineola, NY, USA, 2006. [Google Scholar]

- Massina, C. Characterization of Dynamic Thermal Control Schemes and Heat Transfer Pathways for Incorporating Variable Emissivity Electrochromic Materials into a Space Suit Heat Rejection System. Ph.D. Thesis, Graduate School of the University of Colorado, Denver, CO, USA, 2016. [Google Scholar]

- Matweb Material Property Data. Available online: https://www.matweb.com/ (accessed on 1 January 2023).

- Webster, B. First-Order vs. Second-Order Elements in FEA. Available online: https://www.fidelisfea.com/post/first-order-vs-second-order-elements-in-fea (accessed on 8 April 2021).

- Finite Element Mesh Refinement Definition and Techniques. COMSOL, Inc. Available online: https://www.comsol.com/multiphysics/mesh-refinement (accessed on 21 February 2017).

- Skotny, Ł. Correct Mesh Size—Quick Guide. Enterfea. Available online: https://enterfea.com/correct-mesh-size-quick-guide/ (accessed on 7 March 2017).

- Boushon, K. Thermal Analysis and Control of Small Satellites in Low Earth Orbit. Master’s Thesis, Missouri University of Science and Technology, Rolla, MO, USA, 2018. [Google Scholar]

- Zarzycki, R. Wymiana Ciepła i Ruch Masy w Inżynierii Środowiska, 1st ed.; WNT: Warsaw, Poland, 2005. (In Polish) [Google Scholar]

- Eggenberger, P.; MacRae, B.A.; Kemp, S.; Bürgisser, M.; Rossi, R.M.; Annaheim, S. Prediction of Core Body Temperature Based on Skin Temperature, Heat Flux, and Heart Rate Under Different Exercise and Clothing Conditions in the Heat in Young Adult Males. Front. Physiol. 2018, 9, 1780. [Google Scholar] [CrossRef] [PubMed]

- Renard, M.; Puszkarz, A. Modeling of Heat Transfer through Firefighters Multilayer Protective Clothing Using the Computational Fluid Dynamics Assisted by X-ray Microtomography and Thermography. Materials 2022, 15, 5417. [Google Scholar] [CrossRef] [PubMed]

- Drobina, R.; Rysiński, J. Assessment of the Simultaneous Influence of Yarn Linear Mass and the Real/Service Loading Cycle on the Fatigue Life of Smooth and Flame Cotton Yarns. Fibres Text. East. Eur. 2020, 28, 21–28. [Google Scholar]

- Płonka, S.; Postrożny, J.; Drobina, R. Methodology of Optimum Selection of Material and Semi-Folded Products for Rotors of Open-End Spinning Machine. Autex Res. J. 2021, 21, 393–402. [Google Scholar] [CrossRef]

- Frant, M.; Kachel, S.; Maślanka, W. Gust Modeling with State-of-the-Art Computational Fluid Dynamics (CFD) Software and Its Influence on the Aerodynamic Characteristics of an Unmanned Aerial Vehicle. Energies 2023, 16, 6847. [Google Scholar] [CrossRef]

- Trevino, L.A.; Orndoff, E.S. Advanced Space Suit Insulation Feasibility Study. NASA Johnson Space Center. Available online: https://ntrs.nasa.gov/api/citations/20100042640/downloads/20100042640.pdf (accessed on 13 March 2000).

- Birend Pratap Singh: What Is a Transient Response? Available online: https://www.quora.com/What-is-a-transient-response (accessed on 1 January 2023).

- Ahmad, S.B.; Irons, M.; Zienkiewicz, O.C. Theory Reference for the Mechanical APDL and Mechanical Applications. Available online: http://www.ansys.com (accessed on 1 February 2009).

- Korycki, R.; Szafranska, H. Thickness Optimisation of Sealed Seams. in Respect of Insulating Properties. Fibres Text. East. Eur. 2017, 25, 68–75. [Google Scholar] [CrossRef]

- Korycki, R.; Szafranska, H. Thickness Optimisation of Textiles Subjected to Heat and Mass Transport During Ironing. Autex Res. J. 2016, 16, 165–174. [Google Scholar] [CrossRef]

| Layer Number | Material | Thickness (mm) | λ (W/mK) |

|---|---|---|---|

| 1 | Skin | 0.2 | 0.210 |

| 2 | Nylon | 0.3 | 0.233 |

| 3 | Nylon | 0.3 | 0.233 |

| 4 | Dacron | 0.3 | 0.144 |

| 5 | Nylon | 0.3 | 0.233 |

| 6 | Mylar | 2.8 | 0.155 |

| 7 | Kevlar | 0.4 | 0.040 |

| 8 | Nomex | 0.3 | 0.140 |

| 9 | Goretex | 0.3 | 0.251 |

| Total | 5.2 |

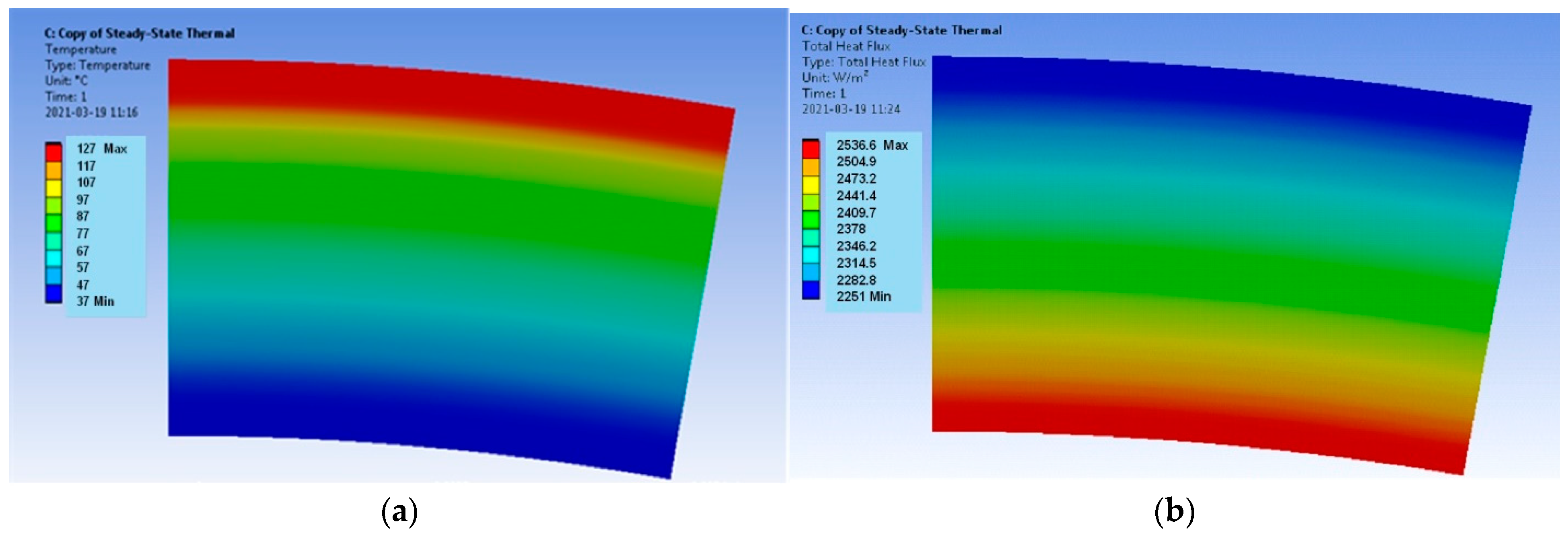

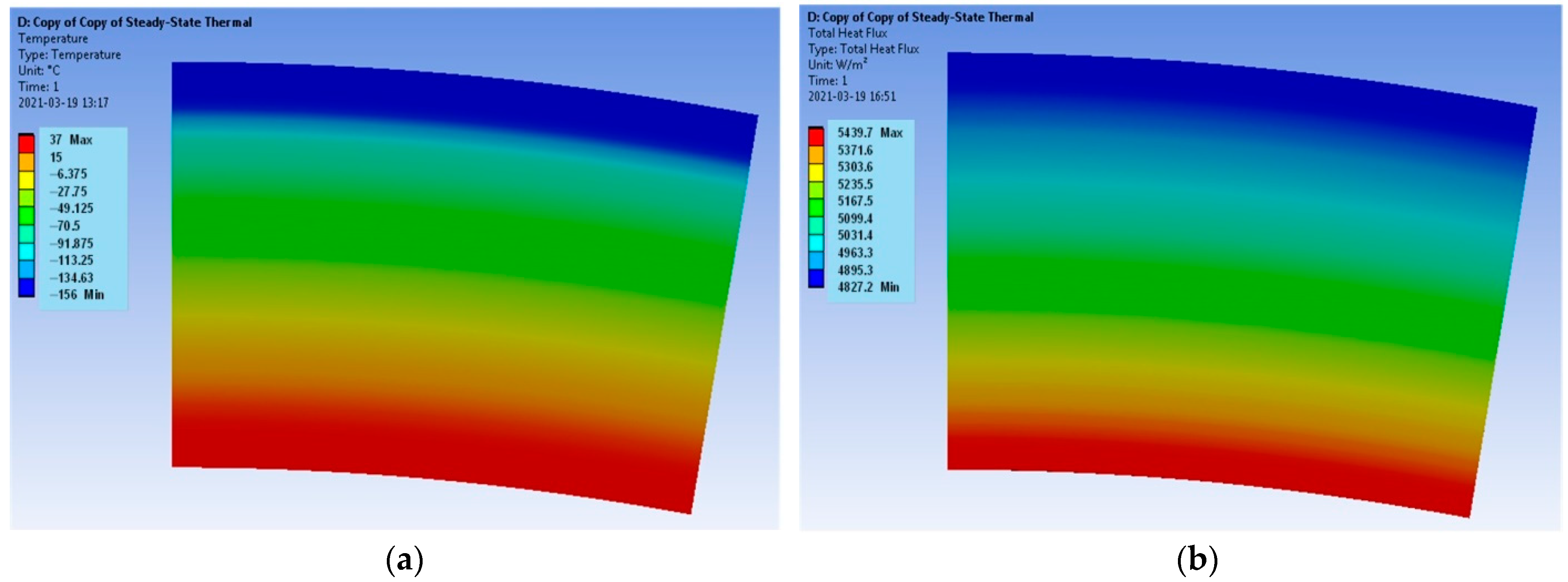

| Boundary Conditions | Verification Model | Actual Model | ||

|---|---|---|---|---|

| Hot Case | Cold Case | Hot Case | Cold Case | |

| CT | 37 °C | |||

| Outer layer temperature | 127 °C | −156 °C | - | |

| External temperature | - | 127 °C | −156 °C | |

| Surface emissivity | - | 0.98 | 0.98 | |

| Configuration coefficient | - | 0.50 | 0.50 | |

| Insulation on the sides of the model | yes | yes | ||

| Meeting Point of the Materials | Tcal (K) | Tsol (K) | ΔT (%) |

|---|---|---|---|

| 1/2 | 312.55 | 312.56 | 0.005 |

| 2/3 | 315.77 | 315.71 | 0.019 |

| 3/4 | 318.97 | 318.84 | 0.041 |

| 4/5 | 324.11 | 323.70 | 0.124 |

| 5/6 | 327.26 | 326.78 | 0.145 |

| 6/7 | 369.89 | 369.70 | 0.053 |

| 7/8 | 392.64 | 392.59 | 0.012 |

| 8/9 | 397.47 | 397.45 | 0.005 |

| Meeting Point of the Materials | Tcal (K) | Tsol (K) | ΔT (%) |

|---|---|---|---|

| 1/2 | 305.01 | 304.98 | 0.011 |

| 2/3 | 298.10 | 298.23 | 0.043 |

| 3/4 | 291.24 | 291.52 | 0.098 |

| 4/5 | 280.22 | 281.09 | 0.310 |

| 5/6 | 273.46 | 274.49 | 0.374 |

| 6/7 | 182.04 | 182.47 | 0.236 |

| 7/8 | 133.26 | 133.37 | 0.079 |

| 8/9 | 122.90 | 122.93 | 0.028 |

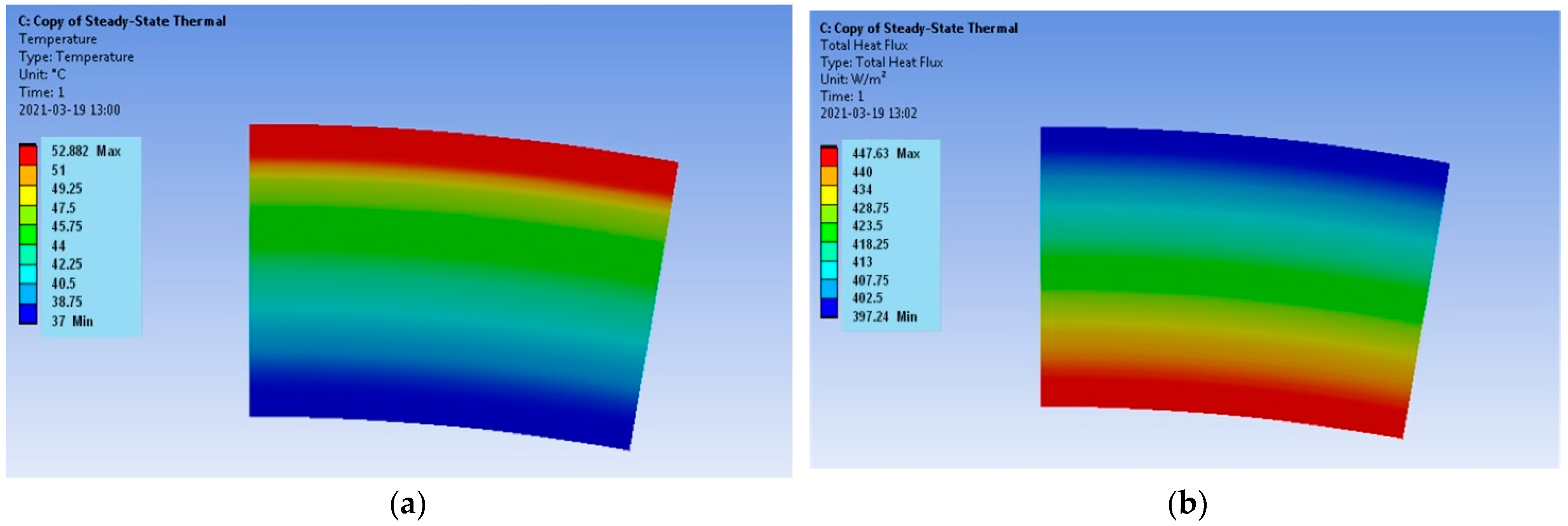

| Key Parameter | Hot Case | Cold Case |

|---|---|---|

| Tsurf | 326.03 K | 301.21 K |

| qsurf | −397.24 W/m2 | 223.73 W/m2 |

| Tskin | 310.58 K | 309.91 K |

| qskin | −446.26 W/m2 | 251.34 W/m2 |

| Q | −852.36 W | 480.05 W |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dzięgielewski, M.; Korycki, R.; Szafrańska, H.; Barburski, M. Numerical Modeling of the Thermal Insulating Properties of Space Suits. Materials 2024, 17, 648. https://doi.org/10.3390/ma17030648

Dzięgielewski M, Korycki R, Szafrańska H, Barburski M. Numerical Modeling of the Thermal Insulating Properties of Space Suits. Materials. 2024; 17(3):648. https://doi.org/10.3390/ma17030648

Chicago/Turabian StyleDzięgielewski, Michał, Ryszard Korycki, Halina Szafrańska, and Marcin Barburski. 2024. "Numerical Modeling of the Thermal Insulating Properties of Space Suits" Materials 17, no. 3: 648. https://doi.org/10.3390/ma17030648

APA StyleDzięgielewski, M., Korycki, R., Szafrańska, H., & Barburski, M. (2024). Numerical Modeling of the Thermal Insulating Properties of Space Suits. Materials, 17(3), 648. https://doi.org/10.3390/ma17030648